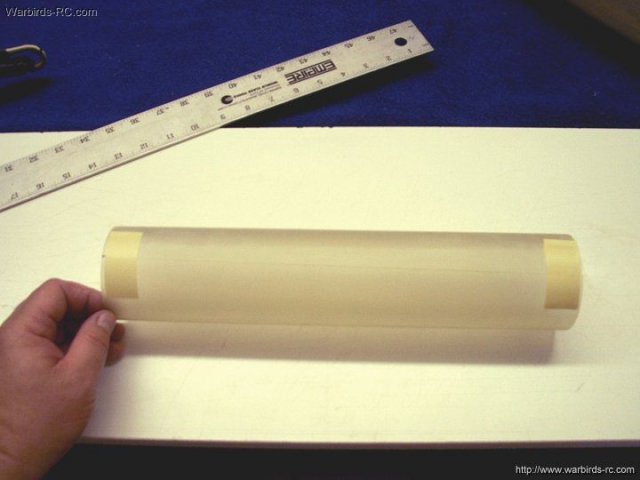

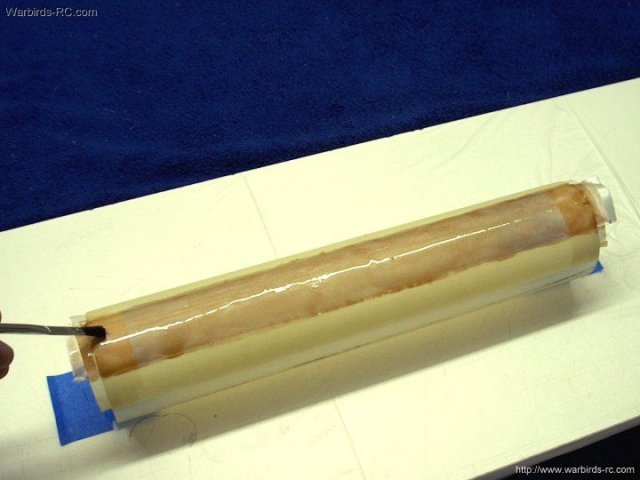

6oz glass cloth is taped to the duct as

shown | |

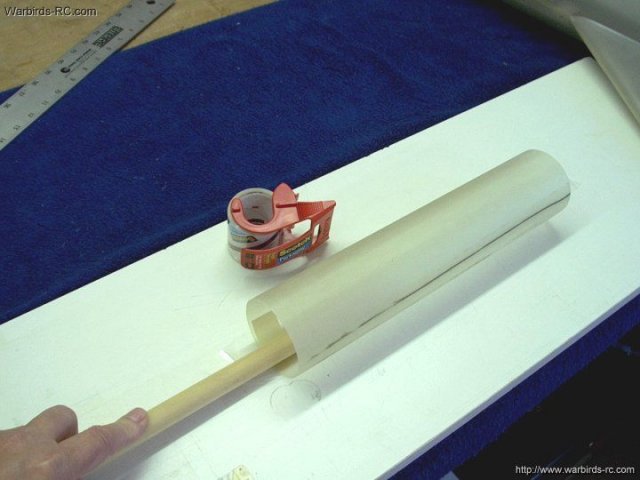

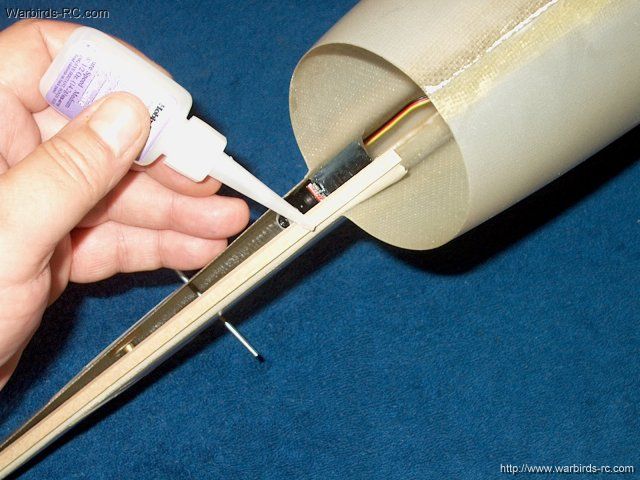

Medium CA is used down the side to anchor

the cloth for glassing | |

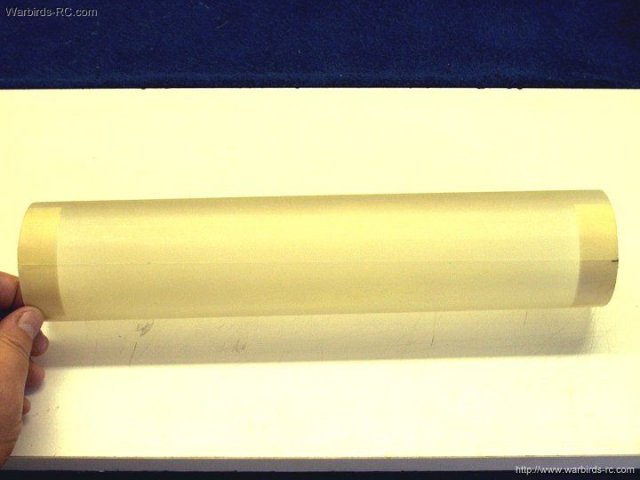

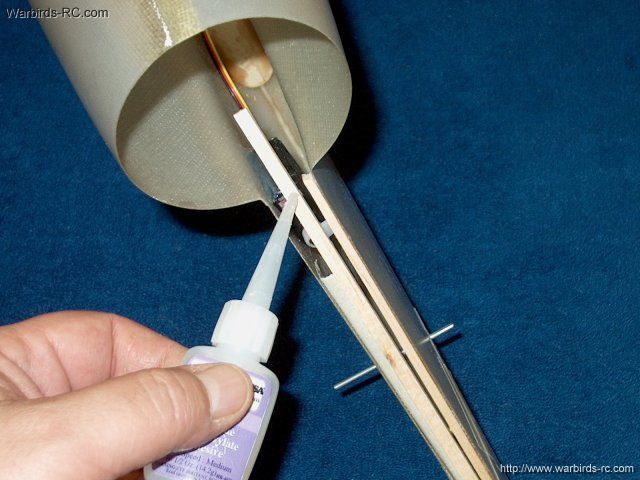

A good glassing resin such as West Systems

is used to glass the cloth to the intake

| |

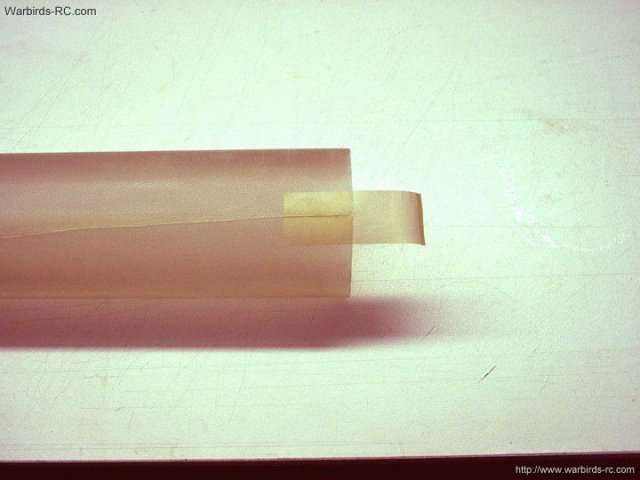

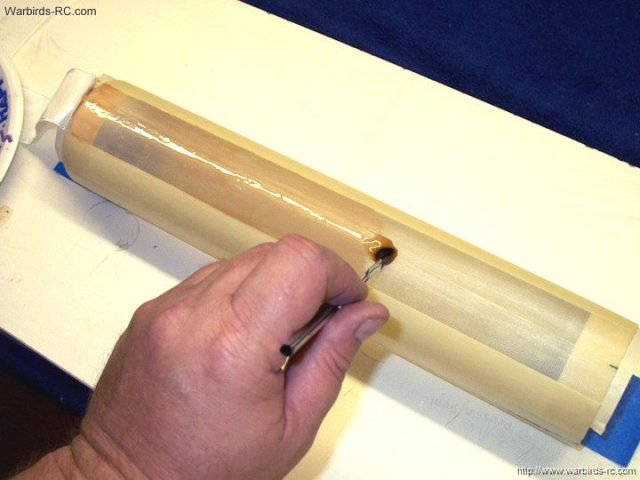

The intake is wrapped in a plastic sheet

and left to set |

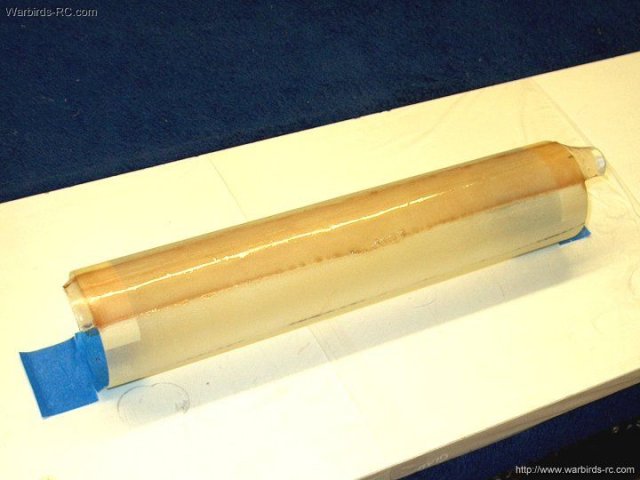

The sheet is removed, the end caps are

removed and the ends are trimmed while the epoxy has set but

is still soft. Keep an eye on the inside for epoxy dripping,

which actually seaped through pinholes in the thin intake tube

material during the glassing process. Keep it clean with

denatured alcohol and a paper towel so you don't have these

bumps and drips to deal with later | |

Once completely dry, remove the inside

packing tape. A piece of 1/2" wide masking is installed down

the center of the fan housing and the intake is installed

flush to one end of the tape and held temporarilly in place

with packing tape or electrical tape

| |

The intake side needed some sanding to

make it flush |

The intake tube is sanded flush to the

fuselage front | |

The forward former is installed next and

you may have to sand down the center so the intake tube fits

from front to rear. It is best to do this before gluing the

former in place. Be sure to take off a little at a time and

deepen the center. You can use the template to insure it stays

round at the bottom | |

The fuselage is roughed up with 60 grit

sandpaper about 1" wide, centered over the front former

area | |

The former is tack glued using 5 minute

epoxy, with the rear of the former on the marks you made

earlier. Then it is glued and glassed in place with 1" wide x

6 1/2" wide strips of glass cloth. Crosscut your cloth at 45

degrees from the weave so it can accordion easily and be

shaped to fit around the curved area. Clean up any excess

epoxy | |

For the MF480, one end of the exhaust tube

is lightly trimmed to straighten the cut from the

manufacturer. If you are using a larger fan, omit this and the

next several steps and proceed to glassing

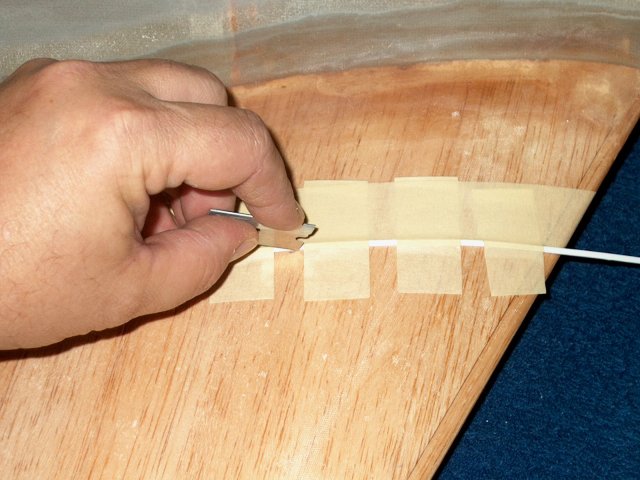

| |

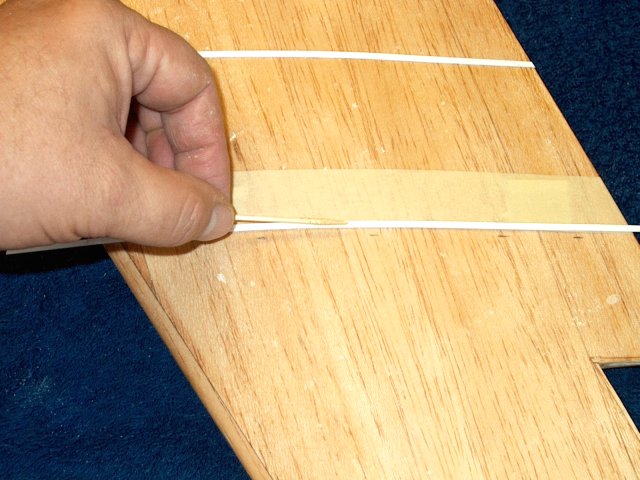

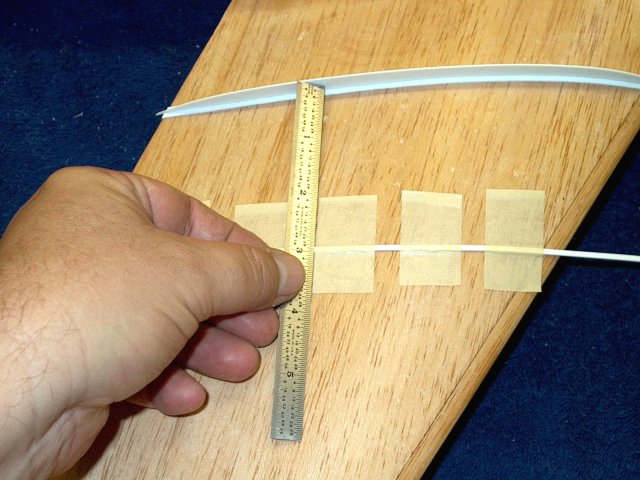

The smaller end is taped flush using

masking tape | |

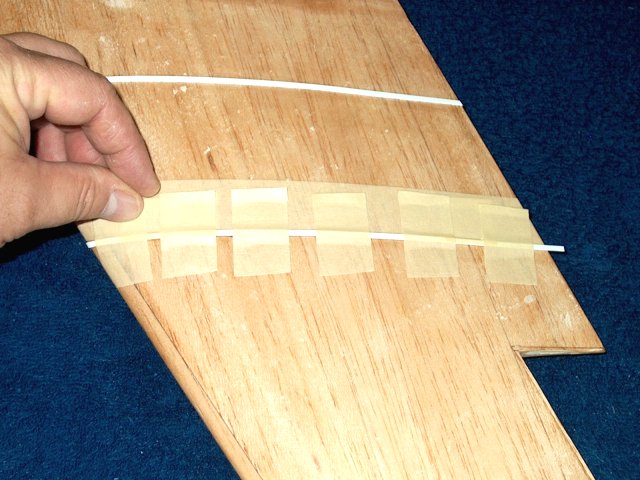

A piece of masking is used to "space" the

duct away from the fan housing. This is to allow room for a

smaller plastic fim exhaust duct to be installed later and is

only for the Minifan 480. For the larger fans, you can omit

this step | |

For the MF480, the duct is installed on

the housing and taped tight. Then a mark is made on the

unevenly cut side of the duct at the overlapped area

| |

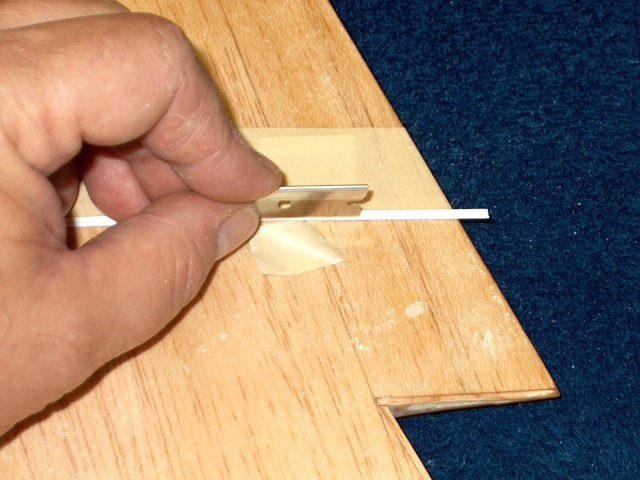

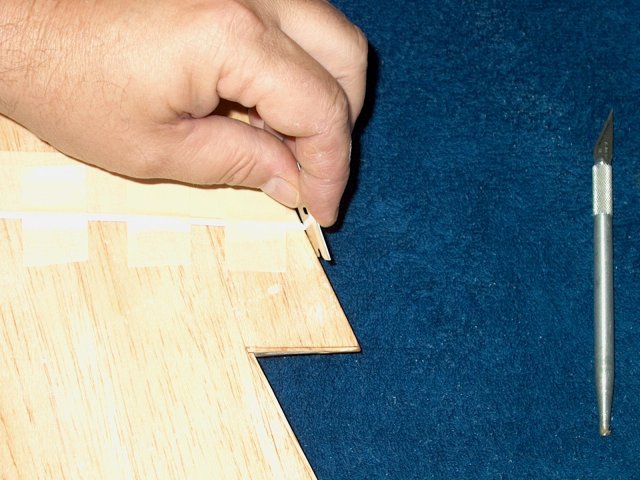

The other uneven side of the duct is cut

away from the mark | |

The piece is shown removed

| |

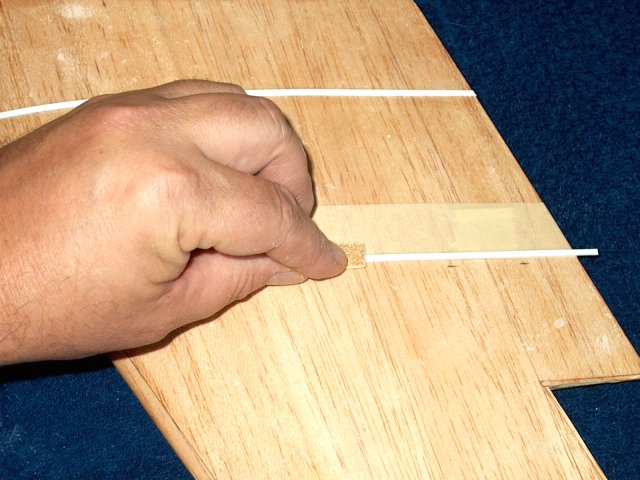

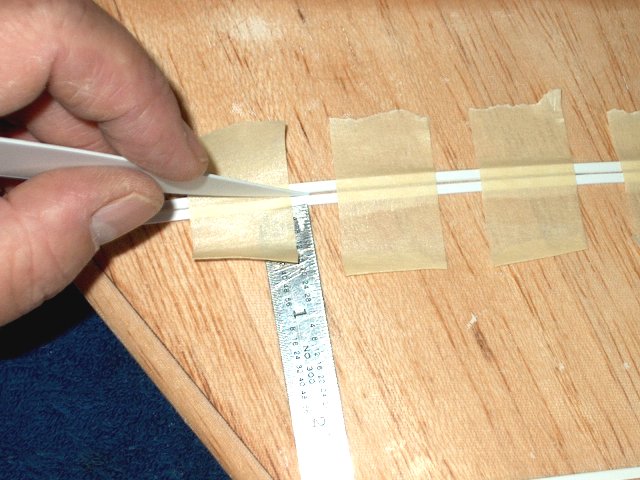

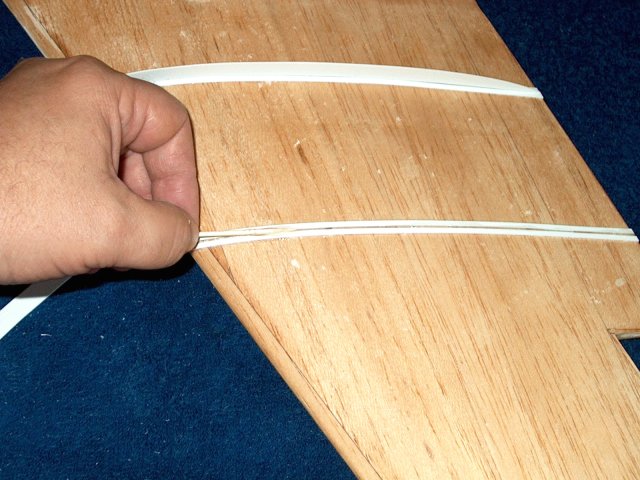

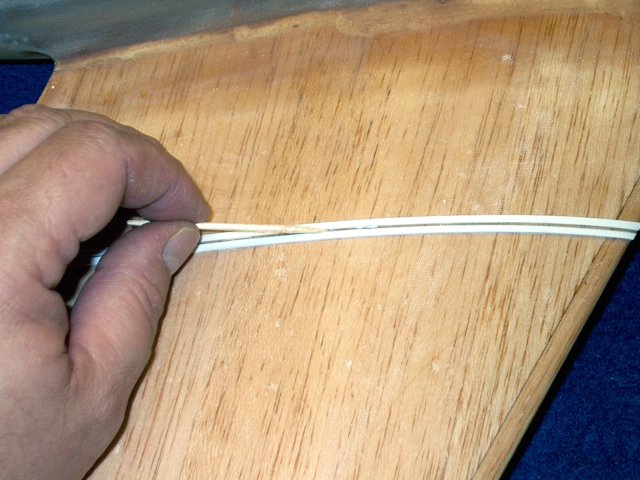

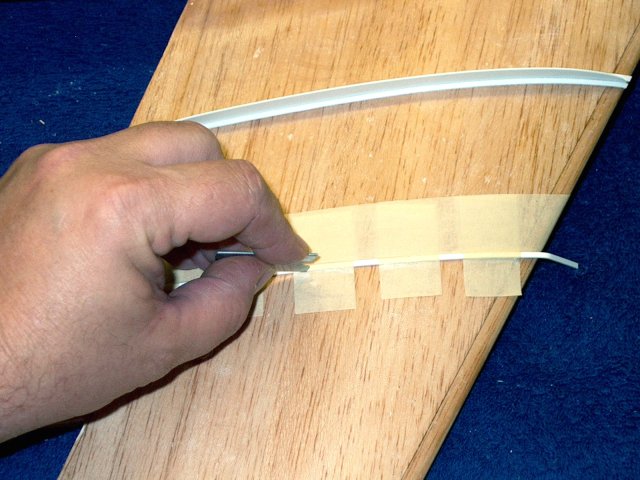

The tube is held flush at the ends with

masking tape. If necessary, lightly sand the two edges so they

are flush all the way down the tube

| |

Packing tape is used on the inside to hold

the two edges flush | |

A wooden dowel is used to push the packing

tape down on the inside where you cannot reach

| |

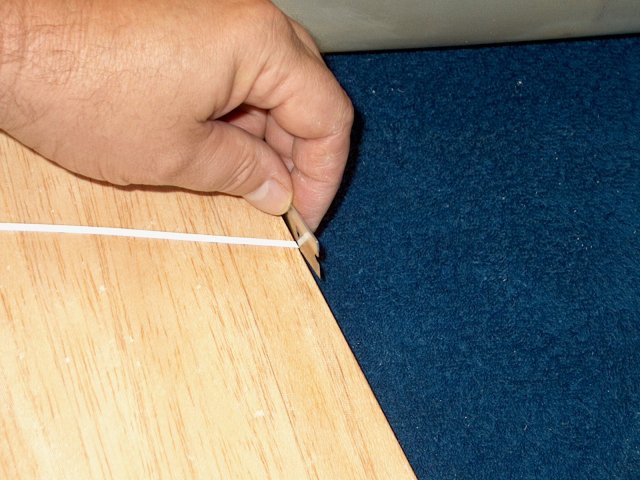

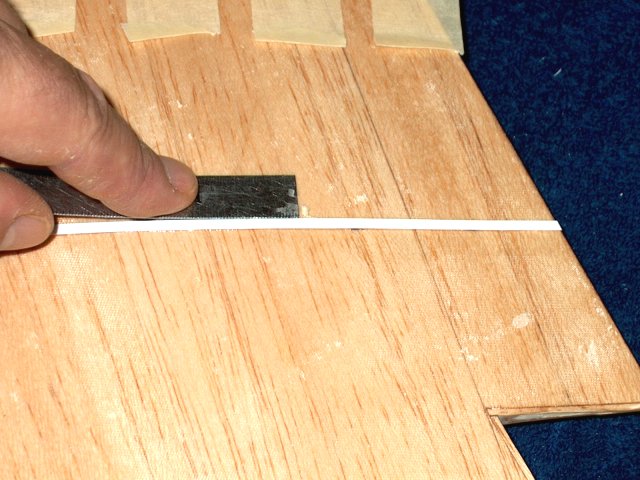

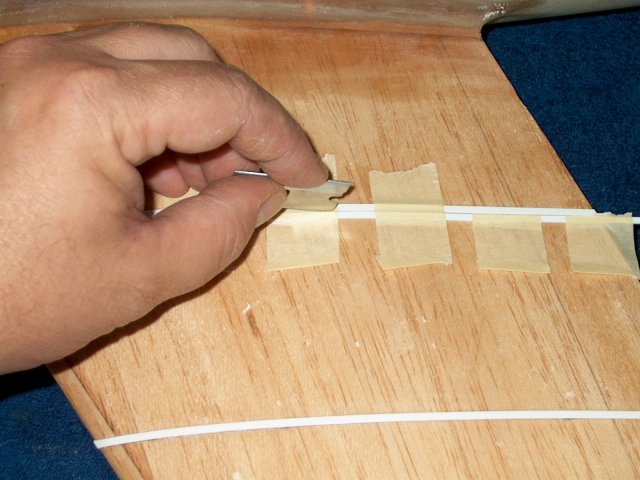

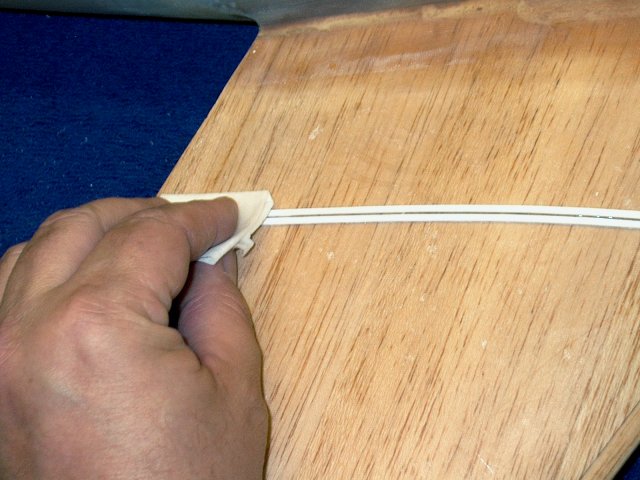

The excess tape is removed with a

razor | |

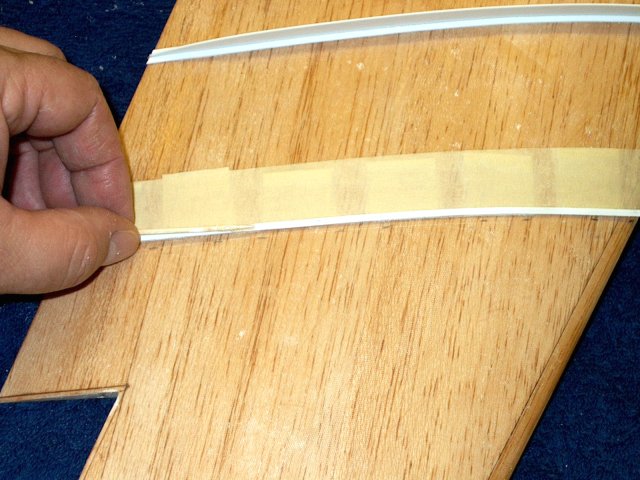

The outside masking tape is removed and a

couple of layers of masking are used on the inside ends for

drips | |

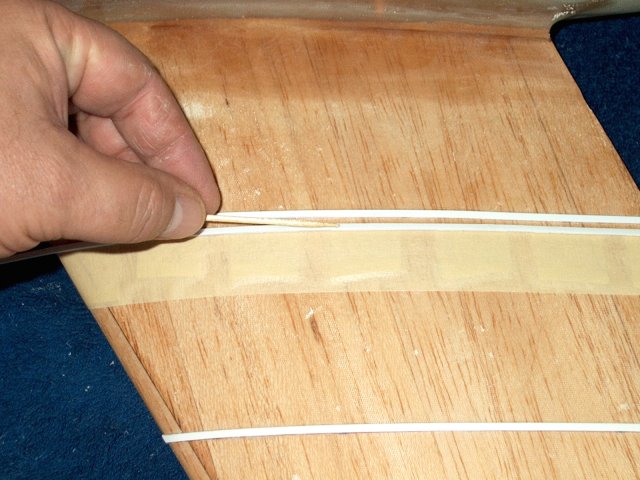

The tube is taped to your working surface

so it is easier to glass | |

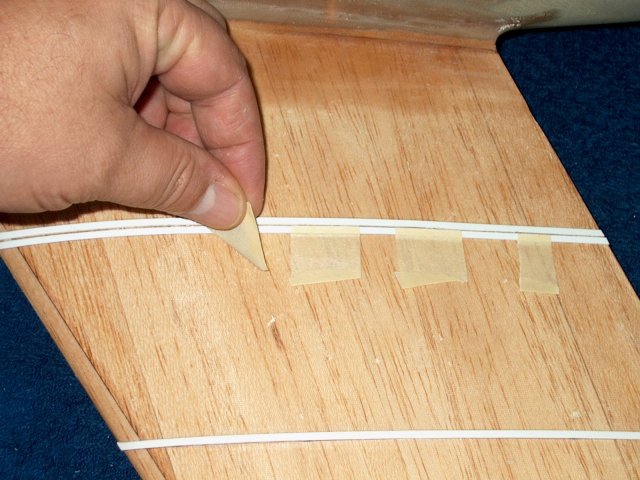

An area is sanded about 3/4" wide on each

side of the seam | |

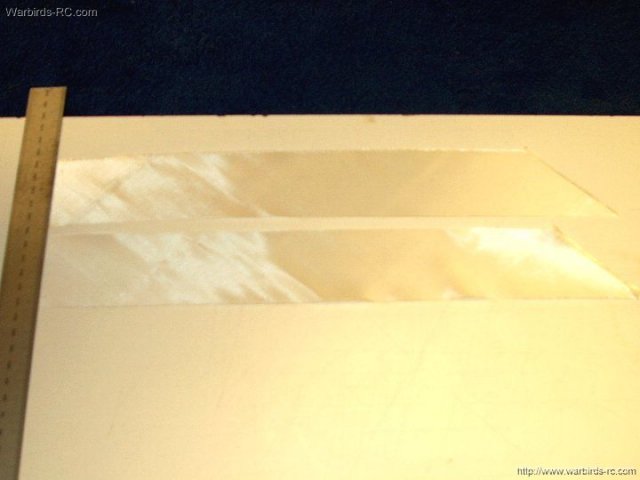

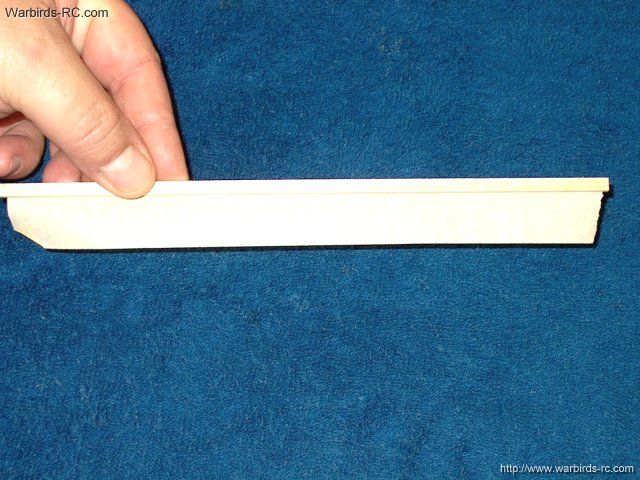

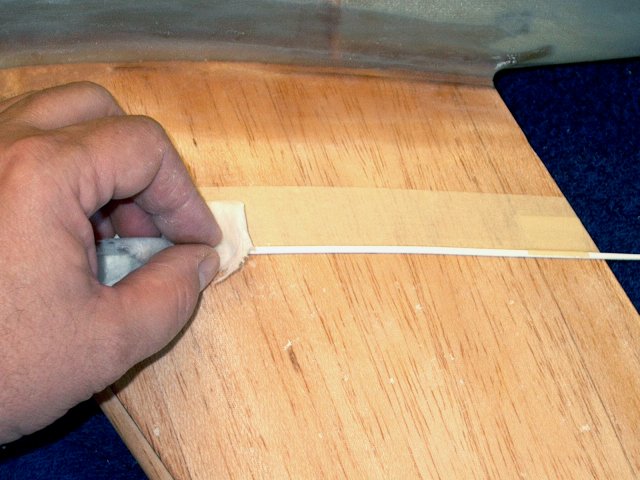

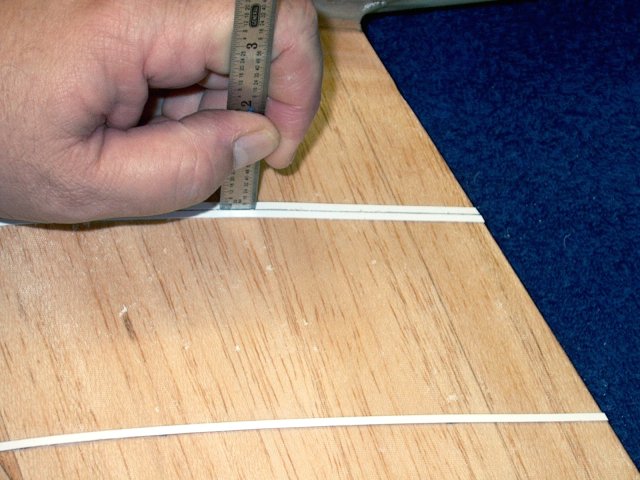

Glass cloth shown is cut to about 1

1/2" | |

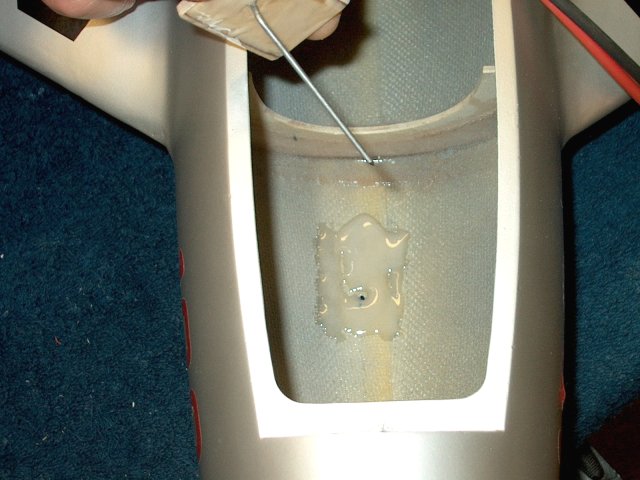

Epoxy resin is applied to the seam area of

the exhaust tube | |

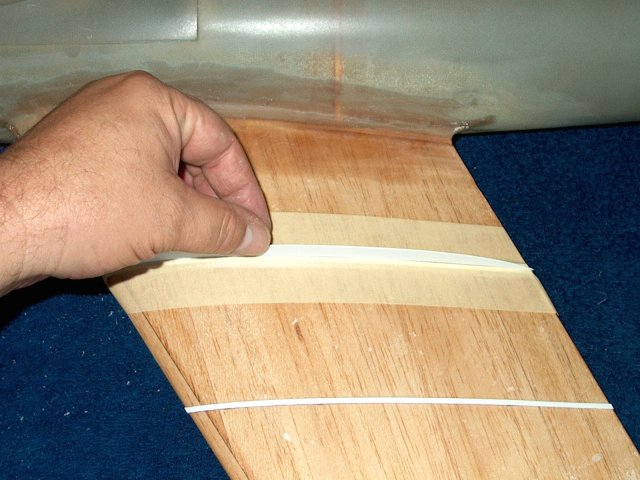

The cloth is layed over the resin area and

pressed down | |

Resin is brushed on the top of the cloth

to make sure it is saturated | |

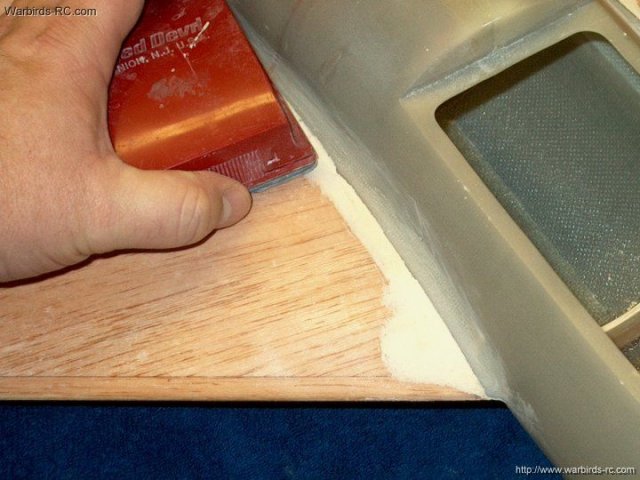

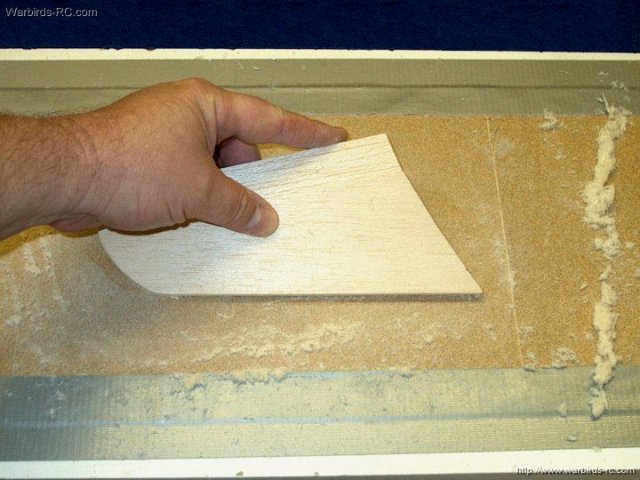

The excess resin is removed with a

spreader and the tube is left to set

| |

The seam was sanded to remove excess epoxy

and keep it light | |

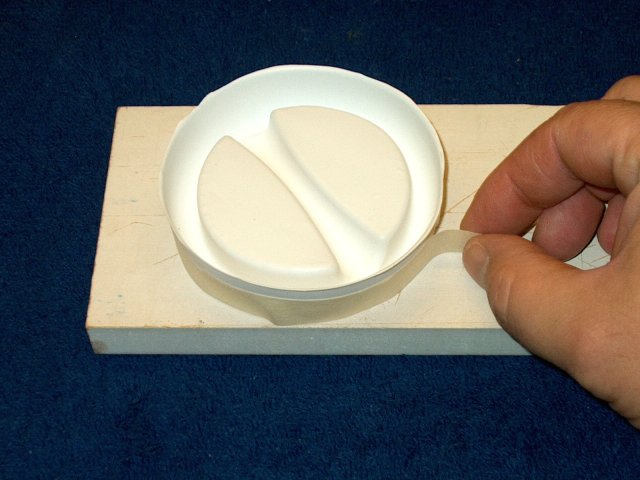

A ring is made from 1/16" ply to fit in

the end of the fiberglass tube and the inside is cut to 55mm

diameter | |

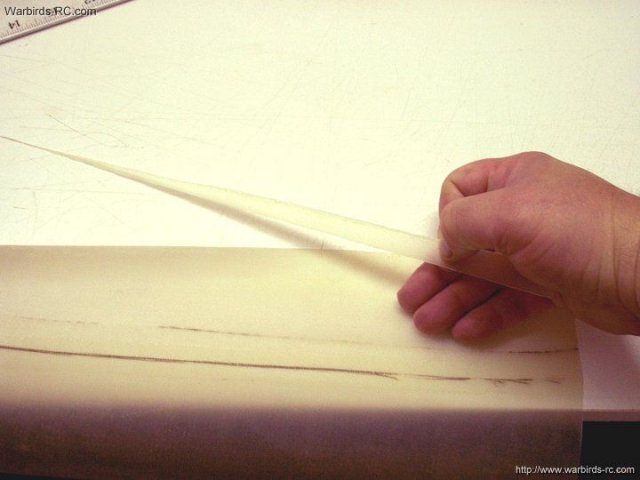

A piece of clear 5 mil Dura Lar used as an

inner thrust tube for the Minifan is cut oversized, then

inserted in the glass tube at the fan side and trimmed flush

to the end | |

Masking tape is used to hold the inner

liner flush with the fan end | |

The ply ring is installed and the inner

thrust tube is cut flush with the fiberglass tube at the

exhaust end | |

Apply masking to hold the tube in place,

then cut a 1" wide piece of clear packing tape and seal the

tube seams inside and out | |

Inner thrust tube assembly

completed | |

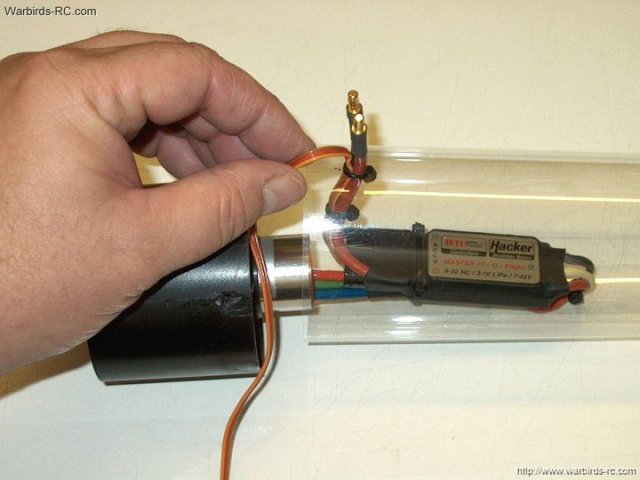

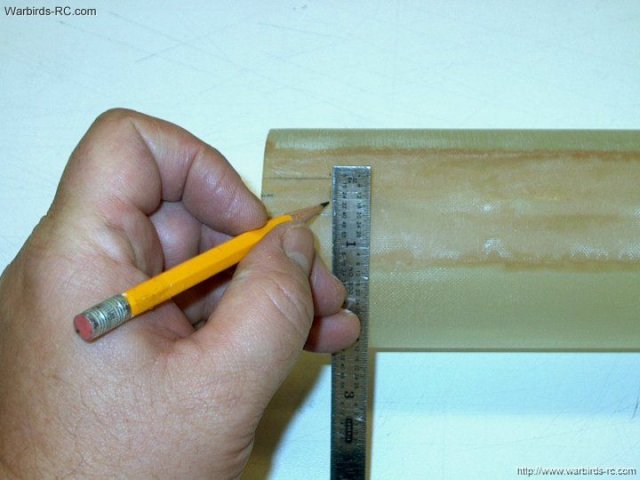

A mark is made 1/2" from the edge of the

tube | |

3/8" Washers on each side of the plastic

make cutting a hole easy | |

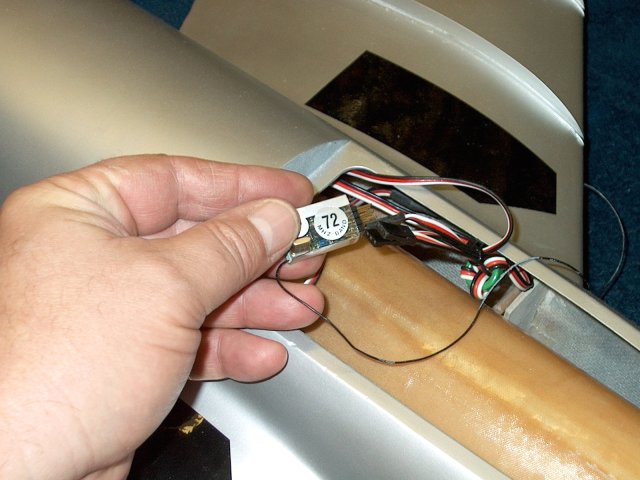

Hole is shown cut for ESC wires

| |

Wires are inserted through the hole

| |

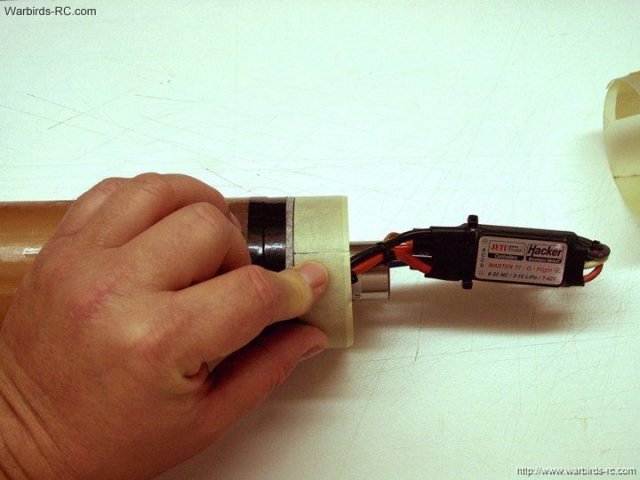

The tube is slid 1/2" over the fan housing

and taped in place | |

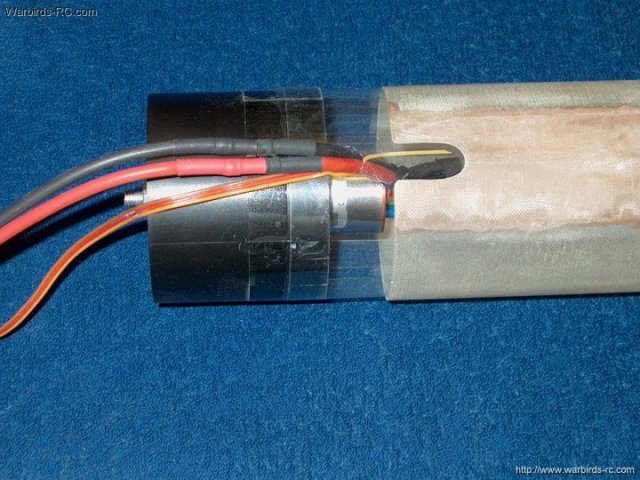

Fan assembly and inner thrust tube

completed | |

The fiberglass thrust tube is marked to

slot it for the ESC wires | |

The slot is 7/8" deep and 1/2" wide and

rounded at the edges | |

The fan asembly and inner thrust tube

slide into the outer glass thrust tube

| |

The tail end of the fuselage should be

checked for round and sanded straight if necessary

| |

Tail is shown sanded and ready

| |

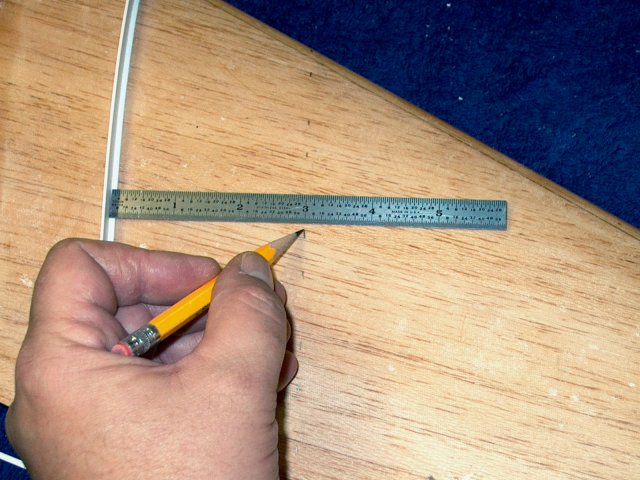

Location marks are made 4 3/4" from the

tail for the rear former | |

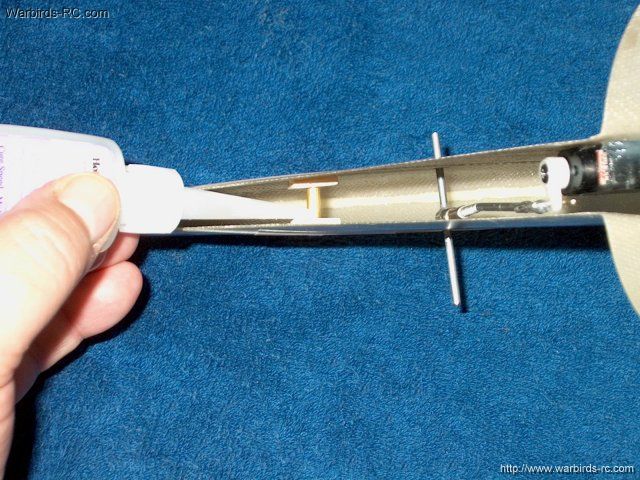

Fine sand the former until it fits flush

| |

60 grit sandpaper taped to your finger

makes it easy to sand the inside of the fuselage area for the

rear former | |

Once sanded, clean the dust off with

alcohol and a towel | |

Thirty minute epoxy was used to glue the

former in place and a fillet mix of epoxy and fiberglass mil

was applied to the joint | |

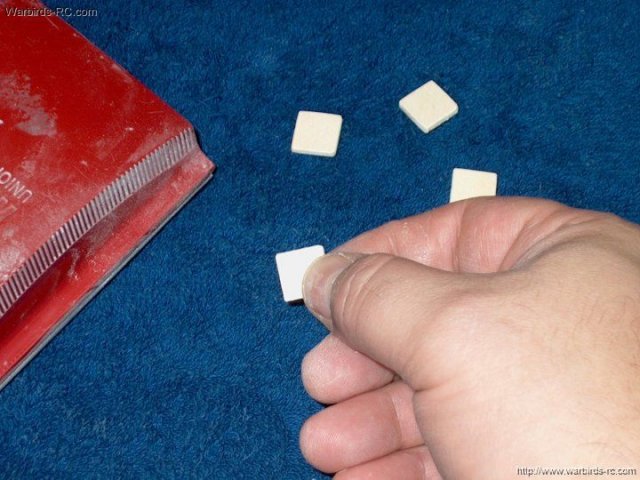

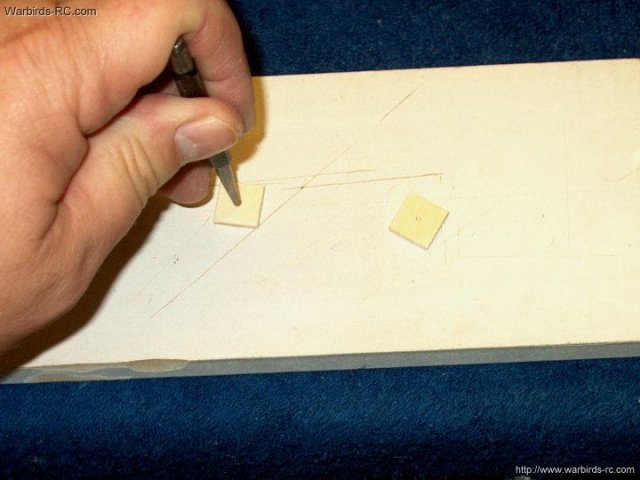

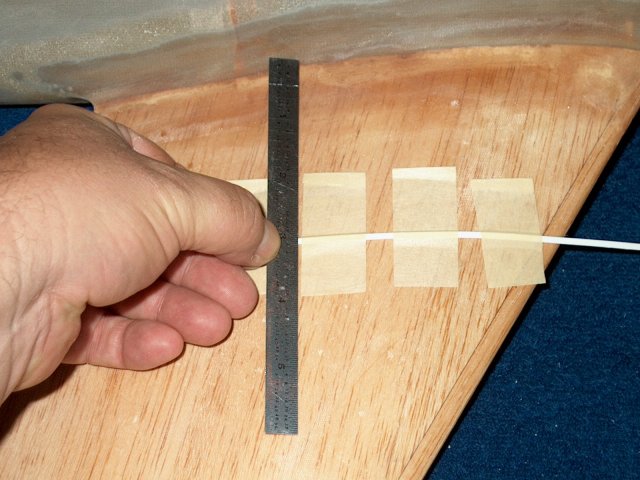

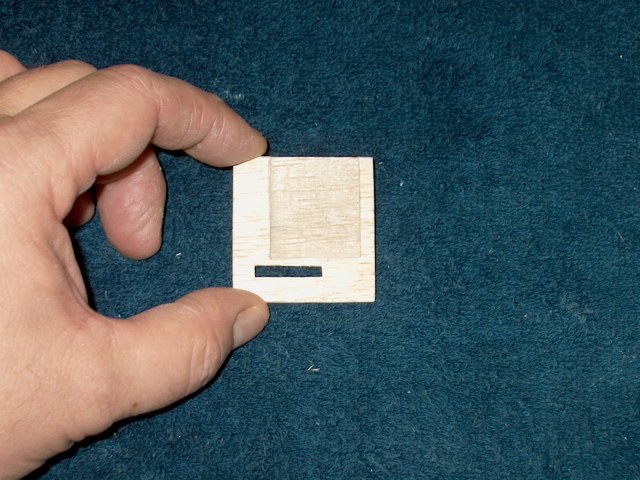

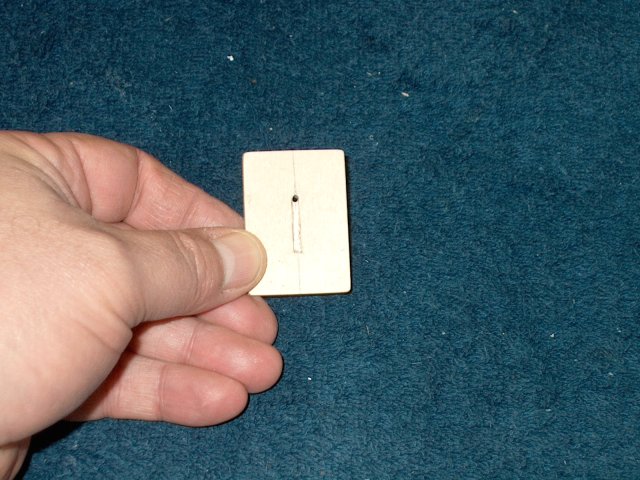

Coat four of the 1/8" thick x 1/2" ply

squares with CA on one side | |

Sand the CA side and round the corners on

the squares | |

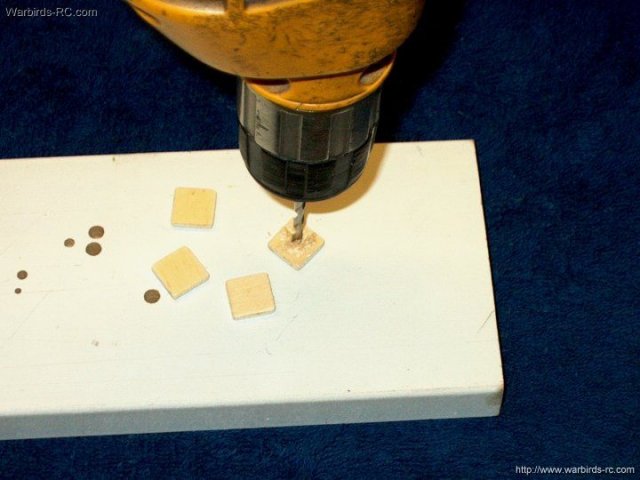

Drill a 1/8" hole in two of the squares

and a 3/16" hole in the other two squares

| |

Photo shows all four squares prepared and

ready to use as retainers | |

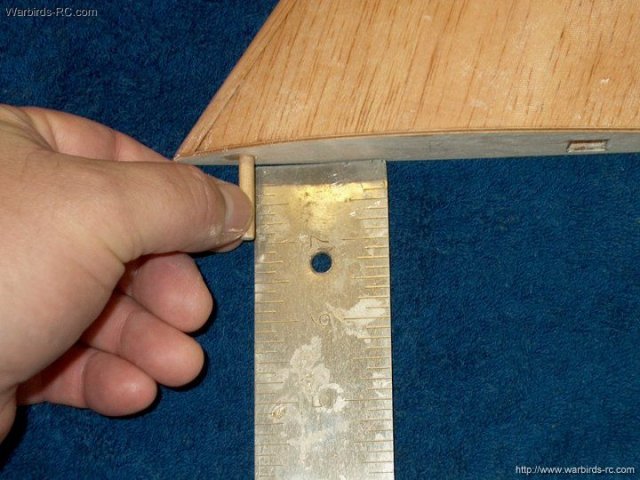

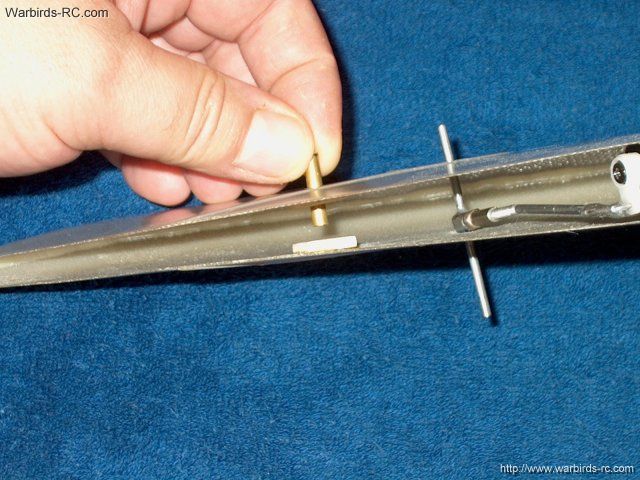

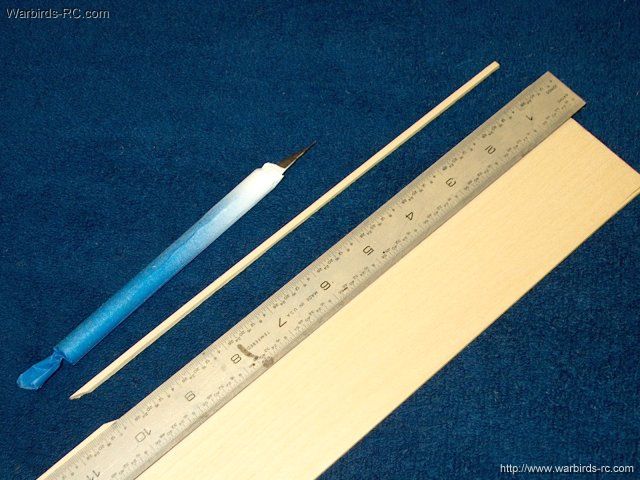

The 3/16" and 1/8" wood dowels are pressed

into the wing to make a guide hole. Keep the dowels square to

the root | |

Epoxy is applied to each hole using a

toothpick | |

The wood dowels are inserted and kept

square with 1" protruding | |

The dowels for the second wing are

installed | |

Photo shows all wing dowels installed

| |

The wing root is roughed up with 60 grit

sandpaper | |

Wing root is ready to final prep for wing

installation | |

Drill holes as shown with a 1/8" bit to

allow for better glue adhesion | |

The wing spar is also drilled as

shown | |

The outside of the fuselage and wings are

covered with masking tape to catch the overflow when

gluing | |

Wing and Fuselage root shown ready to

epoxy | |

Wing was temporarily installed and checked

while the fuselage is squared up. The wing root when flush to

the fuselage was in the correct position

| |

Clear epoxy is applied to the wing root

and left to soak in...do not apply epoxy to the wood

dowels | |

Epoxy is thickened with fiberglass mil and

spreaded thick as shown | |

The forward and rear wood dowel holes are

cleaned with a Q-tip | |

The wing is installed on the

fuselage | |

The wing is pressed down in place and

excess epoxy is cleaned with denatured alcohol and a paper

towel | |

Make sure the wing is flush to both the

root and the bottom of the fuselage. You can slide the ply

squares over the wood dowels on the inside to help hold the

wing to the fuselage | |

Remove the tape from the wing and fuselage

before the glue sets | |

Allow some time for the epoxy to

set | |

Once the epoxy has set but is still soft,

you can check the rivots that were formed at the drill points.

Use your finger to round them out and slightly flatten them

for a better hold as shown | |

Apply epoxy to the other fuselage root and

wing | |

Clean the wood dowel holes out as

shown | |

The wing is installed on the fuselage

| |

Seat the wing, clean up the excess epoxy

and remove the tape as with the first wing, then allow some

time for the glue to set | |

Both wings are shown installed

| |

The wing seams are filled with a

lightweight body filler and sanded to shape

| |

A piece of 60 grit sandpaper is used to

rough up the fuselage area for glassing. Sand about a 1" wide

area from front to back | |

Strips of 2-5oz cloth are cut 2" wide in

preparation for glassing | |

Epoxy is applied to the side of the

fuselage and wing area | |

The glass cloth is placed in position and

excess epoxy is removed | |

Wing to fuselage area shown glassed and

allowed to set up | |

The bottom of the wing area is glassed the

same way | |

Strips of glass cloth are applied to the

area. I used 2 oz fiberglass cloth on the top for a nicer

finish and 5oz cloth as shown on the bottom for

strength | |

The bottom of the wing is shown glassed.

Sand and blend the seams | |

The horizontal stab and elevator pieces

are shown in the pic | |

Thin CA is applied to the leading edge of

the Elevator | |

The Elevator is installed centered over

the edge of the Stab and flush with the inside

| |

The elevator is mounted to the second stab

in the same manner | |

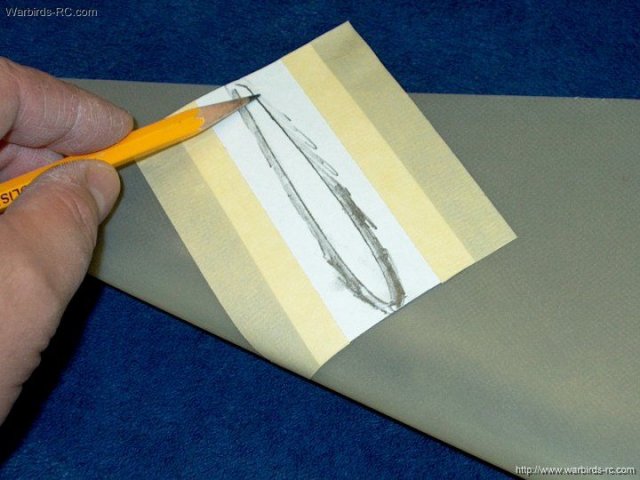

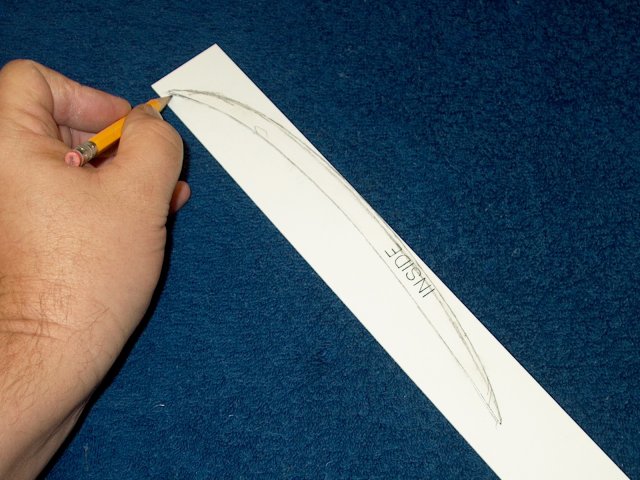

A piece of paper is taped to the vertical

stab at the Elevator location and the airfoil shape is traced

out as shown | |

The shape is cut out from the

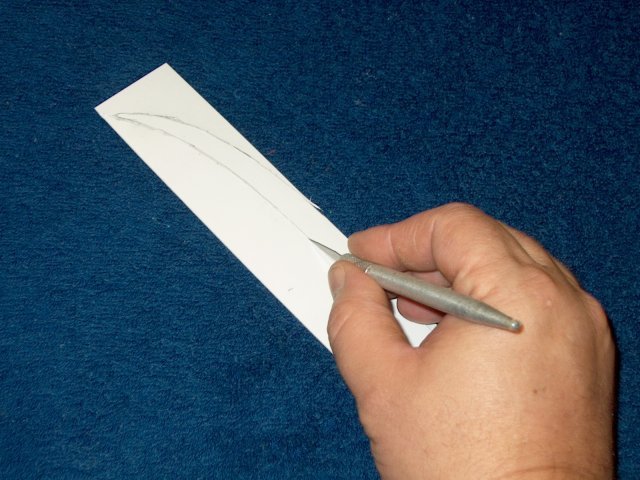

tracing | |

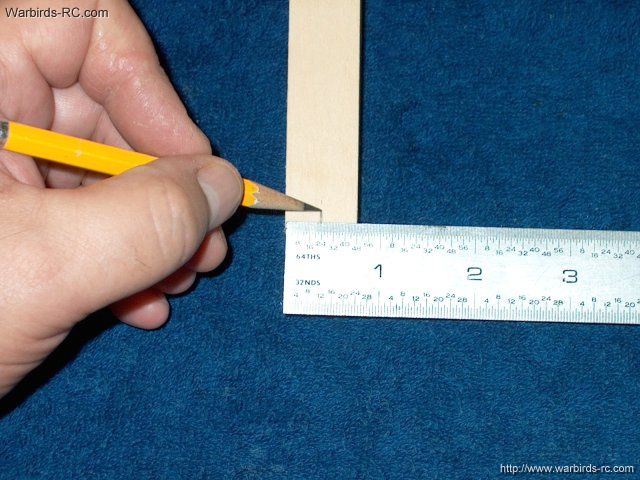

A center line is marked down the leading

edge of each Flying Stab | |

A center line is drawn down the leading

edge at the marks | |

Center line is drawn on the second stab as

shown | |

The cut out pattern is used to trace the

airfoil shape to each stab inner root

| |

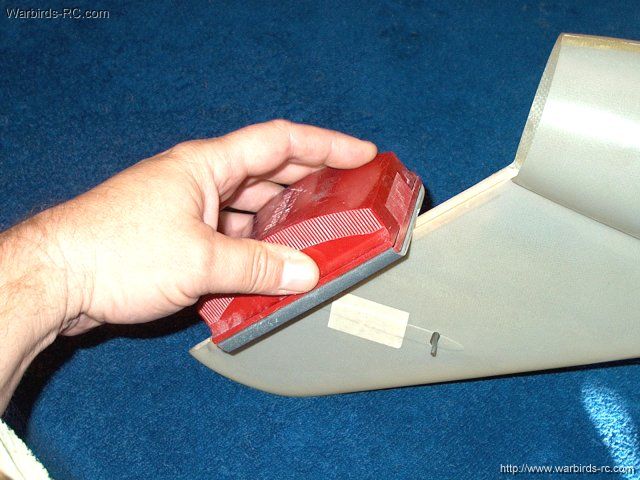

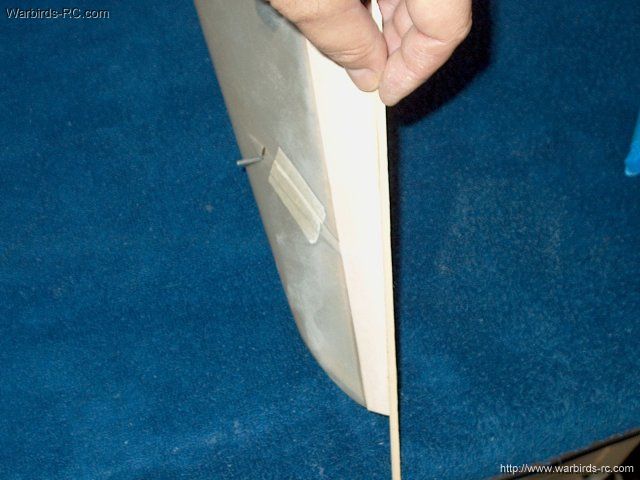

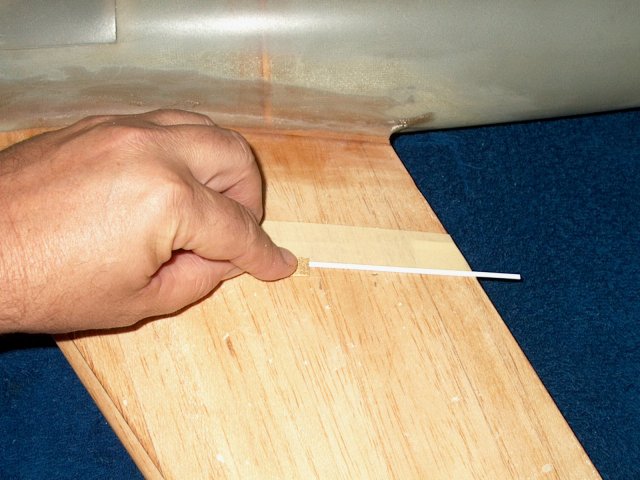

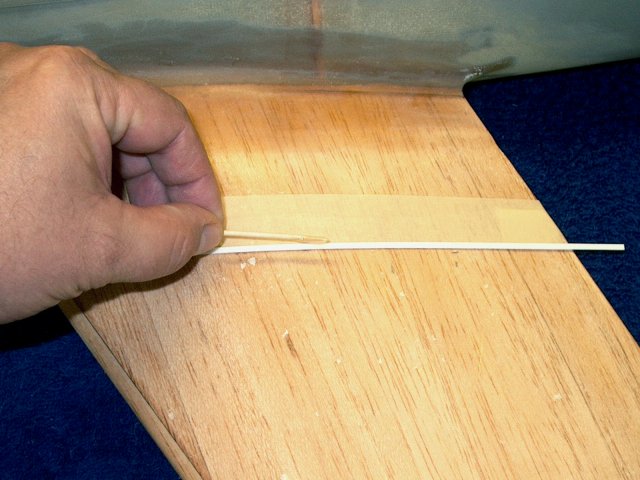

The sanding board is used to form the

airfoil shape and taper the tail to 1/16" thick for each of

the two Stabs | |

The leading and trailing edge has been

tapered as shown | |

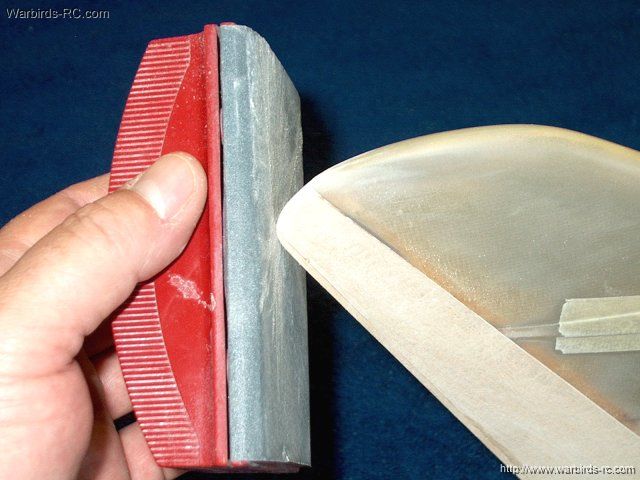

Both Stabs are aligned on top of one

another and the inner rear edge is shaped to align itself with

the root (top right), then the outer side is shaped with a

sanding block as shown (left) | |

A center line is drawn down the outer edge

of each stab | |

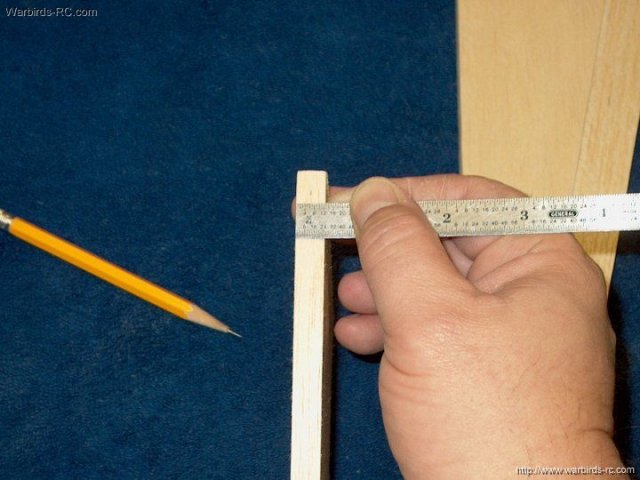

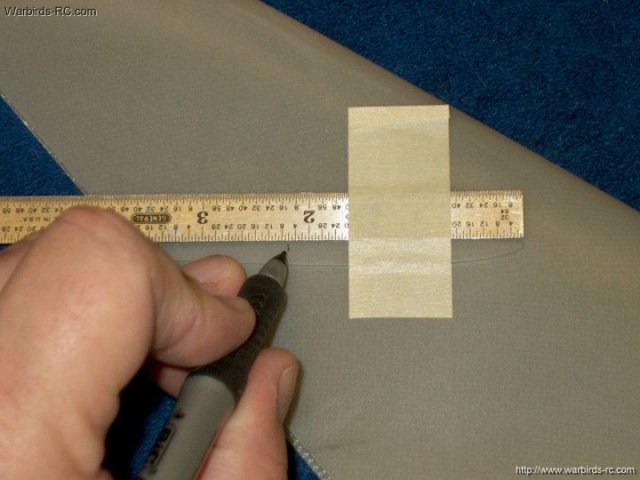

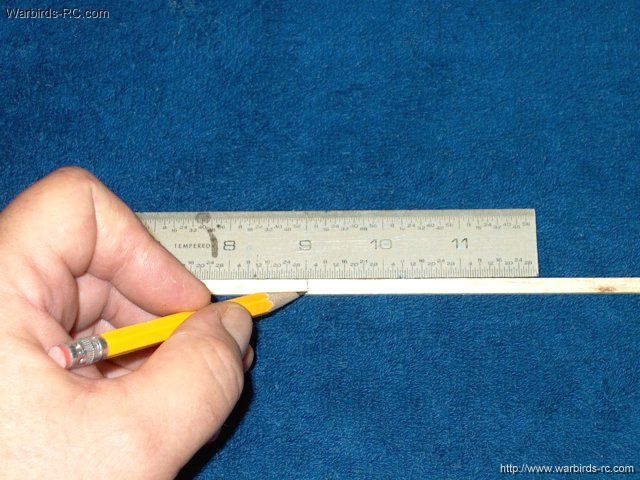

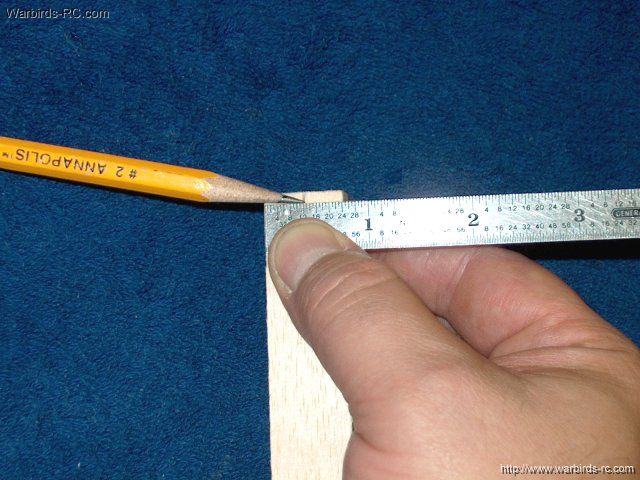

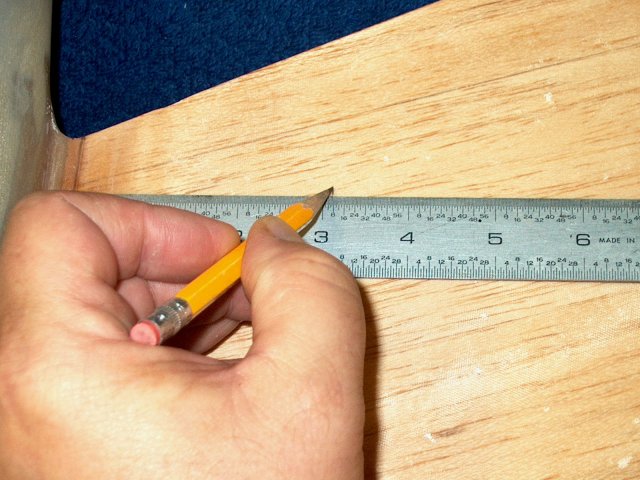

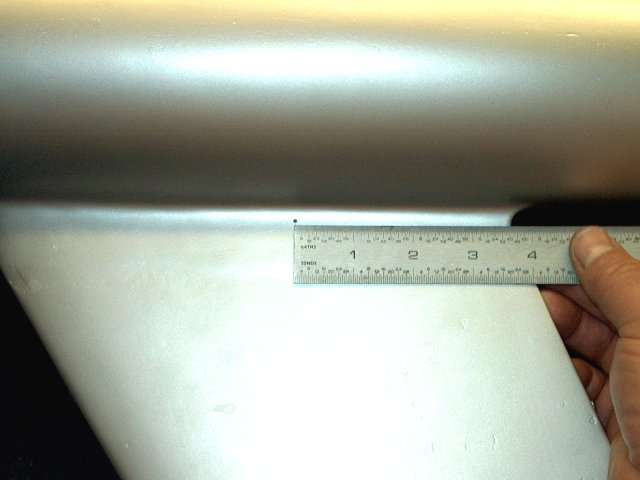

A ruler is used to measure 6 1/2" from the

inside root | |

Lines are drawn as shown on each

stab | |

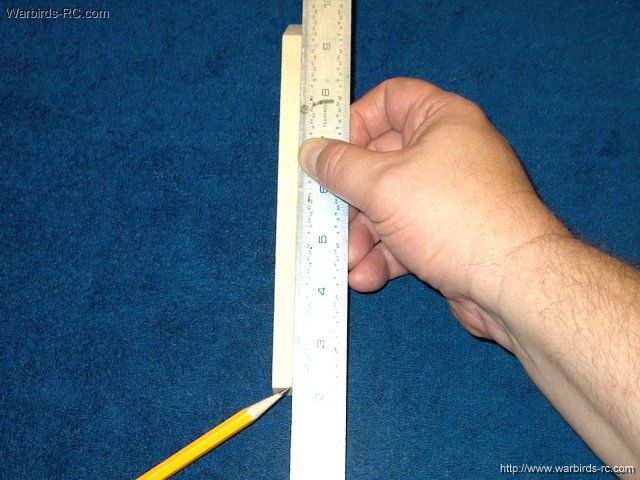

A sanding block is used to taper the stab

outer tips in the same way the wing tips were shaped. Sand

from the line that was drawn to the tip making an even bevel

| |

The second stab was tapered as

shown | |

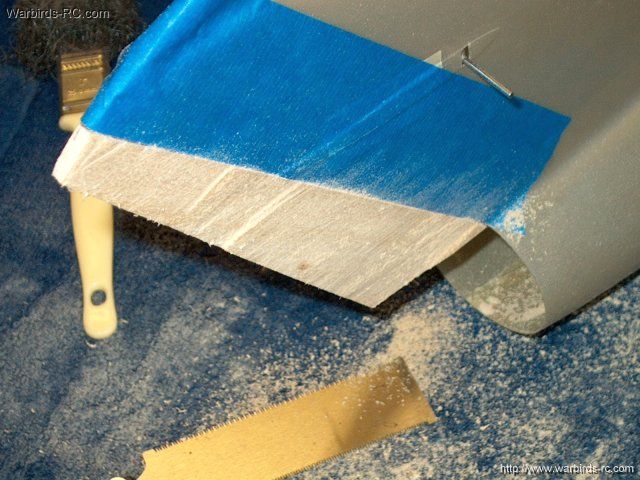

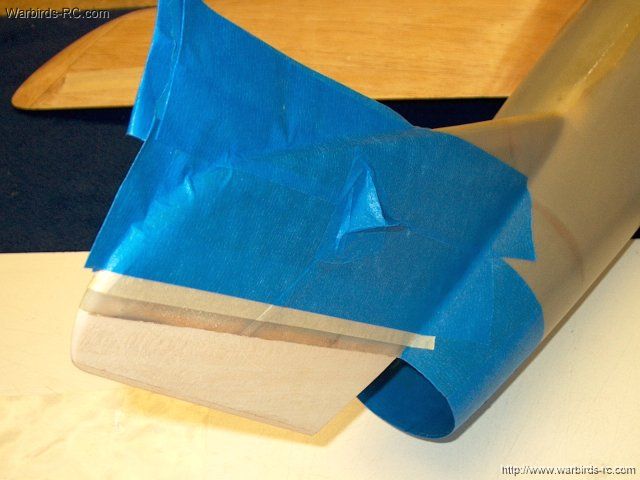

Two pieces of 3/4 oz fiberglass cloth were

cut to overlap and cover both sides of each stab. Use medium

CA to anchor the leading edge as shown and wipe away any

excess glue while pressing the cloth down

| |

Epoxy finishing resin is applied to the

inside root, leading outer and trailing edges, then to one

side of the stab. The cloth is applied and stretched to remove

wrinkles | |

The other side of the stab is glassed in

the same manner | |

A thin sheet of plastic is used to help

seal the stab and remove the excess resin without disturbing

cloth position | |

The plastic sheet is applied to the other

side of the stab and the excess resin is removed. Once done,

the plastic edges are trimmed as shown and the stab is placed

in a phonebook while the resin sets

| |

The second stab is glassed in the same

manner as the first | |

It is shown placed in plastic. Insert into

a phonebook while the resin sets | |

Horizontal Stabs are sanded and ready to

install | |

Make a center line on the stabs, around 2

3/16" from the front | |

Make a starting divot in the center of

each Stab | |

Center mark shown in the pic

| |

Mark the same distance, in this case 2

3/16", from the front tip of the stab molding on the vertical

fin | |

Make a vertical center mark

| |

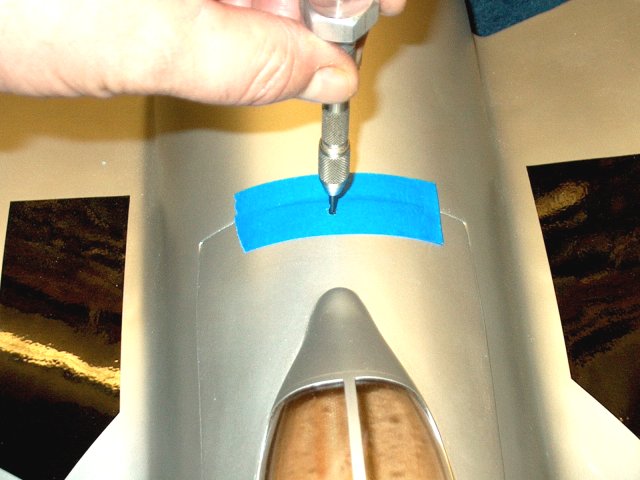

Take great care and drill dead center on

the mark | |

The hole is opened up with a 5/32" drill

bit | |

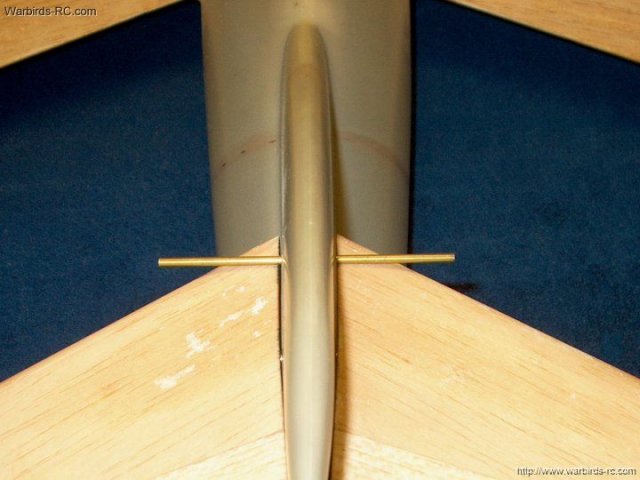

Install a piece of 5/32" OD brass tube

through both holes and check alignment. If it is off, you may

have to file the holes so both sides are the same

| |

Seal one side of the two remaining 1/8" x

1/2" ply squares with CA | |

Mark punch holes in the pieces at the

center for drilling | |

Drill a 5/32" hole in each of the two ply

squares | |

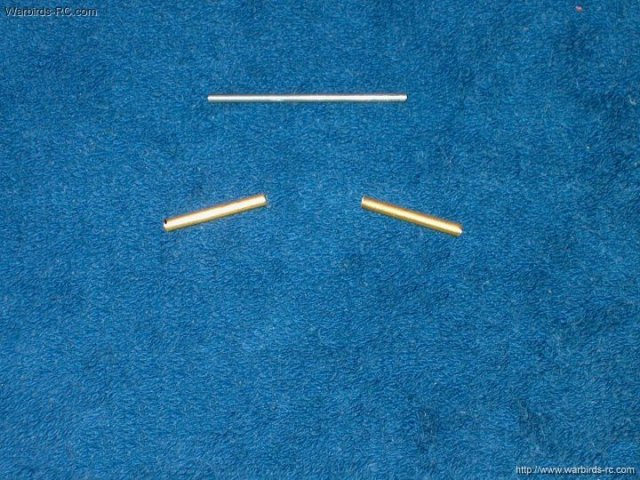

A piece of 1/8" wire is marked and cut to

3" long | |

Two pieces of 5/32" brass tube are marked

and cut to 1 1/4" long | |

The brass tube is inserted into the

vertical fin area and marked to cut so it will remain flush to

the sides of the fin. The two ply plates are positioned and

checked for center, then tacked in place with epoxy

| |

The piece for the fin is cut to

length | |

The brass tube is installed and checked to

make sure it is flush on each side. Sand as necessary for a

good fit | |

Photo shows the brass tube and plates in

place | |

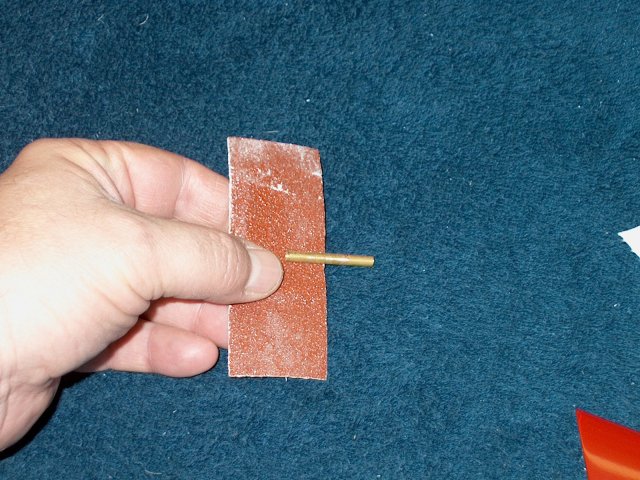

The two 1 1/4" brass tubes should be

roughed up on the outside with sandpaper before gluing in

place | |

The 1/8" rod and tubes are test fit for

free movement | |

A drill is run through the center of the

fin, drilling the pivot hole in the stab. Hold the stab flush

to the side of the fin and perpendicular to the fin while

drilling | |

The Horizontal Stabs are test fit and

position is checked | |

Check position of the Stabs from the rear

to make sure they are parallel to the wings and perpendicular

to the tail | |

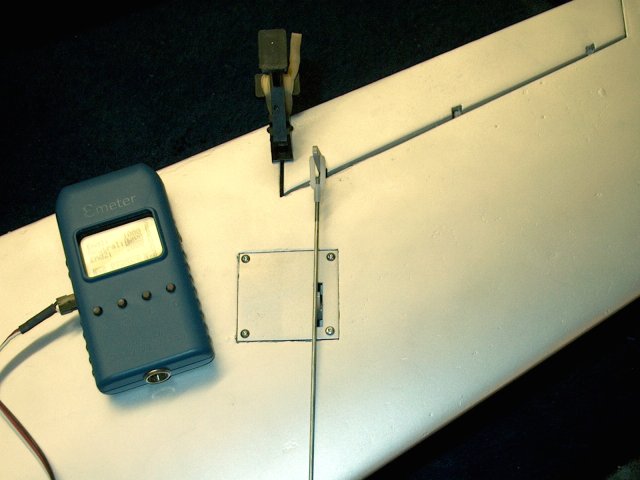

With the 1/8" wire installed, make a mark

1 5/8" from the front of the wire forward to mark the front

position for the actuator wire | |

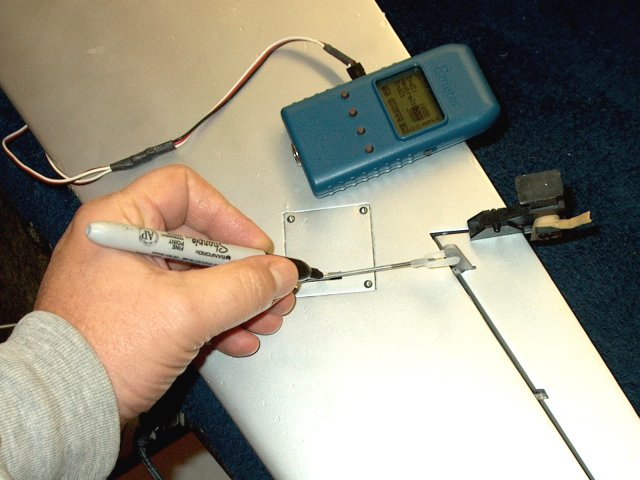

Measure and make a mark 1/8" back from the

front line you made for the area that needs cut

| |

Use a sharp knife or cutting tool to open

the area, then fin shape it with a file or small router

bit | |

The slotted area is shown shaped and ready

for installation | |

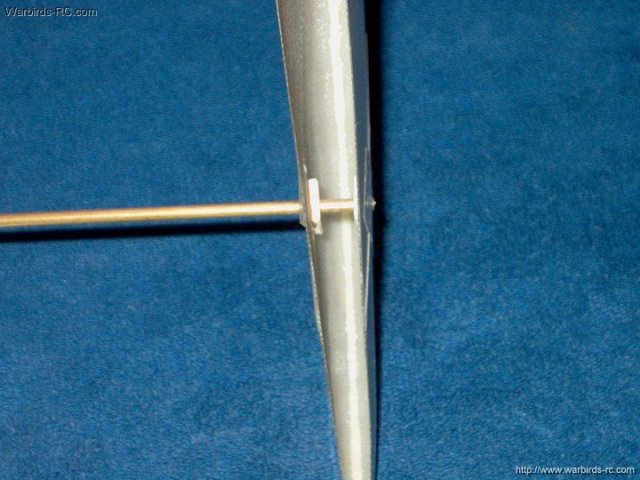

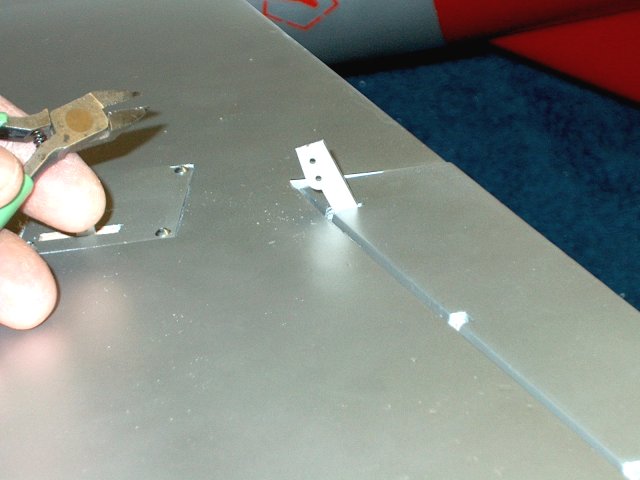

A piece of 1/8" brass tube is used for the

actuator assembly and should appear squared up to the sides of

the vertical fin as shown | |

Mark and cut a piece of 3/32" wire (4-40

push rod) to 2" in length | |

This pushrod is used as the actuator for

the Elevator | |

A piece of 1/8" brass tube is marked and

cut to a length of 1" long. Make two of these tubes

| |

The 3/32" rod and two 1/8" diameter brass

rods are ready to install | |

Slide the brass tubes over each end and

install the assembly through the slots. Holding the rod

against the front on both sides so it is kept straight, mark

on the front part of each Stab to indicate their

position | |

Make a center mark on each Stab

| |

Use a punch to start a hole. Keep it

centered on the airfoil and between the two fin marks you made

when the rod was installed | |

Use a 1/8" drill to bore the holes for the

brass tubes. Keep it centered and at the same angle as your

two lines and be careful to not overdrill

| |

Both Stabs have been drilled and the brass

tubes installed. Check the front and rear of the Stabs to make

sure they are even with eachother. If one side is lower than

the other, you may have to enlarge one hole to lower the brass

tube | |

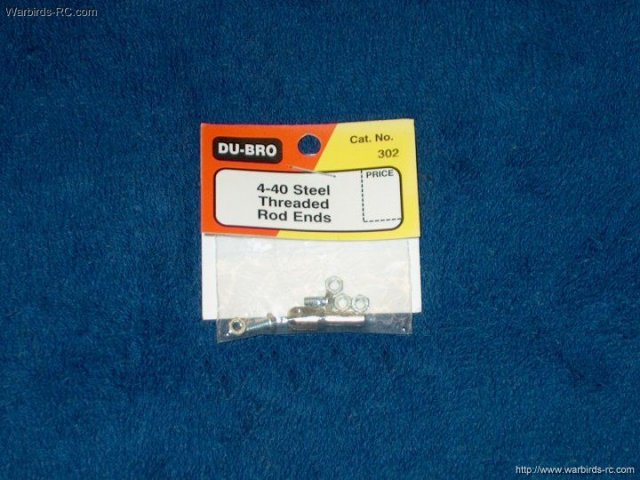

A "T-Bar" Elevator Control Rod will need

to be made using the 2" rod you cut. There are two methods of

doing this and both are included with this construction

manual. The first and prefered method is to use a 4-40

threaded rod end for the "T" as shown below

| |

Shown is a closeup of the heavy duty rod

clevis. One side is open for a bolt to pass while the other

side is threaded | |

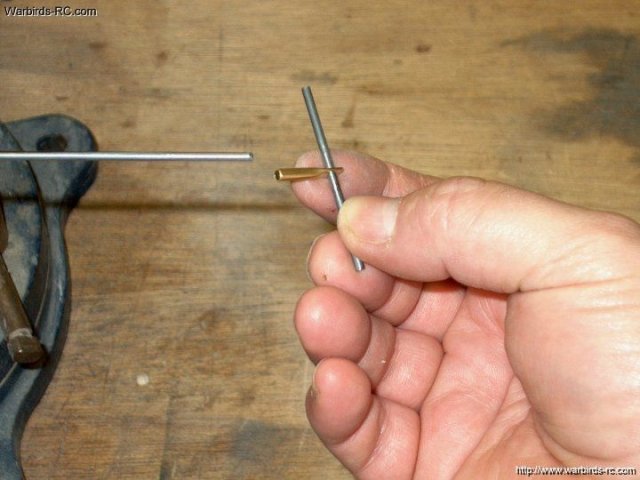

Install a 4-40 threaded push rod on the

clevis to help hold it and drill the threaded clevis arm with

a 3/32" bit so the rod will fit | |

The 3/32" x 2" rod and clevis are dipped

in soldering flux, then the rod is inserted and centered in

the clevis | |

Use a high quality silver solder for the

job and fill the area with solder between the two clevis arms.

Make sure the "T" is squared and perpendicular to the control

rod | |

Clean up the assembly with a micro wire

wheel and check for a strong joint. This is the prefered

method of making a T-Bar as it is adjustable using the 4-40

threaded rod | |

If you do not have a pushrod assembly, you

can use a piece of 1/8" brass tubing instead. Cut a piece to

3/4" in length | |

Flatten the first 1/4" of the tubing using

pliers | |

Using a 3/32" drill, make a hole in the

center of the flattened area | |

A center line is marked on the control

rod | |

The control rod is inserted through the

hole while the rest of the brass tube is slipped over a 4-40

rod. Make sure the brass and rods are clean and add soldering

flux before installing | |

The assembly is soldered at the T and the

pushrod joints. Be sure to keep the control rod perpendicular

to the pushrod | |

The T-Bar on the left only weighs one more

gram than the one on the right and is adjustable. However, the

one on the right is simpler and cheaper to make, so it's your

choice. The key to success is to use a good solder and flux,

otherwise you will never get the joint strong

| |

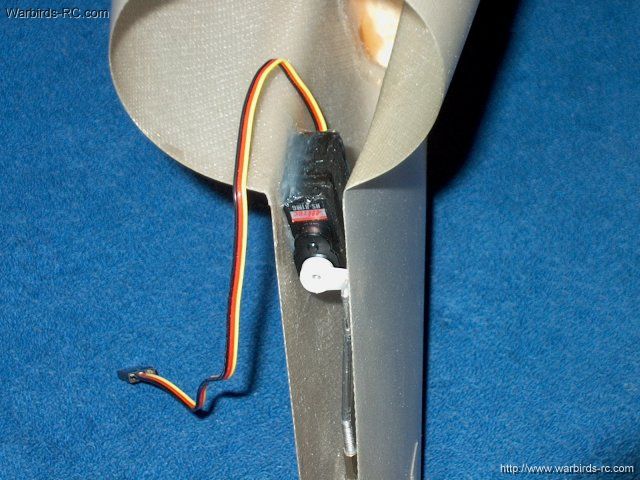

The servo for the Elevator should be metal

gear, as others have been known to strip in as few as a couple

flights. | |

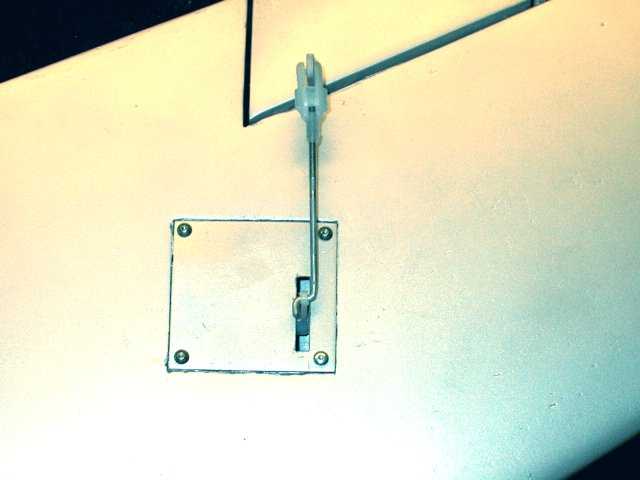

One end of the "T" Rod is inserted into

the slot, then the center is spread so the other side will fit

into it's slot | |

Control shown in place

| |

The Elevator servo is centered with the

receiver or a servo tester | |

Trim off one side of the servo horn

| |

The other side of the horn is shortened to

the first hole, then installed on the servo

| |

The servo area is cleaned with Denatured

alcohol | |

Silicone rubber is applied evenly to one

side of the servo | |

A piece of wood keeps the vertical spread

apart so the servo can be placed in its location and the

control rod is used to align and square up the servo

| |

Install the servo to one side of the

fuselage as shown | |

Tape up one of the holes for the flying

stab main shaft | |

Install the brass tube for the

shaft | |

Use thick CA to glue one side of the tube

to the inside ply plate | |

Glue the other side of the tube with thick

CA | |

Find the 1/8" x 3/16" balsa strip that is

about 18" long. Cut the strip into two pieces

| |

Make a mark inside the fuselage about 5/8"

from the top of the vertical stab | |

Use tape on the first stick to help hold

it in place | |

Tape the stick flush along the inside edge

of the stab and down to the 5/8" mark. Pivot the stick and

apply thick CA along its length | |

Clamp the stick in place, flush with the

end of the stab until the glue sets

| |

Remove the excess balsa from the end of

the stick | |

Apply thick CA to the other stick and

install on the other side of the inner stab wall, flush with

the end | |

Clamp the stick in place until the glue

sets | |

Use a scrap piece of 1/4" thick balsa and

outline the stab top pattern, then cut the piece to fit

| |

Apply some thick CA to the area as

shown | |

Install the balsa filler piece in the top

of the stab | |

Lightly sand the rear of the stab to

remove any exposed balsa, but do not sand into the

fiberglass | |

Mark the inside center of the

rudder | |

Mark the center rear of the rudder

| |

Draw a vertical line down the middle of

the ruddder end | |

Apply several strips of masking tape to

the rear of the vertical stab | |

Using thick CA, apply a bead down both

wood stab spars | |

Position the rudder in place, making sure

it is centered at both the top and bottom

| |

Use the masking tape to hold the rudder in

place while the glue dries | |

Rudder installation completed

| |

Use a surface saw to cut away the larger

portion of balsa. Be careful to not cut too much

| |

Apply masking tape to the fiberglass stab

so you don't sand into it and the use a 100 grit block for the

basic shaping | |

Use a saw to cut down the other side of

the rudder | |

Tape should be used so the fiberglass

surface doesn't get marred. Shape the other side of the

rudder | |

Remove the tape and blend the rudder even

with the stab | |

Cut a 3/32" thick strip of basswood to 10"

long | |

Use thick CA and cap the trailing edge of

the rudder with the basswood | |

Cap shown in place

| |

Remove the excess spar from both the top

and bottom | |

Use a fine sanding block to shape the

trailing edge of the rudder | |

Wipe the rudder down with a tac cloth to

prepare it for fiberglassing. Rudder shaping shown

completed | |

Cuta piece of 1/2oz glass cloth long

enough to wrap around the fin | |

Tape off the Stab as shown to catch excess

epoxy | |

Use thick CA to anchor the cloth at the

trailing edge of the rudder | |

Smooth out the CA evenly and allow it to

dry | |

Apply a small ammount of epoxy at the

cloth seam on both sides | |

Use a brush to apply epoxy to the cloth.

Glass both sides | |

Use a spreader to remove excess epoxy from

the sides of the rudder | |

Apply a sheet of plasic to the rudder with

the spreader, removing excess epoxy. Clean up the tape with

alcohol | |

Once the epoxy sets, make a light cut only

through the glass cloth at the point where tape begins. Remove

the tape from the stab | |

Sand and blend the glassed rudder to the

stab, making sure not to oversand. Fine sand with 400

grit | |

Rudder and Stab fiberglassing shown

completed | |

Mig-15 basic airframe assembly completed

and ready for paint | |

Carefully rough cut the canopy frame

outside the marked lines to remove the window area

| |

Use a sanding drum to shape each

rail | |

Fine sand the canopy to a finish as

shown | |

Install the fiberglass frame over the

clear canopy | |

While holding the canopy against the frma,

mark the bottom edge of the clear canopy for cutting

| |

Use a pair of scissors to trim the

canopy | |

Test fit and recut if necessary, but do

not remove too much of the canopy | |

Use alcohol to clean the canopy

marks | |

Fine sand the canopy edges

| |

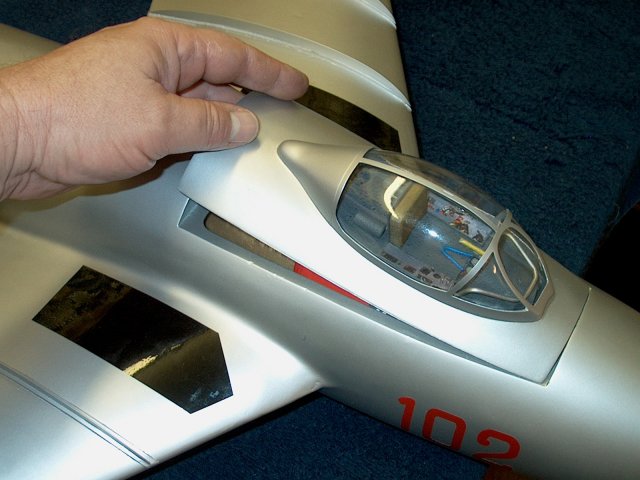

Cockpit frmae and canopy completed

| |

Position the cockpit frame so it is

centered and flush with the front of the fuselage and tape it

in place | |

Use a 1/8" drill from the front to drill a

dowel hole throght the frame and fudelage

| |

Round the tip of the 1/8" dowel included

in the kit | |

Install the pin with the round side out to

help is slide easier into the fuselage

| |

Use thick CA to glue the dowel in

place | |

Carefully cut out the intake

| |

Use 1/2" masking tape and apply around the

circumference of the plastic intake

| |

Cut along the tape edge for an even cut

all the way around the intake | |

Sand the bottom on a flat surface

| |

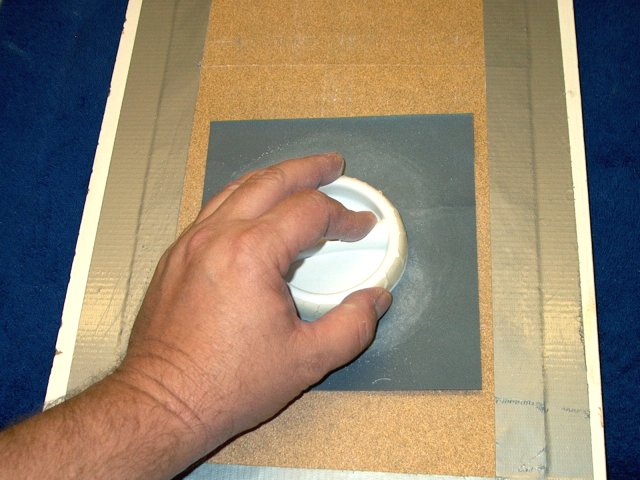

Sand with finer sandpaper to a good

finish | |

Cut the center evenly, leaving a finished

intake as shown | |

Measure 3 1/8" from the wing seam on the

fuselage. Make several marks along the length of the

wing | |

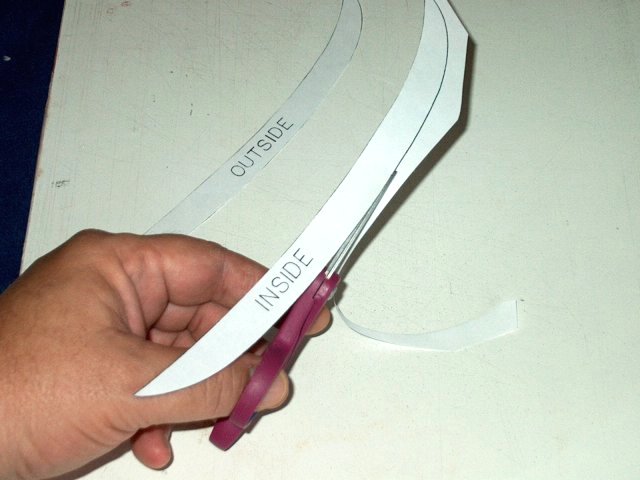

Trim the patterns for the wing fences from

the paper | |

Cut eight 3/32" strips from one of the

pieces of plastic fence material | |

Transfer the fence patterns to the

remaining four plastic sheets | |

Cut out each fence as shown

| |

Place a strip with its outside along the

pencil marks at 3 1/8" from the fuselage seam

| |

Use masking tape in the rear so it does

not shift backward, then tape the strip in place

| |

flip the strip over and apply epoxy with a

toothpick along the strip | |

Flip the strip back over and press it down

to squeeze out excess epoxy, which is cleaned up with

alcohol | |

Tape the strip in place until the glue

sets | |

Trim the ends with a razor

| |

Test fit the inside fence

| |

Sand the fence until it is a good fit on

the wing | |

Finish sand the fence, rounding the top of

the fence with fine sandpaper | |

MEasure and make several marks from the

first fence strip 3" past its location

| |

Tape the second strip in place

| |

Trim the excess tape flush to the outside

of the strip | |

Sand the inside of the strip to rough it

up | |

Apply epoxy to the strip

| |

Flip the strip over, then clean excess

epoxy and tape in place. Make sure it remains straight with a

ruler | |

Trim the ends flush

| |

A ruler can be used to scrape away the

excess soft epoxy before it completely hardens

| |

Tape the second strip in place, using a

fence for proper spacing | |

Tape the fence in place and trim the tape

flush to the inside of the slot | |

Test fit the fence

| |

Flip the strip over while it is still

taped and rough it up | |

Apply epoxy to the strip

| |

Flip the strip over and press down. clean

the puside with alcohol and the excess epoxy from the inside

using a left over piece of fence material

| |

Tape the strip in place until the glue

sets | |

Remove the tape

| |

Check again the inside slot and clean if

necessary | |

Apply glue along the slot as shown. Remove

any spill over wiht alcohol and a paper towel

| |

Install the fence

| |

Check it with a ruler for straightness.

Make sure it is perpendicular to the wing surface

| |

Let the glue set, then remove all

tape | |

PRepare the second outside fence strip as

shown | |

Rough it up, then apply glue along the

strip, then flip it over and clean up

| |

Install the second shorter fence the same

as the first | |

Measure the second wing 3 1/8" from the

fuselage joint | |

Tape a strip in place with the marks on

the outside | |

Trim the tape flush to the outside. Glue

the strip in place like the first side

| |

Glue the second strip to the fuselage,

making sure it remains straight and tape it in position

| |

Trim the ends | |

Trim the front | |

Clean up any excess soft epoxy

| |

Apply epoxy to the slot

| |

Clean up excess epoxy

| |

Install the larger fence, maaking sure it

remains straight and perpendiculaer

| |

Measure 3" from the fence

| |

Tape a strip on the inside of the

marks | |

Cut the tape flush as shown

| |

Flip the strip up, rough it with sandpaper

and apply epoxy | |

Flip it over and clean up excess, then

pate it in place until the epoxy sets

| |

Check for straightness, then install the

second strip and last fence as previously described

| |

Fence installation shown completed

| |

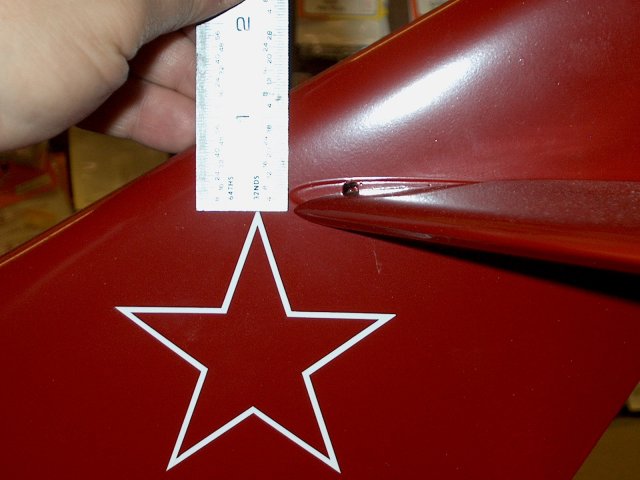

Paint your model before final assembly.

The model chosen in the photo was the "Red Tail" MIG-15

| |

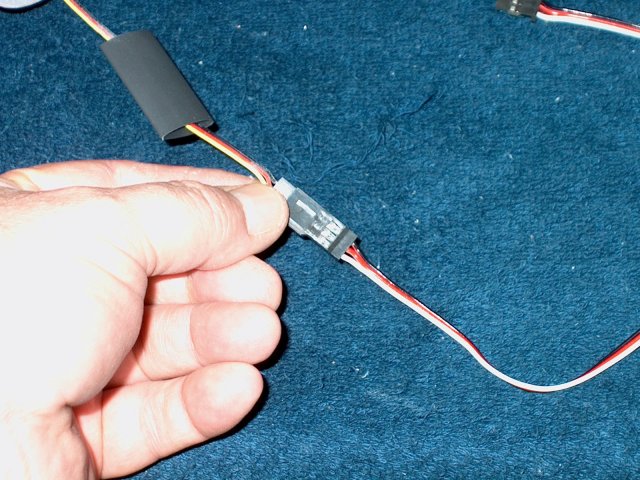

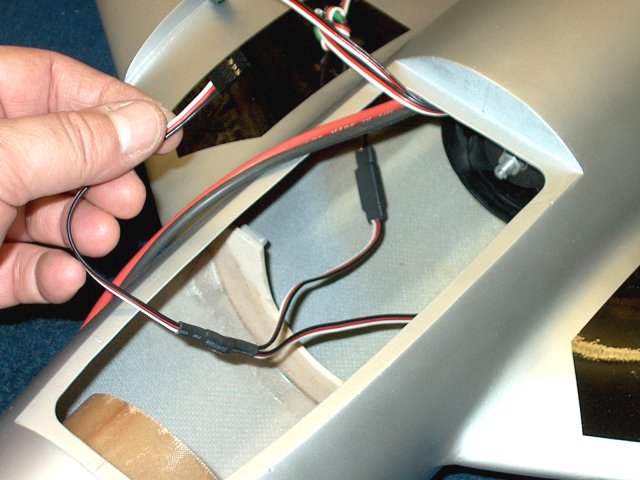

Install a 12" servo extender wire on the

Elevator sevo lead and use heatshrink to retain it. Run the

lead forward into the cockpit area | |

Install the fiberglass thrust tube in the

model from the rear. Make sure the Elevator servo lead runs

through the top of the center former and the tube engages the

center former | |

Push away the rear of the thrust tube into

the fuselage and run a bead of clear silicon sealer around the

edge. Wipe away the excess, push the thrust tube rearward,

flush with the end of the fuselage and allow the sealer to

dry | |

Run a bead of medium CA about 1/4" away

from the exit. Install the thrust ring 1/4" away from the

end | |

Use your finger to make a fillet of CA

against the back of the thrust ring

| |

Install the fan assembly and clear thrust

tube from the front of the fuselage

| |

Press and seat the fan in the rear outer

fiberglass thrust tube. It should be a tight fit

| |

The clear thrust tube should be centered

in the rear thrust ring as shown | |

If necessary, install 6" extender wires on

each Aileron servo. It was not necessary for the Hitec

HS-81's | |

Use a thin strip of Carbon Fiber to pull

the Aileron lead through the wing and into the fuselage

compartment. Use servo tape on the back of the servo and

install each servo in the wings | |

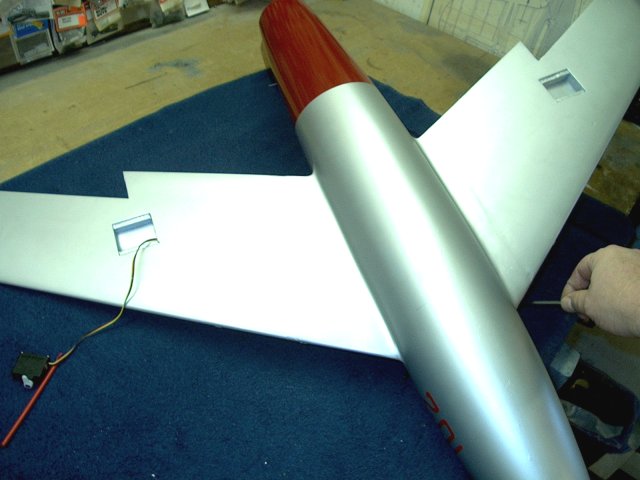

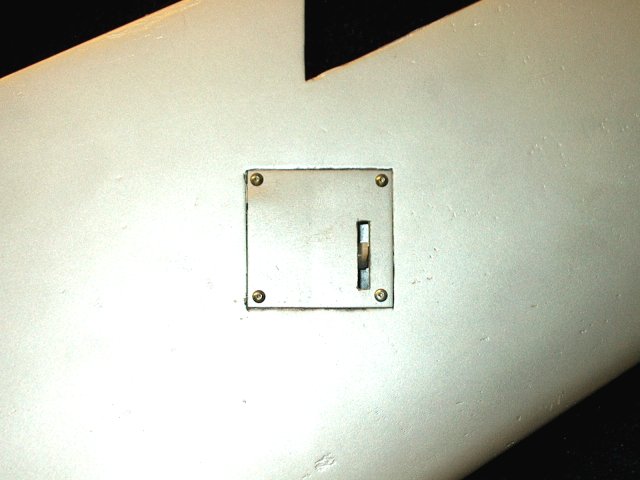

Cut a 3/16" wide slot in each servo door

for the horn to exit | |

Remove the balsa from the servo area of

each door so the door sits flush | |

Drill 1/16" holes 1/8" away from each

corner of the doors and into the wing mounts, then open up the

holes in each door so #2 button head screws will slip through.

Install the doors with #2 x 3/8" button head screws

| |

Connect an Aileron "Y" adapter to the

servo leads and use heatshrink to retain them

| |

Prepare each Robart Pin Hinge by

installing a piece of thin plastic over the hinges as

shown | |

Apply epoxy to the hinge holes in the

Ailerons with a toothpick | |

Install each hinge so they are seated

fully and pivot correctly. Clean up any excess and make sure

the hinges pivot without binding. Remove the plastic once the

epoxy sets | |

Install frsh plastic on each pin hinge.

Apply eposy to the wing holes and install the Ailerons. Clean

up excess epoxy and remove the plastic once the glue

sets | |

Install a clevis on each of two 2-56

pushrods | |

Clip the clevis in the second hole from

the Aileron | |

Use a receiver or servo tester to center

the servo | |

Clamp the Aileron in a neutral position

and mark the rod at the servo horn outer hole location

| |

Make a Z-bend at the marked location as

shown | |

Drill the servo horn outer hole with a

5/64" bit so the wire will fit | |

Trim the Aileron horn as shown, then sand

and shape, rounding the ends | |

Install the pushrod assembly and adjust

the clevis as needed | |

Repeat the procedure and install the

pushrod for the second Aileron | |

Cut a piece of 1/4" thick ply or two

laminated pieces of 1/8" ply to 1 3/4" x 1 1/4". Drill a hole

5/8" from the front of the plate and cut a recess 3/4" long

for the towhook wire | |

Use a piece of 2-56 wire 3" long and bend

a right angle 3/4" long at one end. Check the fit in the ply,

then apply epoxy and install the wire in the hole

| |

Add a bead of epoxy across the top of the

wire as shown | |

Measure 6" back from the front of the

fuselage and mark a center location

| |

Drill a hole for the towhook wire

| |

install the plate and use a pencil to mark

the area of the towhook plate | |

Install a thick layer of epoxy and

fiberglass mil in the bottom area of the fuselage

| |

Apply epoxy to the bottom of the towhook

plate and install the plate. Remove excess epoxy, allowing for

a fillet around the plate | |

Cover the fuselage with tape so you don't

mar the finish and bend the towhook to shape

| |

The towhook should have a slight down

angle to it | |

Install the intake tube from the front of

the fuselage so that about 1/8" extends past the front. Apply

a bead of Silicon around this joint

| |

Apply a thick bead of silicon sealer to

the inside edge of the intake nozzle, then install it centered

on the fuselage. Allow the silicon to set overnite

| |

Rough up the small forward brass tubes for

the Elevators with sandpaper, leaving about 3/8" smooth on one

end | |

Rough up the larger pivot brass tubes with

sandpaper | |

Apply epoxy to the forward holes and

install the small brass tubes so about 1/4" extends past each

Elevator | |

Install the 1/8" pivot rod in the

center | |

Apply epoxy to one Elevator hole and

install the brass tube so about 1/32"-1/16" remains past the

surface to act as a bearing. Install the Elevator and check

for clearance. You want the joint close without binding

| |

Repeat the procedure for the second

Elevator and mount it in place. Tension on the front steering

rods will hold them on and you can remove the Elevators and

put a very slight forward bend in each of the forward rods to

adjust tension | |

Sand the outer edge of the canopy about

1/8" wide with 100 grit sandpaper to rough it up

| |

Apply a bead of RC-56 canopy glue around

the canopy and across the back | |

Install the canopy and let it dry. You can

use some weights to make sure it is seated well in the

frame | |

Cut a piece of 1/4" square hardwood about

1 1/2" long. Drill a small hole down the center

| |

Epoxy the piece in place at the rear of

the canopy as shown, flush with the bottom

| |

Drill an outer hole in the canopy using

the hardwood as a guide | |

Install the canopy, make sure it is

centered, then drill a hole down through the fuselage lip with

a hand drill | |

Open the hole so a #4 hex head screw can

be installed, then mount the canopy on the fuselage and

install the #4 hex head retaining screw. This leaves the

fuselage outside surface smooth and free of screw heads

| |

To build a cockpit, you will need to make

a floor first that will clear the batteries. Cut a piece of

paper to the size of the canopy area. You can hold it up to

the light to rough trace it | |

Transfer the pattern to a piece of 1/32"

ply and cut it from the sheet | |

Sand and shape the floor so it fits in the

recess and sits on the top edges of the canopy

| |

You can build a semi scale cockpit if you

wish from scrap wood | |

A Cockpit adds realism to your model,

however, if you decide on a 3S setup, you may need to paint

the canopy black and leave the cockpit area open for battery

clearance | |

Install a full range receiver and plug in

your Aileron, Elevator and ESC wires. You can tie wrap and

dress them so they are out of the way

| |

Use servo tape or velcro to attach the

receiver to the side wall of the model as shown. Route your

antenna out the rear or drill a small exit hole in the side of

the fuselage under the wing. Be sure to range test your

antenna location before flying | |

Two 3300 2S 20C Lipos are installed so

they saddle both sides of the forward cockpit area. The

batteries are run in series for a 4S setup

| |

For battery retention, cut two double

sided velcro straps to a length of 4 1/2"

| |

The straps will be installed as shown. You

are viewing the bottom side of the batteries that go face

down | |

Install a battery and push it forward,

then install a piece of 1" velcro square on the center of the

intake. Fold the strap over to the other side for the second

battery | |

Install a second velcro square under the

rear strap. You could also run a velcro strip down the entire

center top of the intake to allow for adjusting battery

position. The straps will keep the battery pack in its side

slot, while also preventing it from shifting backward during

flight | |

Install the second battery and then the

canopy, making sure the batteries do not bind against the

bottom of the canopy. With the batteries shown or similar

ones, this will not be a problem | |

Make a mark for the CG location on each

wing at 3 5/8" from the rear root. Adjust your battery

position so the plane balances at CG

| |

Set Aileron throws at 1/8" up and 3/16"

down for initial settings, then add more throw if desired

after your first flight | |

Set Elevator throw at 3/16" up and down

for the first flight, then add more if necessary | |

Front view of the intake shows a clean and simple design

| |

Right side view of the MIG-15

| |

Top view of the MIG-15

| |

Rear view of the MIG-15

| |

The K&A MIG-15 Fagot EDF Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| | | |