1 - A simple Bungee Pedal launcher can be

made for parts readily available at your local hardware store such

as Lowes or Home Depot. Nearly all the parts are shown

|

|

2 - Required hardware includes the Spring Hinges

as shown, Stainless Steel rustproof harware for the bolts to include

three 8-32 x 1" countersink bolts, three 8-32 nylock nuts, a 1/4" x

2 1/2" bolt, a 1/4" "T" nut, a 1/4" fender washer (not shown) and a

1/4" nut. In addition, a 1" chrome ring, a piece of 3/4" x 1 1/2"

long heat shrink (not shown) and some 3mm nylon cord round off the

necessary supplies

| |

3 - The pedal is made from a single 24" long piece

of hardwood, in this case we used Oak. It is a 1/2 x 3 that is 2' long

| |

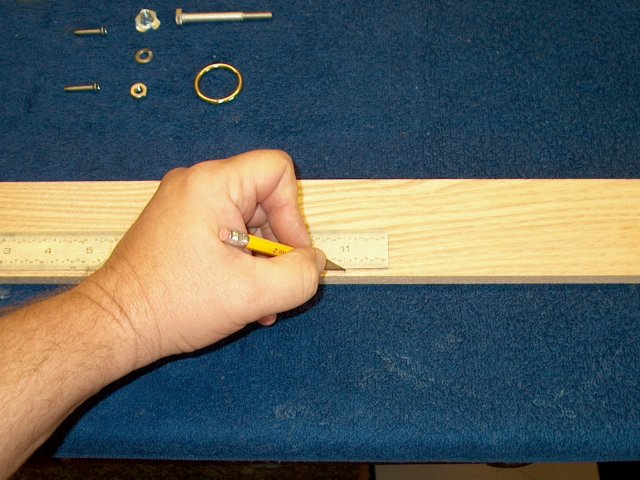

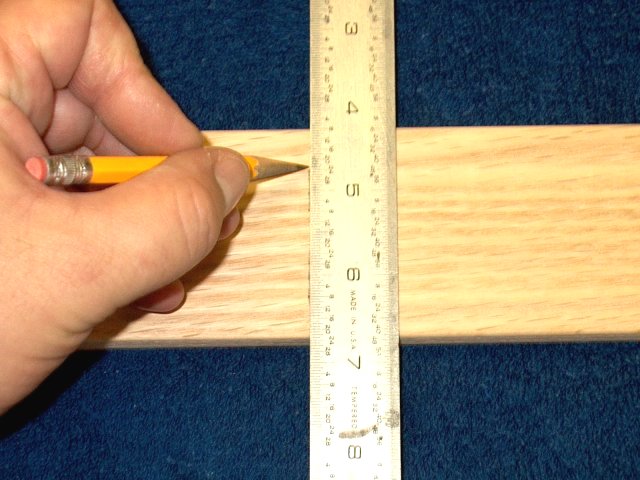

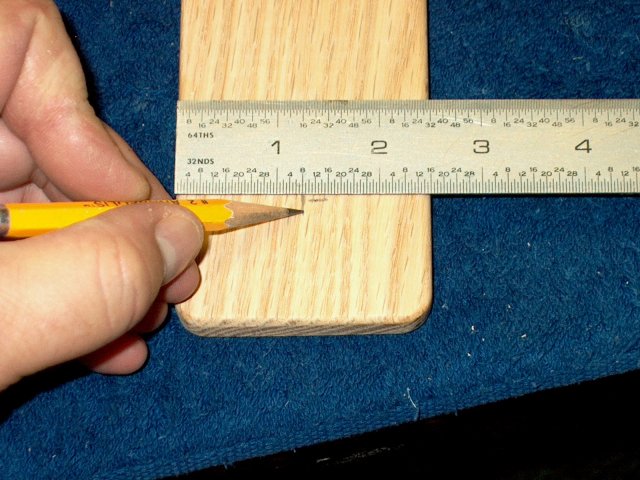

4 - Construction begins with the wood piece.

Make a mark 11" from one end of the oak board

CG. | |

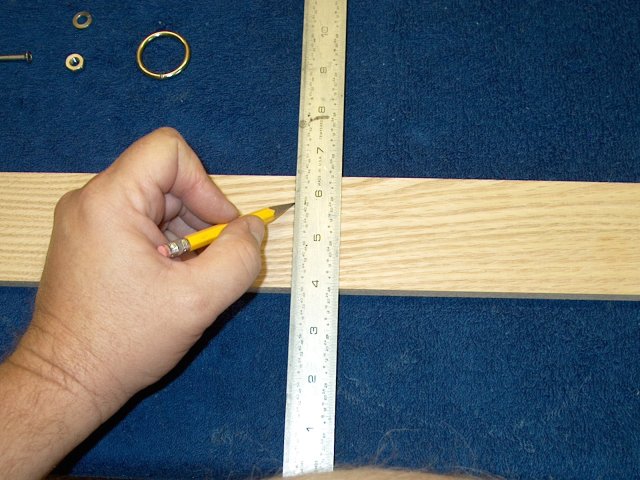

5 - Draw a vertical line at the 11" mark

| |

6 - Use a saw to cut the board into two pieces.

One will be 11" long and one will be around 13" long

| |

7 - Use a small 1/2" diameter cap or coin to

draw a 1/4 round at the corners of each board

| |

8 - Use a sander or block to round the corners as shown

| |

9 - Slightly round the edges on each board to prevent

splintering

| |

10 - Fine sand both boards, top, bottom ends and

sides

| |

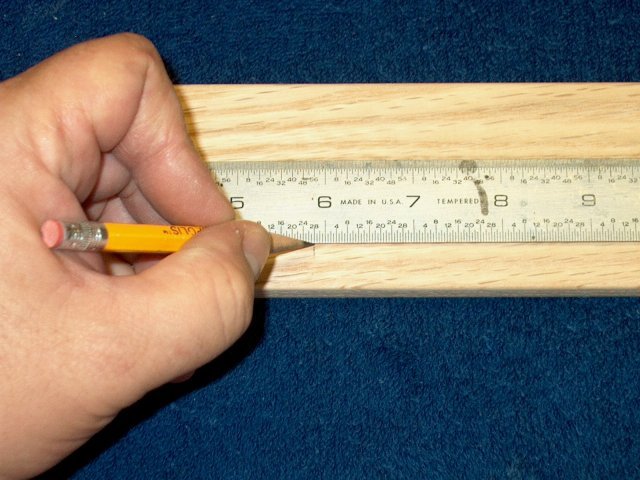

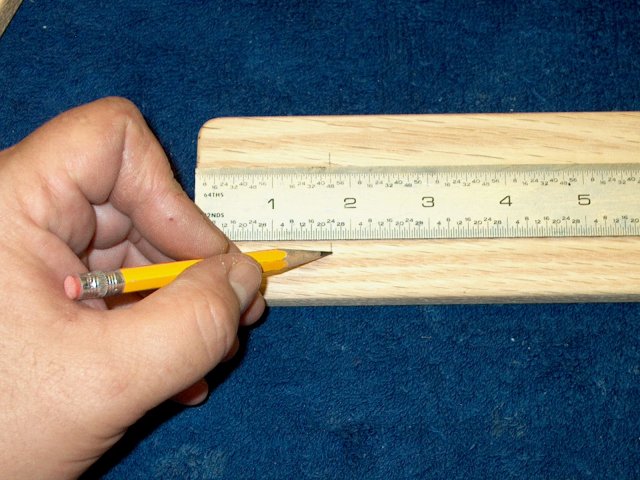

11 - Make a mark on the long board at 5 7/8" from

one end

| |

12 - Draw a vertical line using a ruler or square

at this mark

| |

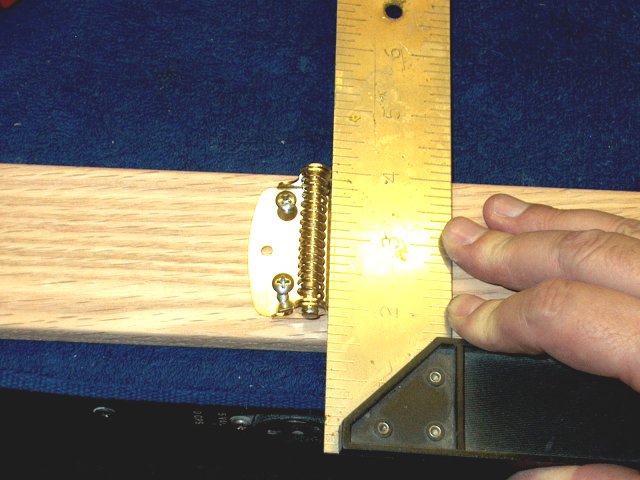

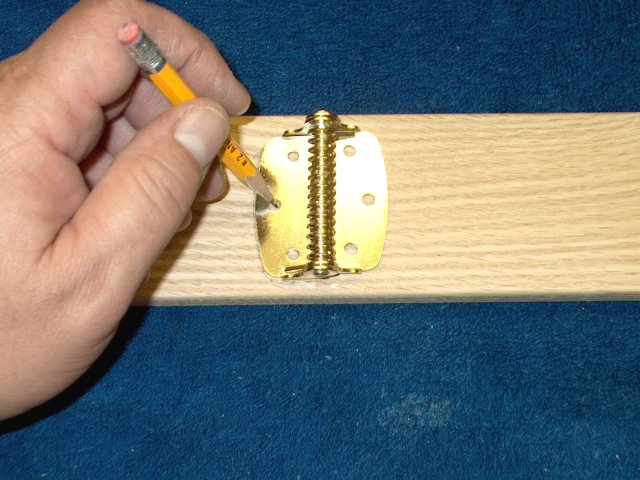

13 - Center the hinge's two inside holes over the

mark with the hinge positioned as shown, mounting side of the hinge

to the right and the 5 7/8" side of the board to the left. Draw

circles in the hinge holes to transfer their location to the wood.

IMPORTANT: Make sure the spring is positioned perpendicular at the

location

| |

14 - Use a punch to mark the hole locations

| |

15 - Drill only the two end holes with a 5/32"

drill. A drill press is recommended to keep the holes straight and

centered

| |

16 - You need to open up the holes a bit for

the 8-32 bolts, using the drill as shown

| |

17 - Install the two end bolts

| |

18 - Check once again that the spring is

vertical. If not, you can slightly elongate one of the holes

to straighten the hinge

| |

19 - Keep the hinge straight and drill the center hole

| |

20 - The holes can be countersunk on

the bottom for the bolts

| |

21 - Install the bolts in each hole

| |

22 - Use nuts to hold the hinge in place and centered

| |

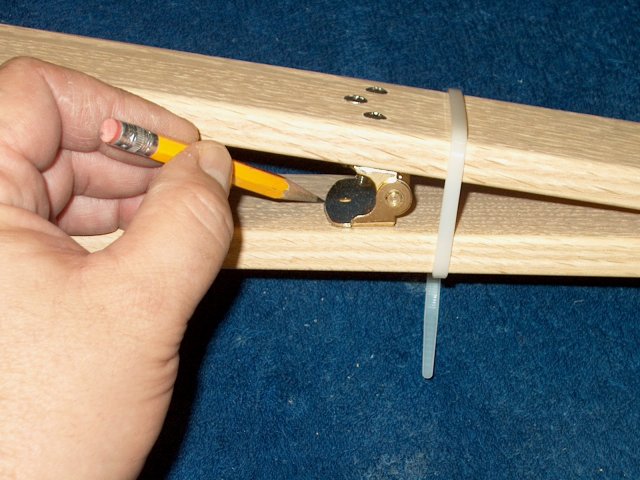

23 - Place the short piece over the long board, with

the end flush as shown on the measured side (the 5 7/8" marked side)

| |

24 - Use a tie wrap to temporarily secure the

end of the boards

| |

25 - Flip an hold the hinge up, then set the

short board over it and while holding it together, use another

tie wrap to keep it in place. Align the end of the two boards

flush and keep the sides of each board even with eachother, then

transfer the hinge location to the short board, outlining it with

a pencil

| |

Remove the short board by cutting the tie

wraps and be careful of the rebounding spring hinge. Remove the

hinge from the long board and place the correct short board side

over the drawing Remove the short board by cutting the tie

wraps and be careful of the rebounding spring hinge. Remove the

hinge from the long board and place the correct short board side

over the drawing

| |

27 - Make a mark at each hole location

| |

28 - Mark each location center with a punch

| |

29 - A small 3/32" hole is drilled at each

screw location. The drill is set so it does not go all the way

through the wood, leaving the last 1/16" or so undrilled. This

will keep the top of the board looking clean

| |

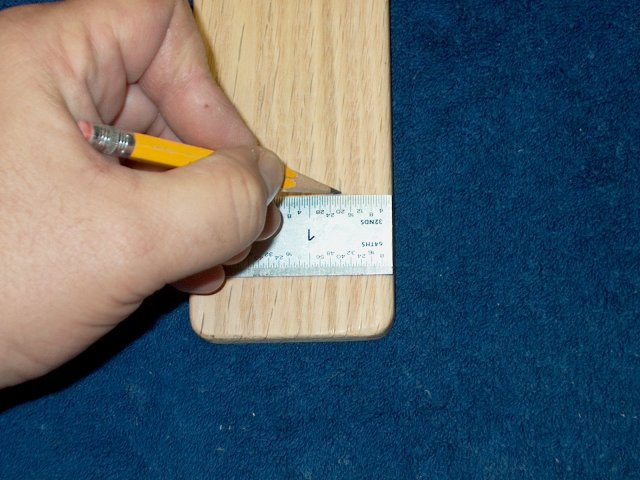

30 - Make a mark on the end of the long board,

at the short 5 7/8" side. The mark is 1 1/4" from the end

| |

31 - Draw a center line over the mark you just made

| |

32 - Use a punch to mark the location

| |

33 - Drill a 1/4" hole at the center. If you

wish to countersink the location of the "T" nut, then use a 3/4"

forstner and cut about 1/16" deep at the center bottom of the

board. Make sure you countersink the bottom side

| |

34 - Open the hole to the width of your

1/4" "T" nut, which may be around 5/16" - 3/8" depending on the

"T" nut you purchase

| |

35 - Transfer the location of the 1/4" hole

from the long board to the short board. Make sure you mark the

correct end of the short board

| |

36 - Use a 5/8" Forstner to bore a hole in

the short board at the location you marked

| |

37 - On the opposite end of the long board,

make two marks at 1 3/4" from the end as shown

| |

38 - Measure in 5/8" from one side of the

board to make the cross mark

| |

39 - Make another mark 5/8" from the other

side of the long board

| |

40 - Use a punch to mark the first location for drilling

| |

41 - Use the punch to finish marking the second location

| |

42 - A 5/32" drill is used to bore a hole

through the long board at each of the locations you marked

| |

43 - Use a hobby knife and sandpaper to

slightly round the exit areas of each hole on both the top and

bottom of the board. This is so there are not any sharp edges

to cut into the nylon cord

| |

44 - Both boards have been prepared,

drilled and sanded and are ready for assembly

| |

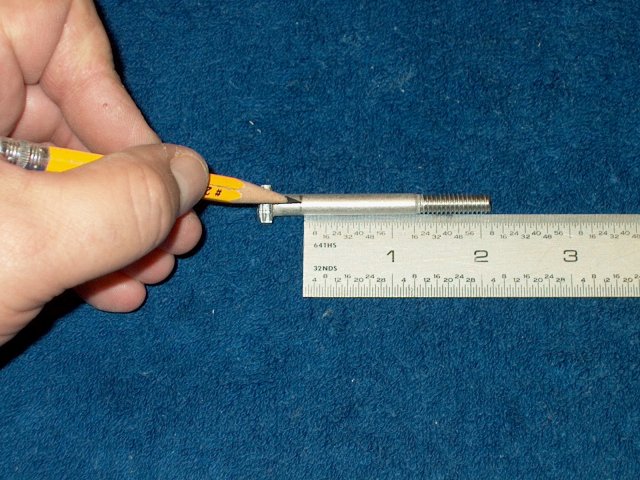

45 - Mark the 1/4" bolt 2 1/8" from the

threaded end. Note that Stainless Steel hardware was used in the

assembly to prevent rusting

| |

46 - Cut the head off the bolt at the mark as shown

| |

47 - Grind and sand the cut area to round it

| |

48 - Hammer the "T" nut into the bottom of the

long board until it is flush

| |

49 - Install the large fender washer, then

the lock washer and nut over the bolt/pin as shown. Screw the

bolt pin into the "T" nut

| |

50 - Use a wrench to tighten the bolt pin

| |

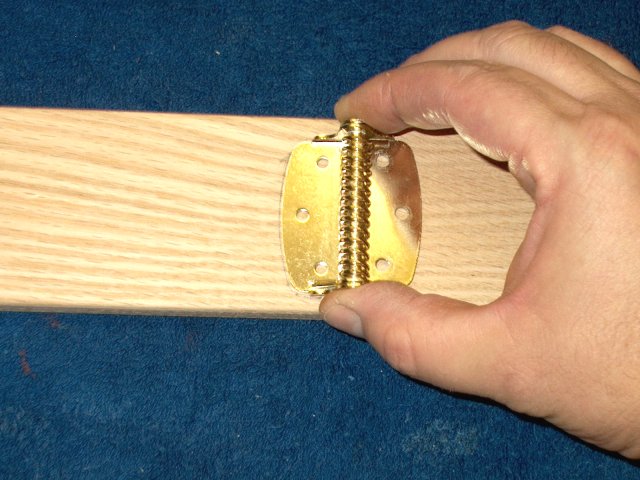

51 - Place a screw included in the pack

of hinges along the side of the short board. Mark each screw

to be cut so they will just be clear of punching through the

top of the board

| |

52 - Cut each screw to shorten them and check

the length so they are shorter than the board thickness

| |

53 - Install the hinge using the screws you

just cut. Tighten them down all the way and keep the hinge spring

centered

| |

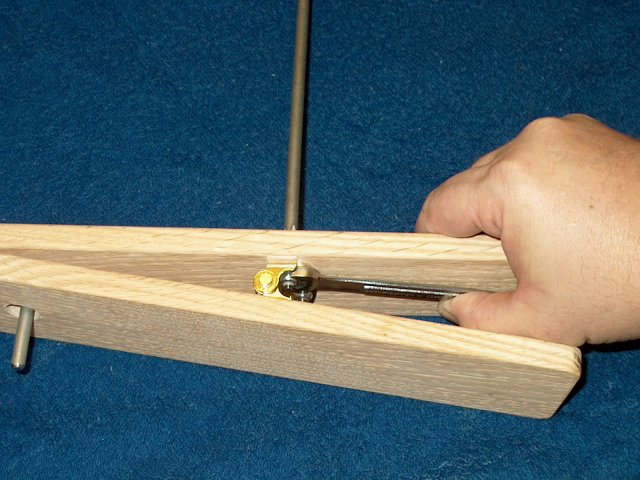

54 - Slide a ruler under the hinge to assist

with the next step to install the long board

| |

55 - Install the three 8-32 bolts through the

bottom of the long board

| |

56 - Position both boards, and while holding

the spring, install the long board so its bolts run through the hinge

| |

57 - Hold the pieces together and start the

nylock nuts as shown, holding them with one hand while turning

the screwdriver with the other hand

| |

58 - Photo shows nylock nuts in position

| |

59 - Make sure the two boards are lined

up with eachother and then tighten all three bolts

| |

60 - With the bolts tightened and the boards

centered, the 1/4" bolt pin should be centered in the hole as shown

| |

61 - When depressed, the pedal lifts

up and the hole should clear the pin by about 1/4"

| |

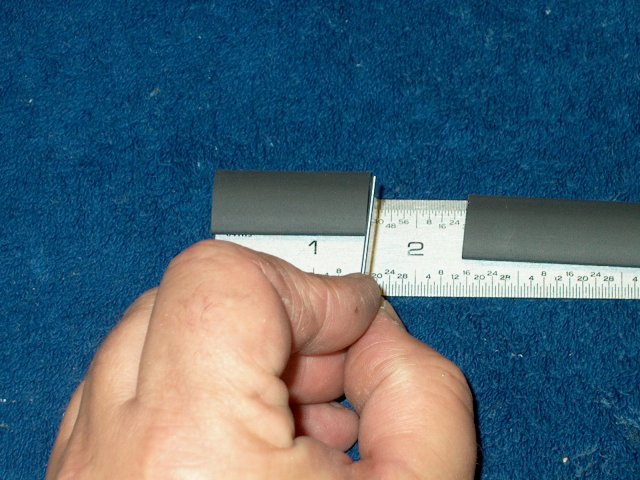

62 - Cut a piece of 3/4" heatshrink to a

length of 1 1/2"

| |

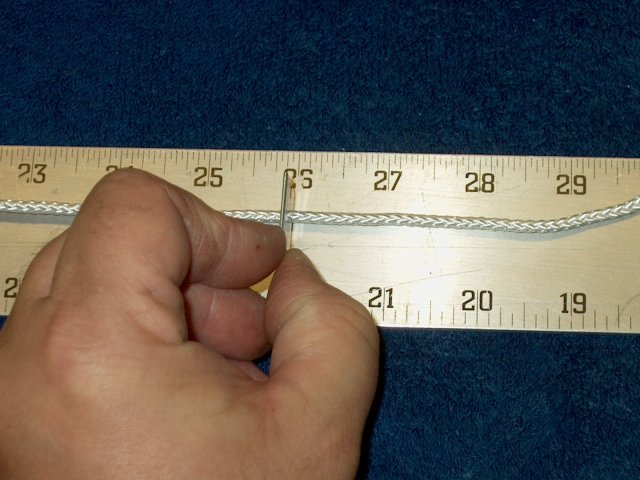

63 - Cut a piece of the 3.2mm nylon cord

to a length of at least 26"

| |

64 - Use a lighter to melt and seal each

end, which will keep the cord from fraying

| |

65 - Install the cord in one of the two

rear holes from the top

| |

66 - Loop the cord from the bottom to

the second hole and thread back through

| |

67 - From the top, pull each cord and

adjust until they are the same length

| |

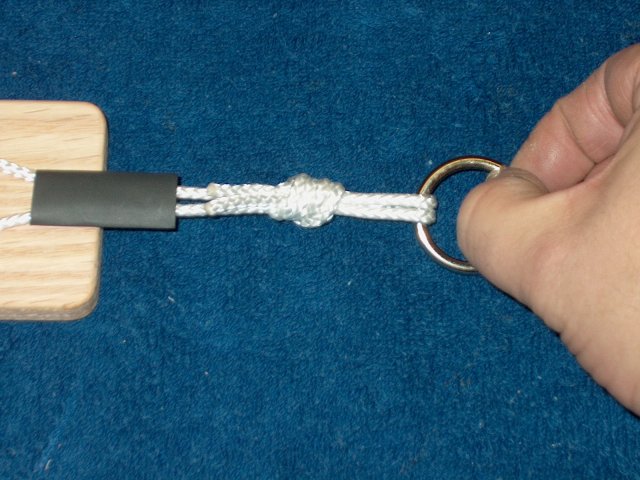

68 - Slide the heatshrink over both cords,

then slide the 1" chrome ring over both cords

| |

69 - Fold the cord ends over and tie them

in a knot as shown, passing the ring through the cord loops

| |

70 - Pull and tighten the knot so it is tight.

You can dab it if you wish with a bit of epoxy

| |

71 - Cut some of the excess off the ends,

leaving about 1/2" exposed. Re-seal them with a lighter to prevent

fraying

| |

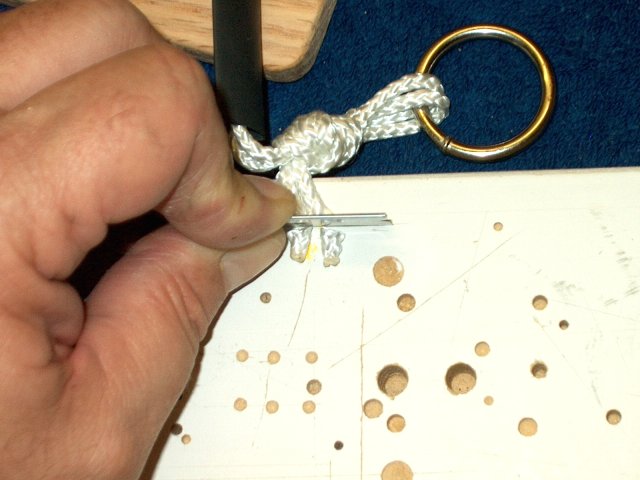

72 - Stretch and slide the heat shrink over

the knot as shown

| |

73 - Use a heat gun to seal the knot

| |

74 - You can add a thin layer of epoxy

to the bottom of the long board to waterproof it from the

ground during use

| |

75 - The completed pedal assembly is shown.

The aircraft release loop is placed over the 1/4" pin

| |

76 - When depressed, the pedal pushes the

release loop off the pin

| |

77 - A 12" galvanized nail with a matching

fender washer can be installed through the chrome ring and is

used to stake down the rear of the pedal. This completes the

assembly of the Bungee Release Pedal

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |