01- The HET-RC Sniper double boxed as it

arrives from Warbirds-RC | |

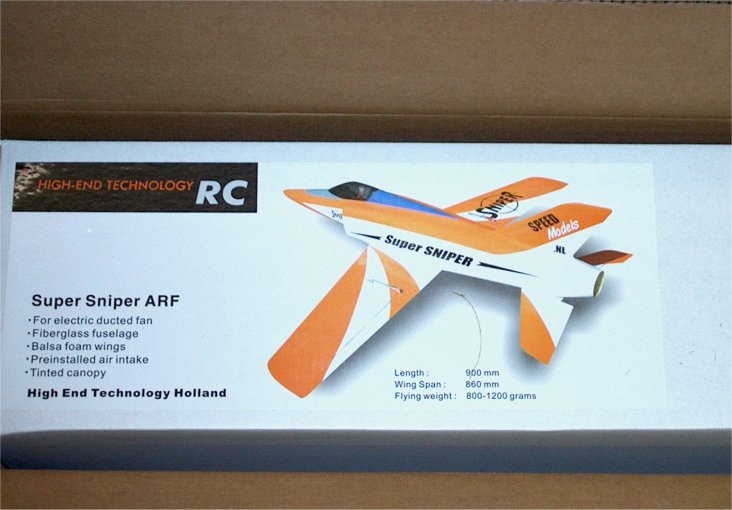

02 - Front label shows a picture and

specification. | |

03 - The package, in good shape with no

shipping problems. | |

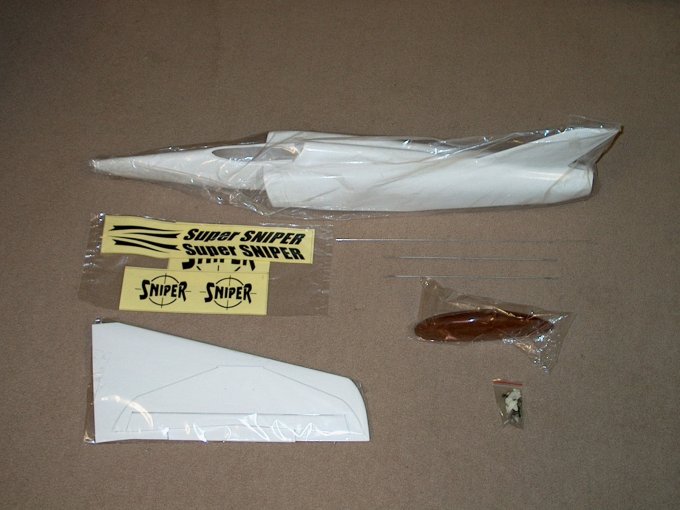

04 - Inside the box reveals a well packed

kit, typical of HET-RC. | |

05 - The components include a fiberglass

fuselage, two wing halves, a horizontal stab, canopy, hardware

bag and decals. | |

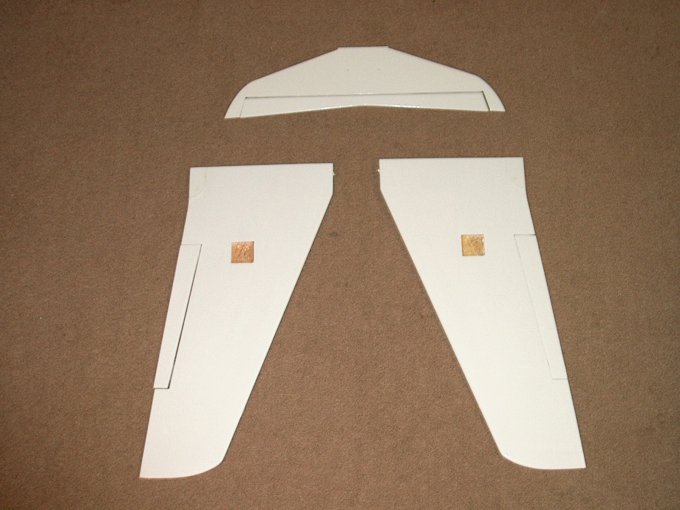

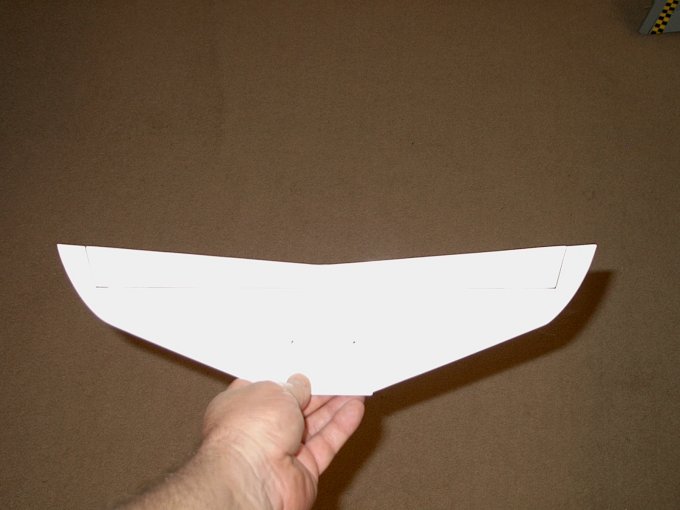

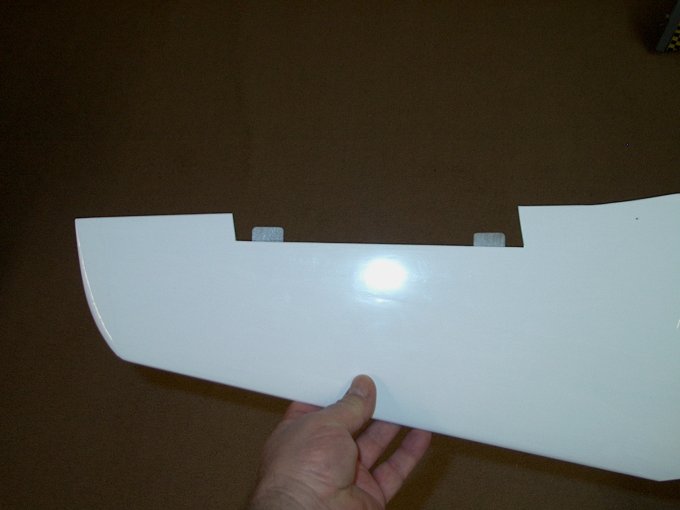

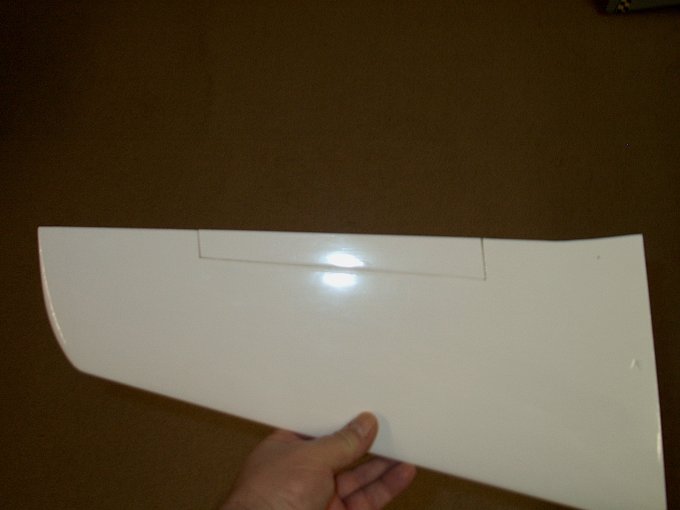

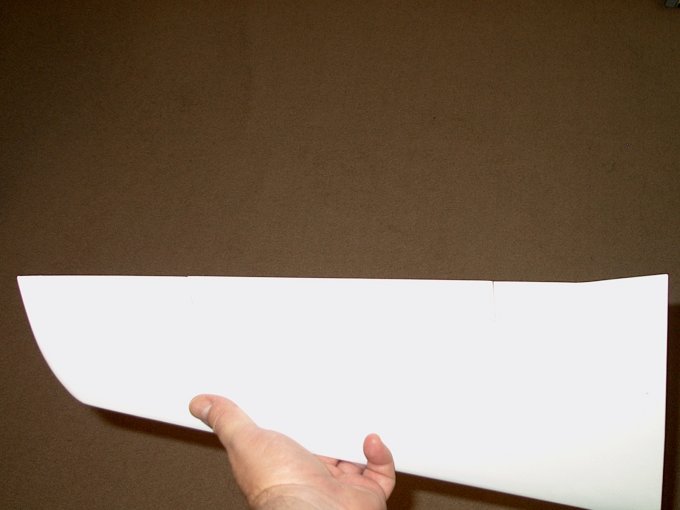

06 - Wing sections and stab come

pre-covered in plastic covering, note though that the control

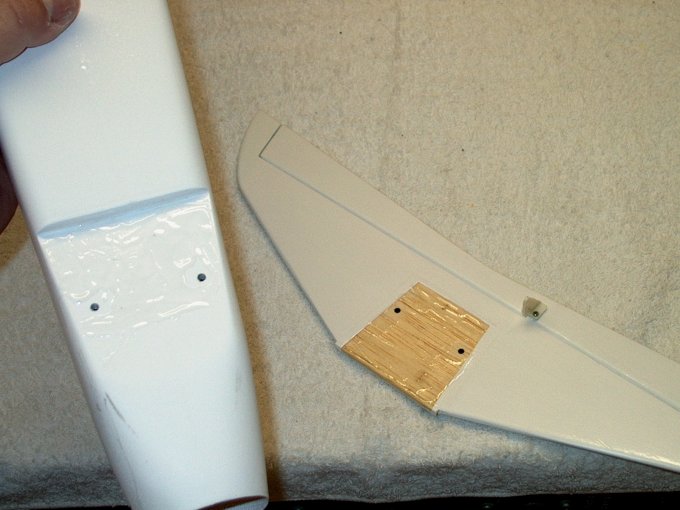

surfaces are not yet glued. | |

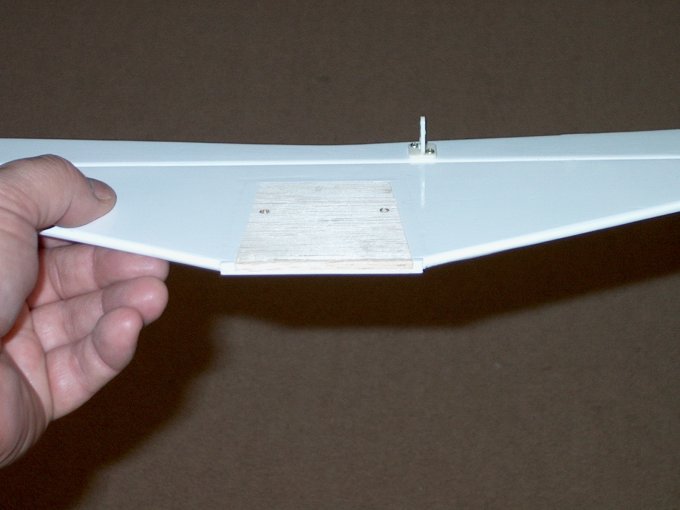

07 - Hardwood plates support the wing

mountings holes. | |

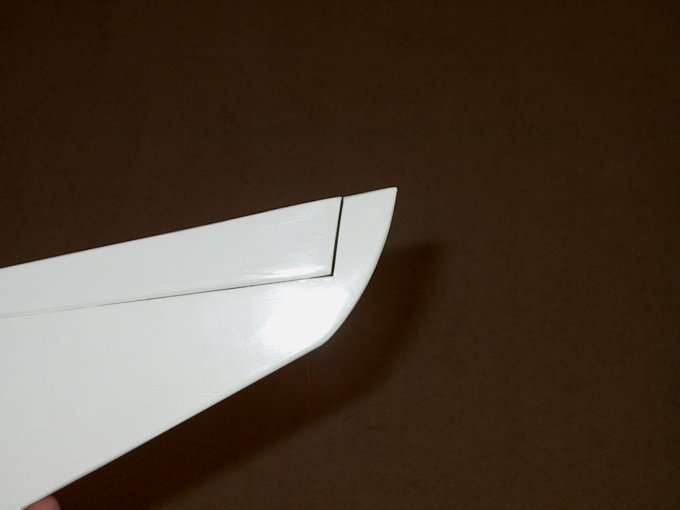

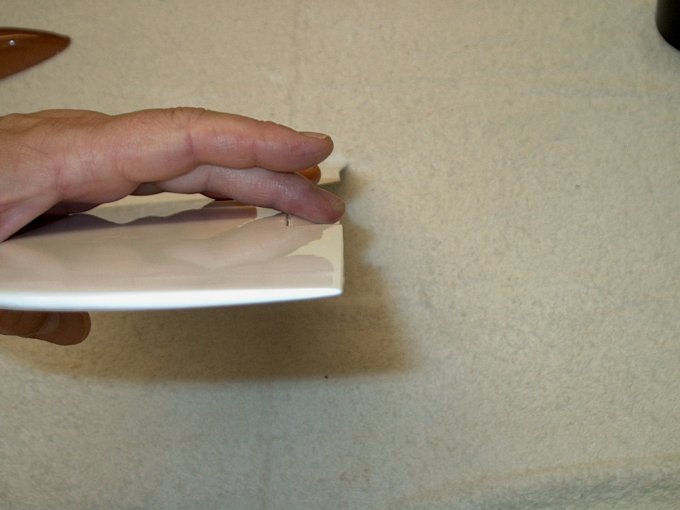

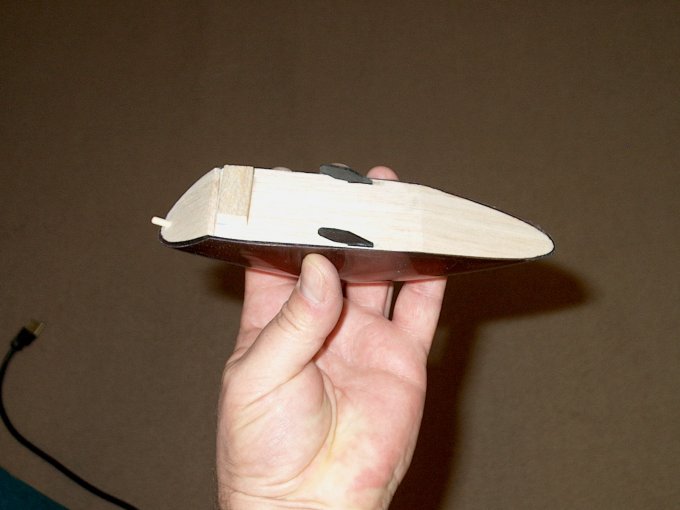

08 - The leading edge of this

semi-symmetrical wing is shaped well.

| |

09 - The intake duct work is made from

glass, it's not super smooth, but has been finished

well. | |

10 - Tow hook location is beefed up

inside. I noticed all the mounting points for the wing, tow

hook and tail feathers have hardwood supports epoxied in place

inside... a nice touch. | |

11 - Hardware package should include the

following: 3 Horns 6 Horn mounting screws 3 Clevis' 4 Wing /

Tail mounting bolts & washers 3 Control rods 1 Tow hook

| |

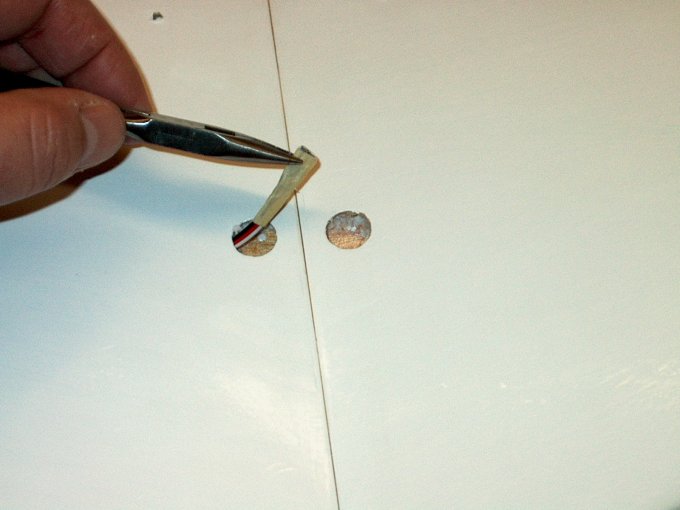

12 - Another nice feature is the aileron

servo wire exit holes, which have been pre-made.

| |

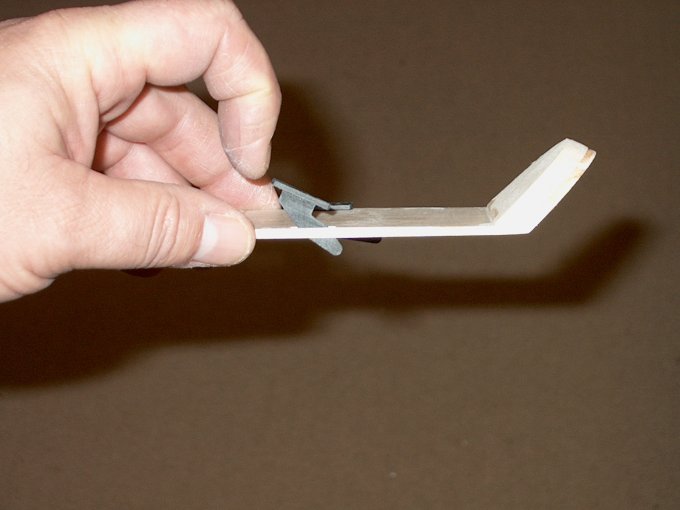

13 - The build begins with the elevator

hinges removed in order to mark the center lines.

| |

14 - Hinges are inserted up to the line

inside the horizontal stab. They are placed with their left

side 3/8" and 3" away from the end joint.

| |

15 - Thin CA glue is used to mount the

hinges... it will "wick" into the joint.

| |

16 - Horizontal stab with hinges

installed. | |

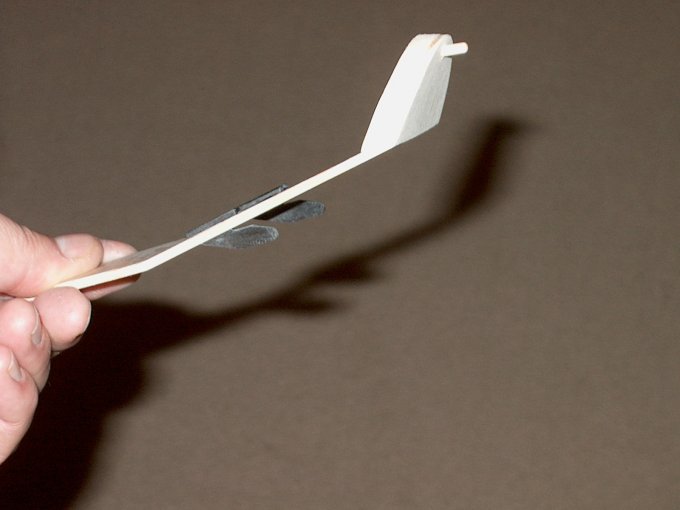

17 - The elevator is installed on the

stab. Make sure it is evenly spaced from the tip on both sides

before gluing. | |

18 - Elevator is moved downward before

gluing, allowing it to pull away a bit from the stab so it

won't bind during use. | |

19 - Elevator installed on stab and glued

in place. Once again, make sure the ends are evenly spaced,

then use thin CA to attach the elevator.

| |

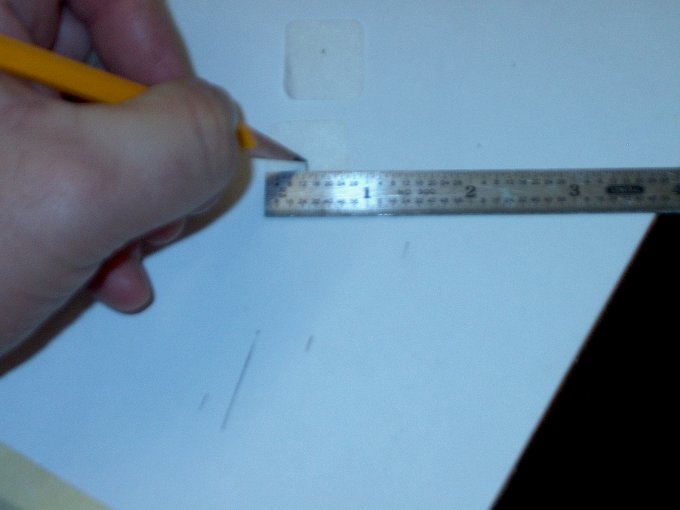

20 - Marking center lines for the aileron

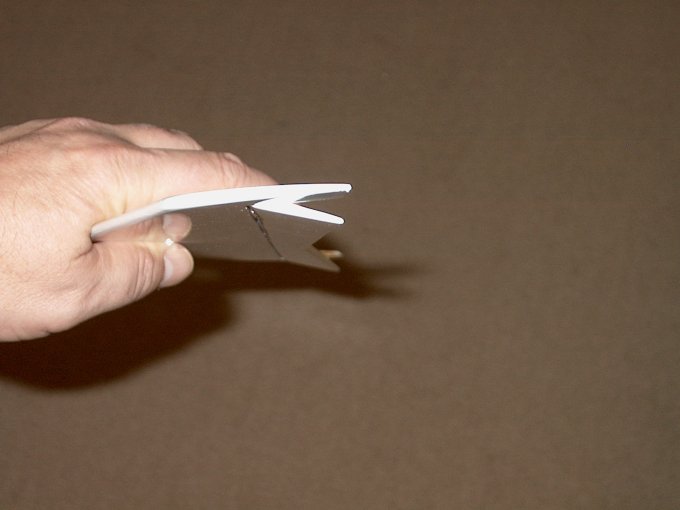

hinges . | |

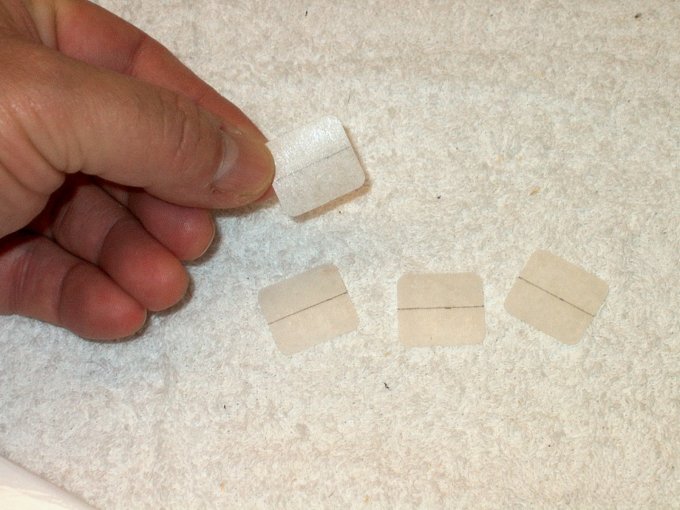

21 - Hinges are installed 1/2" from each

side. | |

22 - Hinge is glued in place and aileron

is shown being installed. | |

23 - Aileron installed.

| |

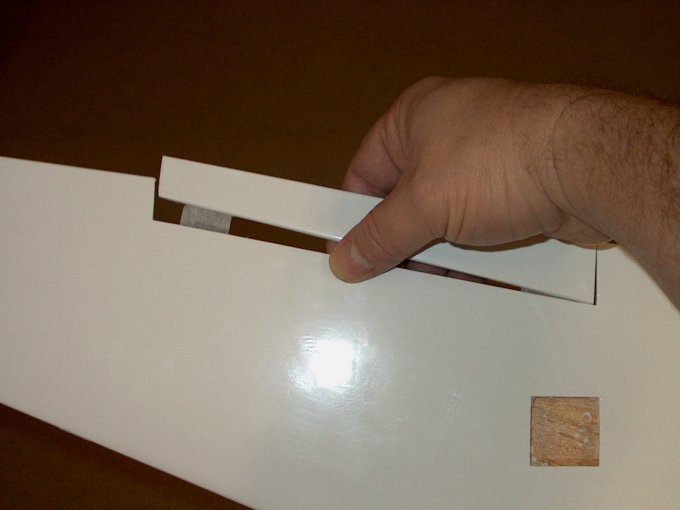

24 - Aileron flexed downward to have it

space itself slightly away from the trailing edge of the wing

for freedom of movement . | |

25 - Next, the aileron is glued in place

with thin CA. | |

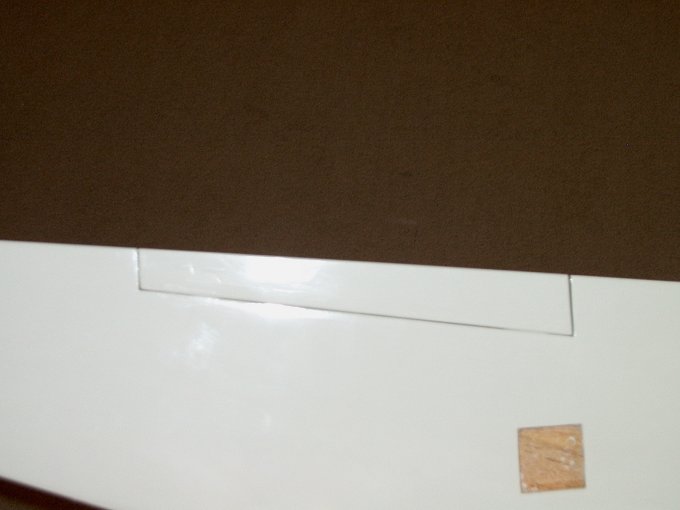

26 - The second wing half showing hinges

installed. | |

27 - Using a Q-Tip makes a nice cleanup

tool for excess thin CA. | |

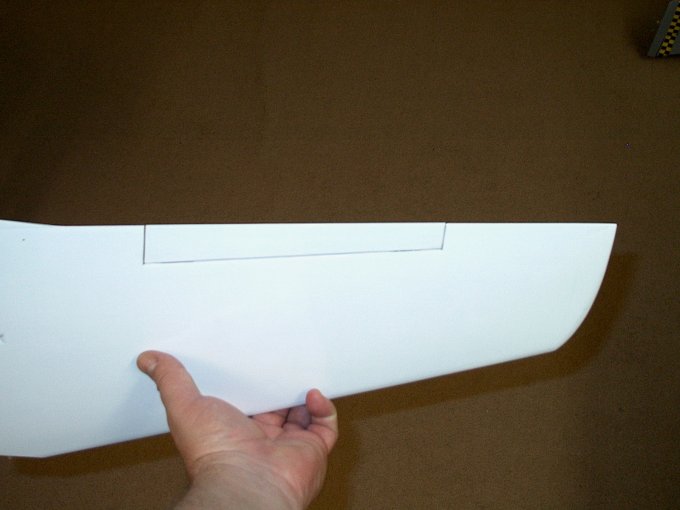

28 - Aileron fitted to second wing half.

| |

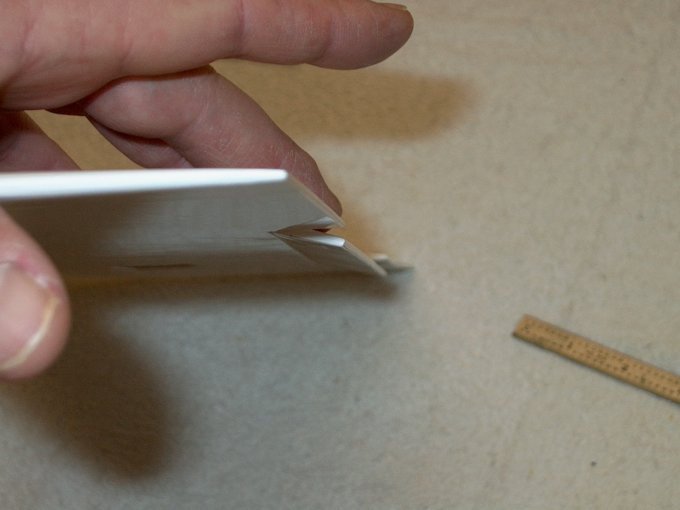

29 - Once again, the aileron is flexed to

space it from the trailing edge. | |

30 - Second aileron glued in place.

| |

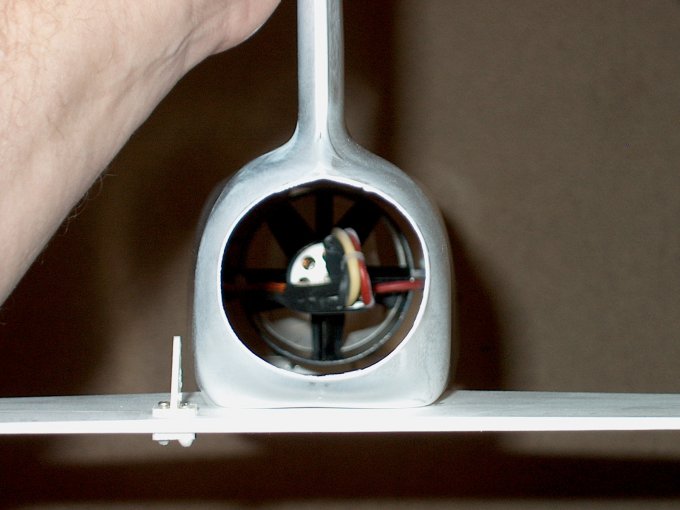

31 - Preparing the power plant.

| |

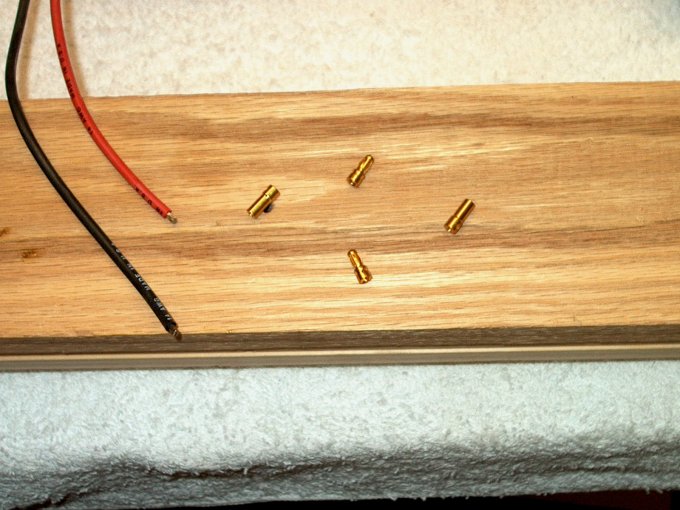

32 - 3.5mm plugs are installed on the

motor. | |

33 - A piece of hardwood makes a good plug

holder. | |

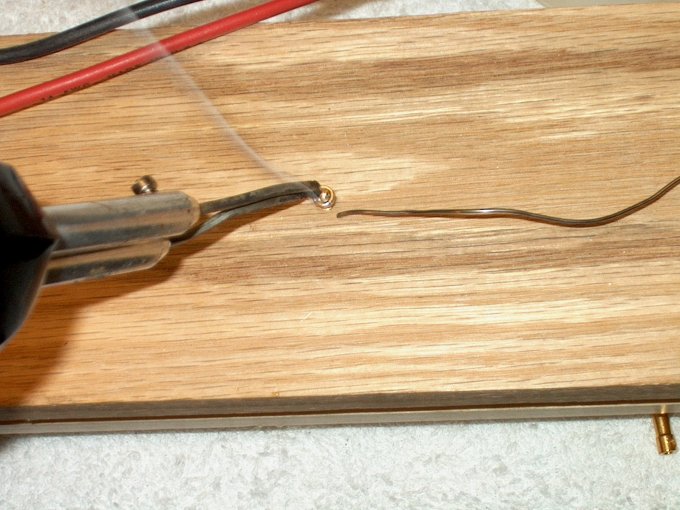

34 - Filling the cup with solder.

| |

35 - Motor lead and plug are heated, then

the lead is pushed down in place. | |

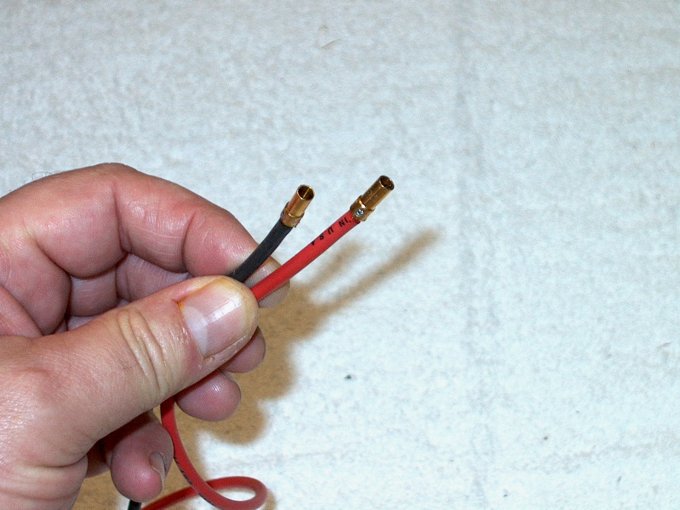

36 - All three leads connected.

| |

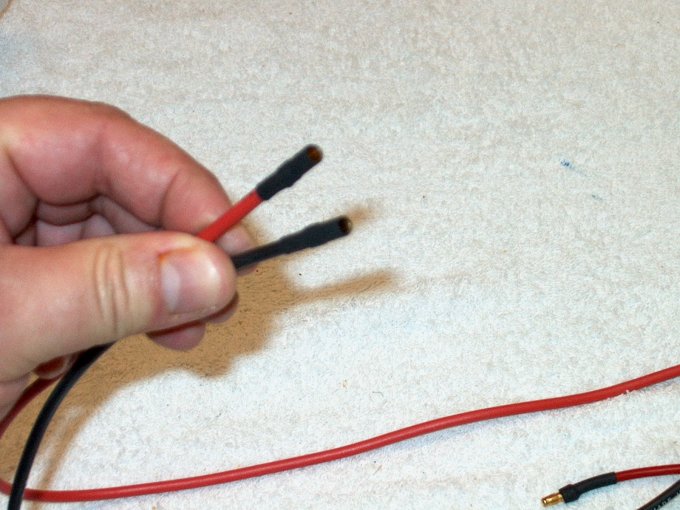

37 - Adding heat shrink to the

plugs. | |

38 - Motor assembly completed.

| |

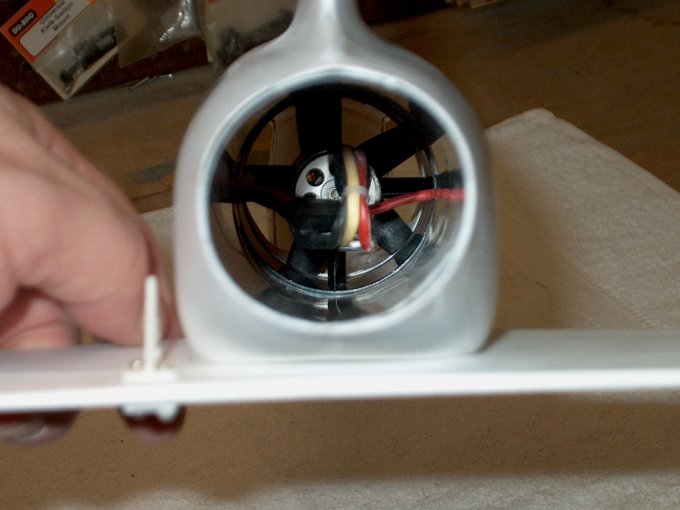

39 - Preparing to assemble the MiniFan480,

the shaft adapter is slotted at the tip so a screwdriver can

be used later to help tighten the nut.

| |

40 - Shaft adapter slotted.

| |

41 - Heat the shaft adapter with a

torch... a hair dryer or heat gun can be used as an

alternative. | |

42 - Heating the shaft is necessary as it

is slightly undersized on purpose to insure a tight fit to the

motor shaft. | |

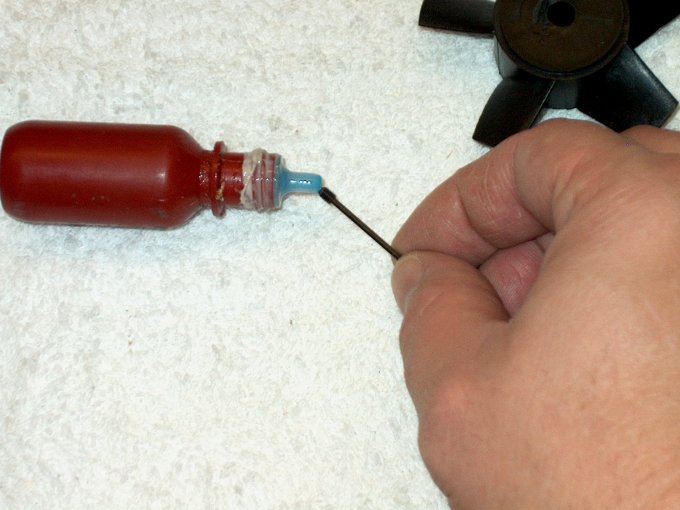

43 - Loktite is used on the setscrew.

WARNING - Not not allow any Loktite to come in contact with

any part of the fan. | |

44 - Set screws are installed in the shaft

adapter and tightened. | |

45 - Use a Q-Tip to clean off all excess

Loktite. | |

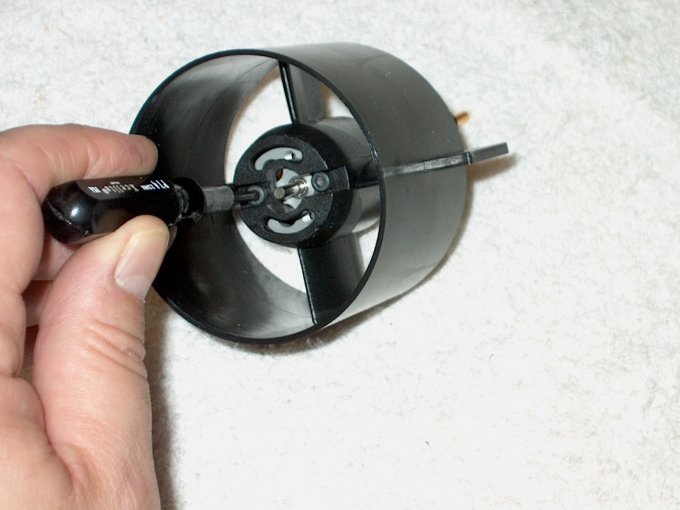

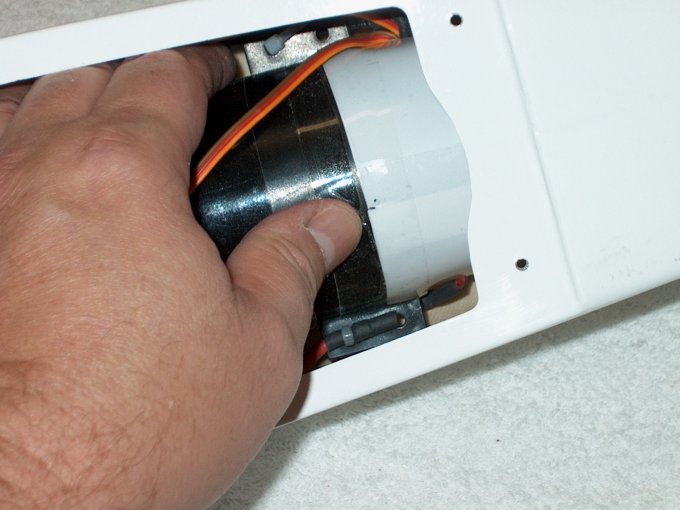

46 - Install the motor in the fan shroud.

| |

47 - The screws that come with the Mini480

fan are 2.5mm, so you will need some 3mm bolts to mount the

motor to the shroud. | |

48 - 3mm bolts used to secure the motor.

| |

49 - A sanding wheel opens up the plastic

spacer ring so it will fit over the motor.

| |

50 - Ring checked for fit.

| |

51 - Ring slipped over the rear of the

motor. | |

52 - The ring is seated flush with the

rear of the shroud. | |

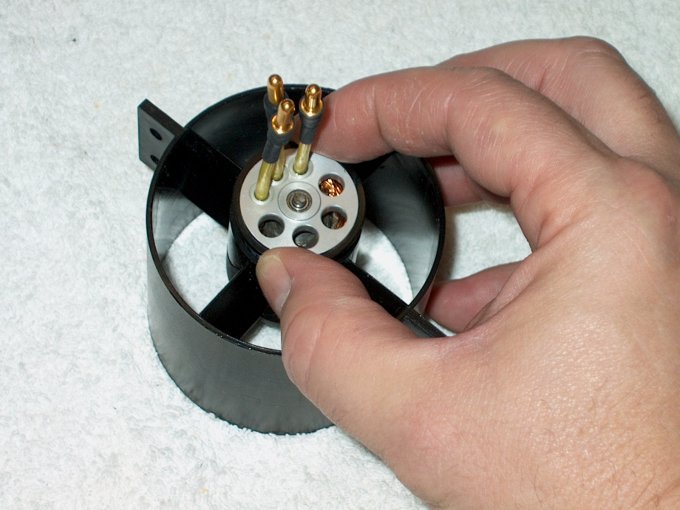

53 - Important: Check to make sure the

shaft base protrudes at least 1/64" from the fan shroud face,

as shown by the pencil. If not spaced correctly, the rear of

the fan unit will rub the shroud once it is installed. If you

need clearance, remove the motor, loosen the shaft set screws,

heat up the shaft and pull it out a bit. Then reinstall and

check again. | |

54 - Fan is installed on the shaft

| |

55 - Followed by a washer included in the

fan kit. | |

56 - Next, the aluminum nut is

installed. | |

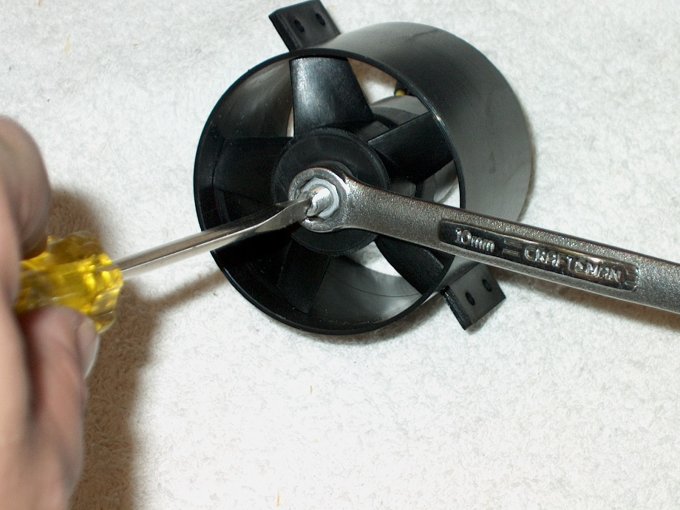

57 - Here is where the slot you made

earlier comes in to play. Using a screwdriver in the slot to

hold the shaft, tighten the fan unit.

| |

58 - Hub and retaining bolt installation

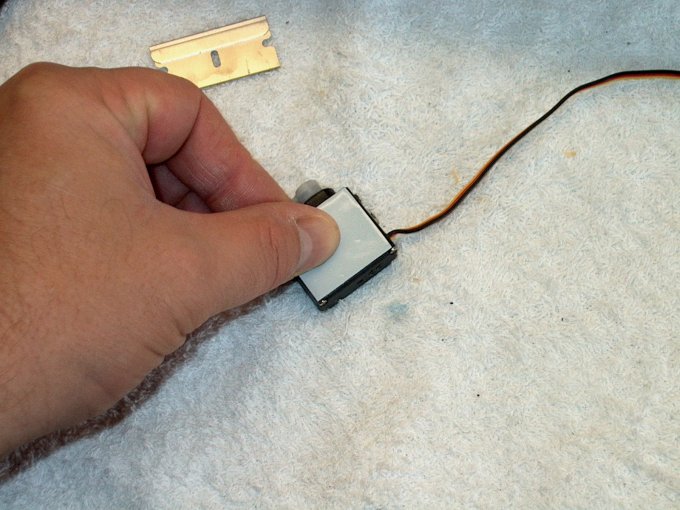

is optional. You can run the fan without the hub with almost

very low loss in power | |

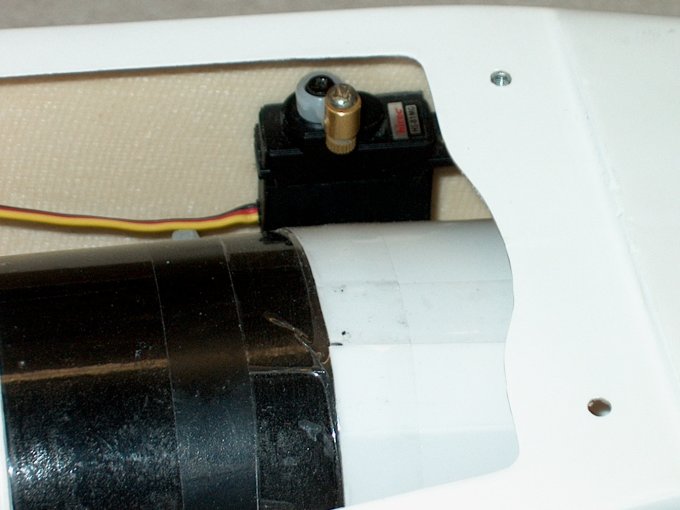

59 - Fan assembly completed.

| |

60 - VERY IMPORTANT: Please make sure

there is no rubbing or binding between the fan rotor and the

fan shroud. Now would be a good time to check, if the rotor

does not spin freely without making contact with the fan

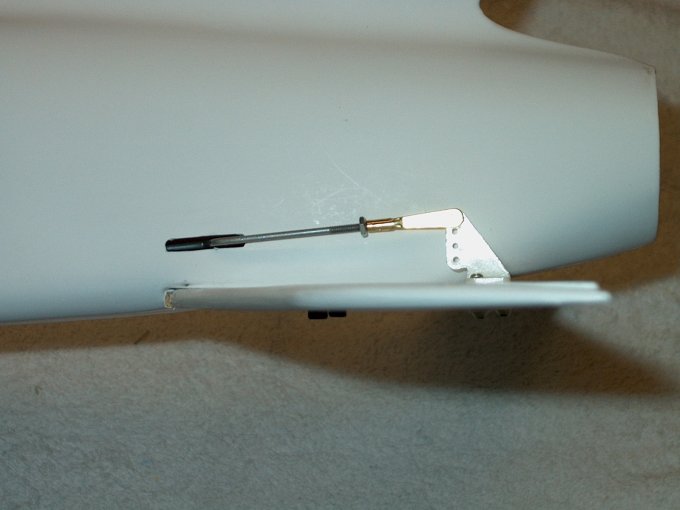

shroud, please go back to step #52 and check that you provided

adequate spacing between the adapter and the motor. Also, if

you use a lock tight type chemical to hold the aluminum nut in

place, make sure it does not come in contact with any of the

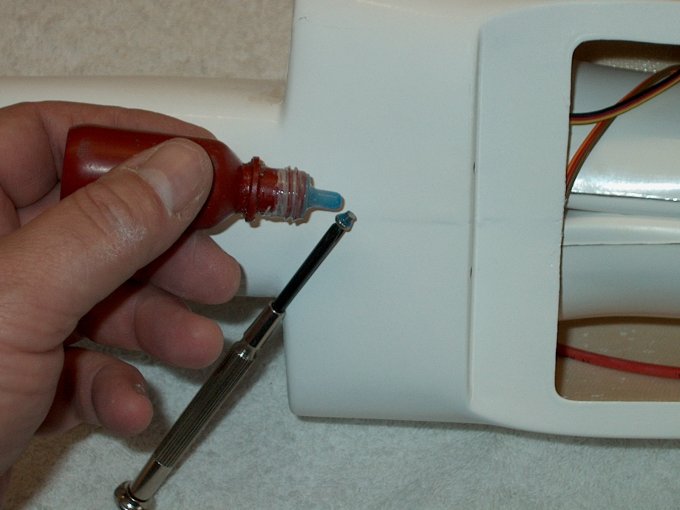

ABS plastic parts as it will soften and later destroy your fan

over a period of time. If you opt to use such a chemical make

sure it only comes in contact with ONLY the metal parts and

wipe any excess away right away. | |

61 - Socket rear is pre-tinned and filled

with solder. | |

62 - Wire is soldered to the 3.5mm socket.

| |

63 - Both wires soldered.

| |

64 - Heat shrink tubing is added for

insulation. | |

65 - The three sockets are connected to

the motor wires on the ESC, while the two 3.5mm plugs are

installed on the battery wire. | |

66 - Heat shrink tubing is added to finish

the sockets. | |

67 - A good quality ESC is

recommended | |

68 - The battery harness is cut to 12" in

length. The fuselage is shown in the rear to show how the run

would fit, from the fan/motor location on the right to the

center of the battery compartment on the left.

| |

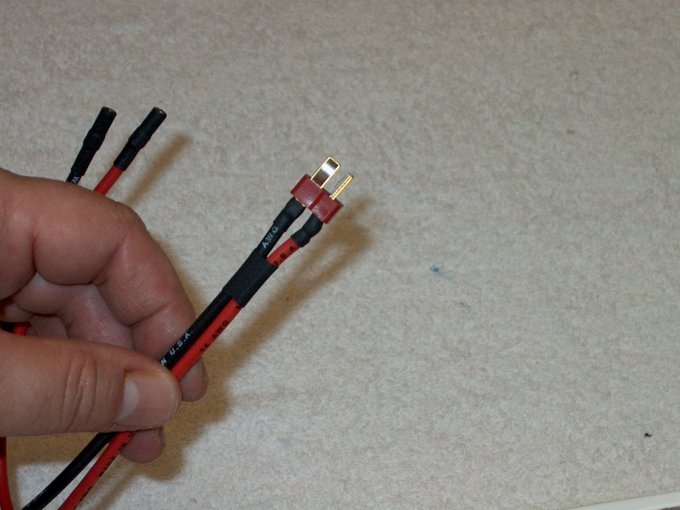

69 - A Deans "Ultra-Plug" is soldered to

the other end of the harness. | |

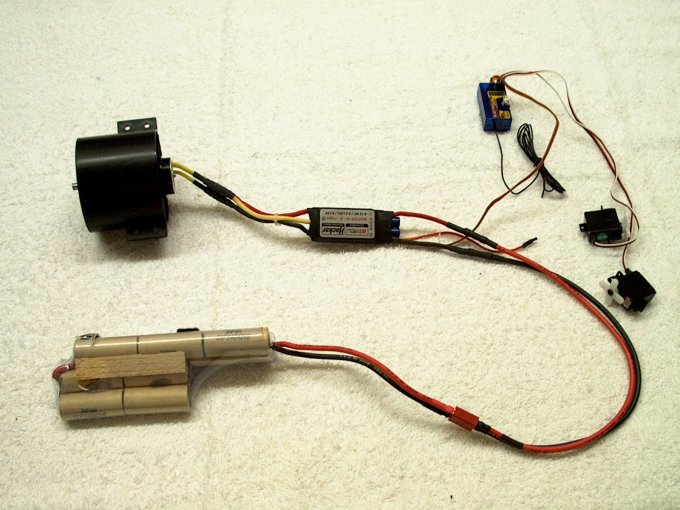

70 - The entire assembly is connected and

the fan is checked for balance. | |

71 - Heat shrink is applied to the motor

connector to insure they will not come loose.

| |

72 - Fan would not fit inside of the

fuselage as the opening was not large enough.

| |

73 - The fan was positioned over the

opening and a pencil was used to mark the rear wing saddle

area. | |

74 - You can see where it was hitting...

DO NOT FORCE IT IN as you can crack the ductwork..

| |

75 - Mark made from previous setup is

shown. | |

76 - A Dremel with a cutting wheel is used

to rough cut the area. | |

77 - Then a Dremel with a drum sander is

used to shape the opening. | |

78 - The fan fits inside now and very

little saddle was removed. | |

79 - Fan shown completely inside of the

fuselage. | |

80 - Note the ends were also rounded,

which "relieves" them and helps prevent cracking.

| |

81 - A Dremel with a sanding drum was used

to even up the ducting. | |

82 - NOTE: If you are not painting your

model, skip the next six steps. 320 Grit wet/dry sandpaper was

used to flatten the surface of the fuselage for good paint

adhesion. | |

83 - Once sanded, wash down the area to

remove any excess paint. | |

84 - The surface should still appear

white, but "flattened" in color. | |

85 - 320 grit sandpaper was used to "dry

sand" the horizontal stab. | |

86 - The wings were also sanded to allow

for good paint adhesion. | |

87 - All surfaces washed and shown now

with that "flat white" look. | |

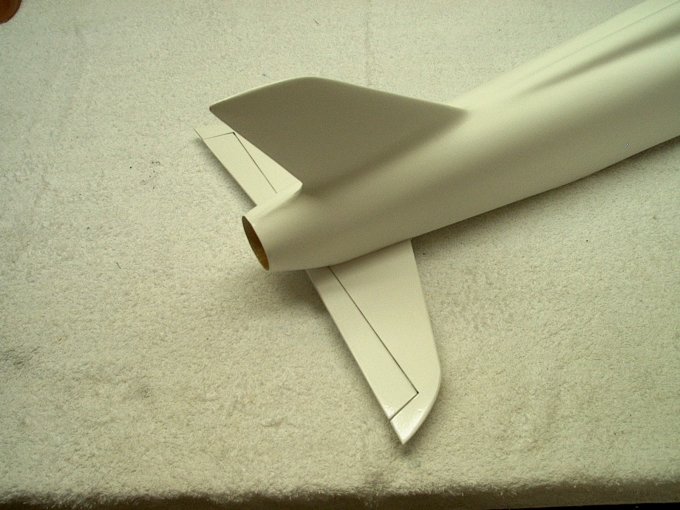

88 - The tail assembly is temporarily

connected to the fuselage using two of the bolts and small

washer provided. | |

89 - The tail shown installed and flush

with the fuse at the top. | |

90 - The elevator horn was placed on the

elevator with its center 1/4" away from the fuselage side to

allow for clevis clearance. | |

91 - The elevator was drilled using a pin

vise. | |

92 - The bolts supplied in the kit are

used to attach the horn to the elevator.

| |

93 - Excess bolt length is cut flush to

the horn retainer. | |

94 - A drop of medium CA is applied to the

top of each bolt end. | |

95 - Hinge shown installed.

| |

96 - Rod supplied in the kit was tried but

it was too loose in the horn. | |

97 - Preliminary check of tail alignment.

It appears that mounting the tail and pushing it forward flush

to the fuselage makes for a worry free install with no check

needed. | |

98 - Stab being marked for permanent

installation. | |

99 - Stab marks shown.

| |

100 - Plastic covering from the inside

area was removed so that stab could be epoxied to the

fuselage. | |

101 - Plastic covering shown being

removed. | |

102 - Stab prepped for final install. Make

sure you remove the top area and not the bottom.

| |

103 - Epoxy applied to stab area. The stab

needs to be epoxied as the bolts cannot be tightened without

crushing the balsa. You may try cutting the bolt area out and

replacing with a plywood plank. This would allow for a "bolt

on" stab. | |

104 - The fuselage area was roughed up

with 60 grit sandpaper and then both surfaces had epoxy

applied. | |

105 - The stab was bolted permanently in

place with the leading edge pushed flush against the

fuselage. | |

106 - Horizontal stab installation

completed. | |

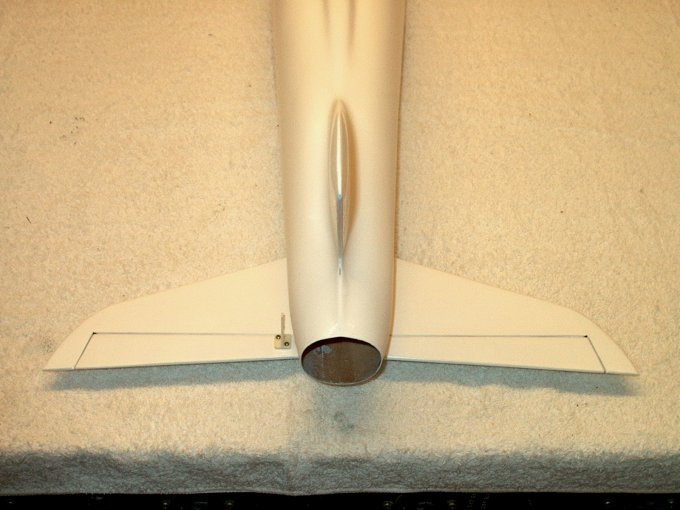

107 - Stab installed, rear view showing

horn location. | |

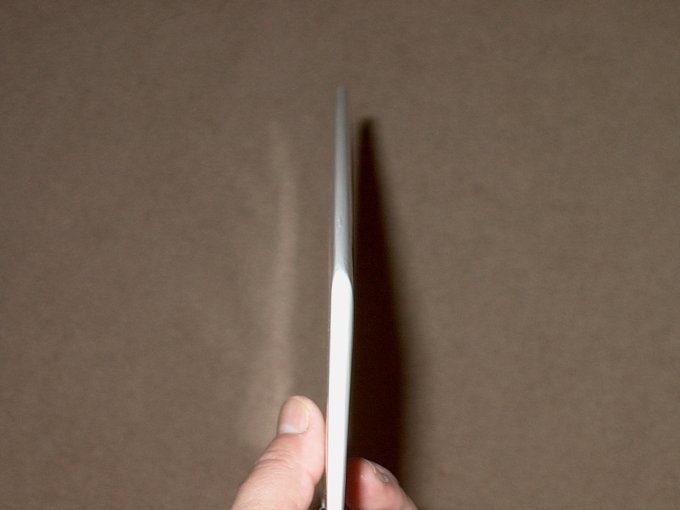

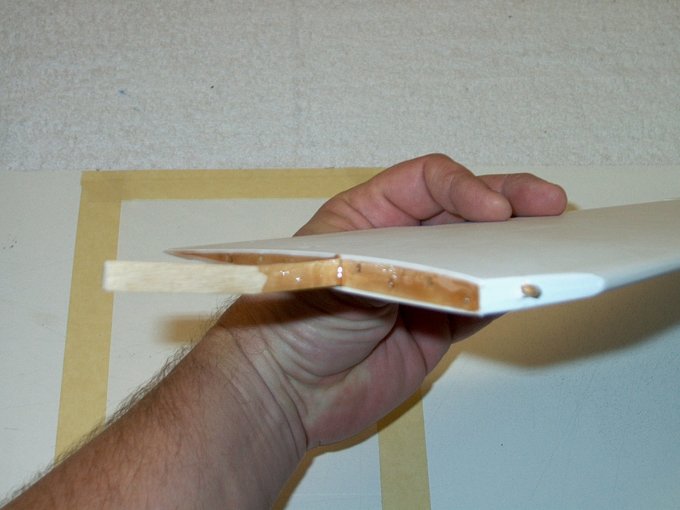

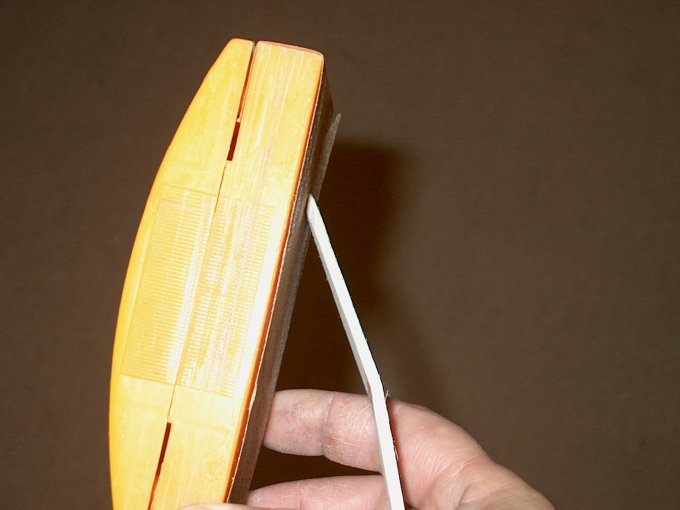

108 - Main wing spar, ready to install. I

drew a center line on it for reference.

| |

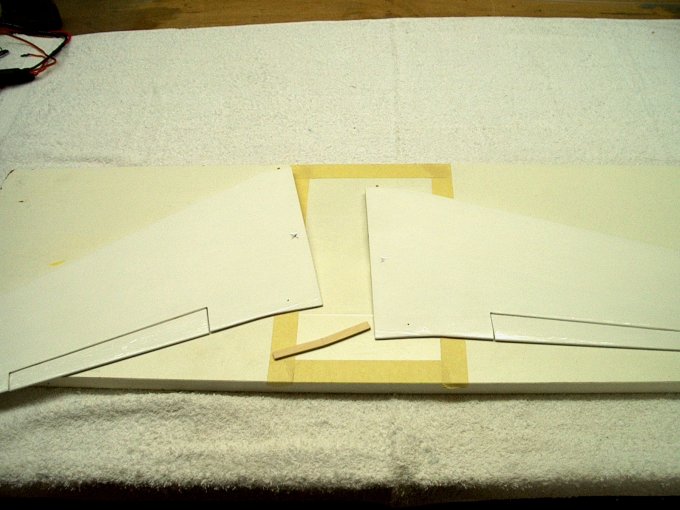

109 - Wing components ready to go.

| |

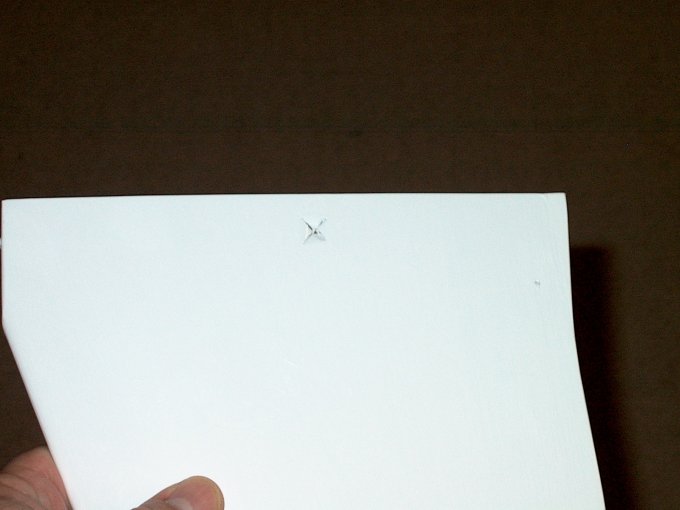

110 - Root spar drilled with a 3/32 bit to

add more strength once glued. | |

111 - Epoxy added to main spar and root,

then spar is installed. | |

112 - Spar inserted up to center line.

| |

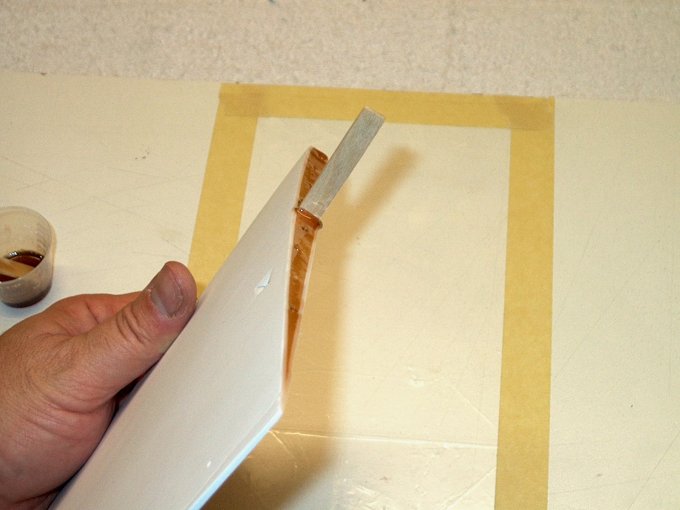

113 - 15 Minute Epoxy added to other wing

root and exposed spar. | |

114 - Wing halves joined and excess epoxy

cleaned up with denatured alcohol. | |

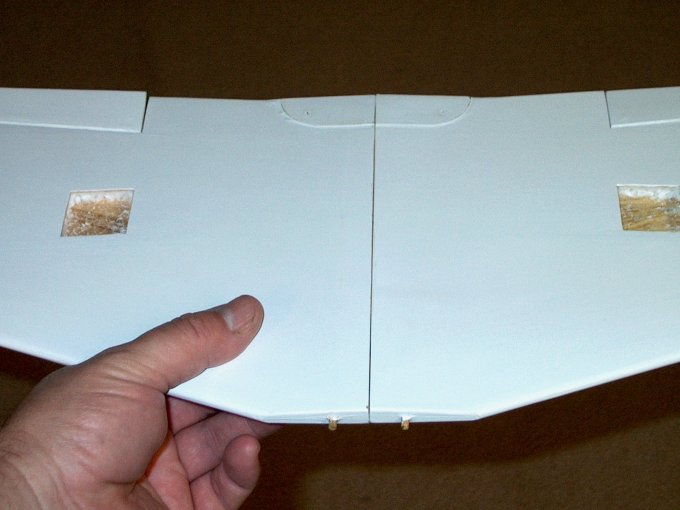

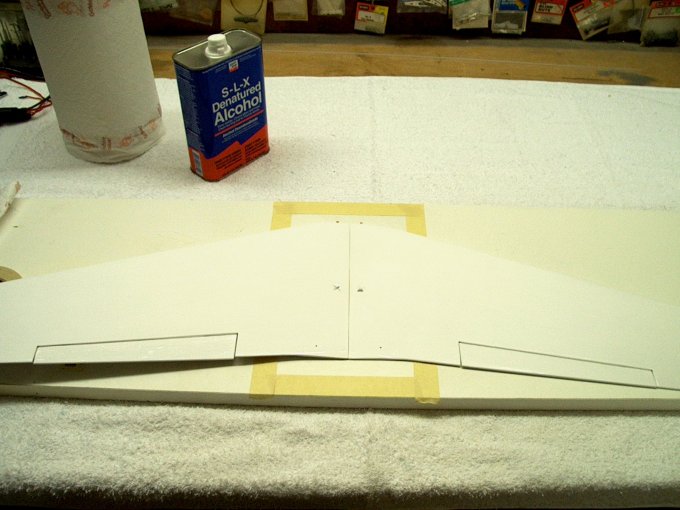

115 - Wing assembly laid flush on table to

keep it aligned. Both halves were pressed down on the table to

make their joint even, so incidence would be aligned.

| |

116 - Wing tip propped up at proper

dihedral while epoxy sets. | |

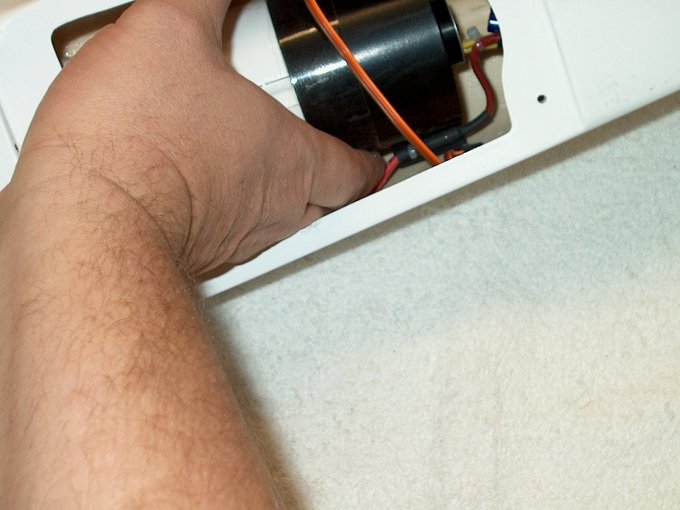

117 - Final fan assembly... cleaning up

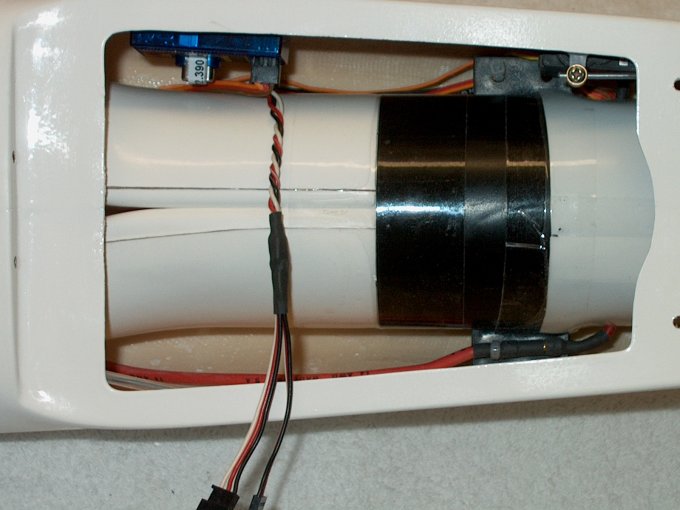

the wiring with ties. | |

118 - Rear view of wiring tied

down. | |

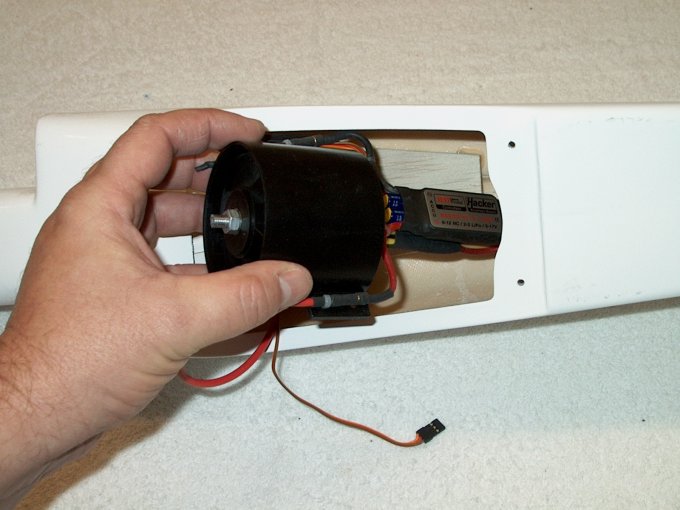

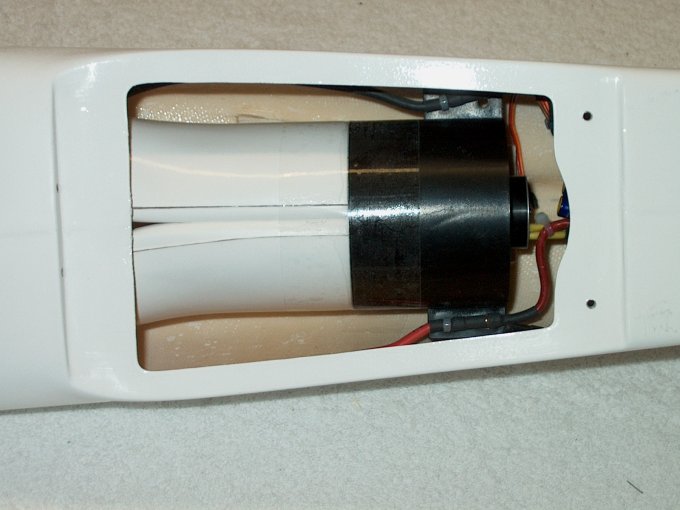

119 - Final installation of the fan

assembly. | |

120 - The power wire was pulled across the

top of the duct (inverted, so it's seen on the bottom.) This

routed it right into the cockpit bay.

| |

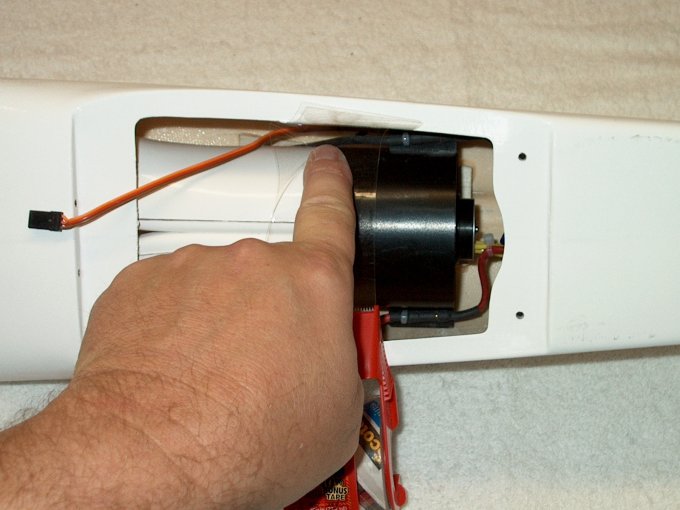

121 - Heavy duty packing tape used to

attach fan to duct. | |

122 - Tape applied on one half from the

opening. | |

123 - Tape pushed down to inside

area. | |

124 - Tape trimmed and other end worked

around. | |

125 - End is tucked under the

bottom. | |

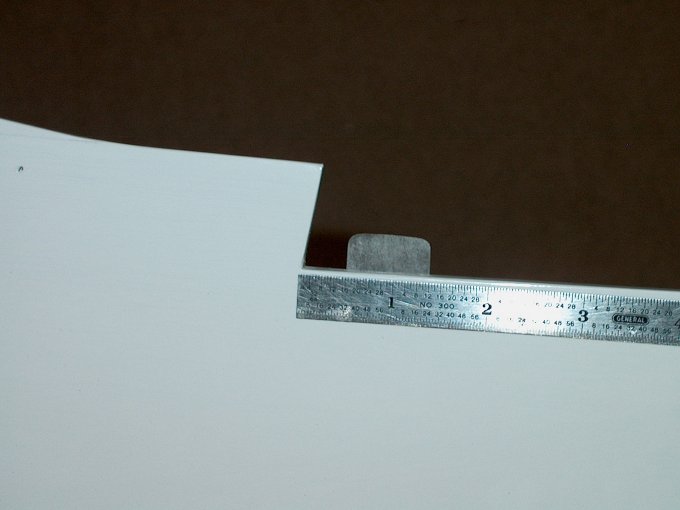

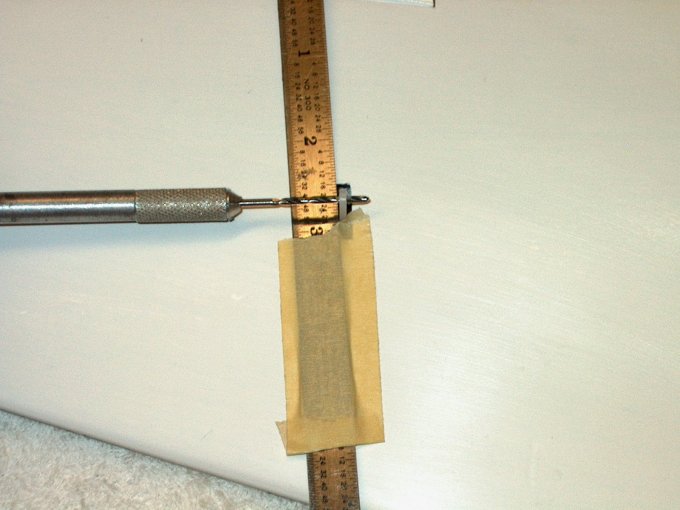

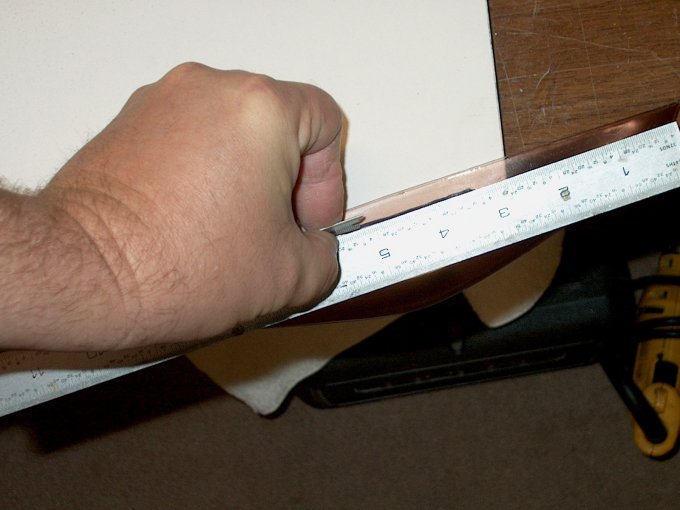

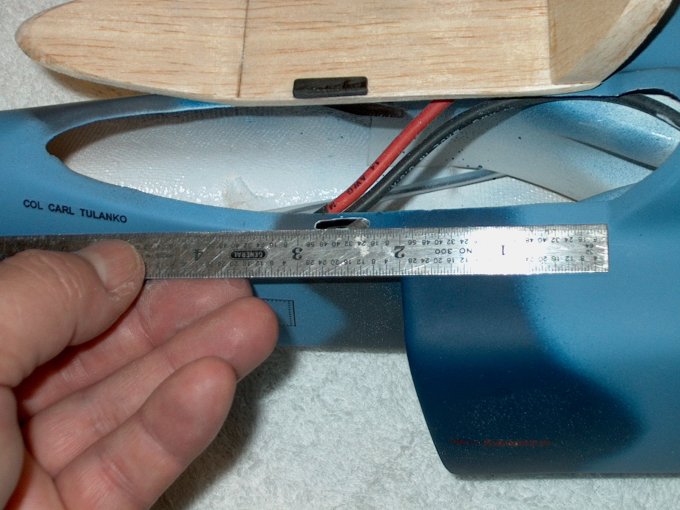

126 - A ruler taped to a stick was used to

push the remaining tape around the top of the duct.

| |

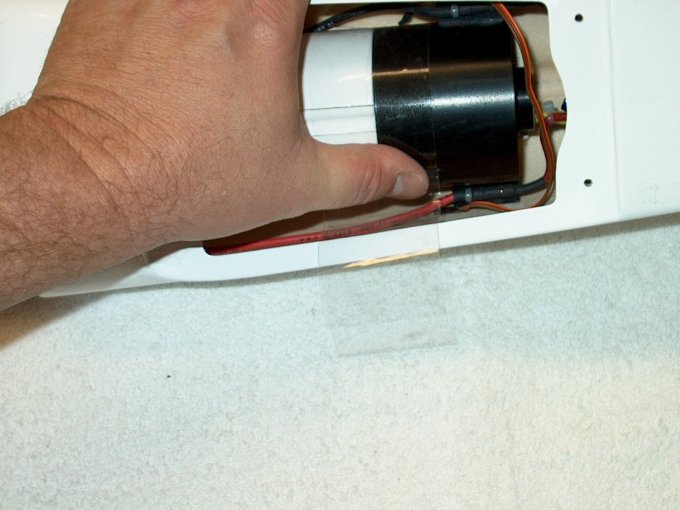

127 - Fan assembly installed, showing ESC

that will reside in the duct. | |

128 - Top view showing fan connected to

ductwork. | |

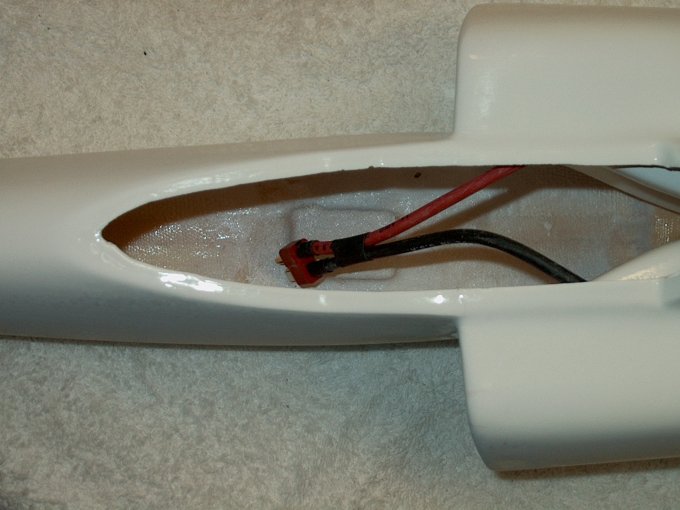

129 - Battery wires that were routed into

the cockpit compartment. | |

130 - Battery harness shown with enough

length to reach anywhere in the compartment.

| |

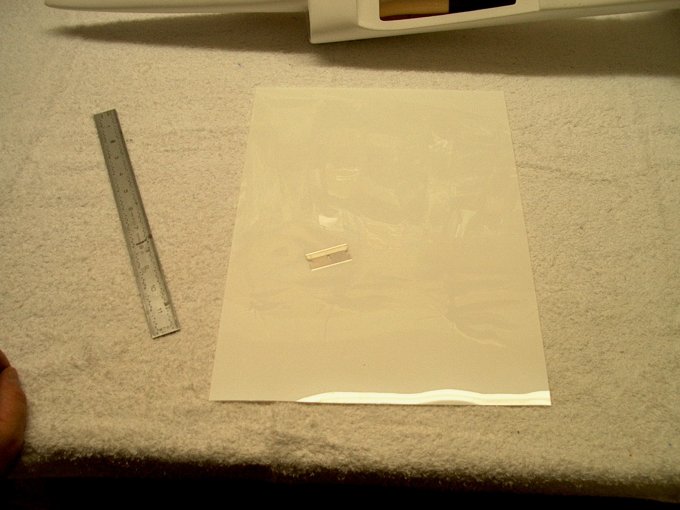

131 - A piece of poster board purchased at

a craft store will be sued for the final ductwork. NOTE:

Poster board cardboard is supplied with the kit.

| |

132 - Wiring removed from battery leads

and routed inside fan so the exhaust duct can be

fitted. | |

133 - Initial piece of 10" x 15" cut from

sheet. | |

134 - Shape was rough cut...

| |

135 - ... then fit to rear of fan. This

will take a while to fit and was a bit challenging due to the

taper in the duct, so just take your time.

| |

136 - Final sheet ready for assembly. I

used the first sheet to mark up and abuse, then cut a final

pattern from the first sheet, that way there were no wrinkles

in the duct. | |

137 - The same heavy duty clear packing

tape that was used to mount the fan was used to roll the

tube. | |

138 - A piece of aluminum tube was used to

cut exit holes fro the ESC wires. | |

139 - Holes cut, tube ready to

install. | |

140 - Duct tube folded in half for

installation, then inserted from the rear.

| |

141 - ESC wires routed through the punched

holes. | |

142 - Packing tape used to hold the

exhaust duct in place. | |

143 - Exhaust duct installed

| |

144 - End of exhaust area trimmed even

with the tail cone. | |

145 - Exhaust finished.

| |

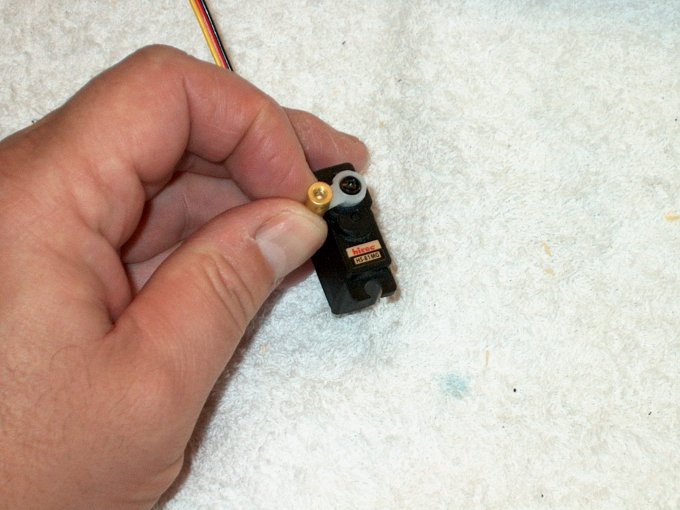

146 - The servo horn was installed and the

EZ Connector supplied with the model was installed in the

outer horn hole. The hole needed to be enlarged for the

threads. Make sure it turns freely once installed and use

Loktite on the threads. | |

147 - Servo side is cleaned with

acetone. | |

148 - Mounting tape is applied to the

servo side. | |

149 - Servo is then installed on the

sidewall. Make sure you clean this area with acetone before

mounting the servo. | |

150 - Elevator servo installation

completed. Note that the washers supplied with the gold

connector were not used as they would have caused binding on

the servo arm when rotating. | |

151 - Hole is opened on side of fuselage

for the elevator control rod. | |

152 - Hole shown below... NOTE: It was

extended to 7/8" in length later on during the build. It is

3/32" wide and the bottom is 3/8" above the horizontal

stab. | |

153 - Clevis installed on a new 2-56 x 12"

long pushrod. | |

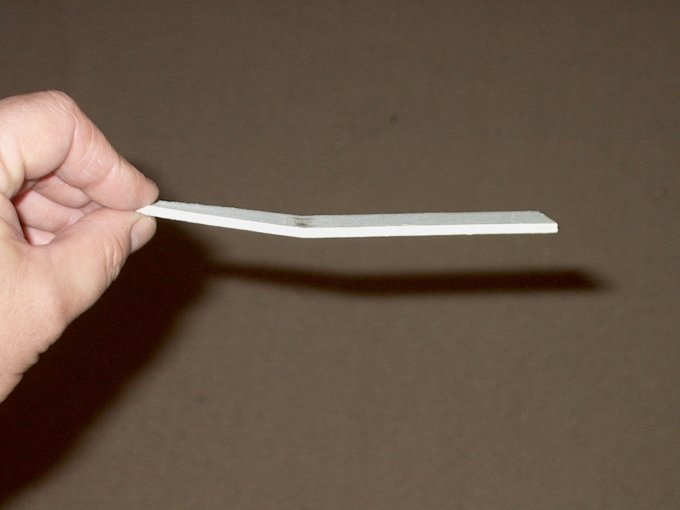

154 - Rod bent and shaped for

opening. | |

155 - Picture shows rod shape and points

to bend. | |

156 - End was slightly bent to align with

the EZ Connector for the servo. | |

157 - Rod final installation.

| |

158 - Pushrod installed.

| |

159 - Loktite added to EZ Connector set

screw. | |

160 - Turn on your radio, then center the

servo, center the elevator and tighten the screw.

| |

161 - Inside of fuselage cleaned for

receiver location. | |

162 - Original receiver installed in the

following location. | |

163 - Originally the antenna was installed

in a tube and installed partially up in the nose and the rest

of the antenna out the back of the fuse. This was later found

to produce glitching and changed. NOTE: If you decide to

install your antenna this way you must do a range check. We do

not recommend you install your antenna this particular way for

the Sniper. | |

164 - Do not use the antenna tube if you

have glitching problems and always range check

| |

165 - The rest of the antenna out the back

of the fuse. This was later found to produce glitching and

changed. | |

166 - Tube shown in place...

| |

167 - ...and epoxied to the side of the

fuselage | |

168 - Y-Connector added for aileron servo

wires... build completed. | |

169 - Basic fuselage assembly

completed. | |

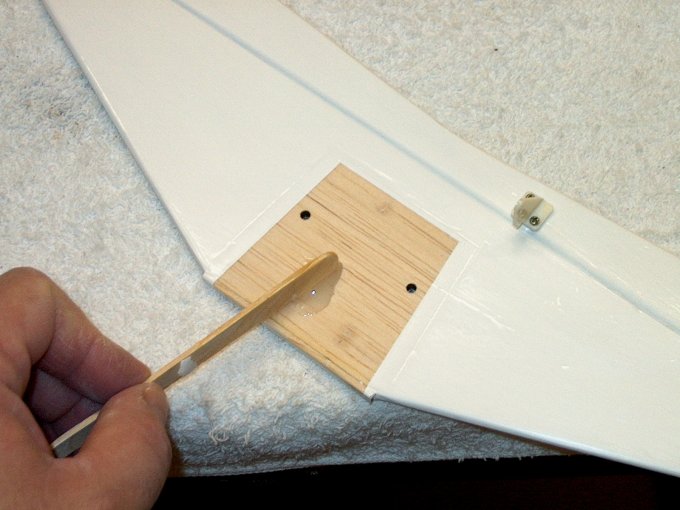

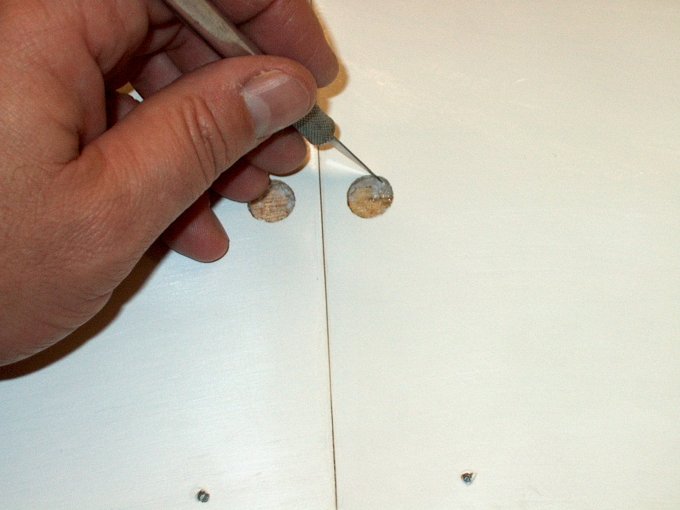

170 - Aileron servo area was soaked with

thin CA to strengthen, then sanded smooth.

| |

171 - Area cleaned with denatured

alcohol. | |

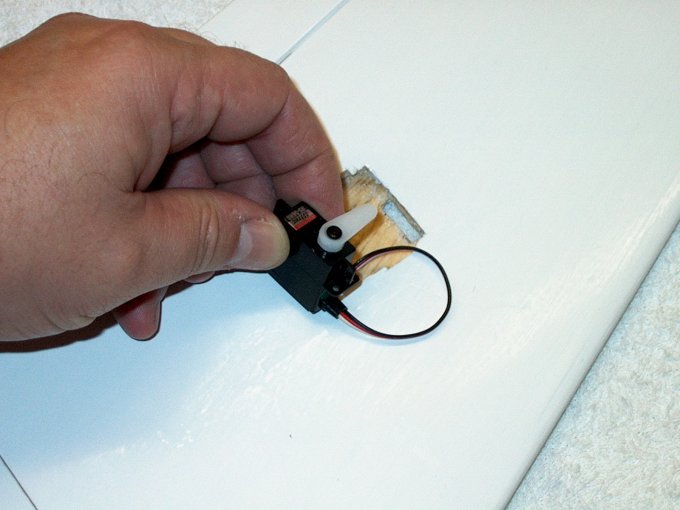

172 - Servo temporarily fit to cut horn

slot. | |

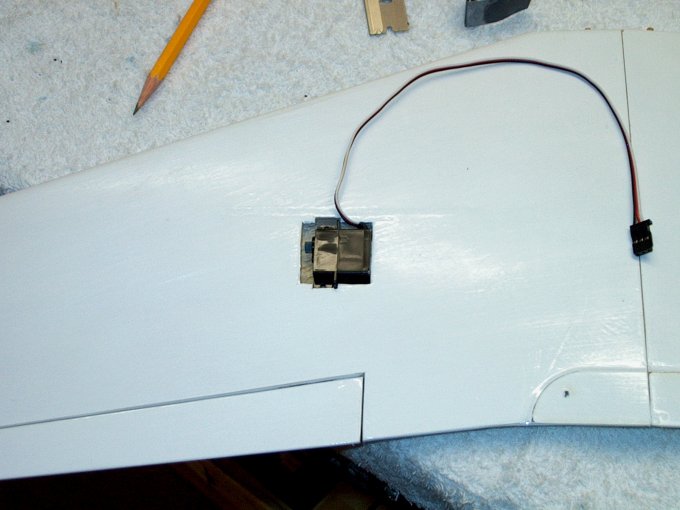

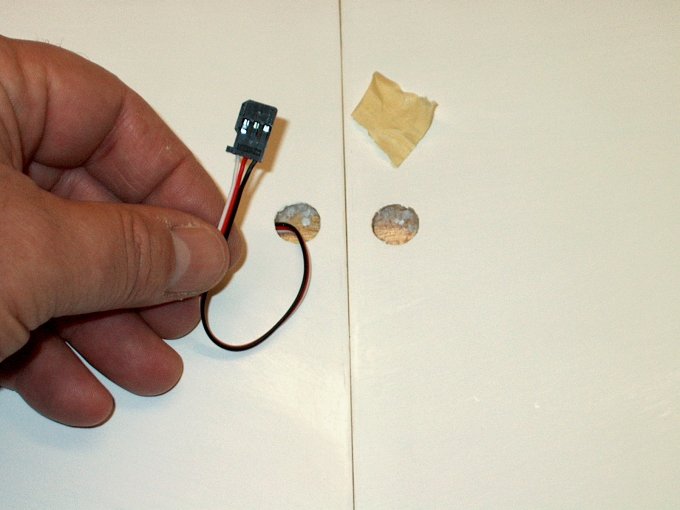

173 - Servo wire holes opened up in the

wing. | |

174 - Servo plug removed and wires run

through pre-cut channel. | |

175 - Wire pulled throgh from aileron

servo bay. | |

176 - Plug re-installed on servo

wires. | |

177 - Servo arm installed.

| |

178 - Servo cleaned with acetone and

double sided tape added. | |

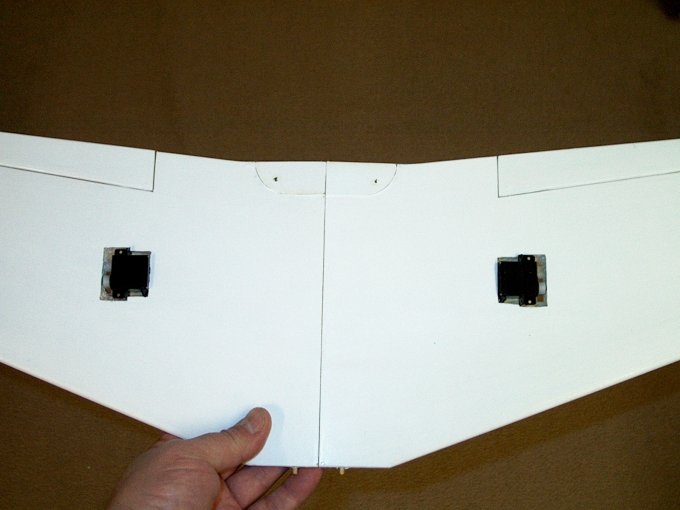

179 - Servos installed in both

wings. | |

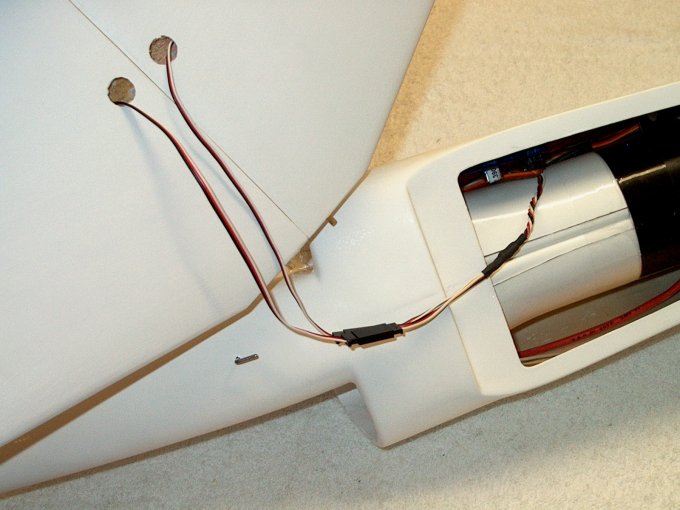

180 - Aileron wires exiting wing.

| |

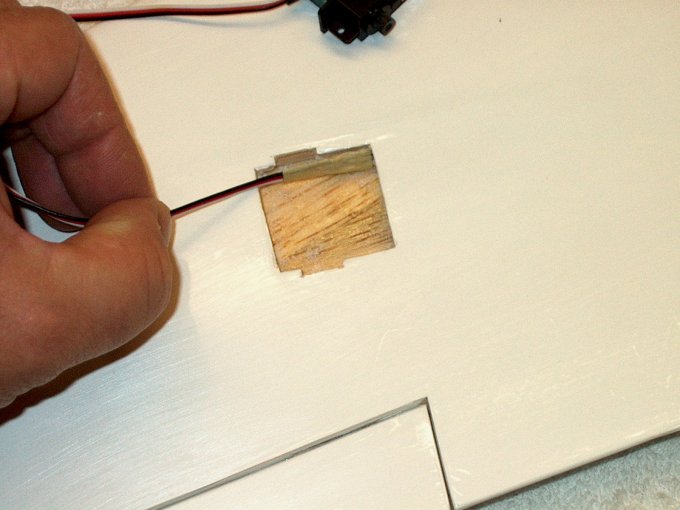

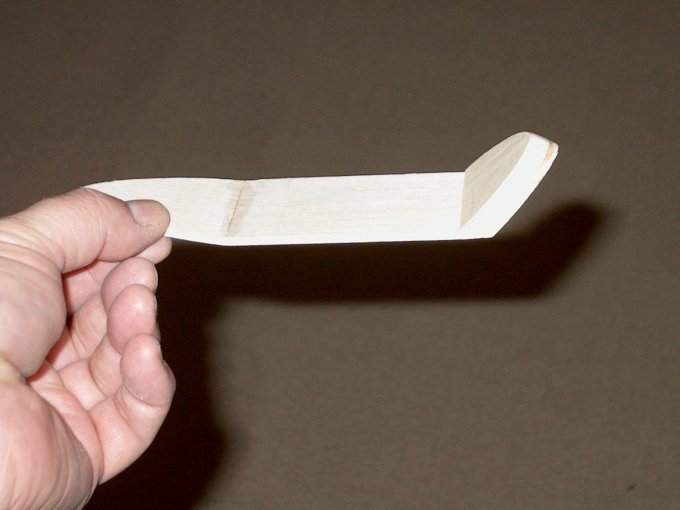

181 - Shaping the aileron pushrod. A

Z-bend was used on one end. | |

182 - A ruler was used to align the

pushrod while the aileron horn was installed.

| |

183 - Horn bolts were trimmed

flush. | |

184 - Left aileron servo and pushrod

assembly completed. | |

185 - Installing the right side pushrod.

Note the horn did need to be drilled to accept the

pushrod. | |

186 - Aileron control completed.

| |

187 - Tow hook made from extra rod and

installed in pre-drilled location. | |

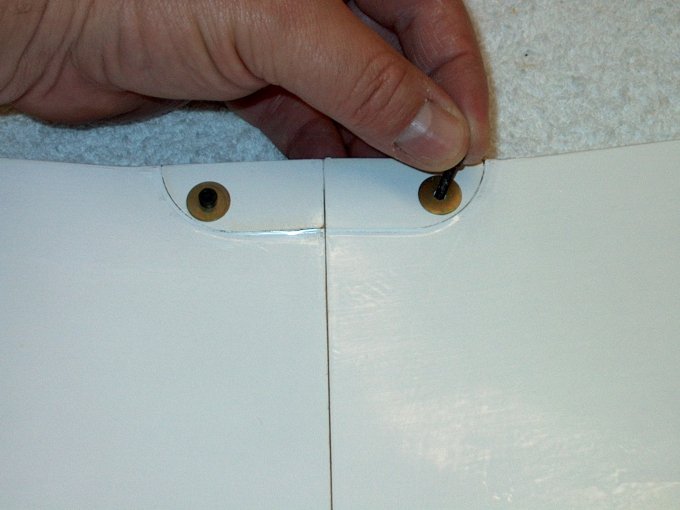

188 - Wing bolts installed.

| |

189 - Aileron servos hooked up to the

receiver. | |

190 - Wing leading edge dowels plugged

into front of fuselage. | |

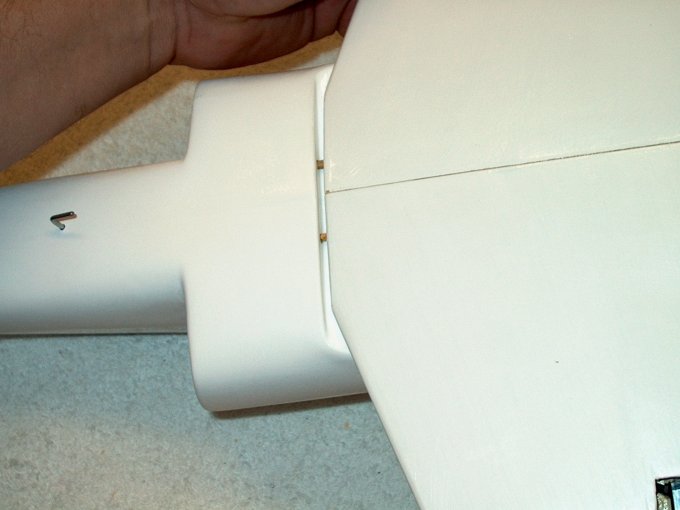

191 - Wing mounted to fuselage.

| |

192 - Wing assembled.

| |

193 - Cutting out the canopy. It was

scored with a razor. | |

194 - Canopy cut out along score

marks. | |

195 - Canopy sanded and shaped.

| |

196 - Canopy finished and ready to

install. | |

197 - Canopy placed on fuselage for size.

It will be permanently mounted later.

| |

198 - HET-RC Sniper basic construction

completed. | |

199 - Elevator throws are as follows: High

Rates: UP 8mm / DOWN 6mm Low Rates: UP 5.5mm / DOWN 4mm

| |

200 - Aileron Throws: High Rates:

LEFT/RIGHT 8mm / DOWN 6mm Low Rates: LEFT/RIGHT 6mm / DOWN 4mm

| |

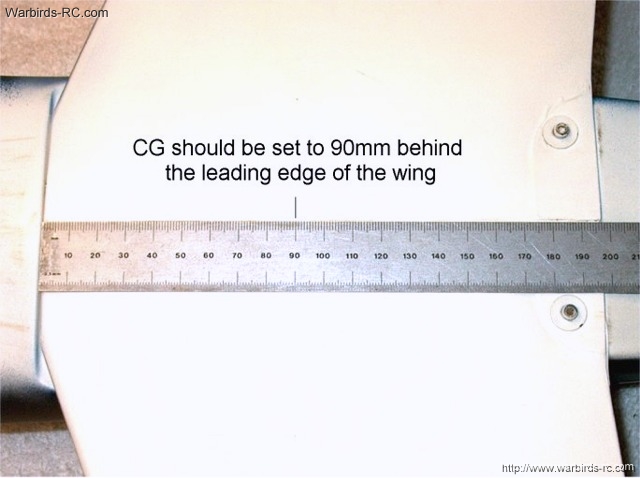

201 - The C/G (Center of Gravity) point is

90mm from the base of the leading edge of the wing. You may

opt to move it forward or back, but based on our findings 90mm

is the best starting point. | |

202 - Bottom painted flat white.

| |

203 - Started the top side using flat

light sky blue. | |

204 - Second color added... dark

blue. | |

205 - Model colors finished.

| |

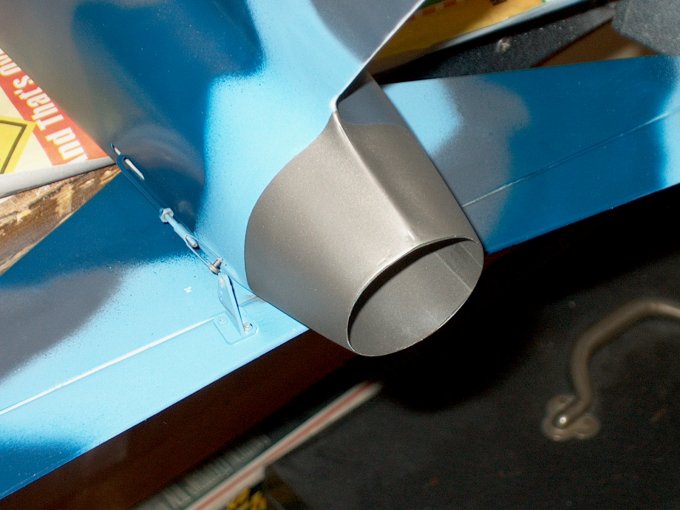

206 - Painted the tail cone with "Burnt

Metal". | |

207 - Tail cone finished.

| |

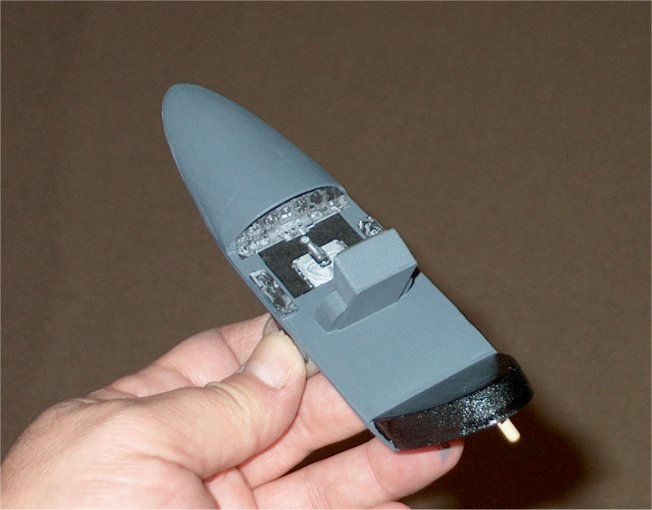

208 - Canopy /Cockpit Build: NOTE: If you

are going to place the batteries in the wing saddle area, the

canopy can be simply glued to the fuselage with canopy glue.

The following steps will show how to build a simple removable

canopy. A base plate was traced onto 1/8" balsa.

| |

209 - A center line was drawn where the

canopy bend is located. | |

210 - A saw was used to cut a "bend slot"

... do not cut all the way through.

| |

211 - Balsa cockpit base placed on the

fuselage. | |

212 - Cockpit held down in place while

using thin CA to glue the joint. | |

213 - Cockpit angle finished.

| |

214 - The seam was filled all the way

across and the angle was measured to make sure it fit the

cockpit. | |

215 - Beveling the front edge.

| |

216 - Cockpit plate fit to the

canopy. | |

217 - Drawing a back plate.

| |

218 - Plate cut from 1/8" ply.

| |

219 - Plate beveled and checked for

fit. | |

220 - Back plate pressed into place at

correct angle. | |

221 - Back plate glued to cockpit.

| |

222 - Plate glued then canopy painted with

thin CA. | |

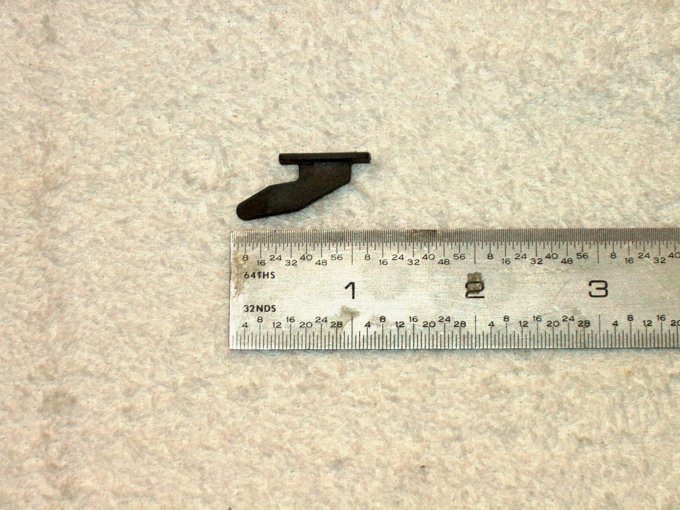

223 - 1/4" Think piece of balsa added to

rear. | |

224 - I used a Bob Violett canopy mount,

but you could also make them from 3/32" ply using the shape

below as a reference. | |

225 - Canopy plate slotted. Fuselage

slotted with a Dremel cutting wheel.

| |

226 - Canopy mount installed.

| |

227 - Measurement showing location of the

slots. | |

228 - Canopy mounted and held in place,

then drill used to bore through the canopy and

fuselage. | |

229 - Installing an alignment pin from

1/8" dowel. | |

230 - Pin installed.

| |

231 - A piece of 1/4" x 1/2" balsa cut and

fit to opening below, lightly wedged in place. CA applied to

the top only. | |

232 - Canopy set in place, lifting the

rear, pushing all the way back, then dropping the rear on the

balsa piece from the previous step.

| |

233 - Dropping rear forced the piece to

glue on canopy for a perfect fit. This piece of balsa will

insure the canopy will not twist under stress of

flight. | |

234 - Cockpit painted.

| |

246 - Cockpit detailing was done to model

an F-5 | |

235 - Canopy Glue used to mount the canopy

to the cockpit. Tape is used to hold it in place until it

dries. | |

236 - Cockpit plate installed on

canopy. | |

237 - Canopy installation completed. It's

a simple way to mount it and the canopy should not come off

during flight as it needs to move forward and up to be

removed. | |

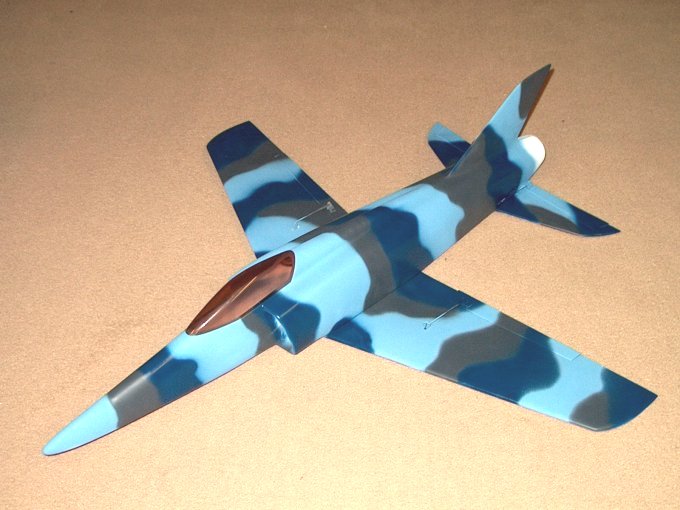

238 - HET-RC Super Sniper ARF Model

finished (FRONT VIEW) | |

239 - (FRONT / TOP VIEW)

| |

240 - (REAR VIEW)

| |

241 - (RIGHT SIDE)

| |

242 - (LEFT SIDE)

| |

243 - (NOSE PROFILE)

| |

244 - (RIGHT ANGLED VIEW)

| |

245 - (TOP VIEW)

| |

247 - The completed HET-RC Sniper from

Warbird-RC | |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |