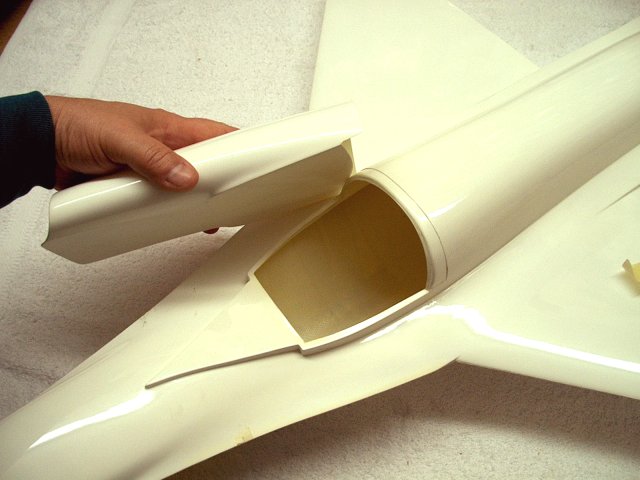

The Wemotec F-16C Fighting Falcon kit as

shown with major assenblies fitted | |

The model comes well packed from the

manufaturer | |

Parts are shown that come with the

kit | |

The two halves of the intake tube are made

from carbon fiber | |

The fuselage and wings are molded as one

piece, keeping the assembly lightweight

| |

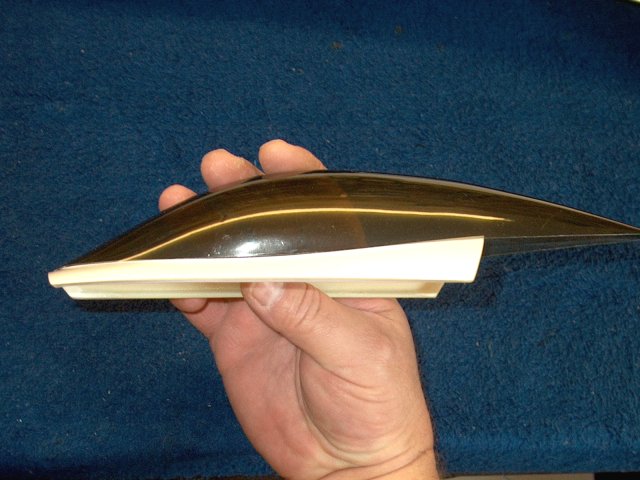

Side view of the scale shape of the

fuselage | |

Front view shown

| |

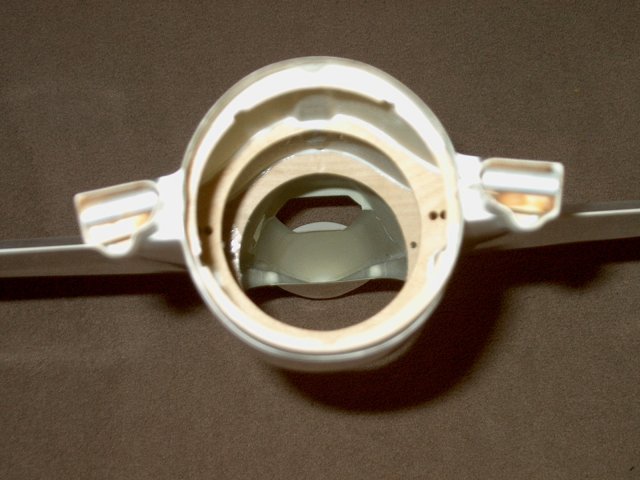

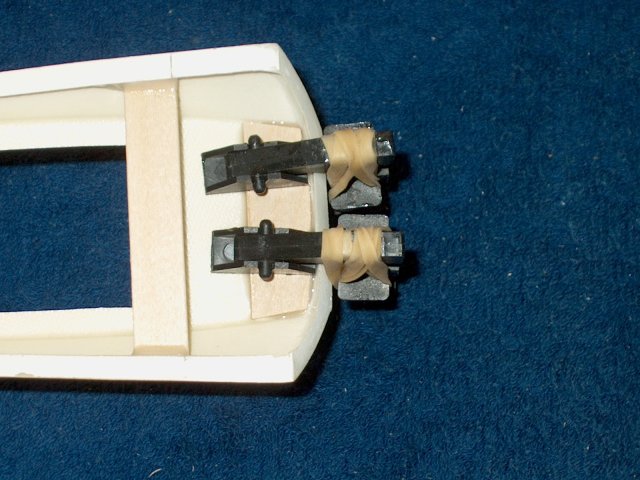

Rear view of pre-installed formers

| |

Bag of hardware is shown that is included

with the kit | |

The HW 620 86mm custom Midifan from

Wemotec is included in the kit | |

Contents of the fan assembly are

shown | |

The fan housing is molded from carbon

fiber to keep it light weight and strong

| |

Shown are the basic parts from the fan kit

that are required to assemble it for this model

| |

Construction begins with the power plant

assembly. Install the shaft adapter for the fan over your

motor shaft | |

Apply Loktite to the shaft adapter set

screw and install it in the adapter

| |

Make sure there is enough clearance on the

adapter so the fan does not rub on the housing. A good

starting point is shown. | |

Install plugs if you wish on the motor

wires | |

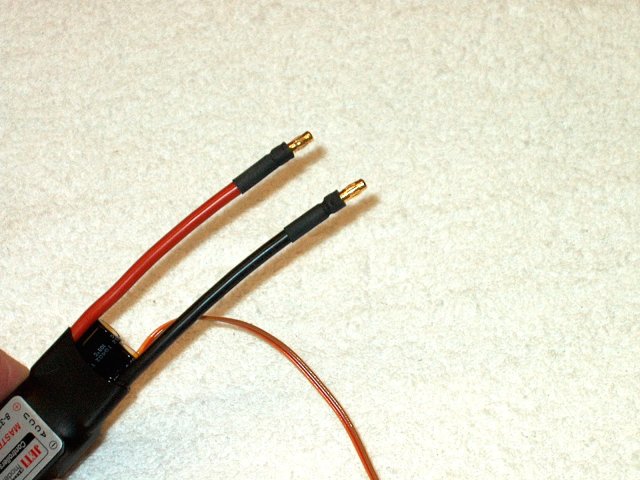

Install sockets on your ESC to match the

motor | |

Plugs are also installe don the power

wires for the ESC. This allows you to interchange motors and

ESC's if necessary | |

Loktite is applied to the motor threads

only!!! Do Not apply blue Loktite to the screws as it will

touch the housing and can disolve the housing plastic. Clean

up any excess Loktite | |

Install the motor in the housing

| |

Install the retaining screws in the motor

to mount it to the housing | |

Insure the motor is centered in the

assembly | |

Use a tool to balance your fan assmebly.

Small pieces of electrical tape can be placed inside the fan

outer hub and CA'ed in place to adjust balance

| |

Install the fan rotor on the shaft

adapter | |

Install the supplied washer, then the

aluminum nut | |

A slot can be cut into the shaft to allow

for tightening. Be sure to cover the motor anf fan with a

cloth so metal dust from cutting doesn't contaminate the

assembly | |

Use a screwdriver to hold the shaft in the

slot you cut, then tighten the nut with a wrench

| |

Install the hub if desired and tighten

with the supplied screw | |

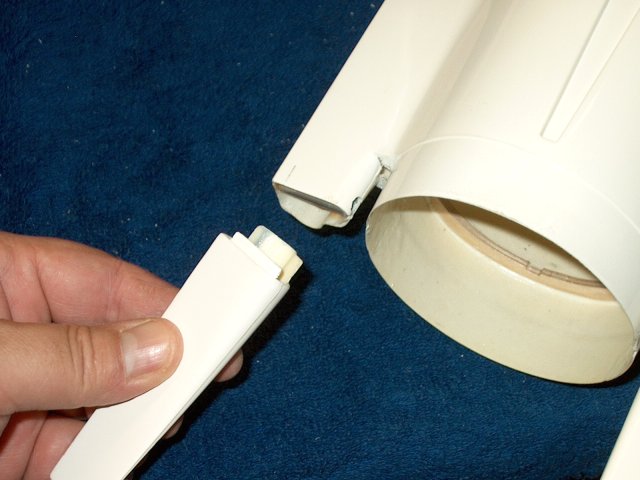

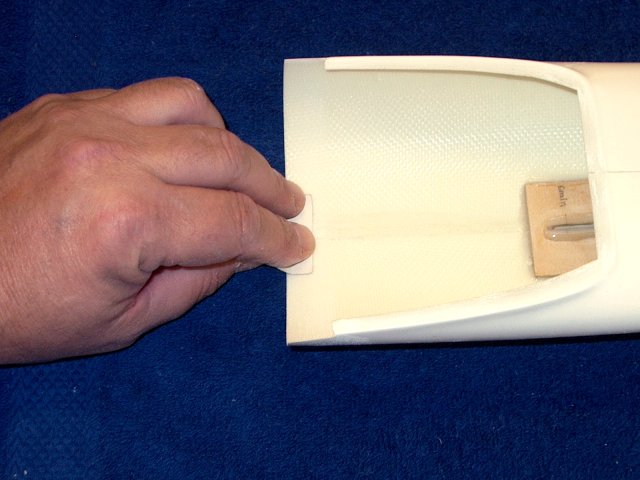

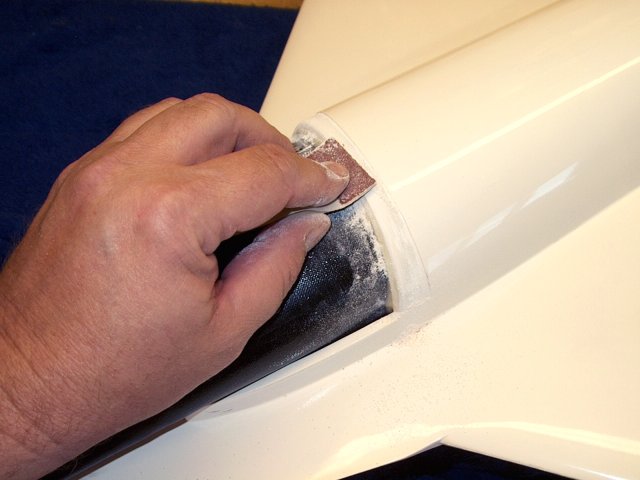

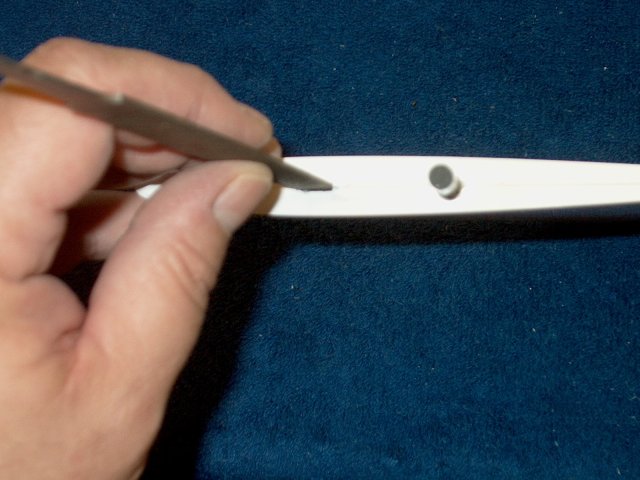

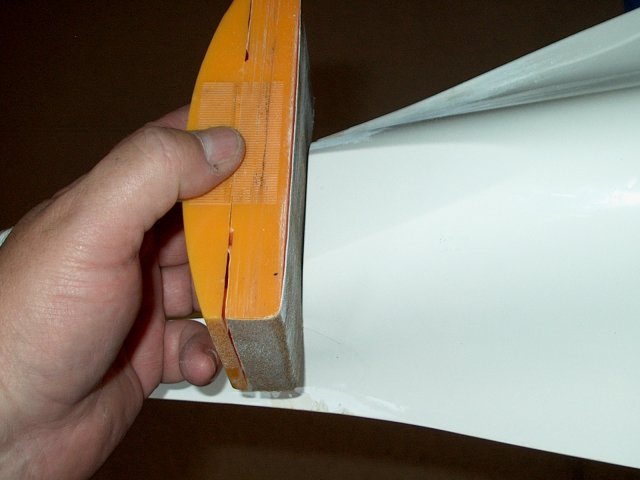

Sand the outer lips of both halves of the

carbon fiber intake duct | |

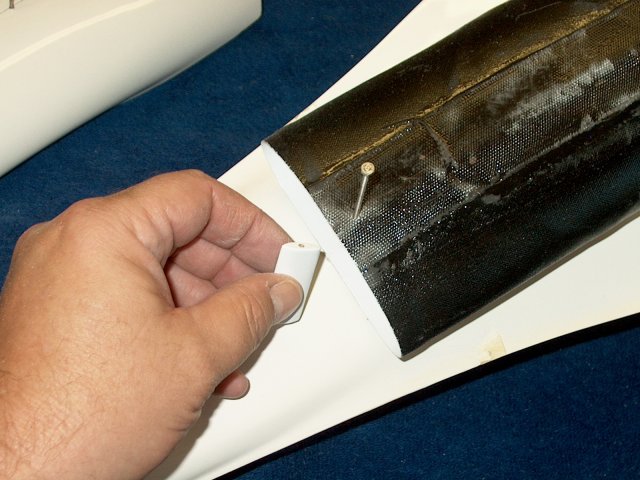

Halves are shown preped and ready to be

glued | |

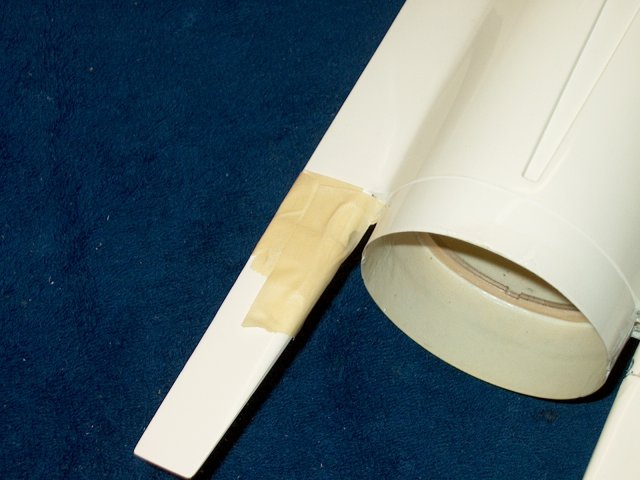

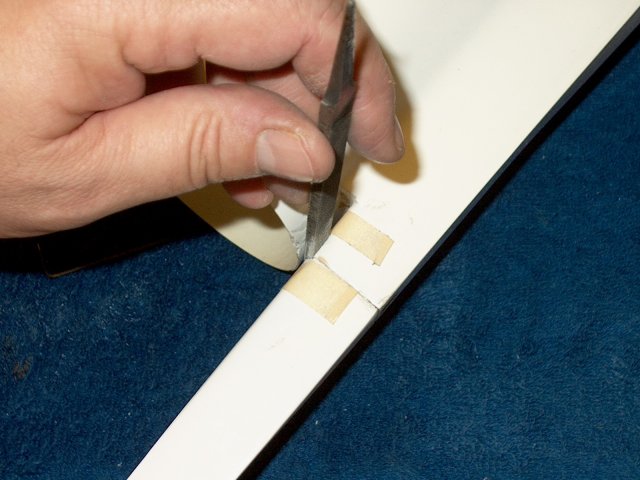

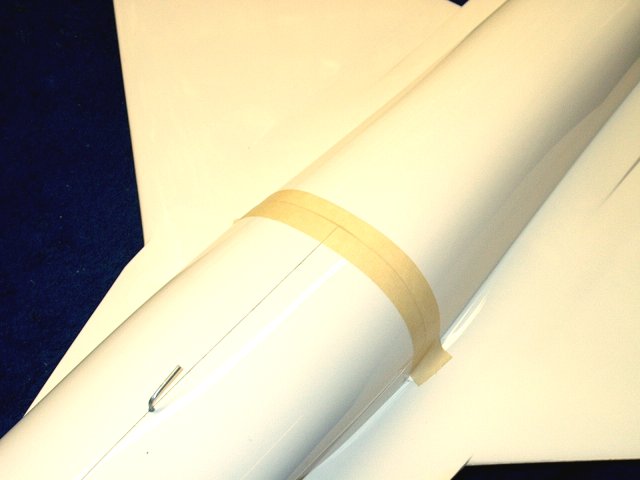

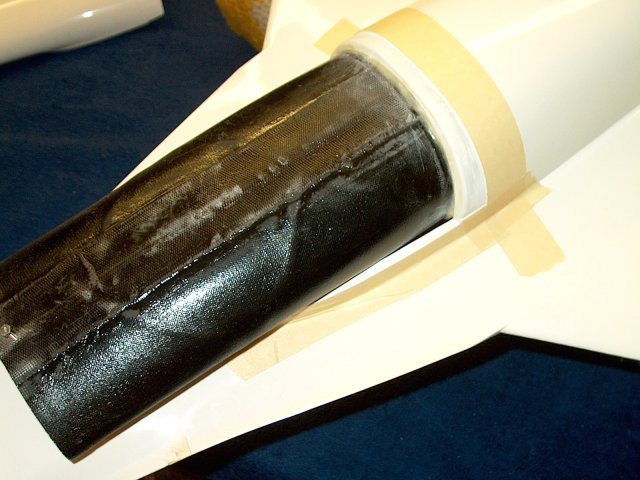

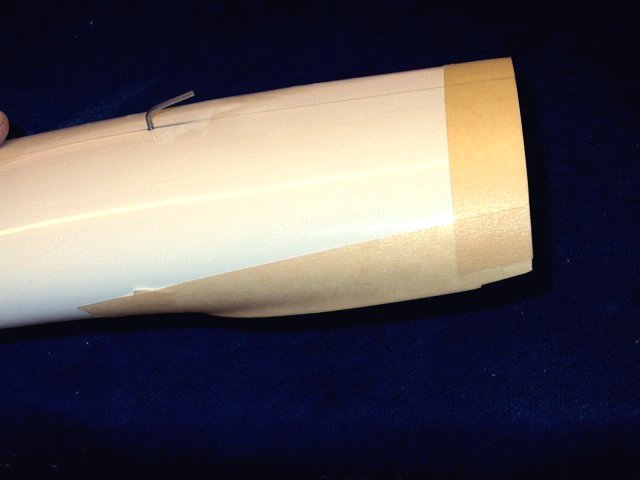

Apply a piece of masking tape that was

made 3 layers thick along the lenth of the seam

| |

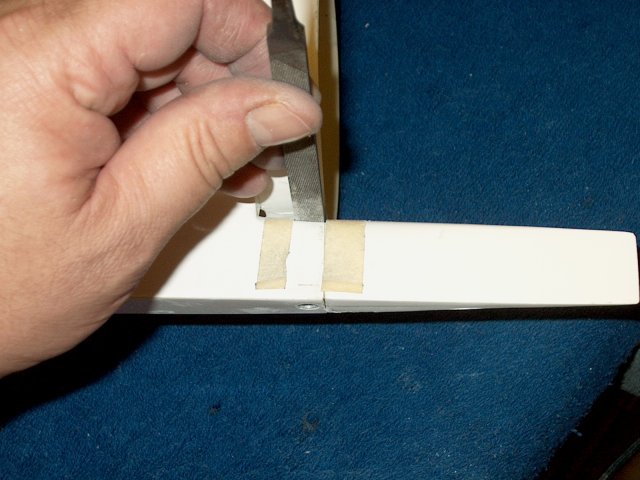

Install the second half, using th masking

to hold it in place | |

Apply epoxy with a small brush along the

seam lip | |

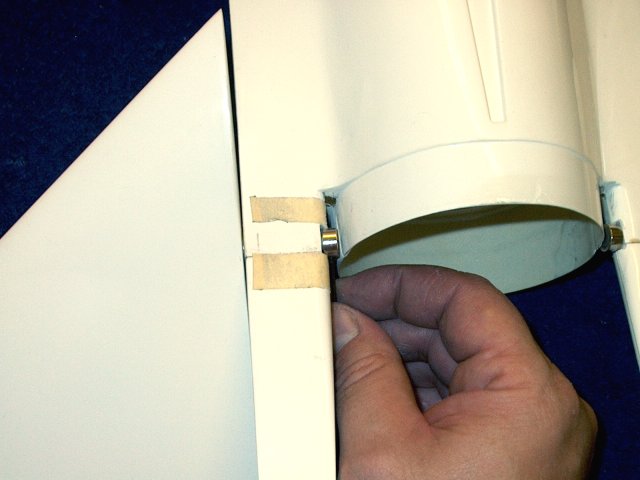

Clamp the assembly until the eopxy

sets | |

Remove the clamps once the epoxy

sets | |

Remove the tape from the inside of the

duct | |

Repeat the procedure for the other side,

applying a 3-layered tape strip tot he inside, then epoxy

along the seam | |

Clamp the second half and allow the epoxy

to set | |

Remove the clamps and tape

| |

The tape prevents overspill of epoxy in

the inside of the intake | |

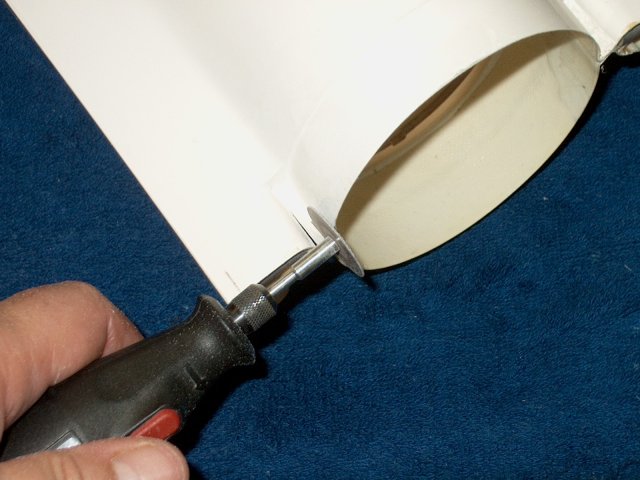

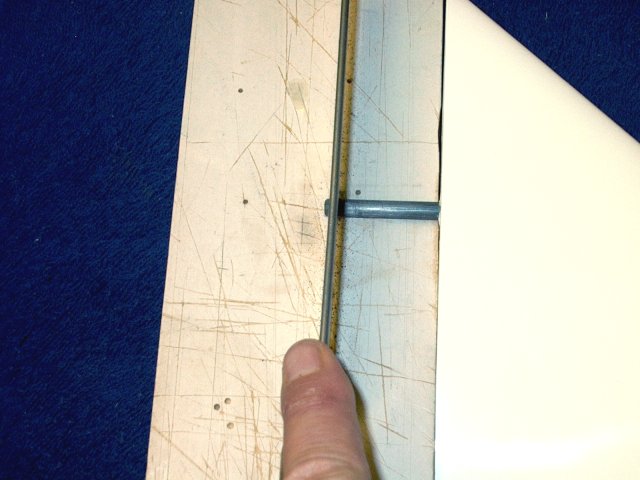

Use a dremel and cutting wheel to remove

most of the lip | |

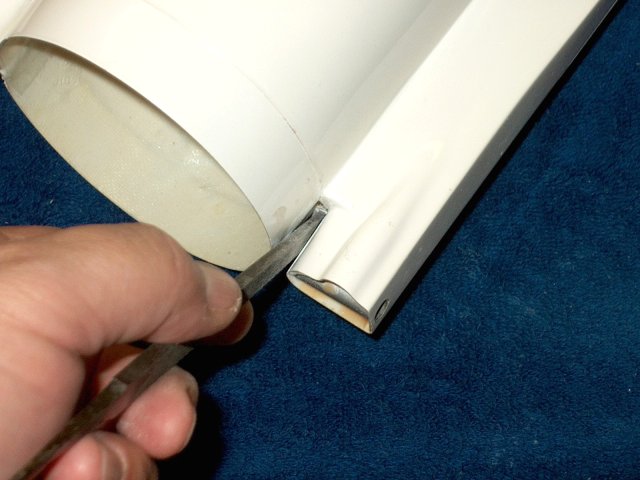

Remove the lip from the other side

| |

Cut off as much of the lip as you

can | |

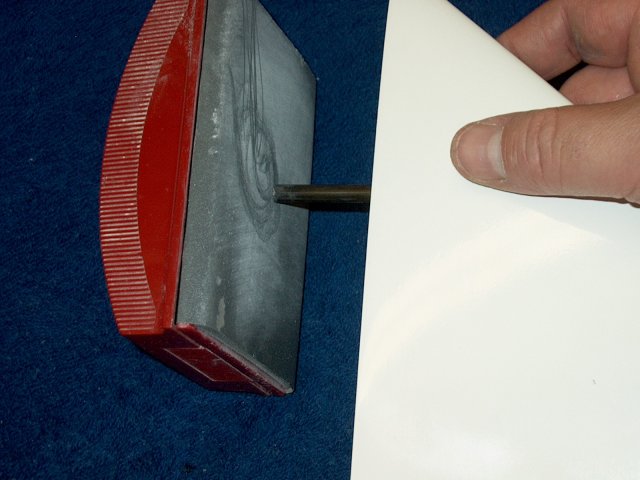

Sand the remaining area until it si nearly

flush | |

Prepare a 2" strip of 5oz fiberglass cloth

by soaking it in resin | |

Apply the cloth along the seam, then

remove all excess and allow it to set

| |

Apply a second strip to the other seam

along the bottom | |

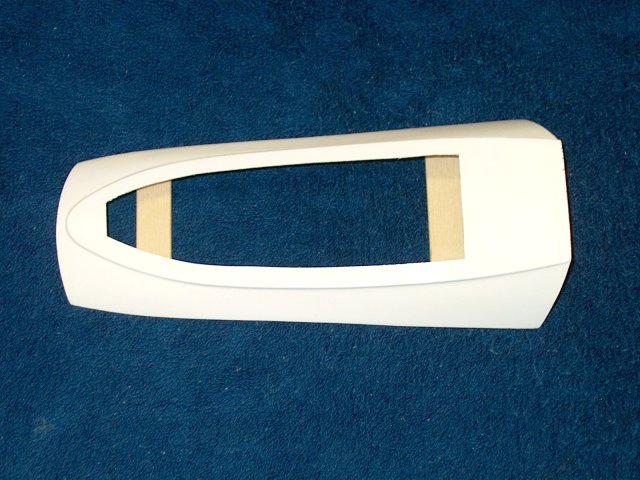

Trim the rear of the Intake Cover as

shown | |

Trim the top of the cover along the

molding lines | |

Remove the trimmed fiberglass and

sand | |

Install the fiberglass intake on the

fuselage and check for fit, then trim as necessary

| |

Use tape to hold the intake in

position | |

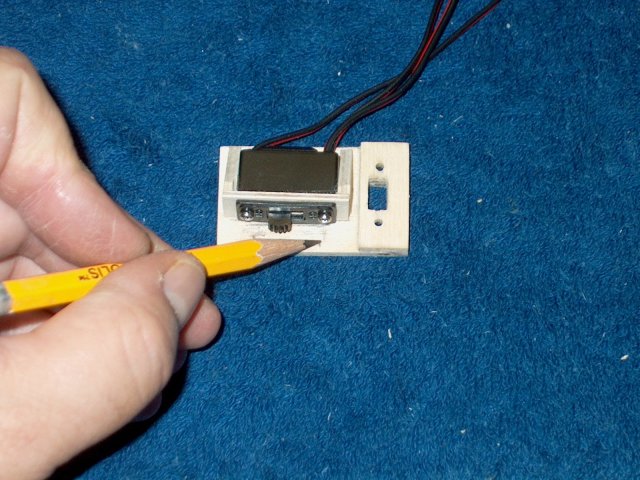

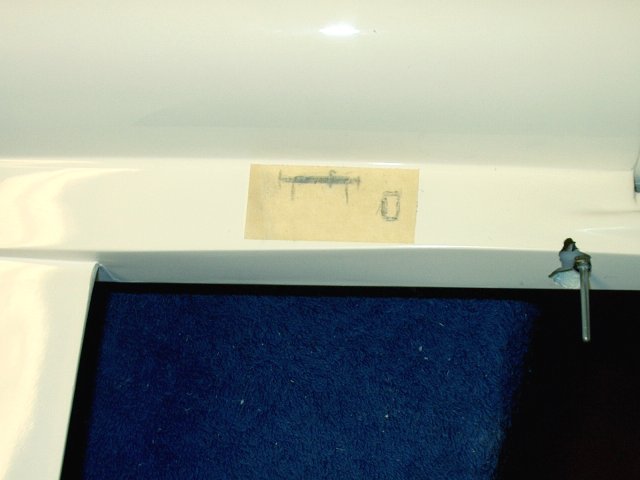

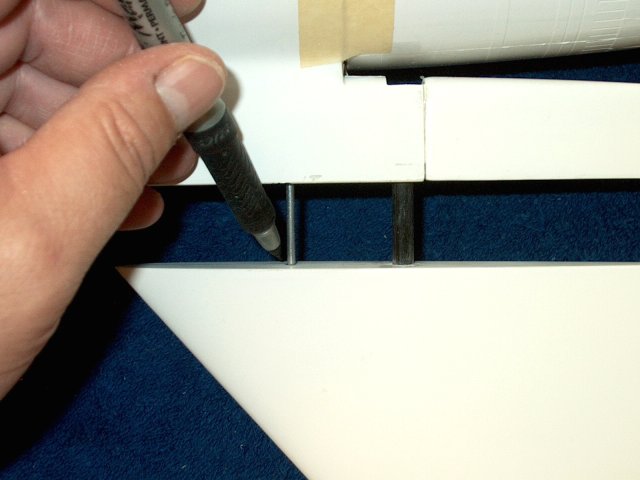

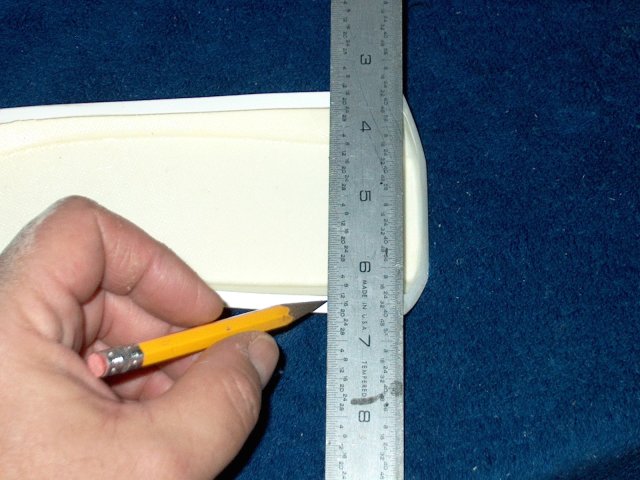

Use a pencil to transfer the inside

pattern of the fuselage to the top of the intake

| |

Pattern is now drawn on the intake

| |

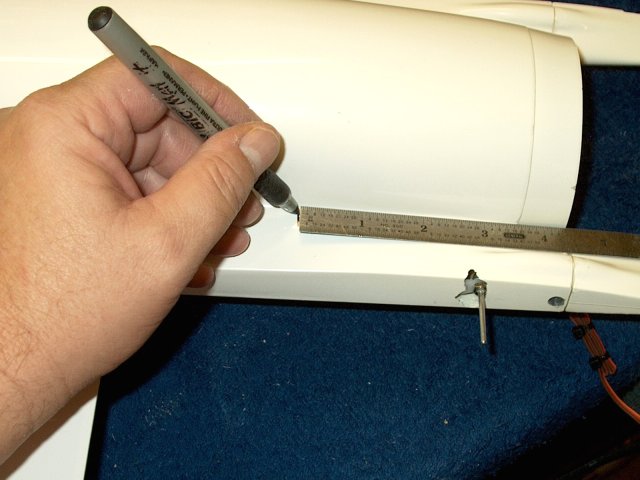

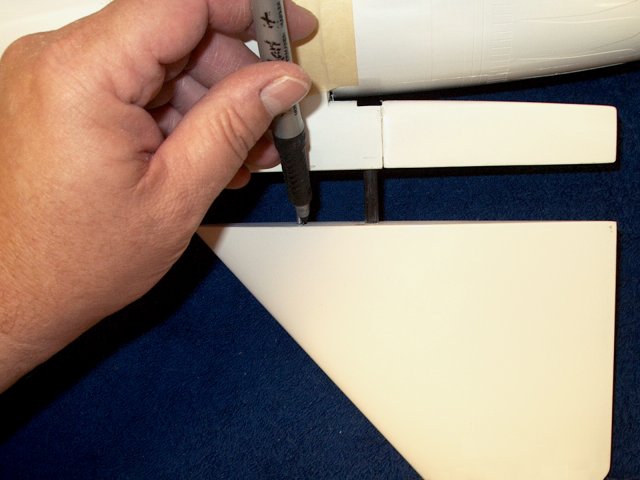

Outline the pattern in marker so it is

easier to see | |

Use a Drenel and cutting wheel to rought

cut the marked area | |

Remove the center piece

| |

Sand the edges to a smooth finish, then

remove marks with alcohol and a paper towel

| |

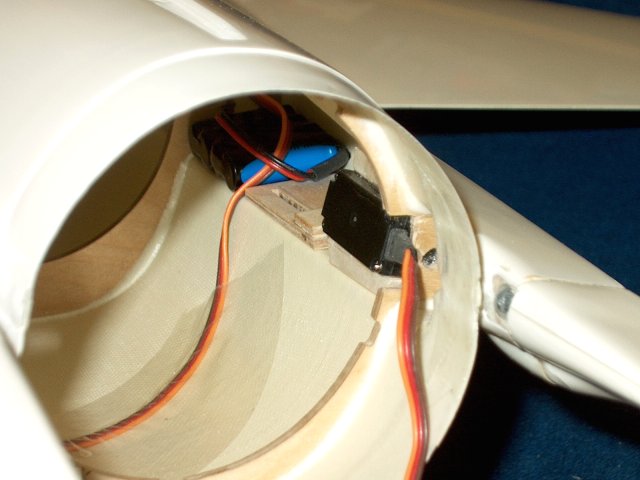

Install the carbon fiber intake duct in

the fuselage | |

Check for fit at the rear former

| |

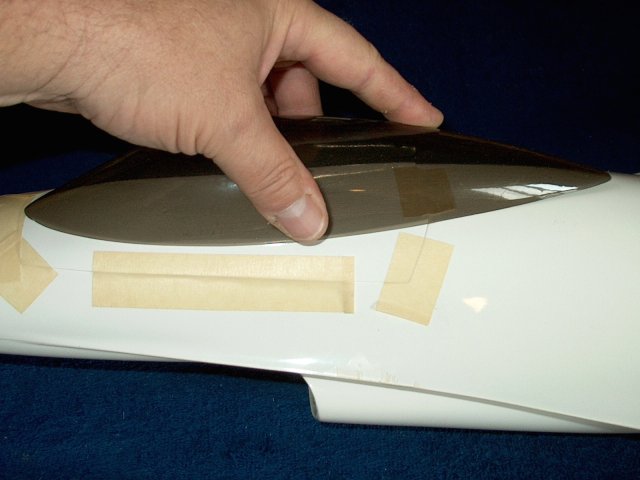

Install the intake cover and make sure it

does not bind on the duct | |

Check the fit of the cover

| |

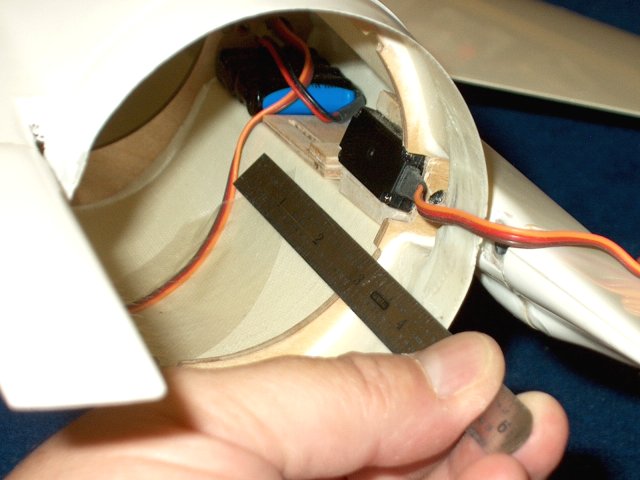

Make sure the edge of the inner carbon

fiber duct is flush against the bottom inside ridge of the

fiberglass intake cover | |

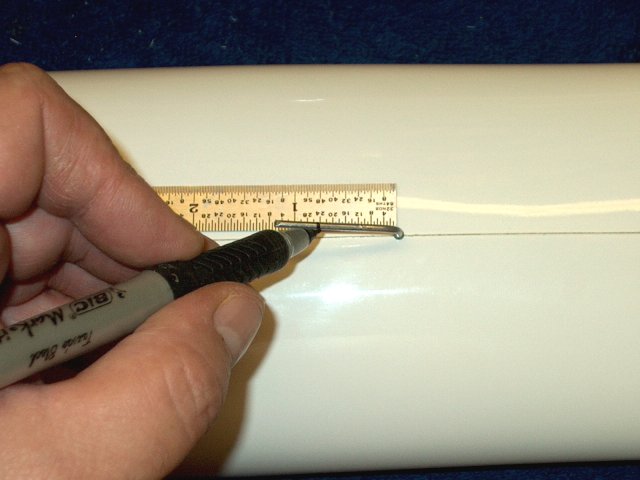

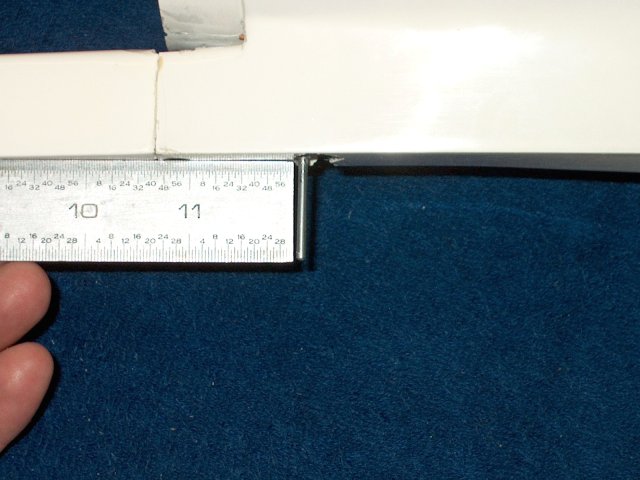

Make a mark on the bottom of the cover

100mm from the front | |

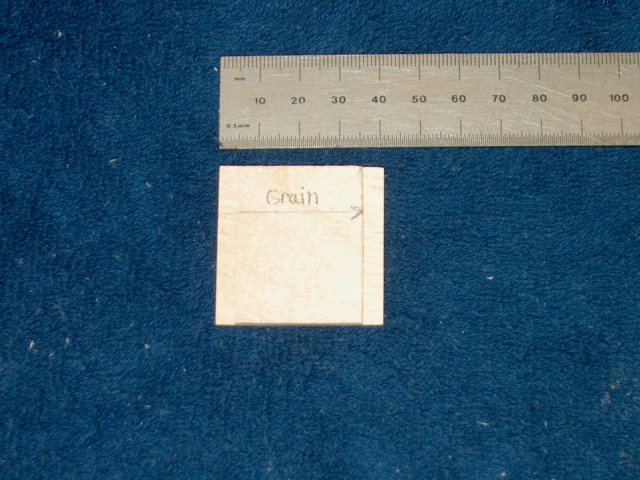

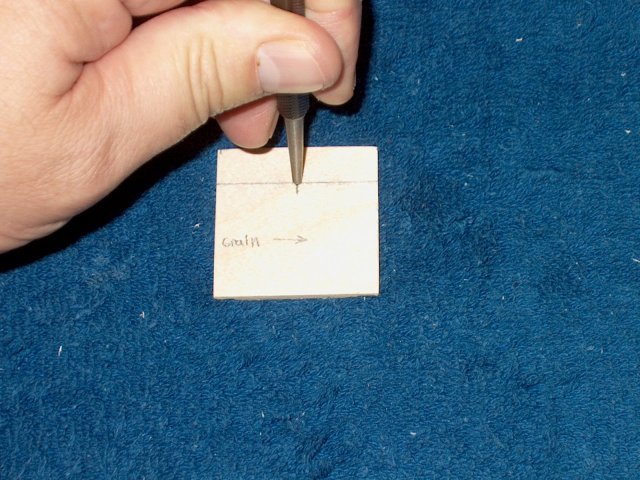

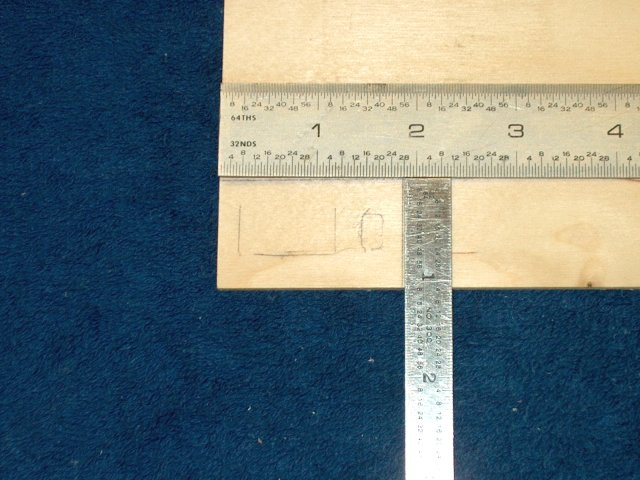

Make a 1/16" ply plate 40mm x 40mm and an

inside 1/16" plate 30mm x 40mm. Note the grain

orientation...this is important | |

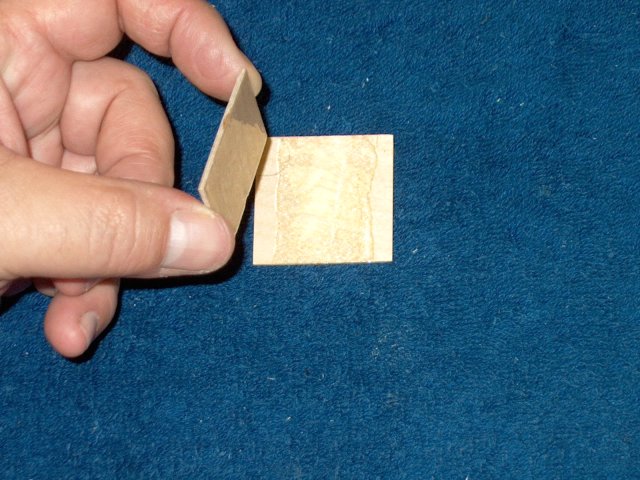

Epoxy the two halves together, making sure

the inner place is centered | |

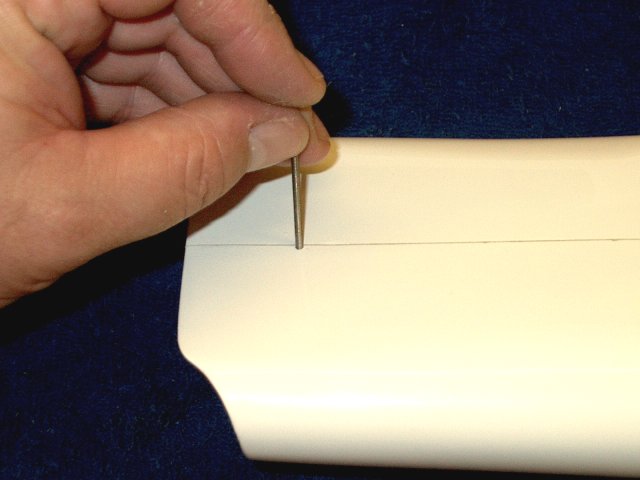

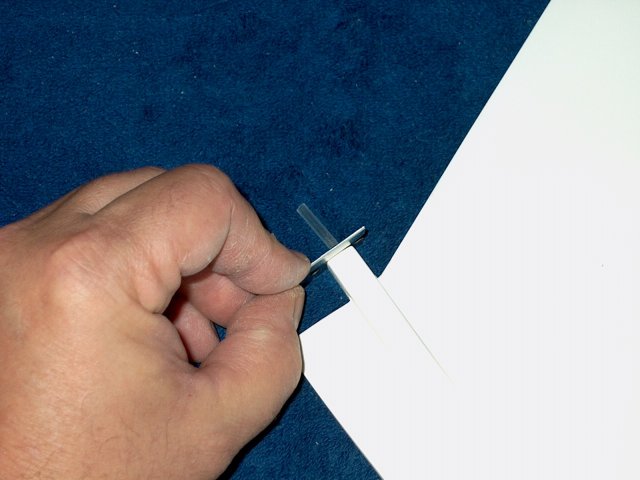

Use a punch to make a mark for drilling at

the 100mm line you drew earlier | |

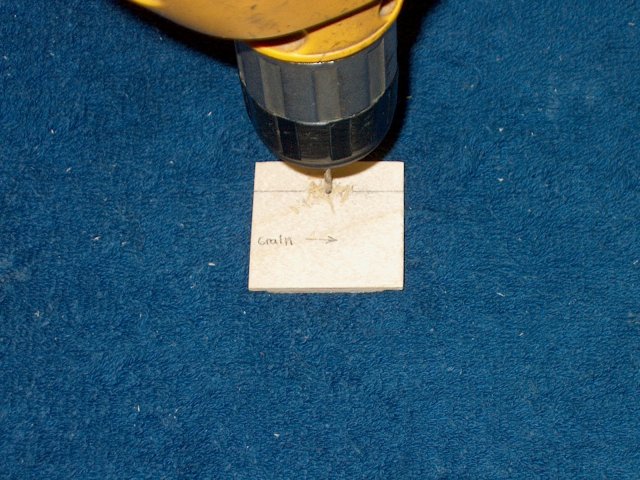

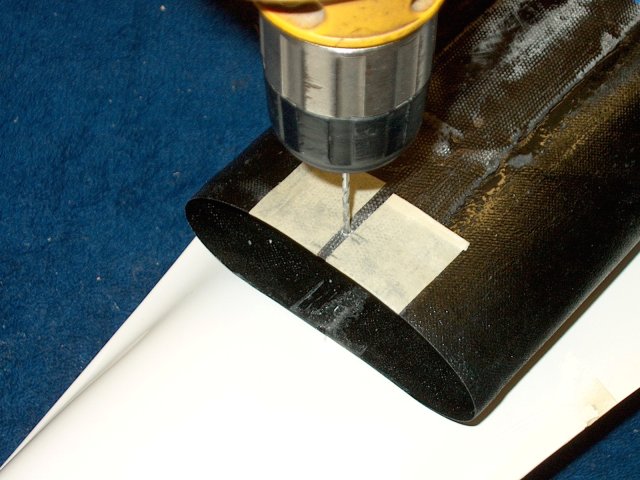

Drill the hole with a 5/64" bit

| |

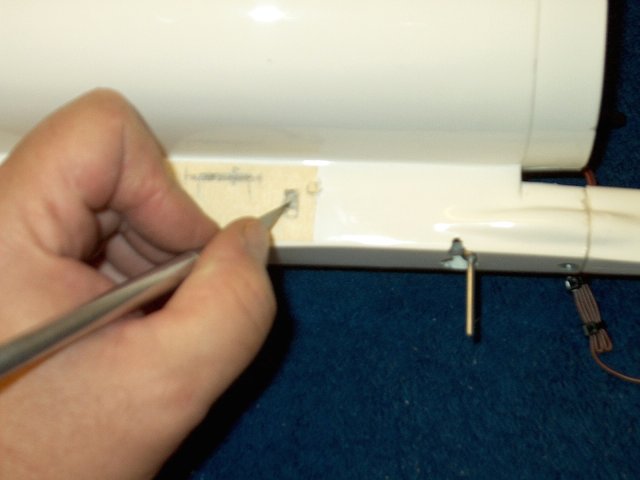

Rough up the inside area for the towkhook

plate with some 60 grit sandpaper | |

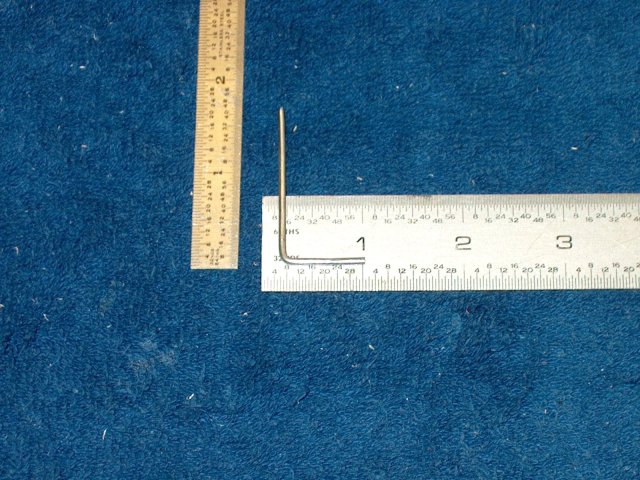

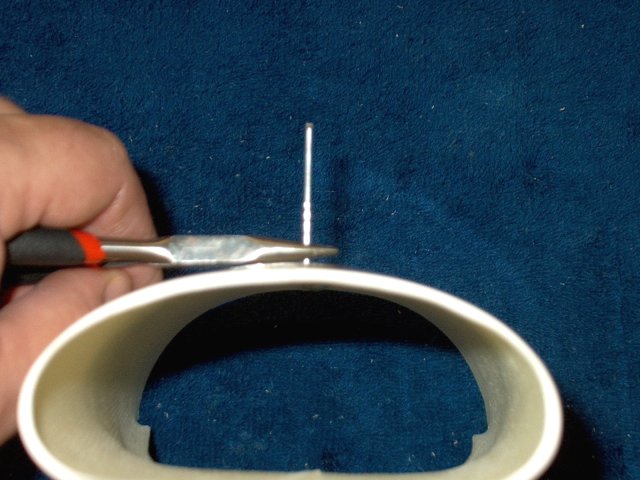

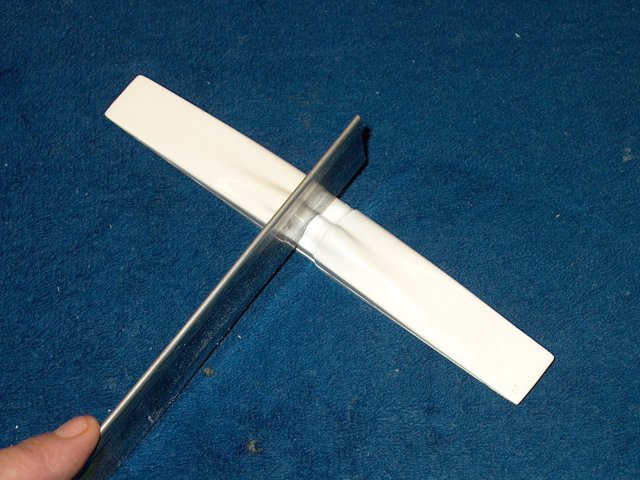

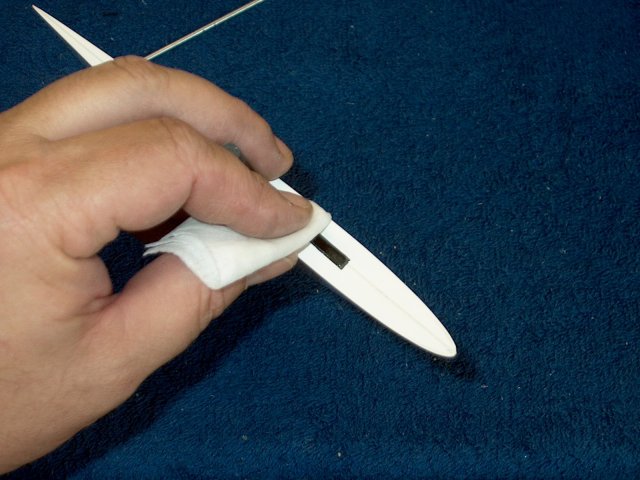

Make a towhook as shown using 2-56 steel

rod | |

Mark a drill hole with a punch centered on

the two ply pieces and 10mm from the front edge

| |

Drill the hole for the towhook

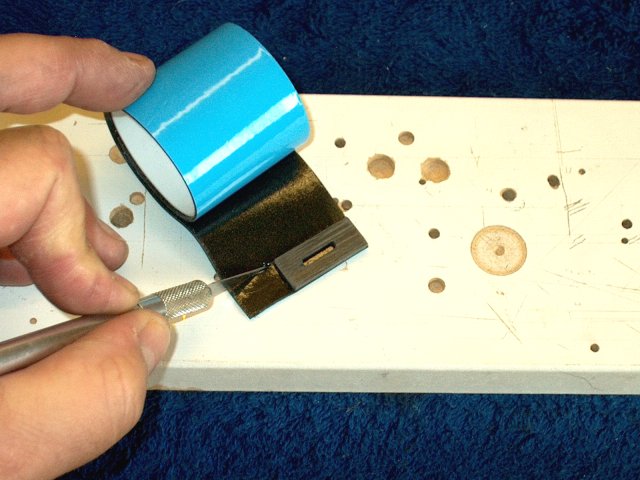

| |

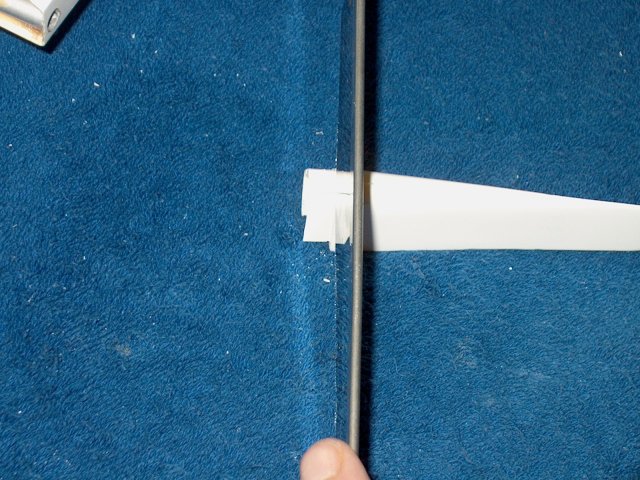

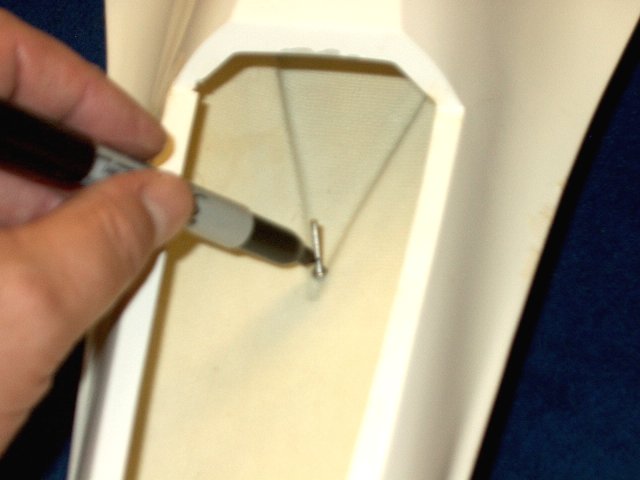

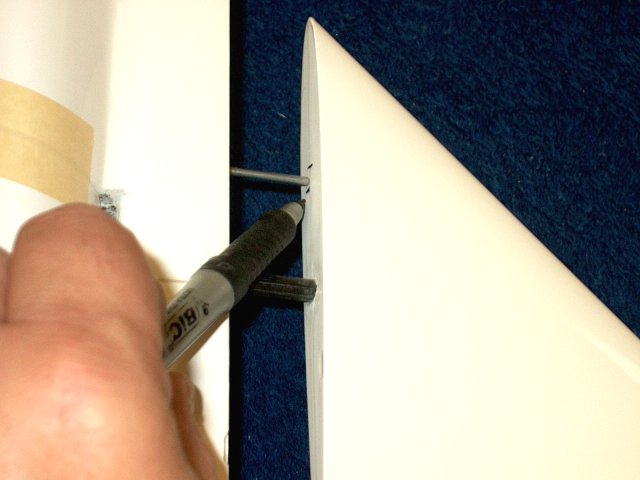

Use a dremel to slightly slot the area for

the towhook. Cut about 1/32" deep, just enough to prevent the

hook from twisting | |

Clean up the slot with a knife

| |

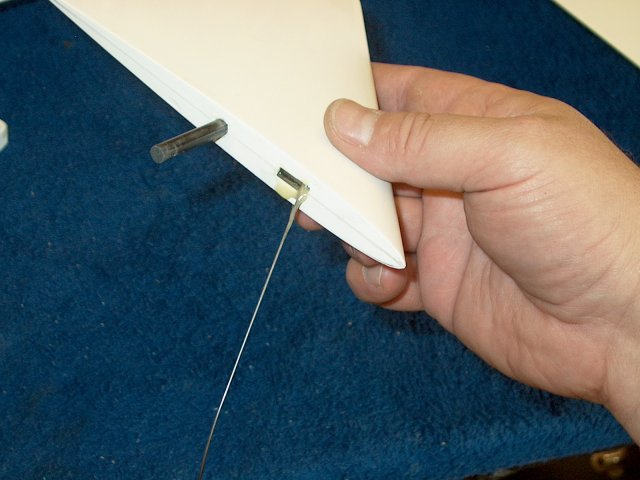

Use coarse sandpaper to rough up the hook

on the short side | |

Insert the hook in the ply

| |

Use epoxy to glue the hook in place

| |

Slightly taper the outside edges to the

contour of the intake, then apply epoxy as shown

| |

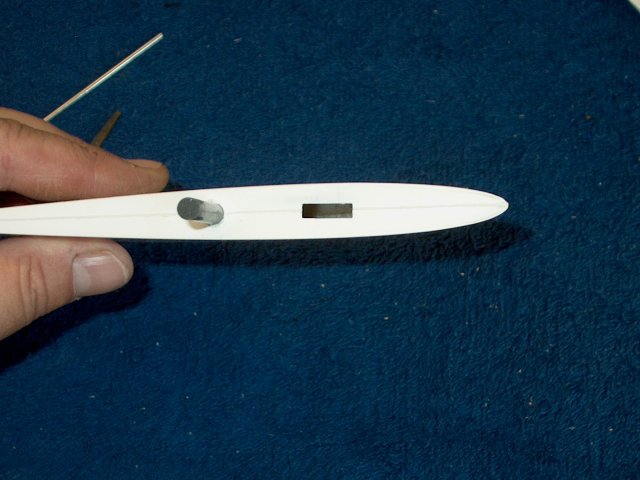

Install the towhook through the hole in

the intake and allow the epoxy to set. Note the orientation of

the plate with the 10mm of spacing at the front

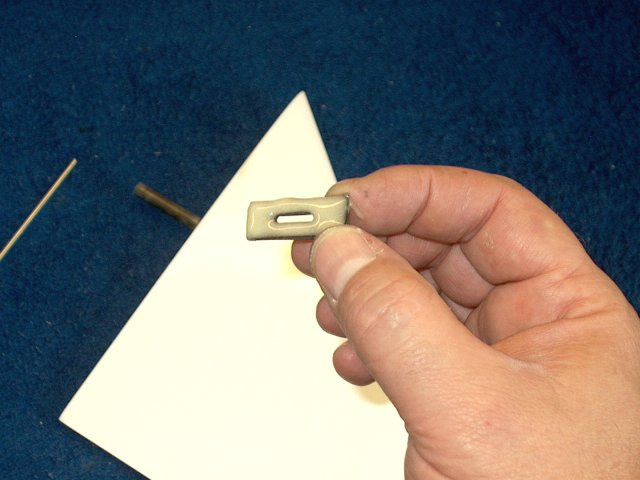

| |

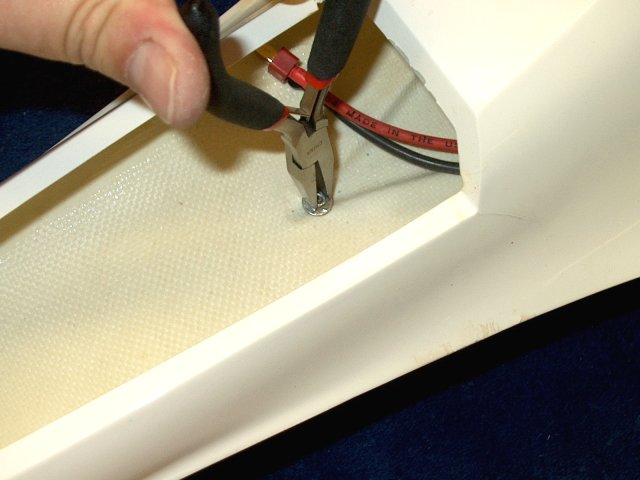

Use a pair of pliers to bend the hook into

shape | |

Mark the hook to a length of 3/4" and

remove the excess. Round the end with sandpaper

| |

Check the clearance of your towhook ring,

then set the assembly aside | |

Use a dremel to cut out the notches in the

tail area of the fuselage | |

A file and sandpaper can be used to smooth

the area | |

A saw can also be used to cut and remove

the excess fiberglass | |

Use a small saw to cuth the Tail Brake

pieces in half | |

Sand and round the edges

| |

Use a drill to open up the holes for the

tailerons on both sides | |

Custom cut the tail of the brake so it

fits arouns the taileron shaft, then apply epoxy to the

area | |

Apply epoxy to the shaft lip and install

flush to the fuselage | |

Make sure it is recessed completely and

even with the outside. | |

Custom fit the second brake

assembly | |

Apply epoxy to the hole and brake, then

glue it in place | |

Tape the piece to hold it straight until

the glue cures | |

Install a Taileron, then mark a cut line

with a saw | |

Remove just enough of the shaft so there

is enoguh for the wheel collar to hold

| |

Sand the end and remove all ridges

| |

Install the taileron and wheel collar,

then mark the outer locations of the wheel collar on the

fuselage with masking tape | |

Use a file to notch the area, so the

collar is far enough away from the exhaust area so it doesn't

rub | |

Fine sand the area

| |

Install the supplied washer

| |

Install the Wheel collar, holding the

taileron to the fuselage side. Remove and sand the shaft until

it is flush with the inner part of the collar

| |

Final fitting completed, you will have

space between the collar and Exhaust nozzle

| |

Notch the other taileron shaft

| |

Shorten the shaft the same as the

first | |

Make sure to remove any ridges on the

inside of the taileron | |

Sand the shaft and round the end at the

edges | |

Install the taileron and wheel collar,

then use masking to mark the outer sides of the collar

| |

Once again, use a file to notch the wheel

collar area. It should be wide enough to allow the wheel

collar to turn without binding. | |

Install the second washer

| |

Install the wheel collar over the shaft

and tighten | |

Taileron mounting completed

| |

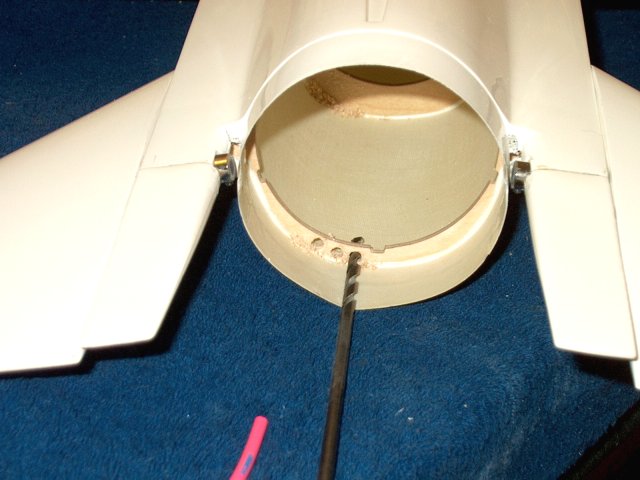

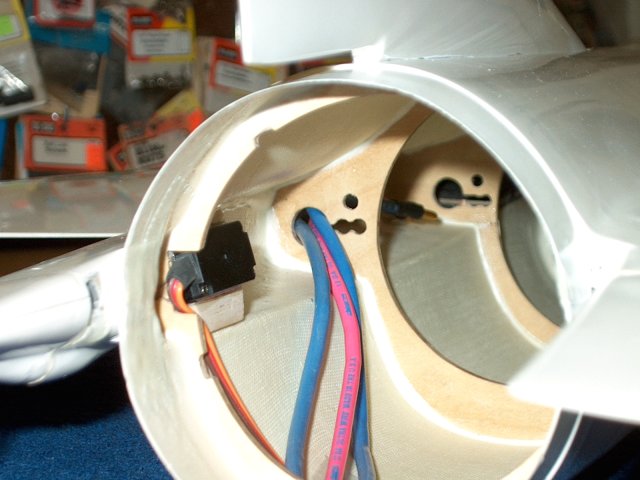

Drill three holes for the motor to ESC

wires as shown | |

Solder ends to the 12ga wires that will

plug into the motor | |

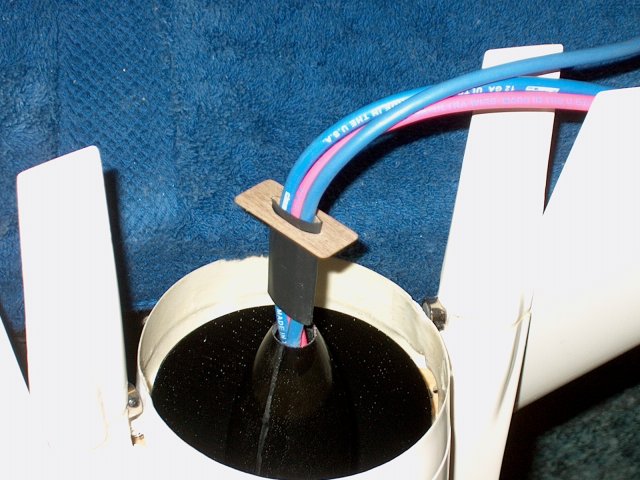

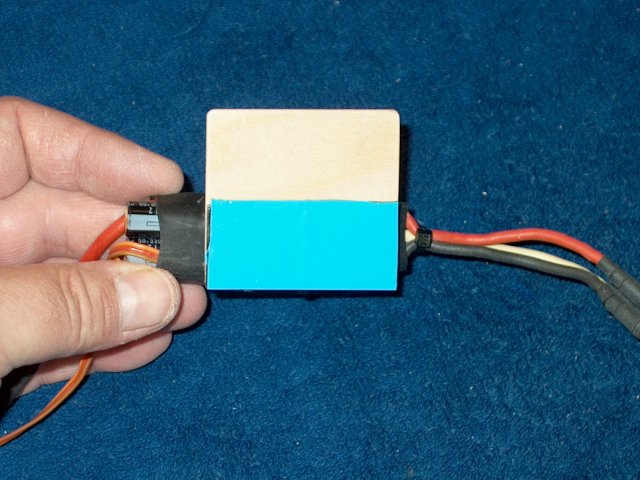

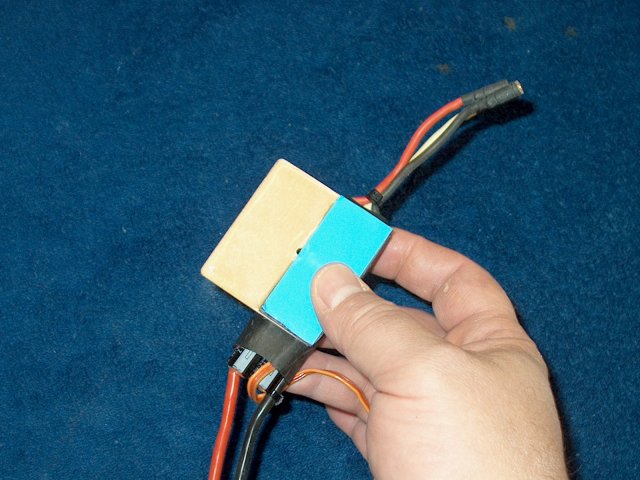

A piece of 1/64" ply is cut 3/4" wide to

make an airfoil for the wires | |

The ply is inserted into the heat shrink

and just fits | |

Solder plugs for the ESC side to the

wires | |

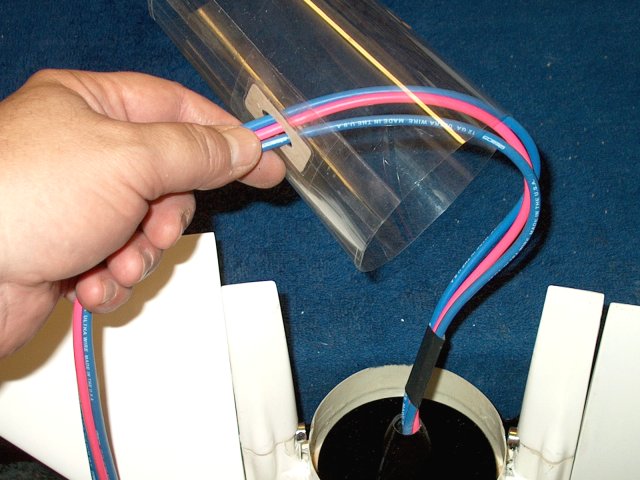

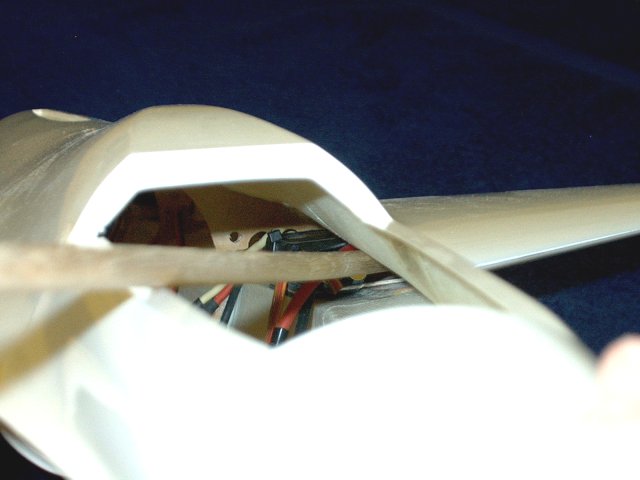

Slide the airfoil over the wires as

shown | |

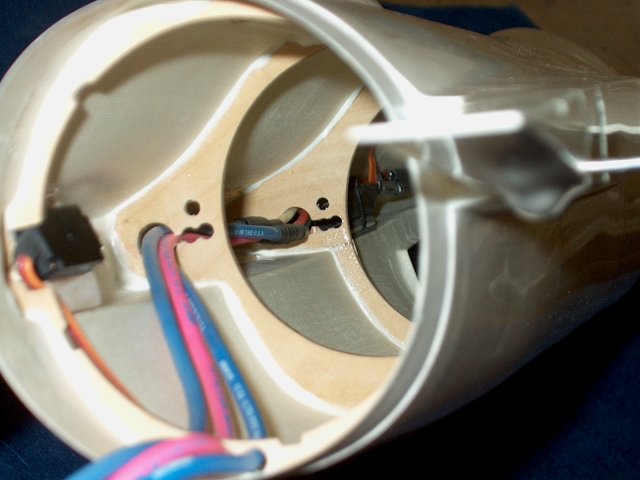

Run the wires through the Carbon fiber

motor cover that was supplied with the motor assembly

| |

Slide pieces of heat shrink over the motor

wires | |

Install the wires on the motor

connectors | |

Slide the heatshrink in position, then use

a heat gun to shrink the tubing in place

| |

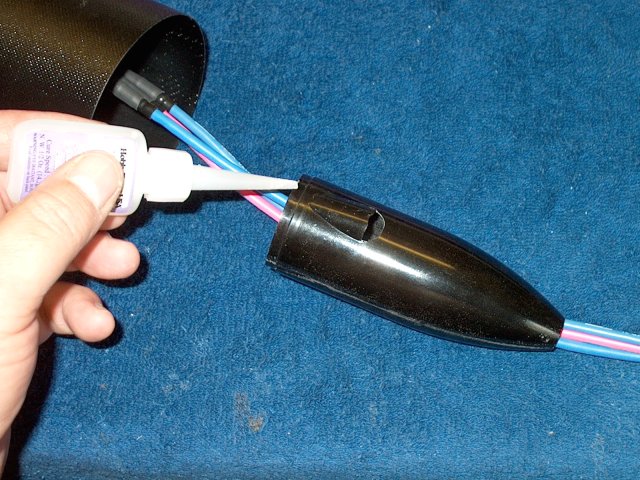

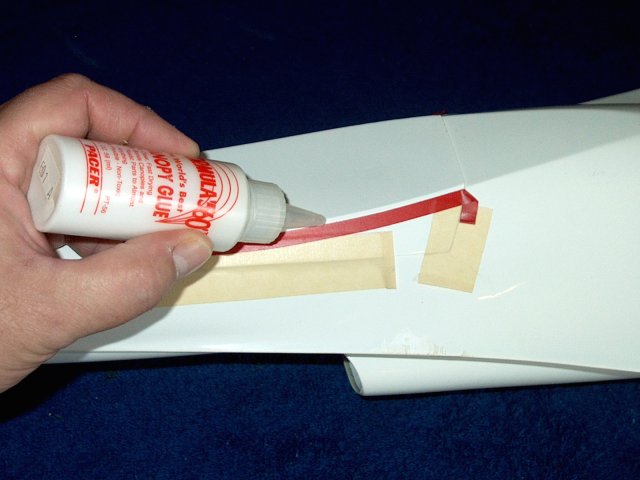

Apply some thick CA to the lip of the

motor cover | |

Install the cover in the motor

housing | |

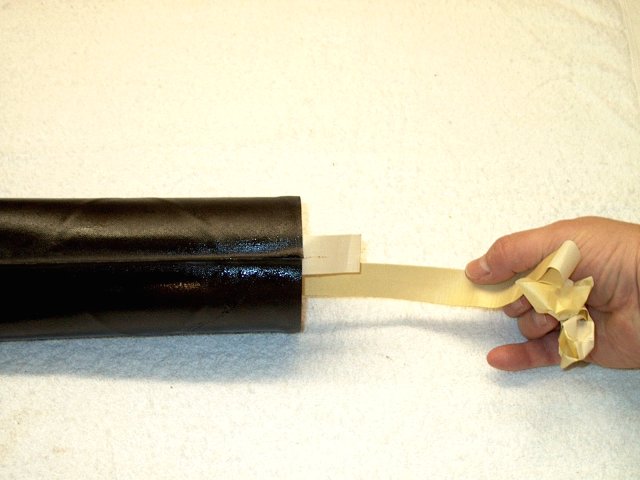

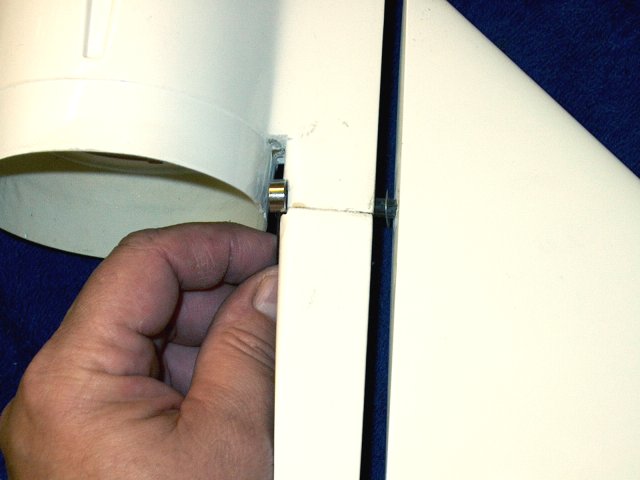

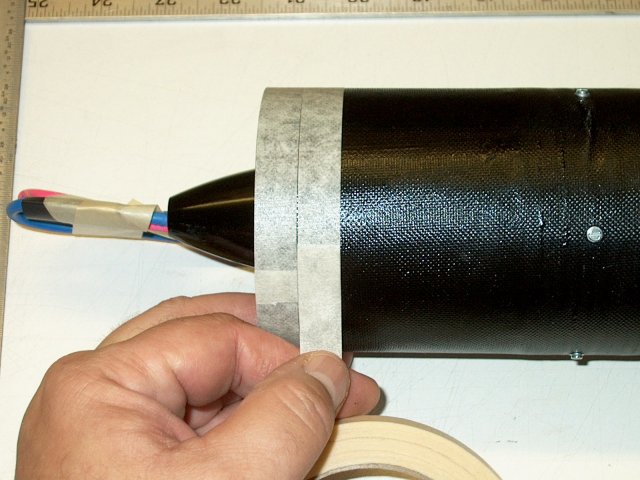

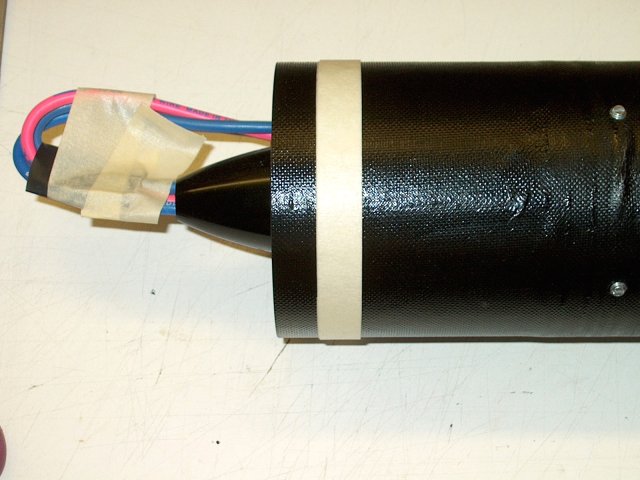

1/2" tape is applied to the rear of the

motor housing to build up the area around the former

| |

Remove the outer spacer tape

| |

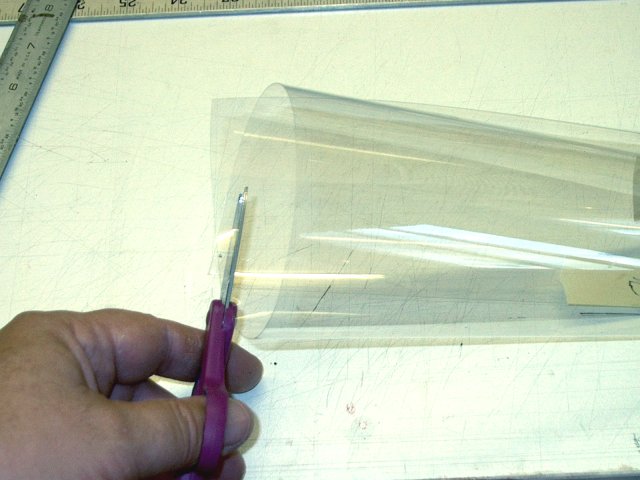

An Exhaust Duct is made from clear

mylar | |

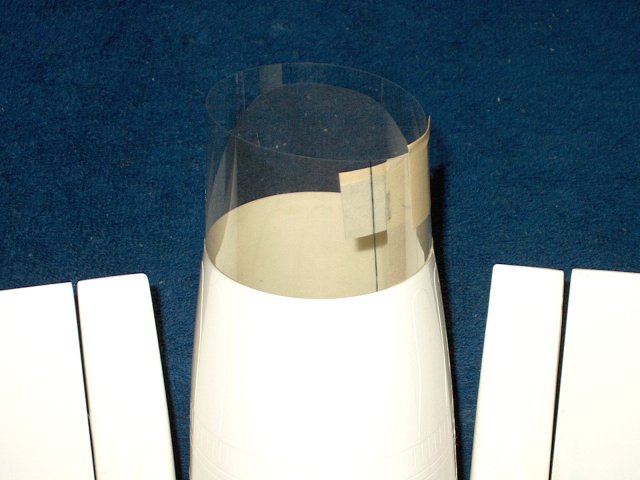

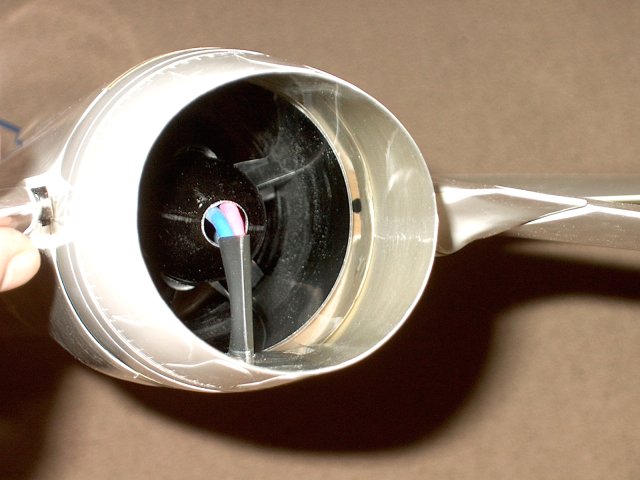

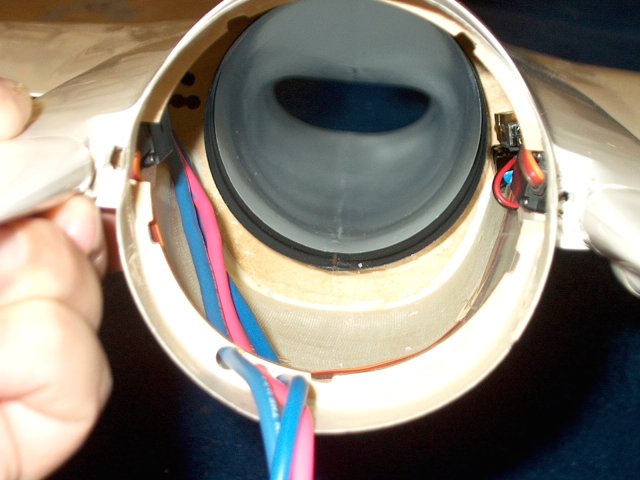

Temporarily tape up the motor wires and

run them down through the fan so they are out of the wya, then

shape the duct | |

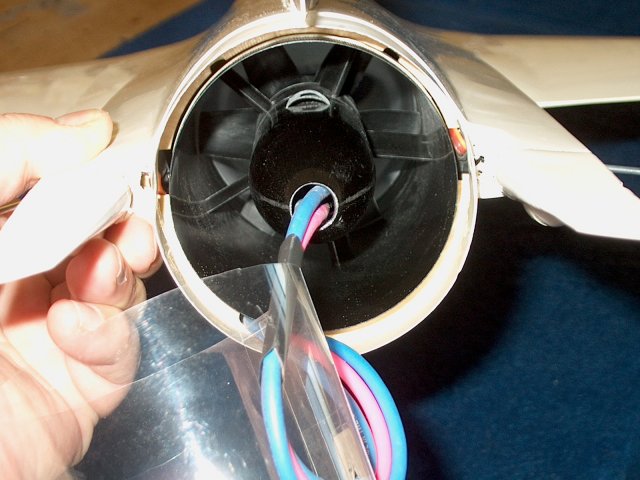

Tape the Nozzle flush to the rear of the

fuselage. Make sure the mylar duct fits well to the rear of

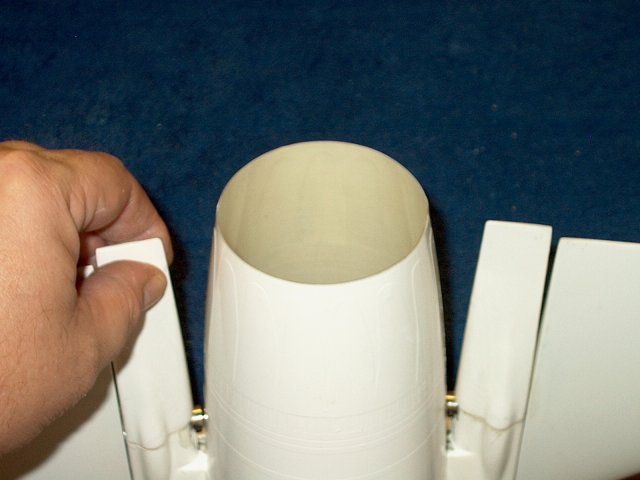

the Exhaust Nozzle | |

Trim away any excess material with a

razor | |

Duct should be flush to the rear and note

that the wheel collars should clear the nozzle

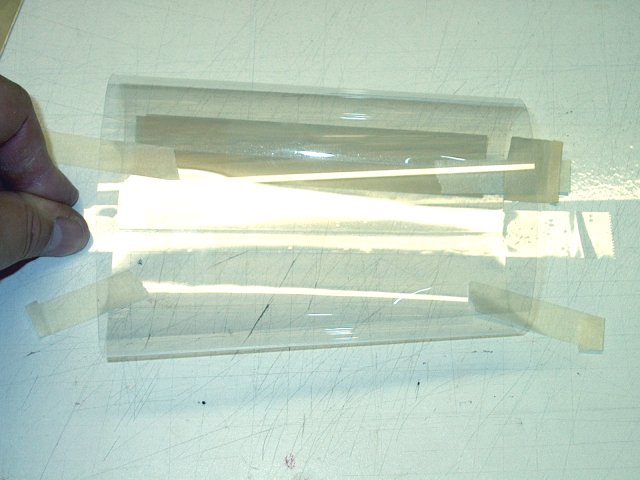

| |

Use 1" strips of packing tape to seal up

the inside of the duct | |

Tape the outside of the duct as well with

a 1" wide strip | |

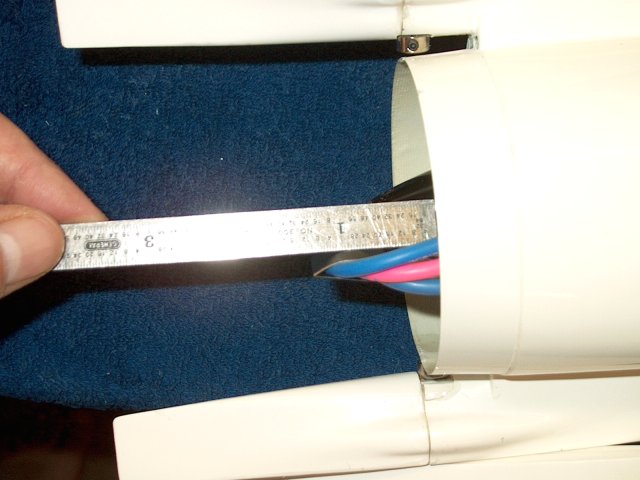

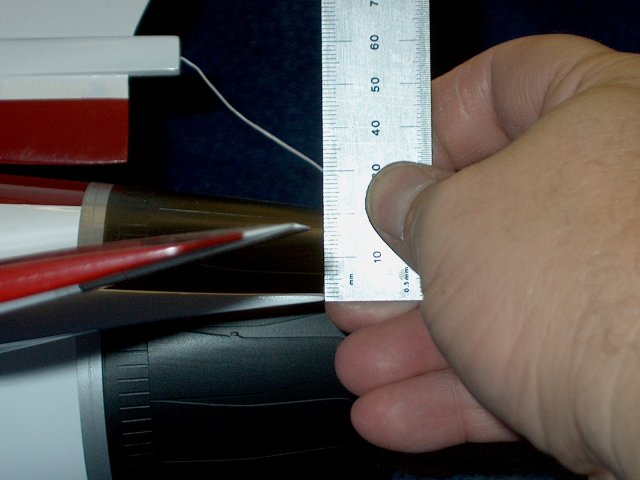

Measure the distance from the end of the

fuselage to the rear of the motor cover

| |

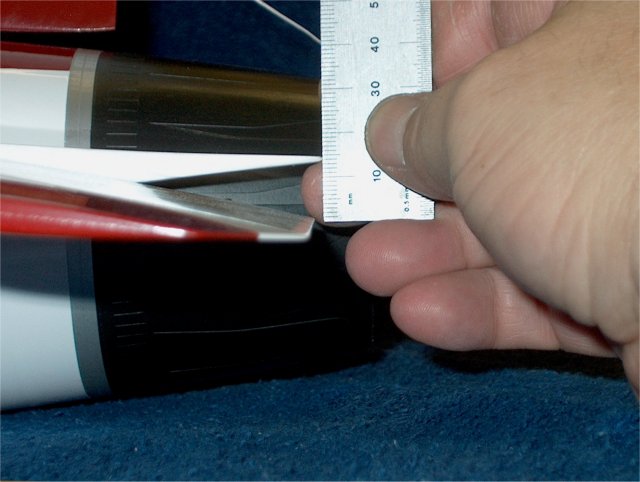

Make amark on the duct at this distance.

Note you will cut rearward from this mark for the airfoil to

exit | |

Make a small plate from 1/64" ply for the

airfoil as shown | |

Mark the area with tape, then cut the

airfoil at the thick side of the duct, where it overlapped.

Glue the plate in place with CA or epoxy, then another piece

of 2" wide packing tape can be used to seal the plate to the

duct | |

The airfoil was removed and the bottom was

tapered rearward to the andgle of the tapered mylar exhaust

duct | |

Install the airfoil, then run the wires

through the duct | |

Test fit the assembly and adjust as

necessary. Shown is a fitted and assembled tail section

| |

Solder to 4mm sockets to the battery wires

for the ESC | |

Plug the wires into the ESC

| |

Use heat shrink to hold the wires in place

and prevent them from coming loose | |

Solder a Deans Ultra plug to the other end

for your battery, or use any other plug that you use for your

power needs | |

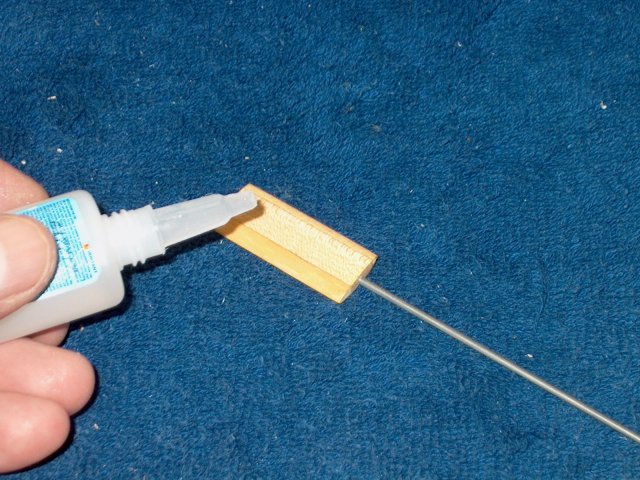

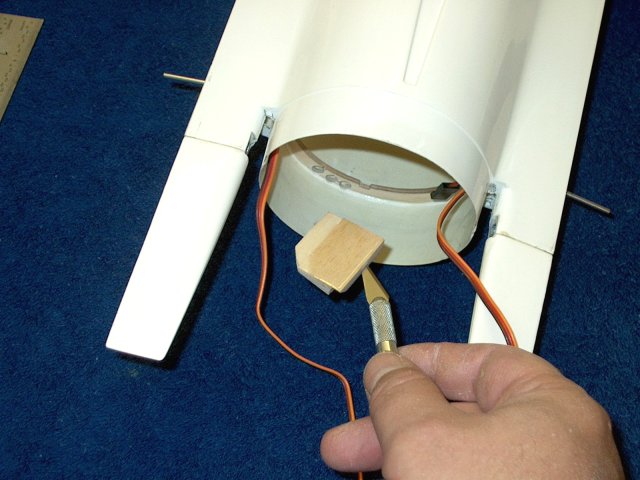

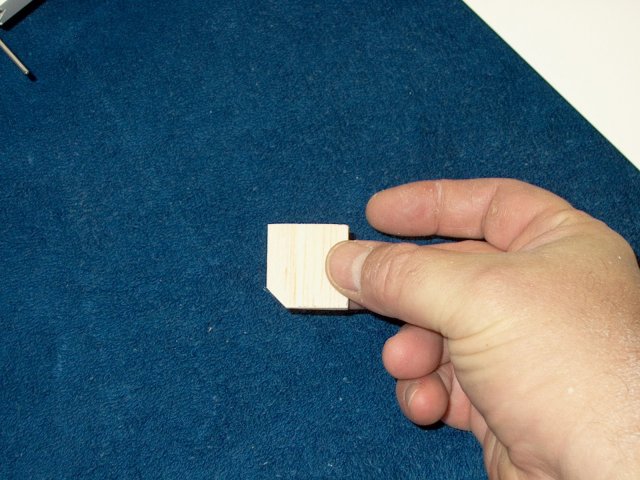

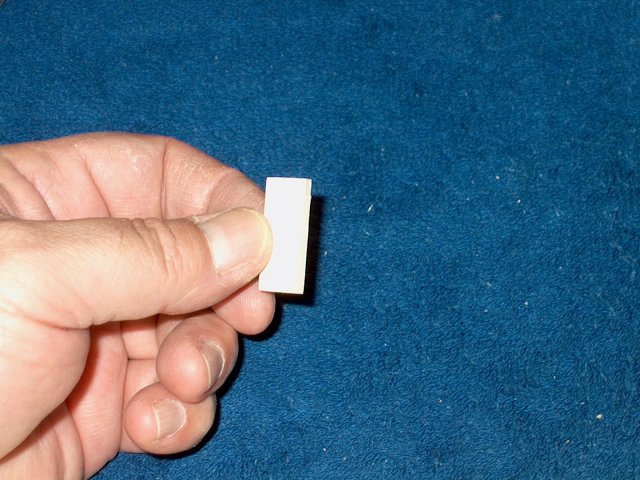

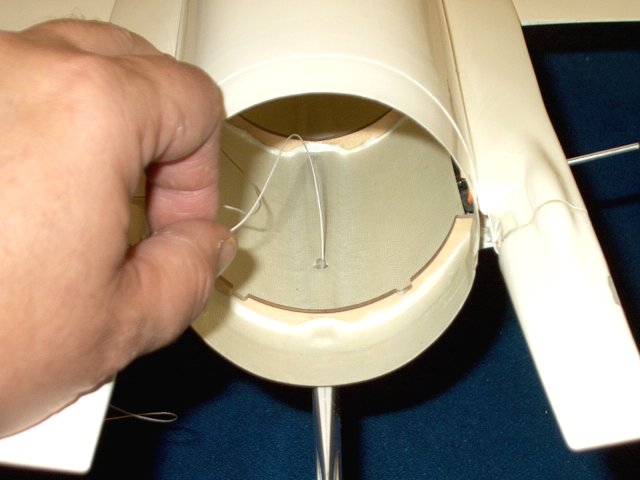

Make an airfoil from hardwood about 3/16"

thick and 3/4" wide. An old piece of wooden Helicopter tail

rotor blade was used and cut to shape as shown. It already had

a good airfoil shape to start and was long enough to act as a

spacer for the intake duct. CAREFULLY drill a hole straight

through the center length of the airfoil with a 5/64"

bit | |

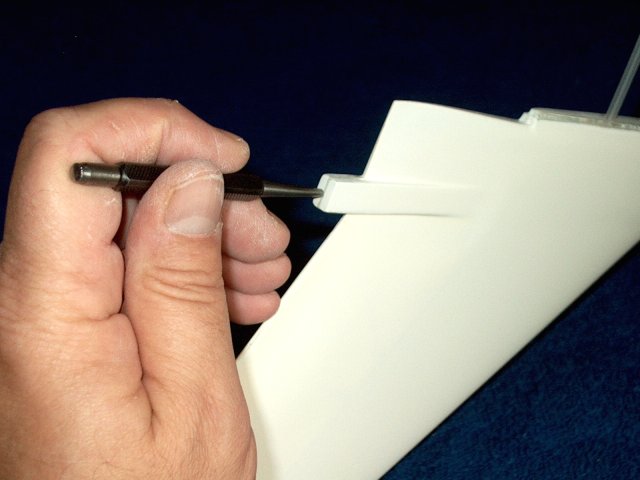

Drill a hole about 3/8" - 1/2" from the

front lip of the intake duct | |

Position the duct, then drill a mark on

the other side, using the airfoil as a guide , which will hlp

you keep it visually centered. Sand the length of the airfoil

spacer so it matches the contour of the intake duct and fits

flush ont he top and bottom. it shoudl also fit without

deforming the shape/opening of the intake

| |

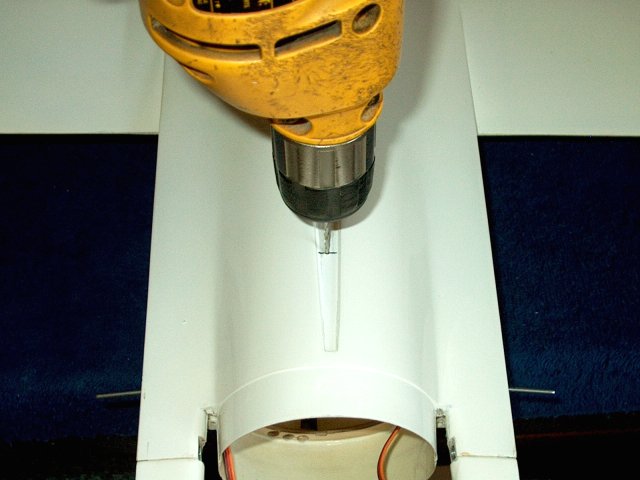

Use a hand drill to finish, drilling

through the duct and fudelage | |

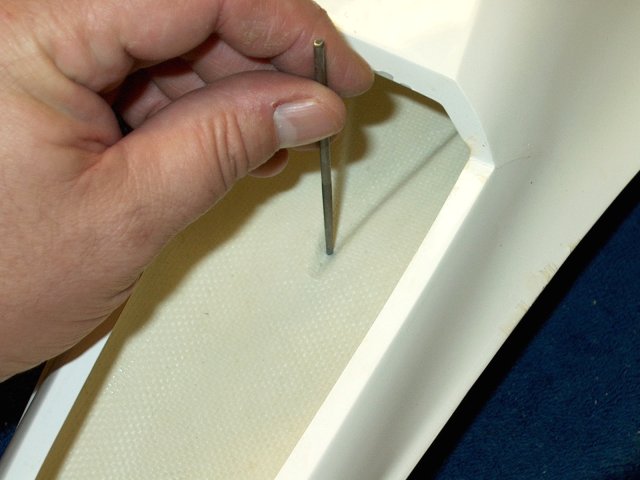

Hole throught he fuselage is shown. This

will also help with alignment during final assembly and gluing

and also strengthen the ductwork | |

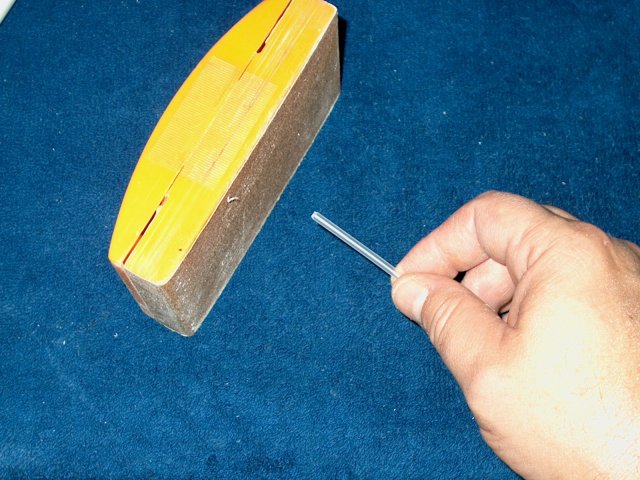

A small file was used to slightly open the

hole so 2-56 threaded rod can pass through

| |

The airfoil is covered with CA to seal the

wood | |

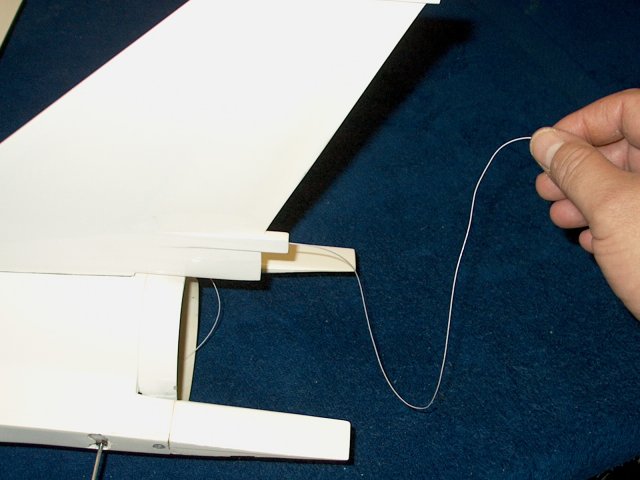

A 2-56 nut is soldered flush to one end of

the allthread rod | |

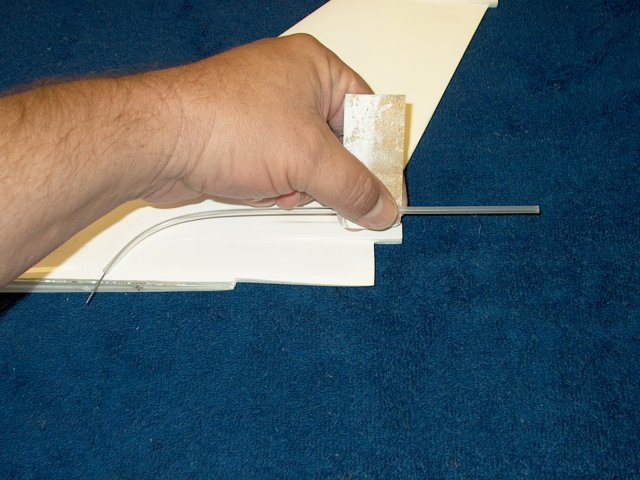

The rod is installe dthrough the duct into

the fuselage, then marked to trim. Allow enough length for

spacers and lock washer/nut | |

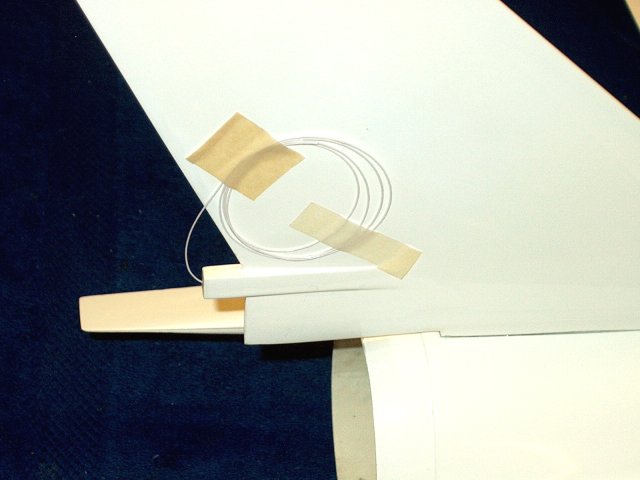

Install the fiberglass intake. Align it

and tape the intake in place | |

Drill through the hole in the fuselage and

into the intake | |

Remove the intake and file the hole so the

2-56 rod fits | |

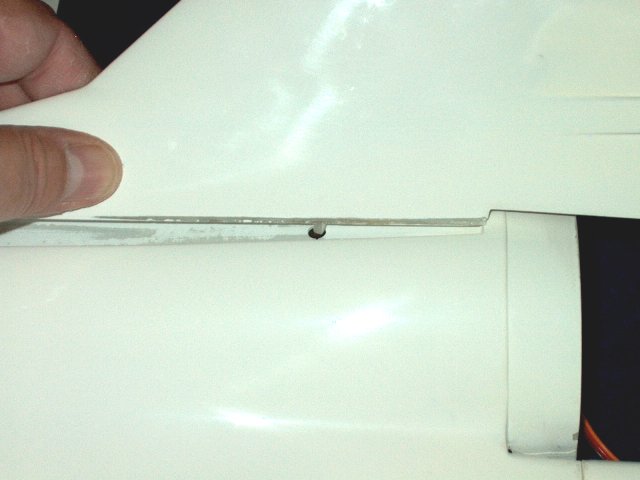

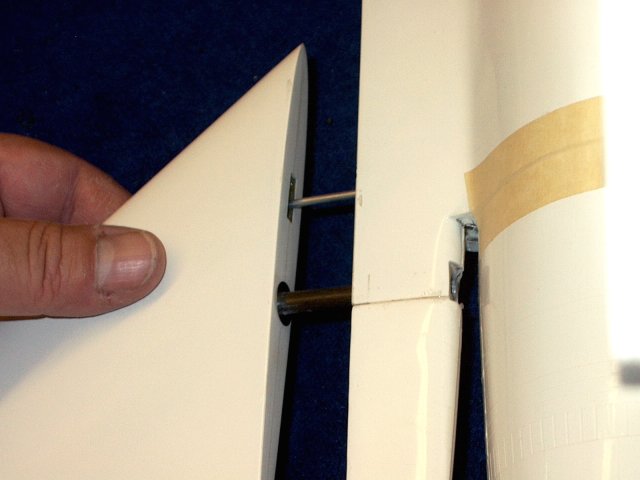

Hole shown drilled through only the top of

the fiberglass intake and through both sides of the carbon

fiber duct | |

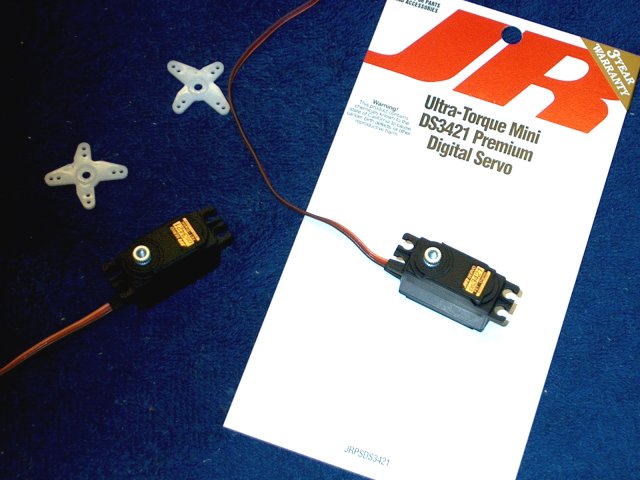

JR DS3421 metal gear servos are used on

the tailerons. These are the ONLY recommended servos as their

low profile makes them the only ones that fit

| |

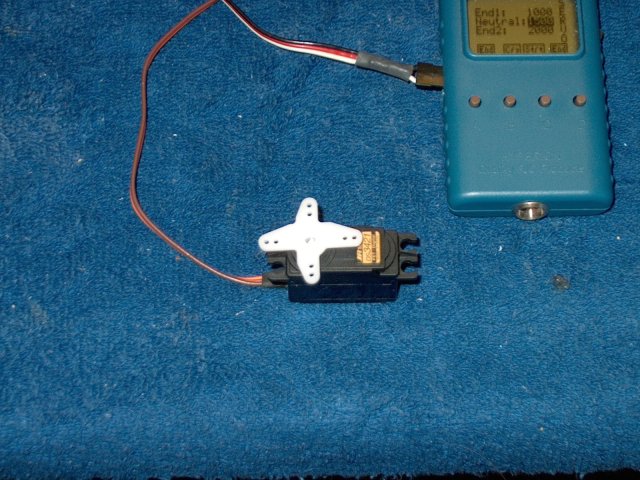

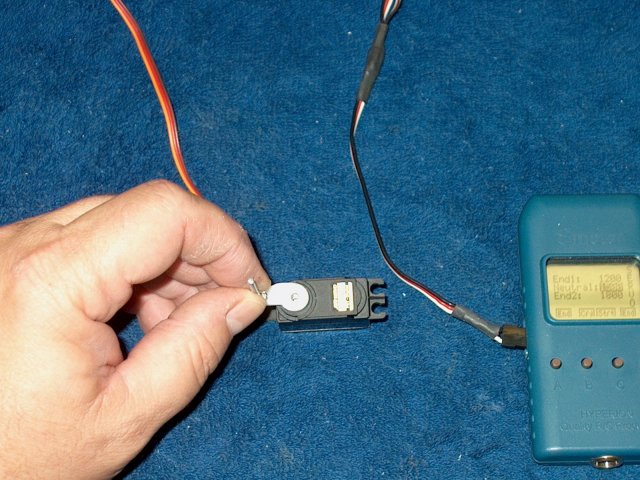

Use a receiver or servo tester to center

the servo, then install the horn | |

Trim away the unused sides from the

horn | |

Trim the mount from the wire side that is

closest to the servo output gear | |

Center the servo, install the horn and

install the retaining screw | |

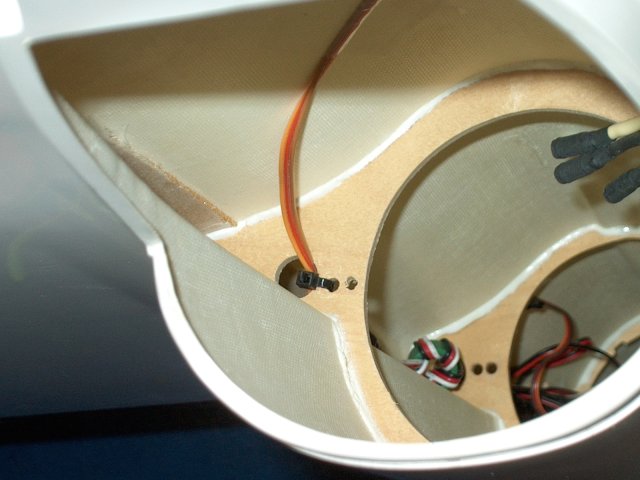

Poaition the servo in the fuselage, then

mark the former for wire clearance | |

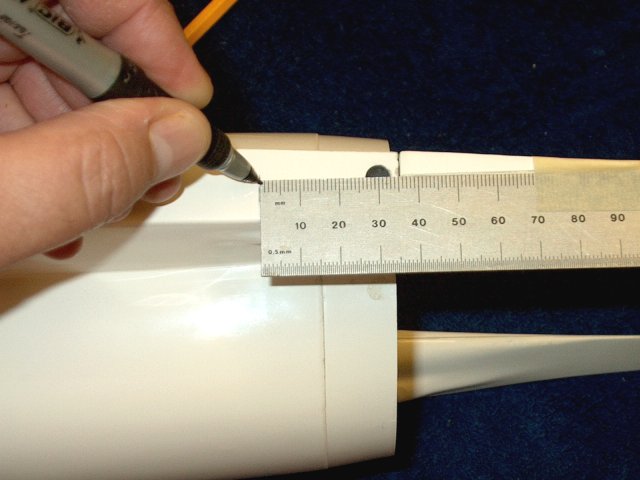

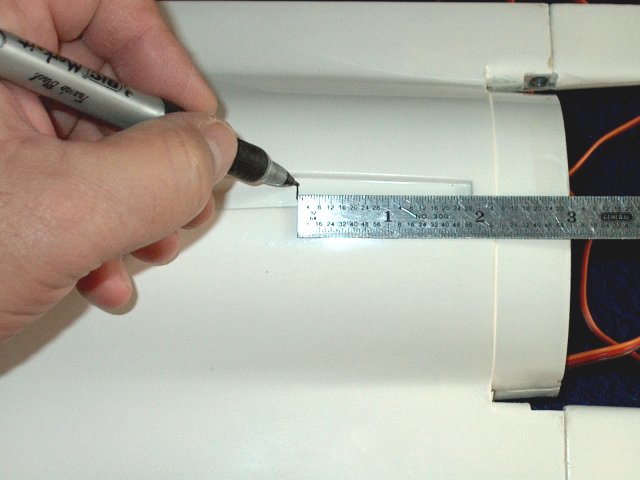

Mark the side of the fuselage 30mm in

front of the center of the tailron shaft

| |

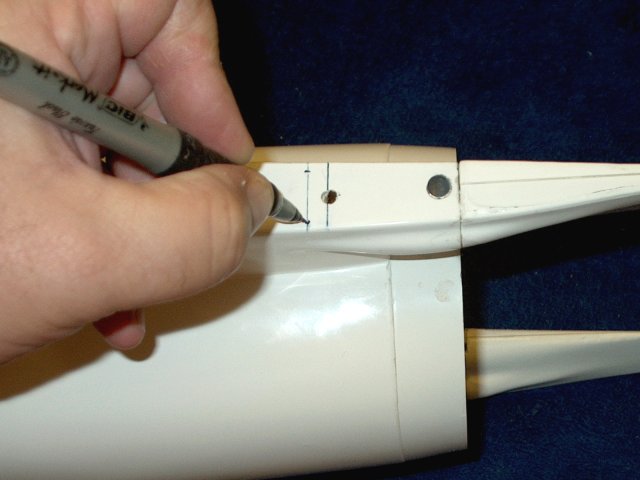

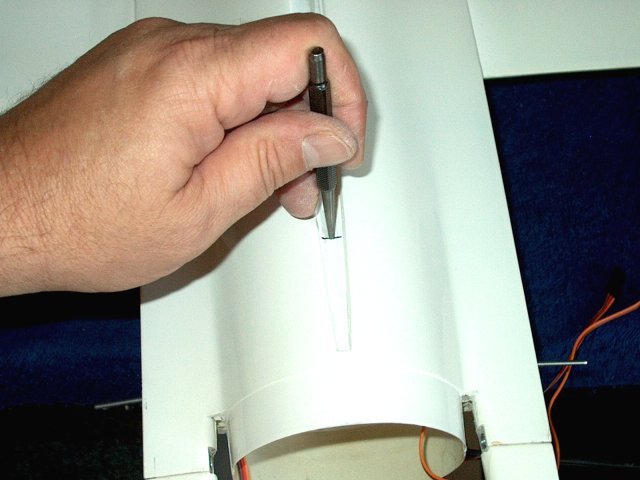

Mark the location with a punch

| |

Drill a pilot hole a tthe mark

| |

Use a saw to remove some of the former on

the inside so the wire passes through while the servo fits

flush against the inside wall of the former

| |

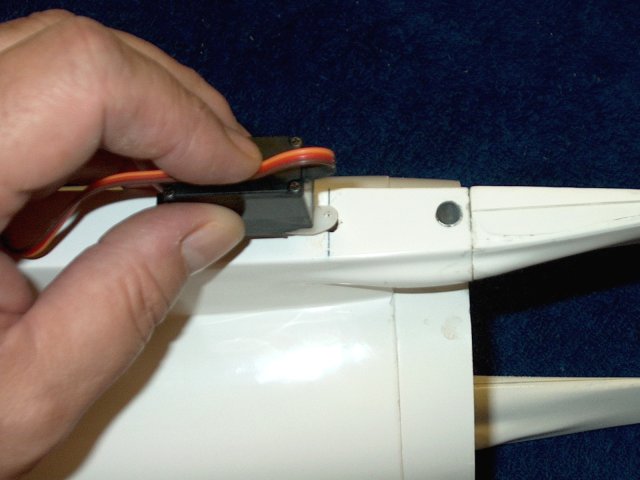

Center the servo and check the outside

hole | |

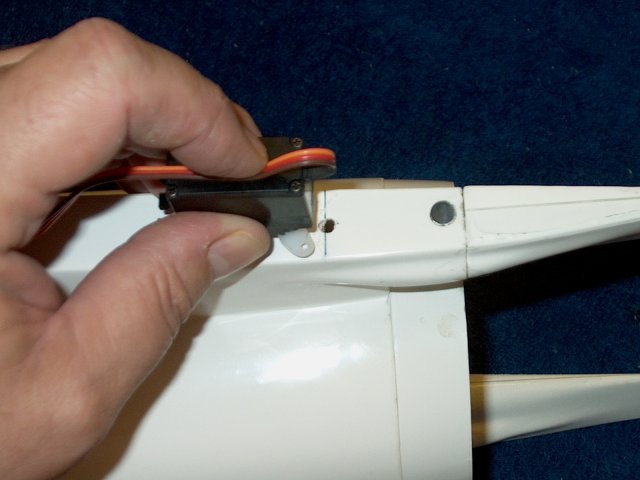

Pivot the servo to the end side of the

fuselage and make a mark | |

Draw a line showing the movement area of

the srvo horn | |

Use a punch to mark the end points

| |

Drill each end point, then carve between

them | |

This was the most difficult part of the

build. The former is right in the middle of where the servo

arm should be and the slot needed enlarged enough to remove

the former pieces, from the outer wall to about 3/8" deep.

Cutting and grinding with a dremel router made the job

easier | |

New tailron pushrods were made from 4-40

rod | |

Cut the rod to length

| |

Drill the outer hole for each rod

| |

Install a top nut flush to the inner side

of the threads and rod | |

Install a nylock nut on the other

side | |

Center the servo and reposition the

horn | |

Install each horn screw

| |

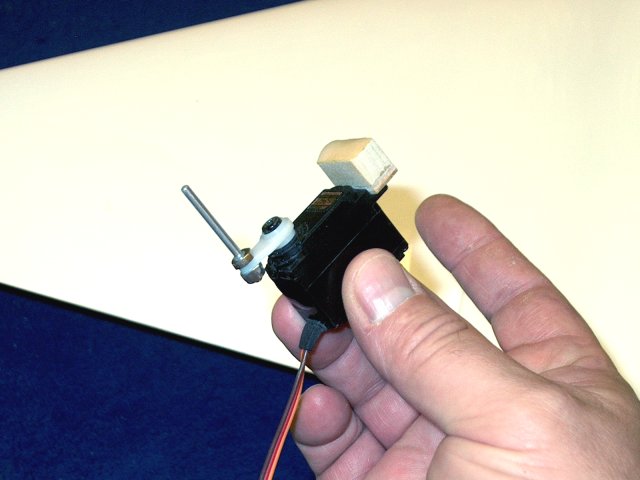

A 1/2" wide x 3/8" thick hardwood block is

cut 3/4" wide ans screwed to the servo

| |

Screws on the bottom side of the servo are

shown | |

Apply epoxy to the top of the block and

the side of the servo by the wire, then install it in the

fuselage. NOTE... pay close attention to alignment and check

for correct position before gluing the servo

| |

The servo must be positioned so the

pushrod is perpendicular to the fuselage

| |

Important: Not only must it be aligned to

the fuselage, the servo must run at a parallel downward angle

to the taileron. You will need to install a taileron and

check, then hold the servo in place while the glue sets. For

these reasons, 5 minute epoxy is recommended

| |

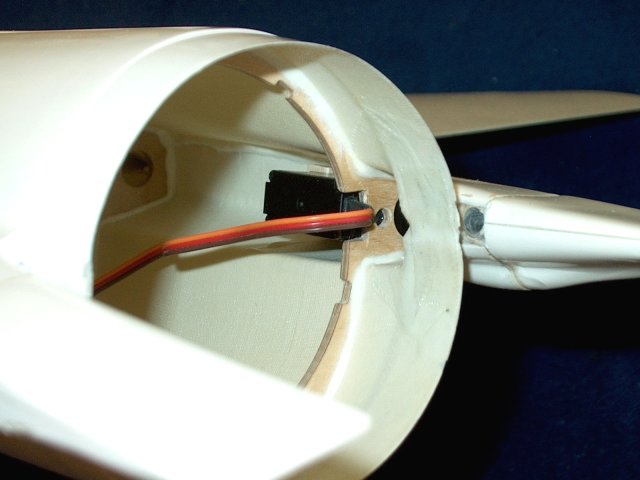

Servo is shown with wire side glued to

inside of former and the wood block is glued to the outer wall

slot (located behind servo) | |

Another Important Note! Both sides of the

fuselage were not even...one side had the former closer to the

taileron shaft hole than the other. You should space the

shorter side with a piece of ply between the inside of the

former and servo | |

Ply spacer was needed on the short side,

where the former was closer to the taileron shaft hole. This

insured that both servo pushrods would be equally spaced from

their respective taileron shaft holes

| |

The second servo is glued into place, the

same as the first | |

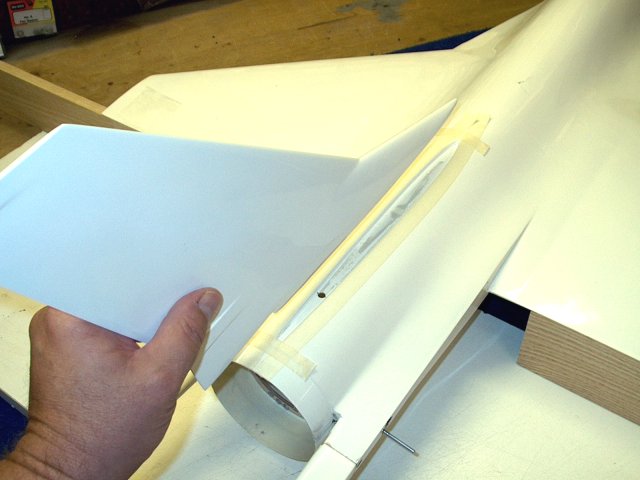

The intake duct was taped and primed, then

painted prior to completing the build

| |

Photo shows intake primed first, then

sanded | |

Intake painted with gloss white

| |

The spacer airfoil was also painted

| |

The rear of the inside area was cleaned

with an alcohol pad | |

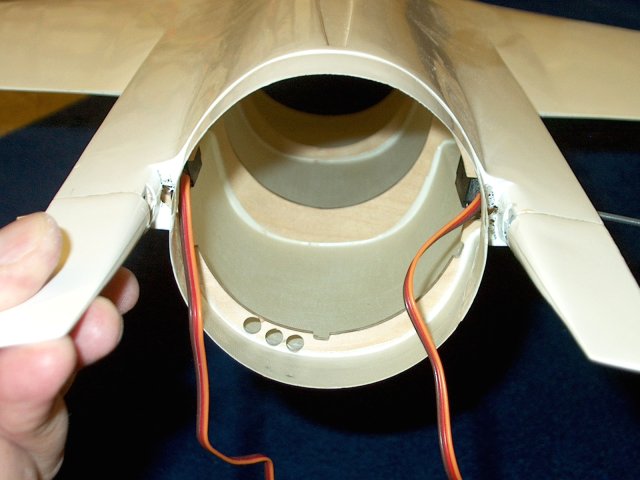

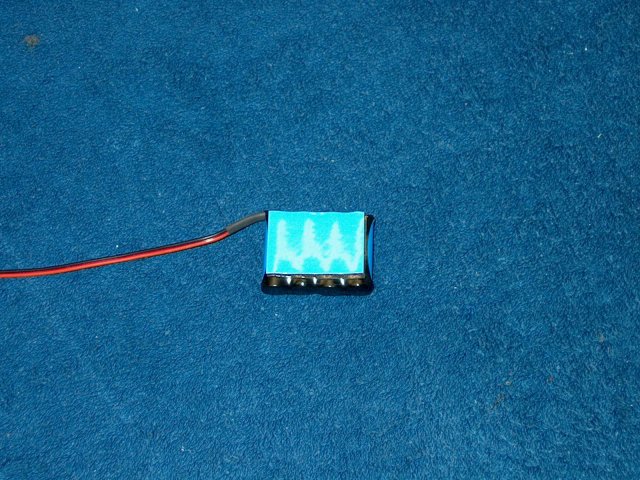

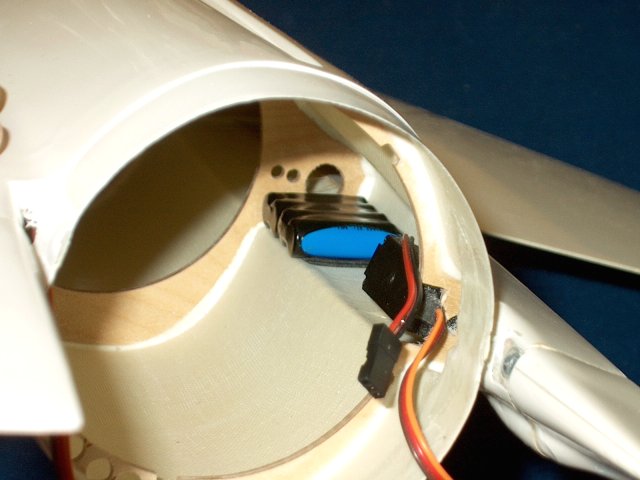

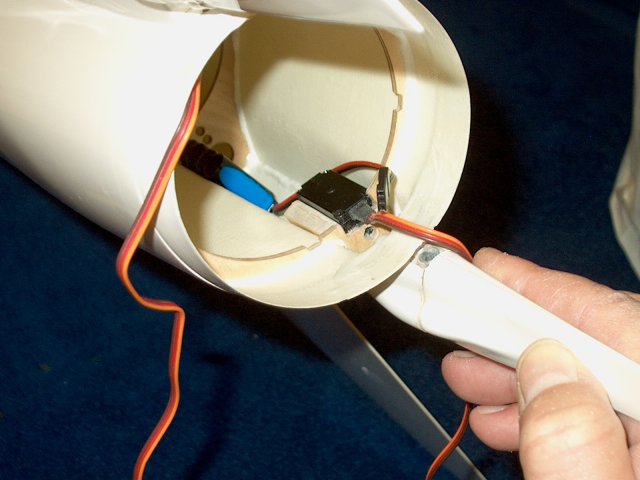

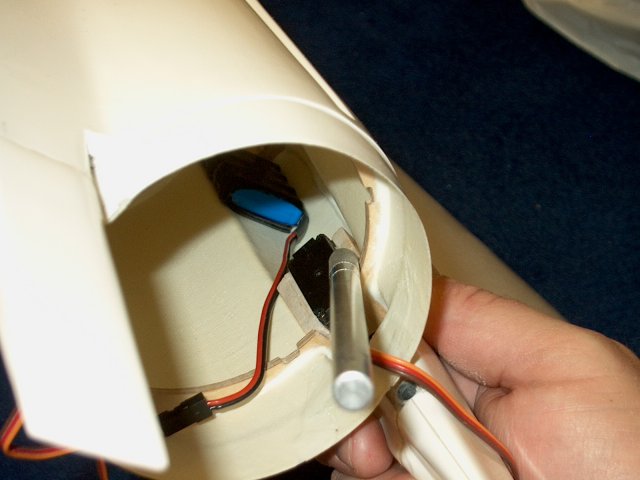

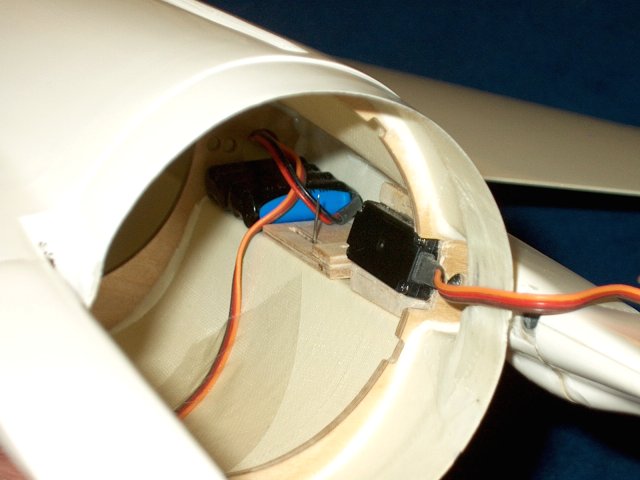

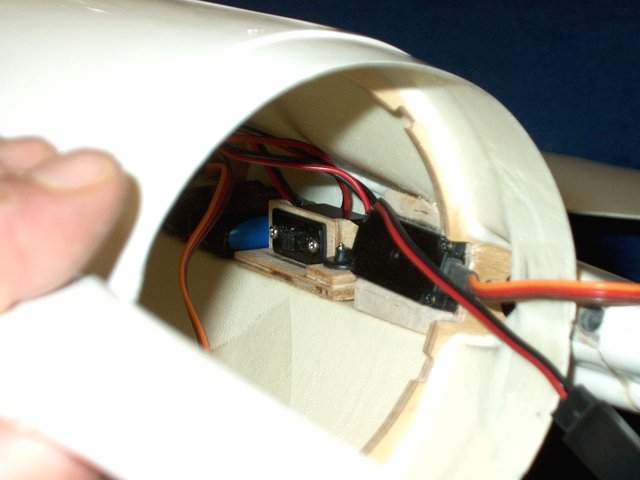

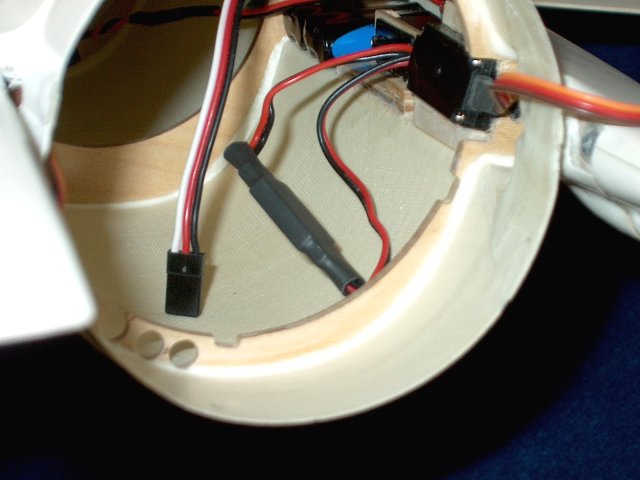

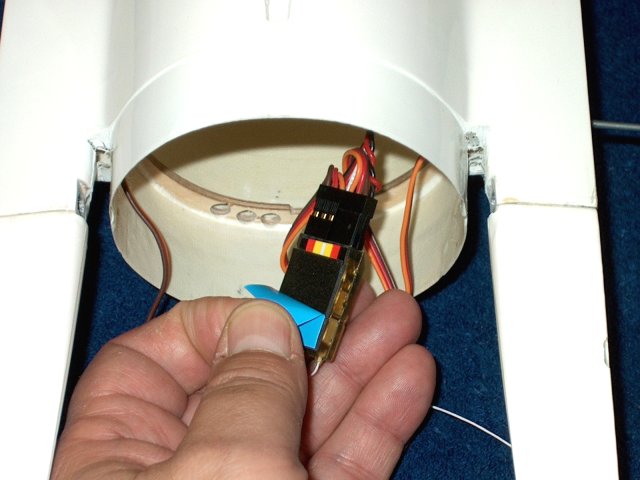

Apply two layers of servo tape to your

receiver | |

Install your receiver battery or BEC as

shown. A 2/3AAA 400mah NiMH pach was used for this model and

it weighs about the same as a U-BEC

| |

Make wedges for the servos on the top and

bottom by cutting a couple pieces of 3/16" thick balsa to

shape | |

Apply epoxy to each wedge

| |

Install them in place on one servo

| |

Apply epoxy to the second wedge

| |

Install the wedge on the bottom for the

other servo | |

Cut two more wedges for the top

| |

Apply epoxy and install each of the two

balsa wedges on top of the servos | |

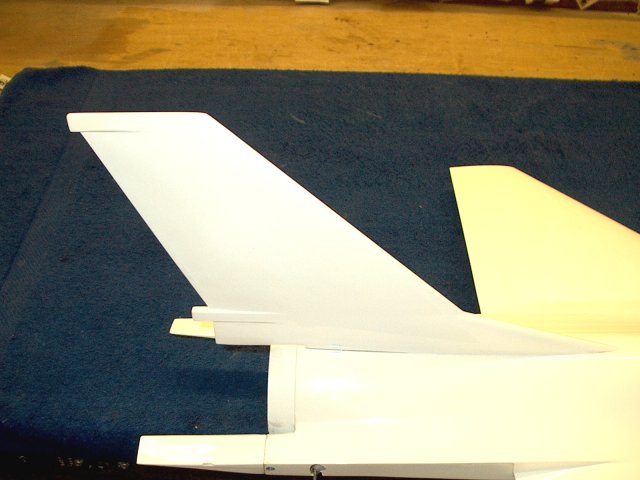

Rough up the edge of the Vertical

Stab | |

Sand the shelf for the vertical

stab | |

Make a mark in the stab well 3" from the

rear of the model. This will be for the antenna. Note that

this is only one method of installing the antenna

| |

Transfer the mark from the fuselage to the

bottom of the stab | |

Mark the location with a punch

| |

Drill a 1/8" hole for the antenna

tube | |

Mark the rear center of the fin as

shown | |

Drill a 1/8" hole for the antenna

tubing | |

Cut about 9" of antenna tubing

| |

Bend a small pushrod wire so it curves

down and passes through the bottom hole

| |

Slightly round the end of the antenna tube

so it passes through easily | |

Check the antenna tubing run and make sure

you have enough length for your guide rod

| |

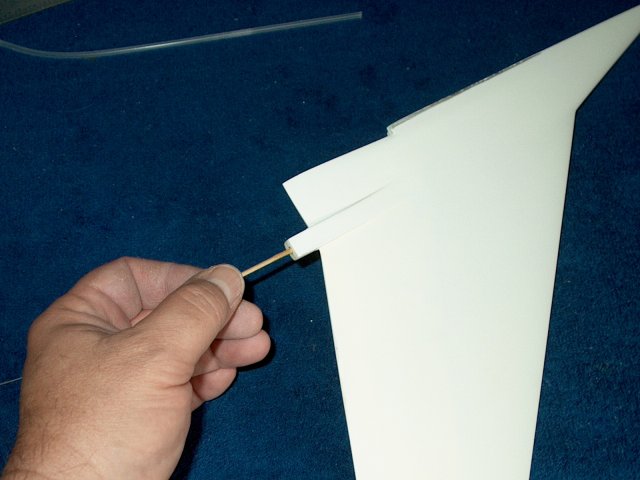

Apply some epoxy in the rear hole with a

toothpick | |

Install the antenna, working it to the

bottom center of the stab using the wire as a guide. A piece

of paper towel along with a couple drops of alcohol can be

pushed torugh to remove any epoxy the inside of the

tube | |

Allow the epoxy to set

| |

Trim the tubing flush with the end of the

stab | |

Antenna tube installation completed

| |

Use a punch to mark a hole for the antenna

tube exit | |

Drill a 3/16" hole for the tube

| |

The oversized hole will allow for easier

installation | |

Check the fit and make sure the tube

clears the hole | |

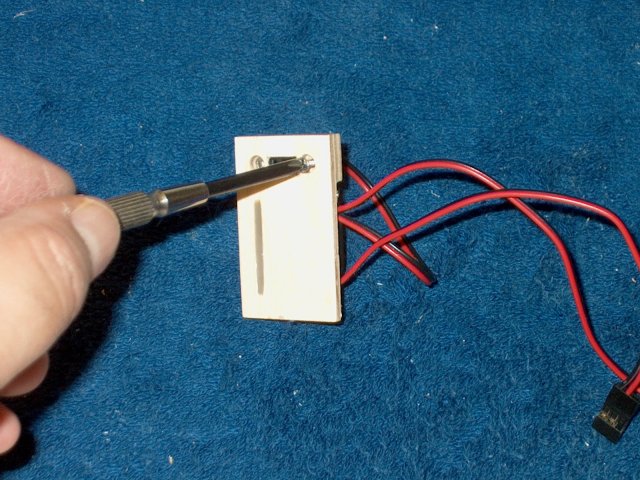

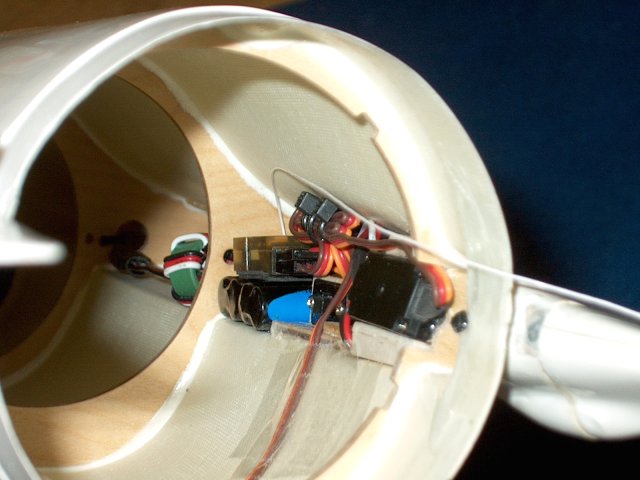

A small plate was made from 1/16" ply to

hold the ESC. The ESC is mounted to the plate and tied in

place | |

A piece of servo tape is added to the

bottom of the ply under the ESC | |

Apply epoxy to the other half of the plate

| |

Install the ESC inside the fuselage as

shown | |

A wood dowel can be used to hold the ply

plate to the wing sheeting until the epoxy cures

| |

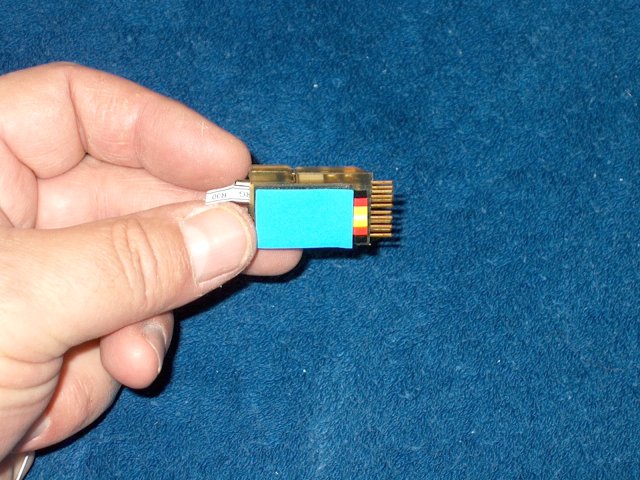

A 18" servo extender is wrapped on a balun

and should be about 12" long when finished

| |

Feed the extension through the hole from

the rear and plug it into the ESC and use heat shrink to

insure it does not come apart | |

Make sure the servo wire run is on the

opposite side of the fuselage, away from the ESC wires

| |

Tie wrap the excess servo wire from the

right side servo | |

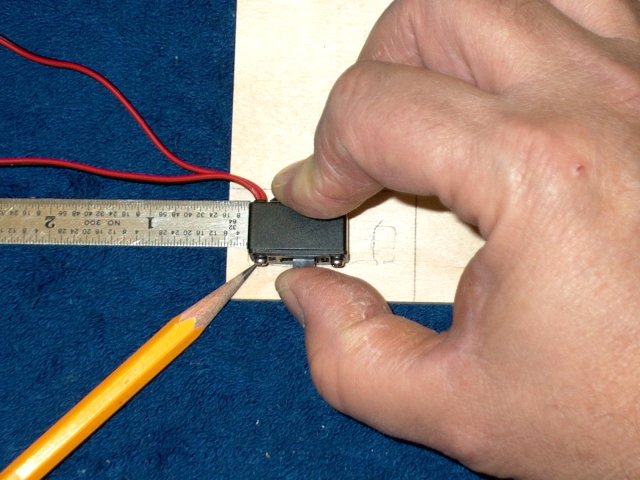

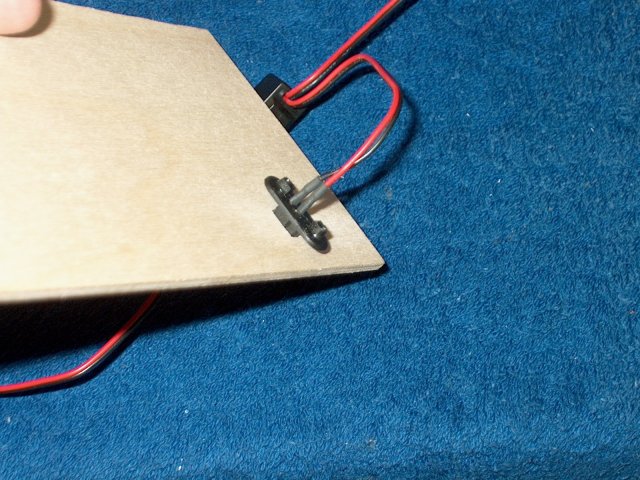

A Deans charge jack is installed on the

radio switch | |

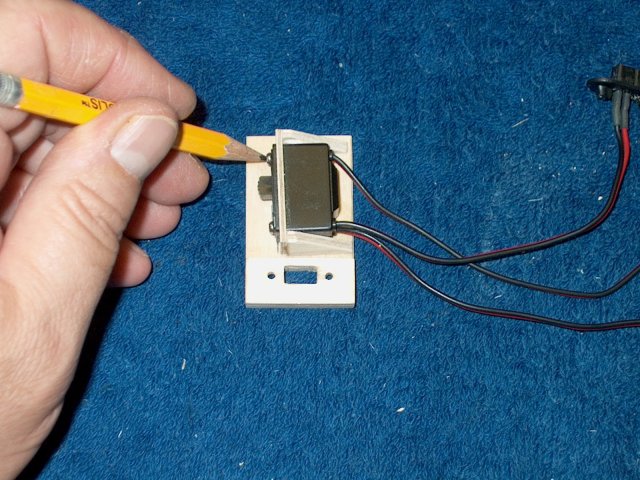

A switch mounting board is cut from 1/8"

ply | |

Transfer the shape of the switch to the

board | |

Also transfer the shape of the charge jack

to the board | |

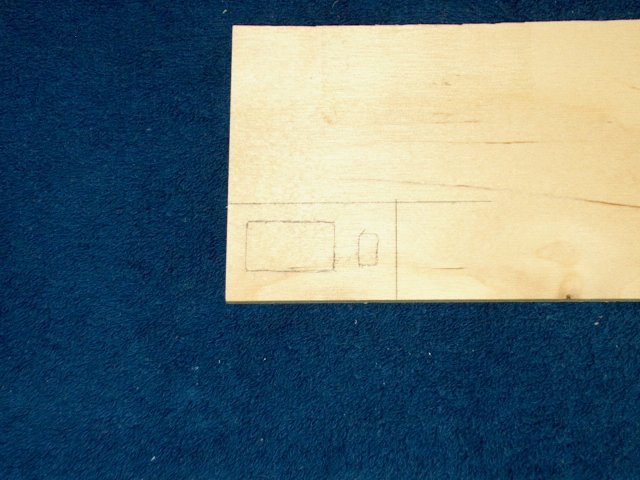

Pattern is shown drawn on the ply

| |

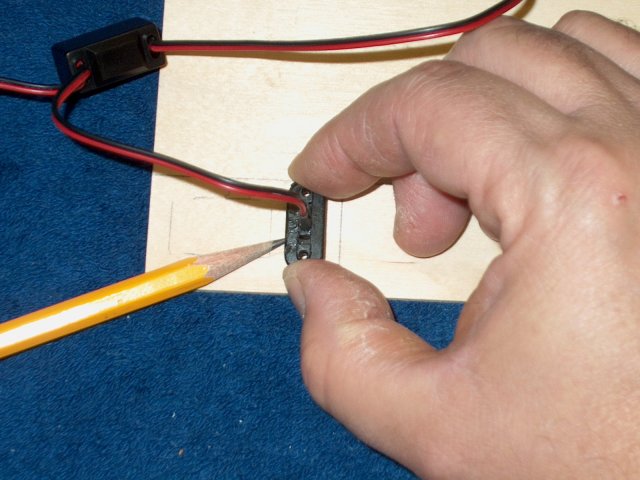

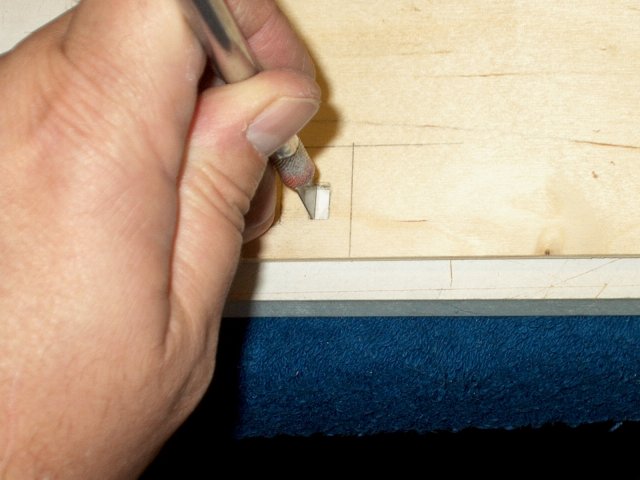

Use a chisel Exacto to cut the slot for

the charge jack | |

Check the fit of the jack

| |

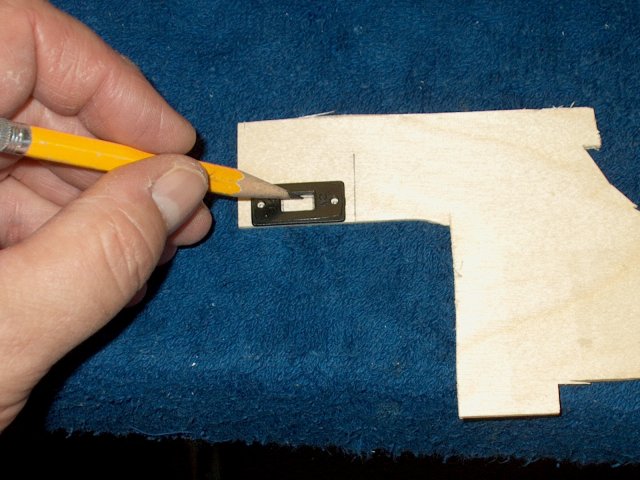

Transfer the switch plate slot to a piece

of 1/32" ply | |

Cut the switch hole in the plate with a

chisel knife | |

Drill the mounting holes for the

switch | |

Cut the mount plate for the switch

| |

Check the switch for fit

| |

Cut a spacer for the charge jack from 1/8"

ply | |

Glue the ply spacer to the board over the

jack hole as shown | |

Install the jack and drill two small holes

for mounting screws | |

Countersink the other side of the

holes | |

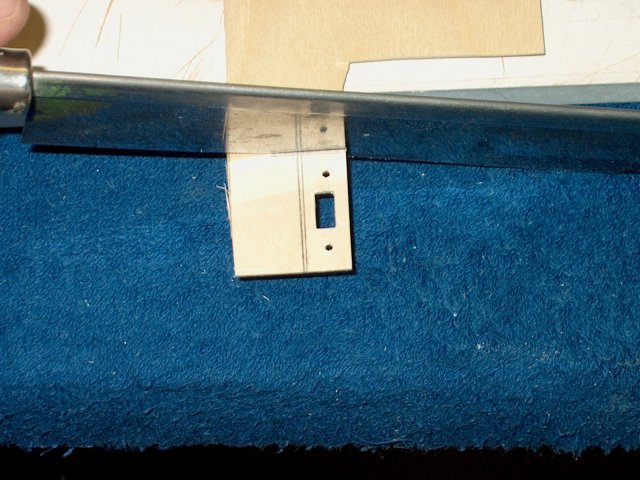

Install 1/8" ply side plates to the

switch | |

Position the switch and draw a line at the

front edge of the faceplate for the switch

| |

Draw a second line 3/32" in front of the

first | |

Cut a slot here so a 2-56 sized pushrod

will fit through the slot | |

Install the plate in the fuselage

| |

Measure from the front of the plate to the

rear of the fuselage | |

Draw a locator line on the fuselage

| |

Place the plate with its front at the

mark, then transfer the slot pattern to the fuselage

| |

Install the plate in the fuselage, then

use a push pin to make sure you are centered

| |

Pin is shown exiting the slot

| |

Place strips of masking tape over the wood

on both sides of the slot and transparent tape over the slot

underneath, then apply candle wax to the slot and scrape away

the excess | |

Remove the tape from both sides. Apply a

piece of masking across the board, covering the slot and jack.

Trace the slot and jack position on the tape, then remov the

tape and set aside. This pattern will be used larter

| |

Apply epoxy to the frame of the

switch | |

Install the switch in place and be sure

not to cover the slot | |

Install the retaining screws for the

charge jack | |

Apply epoxy to the board, but not in the

jack area | |

position the switch and glue in place

inside the fuselage | |

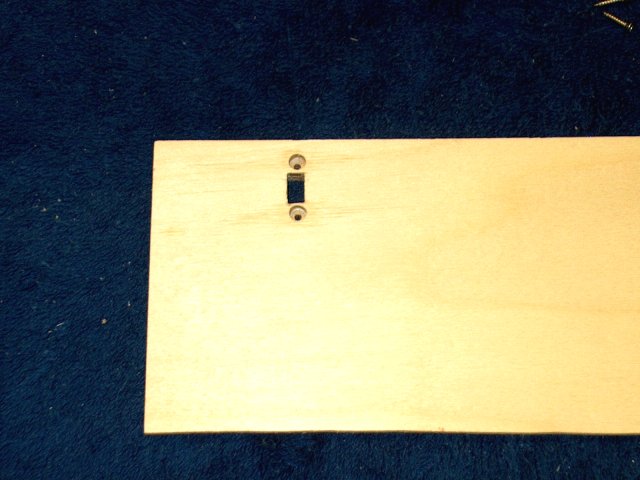

Tie wrap the ESC wire as shown leaving

some slack in the wire | |

Apply your pattern tape ove rthe location

for the switch plate | |

Slowly cut the slot from the outside of

the fuselage and cut the charge jack from the pattern

| |

Use a file to smooth out the slot

| |

Plug the battery into the switch and cover

with heat shrink so it will not unplug

| |

Make sure all four servo wires will reach

to the right side of the fuselage | |

Install a piece of servo tape to the

bottom of your receiver | |

Plug the servo and switch wires into the

receiver | |

Remove the cover from the servo

tape | |

Install the receiver in place as shown.

Neatly dress the wires so they are out of the way

| |

Apply masking around the edges of the

fuselage to catch any excess eopxy spillover when gluing the

vertical stab in place | |

Make a jig to hold the fuselage so

alignment of the vertical stab could be checked. Dry fith the

stab; the one in the picture was a perfect fit when held flat

against the top of the fuselage slot

| |

Apply epoxy to the bottom of the vertical

stab | |

Install the stab on the fuselage

| |

Check alignment and adjust if

necessary | |

Vertical Stab installtion completed

| |

Run the antenna wire through the stab tube

as shown | |

Pull the antenna wire from the rear. LEave

just a little slack inside and tape the wire with masking to

the fuselage wall | |

Roll up the wire and tape it to the side

of the fuselage to keep it out of the way

| |

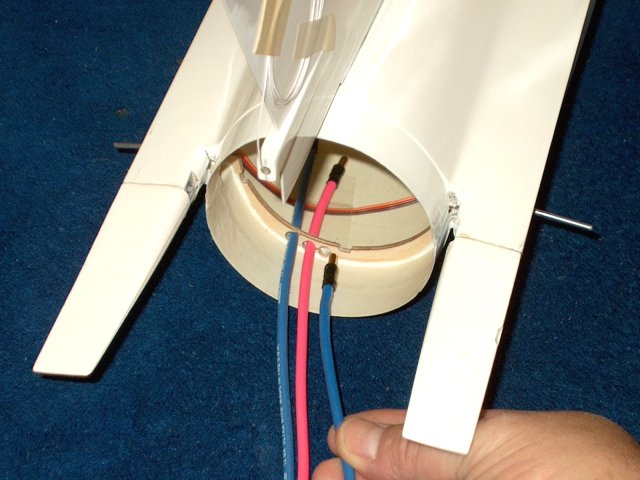

Pass the three ESC wires through the holes

in the rear | |

Run the wires though the hole in the side

of the fuselage and forward to the ESC

| |

Install a piece of heatshrink over each

wire, then plug them in to the ESC. This was most easily

accomplished by inserting one had through the rear opening and

one through the front, then pluging the wires together

| |

Install the heatshrink over each

connection to keep them from pulling apart

| |

ESC Wire installation completed

| |

Install the intake duct in place and check

for final fit | |

Insert the all thread rod to make sure the

duct is aligned with the fuselage | |

Remove the duct, then install masking on

the inside rear | |

Tape the ESC servo wire out of the way,

then apply epoxy to top of the first former

| |

Apply epoxy to the next former as

shown | |

Install the duct in place, making sure the

hole for the allthread is aligned. Apply a thick bead of epoxy

at the joint as shown. You can push down on the duct to get

epoxy under the fuselage area at this location

| |

Clean out the wax from the slot hole in

the plywood. Check thsat you can use a rod from the slot to

turn the receiver switch off and on without binding

| |

Clean any epoxy from the lip of the duct

at the rear. A filet of epoxy can be applied at this rear

joint | |

install the fan asembly in the

fuselage | |

Align the fan as shown

| |

Apply silicon sealer to the rear of the

housing and rear former joint. You can flex the housing away

from the former with the dispenser tip to apply silicon to

this area | |

Clean up any excess silicon

| |

Position the exhaust tube over the rear of

the fan housing | |

Check the fit by installing the exhaust

nozzle | |

Rough up the landing areas of the intake

cover | |

Rough up the rear edge as shown and clean

up any dust | |

Rough up the fuselage area where the cover

will mount | |

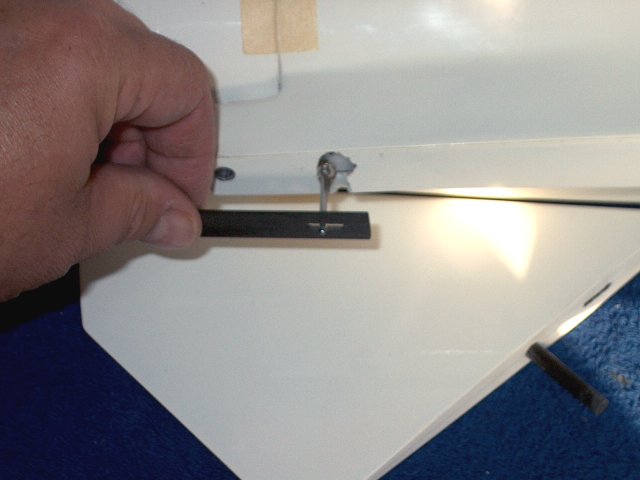

Install the alltread rod and spacer

| |

Apply masking to the glue area to catch

excess resin | |

Apply masking to the cover area to catch

excess resin | |

Apply masking inside the intake to keep it

clean | |

Position the spacer slightly off to one

side so the rod doesn't go through the fuselage hole

| |

Apply epoxy to the intake as shown, as

well as the cover | |

Install the cover; you will have to flex

it open to get it over the allthread rod

| |

Once the cover hole is aligned with the

intake and fuselage hole, push the rod through. Make sure the

airfoil is pointing straight. Clamp the lower joint until the

epoxy sets | |

Install the washer and nut over the

threaded rod and tighten | |

Tape the cover in position until the epoxy

sets | |

Intake Cover installation completed

| |

Apply a couple drops of CA to the threads

and nut | |

Install a Elevon so it butts against the

servo control rod. Make a mark at the front of the rod

| |

Push the servo all the way down and make

another mark at the rear of the rod

| |

Use a file to open up a slot as

shown | |

clean up the marker marks with

alcohol | |

Mark the second elevon the same as the

first | |

A piece of 1/2" x 1/16" thick Carbon Fiber

rod is used to replace the oversized and unuseable round rod

guides that were supplied in the kit. Draw a center line down

the carbon rod | |

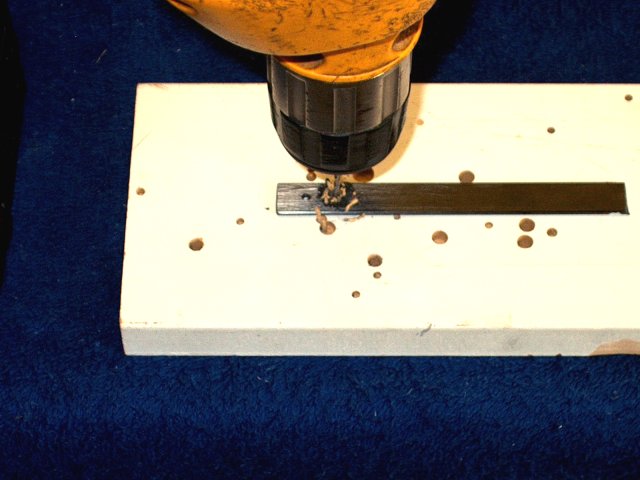

Use a drill to make several small 5/64"

holes down the center | |

Make sure you leave at least 1/4" ov

material on each side | |

Cut, then file the slot and check the fit

over the control rod | |

The fit should be smooth without any

vertical play along the entire 1/2" long slot

| |

Plate contruction completed

| |

Tape the first carbon plate over the rod

and use it as a pattern for a second plate

| |

Drill several holes down the second

plate | |

Carefully cut the second slot, then file

and fit | |

Take your time and make sure it is a

smooth and slop free fit | |

Cut the second plate to length

| |

Rough up the glue side of each plate with

60 grit sandpaper | |

Drill holes and cut the slot in the second

Elevon | |

Apply servo tape to the back of the two

carbon plates. Do not apply to the glue side

| |

Remove the backing, The servo tape is used

to adhere to the T-Pin that's used to install the plates

| |

Cut the excess servo tape from each

slot | |

Apply epoxy mixed with fiberglass mil to

the slot top and bottom | |

Apply epoxy to the plate, then place a

T-Pin through the slot to the stick back servo tape

underneath | |

Install the plate in the slot usint the

homemade T-Pin, which should be wide enough to allow the layer

of epoxy to remain on the plate. Turn the face downward and

use the "T" part of the pin to pull the plate to the

wall | |

Remove the T-Pin and clean up the excess

epoxy | |

Check and align the plate with the Elevon.

Make sure it is even using the seam of the elevon for

alignment. A piece of 4-40 rod makes a good checking

tool | |

First plate is shown glued in place

| |

Apply epoxy mix to the second plate and

elevon opening | |

Glue the plate in place the same as the

first and use the rod for alignment to the seams on the

elevon | |

Remove any excess epoxy

| |

Install the washer over each Elevon

| |

Install each Elevon on the fuselage as

shown | |

Install the wheel collars and tighten them

down with the set screw pointing straight down

| |

Elevon Installation is completed

| |

Slightly sand the cockpit front and rear

if necessary | |

Sand the fuselage area for a good cockpit

fit | |

Ckeck the fit of the cockpit. Note that

there should be a lip at the top rear

| |

Use some trim tape along the seam of the

canopy. The seam can be diffucult to see and the tape will

help | |

Make sure you cut oversized so there is

enough material for a custom fit | |

Draw a line 1" from the front of the

Cockpit | |

Draw a line 1" from the rear of the

Cockpit | |

Use masking tape to pull the front sides

of the cockpit frame in so they fit the fuselage sides

| |

Repeat at the rear and use masking tape to

pull the rear sides of the cockpit frame in so they fit the

fuselage sides. Once adjusted, cut two 1/2" wide x 1/8" ply

strips long enough to hold the sides in place and sand them to

fit, then epoxy them in at the 1" lines you drew

earlier | |

Measure the center of the cockpit front

and mark it | |

Cockpit frame sides pulled in to the

correct shape | |

Drill a pilot hole at the cockpit front

center mark | |

Tape the cockpit in place, centered on the

fuselage. Drill a 1/8" hole by hand through the cockpit and

fuselage | |

Round the end of a piece of 1/8" diameter

wooden dowel. Cut to a length of 3/4"

| |

Push the dowel through the hole in the

front of the cockpit and glue the rear with epoxy

| |

A Test Lead plug is used for the rear

retension of the canopy. An 8-32 nut fits the threads on the

read of the lead plug | |

Glue a 1/16" support plate in the rear of

the cockpit as shown | |

Drill a hole through the center so the

threads of the plug can pass | |

Install the plug through the hole and use

a nut to retain it on top. The nut can be covered with a piece

of balsa, painted as part of the cockpit

| |

Make a plate from 1/8" ply and the rear

piece from 3/8" x 3/8" hardwood, with an angled front end made

from 3/16" balsa. The hardwood block will need to be shortened

in height to fit | |

Drill a hole through the center of the

plate, leaving a small gap between the hole and the rear

hardwood support to compensate for the fuselage wall

thickness | |

Apply epoxy to the hardwood

retainer | |

Install the plate in place as shown, using

the Cockpit to insure sis-to-side alignment. Check the fit of

the Cockpit pin in the rear, then glue the tube in place when

satisfied with the fit | |

Cut the canopy so the front fits the

cockpit frame | |

Use tape to mark the location of the rear

lip through the window, then cut away the excess

material | |

Check the fit of the Cockpit and fine sand

as necessary | |

Tape the Cockpit in place to the

fuselage | |

Apply masking tape to the Canopy as

shown | |

Use Canopy Glue such as RC56 to glue the

Canopy to the Cockpit | |

Install the Canopy and used the tape to

hold the Canopy to the frame until the glue dries

| |

Canopy and Cockpit installation

completed | |

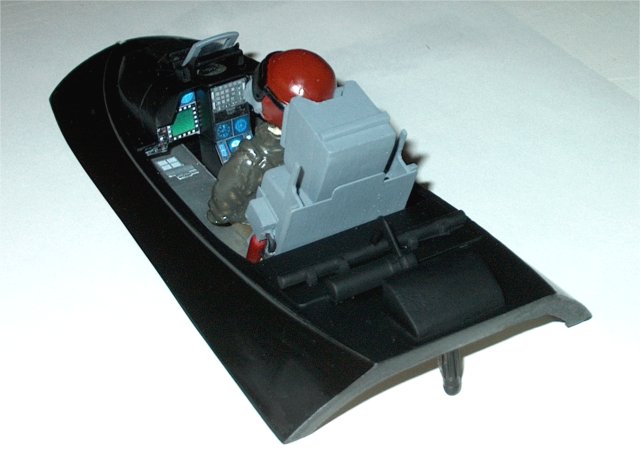

Paint you model, then a detailed Cockpit

can be made to add some realism | |

Drill a hole at the center on each side of

the Exhaust cone | |

Install #2 cap screws to retain the

exhaust | |

Set the Elevator Up throw to a minimum of

16mm; note that more is better with this model and the setting

shown was set to 18mm | |

Set the Elevator Down throw to 14mm

| |

Set Aileron Up and Down throw to

16mm | |

CG is measured from the rear of the wing

trailing edge. Make balance marks so you can set CG to

210mm | |

Battery trays and velcro were added to

ease battery installation and hold them in place

| |

Install the batteries and check CG.

Everything should be below the canopy cover edge of the

fuselage so the canopy will sit flush

| |

This F-16C was painted in Japan's color

scheme after their Technical Research and Development

Institute F-16 FSX/F2 scale jet aircraft

| |

Top Side view of the model

| |

Front view of the model

| |

Side view showing markings on the intake

sides | |

Rear view of the F-16

| |

|