01 - K&A Models MIG-15 EDF as it comes

from Markos at Warbirds-RC | |

02 - The MIG was well packed from the

maufacturer and Warbirds-RC. It comes in two versions, the

Basic version or the Deluxe Pre-Primed version with

Pre-sheeted wings, clear canopy and more for a small

additional charge. The Deluxe version is shown below and worth

it | |

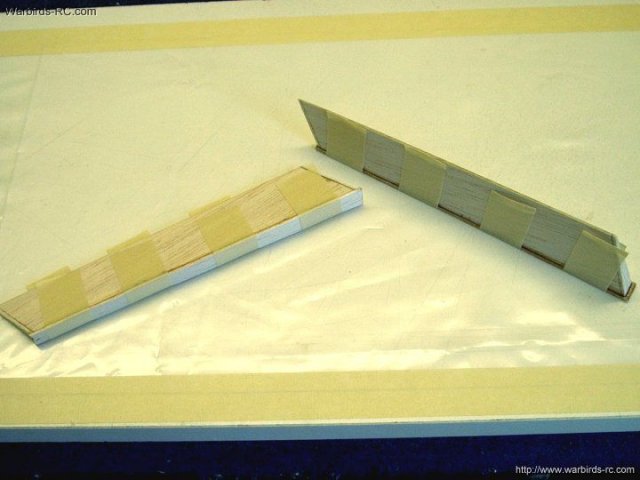

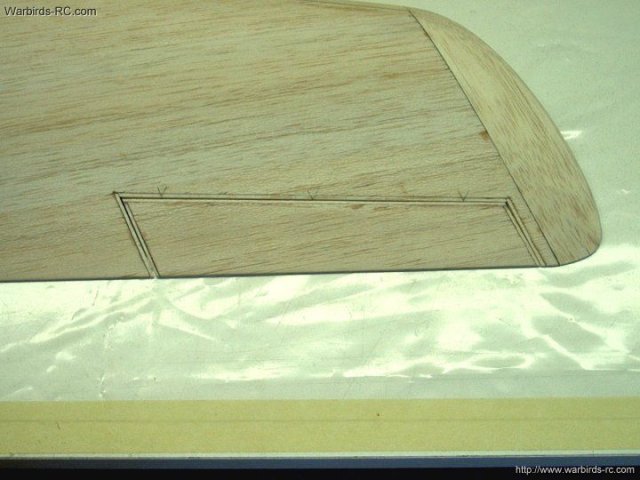

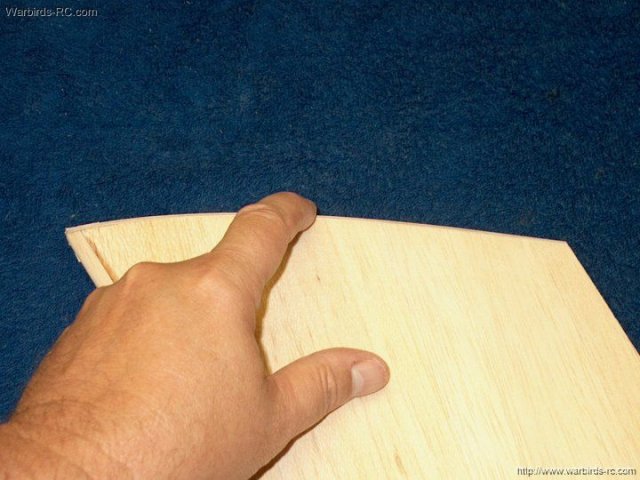

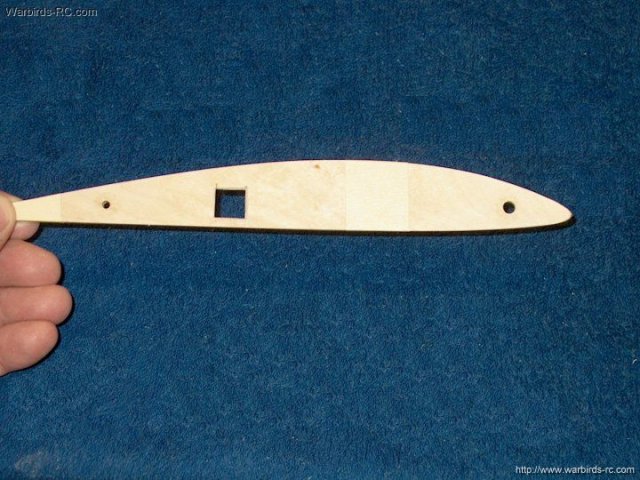

03 - Pre-Sheeted wings come with the

Deluxe Pre-Primed Kit and are well worth the few extra

dollars | |

04 - You also get a clear canopy with the

Primed kit | |

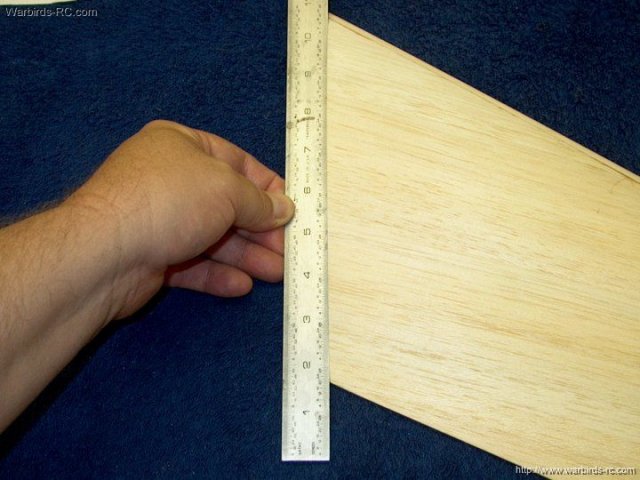

05 - The lumber that comes with the model

is of very good quality | |

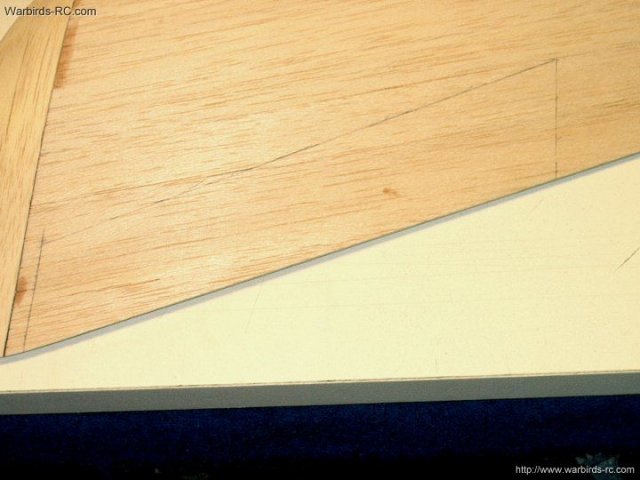

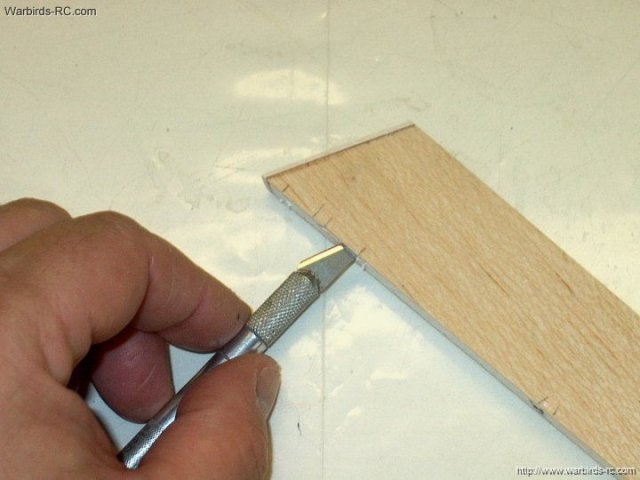

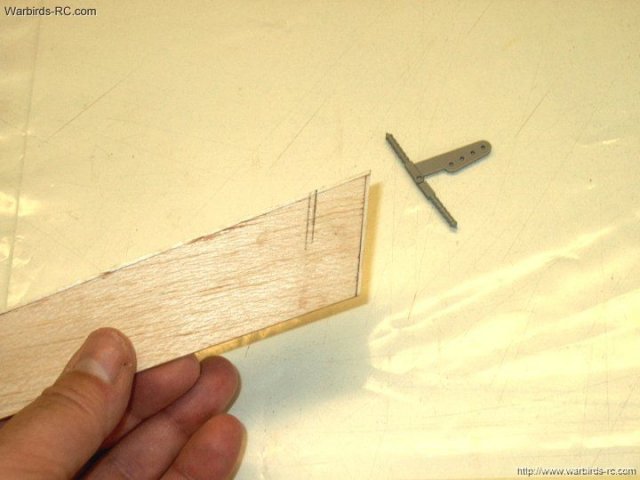

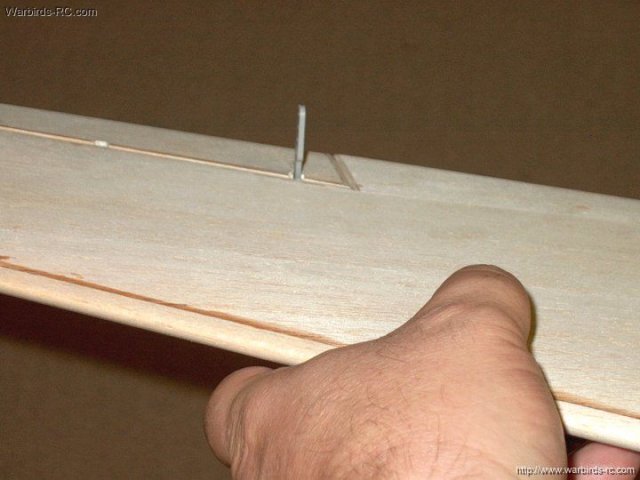

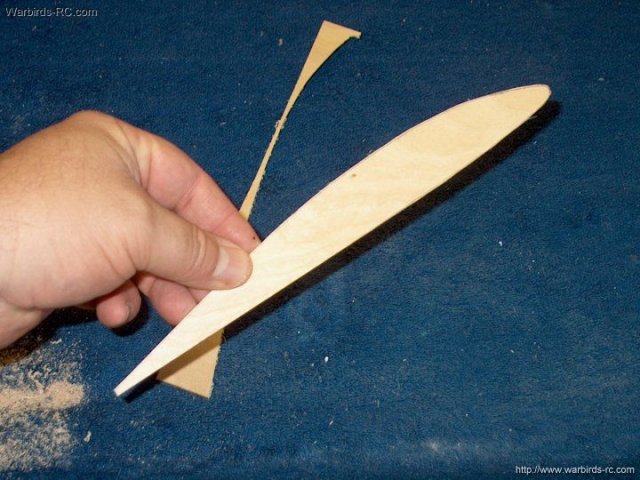

06 - Construction begins with the wings.

As these wings were presheeted, several steps were eliminated.

A 1/4" x 1/2" balsa strip is sanded flush with the correct

angle at the wing tip leading edge. Make sure you hold the

strip centered across the leading edge of the wing

| |

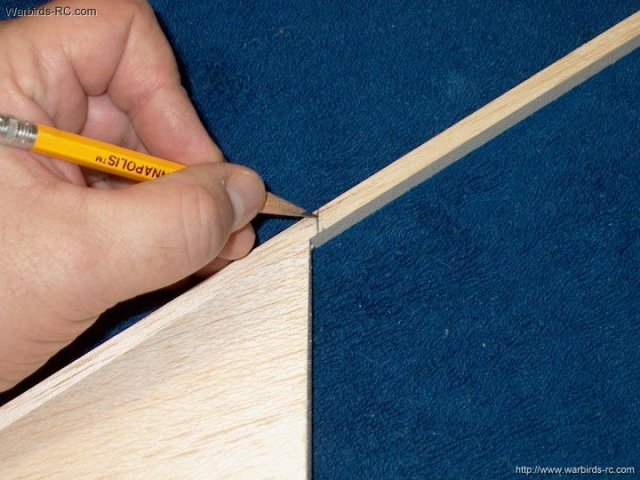

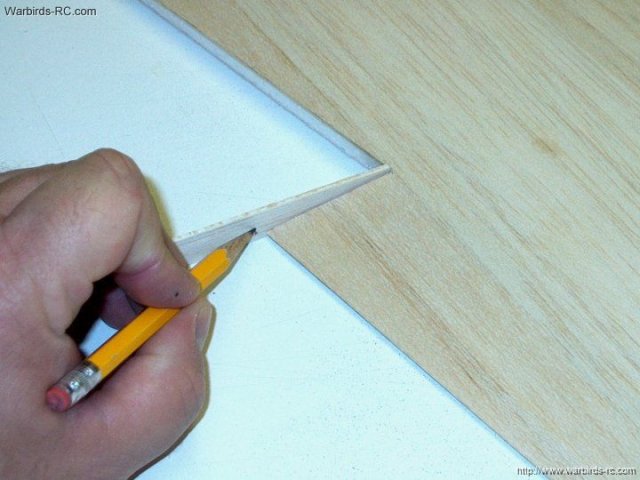

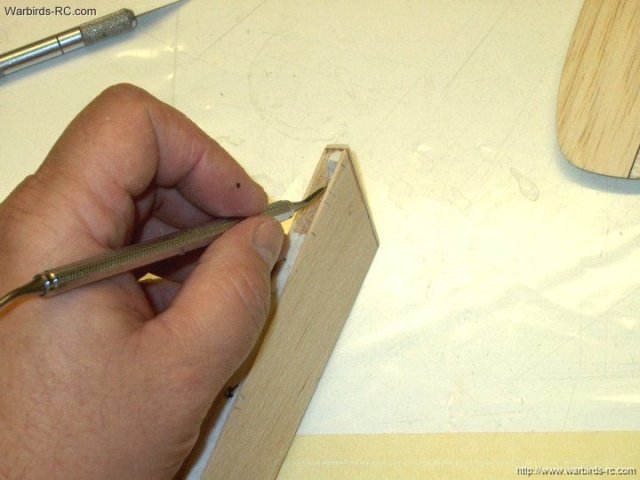

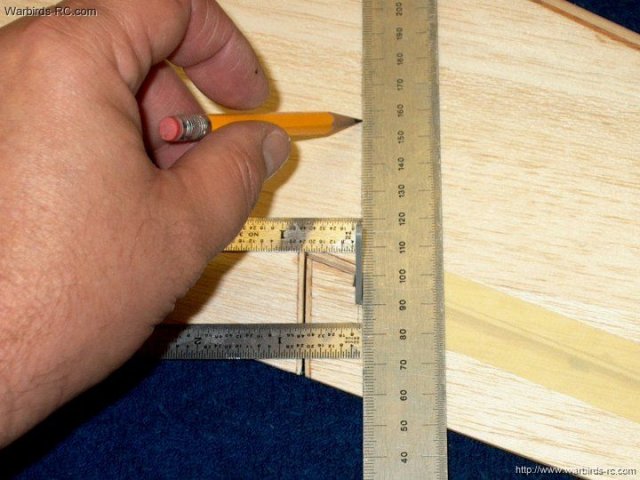

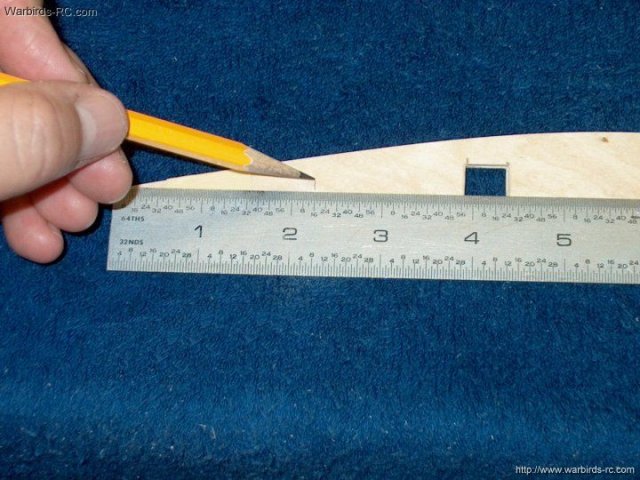

07 - Hole the tip flush and make a mark on

the balsa strip slightly longer than the inside root of the

wing | |

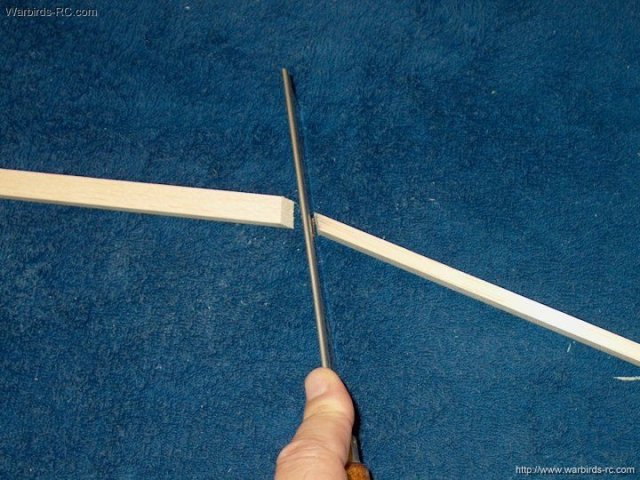

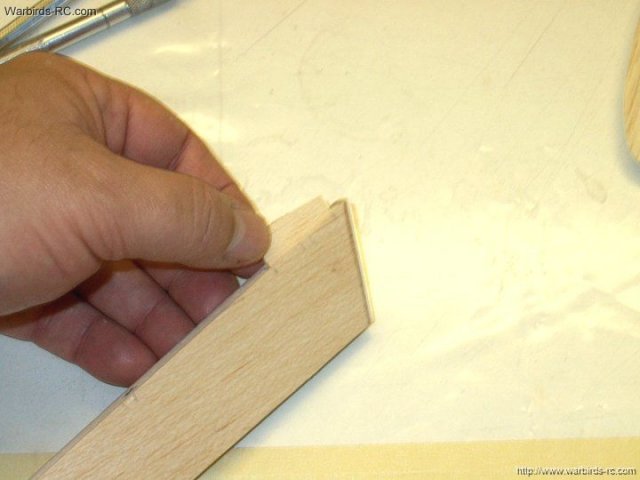

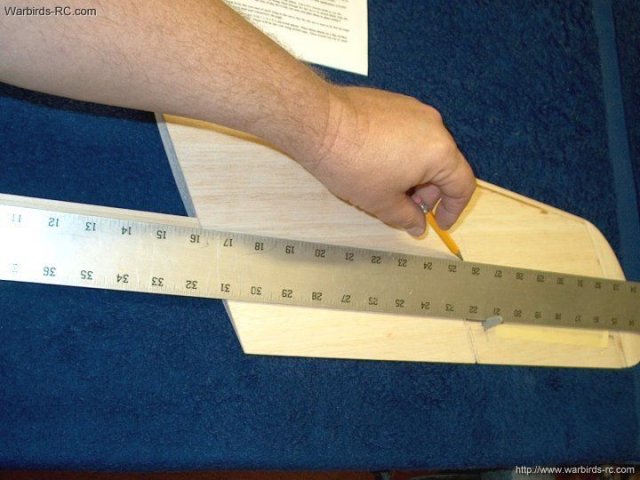

08 - Cut the excess from the balsa strip

at the mark you made | |

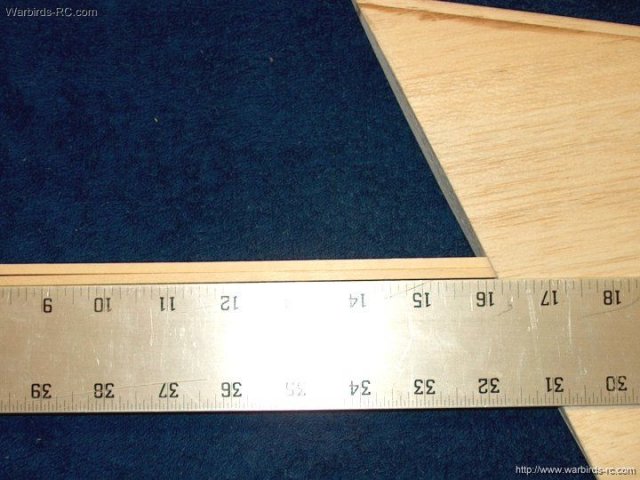

09 - Photo shows the strip flush with the

wing tip to the left and centered down the leading edge

| |

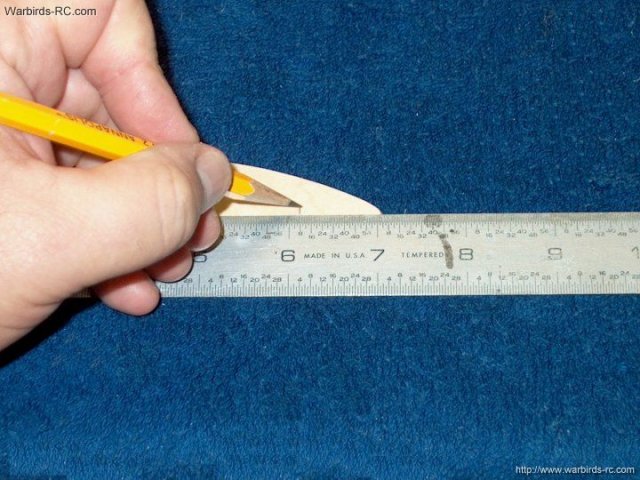

10 - The second wing is prepared by

sanding the tip angle on the 1/4" x 1/2" balsa strip

| |

11 - Strip must be kept centered while

sanding and when gluing | |

12 - The second strip is marked about 1/4"

from the root of the wing | |

13 - The excess is removed from the balsa

strip | |

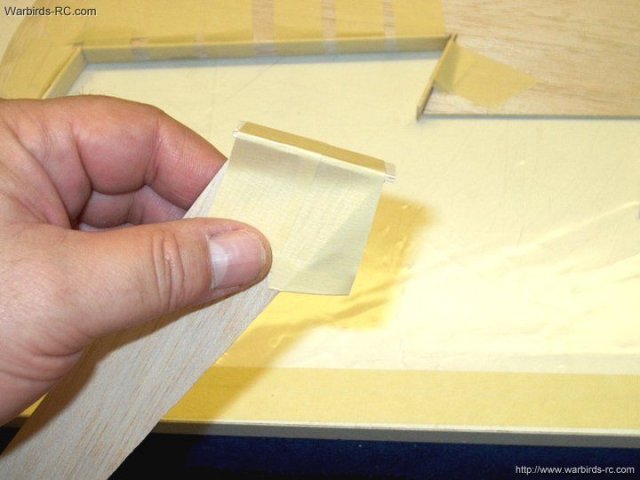

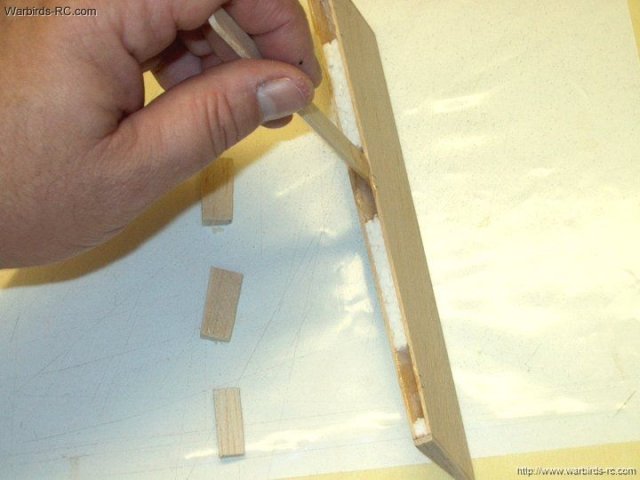

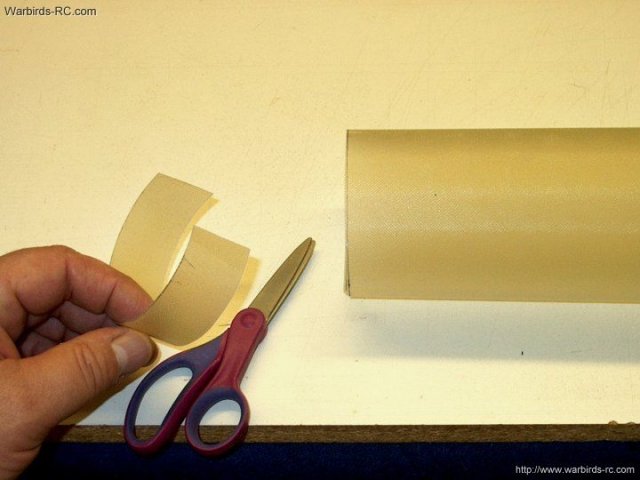

14 - Prepare several pieces of masking

tape around 3" long that will be used to hold the balsa strip

in place. About eight pieces per wing will work fine

| |

15 - Wings, leading edge 1/4" x 1/2"

strips and wing tips ready to glue | |

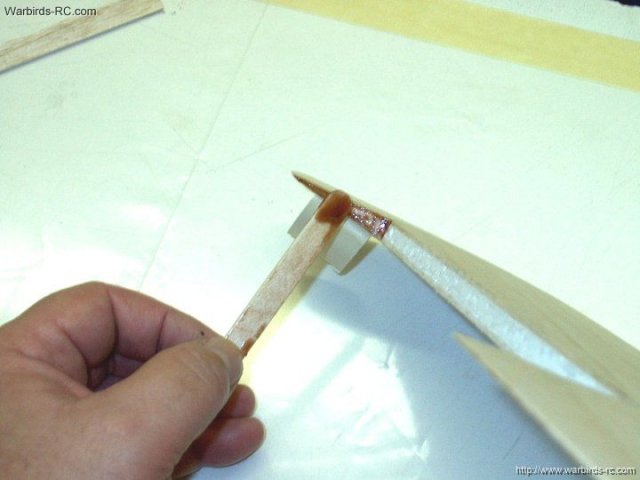

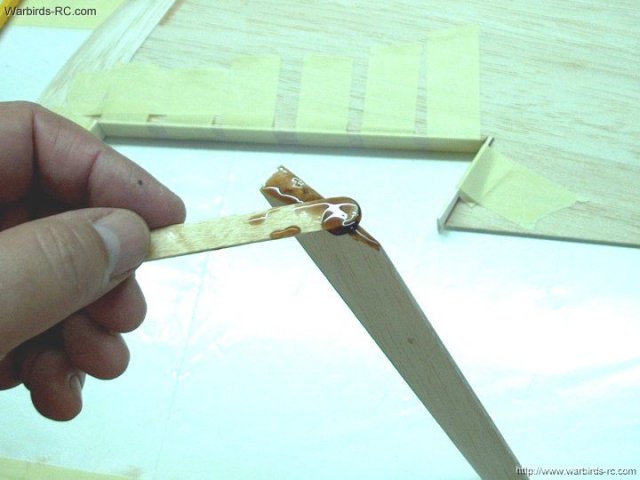

16 - Some 15-30 minute Epoxy is applied to

the leading edge of the wing and the inside of the balsa

strip | |

17 - The strip is positioned over the

leading edge and excess epoxy is removed

| |

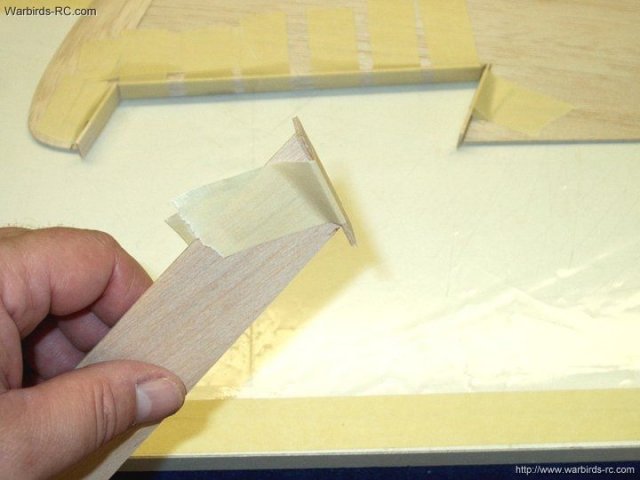

18 - Use the tape strips to hold the balsa

leading edge strip in place. Make sure it is flush with the

wing tip end and centered along the leading edge on both the

top and bottom | |

19 - Make sure the leading edge is flush

with the wing tip root, then apply epoxy to the wing tip

area | |

20 - Apply epoxy to the Wing Tip balsa

stock | |

21 - The balsa wing tip is positioned and

excess epoxy is removed. Make sure you position the wing tip

block in the correct direction, with the shallow curve toward

the front as shown | |

22 - Use long pieces of masking tape to

hold the wing tip block in place. Make sure the block is

centered with both the top and bottom of the wing and also

make sure it is flush with the leading edge as shown on the

right side | |

23 - Epoxy is applied to the second wing

leading edge and balsa strip. Keep the strip centered down the

wing leading edge and flush with the outside tip, then clean

the excess epoxy and tape the strip in place

| |

24 - Epoxy is applied to the wing tip area

of the wing | |

25 - Epoxy is applied to the wing tip

block and the block is positioned as shown with the shallow

curve forward | |

26 - The wing tip and leading edge shown

with masking tape in place | |

27 - Both wings are waiting for the epoxy

to set | |

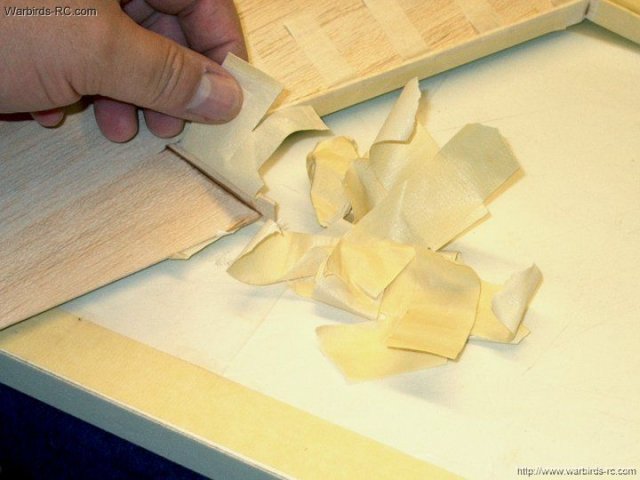

28 - Epoxy has set and tape has been

removed so the wing can be shaped | |

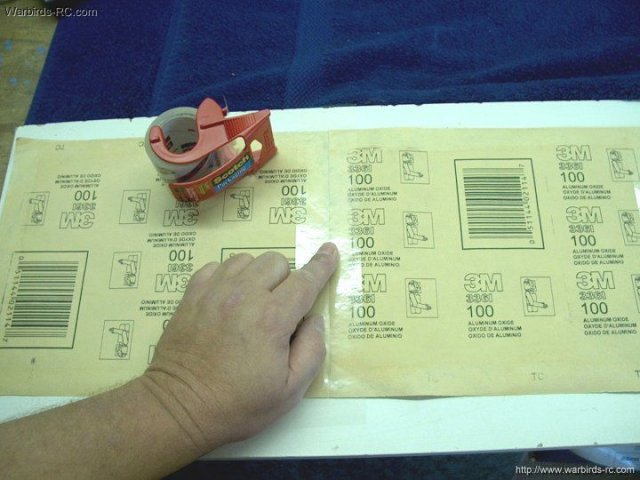

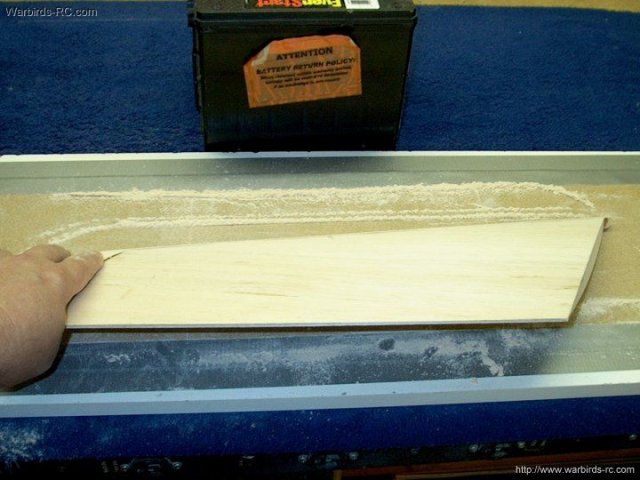

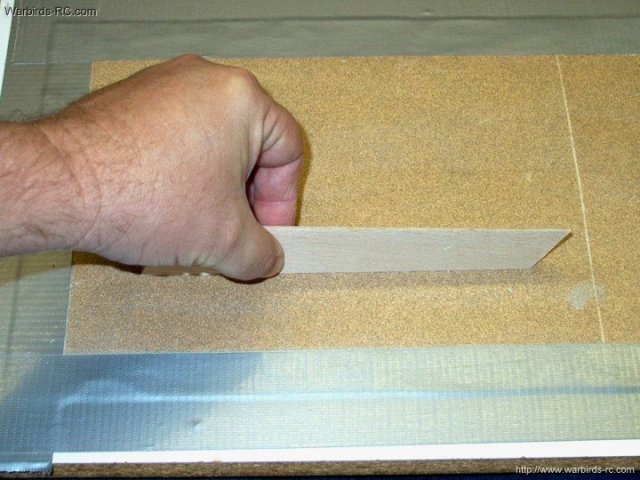

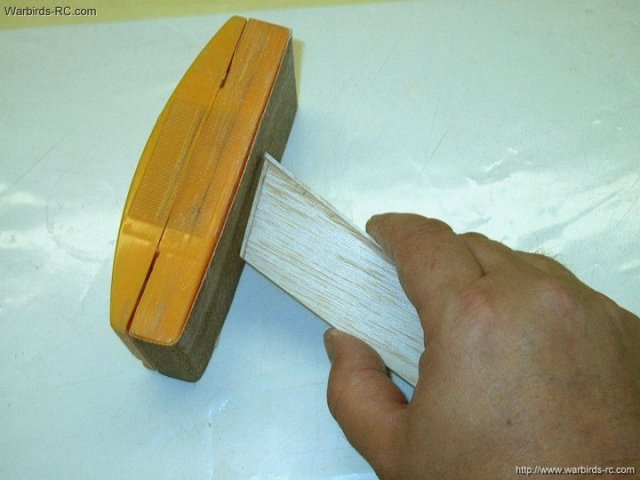

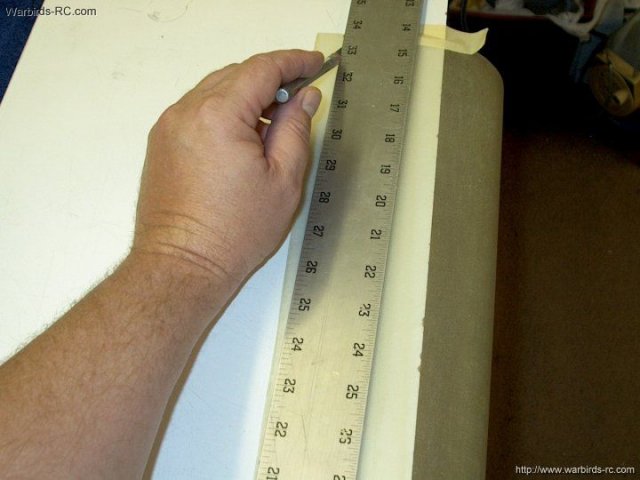

29 - Making a sanding board...I used three

sheets of 100 grit sandpaper and taped them at the seams, then

trimmed the excess tape flush to the outer ends

| |

30 - The long sheet of sandpaper was taped

to a two dollar shelf board that is very flat. Only use duct

tape as it is the only one that will stick to the

sandpaper | |

31 - Hold the wing with both hands and

shape the leading edge...it will go surprisingly fast and the

board helps keep your sanding perfectly even across the

wing | |

32 - Initial sanding of leading edge spar

now flush with the wing top | |

33 - Once both sides are done, you can

drag the wing across the sandpaper toward you and rotate the

wing rear up to make an even leading edge curve

| |

34 - Shaped leading edge completed

| |

35 - The excess spar at the wing root is

sanded down. Stop just short of it becoming flush so there is

enough spar to finish sand | |

36 - Finish sanding the root tip by

dragging the root across the sandpaper

| |

37 - Wing tip spar is completed

| |

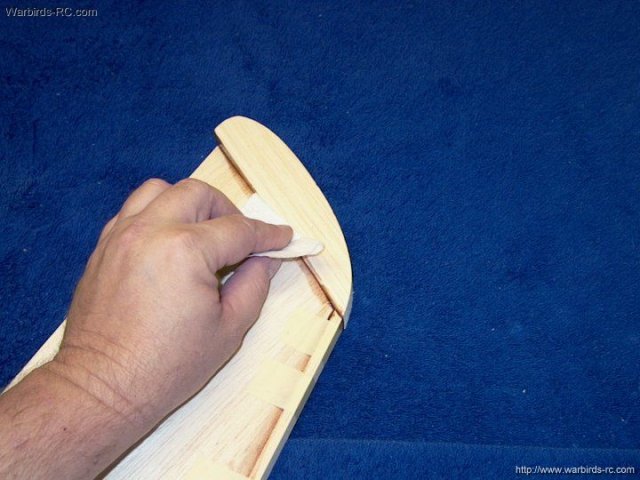

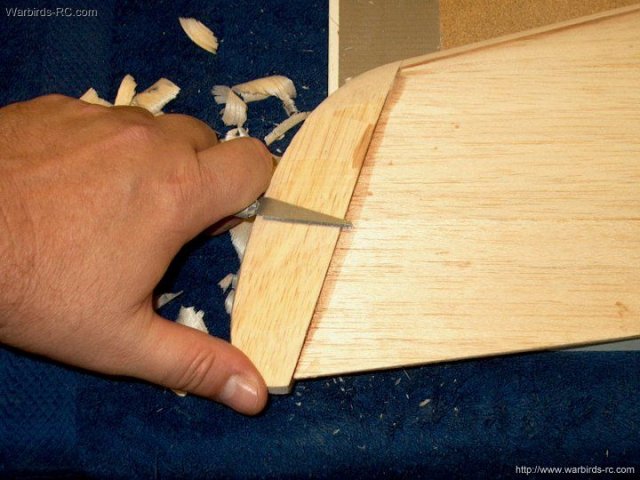

38 - Excess wing tip block is carved away

using a large hobby knife. Be careful to not cut too deep and

leave some excess to sand | |

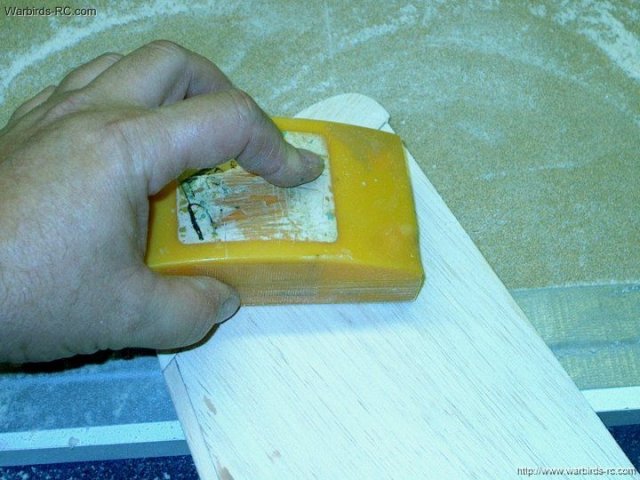

39 - The sanding board and a sanding block

as shown are used to shape the wingtip block

| |

40 - Wingtip Block shaped on top and

bottom | |

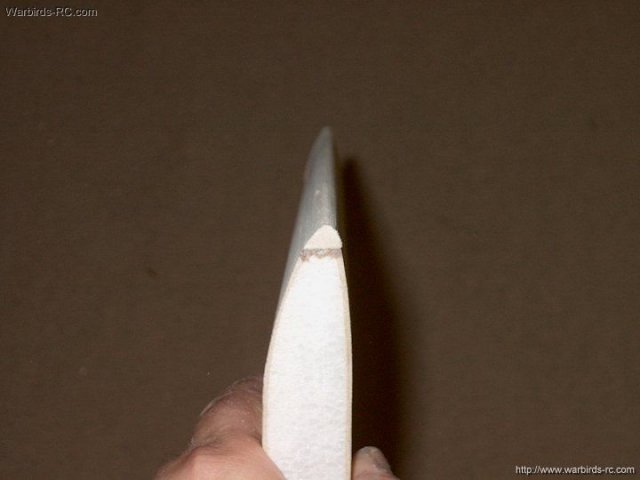

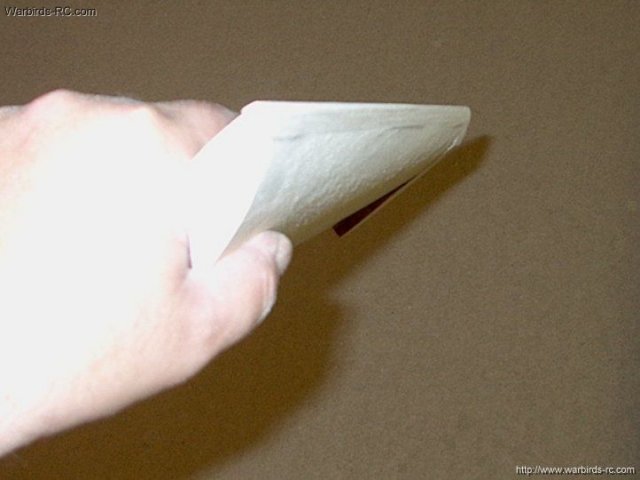

41 - Wing tip shown shaped to the

chord | |

42 - The trailing edge is sanded on both

sides to a taper of 1/16" | |

43 - Trailing edge completed

| |

44 - The seams of the wing sheets are

sanded flush. Check and sand the seams on both sides

| |

45 - The first wingtip is cut to shape

after the trailing edge is finished

| |

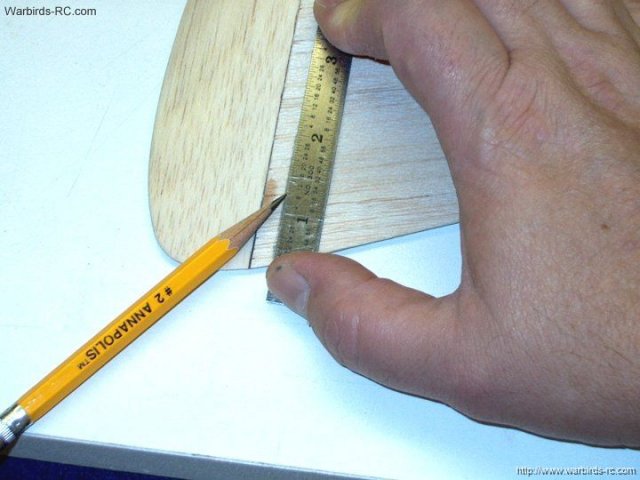

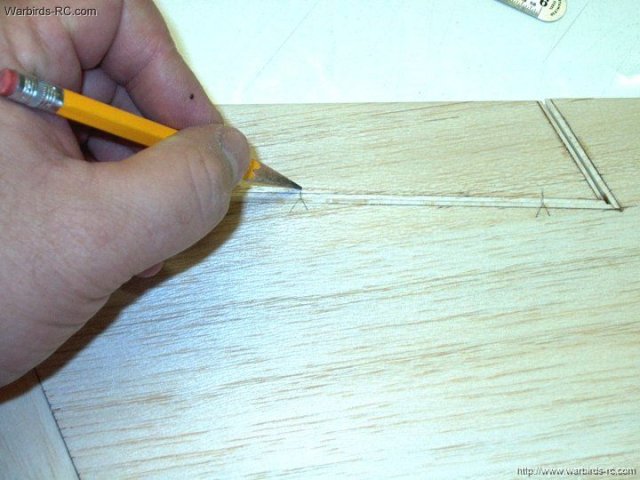

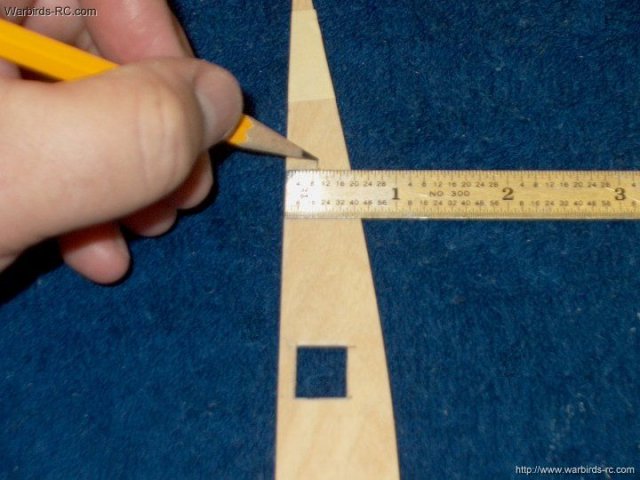

46 - Center marks are made along the

outside edge of the wing tip | |

47 - A center line is drawn through the

marks...this is the line you will sand to when tapering each

side | |

48 - A sanding block is used to taper and

shape the wing tip | |

49 - The second side is sanded to the line

and shaped | |

50 - Keep dusting while you sand to make

sure you are sanding straight | |

51 - Wing Tip taper completed

| |

52 - Another view of the shaping that was

done to the wing tip | |

53 - The second wing is sanded just like

the first, starting with shaping the leading edge

| |

54 - The bottom leading edge has been

shaped to the contour of the wing | |

55 - The top leading edge is shaped the

same way. Check it often to make sure you are sanding evenly

across the wing | |

56 - Leading edge shaping shown

completed | |

57 - Sand down the root tip flush to the

wing | |

58 - Root tip finished

| |

59 - Carve away the large portion of the

balsa tip so there is less to sand later. Be careful not to

over trim | |

60 - The tip is sanded on both sides to

the contour of the wing | |

61 - The trailing edge is again sanded to

a 1/16" taper | |

62 - Next the seams are sanded

flush | |

63 - Seams on the bottom of the wing are

sanded | |

64 - The finished wing is placed evenly

over the second wing and a sanding block is used to shape the

trailing edge | |

65 - Both Wing Tip trailing edges should

match | |

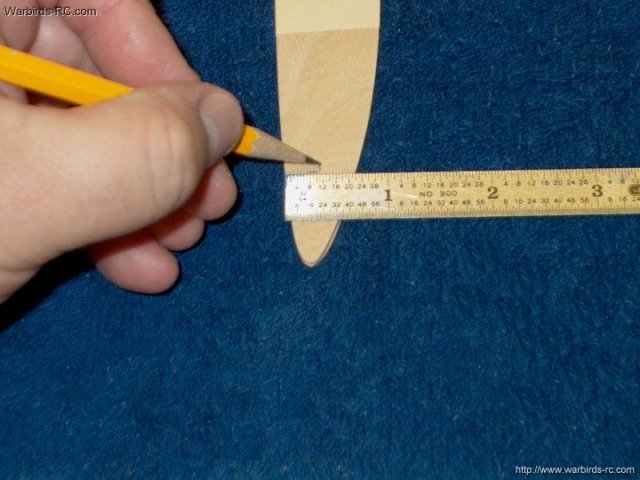

66 - A center line is drawn down the

second wing tip | |

67 - Both sides of the wing tip are

tapered and shaped to the line | |

68 - Fine sandpaper is used for final

shaping of the tip | |

69 - Wing tip shaping completed

| |

70 - Top view of the wing to show final

shape | |

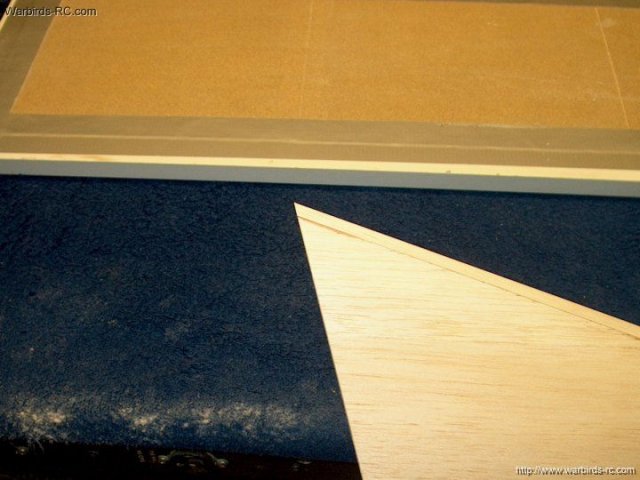

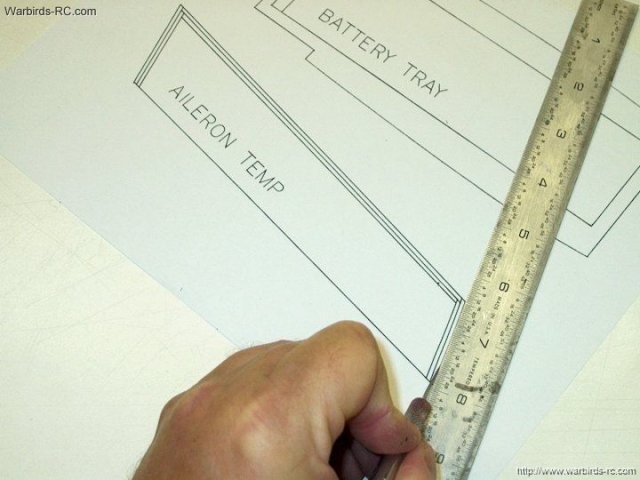

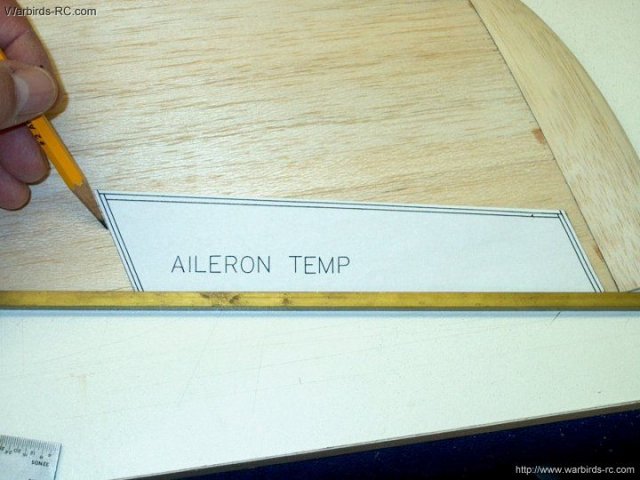

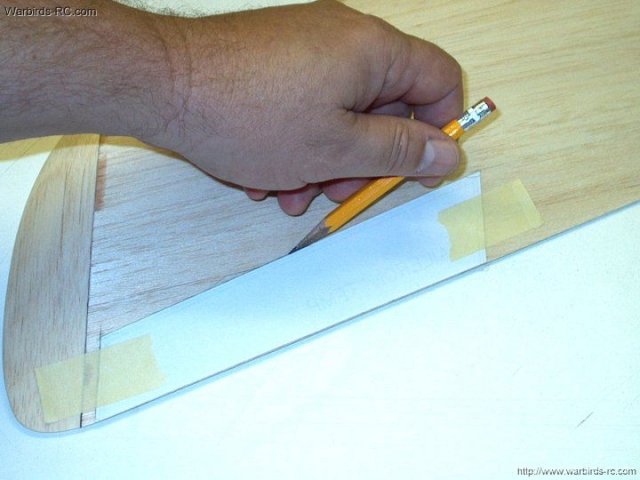

71 - Carefully cut out the Aileron

Template | |

72 - A piece of brass square was used as a

straight edge and placed flush against the bottom of the wing.

The template is placed flush against the square and then

spaced 1/4" to the inside of the wingtip seam. Position the

template with the narrow end toward the wing tip, then draw

the Aileron shape on the wing | |

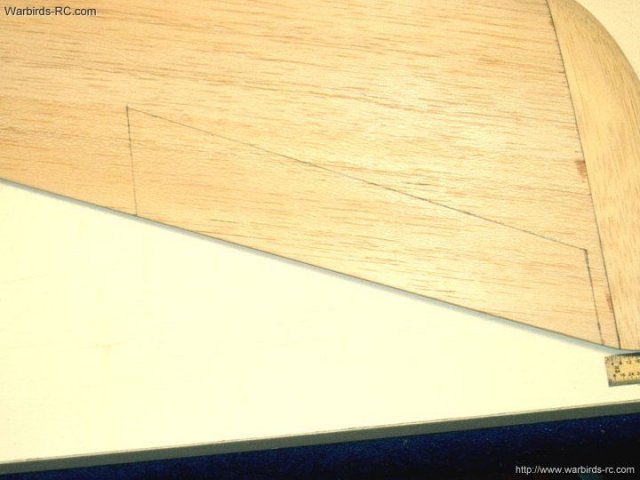

73 - Aileron shape shown drawn on the

wing | |

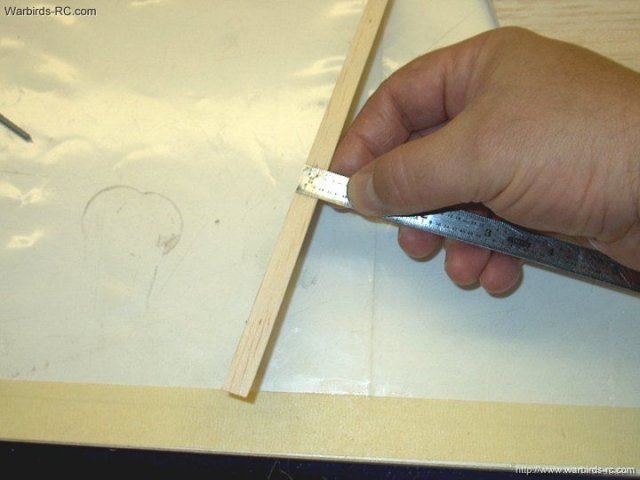

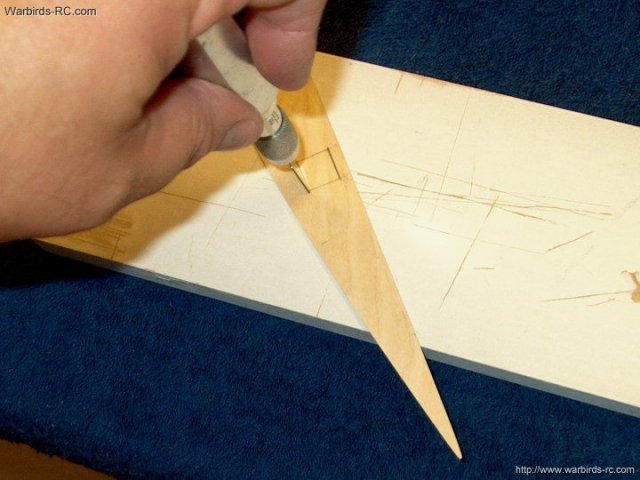

74 - Using a straight edge and a very

sharp hobby knife, carefully cut out the Aileron. Be sure to

hold the knife perpendicular to the wing so you do not cut

down at an angle | |

75 - Aileron shown cut from wing

| |

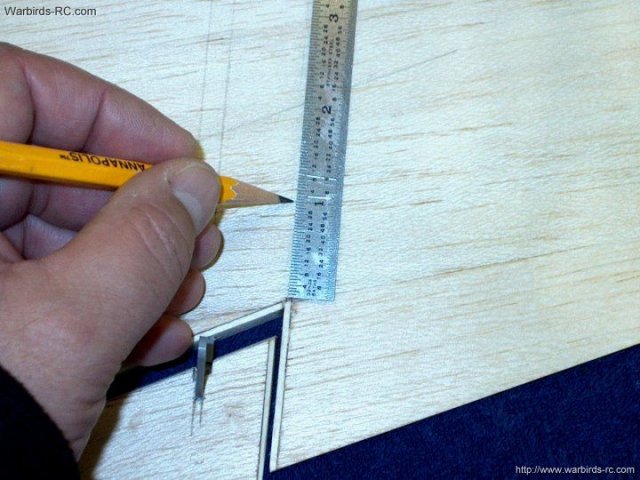

Keep the knife square and cut 1/8" from

the front of the Aileron | |

The Aileron is lightly sanded flush

| |

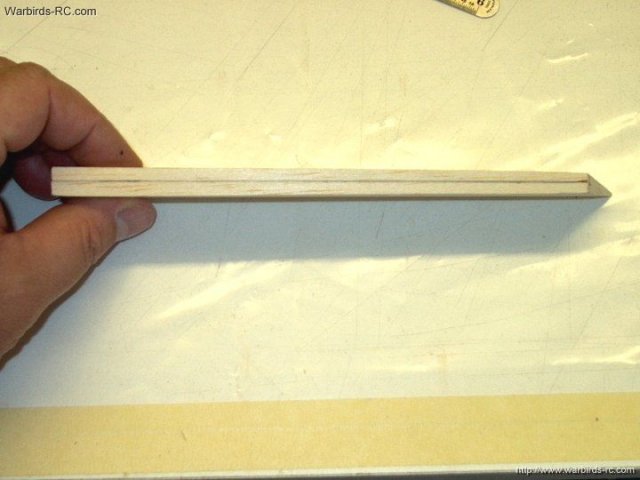

The 1/16" x 1/2" wide balsa strip is

slightly angled to fit the wing | |

Use the strip to cut three pieces to sheet

the inside of the wing in the Aileron well. Do not glue

yet | |

The second wing half is marked 1/4" from

the seam for template position | |

A vertical line is drawn to help align the

template | |

The template is flipped and used to marke

the Aileron cutout. Be sure to keep the smaller end toward the

wing tip | |

Template shape transfered to the

wing | |

Once again, use a fresh blade and an

straightedge to cut out the Aileron. Keep the blade

perpendicular when cutting and make several shallow

passes | |

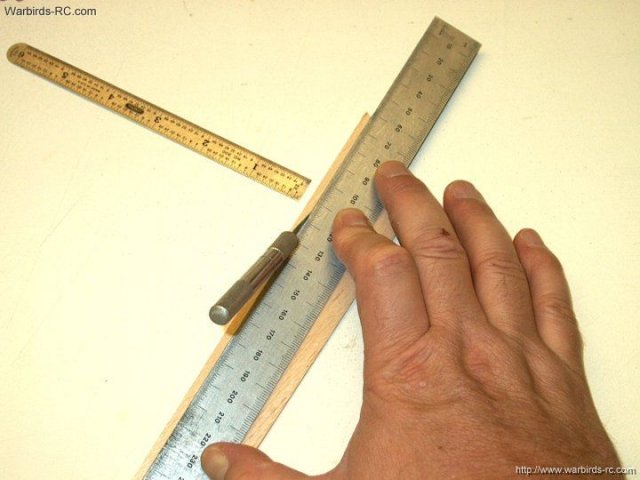

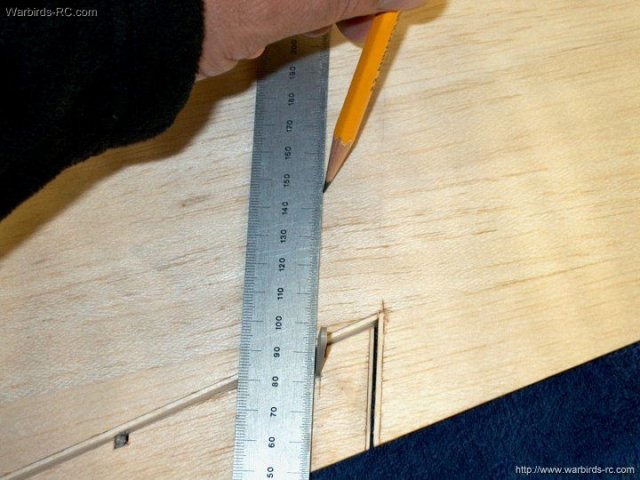

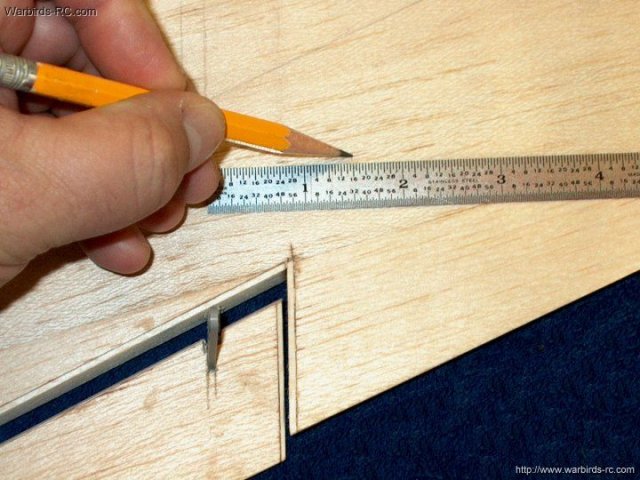

A ruler helps keep the line nice and

straight | |

Second Aileron cut from wing

| |

the 1/16" x 1/2" balsa strip is once again

cut to box in the Aileron area of the wing

| |

Pieces shown cut , fitted and ready to

glue | |

Fifteen minute epoxy was used to mount the

balsa strips | |

Epoxy shown being applied to the Aileron

area of the wing | |

Next, epoxy is applied to the ends of each

Aileron and balsa strips are cut for small Aileron end

caps | |

End cap strips shown installed and held in

place with masking tape | |

Second Aileron is prepped for end cap

strips | |

End cap positioned and secured with

tape | |

Once the glue has set, carefully remove

all the masking tape. Sand the end caps on the Ailerons to

match the shape | |

Carefully shave off the larger portion of

balsa with a hobby knife | |

The strips are sanded flush to the

wing | |

The other wing is sanded flush, top and

bottom | |

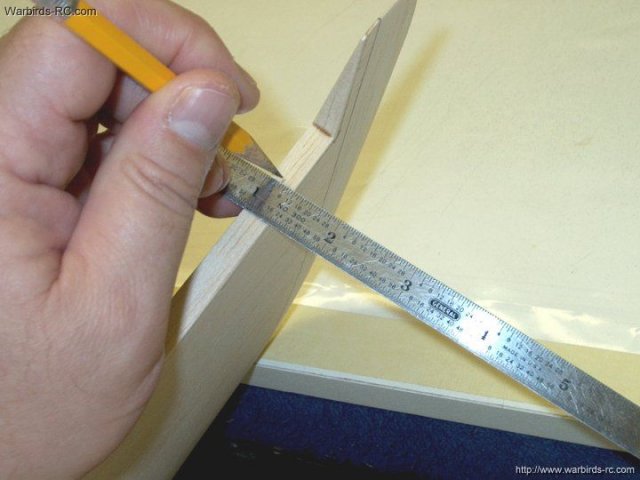

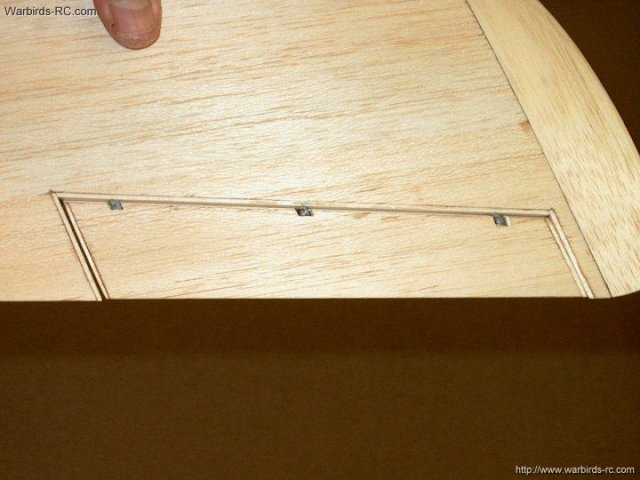

You have the choice of using either Easy

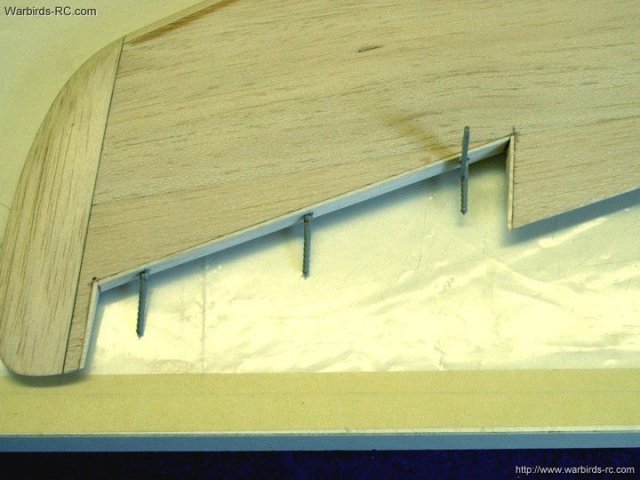

Hinges for Aileron mounts, or an alternate method. Heavy duty

1/8" pin hinges are shown. To install, marks are made 3/4"

from each end of the Aileron well for hinge location

| |

The middle pin location is measured dead

center. All locations shown | |

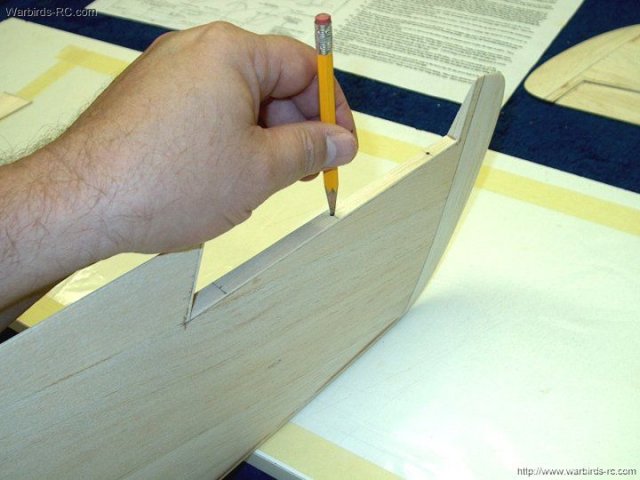

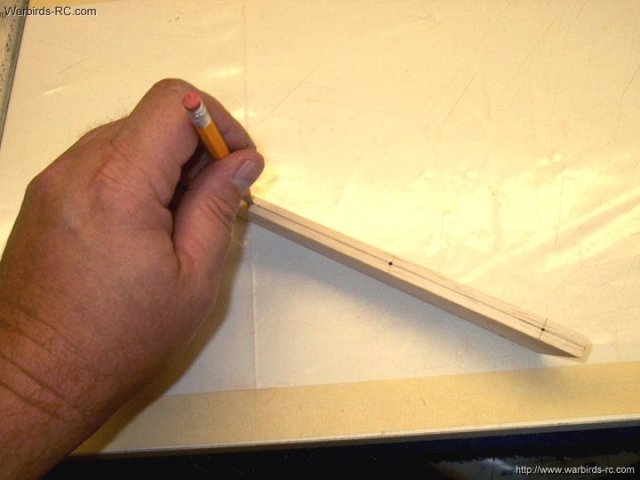

A center mark is made on the wing

| |

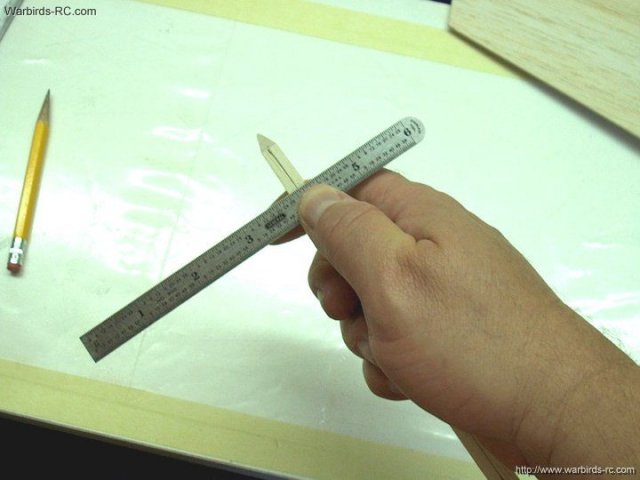

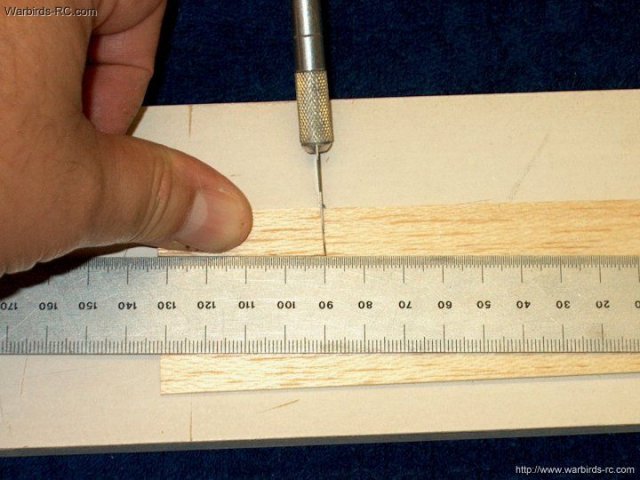

Once you have the three centerlines drawn,

a pencil is slightly pushed into the balsa at each location to

start the mounting holes | |

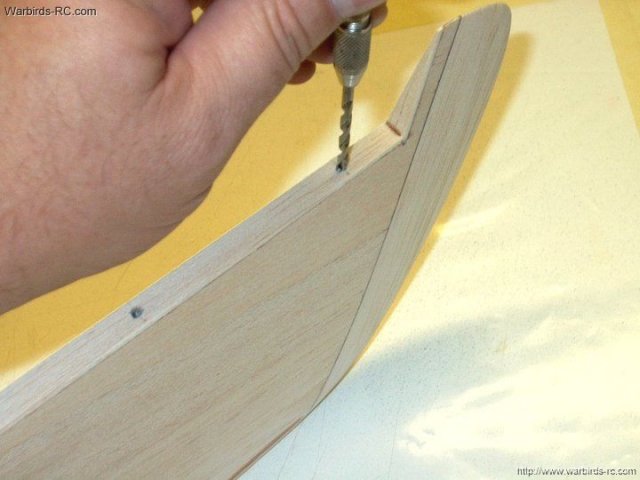

All three holes prepared to drill

| |

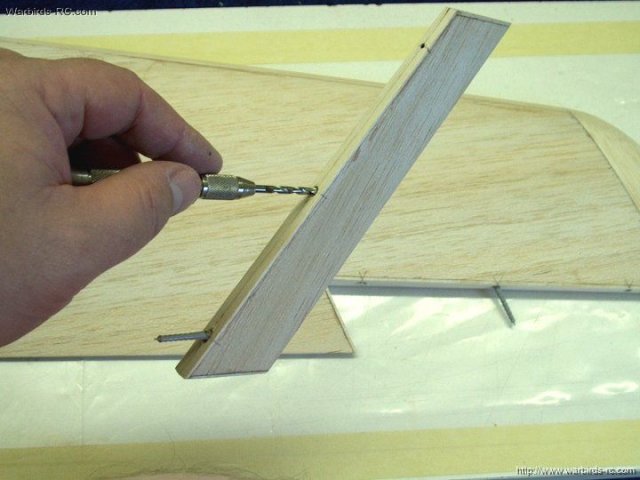

Start the bit straight down, then drill at

an angle parallel to the side | |

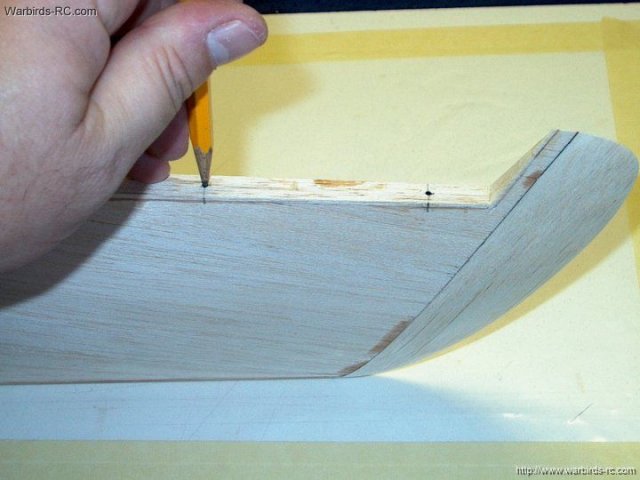

The second wing is marked

| |

Cross lines are drawn next to the center

marks | |

The pencil is used once again to start the

holes, then they are drilled | |

The Aileron is placed and centered in the

wing, then pin locations are transfered. Use a knife to cut

out a 1" wide hole in the foam | |

The foam is removed with a hook

tool | |

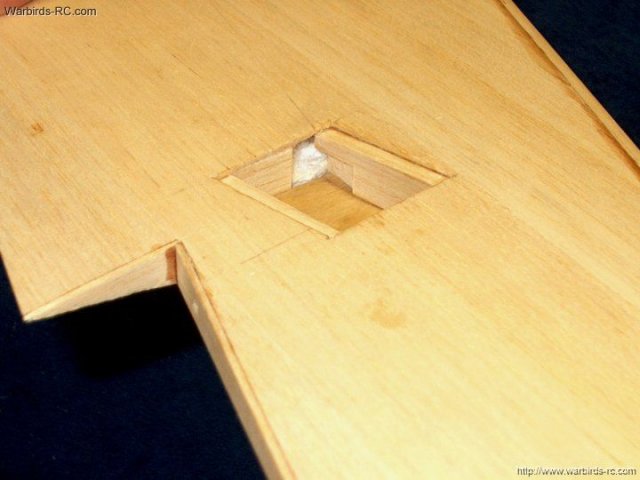

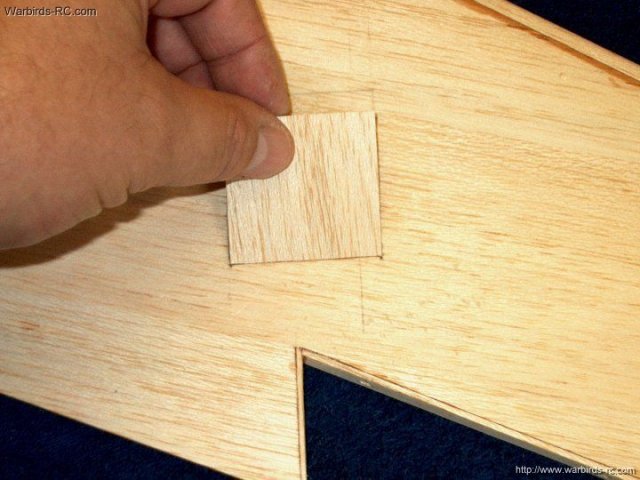

Make a balsa block tapered to fit the

opening. This is done at each pin location to add strength to

the area | |

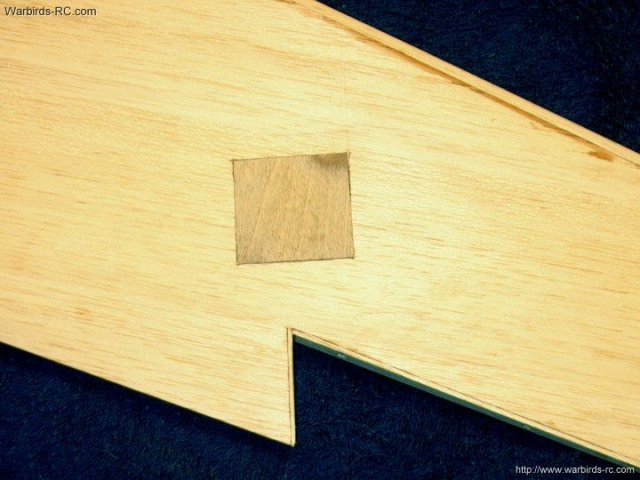

The 1/2" wide block is installed and

sanded flush to the Aileron | |

Photo shows all three blocks fitted and

ready to glue | |

The blocks are removed and 5 minute epoxy

is applied and the blocks installed flush. If you get too much

epoxy, the blocks may hydraulic on you during installation and

not sit completely in place, so push them in a bit deeper and

the excess epoxy should squeeze out the top sides. Clean

excess epoxy with a paper towel | |

The second Aileron is being prepared and

blocks are glued | |

Next, apply 15 minute epoxy to the Aileron

face and strip | |

The strips are mounted to the face and

held in place with masking | |

Hinge pins are installed in the wing for

fit. A Hinge with Horn is used on the inside mount

| |

The long front strip is sanded flush to to

the Aileron | |

The ends are sanded flush

| |

Ailerons ready to shape

| |

Fit of Aileron in wing opening shown,

about 1/32" space on each side | |

Center marks are made on the

Aileron | |

A center line is drawn

| |

Hinge mark locations are drawn. Make sure

it is centered on the ends | |

Cross lines are drawn at the hinge pin

locations | |

Holes are started with pencil point

| |

Hinge holes are drilled with a 1/8" bit at

each location. Test fit in the fuselage often to check for

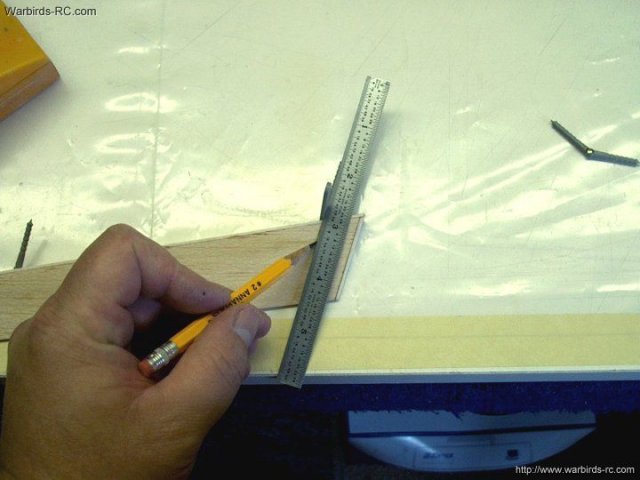

mis-alignment or binding | |

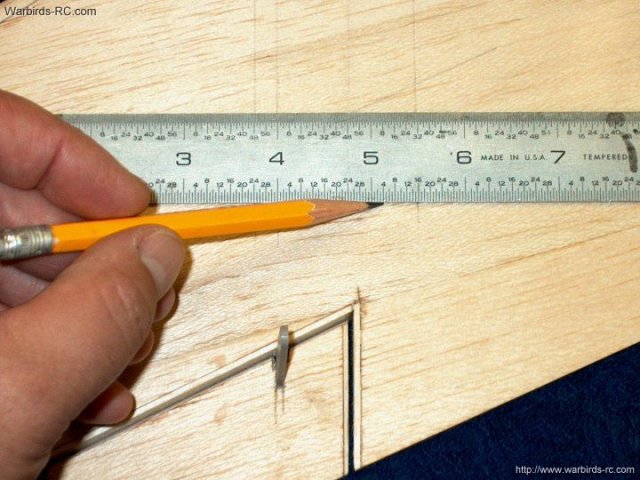

Ruler is placed along each side of the

horn and marks are made | |

Hinge and location marks shown

| |

Carefully sand a taper to center on the

Aileron | |

Angle shown sanded and centered

| |

Hinges are installed as well as the

Aileron Note the areas cut away for the hinges, which allows

center pivot at the Aileron | |

Aileron installed

| |

Underside of wing, showing nice clean horn

installation | |

The second Aileron is drilled for

hinges | |

Holes are shown drilled down the

center | |

The end pin needs to be shortened to

fit | |

Sand an angle on the leading edge of the

Aileron. Sand to the center line | |

A slot is cut for the hinge with the

horn | |

The hinge is fit to the Aileron

| |

Use a hobby knife to cut slots for hinge

movement | |

The back of the slots are cut with a sharp

knife | |

install the Aileron in the wing and check

for fit and movement | |

Photo of the horn as seen from the

bottom | |

A ruler is used to draw a line for horn to

servo alignment | |

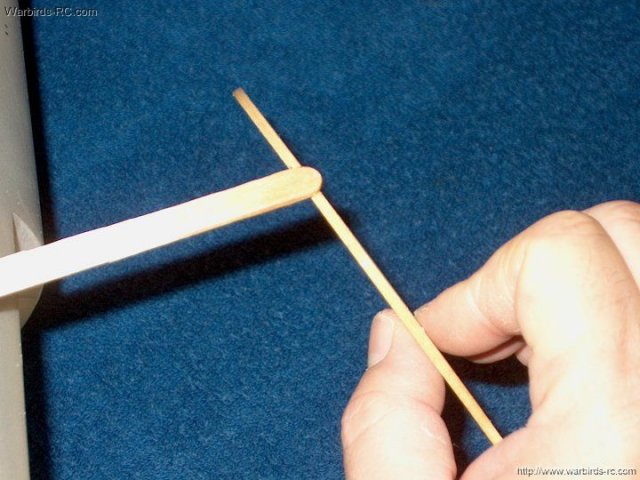

Two 1/8" square harwood sticks were

installed in the wing Aileron wire runs and a yardstick was

placed against these runs, then a line was drawn to indicate

the path of the wires | |

Photo shows yardstick parallel to and

against the wood sticks | |

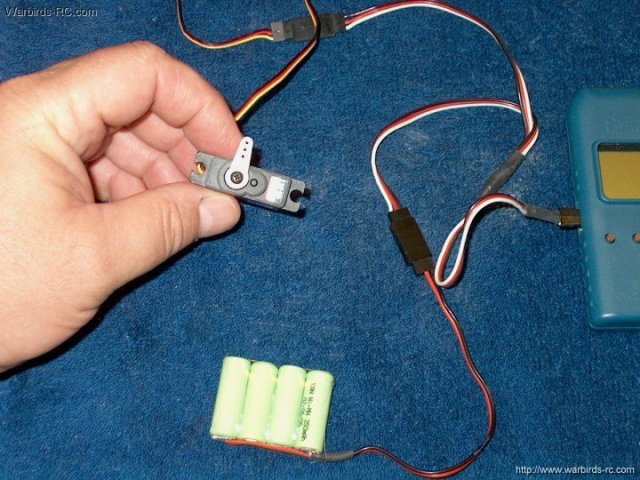

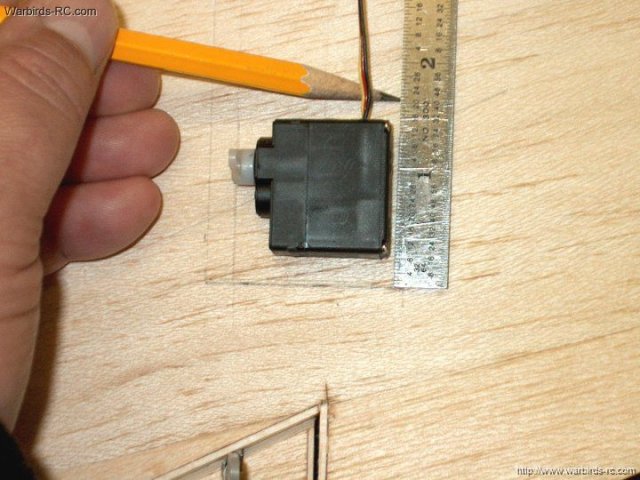

Use a receiver or device to center the

servo | |

One side of the servo horn is

removed | |

The servo horn is rounded with a sanding

block at the cut end | |

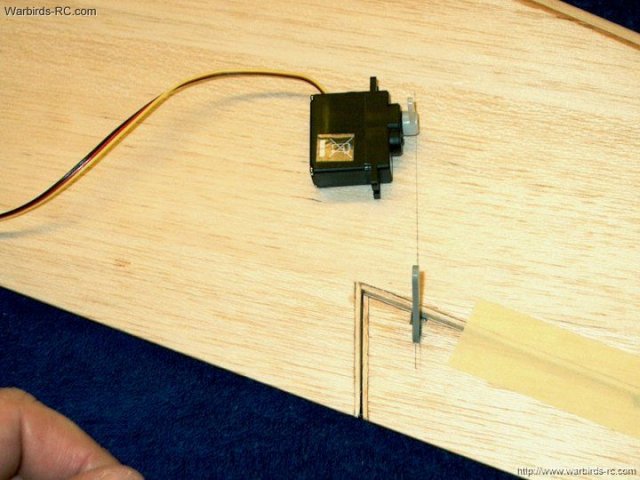

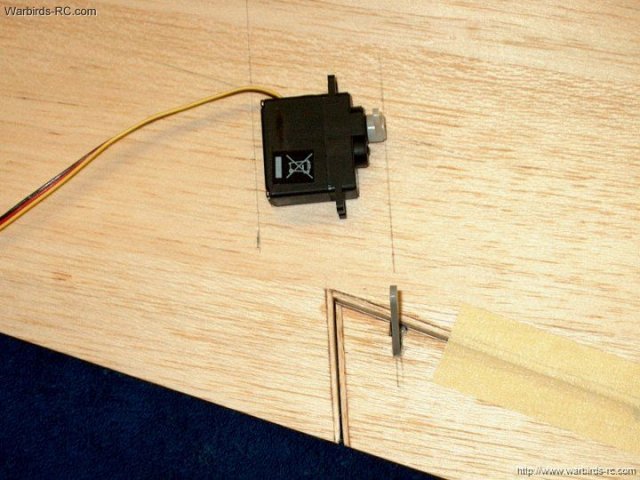

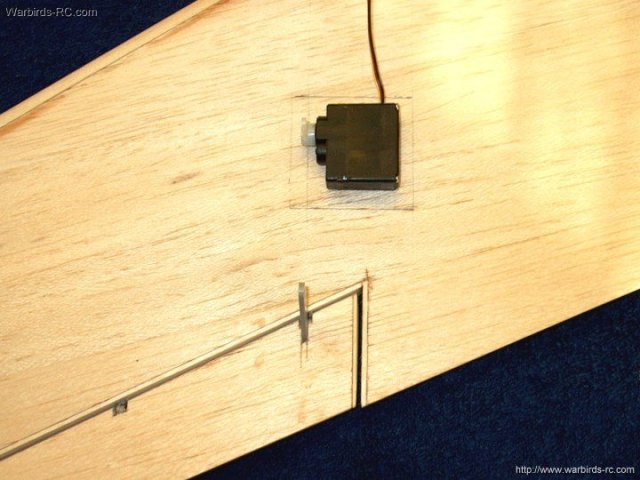

Servo is placed so its horn is aligned

with the Aileron horn | |

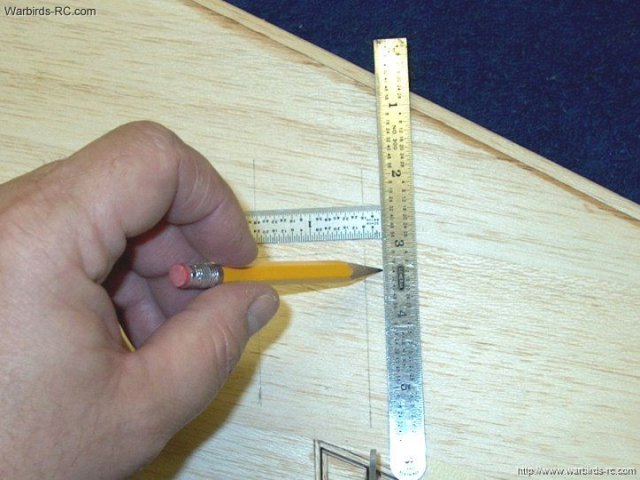

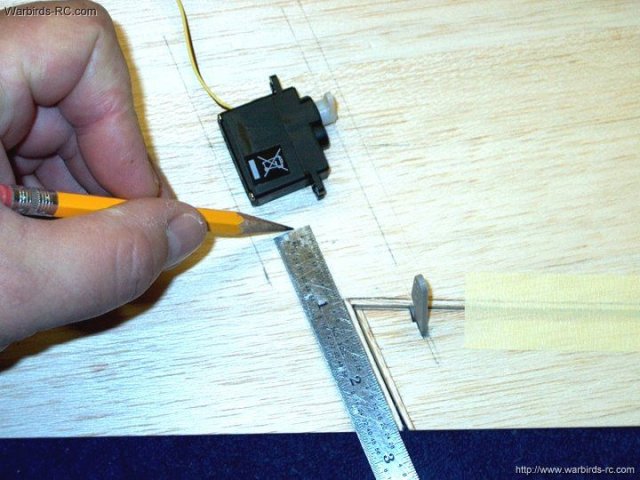

A mark is made 1 1/2"from the servo horn

line | |

A line is drawn to mark the bottom area of

the servo hole (left) | |

A second line is drawn 1/4" past the servo

horn line | |

The bottom is marked 1" from the Aileron

area on the wing as shown | |

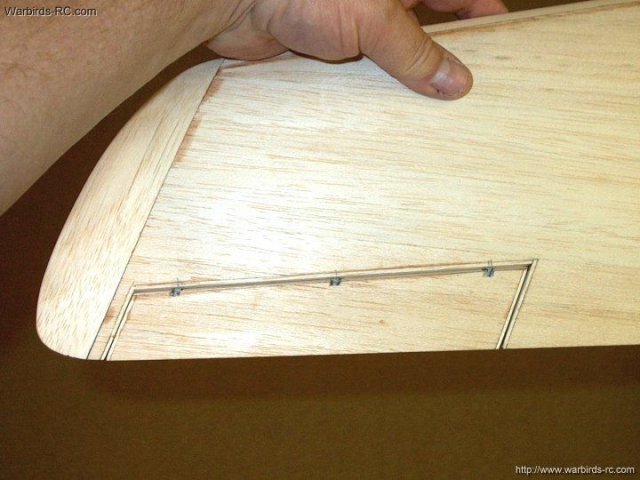

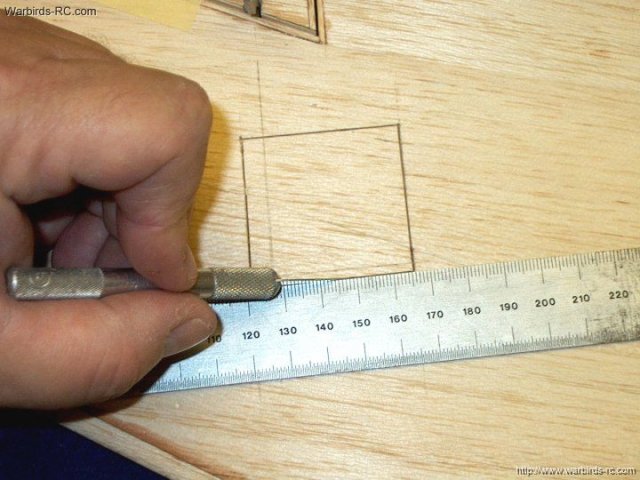

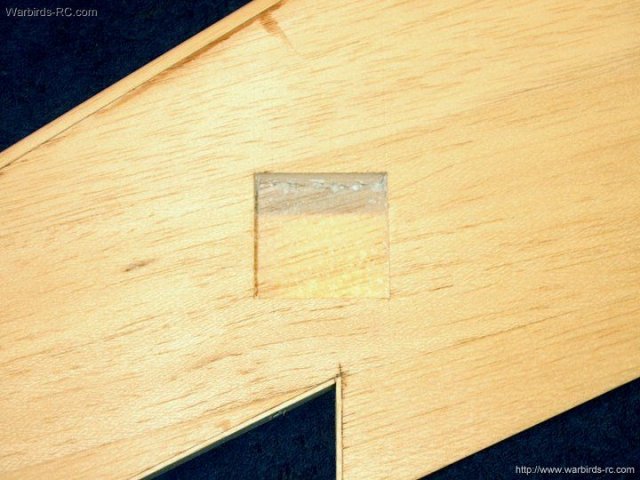

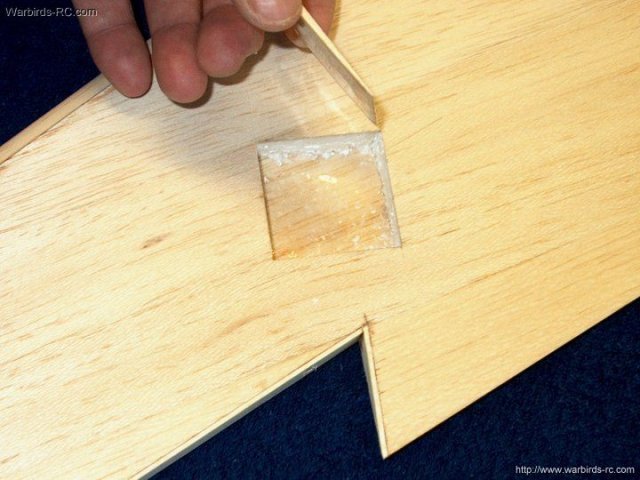

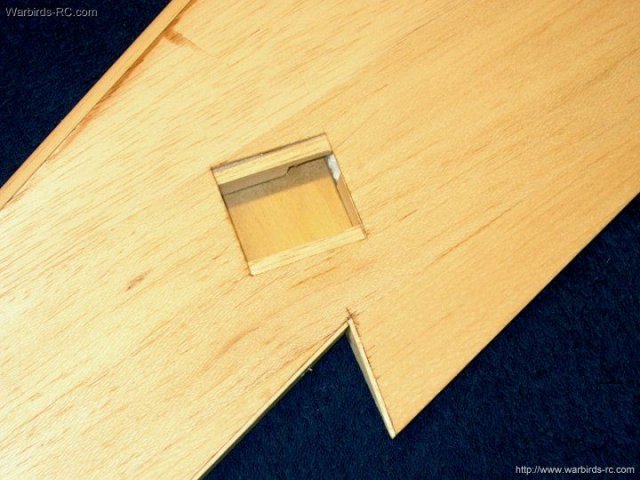

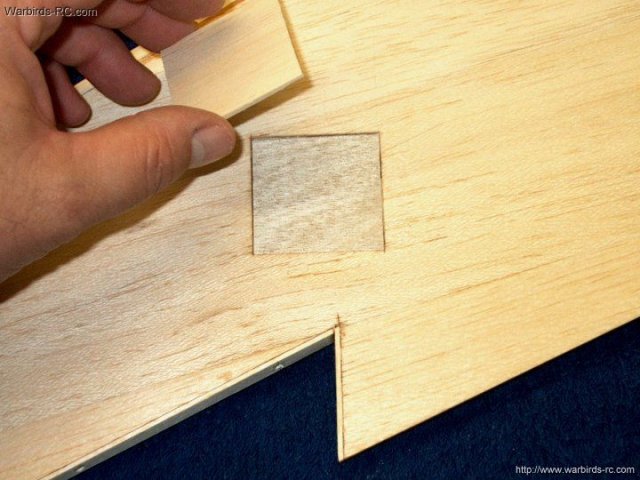

The box is cut with a sharp hobby knife.

Note it is wide enough so that there is 1/4" of space on the

front and back for door mounts | |

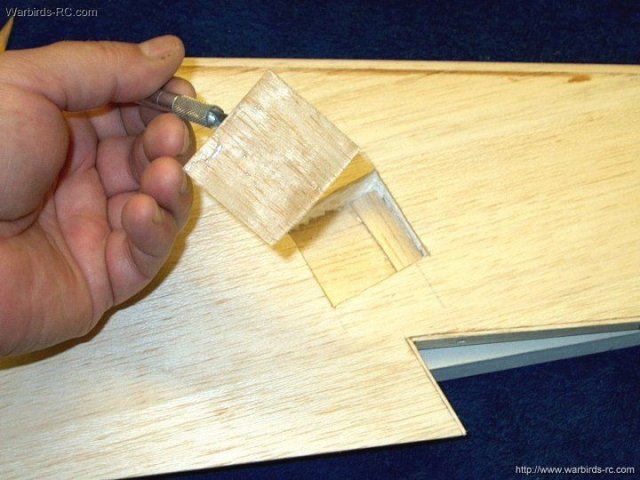

Once the balsa is removed, cut away the

foam | |

Photo shows the approximate position of

the servo | |

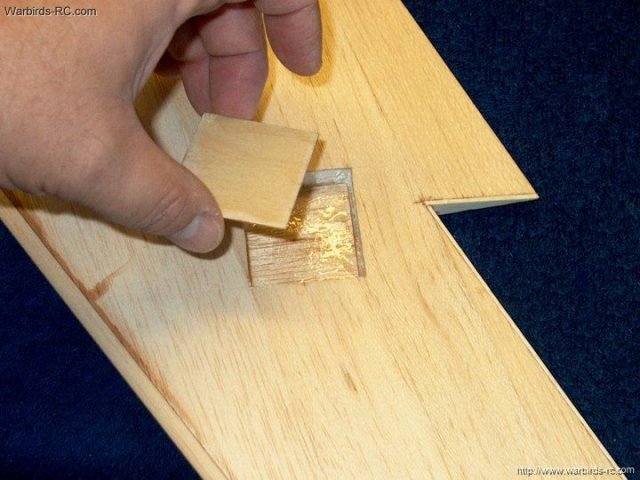

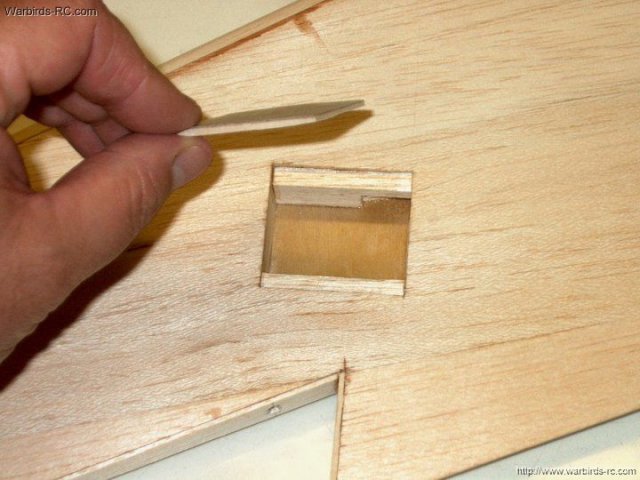

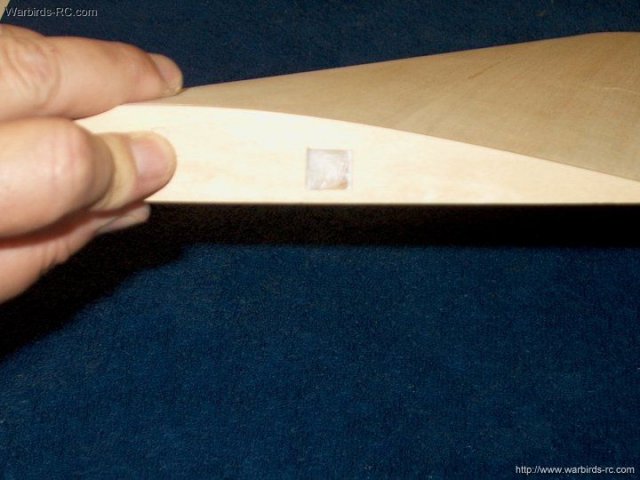

A square piece of 1/8" balsa sheet is

beveled to a wedge so the servo will sit level in the tray

area. The thicker part goes forward

| |

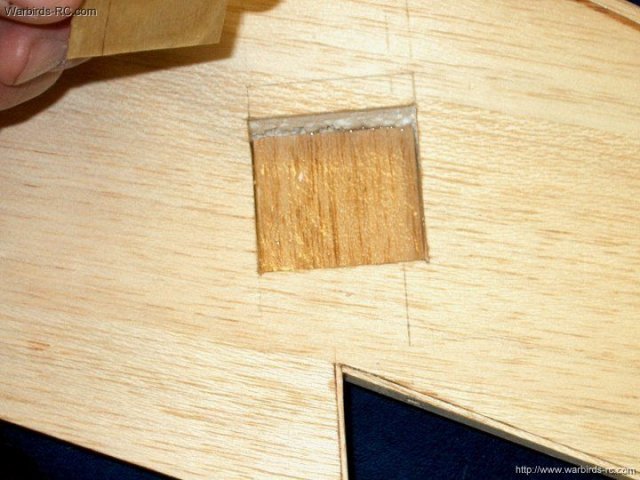

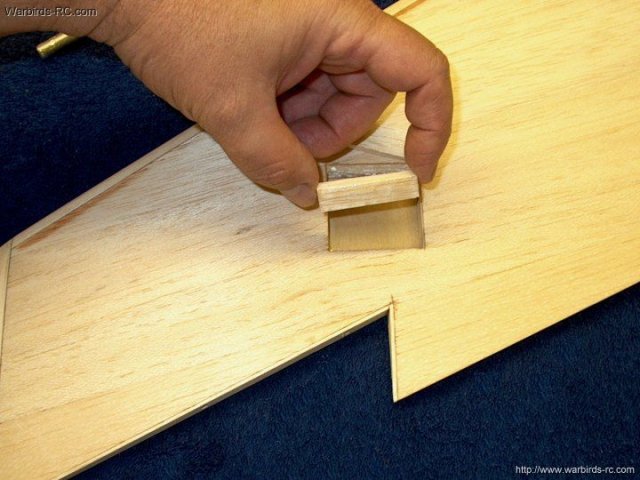

Epoxy is used to glue the wedge shaped

piece in place | |

Tray bottom wedge fitted with the thick

side toward the wing front | |

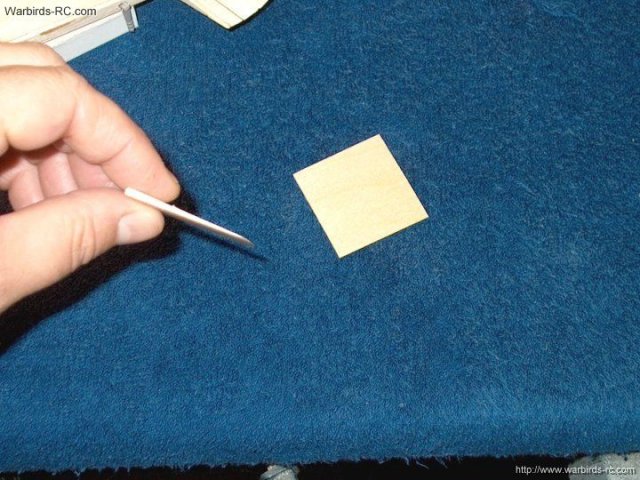

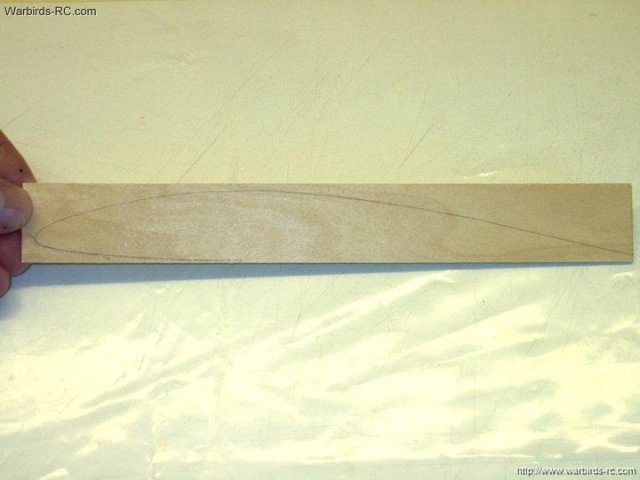

A 1/32" thick piece of ply is cut as a

bottom plate and soaked on one side with thin CA glue

| |

Once the glue dries, sand the surface to a

plastic feel | |

Epoxy is applied to the wedge top and the

ply surface that was not covered in CA

| |

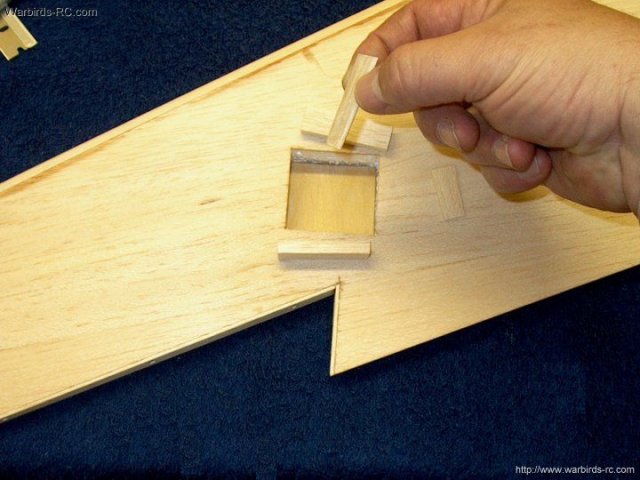

The ply plate was installed, smooth CA

side up and the first wall piece was cut from 1/4" thick

balsa | |

The notch allows the wire to pass into the

wing run | |

1/16" balsa is used on the sides to box in

the servo area | |

All four pieces cut and ready to epoxy in

place | |

Now is a good time to cut a second set for

the other wing. Lay each piece over their corresponding piece

of scrap balsa and cut them to shape. Cut a bit oversized so

you can sand to a good fit later | |

Glue the four pieces in place using five

minute epoxy | |

The hole for the servo leads is shown as

accessible | |

The servo fits just a bit loose from top

to bottom in the pic and is centered side to side

| |

A piece of 1/64" ply is cut to fit as a

cover | |

A piece of 1/16" balsa is cut and laid

over the ply cover | |

With both pieces installed, the balsa

piece on top is sanded flush | |

Laminate the balsa and ply pieces together

with epoxy | |

Next, the cover is installed normally with

the ply on top and lightly sanded | |

Ply and balsa servo cover and tray area

completed | |

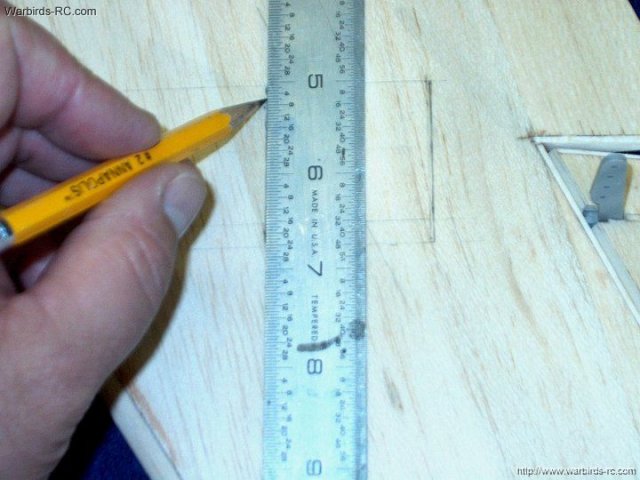

The second Aileron servo is centered using

a receiver or device | |

A centerline is drawn on the second wing

for horn alignment | |

The top of the servo well is drawn 1/4"

past the centerline | |

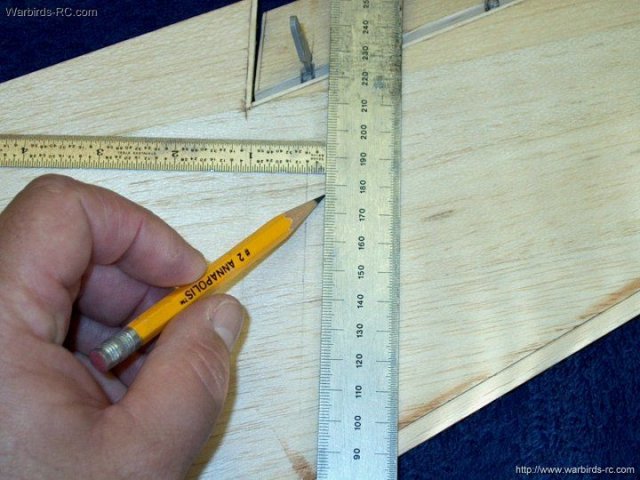

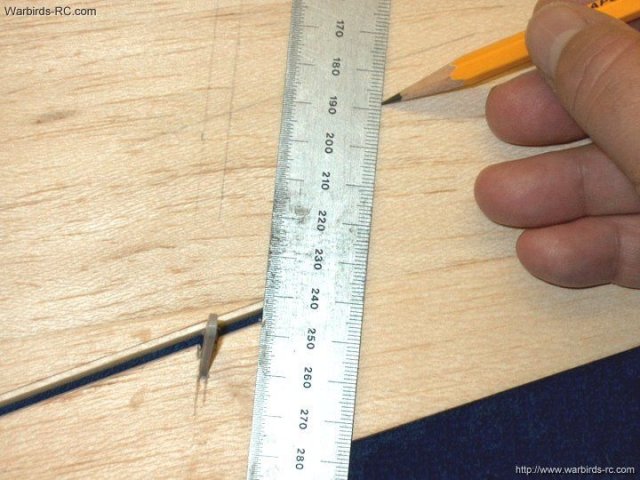

As with the first wing, a rule is used to

draw the aileron wire runs | |

Bottom of the servo well is marked 1"

above the Aileron tip area | |

Another mark is made 1 1/2" away from the

horn center line | |

A line is drawn parallel to the others at

the mark | |

The bottom is kept square and drawn at the

1" mark | |

The ears on the servo are removed

| |

A mark is made so the servo has a 1/4"

space on both sides | |

A line is drawn to box in the servo

well | |

Servo area ready to cut

| |

Servo shows its position realative to the

well | |

A sharp knife is used to remove the balsa

and cut the foam | |

A ruler is used as a scraper to remove the

foam | |

Foam is removed from the well area

| |

A piece of 1/8" thick balsa is sanded to

slope like a wedge | |

Balsa wedge plate is epoxied in place with

the thick part forward. This will keep the servo level in the

well | |

The foam area for the Aileron servo wire

run is enlarged | |

A 1/32" piece of ply has thin CA applied

to one side, then sanded to a plastic feel once dry

| |

Epoxy is applied to ply side that doesn't

have CA , then the plate is installed in the bottom as a servo

mount surface | |

Move the plate around to make sure it is

settled and centered in position before the epoxy sets

| |

The four pieces for the walls that were

previously cut are final cut and sanded to fit the well

| |

The thin sides are epoxied in first, then

the top and bottom thick pieces are epoxied in place

| |

Servo well is shown framed in

| |

A thin 1/64" ply plate is cut to sized and

installed, then a balsa piece in installed.

| |

The balsa is sanded to thickness for the

wing surface | |

The balsa and ply are laminated together

with epoxy | |

Servo cover shown in final position with

ply on top | |

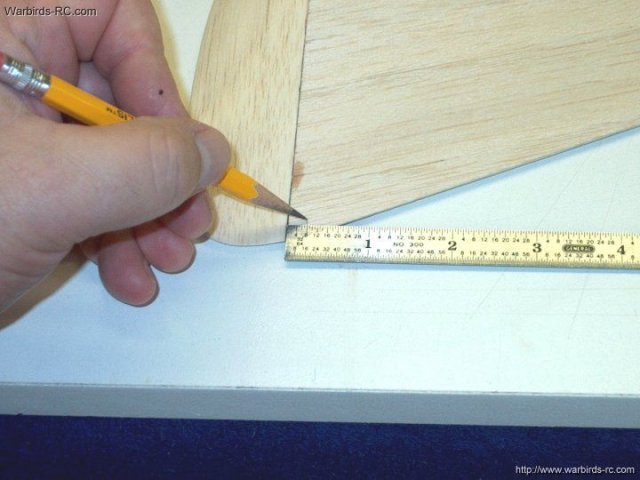

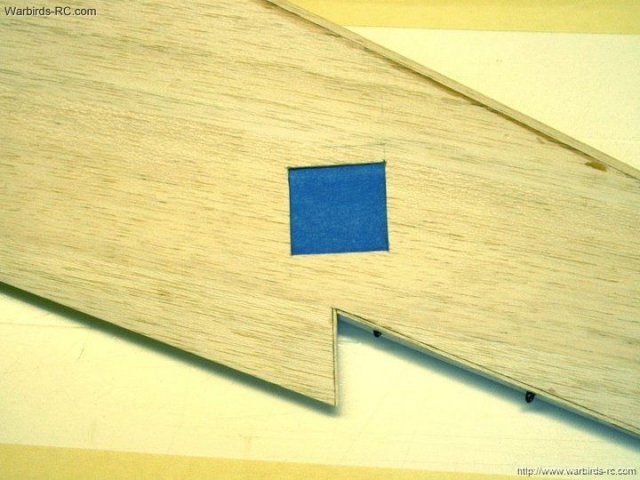

The wing root is placed over one of the

1/16" x 9 x 1 1/2" ply pieces and the shape of the root is

drawn on the ply | |

Ply plate shown with wing root chord shape

transfered | |

The root piece is oversize cut using a

saw | |

The second wing root piece is drawn and

cut to shape | |

Plates are marked Left and Right, then one

is sanded even to and taped flush to the bottom of the

wing | |

With the wing root held flush by the tape,

sand the top of the root level to the wing

| |

Wing root shown sanded to shape top, front

and rear | |

The second wing root is taped and sanded

the same way | |

Once the middle of the root is sanded,

masking can hold it in place at the top while you shape the

leading edge | |

Two marks are made at the location of the

Aileron servo wire run | |

Extra foam is removed from the wing for

easier running of the wire | |

Hole has been angled and opened for easier

wire exit | |

An opening is drawn on the root for the

servo wire exit | |

A heavy flat knife easily cuts the square

opening out | |

Aileron wire hole shown cut from the root

piece | |

Photo shows how it fits over the hole in

the wing | |

The second wing root is marked for the

Aileron wire hole | |

Hole is cut using a flat knife

| |

The fuselage wire exit is once again

enlarged | |

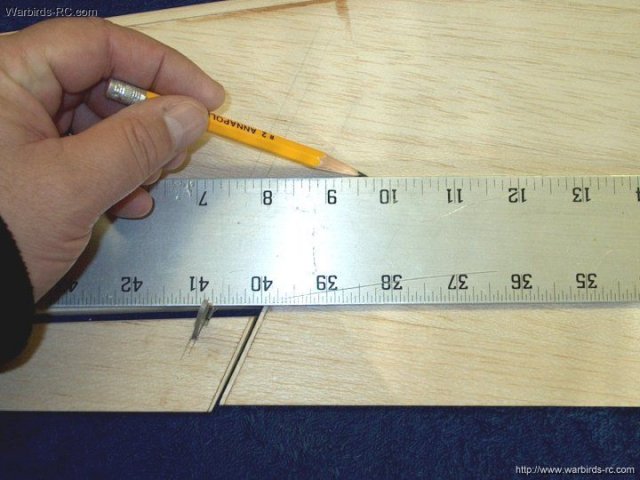

A mark is made 2 1/4" from the rear of the

ply root | |

Another mark is measured 6 1/8" from the

first mark | |

A center mark is made at the rear

location | |

A center mark is made at the front

location | |

A punch is used to mark the drill spots,

then a 1/16" bit is used to start each hole

| |

The two roots are centered over eachother

and taped together, then the rear hole is drilled with a 1/8"

drill bit | |

The forward mark is drilled with a 3/16"

drill bit | |

Wing roots showing drilled areas

| |

The root is taped flush to the bottom of

the wing root on the Fuselage | |

The 3/16" forward drill hole is transfered

to the Fuselage | |

The rear 1/8" hole is transfered to the

fuselage. Make sure the wing root remains flush with the

bottom as this will insure true wing incidence later during

the assembly | |

A marker is used to mark the location of

the Aileron wire run | |

The hole for the Aileron wire is cut with

a sharp hobby knife | |

A file is used to square up the wire

hole | |

Wing root preparation shown completed on

one side | |

The second wing root drill holes are

transfered, keeping the root flush to the bottom of the

fuselage as shown | |

Second wing root is cut out for the

Aileron wire run and shown as finished

| |

Make sure both wing roots are flush with

no bowing | |

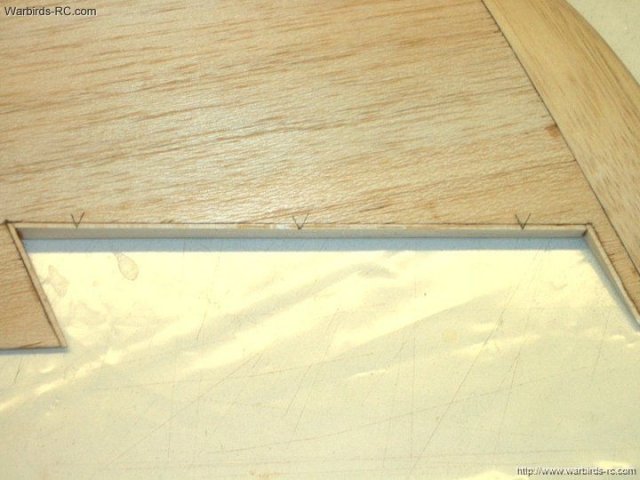

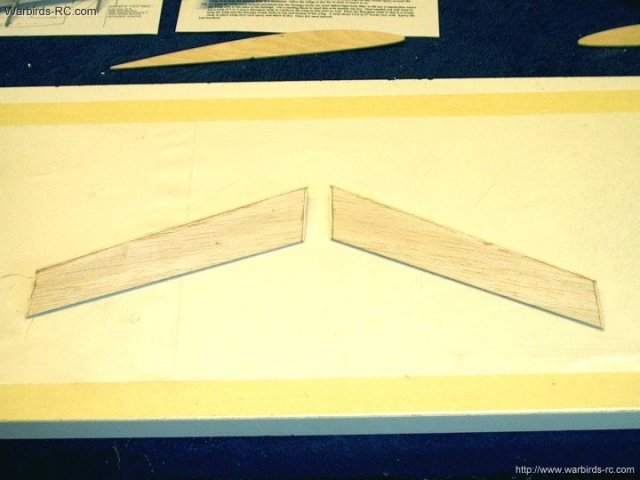

The side of the spar that is not glued to

the wing is covered with masking to keep it free of

epoxy | |

Spar surface shown sealed with masking

tape | |

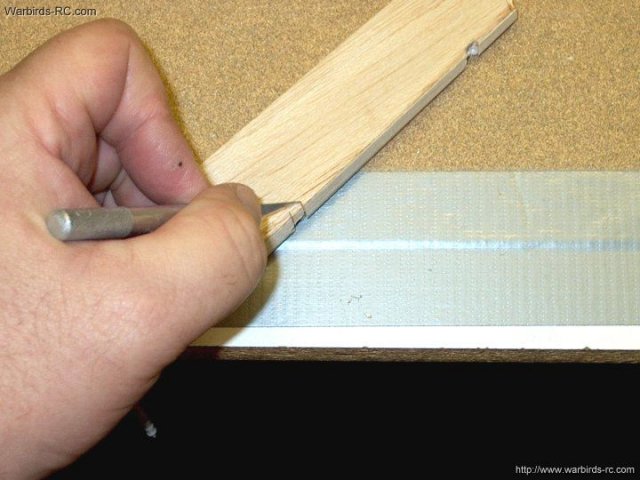

15-30 minute epoxy is applied to the other

side of the spar | |

Place masking tape on the second spar and

apply epoxy | |

The wing root edge top and bottom has

masking tape applied so epoxy will not drip on the surface

edges | |

Epoxy is applied to the wing root

| |

Wing has been prepared

| |

Place the wing root on the spar and press

to squeeze out excess epoxy | |

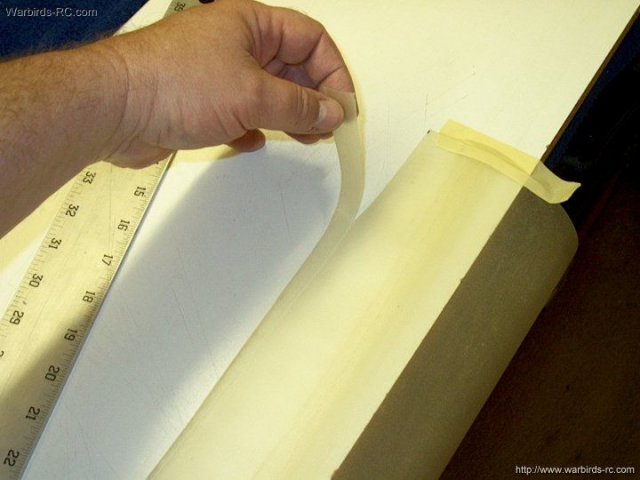

3/4 oz fiberglass cloth will be used to

glass the wings | |

A piece is cut wide enough for both

wings | |

A section of cloth is cut and fit for a

single wing | |

The wing is carefuly dusted of any

particles | |

The cloth is folded over the wing and

centered even on both sides | |

Excess cloth is trimmed prior to

glassing | |

The cloth is centered over the wing

leading edge, then a thin line of medium CA is applied all the

way down the leading edge | |

The CA is pressed through the cloth to the

wing and spread down the leading edge

| |

Leading edge is secured to the cloth. This

will allow you to pull and stretch out the cloth on both sides

for a nice fit | |

The wing is laid on a piece of plastic and

the cloth is formed by hand to the surface contour

| |

West Systems Epoxy was used for the

glassing process. Be sure to mix the epoxy thoroughly

| |

The epoxy is poured into a plastic

disposable food plate so it doesn't cure too quickly

| |

A brush is used to apply the epoxy,

starting with the leading edge | |

Work your way across, then back and across

again and be sure to wet down the cloth well with resin

| |

Epoxy applied to one side of the

wing | |

A putty squegee is used to remove excess

resin, then the wing top is covered with plastic

| |

The bottom of the wing is wetted out

before the resin begins to cure. Watch your working time.

Squegee off the excess and cover with a plastic sheet

| |

The second wing is prepared to

glass | |

The hole for the Aileron servo is plugged

with a double thick piece of tape square

| |

The wing is placed on the cloth and

centered | |

The cloth is formed with your hand to

follow the wing contour | |

Excess cloth is cut away

| |

Medium CA is applied to the leading edge

of the second wing | |

The CA is spread across the entire leading

edge | |

CA has set and anchored the cloth at the

leading edge | |

The wing is placed over plastic sheet then

contoured once again | |

Mix up a fresh batch of epoxy resin and

apply it to one side | |

Once again, the excess resin is removed

from the wing | |

Excess resin has been removed

| |

A 3 mil plastic sheet is laid over the

wing and pressed down | |

The wing is flipped over and resin is

applied to the other side | |

Be sure to wet out the cloth well with

resin. A disposable brush works well

| |

Once again, the excess resin is removed

from the wing | |

Continue with the spreader until all

excess resin is removed | |

Excess cloth is removed prior to

covering | |

A plastic sheet is placed over the wing

and pressed down with the spreader. Be sure to remove all air

bubbles | |

Wing is glassed and sealed

| |

Excess plastic is removed

| |

Wing fiberglassing completed

| |

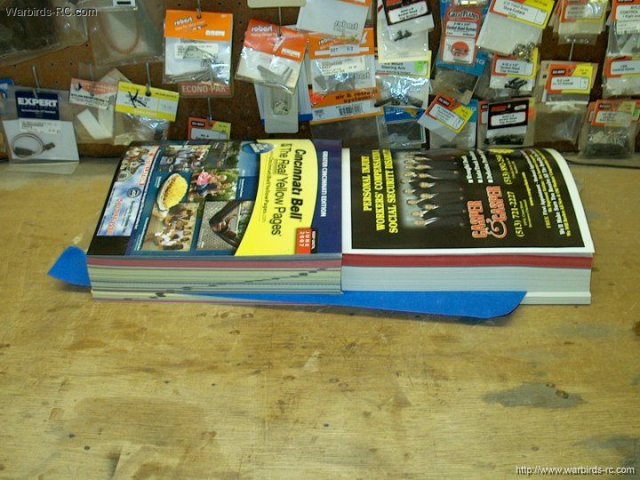

The wing is placed between a couple phone

books and left until it sets | |

Wing fiberglassing has set and is shown

below | |

The Ailerons and covers also need to be

glassed. Cloth is cut to fit each piece

| |

Medium CA is used across the entire

forward surface on both Ailerons | |

Photo shows cloth glassed with CA to the

front of the Aileron | |

The second Aileron is prepared in the same

way | |

The cloth is folded over and resin is

applied to both sides of the Ailerons and the ply side of the

servo covers, then the excess is removed and all parts are

covered in plastic and placed in a phone book to keep them

flat | |

Once the epoxy has set, remove the plastic

covers from each wing | |

The outer edges are rough cut with a hobby

saw and knife | |

The servo hatch is removed from the

plastic | |

Both hatches are rough cut and the excess

cloth is removed | |

Cut off the excess cloth from each

Aileron. Fine sand the Wings, Ailerons and Hatches

| |

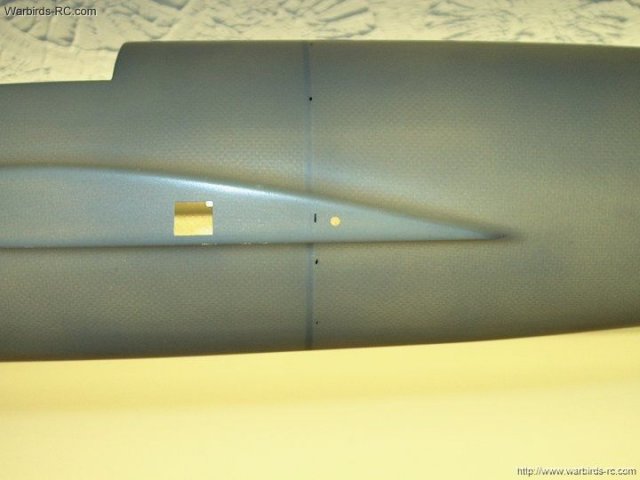

Fuselage assembly begins by sanding the

seam with 400 grit sandpaper | |

The sanded area is wiped down with a damp

cloth | |

A good body filler was used to fill the

seam | |

Seam filled on the top and bottom of the

fuselage and left to set | |

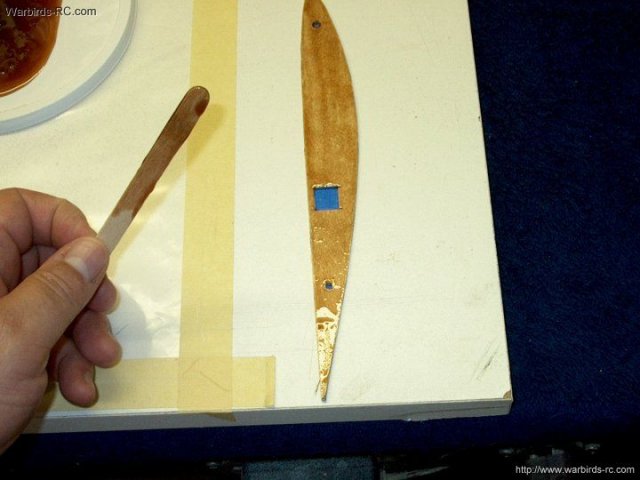

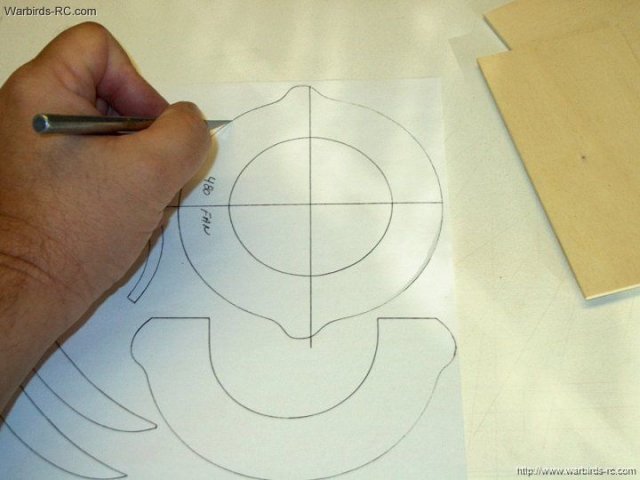

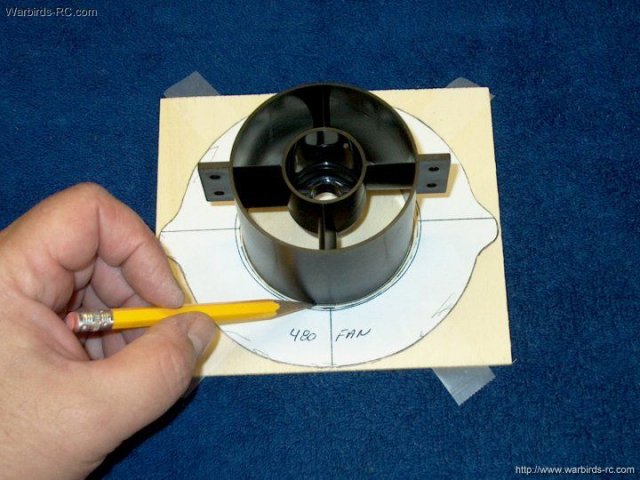

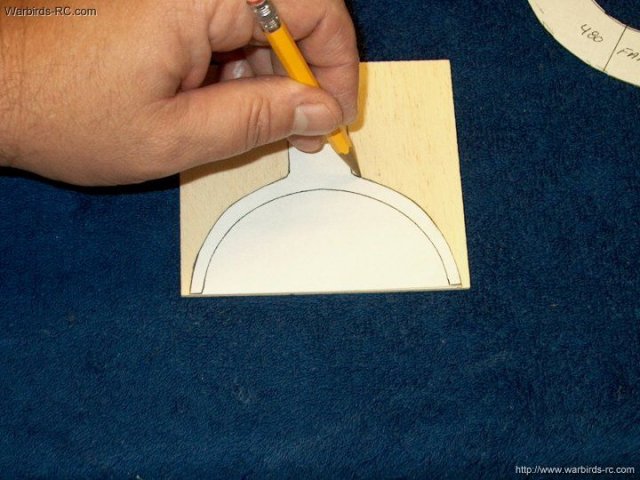

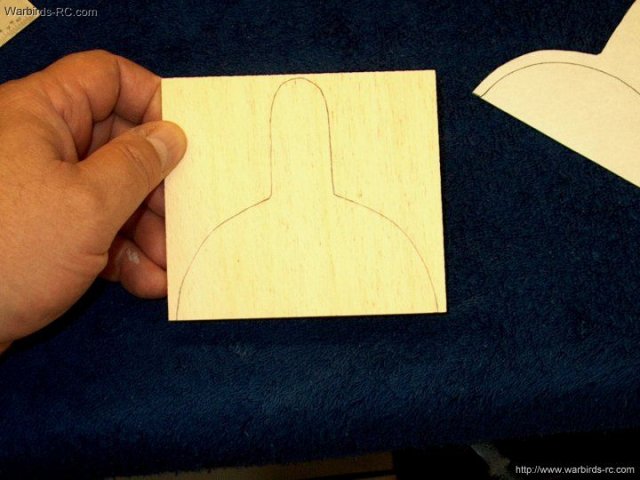

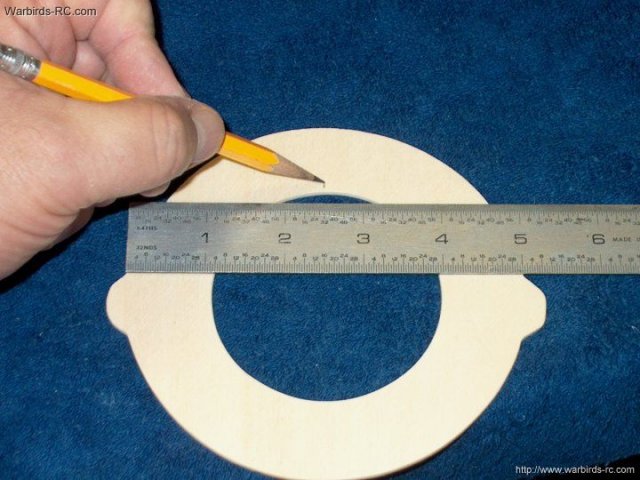

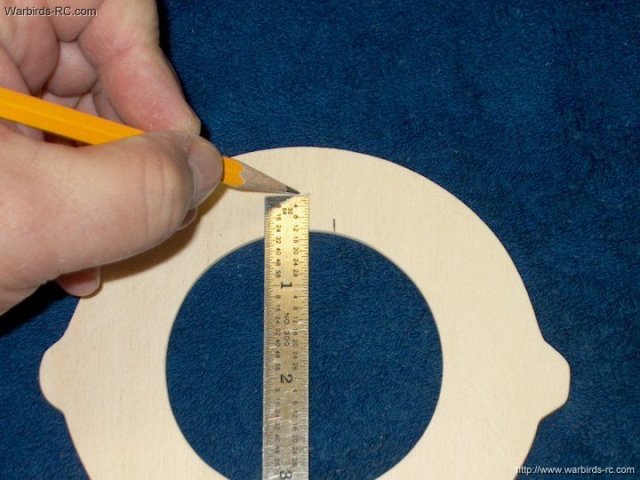

Two patterns for the main former are

supplied, one for the Wemotec HW 609 fan and one for the

Wemotec Minifan 480. Cut out the pattern for the fan you will

use | |

The minifan is used to draw a more

accurate center on the template | |

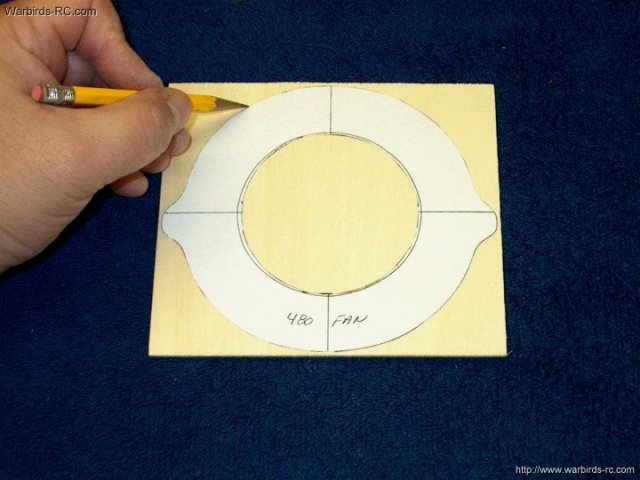

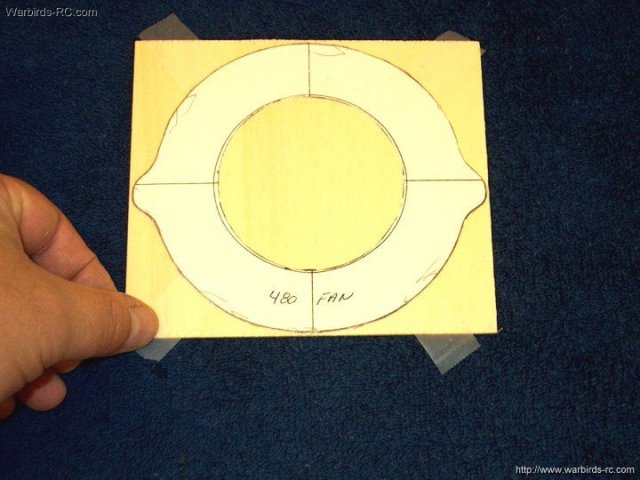

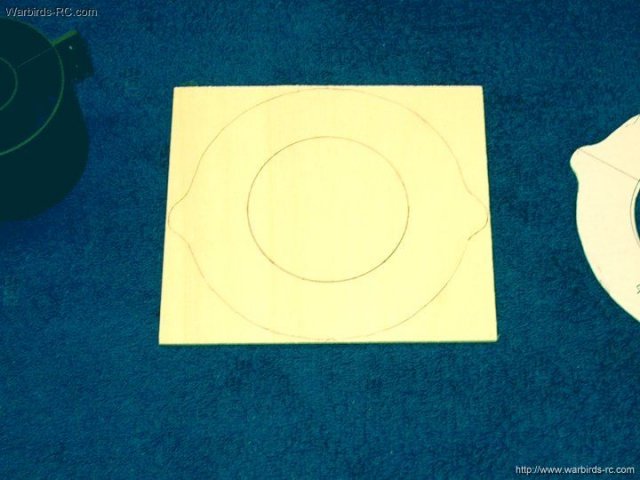

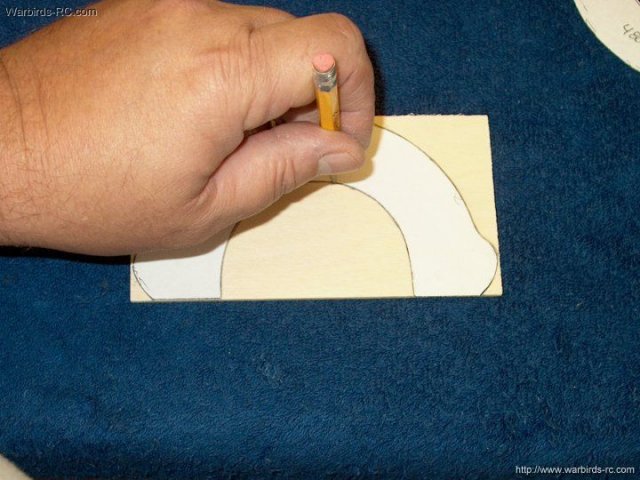

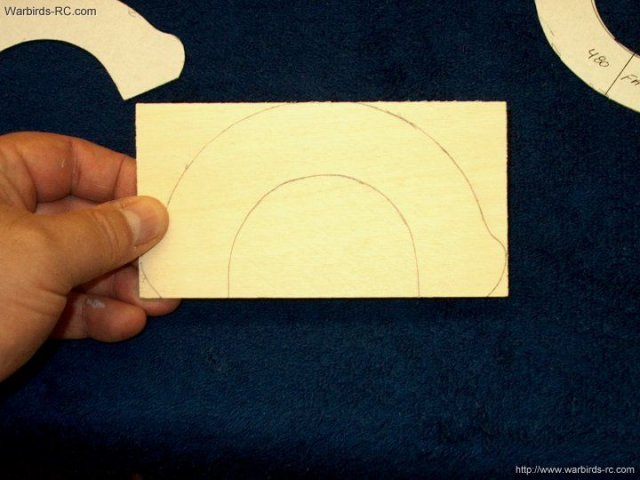

The main former template is transfered to

its repective plywood sheet | |

The sheet for the center former is traced

on the outside, then taped in place

| |

A clean circle is made using the fan

housing | |

Center Former is ready to cut

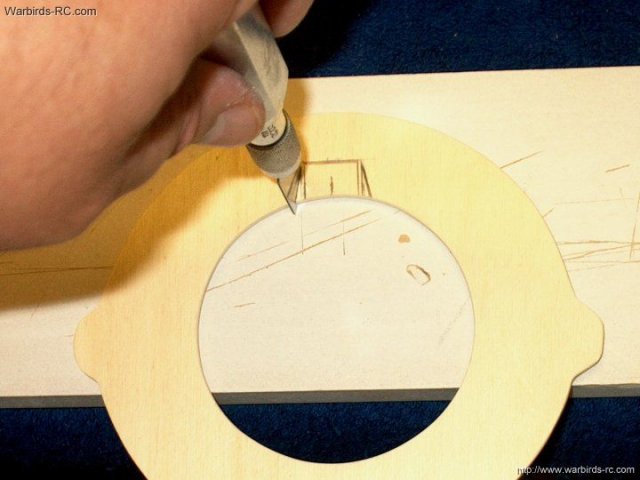

| |

The front former is traced

| |

The front former is ready to cut

| |

The rear former is traced

| |

The rear former is ready to cut

| |

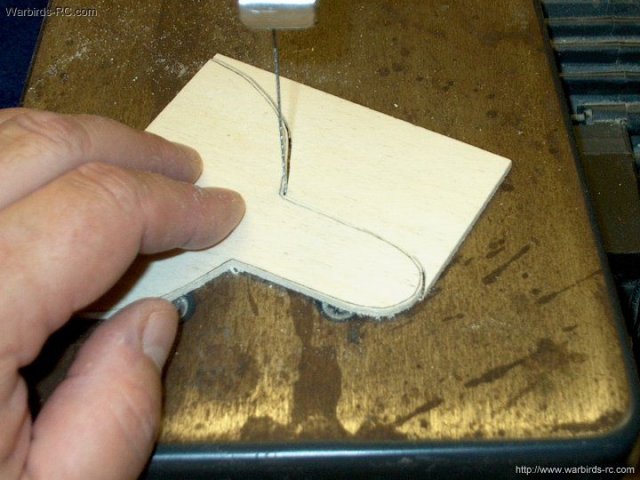

A scroll saw or coping saw is used to cut

out each former. Cut it so you have some extra to sand to

exact shape | |

The center of the main former is shown

drilled and being cut | |

All three formers have been rough cut on

the scroll saw | |

A drum sander on a drill press made

sanding the inside and outside edges much easier. You can also

sand by hand | |

The formers are fine sanded for a good fit

| |

Formers shown ready to install

| |

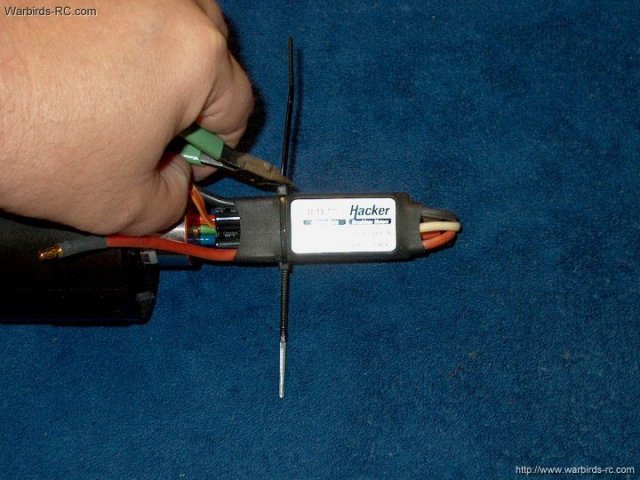

The model will be powered by a Wemotec

Minifan 480 and a Kontronik 480-33 Brushless Motor using a 4S

lipo battery | |

Loktite is applied to the shaft adapter

set screws | |

Set screws are installed in the shaft

adapter but not tightened | |

The motor is temporarily installed to set

adapter spacing | |

The rotor is placed on the shaft and the

shaft is pulled to bottom out and pull away the rotor from the

rear of the housing so it does not rub

| |

The motor is carefully removed and the set

screws are tightened with proper spacing set between the

bottom of the adapter and the motor front plate. Clean up all

excess Loktite with a Q-tip | |

The motor ring is place on the rear so it

will keep the motor centered. Some sanding on the inside of

the ring may be necessary for a good fit and a Dremel with a

drum sander works well | |

The motor is installed and the ring is

pressed in so it recesses flush in the back of the

housing | |

Install two 3mm x 6mm long bolts but do

not use Loktite on the bolts as it will attack and eat away at

the housing! Use either green Loktite or apply Blue locktite

only to the motor threads with a toothpick and wipe of all

excess prior to installing the motor in the fan

| |

Once the motor is tightened, install the

fan rotor. Be sure to balance the rotor per manufacturers

instructions prior to installation | |

Install the fan washer

| |

The aluminum nut is installed next

| |

The fan is covered with a paper towel to

protect it from shavings and a Dremel with a cutting wheel is

used to slot the end of the shaft adapter about 1/8"

deep | |

A screwdriver is used in the slot to hold

the shaft while the nut is tightened

| |

The fan hub can be installed and pops in

place with some pressure. You can add some Loktite to the

inside threads at the tip of the shaft adapter before

installing the hub | |

The hub retaining bolt is installed and

held in place with the Loktite you previously added. Do not

overtighten this bolt or the hub could come off during

use! | |

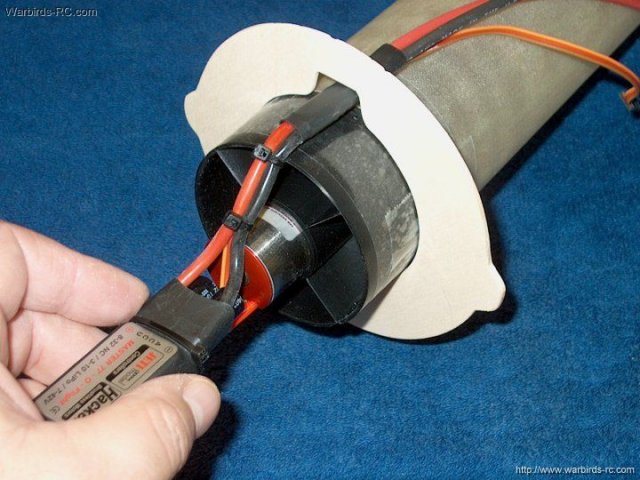

The Wemotec Minifan 480 Fan Assembly is

shown completed | |

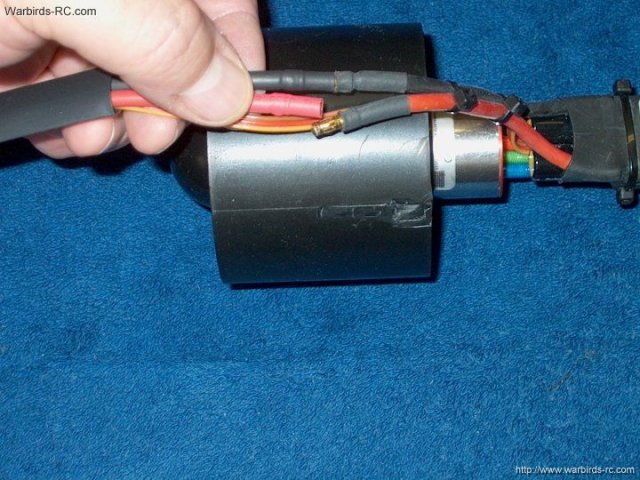

Heat shrink is placed over the ESC wires

and the wires are plugged in to the motor. Hook up a receiver

and test to make sure fan direction is correct. If not, change

any two of the three wires or program your ESC if it has the

reverse feature | |

The heatshrink is centered over the wires

to hold the plugs together | |

Tie wraps are used to tie the ESC to the

motor wires so it doesn't flop around inside the exhaust

duct | |

The tabs on the fan will need to be

removed | |

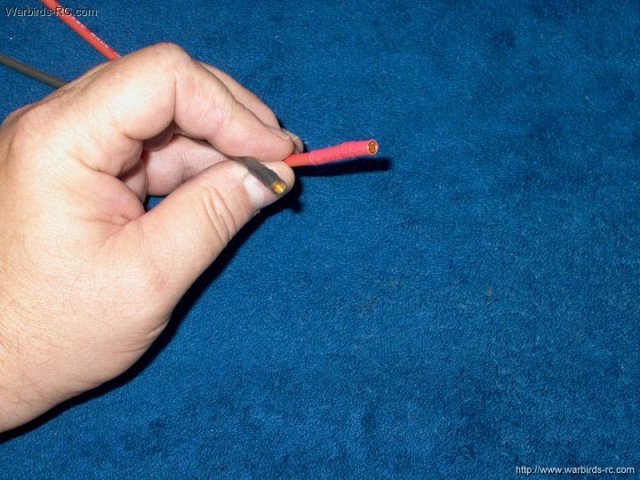

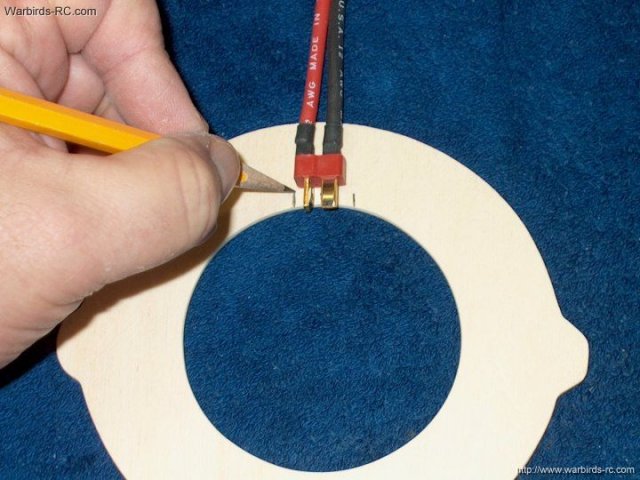

Two wires are cut as shown for the ESC to

battery leads | |

Sockets are soldered to one end of the

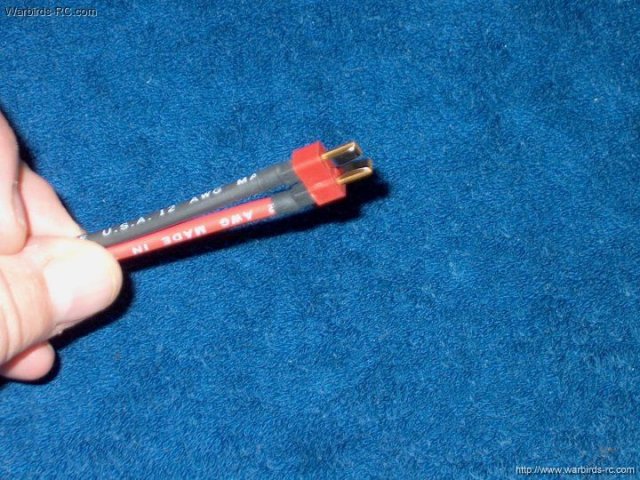

wires | |

An Ultra Deans male connector is used and

soldered at the battery side | |

The leads are connected to the ESC

| |

Heat shrink is installed to prevent the

wires from unpluging and it keeps the assembly neat and easier

to install | |

The Minifan Power Plant ready to install

in the fuselage | |

A large square is used to mark the

locations of the formers | |

The front former is installed 8 1/4" from

the front of the fuselage. Several marks are made around the

fuselage to help with the alignment of the former

| |

Tape is used to indicate the back of the

former position and to aid with the next step

| |

The main center former is located 6 1/8"

from the front former. Make several marks around the entire

fuselage | |

Photo shows locations marked for the rear

of each former | |

Install the main center former and check

for fit. If you hold it up to a light, you will see bumps in

the fuselage as shown by the arrow below. This is where the

former is oversized, so remove it, sand a little at a time,

reinstall and check again. When the former is shaped

correctly, it will not show on the outside

| |

Picture of center main former in place and

fitted | |

Formers are positioned so the rear is on

the marks. This is so you have clearance room to install the

wing dowel clips later | |

Front former shown installed, but the

inside still needs sized | |

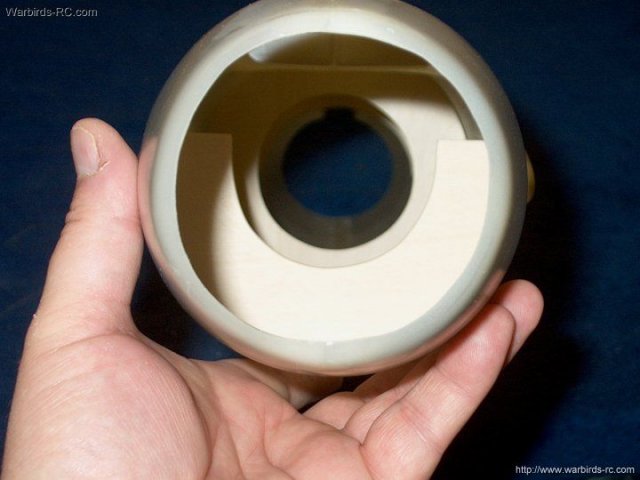

The center former is temporarily fitted on

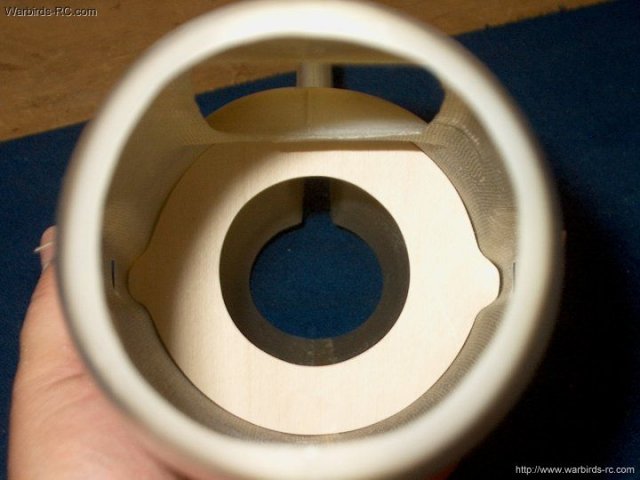

the fan | |

The fit was too tight, so it needed to be

sanded to a loose fit | |

A center mark is made at the inside

top | |

Marks are made evenly from the center and

slightly oversized so the power plug will fit through

| |

The top is marked for clearance

| |

The area is cut to allow clearance for the

power and servo cables | |

The corners are rounded and the former is

ready to install | |

Former is test fit over the fan assembly

and easily clears the duct | |

Now is a good time to trim the Cockpit

opening so you won't get cut while working in this area. Start

by outlining the cockpit with 1/4" trim tape with the outside

at the edge of the cockpit area | |

A cutting wheel is used to rough cut the

heavy areas | |

A dremel and 1/2" sanding wheel on low

speed is used to grind the inside edges to the tape. Be

careful to not cut too much | |

Area has been shaped and is now fine

sanded with 320 grit to round the edges inside to out

| |

Cockpit area shaping shown

completed | |

Use 60-80 grit sandpaper and sand a 1"

wide area inside the fuselage centered on the main former

location for good glue purchase | |

Apply 15-30 minute epoxy to the edge of

the main former | |

The Main Former is installed with the rear

of the former on the marks | |

Epoxy resin is mixed and three stips of

5oz glass cloth are cut. One strip is 5" long and the other 2

are 2 1/2" long | |

Resin is applied in the fuselage area to

glass the former to the wall | |

Glass strips are installed as shown and

excess resin is removed | |

Five 1" x 1" strips are cut, soaked in

resin, then applied to the rear of the main former. Excess

resin is then removed | |

Two fiberglass thrust tubes are supplied

with the kit. The longer tube is used for the intake

| |

The intake is temporarily installed in the

fuselage 1/4" away from the front of the main former and

measured, then rough cut to length | |

For a HW609 or other larger fans, the

small end is used at the intake opening, while the larger end

fits right over the fan. Also if you are using a larger fan,

do not trim the duct and you can omit the next several steps

and proceed to glassing your intake. For the MiniFan 480, one

side of the intake duct was trimmed just enough to straighten

the cut from manufacturing. Note that the smaller end of the

tube is used on the fan side | |

Make sure the intake on the fuselage is

round, then the duct is installed and expanded to fit loosely

in the opening. The loose fit of about 1/64" or more is

required as the tube will be glassed later and this will

increase its thickness | |

The intake tube is removed and marked for

cutting off the overlap | |

A yardstick and knife is used to trim the

excess off the intake duct. Be sure to cut excess the side

that was not previously straightened

| |

The excess is removed from the duct

| |

Packing tape is applied from the inside to

one side of the duct | |

The other side is pushed flush and the

tape is pressed down. You can use a wooden dowel to reach the

center area | |

The intake duct end is checked for

fit | |

Before glassing the duct, the inside ends

are covered with blue masking tape so excess epoxy will not

drip on the inside. Then the intake is sanded on the outside

with 100 grit to rough it up for good glue purchase

| |

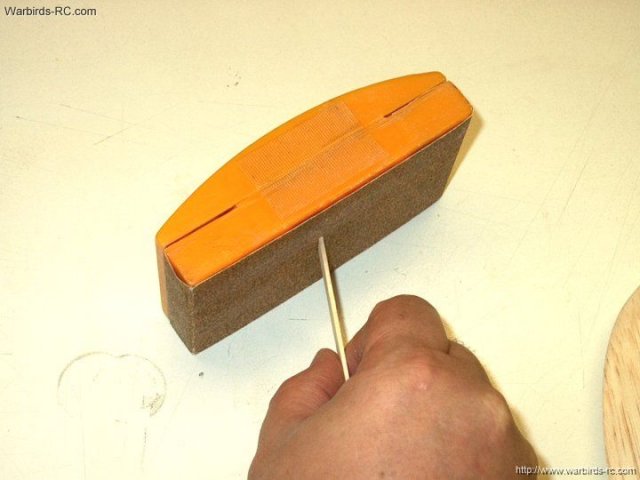

Then ends of the tube were capped with

spare items in the shop to help keep them round during the

glassing. A plastic cap from balsa filler was used on one end

and a 1/4" thick balsa disk was made for the other end. Make

sure what you use fits well; if too large, it can expand and

open a crack at the seam | |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |