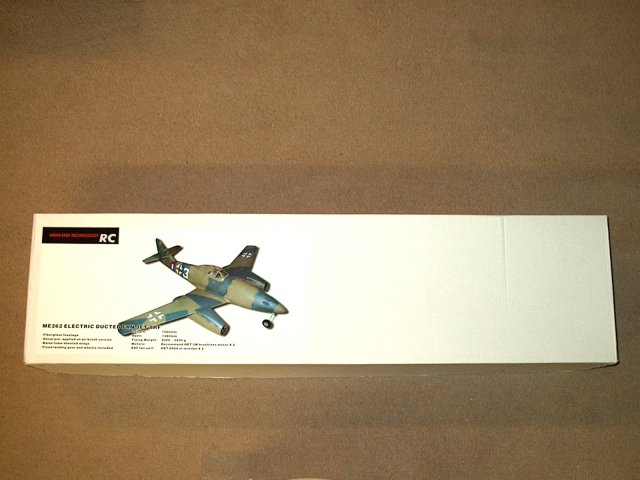

The HET-RC ME-262 Twin Minifan EDF jet as

it comes from Markos at Warbirds-RC

| |

Opening the box reveals well packed

contents | |

All the parts shown are included in the

kit, even fixed landing gear | |

This kit will be retrofitted with some of

the "New" RA-260 Retracts from Airpower and Warbirds-RC

| |

Opening the main bag reveals all the

components necessary to get these air retracts flying

| |

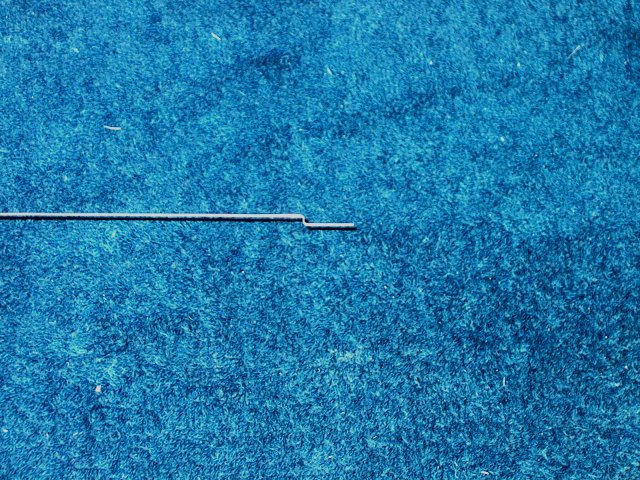

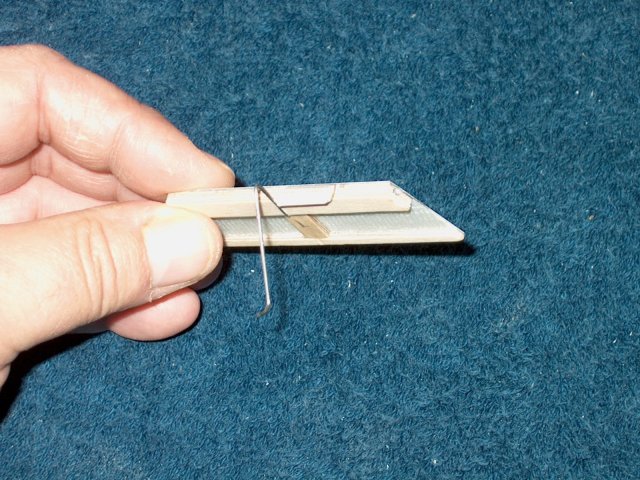

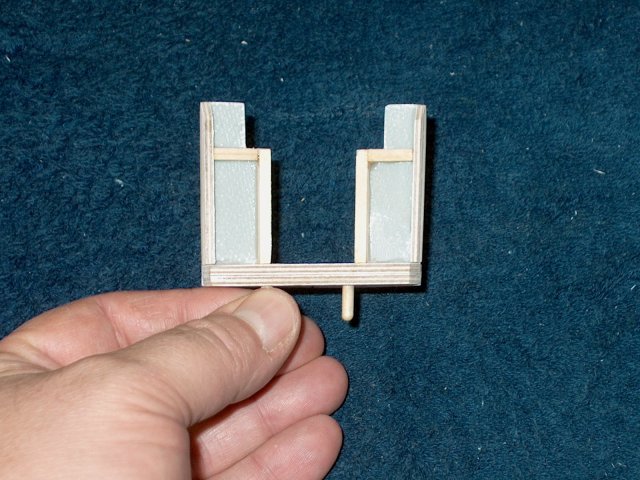

The retract units themselves are very

small, however, they are stout. The units are made from very

thick aluminum alloy and are much sturdier than other brands

of retracts we have used in the past. They also come with 1/8"

gear wire | |

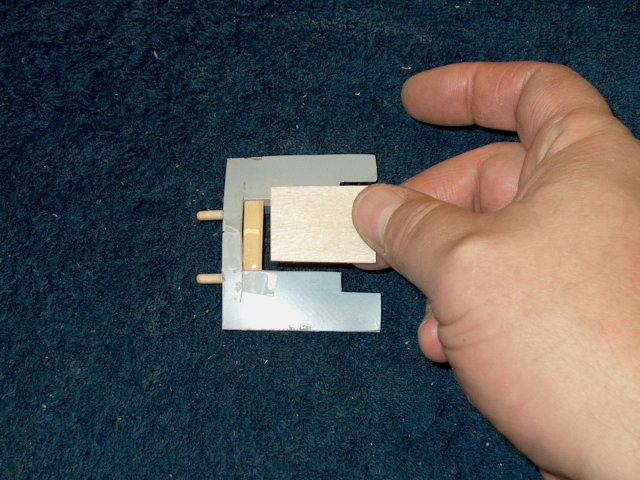

The entire Airpower RA-260 retract setup

weighs only 3.5oz and that includes the 1/8" gear wires and

all air assist accessories | |

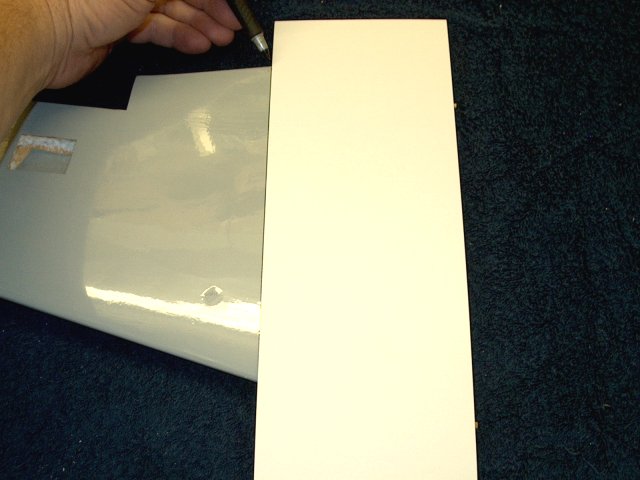

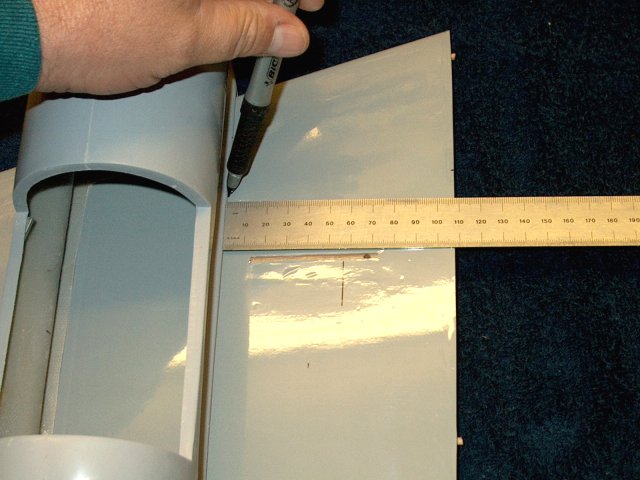

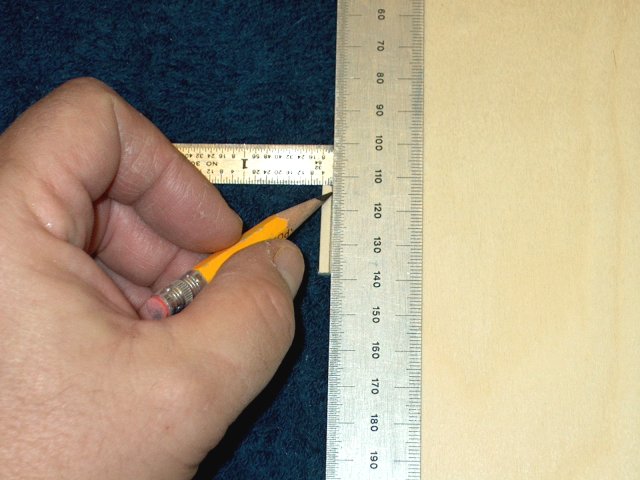

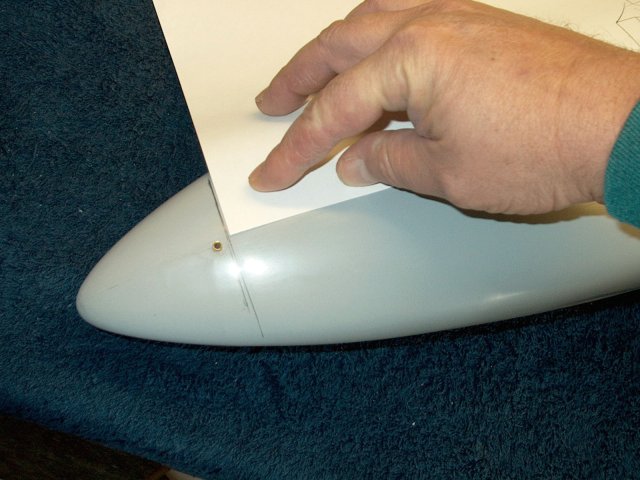

Construction begins by finding the

location of each wing Nacelle. A piece of cardboard is

included in the kit and is 110mm wide, which is a bit too

wide. Hold the cardboard flush with the end of each wing and

draw a reference line | |

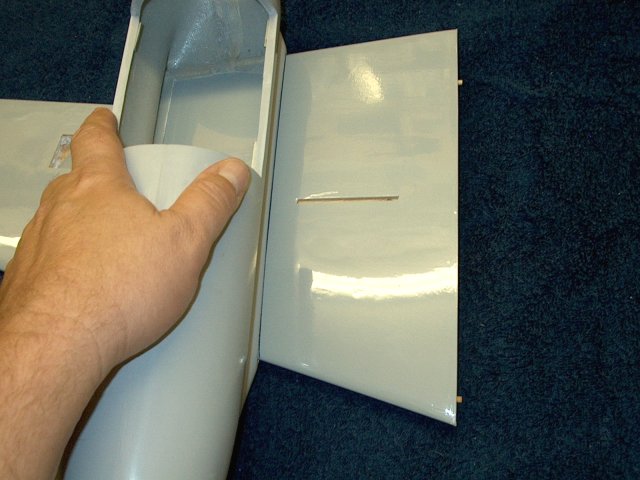

Install a nacelle on each wing up to the

110mm line. Make sure you use the correct nacelle as there is

one for each side | |

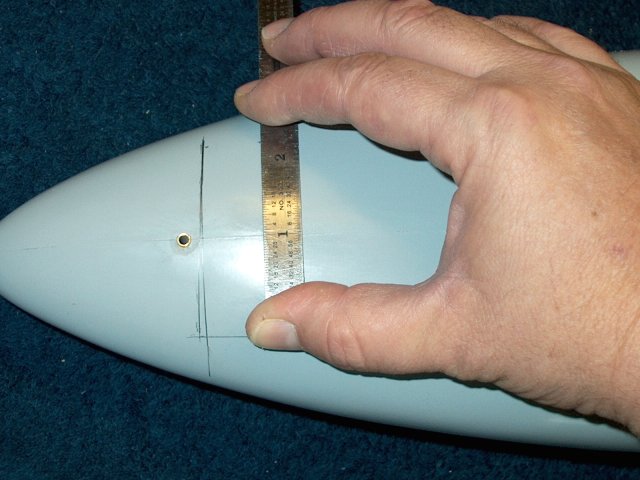

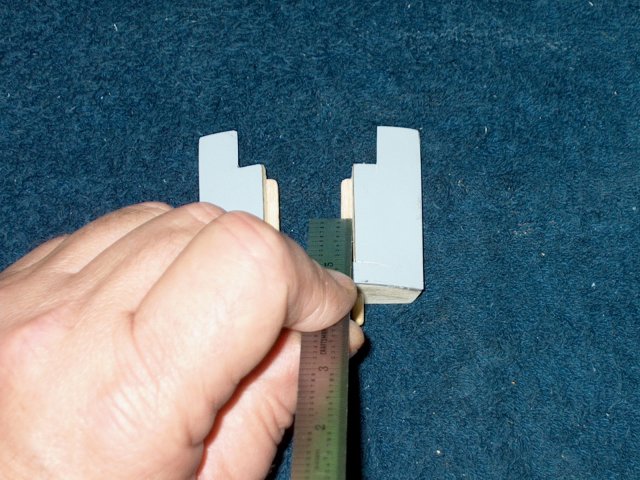

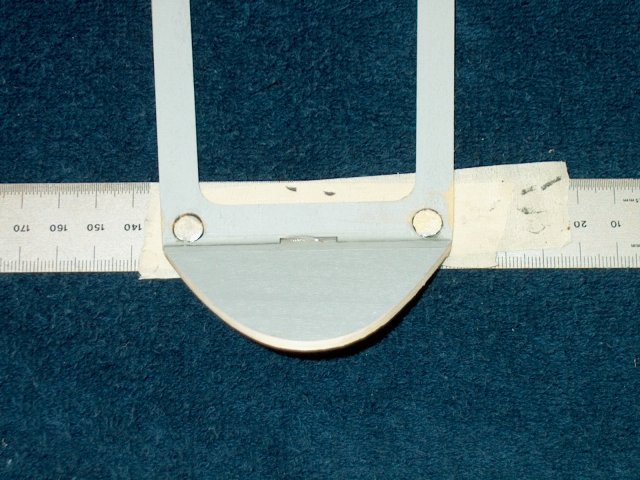

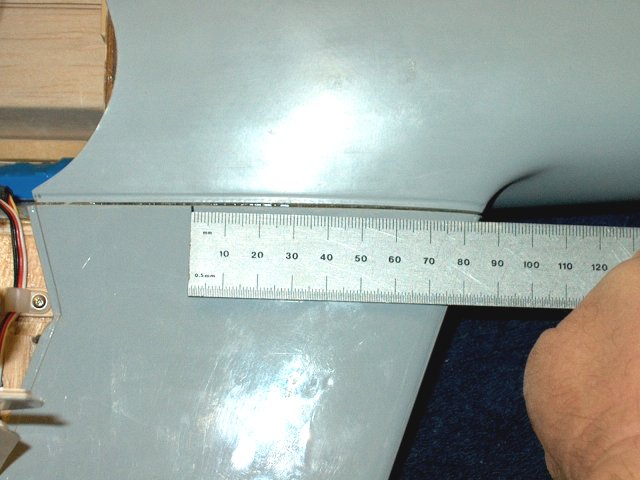

Measure the side of the nacelles at 108mm

from the end of each wing root | |

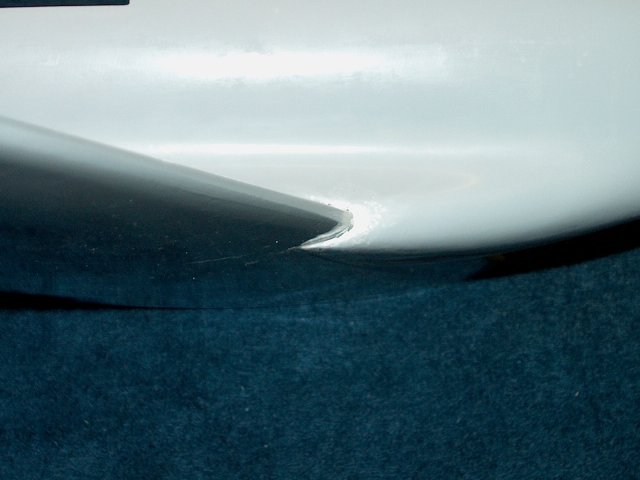

The 108mm measurement moves the nacelle

closer to the fuselage as the original 110mm caused aileron

binding agianst the rear of the nacelle as shown

| |

Draw a new outside line, which should be

2mm closer to the wing root. Make sure the rear of the nacelle

clears the Aileron area | |

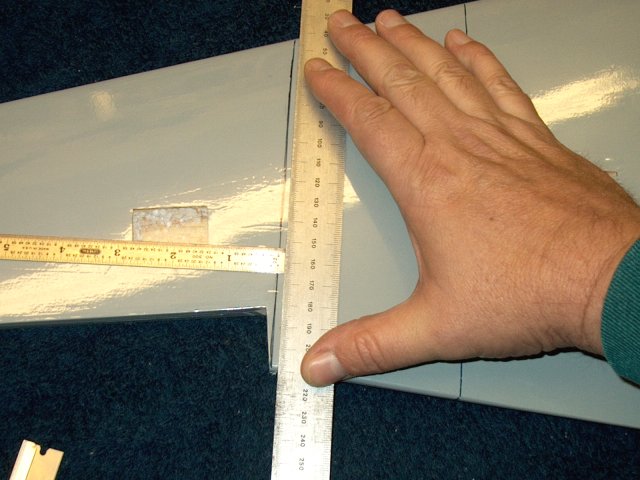

Draw on the top of the wing the location

of each nacelle | |

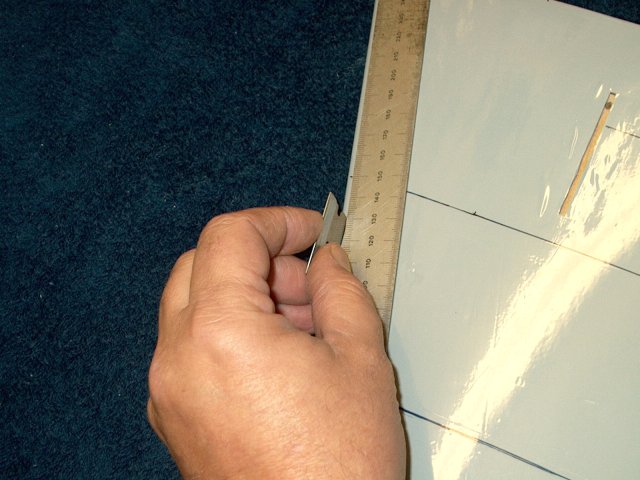

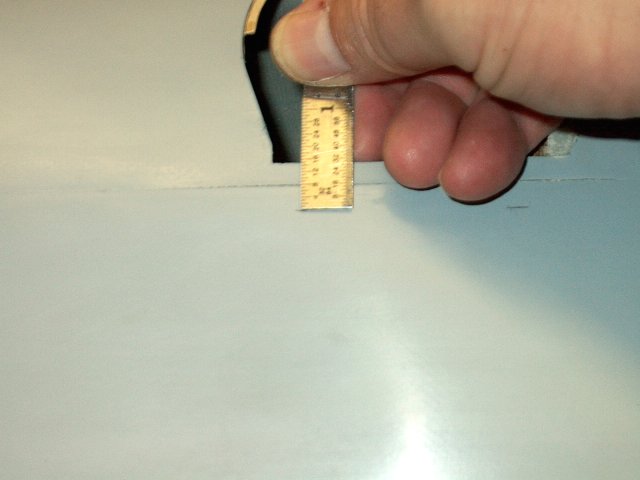

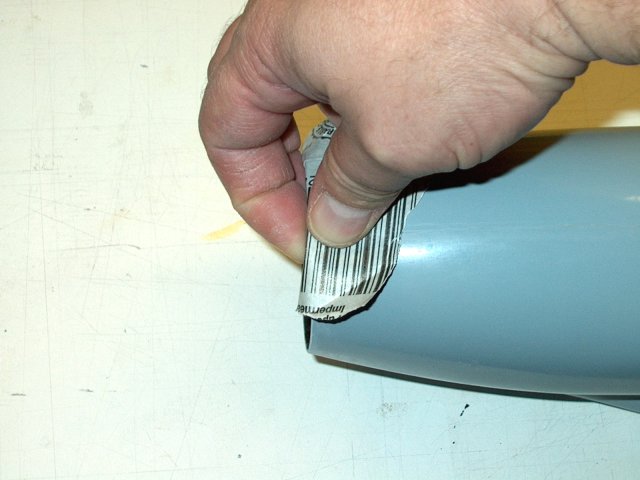

Measure 1/8" inside the outer line on the

bottom of the wing and cut to remove the covering

material | |

Cut along the leading and trailing edge,

making sure you leave a good 1/8" or more for

re-covering | |

Remove the bottom covering as shown

| |

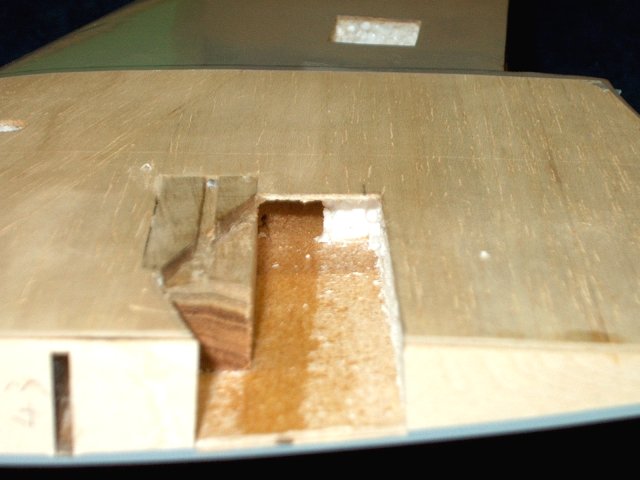

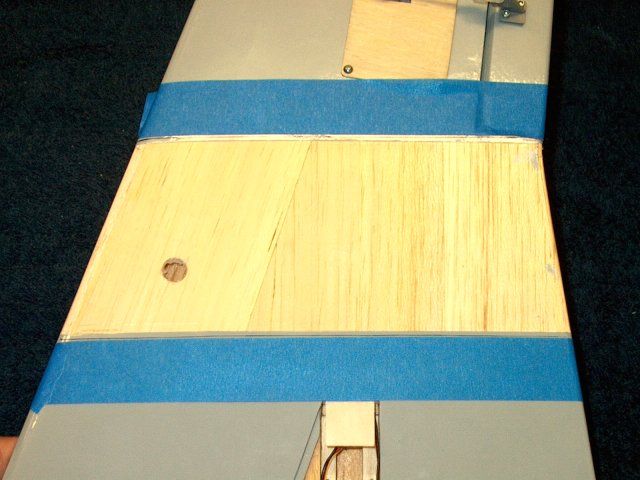

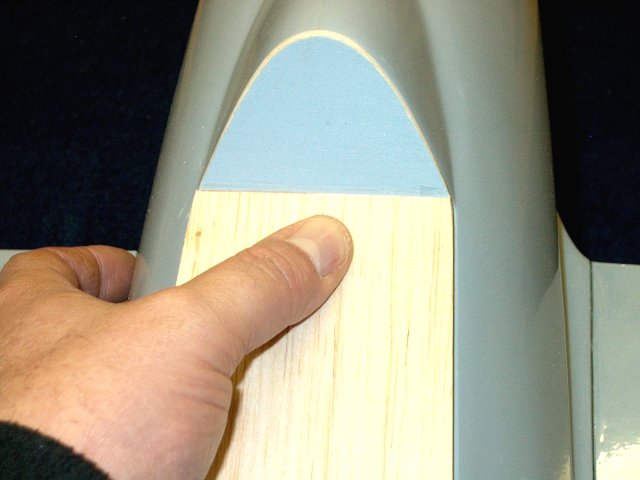

The covering reveals the fixed gear

mounting block, which is used as reference for retract

installation | |

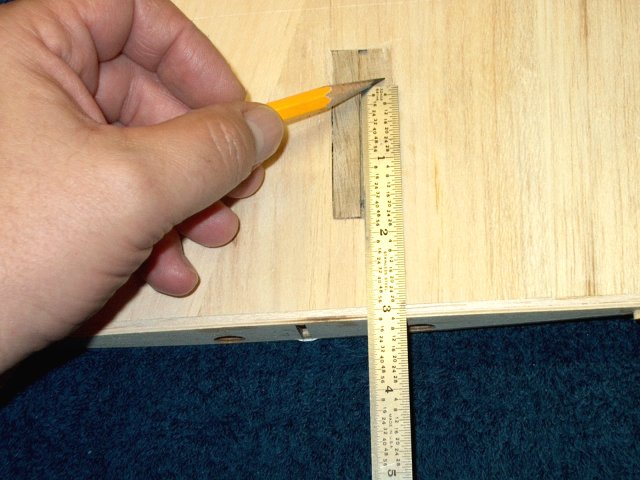

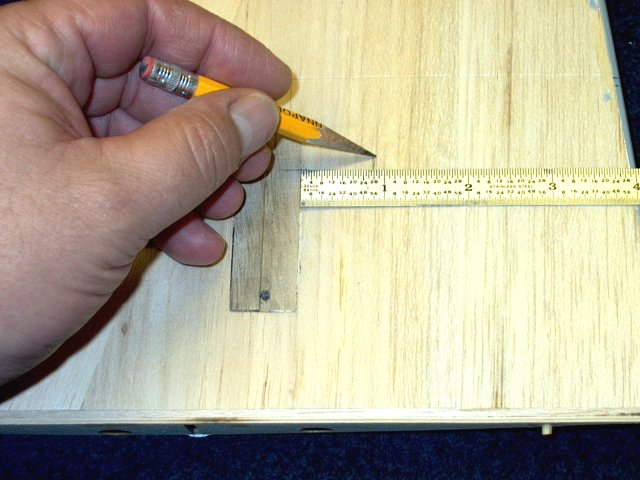

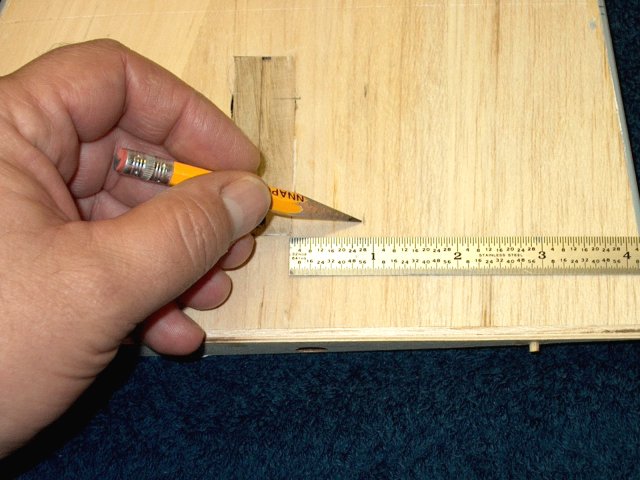

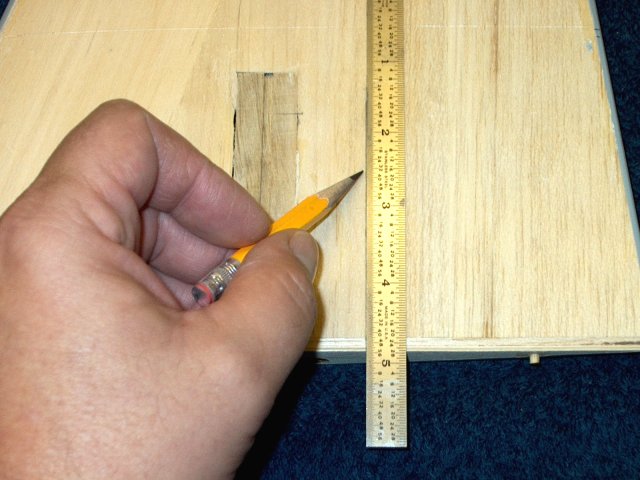

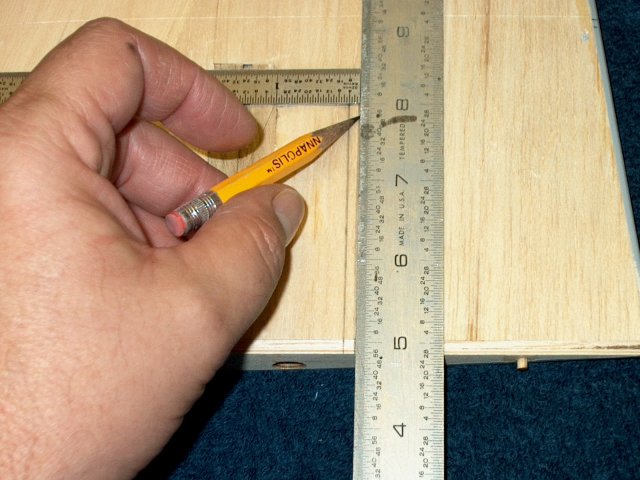

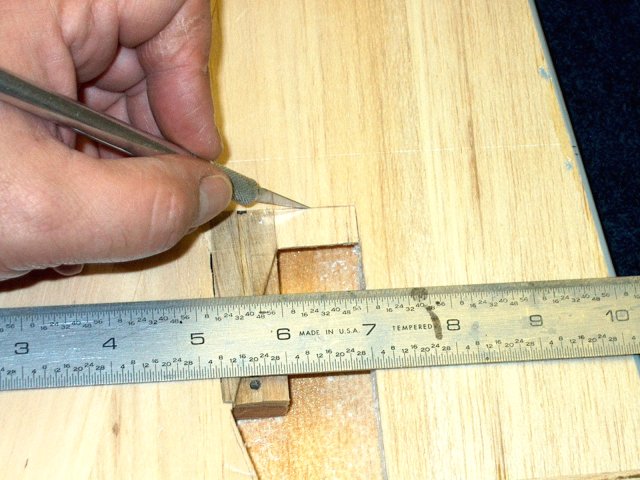

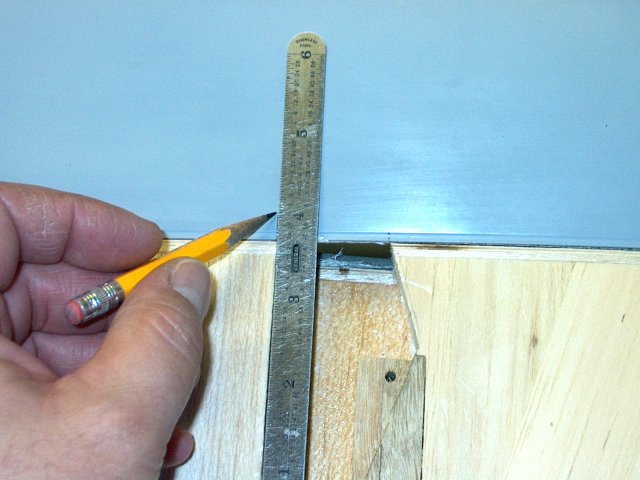

Measure 3 1/4" from the root of the wing

to the rear side of the hardwood block and make a mark

| |

Measure 7/8" from the rear of the block

and mark this location | |

Make a second mark at 7/8" as shown

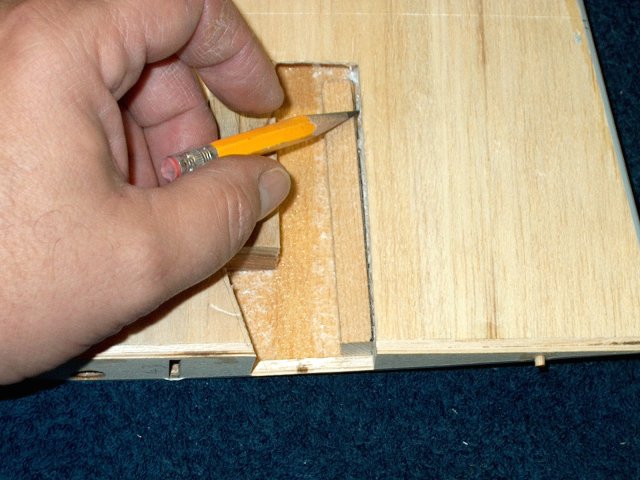

| |

Draw a line through both the 7/8" marks to

the root of the wing | |

Draw the horizontal top line at the 3 1/4"

mark across as shown | |

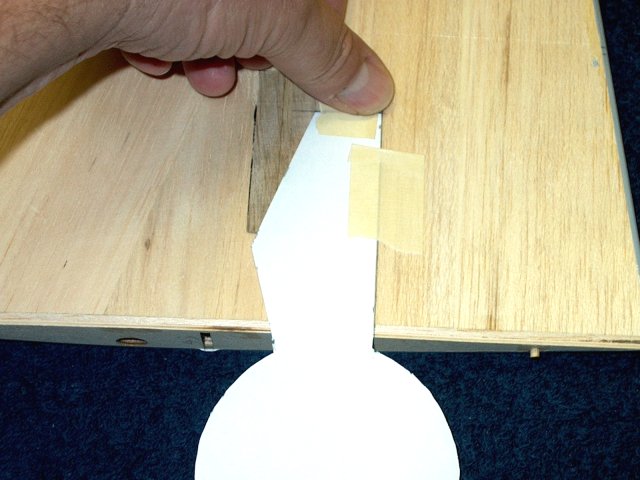

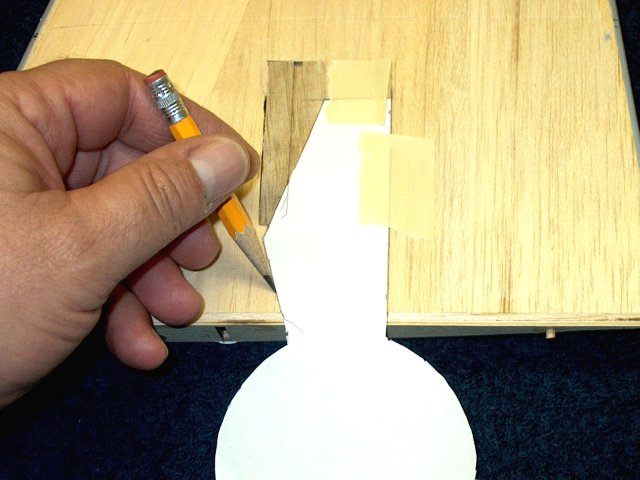

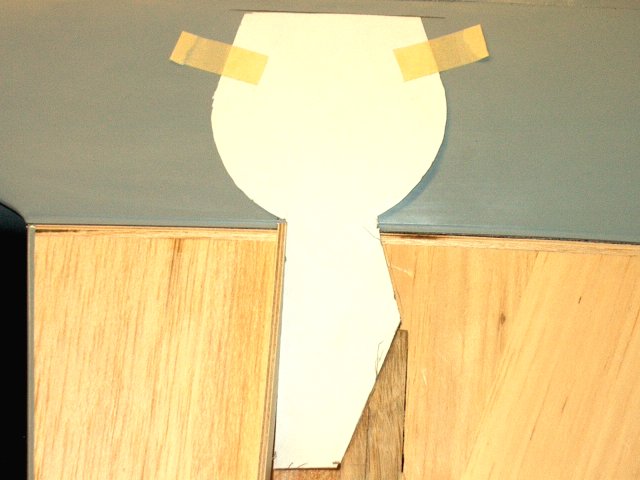

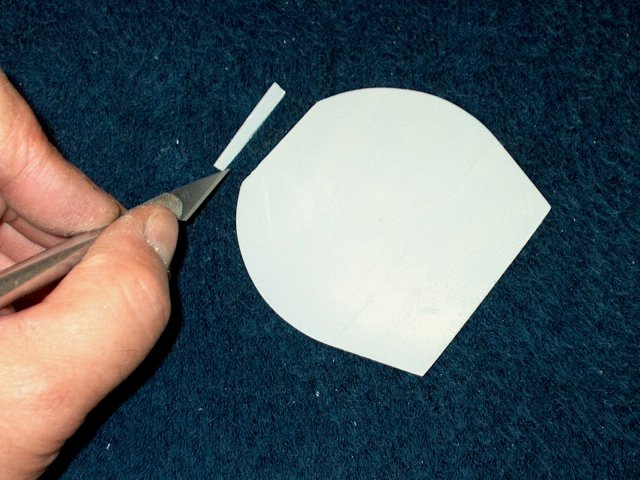

Cut the Main Door Cutout pattern from the

templates and place the back of the door along the vertical

line you drew and the top should be lined up with the 3 1/4"

horizontal line | |

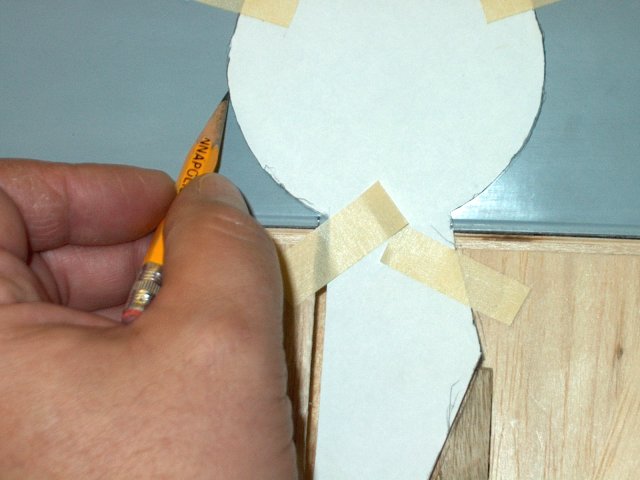

Transfer the front pattern of the door to

the wing as shown | |

Mark and draw a second line at 1/8" past

the first line to allow for the thickness of the Secondary

Spar | |

Cut the balsa from the area that was just

marked | |

Remove the balsa sheeting and foam from

the area | |

Check your measurement and make sure it

shows 3 1/4" | |

The Trailing edge of the block to the rear

should measure 1" as shown | |

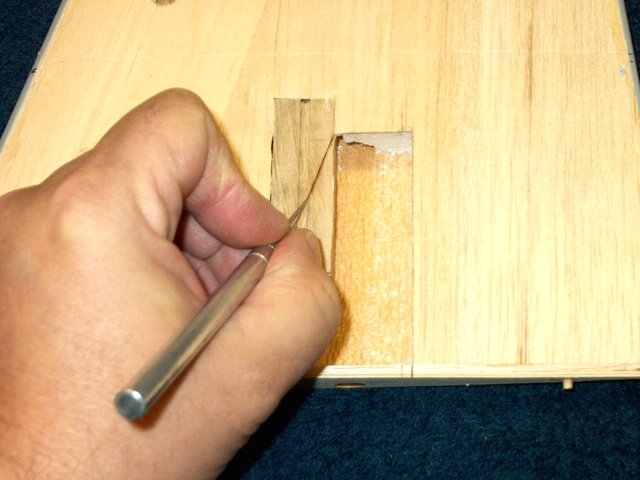

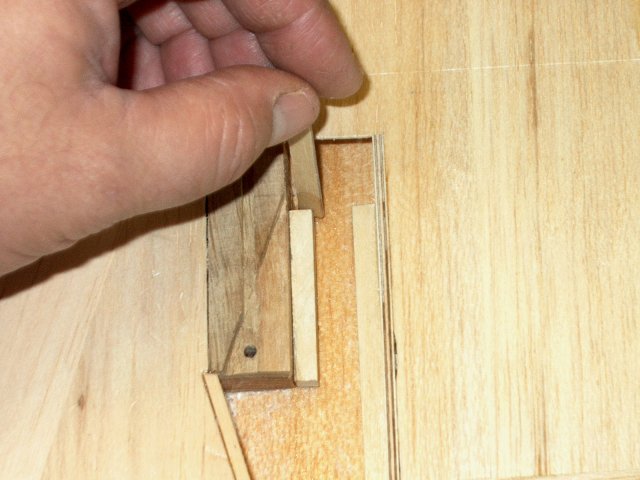

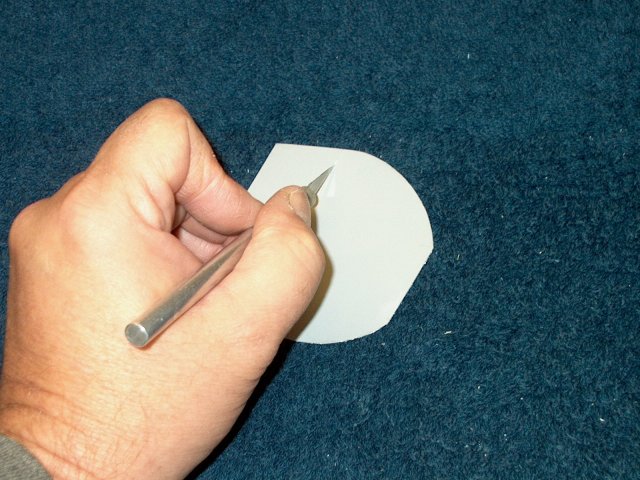

Use an exacto knife to cut into the

hardwood block along the door pattern line

| |

A chisel cutter can be used to cut loose

some of the wood | |

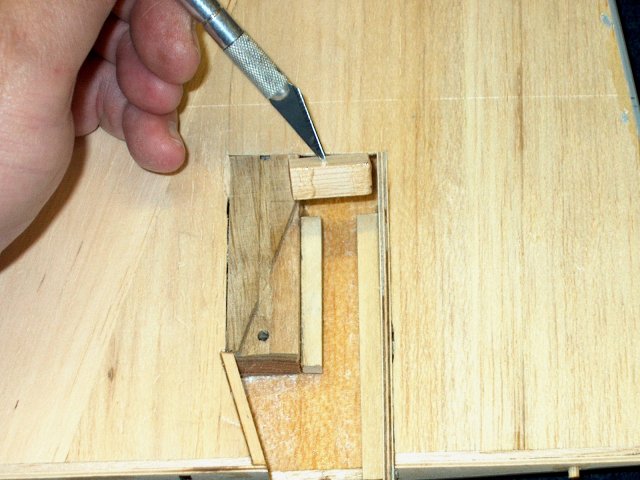

An Exacto knife can be used from the side

of the block to cut the rest of the length

| |

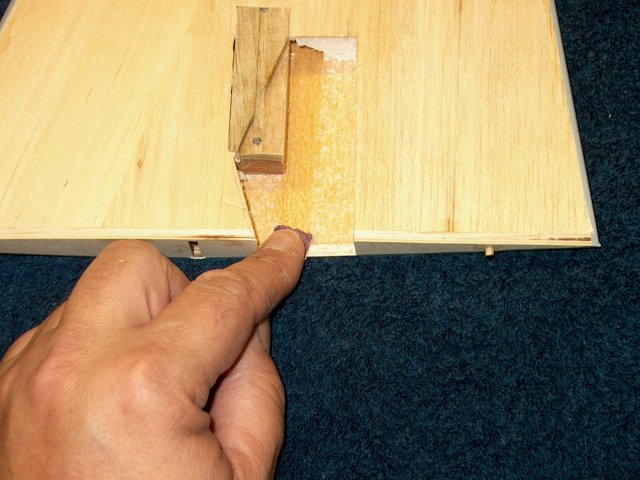

Once cut, remove the excess wood

| |

Cut away the remaining block to the door

line using a chisel knife | |

Sand the area smooth to remove splinters

and burrs | |

Use a hobby saw and cut the root rear spar

down to the balsa. Try to keep the cut parallel to the main

spar hole in the forward area of the wing root

| |

Cut the front root area in a similar

manner | |

use a knife to cut along the inside of the

wing root and remove the excess | |

Sand the bottom of the area flush to the

wing sheeting | |

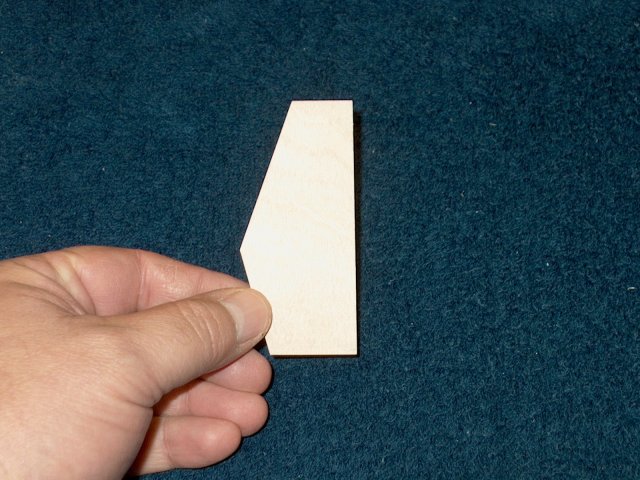

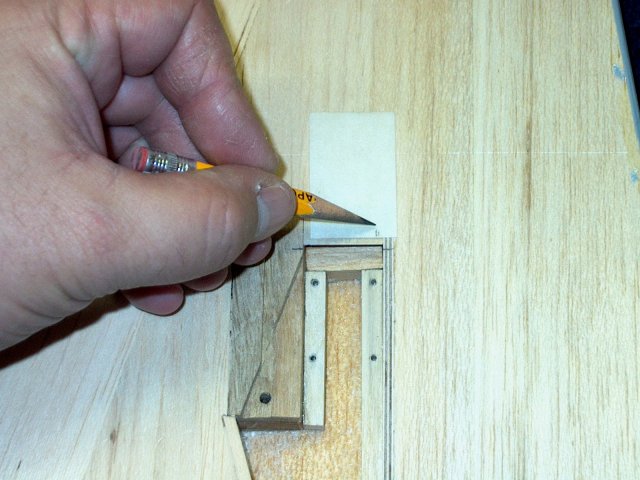

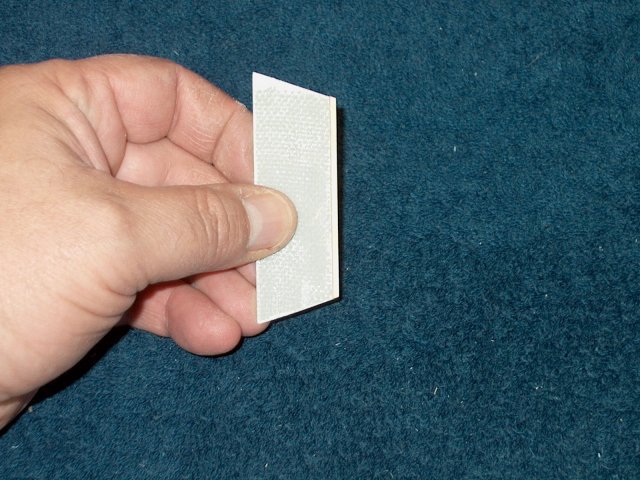

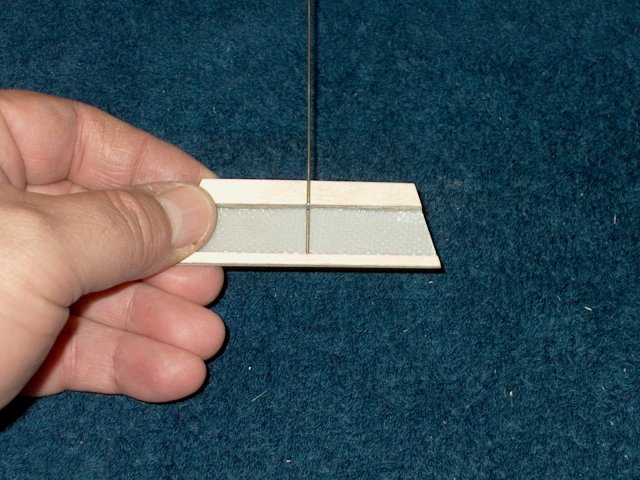

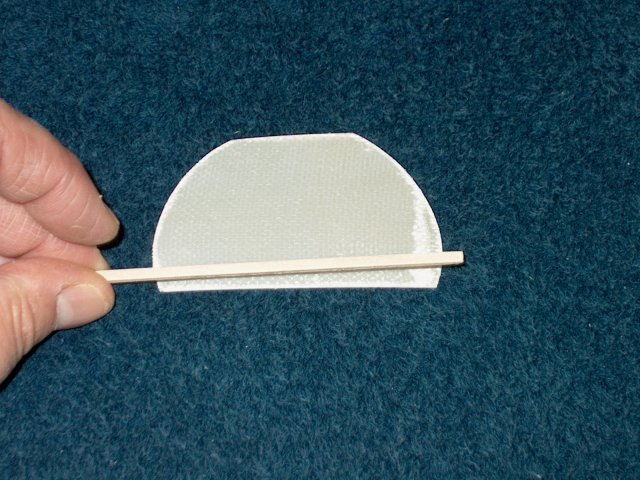

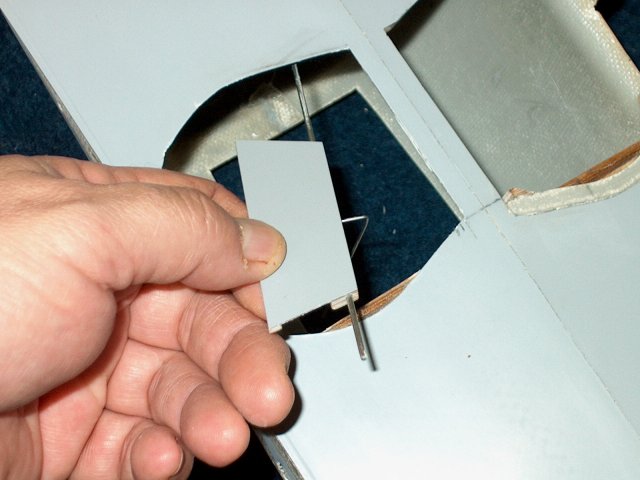

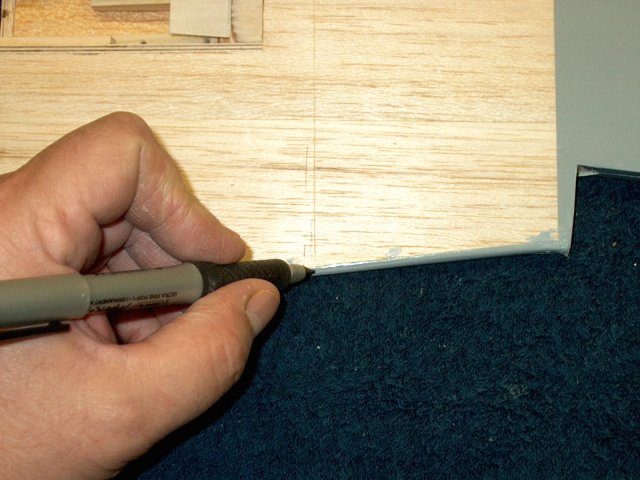

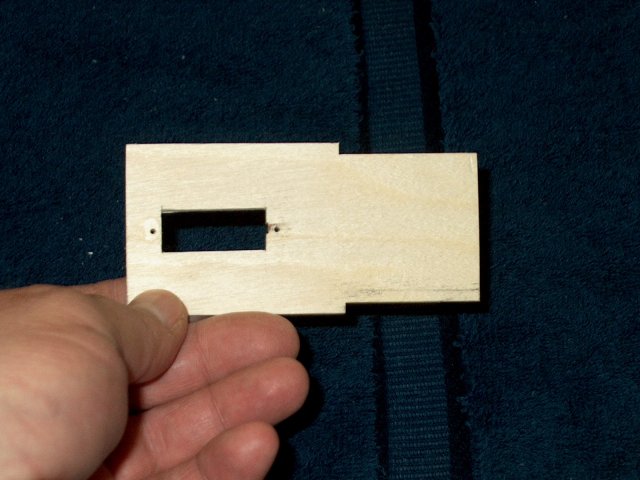

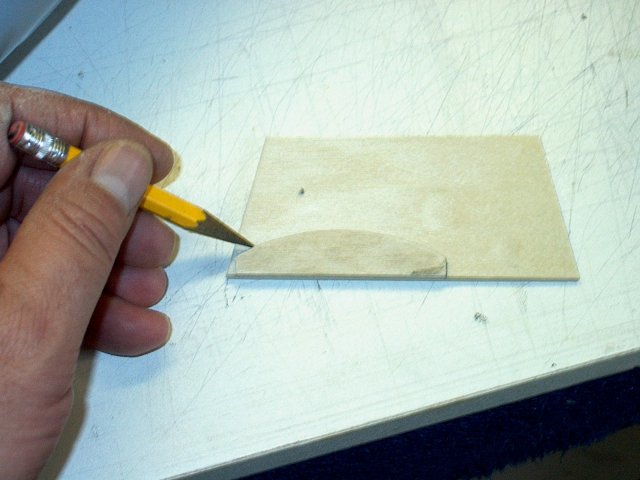

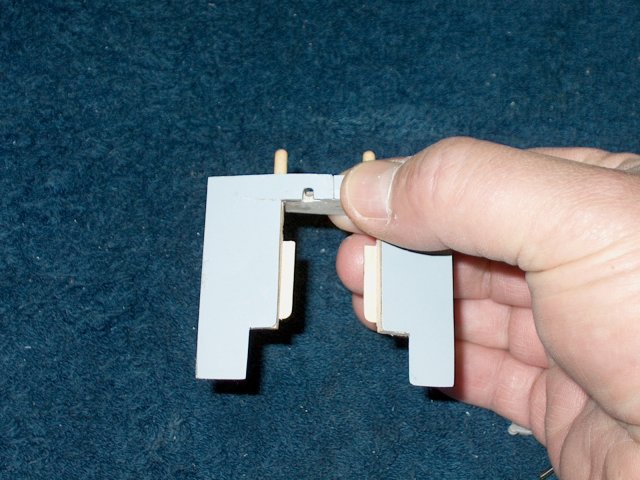

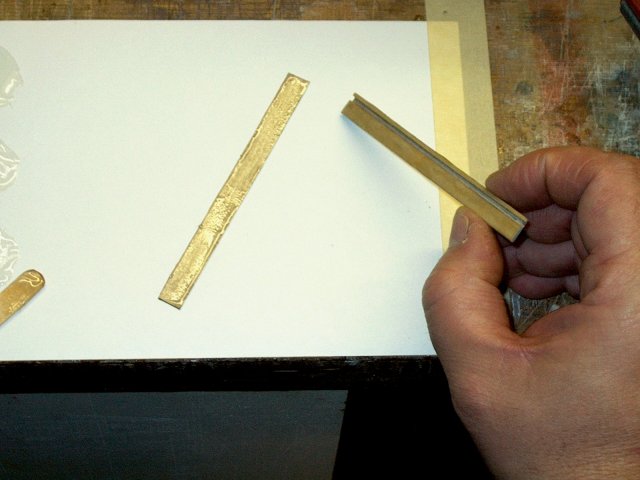

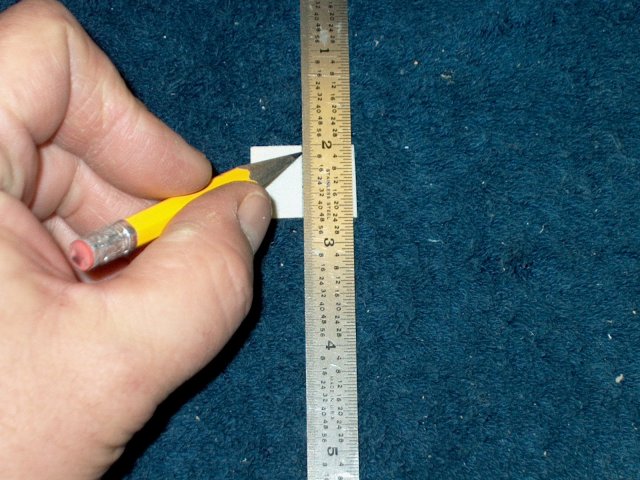

Insert a piece of 1/8" ply sheeting and

draw a line on the sheeting. Cut the Secondary Spar to length

as shown in the templates | |

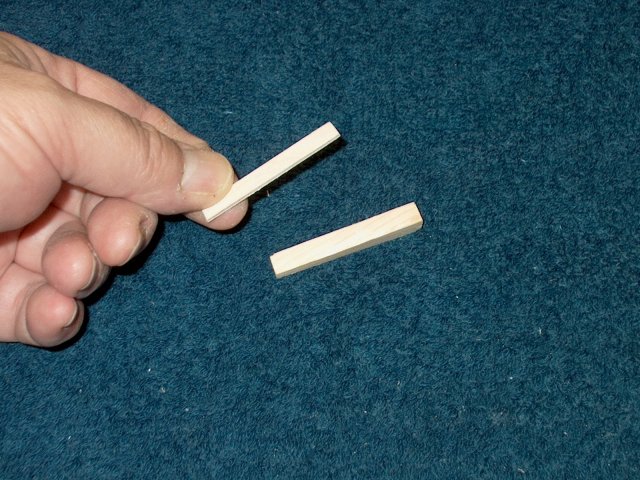

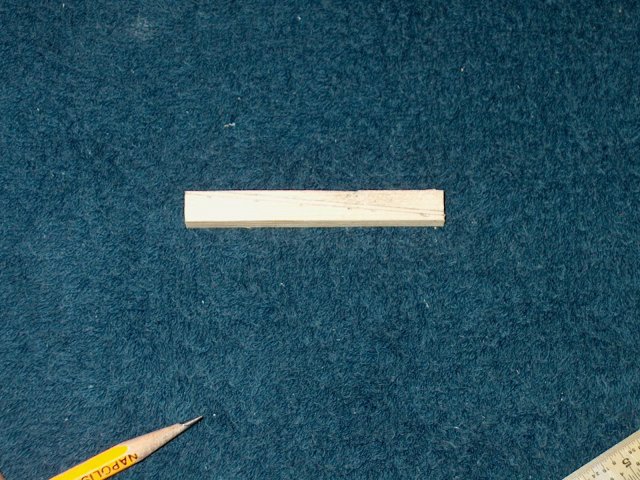

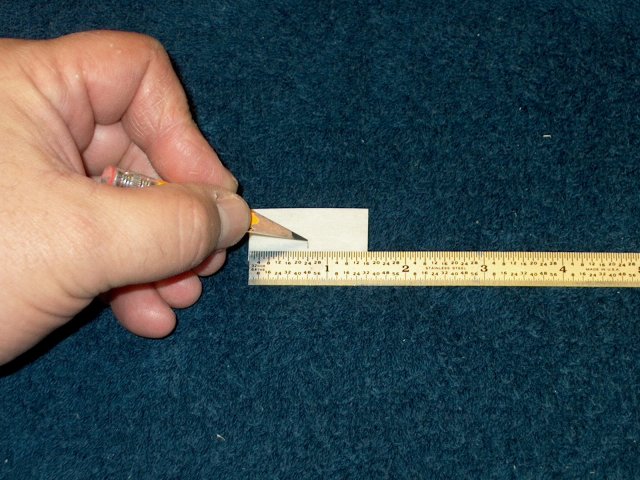

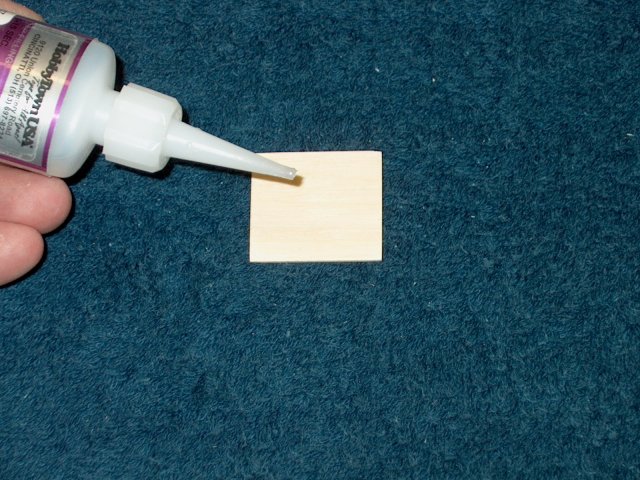

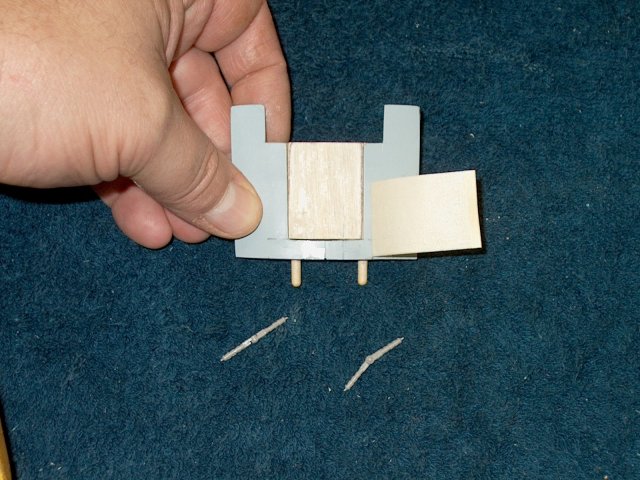

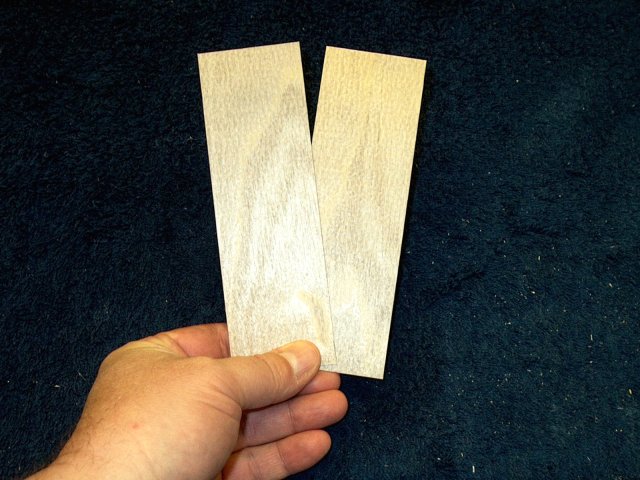

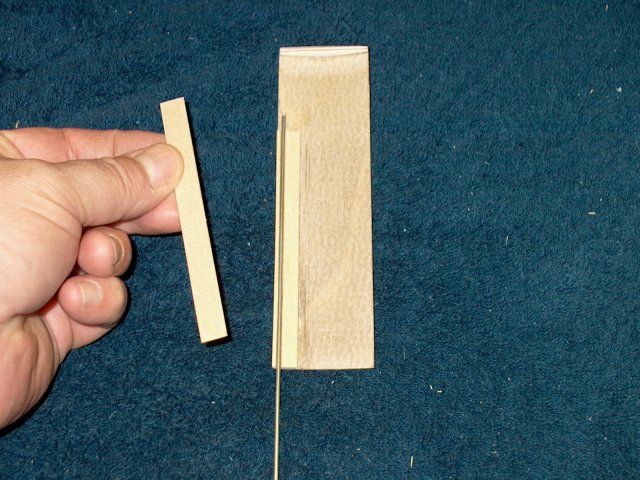

Cut a piece of 1/4" x 3/8" hardwood block

to a length of 1 7/8" ; Note that the wood shown in the pic is

3/8" square and had to be cut to the correct 1/4" x 3/8"

dimensions | |

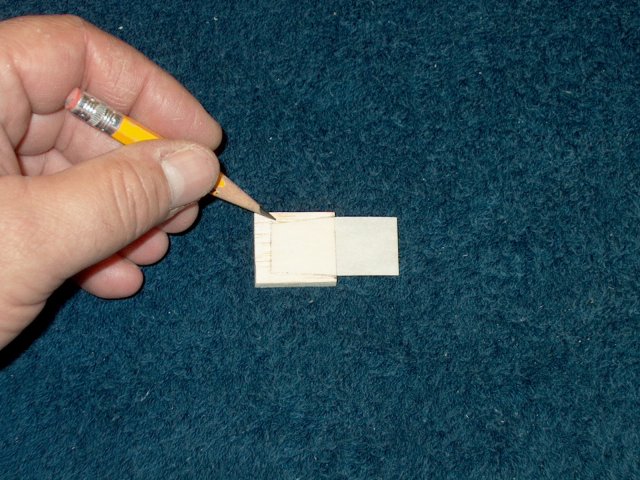

Draw a line along the block as shown to

match the one in the templates | |

Sand the surface smooth

| |

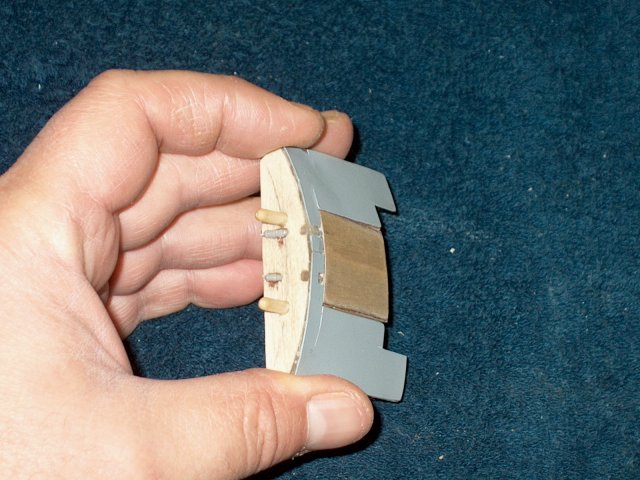

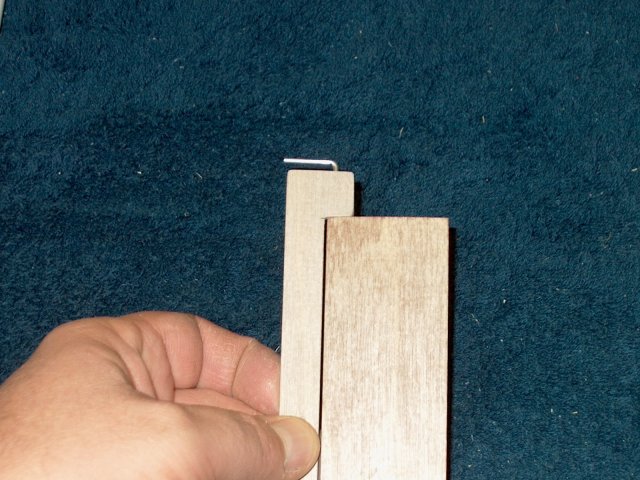

Cap the top of the block with a 1/16"

thick piece of aircraft ply | |

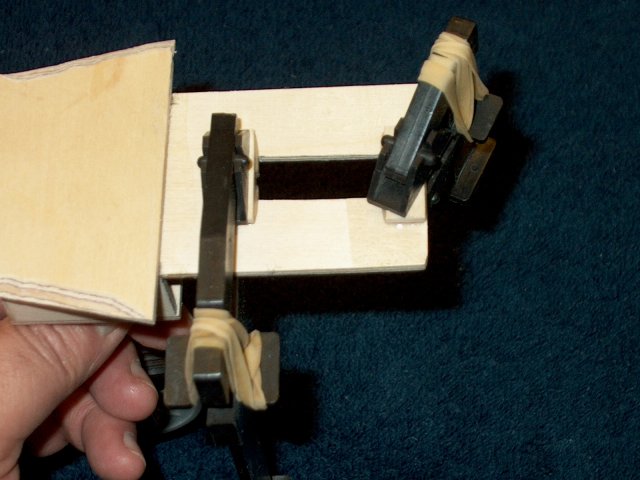

Clamp the assembly until the epoxy

sets | |

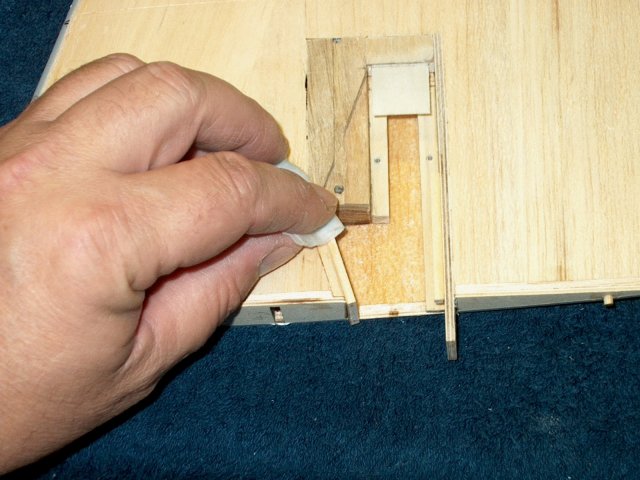

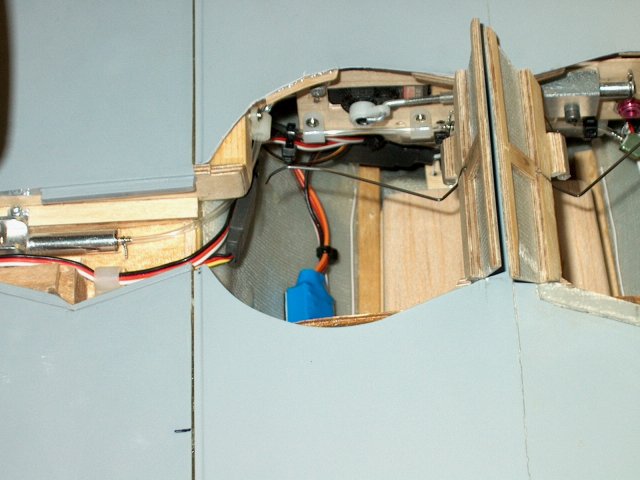

Use a knife to cut away the foam underneat

the top side of the wing as shown | |

Cut back the foam about 1" or more; clean

up the hole for the aileron servo wires

| |

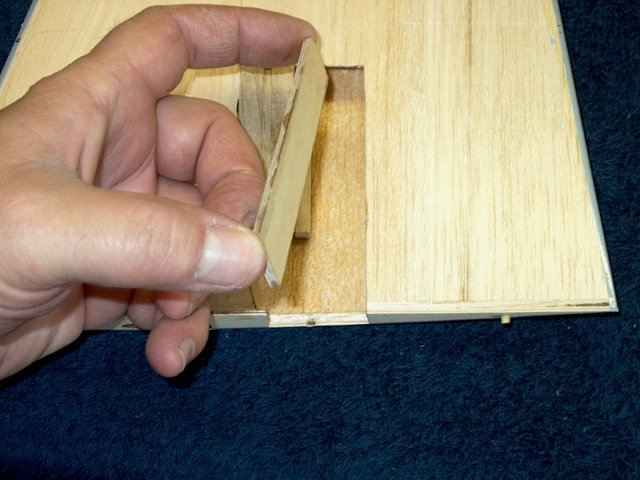

Remove the extra piece of balsa as shown.

Cut it from the fuselage opening to the outside top of the

hardwood block | |

Cut a 3" long piece of 3/8" square

hardwood and use it to mark the foam on the right side as

shown. Remove the foam below the line so the block can sit

recessed in this area under the wing sheeting and even with

the top opening | |

Install the main spar

| |

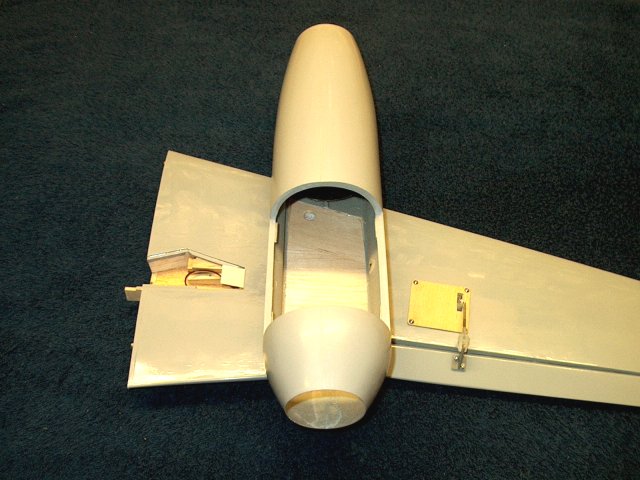

Install the wing in the fuselage

| |

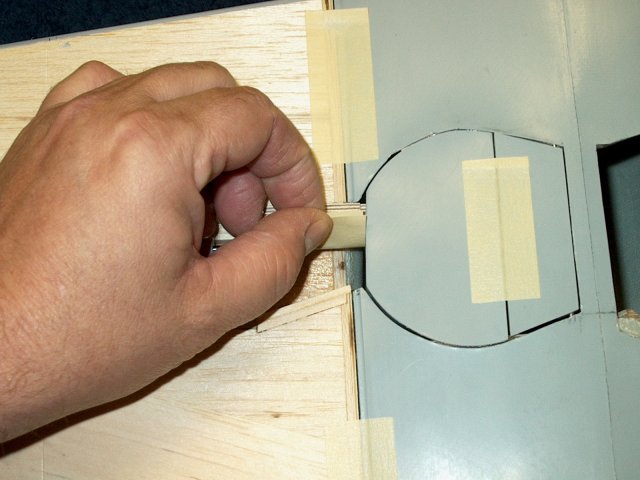

Transfer the outline of the wing's cut out

area to the fuselage | |

Use a sharp knife to remove this area from

the fuselage. Sand the inside edges smooth once

finished | |

Measure 1/4" down from the seam of the

fuselage on the bottom of the jet and draw a line parellel to

the seam | |

With the wing installed flush, make a line

from the rear of the wing opening to the fuselage

| |

Make a line from the front of the wing

opening to the fuselage, matching the angle

| |

Install the template with the top at the

1/4" from the seam horizontal line and the bottom between the

two marks you just made. The rest of the pattern should align

with the wing door area as shown | |

Transfer the pattern to the fuselage

area | |

Carefully cut out the pattern in the

fuselage. This will take some time, possibly an hour or more

and may take 30-40 passes with an exacto knife on each side.

It takes a couple blades to cut through the entire area. If

you run into a glue area, try to pop the fuselage free of the

glue rather than cut through the glue, which will be

reinforced later. Also note that one side will expose some of

the main spar support plywood and glue. Take care not to cut

into the ply | |

Lightly sand the area that was cut out and

clean it up | |

Measure in 1/8" from the front inside door

run as shown | |

Cut the balsa to the elbow, but leave the

foam core in place | |

Cap the area with a 1/8" wide by 1/16"

thick piece of basswood strip. Epoxy it in place

| |

Cut out the wing door from the

pattern | |

Check the fit on the door

| |

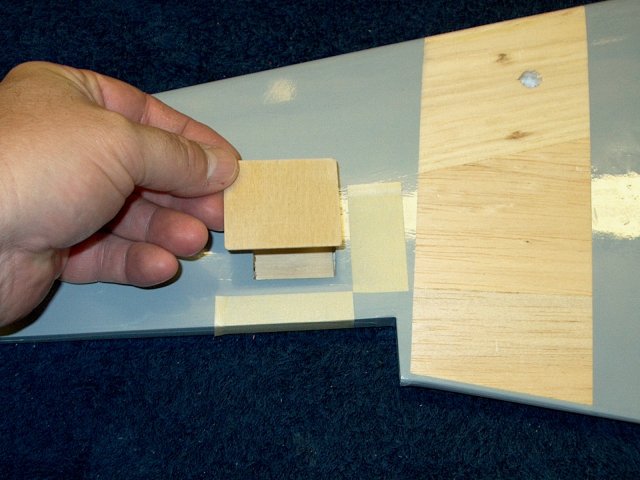

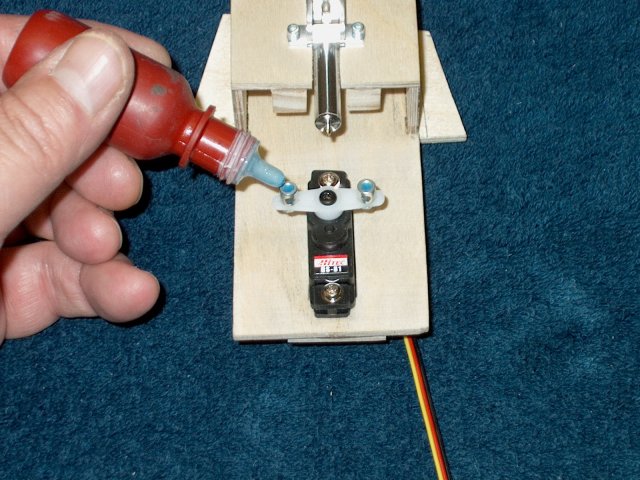

Add Epoxy to the Retract wedge top and

outside | |

Install the wedge as shown, with the

inside of the wedge aligned with the bottom end of the harwood

block | |

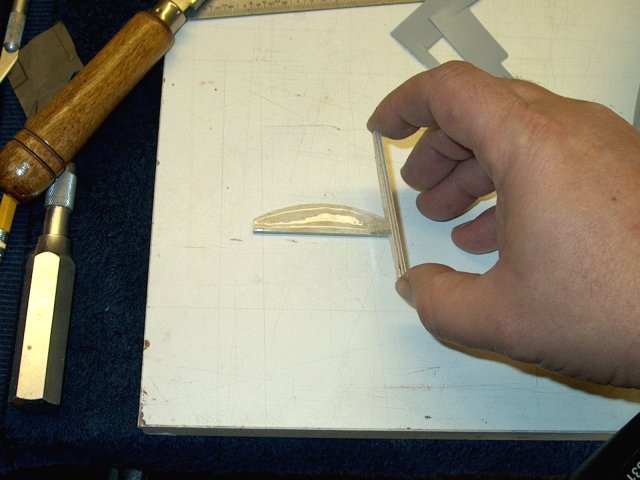

Cut a second wedge, 3" long from 1/4" x

3/8" hardwood using the supplied pattern

| |

Cap the wedge on the top with a 1/16"

thick strip of aircraft ply | |

Clamp the assembly and allow the epoxy to

set | |

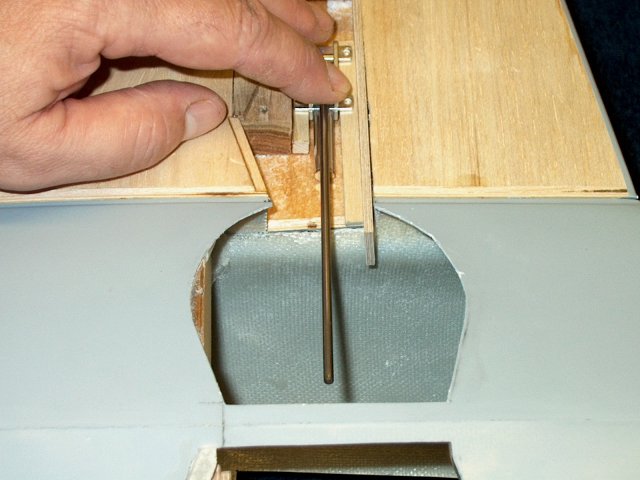

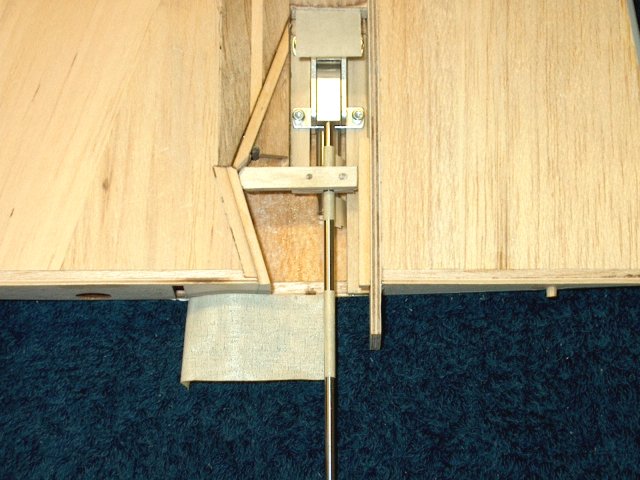

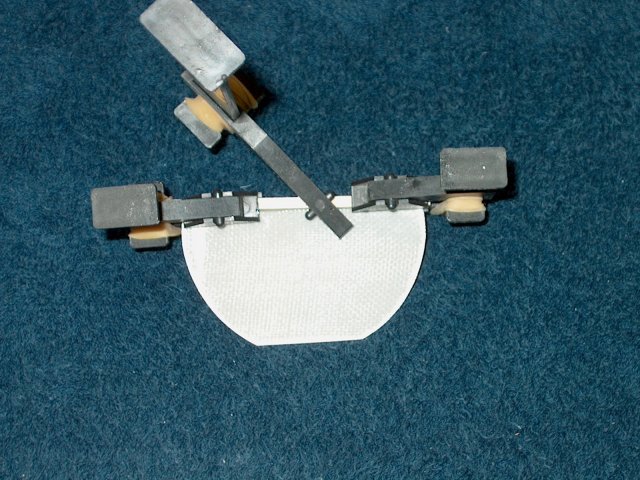

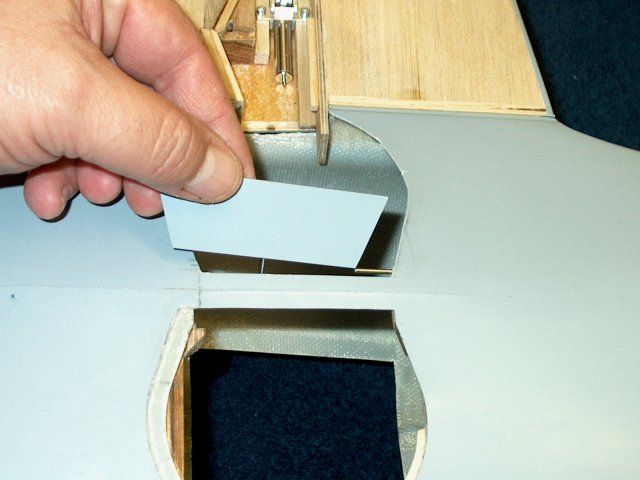

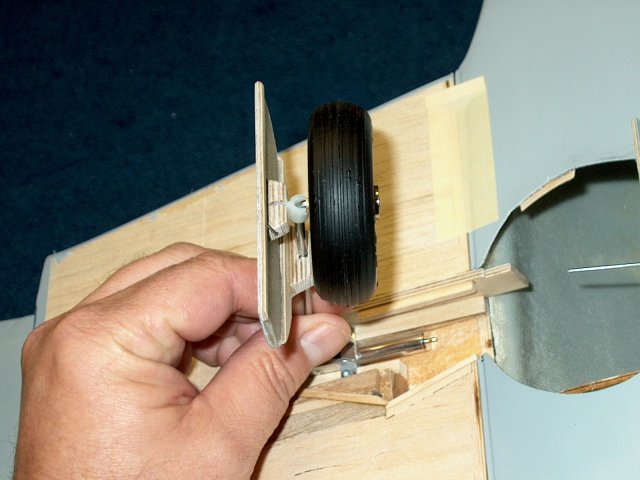

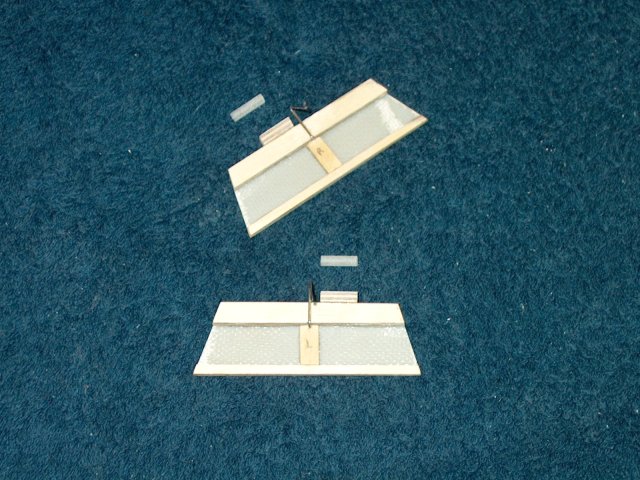

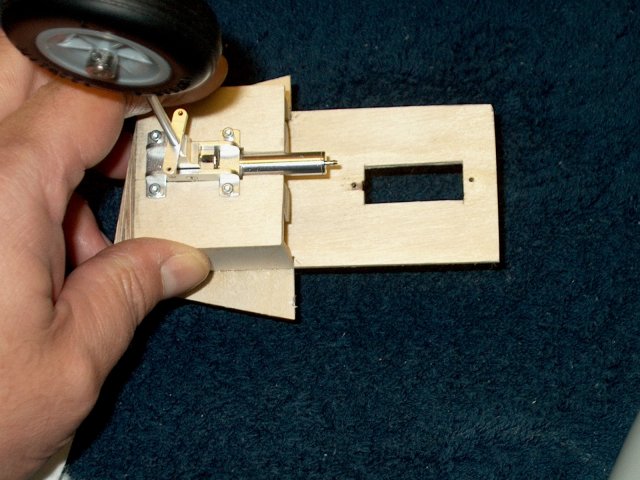

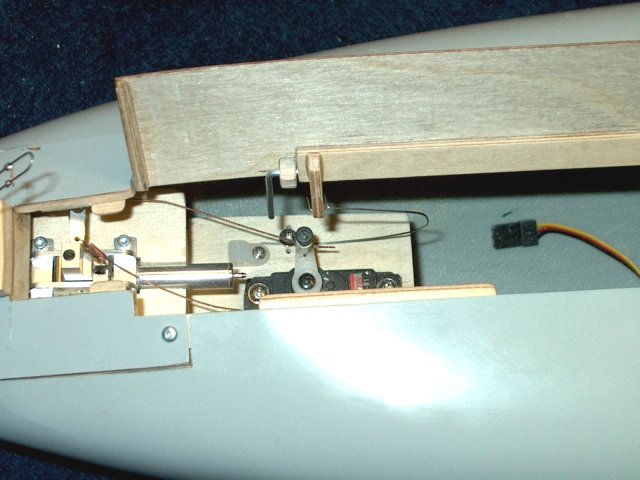

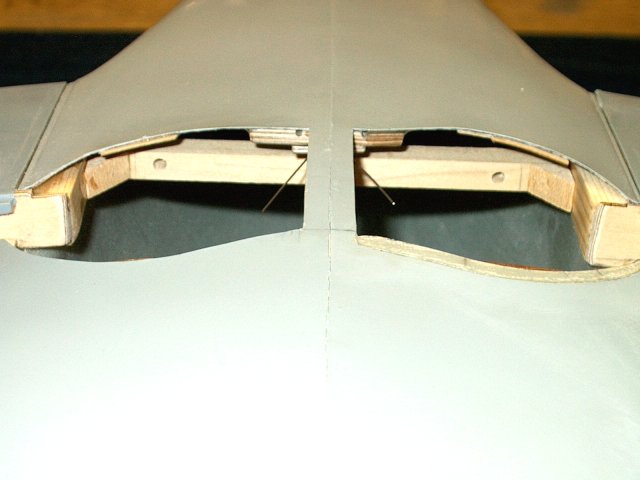

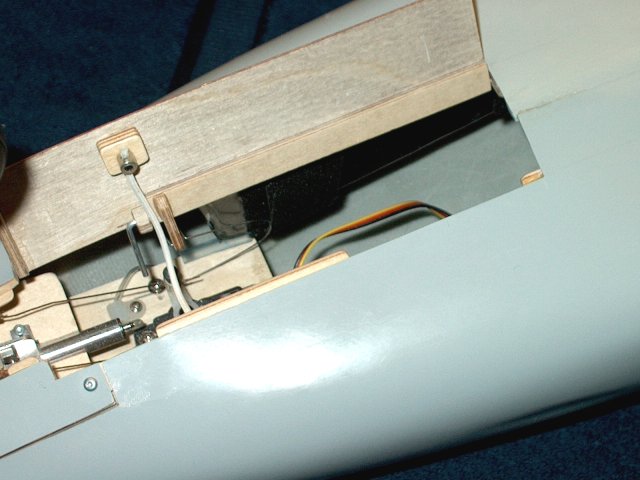

Install the secondary spar, the long wedge

and the retract and check their position. Install the fixed

gear wire in its hole and check that the angle of the retract

wire is similar to the fixed wire ash shown. Also, slightly

sand the inside of the long wedge if the retract is too

tight | |

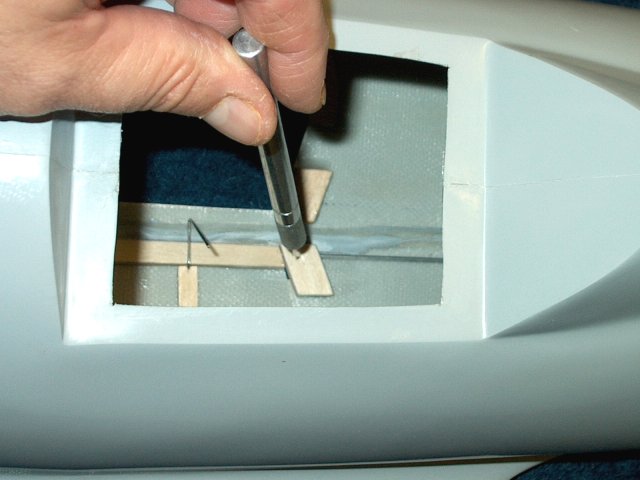

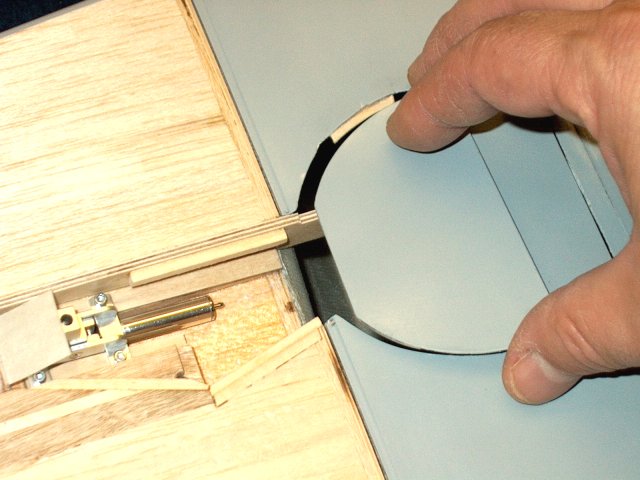

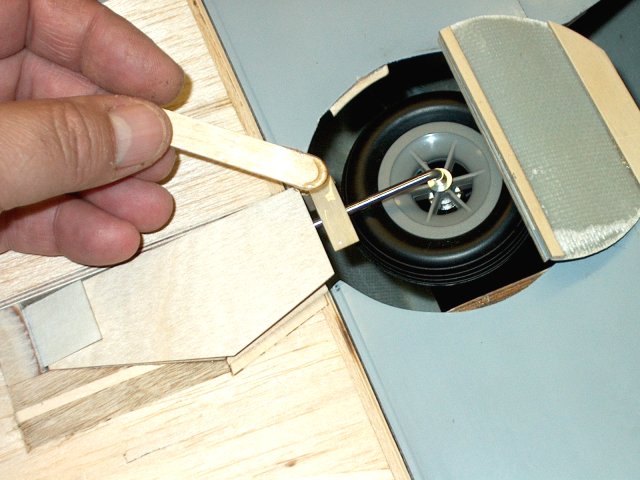

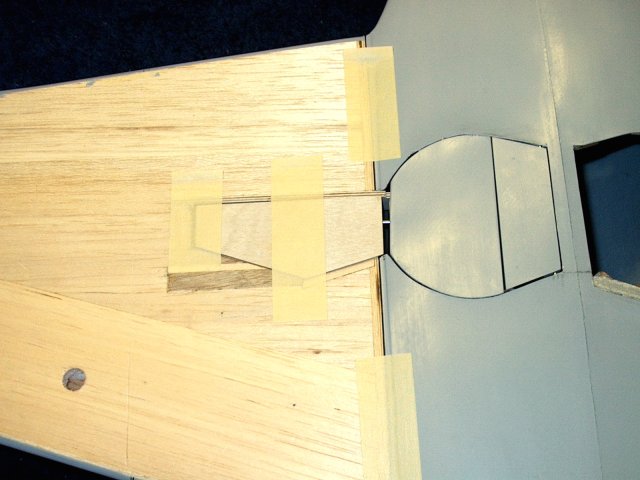

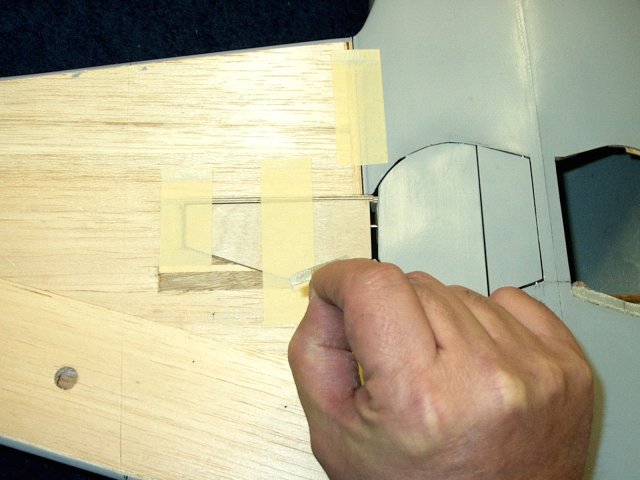

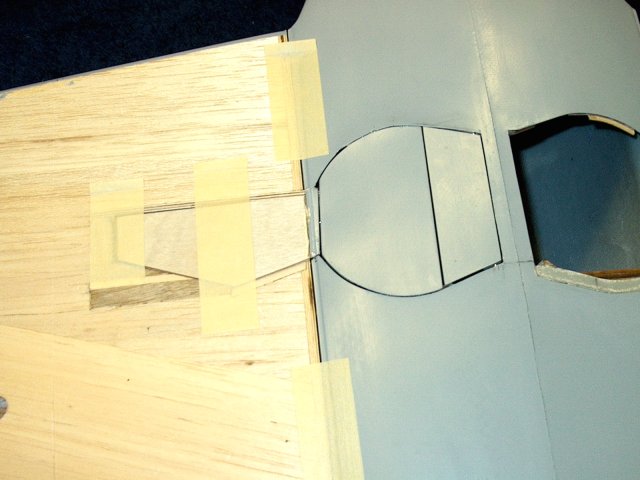

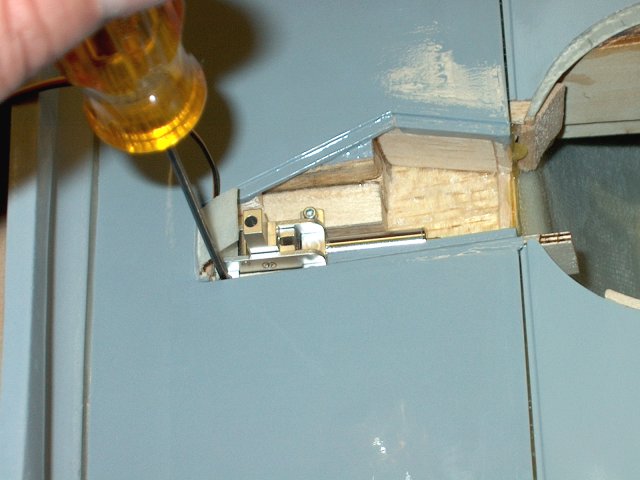

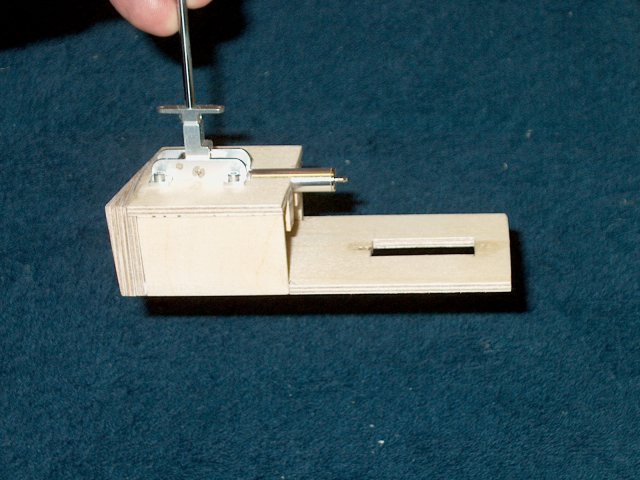

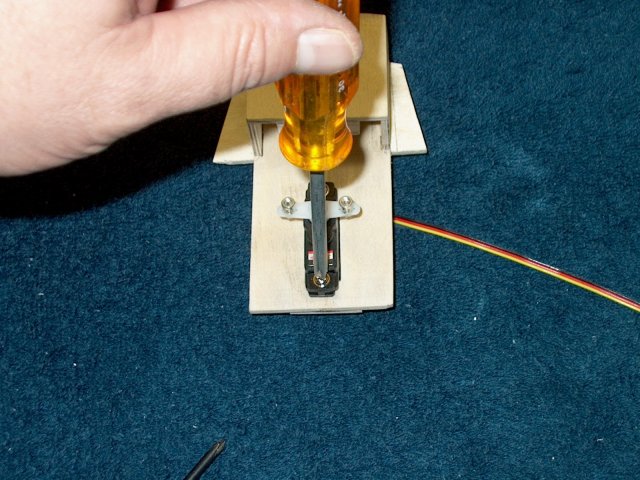

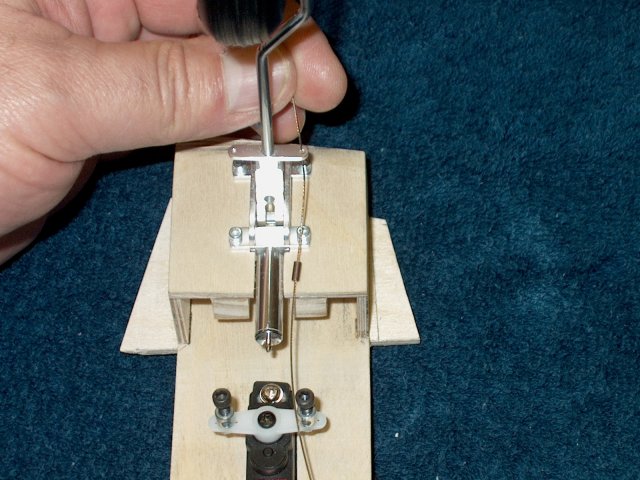

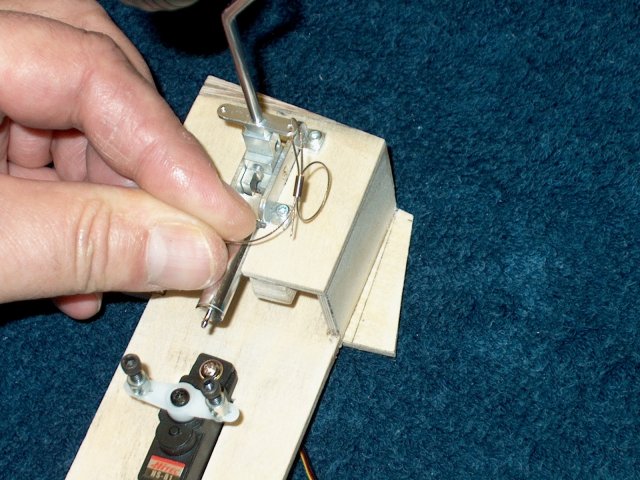

Use a screwdriver to push the roll bar

level forward in the retract and then fold the gear wire into

the wheel well. Check that the wire runs paralled to the wing

door area and that is is fairly centered in the wheel

area | |

Apply epoxy to the 3/8" square block and

install in in the opening you cut so the bottom is pressed

against the inside of the root spar

| |

Use the secondary spar to hold it in place

while the glue sets. | |

The block support is shown glued into

place | |

Apply epoxy to the side and bottom edge of

the secondary spar and install it in place. Do not apply epoxy

to the bottom part of the spare that is exposed and plugs into

the fuselage | |

Clean up all excess epoxy

| |

Apply epoxy to the long wedge bottom and

the one side facing the spar | |

Epoxy the long wedge in place, so the back

is even with the other wedge and the bottom should come near

the end of the wing root | |

Clean up all excess epoxy with a scraper

and paper towels | |

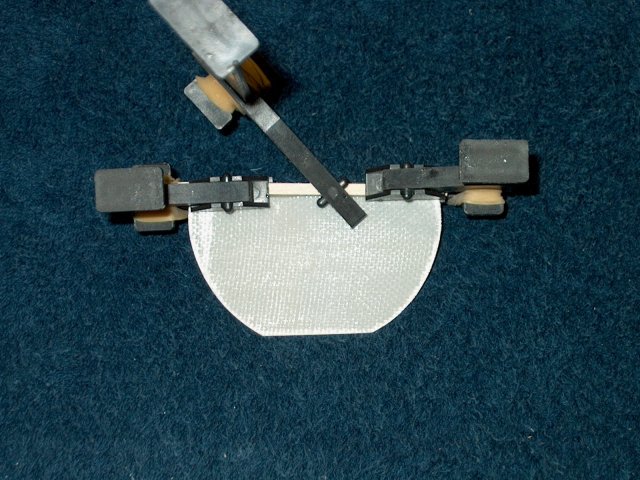

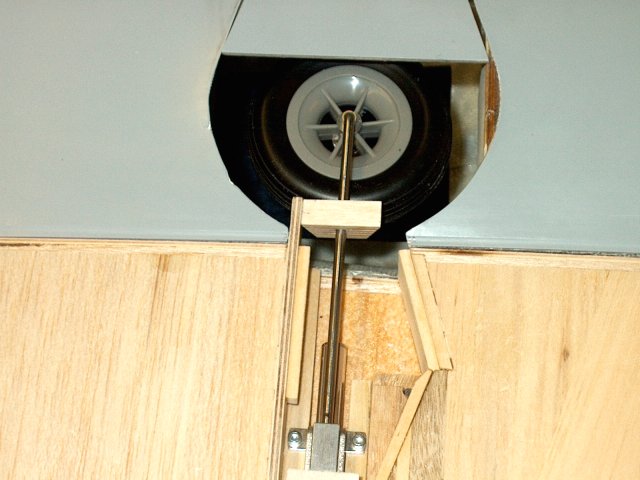

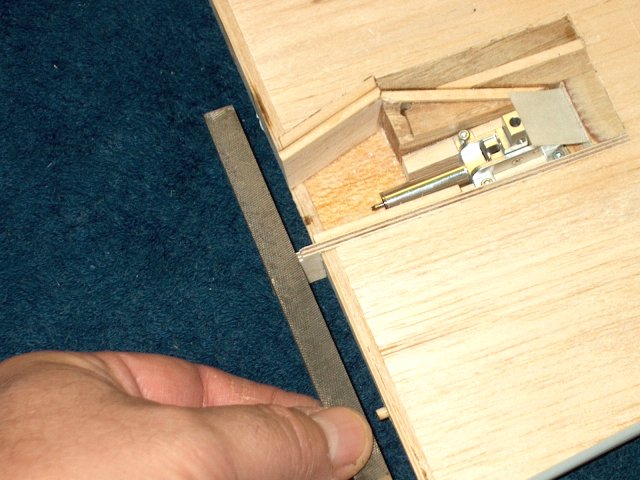

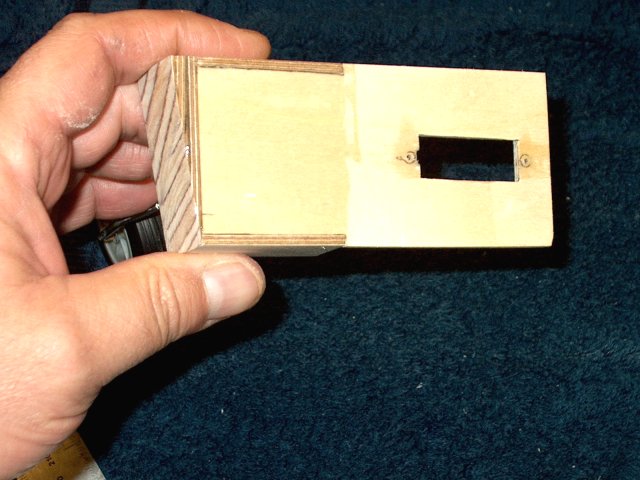

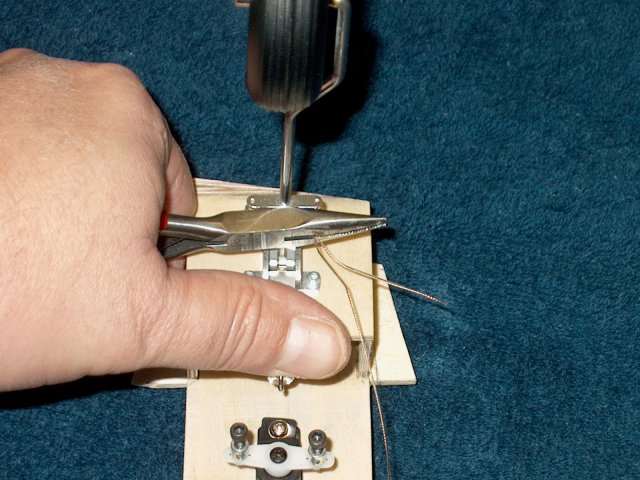

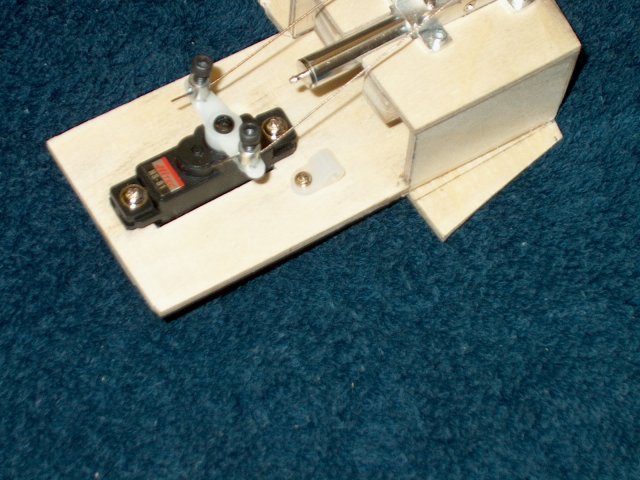

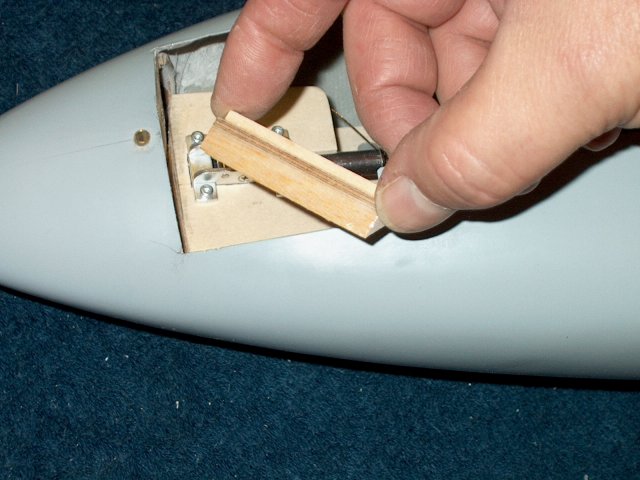

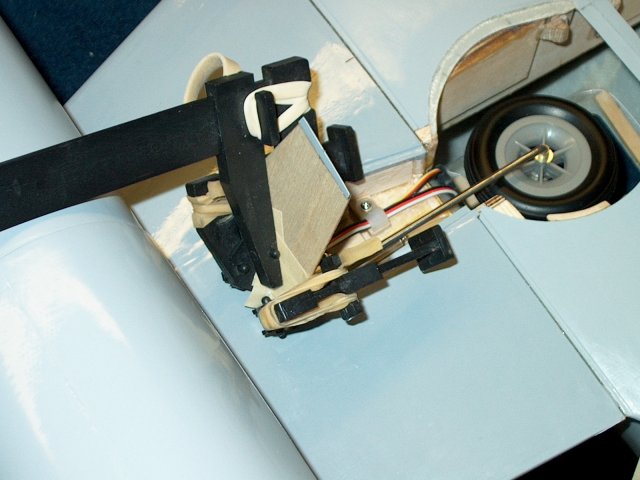

Install the AirPower RA-260 retract. It

should just fit between the two wedge blocks

| |

Cut another piece of hardwood block to fit

behind the two wedge mounts | |

Apply epoxy to the area as shown

| |

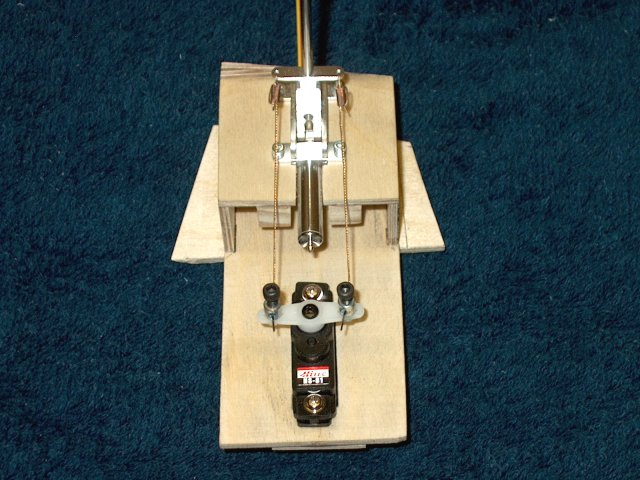

Install the cross block support and epoxy

in place | |

Clean up any excess epoxy

| |

Lightly sand the secondary spar so it is

flush with the wing sheeting | |

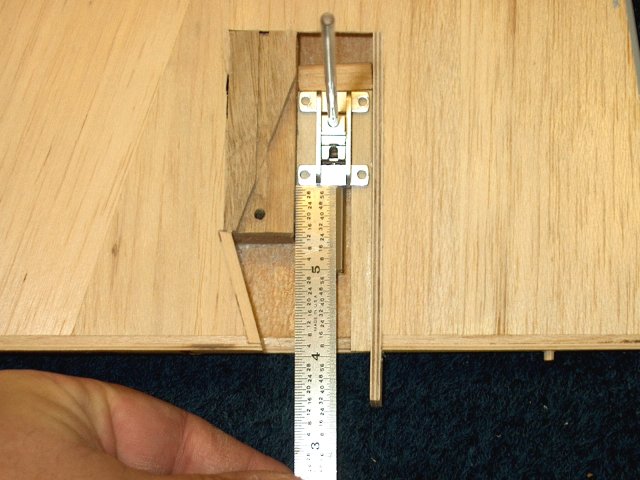

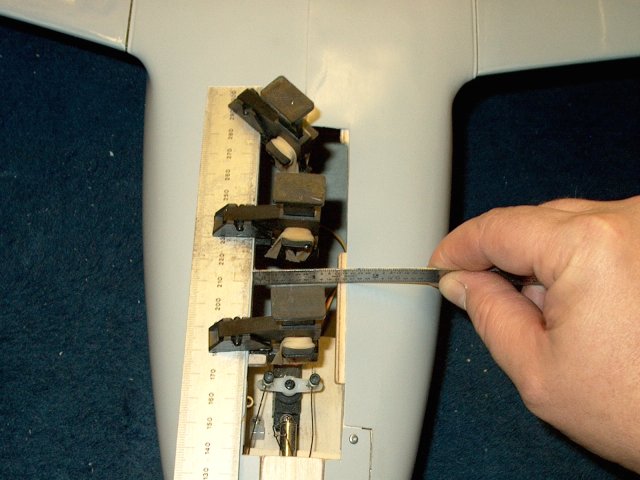

Position the retract so the front of it is

1 15/16" from the root edge of the wing as shown

| |

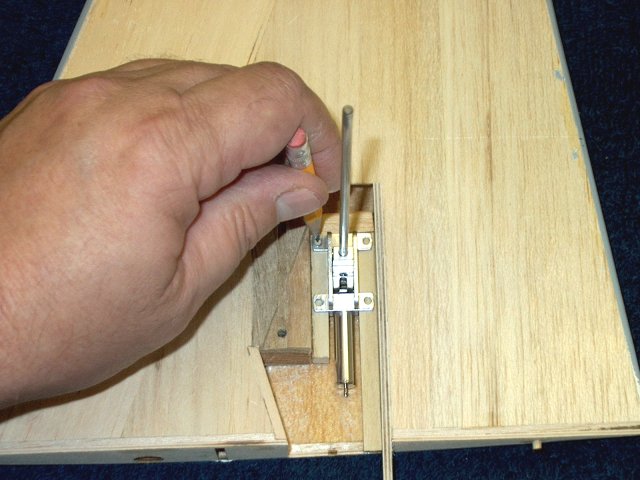

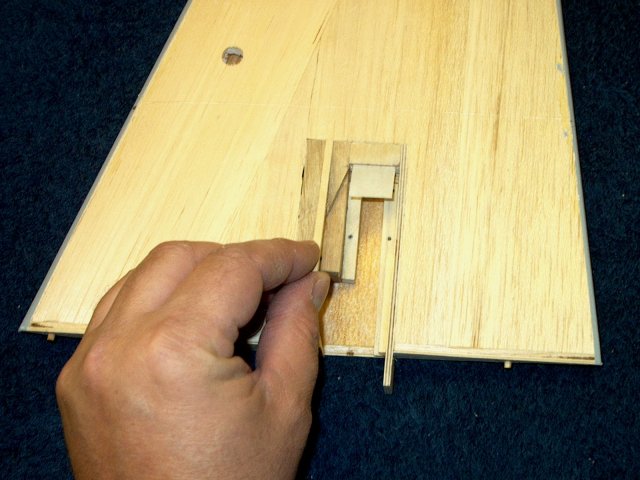

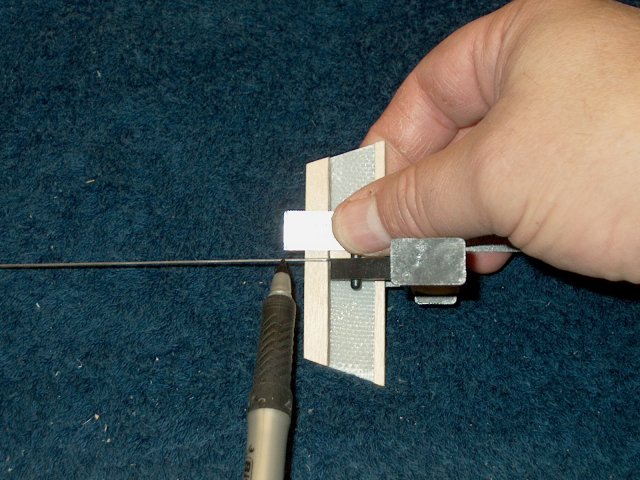

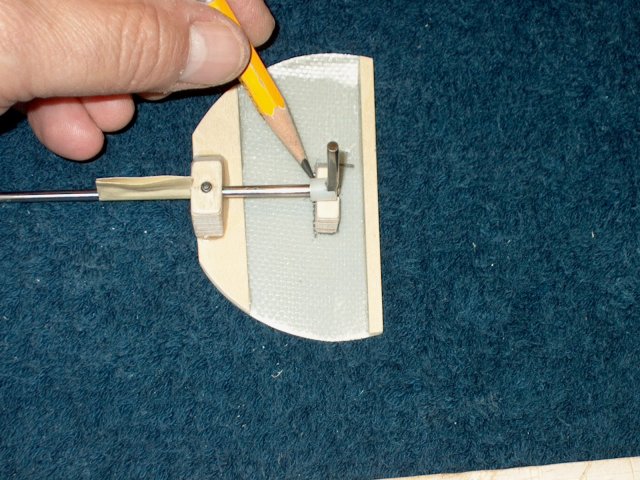

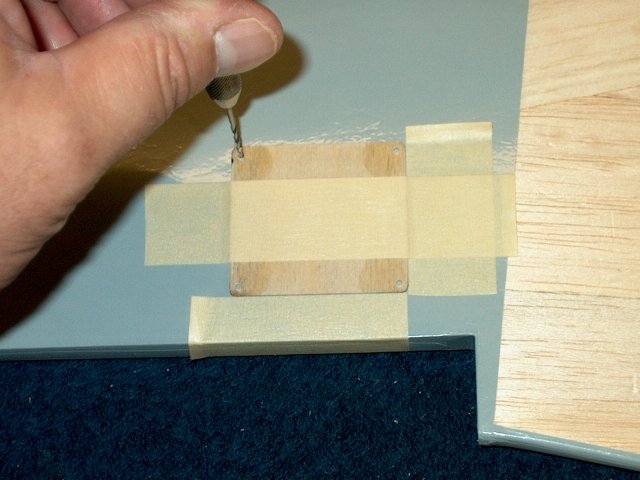

Use a pencil to mark the location of each

mounting hole | |

Use a punch to start the mounting

holes | |

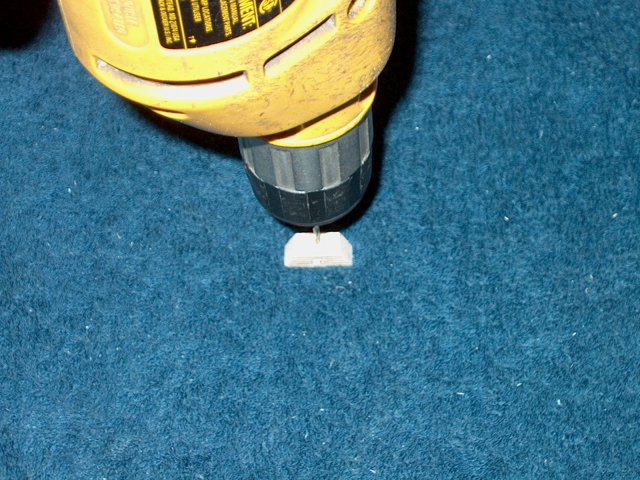

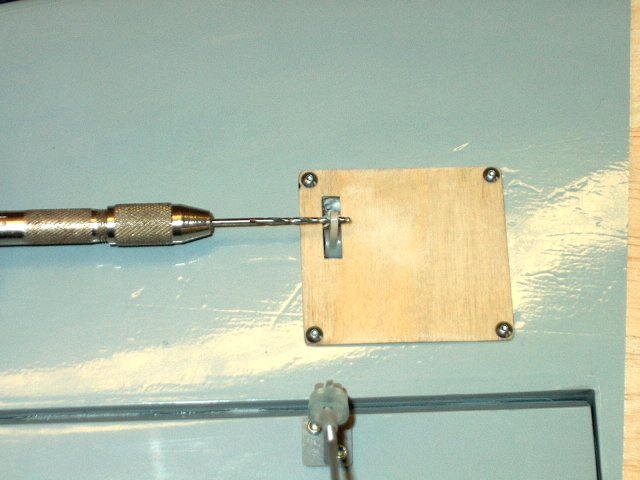

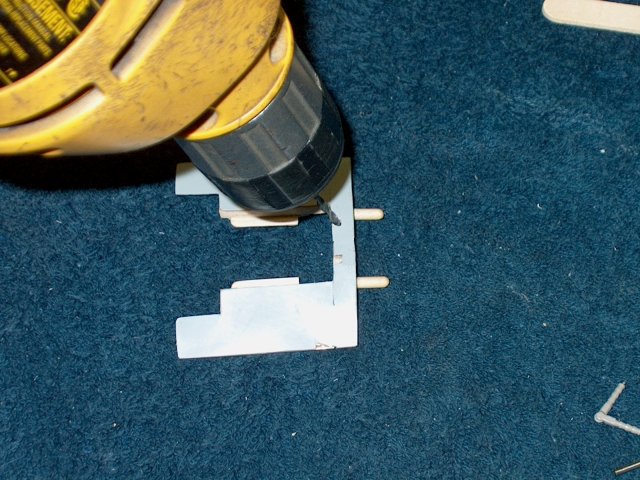

Place a piece of masking tape on the end

of your drill bit, no more than 3/8" from the end. Do not

drill past the tape as this will act like a depth gauge so you

do not drill through the top of the wing. Drill the four

mounting holes with a 1/16" drill, angling the bit from the

side view so it is perpendicular to the wedge

| |

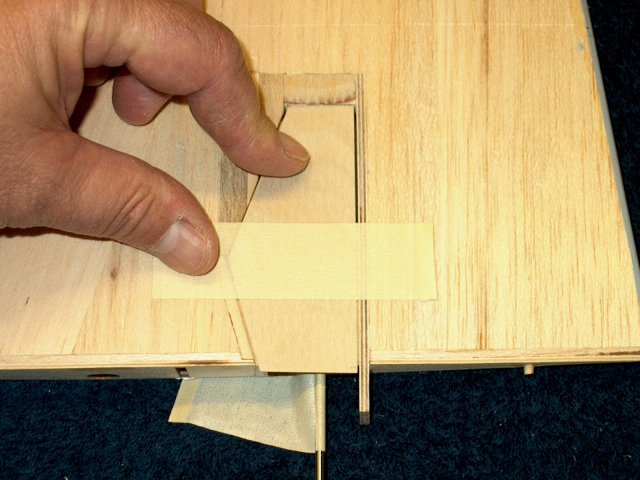

Temporarily install the door and mark its

top location as shown | |

Fit a 1/32" ply plate as shown, just above

the marks you made | |

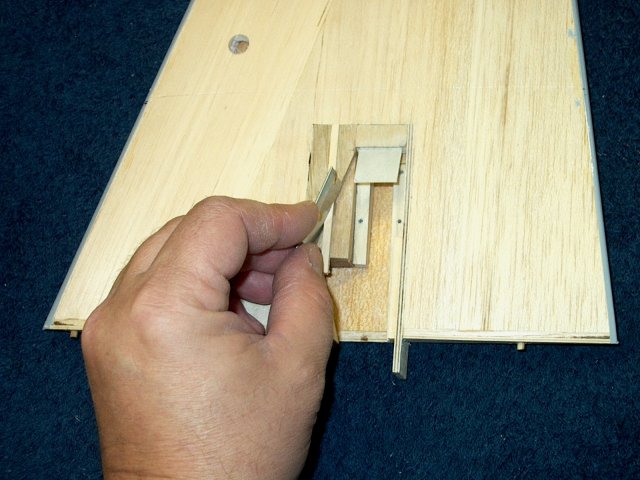

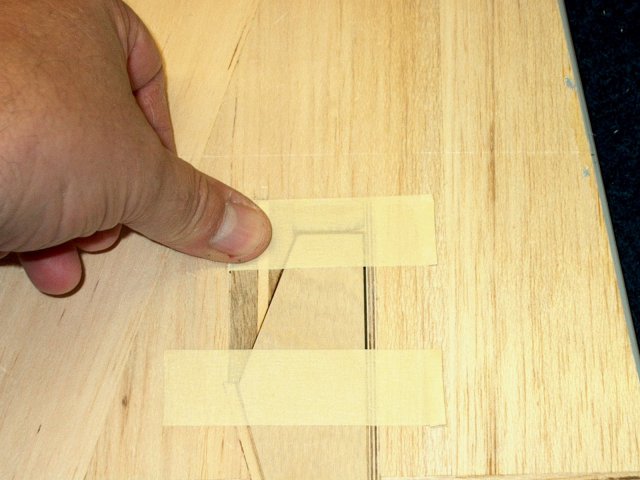

Place a EZ-Hinge in position and mark the

areas that need trimmed down to size the hinge to the

hole | |

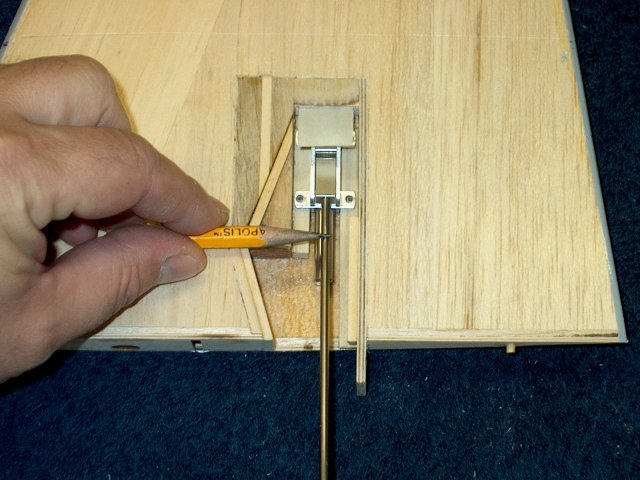

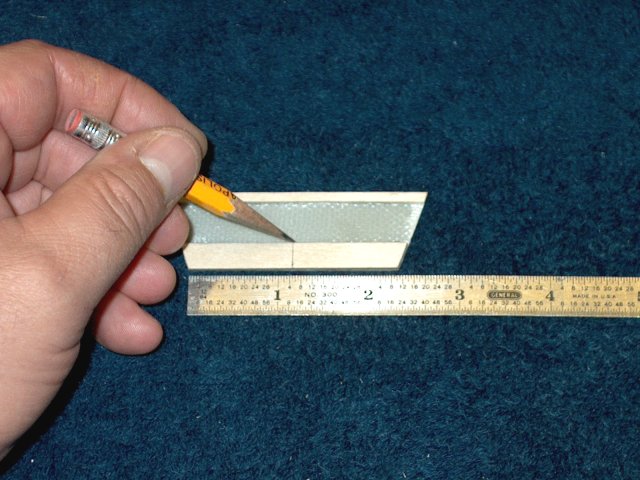

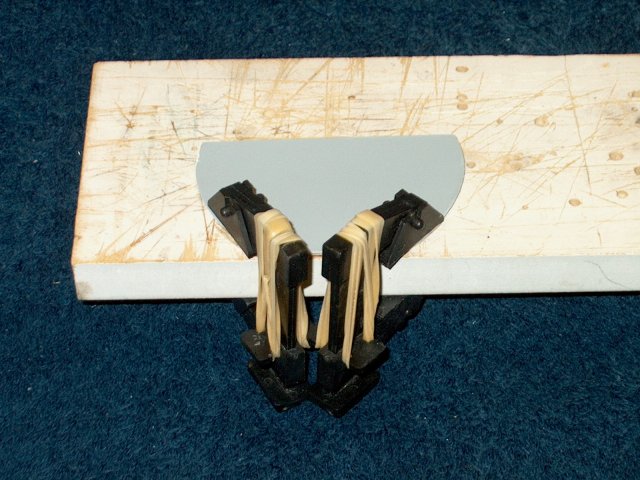

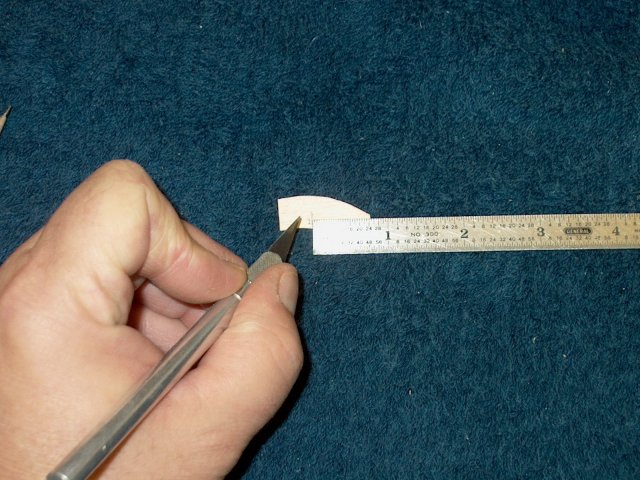

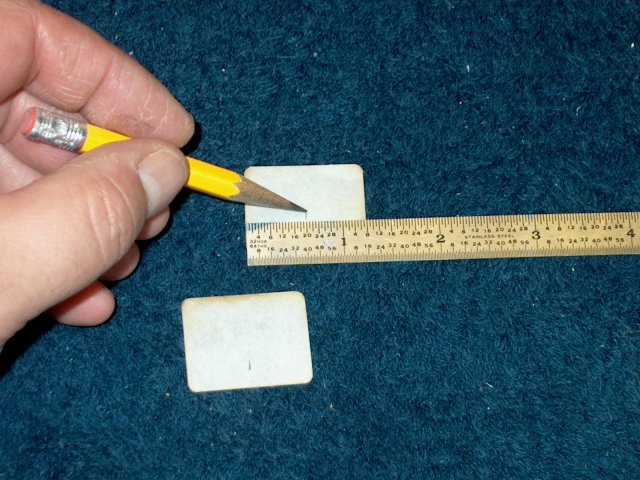

Measure and draw a centerline down the

hinge | |

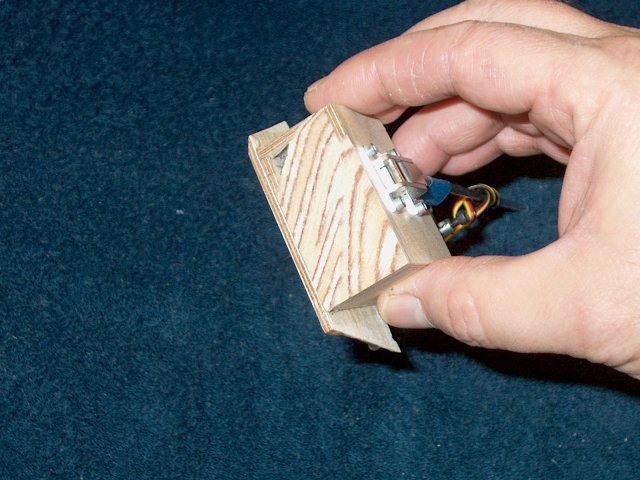

Place half the hinge over a 3/16" thick

piece of balsa and trace the outline of the hinge to the

balsa. Note that the hinge sides were cut slightly angled to

allow for clearance on the sides | |

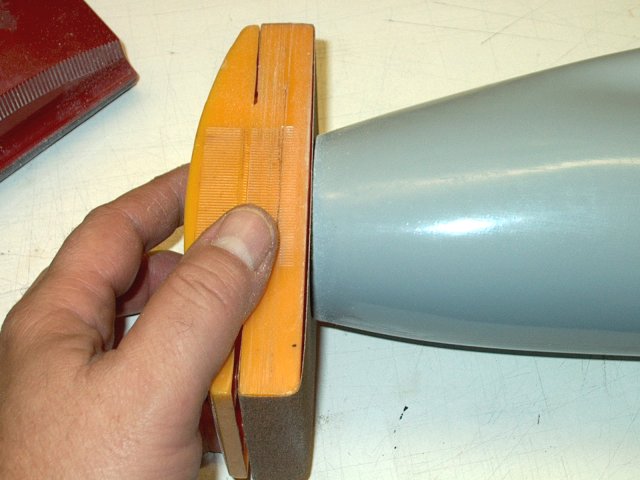

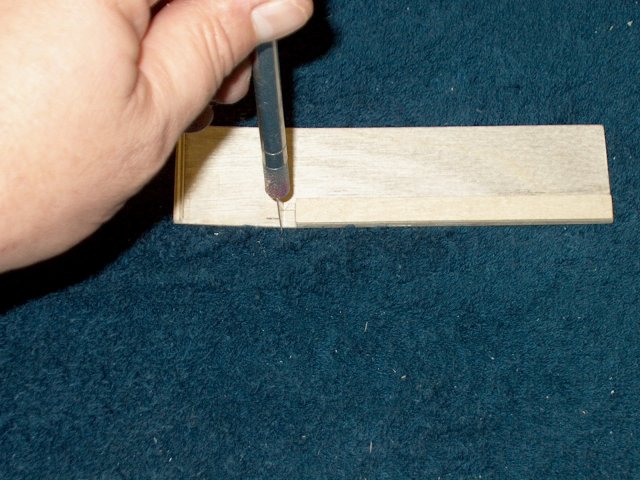

Use a ruler to scrape away and compress

the balsa topcoat on the block so the hinge is recessed and

the top of it sits flush with the balsa block

| |

Round the back bottom side of the balsa

block so that the Aileron Servo cable will not hang up when

passed by it | |

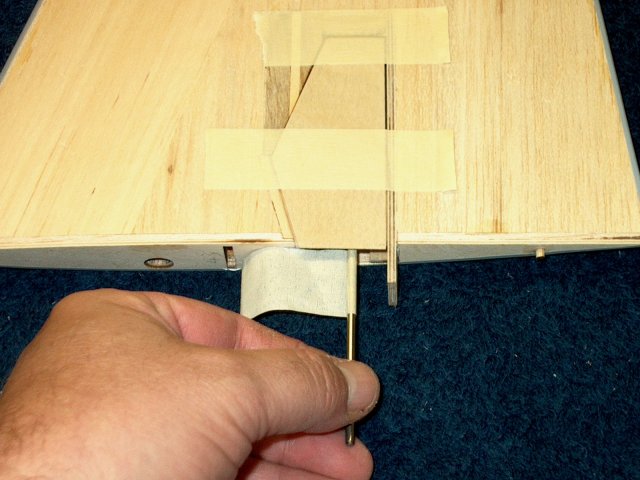

Tape up half the hinge to the centerline,

then epoxy it to the balsa | |

Cap the top of the hinge with the 1/32"

ply coverplate while the epoxy is still wet

| |

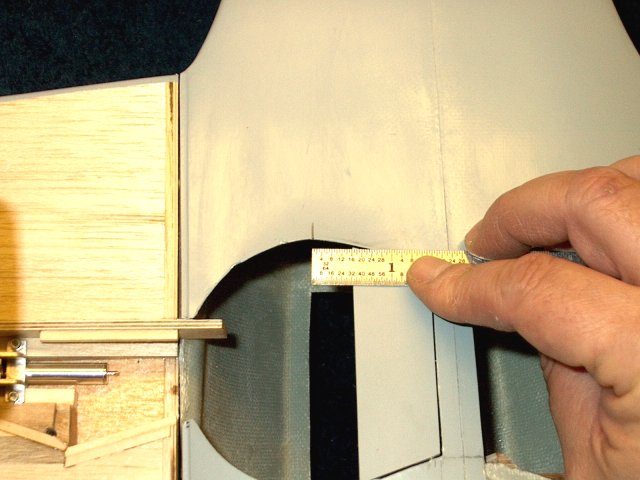

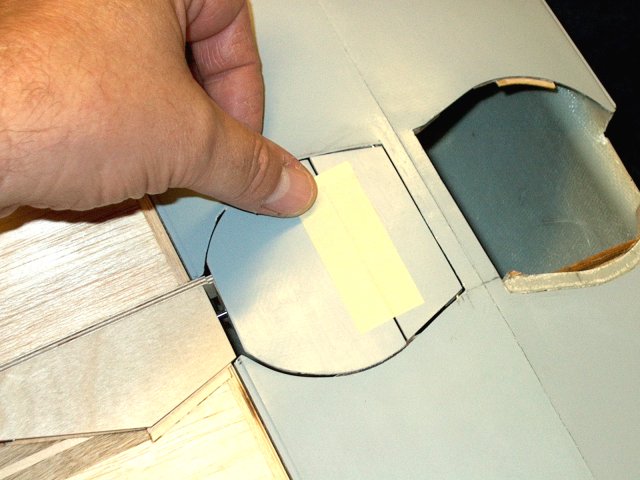

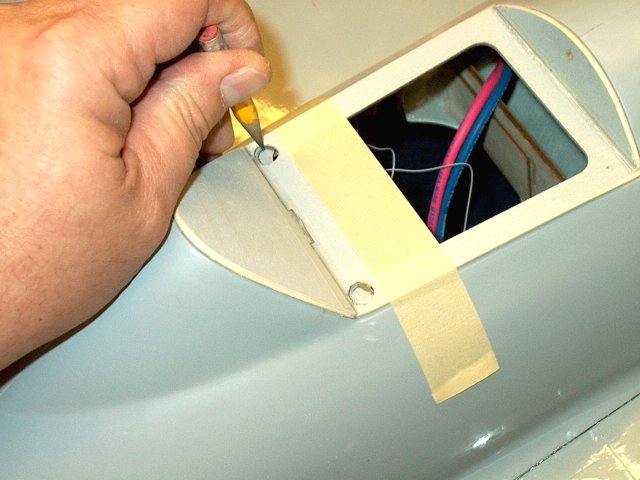

Install the block while the epoxy is still

wet under the top wing area so the front of it comes even with

the top of the door as shown. A piece of tape is used to hold

the ply plate and balsa block in position until the glue sets.

Use a ruler underneath as shown to insure the block is pressed

up against the inside of the wing | |

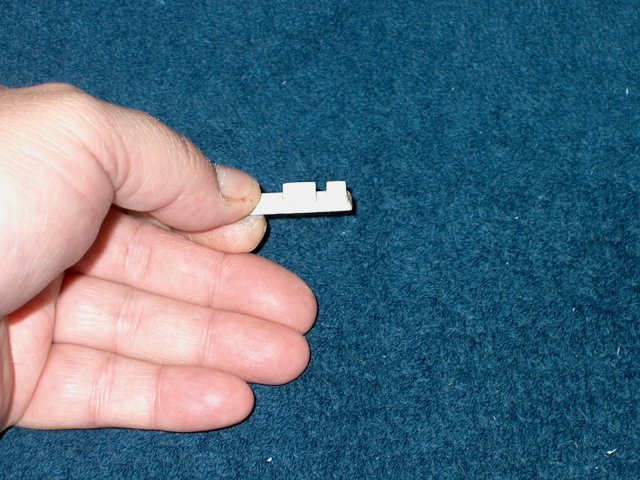

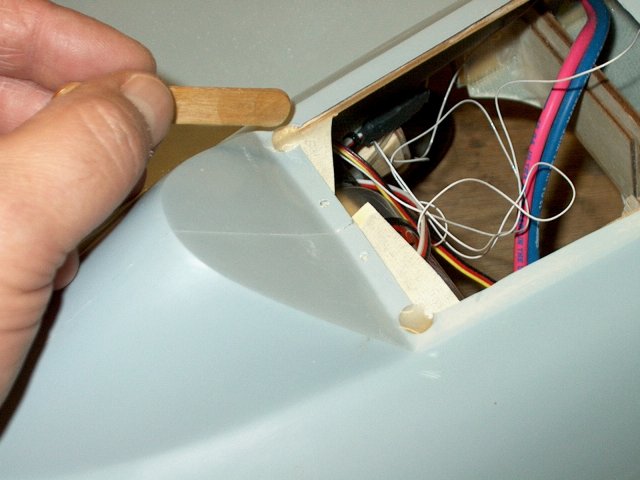

Cut a piece of 1/8" square basswood to a

length that allows the inner retract screw to still be

installed | |

Epoxy the stick in place and use the door

to measure how low to place the stick. The top of the door

should be even to the wing's surface

| |

Cap the top of a scrap piece of 1/8" balsa

with some 1/8" basswood stick | |

Measure and trim the balsa plank to height

and cut to size. Make sure it sits recessed below the top of

the wing | |

Sand a bevel at the end of the balsa

plate | |

Glue the plate in place, with the basswood

stick on top as shown. IT will cover the wing foam and should

sit recessed so the door is flush to the wing

| |

Clean up the excess epoxy. The plate will

cover the wing foam and should sit recessed so the door is

flush to the wing when placed over this stop plate

| |

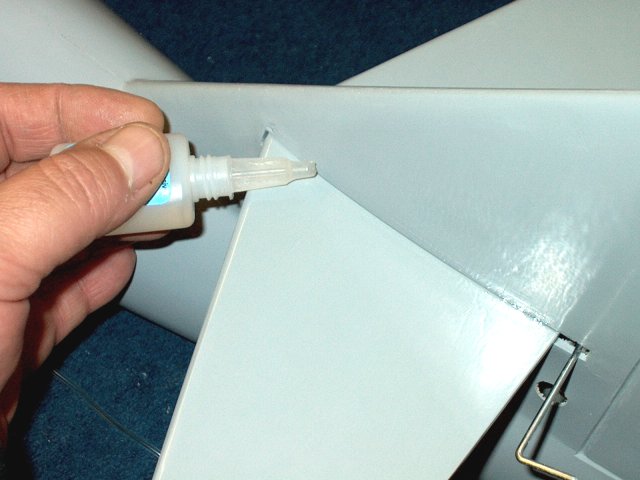

Apply some epoxy to the fixed gear slot in

the hardwood block | |

Use some scrap 1/8" square basswood stick

to fill in the space | |

Cut the excess basswood so it blends in

with the angle of the hardwood door cuts

| |

Epoxy a piece of 1/16" x 1/8" basswood

stick at the angled location to prevent the door from receding

to far, but ratheer give it a landing for which to rest

| |

Place the door over the retract area and

check for fit. It should be recessed enough to sit below the

surface of the wing. Sand the landings to fit if

necessary | |

Cut a piece of 1/8" ply to a width of 1/4"

and to the length and shape as shown. this will act as door

retention and an alignment guide | |

Bevel both the front and rear inward to

allow for alignment of the door | |

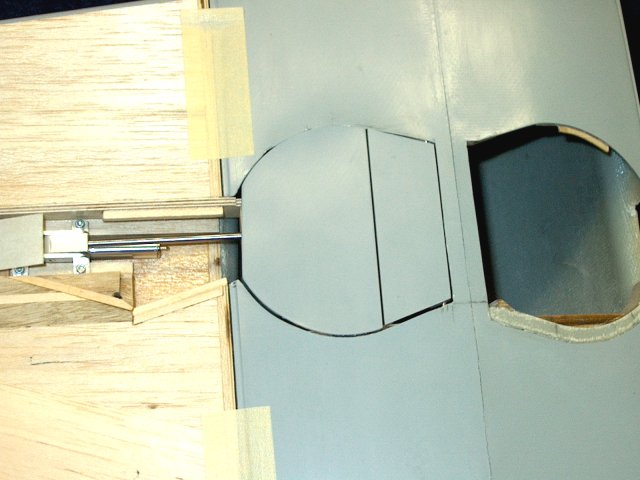

Install the retract and colapse the gear.

Rub a pencil across the top of the gear wire as shown

| |

Position the door bracket in place and

lift the gear wire | |

The gear wire transfered its location to

the bracket | |

Cut a short piece of 1/8" ply and epoxy it

in place to the back side of the gear(right)

| |

Cut a second block and use it to wedge the

gear wire between it and the other block. Apply thin coat of

CA to the top of the two blocks to prep them for

drilling | |

Drill 1/16" holes through the center of

each small block and out the bottom of the bracket. Epoxy a

small diameter piece of elastic cord in one hole, then when

set, epoxy the other side in, keeping some tension on the cord

so it dries while semi-taught | |

Slip the asssembly over the gear wire. Use

small pieces of masking tape to keep it from shifting position

on the wire | |

Apply epoxy to the top surface of the

bracket assembly | |

Use tape to hold the gear wire down and

out of the way | |

Position the door in its opening and tape

in place | |

Tape the top of the door over the

hinge | |

Lift the gear wire until the bracket

touches and glues to the inside of the door. Allow the glue to

set | |

Door Bracket is shown correctly

installed | |

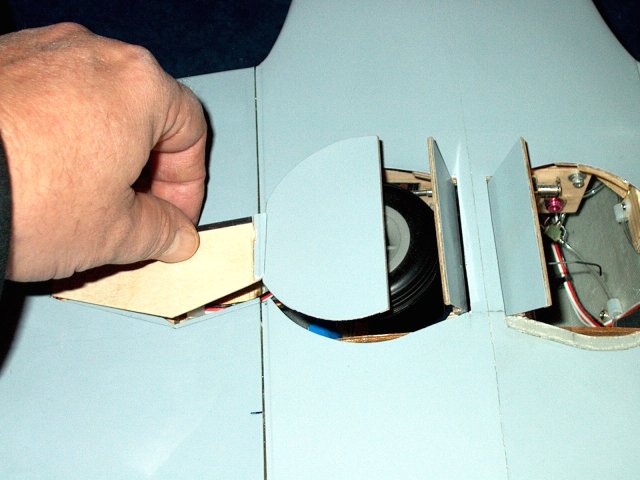

Locate the area of fuselage you removed

for the gear and wheel; this will be used as the doors. Trim

the top of the fiberglass door as shown and keep both

pieces | |

Measure 1" from the inside flat area of

the door and cut the smaller door away from the larger

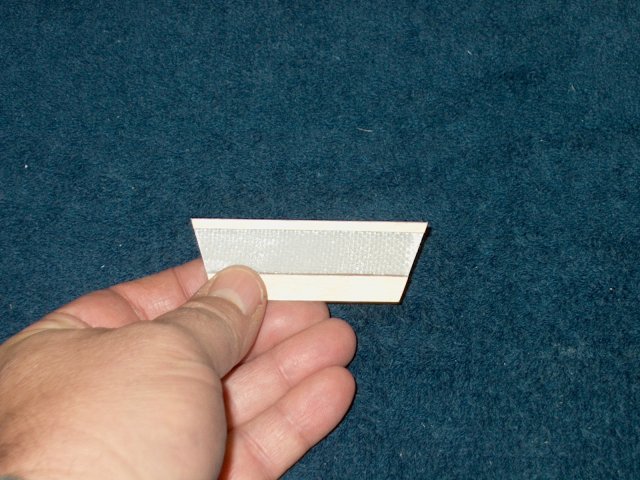

| |

Lightly sand the smaller door to smooth

the ends | |

epoxy a piece of 1/16" thick ply that is

1/16" wide along the short side length of the door

| |

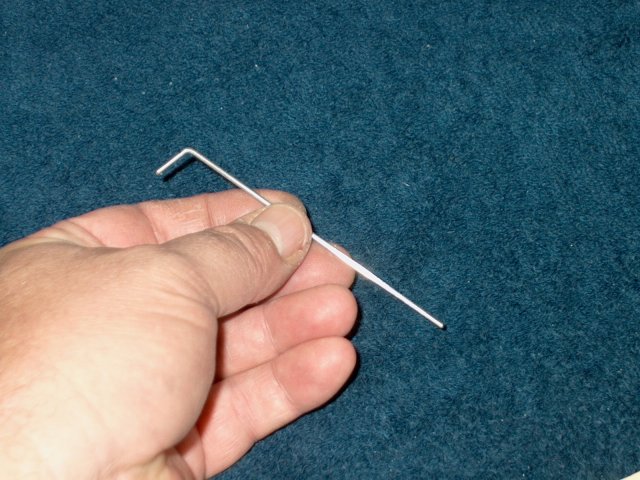

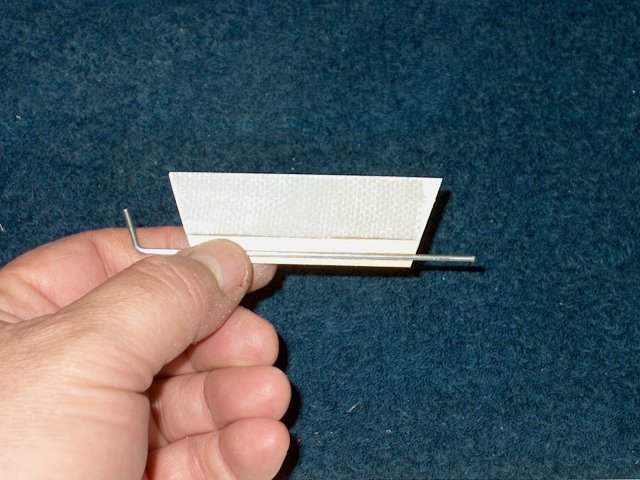

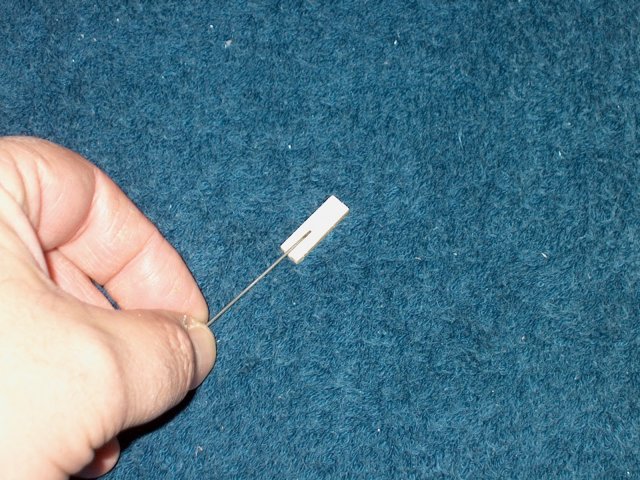

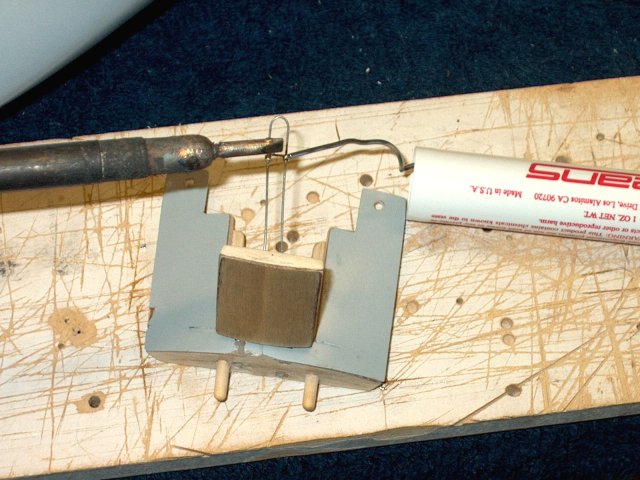

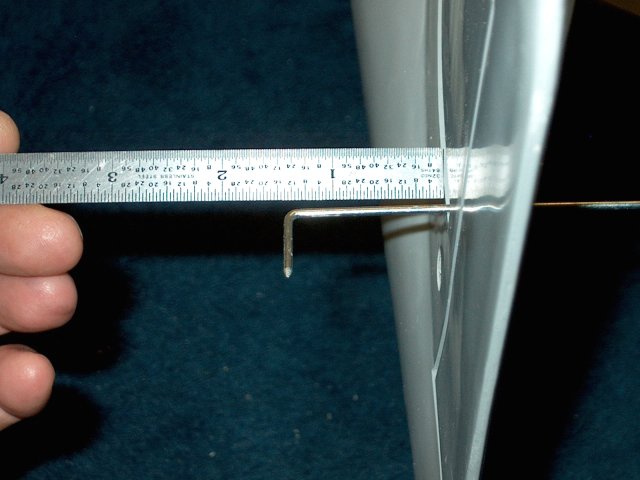

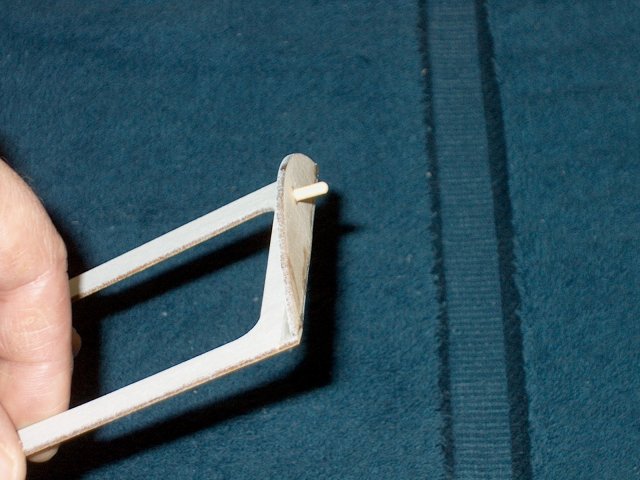

Make a wire hinge from 2-56 pushrod and

bend as shown in the templates | |

Place the wire in position as shown and

cut an inner 1/16" ply piece at least 1/8" wide. It will be

placed above the wire to wedge and hold the wire in

place | |

Cap the assembly with a final piece of

1/16" thick ply wide enough to cap the assembly

| |

Ply ends are shown glued in place

| |

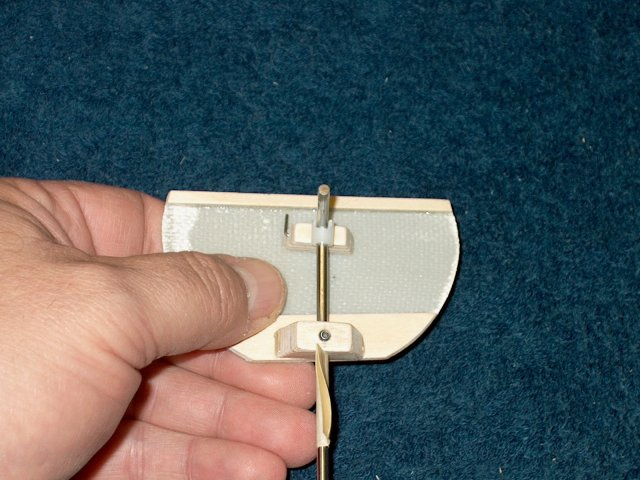

Mark a center line on the wide ply plate.

Use a saw to slot only down to the hinge.

| |

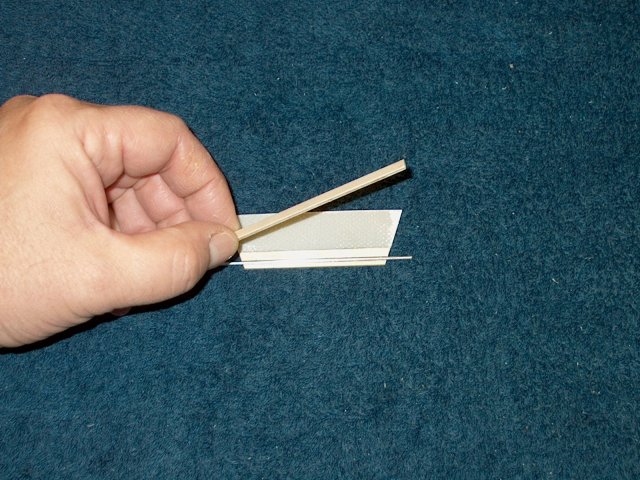

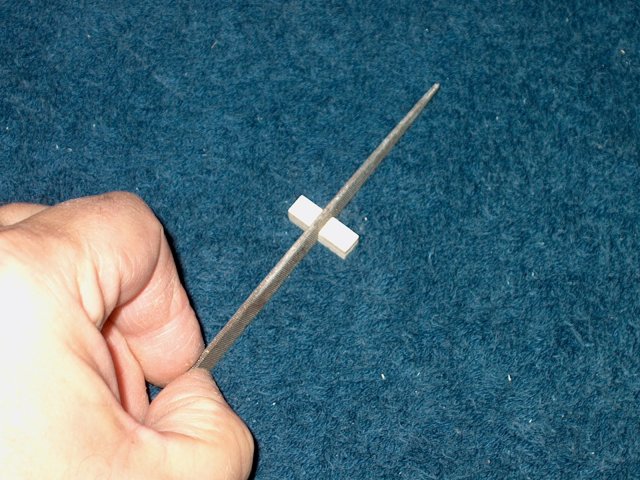

Bend a piece of micro pushrod as

shown | |

The pushrod is a fraction longer so it can

push into the thin ply brace at the bottom, then slide into

the slot you cut with a saw as shown at the top

| |

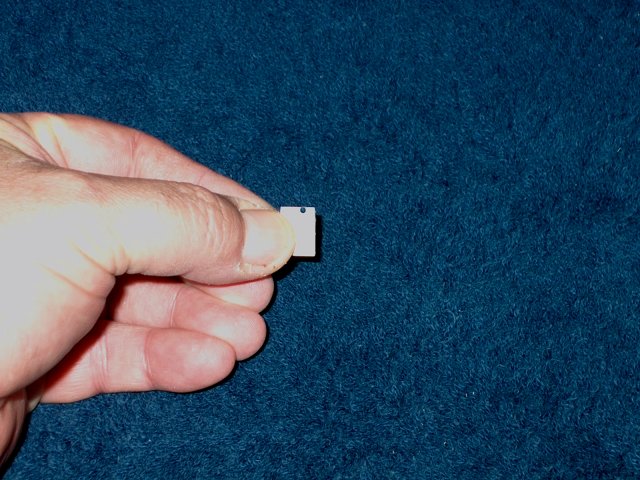

Cut a small piece of 1/16" thick x 1/4"

wide ply so it fits between the two ply braces. Slot it so it

will cover the micro wire | |

Epoxy the short ply over the micro wire as

shown | |

Bend the wire 1/14" past the rear of the

door | |

Position the door temporarily in place.

Remove any fuselage glue that will get in the way over the

next few steps | |

Cut a piece of 1/8" thick ply to 3/8" x

1/2" in size and drill a 1/16" hole on one end as shown

| |

Cut the rear hinge bracket from the

template and glue the bottom side with a thin piece of 1/16"

ply, followed by the hinge rod and capped with another piece

of ply. | |

Remove the excess ply from the bracket

witha saw | |

Rear hinge shown ready to install

| |

the wheel door is prepped by adding a

strip of 1/16" thick x 1/8" ply to the long edge

| |

Epoxy the wood strip to the door

edge | |

Clamp and hold flat the glued side as the

strip of wood can be used to remove any warping in the glass

door | |

Cut a 1/16" x 1/2" wide strip of ply and

shape the ends to the contour of the wheel door

| |

Once again, epoxy the strip in place,

clamping to a flat surface so it reshapes the door and removes

warping | |

Sand the ends of the ply barces flush to

the glassed door | |

Install the wire hinge on the fuselage

door | |

Sand the inside of the fuselage to allow

for good glue purchase | |

Center the door in its location and use

masking tape to hold it in place | |

Apply epoxy to the rear hinge ply bracket,

but keep the slot free of epoxy | |

Position the bracket in the fuselage and

over the hinge wire using a knife to hold the piece

| |

Apply fillets of glue along the sides of

the hinge bracket | |

Remove any excess epoxy from the fillets

and once the glue begins to set, twist the wire hinge so it

doesn't get glued in position and can be removed later

| |

Apply epoxy the the forward ply

hinge | |

Epoxy the forward bracket in place and

push the hinge rod through the hole in the bracket. Reposition

the bracket so the door is spaced evenly in the fuselage and

let the glue set | |

Cut a piece of 1/8" inner diameter brass

tube to the length of 5/32" as shown

| |

Mark the landing gear wires at 1" from one

end | |

Using a vise and hammer, bend right angles

on each rod at the 1" mark as shown. You can tape the wires

together side by side to make sure they are even to

eachother | |

Once bent, measure the length of the wire;

it should be 4 inches | |

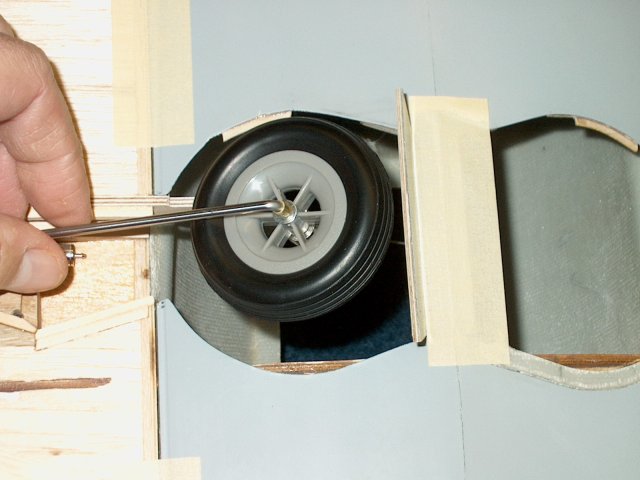

Install the brass tube over the wire,

which is a spacer for the wheel, then install a 4-40

washer | |

Install the wheel and finally the supplied

wheel collar | |

Tighten the wheel collar and make sure the

wheel spins freely with no binding | |

Install the gear wire in the retract

assembly | |

Fold the gear over and check for

clearance | |

Install the short door on the

fuselage | |

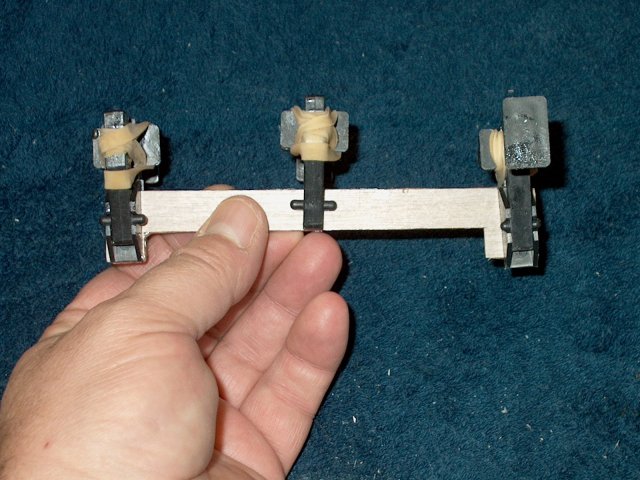

Cut three pieces of 1/8" ply to a width of

5/16" and length of 7/8", then split the center piece in

half | |

Place one of the ply pieces under the gear

and flush to the secondary Spar, then mark the wire side

locations on the ply | |

Epoxy the two short pieces at the

locations, using a 1/8" wire to gauge for a snug fit

| |

Remove the excess ply from the center

pieces that are hanging over the ends

| |

Epoxy the third ply piece in place,

centered over the assembly | |

Sand the bracket to shape, beveling the

edges as shown. The bevel will act as a guide against the

Secondary Spar and keep the wheel aligned when

retracted | |

Apply a coat or two of thin CA over the

top of the bracket | |

Use a 5/64" drill to make a hole dead

center over the assembly. Only drill through the top piece of

wood | |

Use a 4-40 Tap to make threads in the wood

hole. Add a couple drops of thin CA to harden the threads and

tap once again when the glue has dried

| |

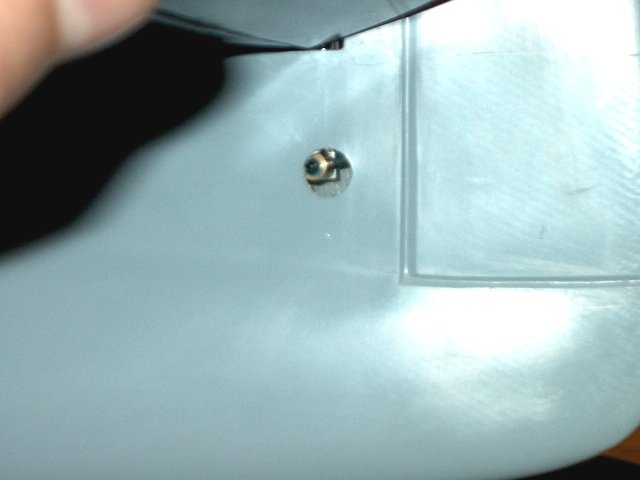

Install a 4-40 set screw in the tapped

hole | |

Use a scrap piece of 1/32" ply and draw

the curve of the wheel opening on the ply

| |

Cut out the piece 1/2" wide and 3/4" long.

Shape and sand/round the corners | |

Make a mark on the fuselage 1/2" from the

short door as shown | |

Epoxy the 1/32" ply stop plate in position

and line up the side with the mark for proper spacing

| |

Use a file to sand down the top area of

the secondary spar as shown so that the wheel door will sit

flush with the fuselage | |

Check to make sure the door sits flush

where you notched the spar | |

Space the round door evenly in the opening

and then tape it to the small door to hold it in place

| |

Flip the door out of the way and apply

epoxy to the upper bracket as shown. Check that the position

of the bracket is high enough so it won't rub against the

wheel | |

Flip the door back over and press it down

on the bracket with epoxy. Allow some time for the epoxy to

set | |

Lift the door once the epoxy initially

sets and allow the glue full set time.

| |

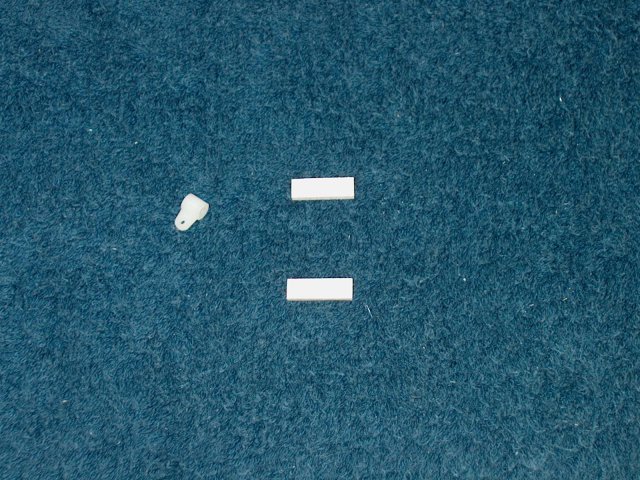

Cut the two lower door mount pieces from

the templates. They are 1/8" thick ply x 1/4" x 3/4" long and

you will also need a 1/8" diameter horn bracket

| |

Notch the top of the horn bracket as shown

so it cannot twist on the elbow of the wire gear

| |

Slide the horn bracket in place as

shown | |

Install the gear and close the assmebly.

Adjust the position of the wheel door and lock it in place

with tape when centered | |

Use masking around the shaft so the door

cannot slide out of position | |

Remove the wheel, make sure the door is

slid against the tape on the left, then check the position of

the bracket horn | |

Draw a center line down one of the ply

lower mount pieces | |

Slot the top of one of the lower door

mount ply pieces so a micro rod sits in the slot flush with

the top of the ply surface. Scraping with the micro rod works

well for this task | |

Use epoxy to glue the two pieces as shown,

using the wire as a guide. Be sure to remove the wire before

the epoxy sets | |

Sand down the end of the bracket to about

half its thickness and round the end when done

| |

Use a dremel to cut a slot in the top

center of the mount. NOTE: The top part of the assembly is the

ply piece that was NOT slotted for the micro rod. The slotted

piece is on the bottom | |

A file is used to widen the slot so the

plastic horn bracket fits | |

The slot will need to be cut deep so that

only one layer or so of ply remains

| |

Use a dremel and sanding drum to bevel the

ends of the assembly. Lightly sand all edges to round

them | |

Install the horn bracket in the assembly,

then pin it in with a piece of micro wire. A small "L" shaped

handle can be bent in the wire to aid with installation

| |

The assembly allows for some pivoting of

the bracket horn so you can adjust the position of the

door | |

Place the mount assembly on the wire, make

sure the tape on the left of the wire is flush with the top

door mount and then use a pencil to transfer the location of

the mount to the door. Make a small mark on the top of the

mount to indicate direction so it doesn't get flipped around,

which could cause alignment problems

| |

Move the wire out of the way, then apply

epoxy to the bottom of the lower mount

| |

Install the mount and clean up any excess

epoxy | |

Install the assembly and adjust the door

position, then use the set screw to lock it in place.

| |

you can adjust the door so it is centered

in the fuselage well | |

The door closing wire is bent to work as

shown. Adjust the wire so the door closes and does not hang on

the wire | |

Find the short piece of fiberglass you cut

from the top of the round door and sand the inside curve so it

is flat | |

Tape the wing door in place

| |

Apply epoxy to the short glass

piece | |

Install the piece to fill in the gap

between the wing door and wheel door and leave a small space

between them as shown | |

Build the door stop assembly from the

templates. It consists of two pieces of 1/8" ply

| |

Use the wheel to adjust the angle of the

inner door while open, allowing ample clearance for the wheel.

Place a piece of masking tape behind the door so it only opens

as far as needed | |

Epoxy the door stop in place as shown.

Close the door to make sure the stop is not too high. you can

treat the door area and stop with CA to harden them and extend

wear | |

Once glued, the extra wood can be removed

with a drum sander so the door stop is shaped as shown

| |

Cut the Door Spring pattern from the

template...it is a piece of ply 1/8" thick by 1/4" wide x 1"

long | |

Make a centerline down the length of both

sides of the ply | |

Grind the lower side to a bevel, from the

bottom of the wood to the line at midpoint. Repeat for the

other side of the wood | |

Your goal is to wind up with a piece that

is diamond shaped as shown from the side

| |

Mark and cut the piece in half so you wind

up with two 1/2" long mounts | |

Epoxy the mount to the rear of the door,

making sure the bottom of the mount starts above the seam of

the ply and fiberglass door, otherwise it will bind with the

fuselage | |

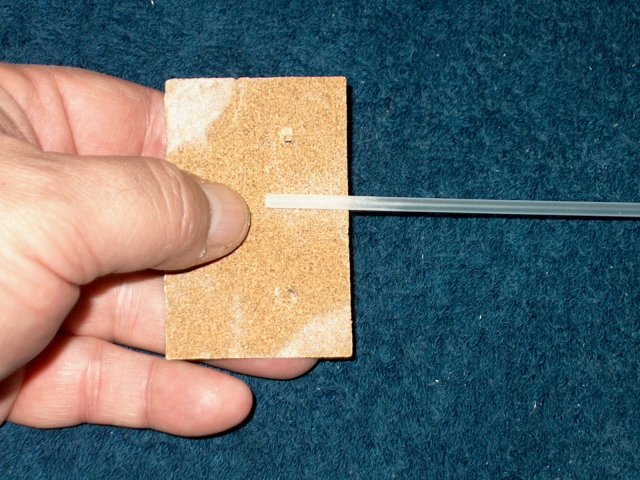

Sand a piece of plastic antenna tube to

rough up the outside | |

Cut two 1/2" long pieces of antenna tube.

Note it is easier to do both doors at the same time

| |

Epoxy the tubes to the upper back side of

the doors and add fillets as necessary

| |

The door closing wire is bent to work as

shown. Adjust the wire so the door closes and does not hang on

the wire | |

Bend a small piece of fine music wire to

the shape below | |

A wood block is cut and drilled through

the top through the front of the bar at two locations for the

inner fuselage door tensioning wires. It is glued in place as

shown, then fine .020" wire is cut and routed to the door

tubes as shown. These doors work similarly to the main

nosegear door, so that they spring open and closed

| |

Install the doors, making sure you thread

the wire through each door spring tube. Once installed, cut

the wires to length. Bend the wire to adjust tension...each

door should open completely against their stops as

shown | |

Mark the wing location for the

nacelle | |

Cover the wing with iron-on material. You

can either reuse the old covering or iron on new

material | |

Cut out the door area and dress it as

shown | |

Make sure you removed the covering from

the top side of the wing, where the nacelle overlaps

| |

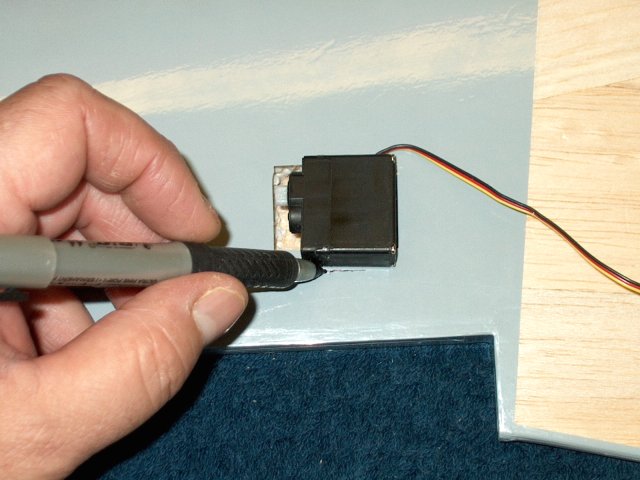

Check the Aileron servo opening and mark

as necessary to cut to size | |

Cut the servo area to fit the particular

servo you plan to use. HS-81's were used in the photos

| |

Center your servo using a receiver or

servo tester, then cut and install the long horn as shown,

then install the retention screw | |

Test fit the servo in the well and make

sure it clears at the horn end | |

Cut a piece of 1/32" ply to the dimensions

in the templates for the Aileron servo ply mount

| |

Glaze the top of the ply with CA and sand

to a smooth finish | |

Apply epoxy to the bottom of the plate and

epoxy the ply servo mount to the wing as shown

| |

Make a cover for the servo from 1/32" or

1/64" ply. It is easier to make both covers at the same time.

Apply thin CA to the top and bottom corners so the wood

doesn't splinter when drilled | |

Tape is used as a guide to position the

cover. There should be about 1/4" of clearance around the

sides of the cover | |

Tape the cover in place and use a 1/16"

drill to make holes at each corner, about 1/8" in from the

ends | |

Remove the cover and mark its location and

direction as shown so they don't get mixed up later

| |

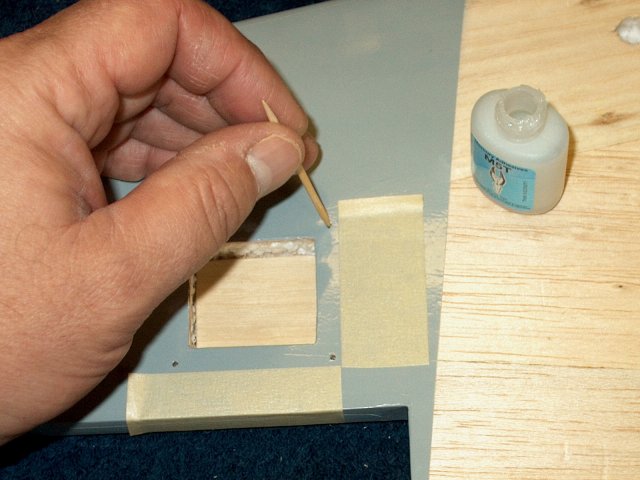

Apply thin CA to the wing holes with a

toothpick | |

Open up the holes in the corners of the

ply with a 5/64" bit so they are large enough for the #2

screws. Place the cover over its location and transfer the

horn area to the cover, then cut out the slot

| |

Clean the servo back with acetone to

remove all grease, then apply servo tape to the back of the

servo | |

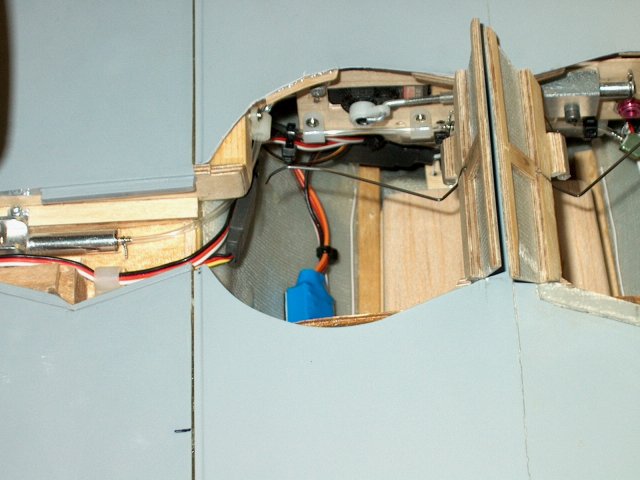

Tape the servo connector to a long, flat

piece of fiber or a thin piece of wire. Insert the wire

through the wing hole. Thread the servo wire through the hole,

then pull the servo connector out into the retract area as

shown. Remove the tape | |

Remove the backing from the tape and

install the servo in the wing | |

Use four button head #2 x 3/8" screws to

install the servo cover | |

Check for clearance between the cover and

horn. File and sand if necessary | |

Find the Aileron hinges that were supplied

in the kit. Draw center lines down each hinge

| |

Install but do not glue the hinges in the

wing. Note that a third "center" hinge was added in the photo

for extra safety but it is not essential

| |

Install the Aileron on the wing

hinges | |

Use thin CA and glue the hinges to the

wing. Clean up with a paper towel and be sure to apply CA to

both sides of the wing at the hinge locations

| |

Install a clevis on one of the pushrods.

Note that plastic clevis' are shown in the pic, but you may

have metal ones | |

Clip the clevis to an Aileron control horn

supplied in the kit. Keeping the wire even with the servo and

side of the cover, position the horn as shown and drill the

hole with a 5/64" bit | |

Install one screw to hold it in place,

then drill the other side and install the second horn

screw | |

Cut and grind the extra screw length from

the top of the wing | |

With the clevis installed and the Aileron

clamped (as shown on the bottom) to keep it centered, make

sure the servo is still centered, then mark the location of

the servo horn hole on the rod | |

Drill the horn at the end hole so it can

accept the pushrod. Use a 1/16" bit, then open it up more with

a 5/64" bit if needed | |

Remove the clevis from the wire and make a

"Z" bend at the mark. A ruler is shown for size

reference | |

Install the clevis on the rod, then

install the pushrod assembly. This concludes the wing retract

and control installation | |

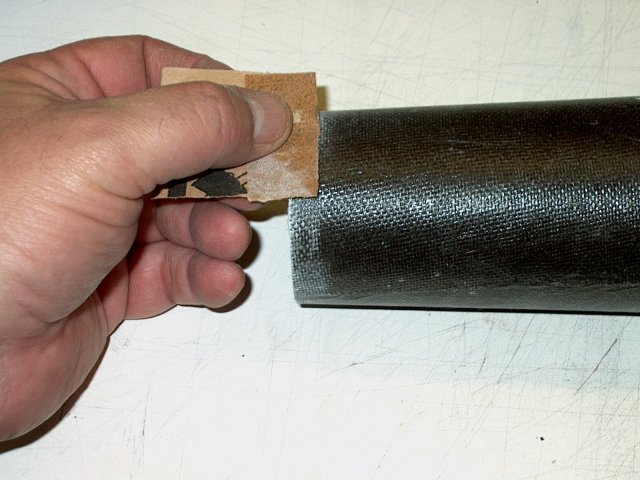

Begin work on the power assembly by

locating a Nacelle, then begin by sanding the lip from the

front of the nacelle. Note that the intake is actually the

long side | |

MEasure your intake so you know how much

to sand. You will need toopen it up to about 62mm so the inner

fiberglass intake tube is at 60mm in diameter

| |

Tape can be used as a guide for sanding.

Wrap some vinyl tape around the end, exposing about 1/8" to

start | |

Sand down to the tape. A dremel with a

sanding drum makes it easy work. Be sure to wear a long

sleeved shirt and full length pants, as well as a mask to

prevent irritation that can occur from the dust

| |

USe a fine sander to finish up the first

cut. Measure the diameter and repeat as necessary until the

hole is opened to the correct diameter

| |

Fine sand the intake lip of the

nacelle | |

Use a drum to sand down the glue seam on

the inside so it is not in the way | |

Final measurement shows the nacelle is

ready for the intake inner tube | |

Install the tube from the bottom of the

nacelle | |

Push the nacelle forward through the

intake hole in the nacelle | |

Locate your fan shroud and trim a

monunting tab from one side. Install the shroud in the rear of

the intake and use it to center the intake at the rear

| |

At the front, draw a line around the

Intake Tube | |

USe a dremel or hobby saw to remove the

excess. Be sure to cut the piece long so you have a little

extra to shape it to exact length | |

Rough up the outside end of the intake

tube | |

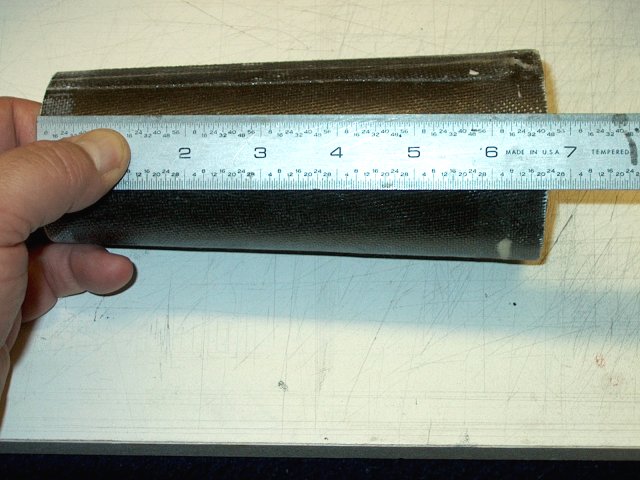

Final Intake Tube length shows around 6

3/4" long | |

Once again, install the intake tube and

Fan Shroud as shown | |

Apply a bead of epoxy around the front

inside of the nacelle as shown | |

Push the fan shroud and intake inner tube

forward through the front until it stops. Remove the excess

epoxy with paper towels and alcohol

| |

Leave the unit upright as shown to alow

the epoxy to flow down into the joint. Also make sure the fan

shroud is seated and centered in the opening

| |

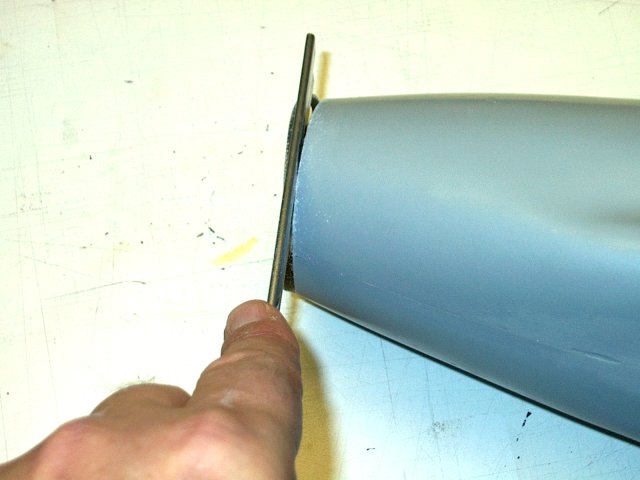

Use a saw or sand the remaining intake

from the front once the glue sets | |

Fine sand the front of the intake

assmebly | |

Lightly sand the edges to slightly round

them as shown | |

Move to the rear of the Nacelle. It should

be 55-58mm in diameter | |

Sand the opening until it is at the

required size | |

When finished, this model's nacelle was

sized for a 55mm exhaust tube | |

Lightly sand the edges of the Nacelle

smooth with fine sandpaper | |

Trim the covering if necessary so that

about 1/16" overlaps on the inside | |

Use a file if necessary to shape the rear

corner of the nacelle on the Aileron side, as the wing may

flatten out at this point. Check the fit

| |

Apply masking tape to each side of the

wing on the outside of each line to catch any epoxy

overflow | |

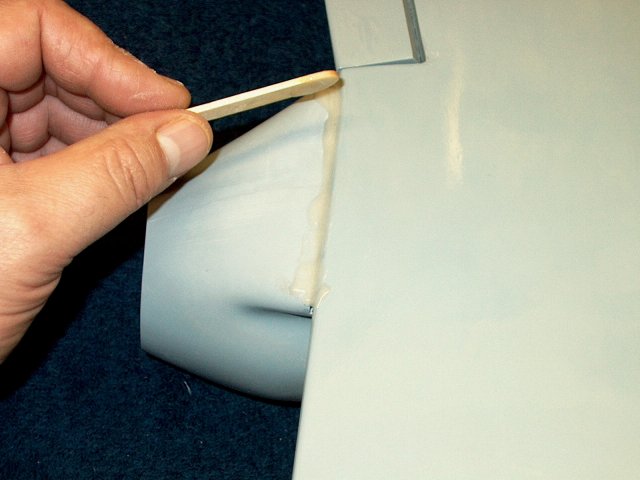

Apply an ample amount of epoxy to the

nacelle only as shown | |

Install the Nacelle on the wing and check

alignment before the epoxy sets | |

If there a gaps between the wing and

nacelle, fill them with a mixture of epoxy and fiberglass mil,

or any other thickener. Remove the tape and clean as necessary

before the glue sets | |

You can apply a small fillet of epoxy

along the rear of the nacelle if desired

| |

Form the thin fillet to a nice transition

from wing to nacelle | |

A similar fillet can applied to the front

of the nacelle | |

If you are painting your model, fill the

gap at the front of the wing with filler, then sand and

paint | |

Use a rolled up piece of fine sandpaper to

open the hole for the ESC wires | |

Apply masking to the wing to catch epoxy

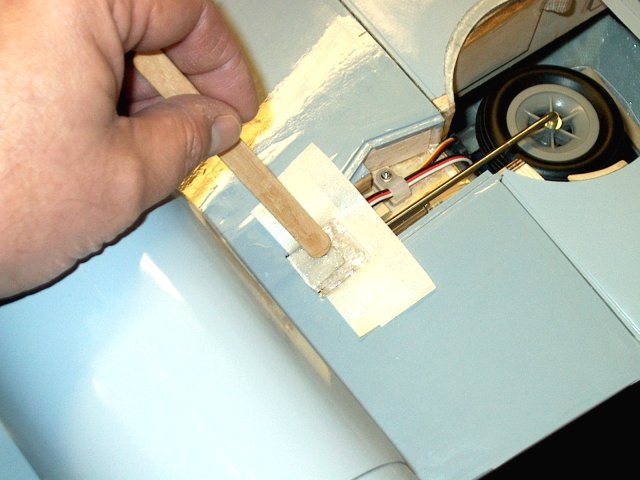

spill over | |

Apply masking tape to the fuselage as you

did the wing | |

Use 15-30 minute epoxy to give you some

working time and apply epoxy to the fuselage root slot with a

mixing stick | |

Apply epoxy to the wing spar. Make sure it

is installed in the correct direction with it angling upward

toward the top of the fuselage | |

Spread epoxy along the fuselage wing root

and sides of the spar | |

Apply epoxy the the wing root and spar

slot. Keep the secodary rear spar clean

| |

Install the wing on the fuselage. Make

sure it fits flush, as this will produce a built in dihedral

in the wing. Clean up the excess epoxy and remove the masking

tape | |

Cut the 1/2" square hardwood block from

the template, then apply epoxy to the secondary spar end and

the inside of the block | |

Install the block in the wing and allow

the epoxy to set | |

This completes our wing installation.

Repeat the procedure from the beginning for the second

wing | |

Installation of the second wing shown

completed | |

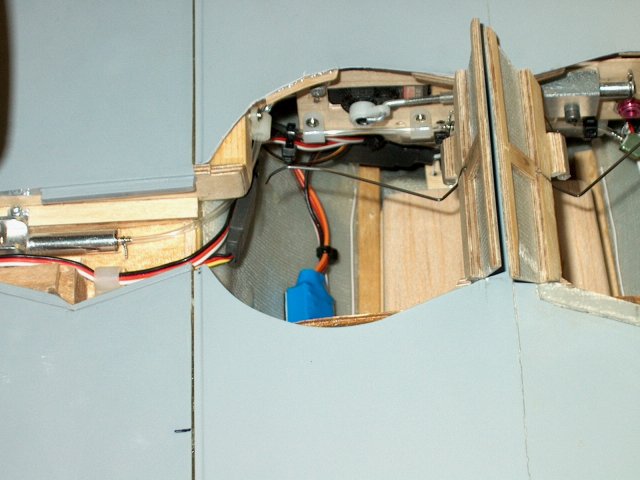

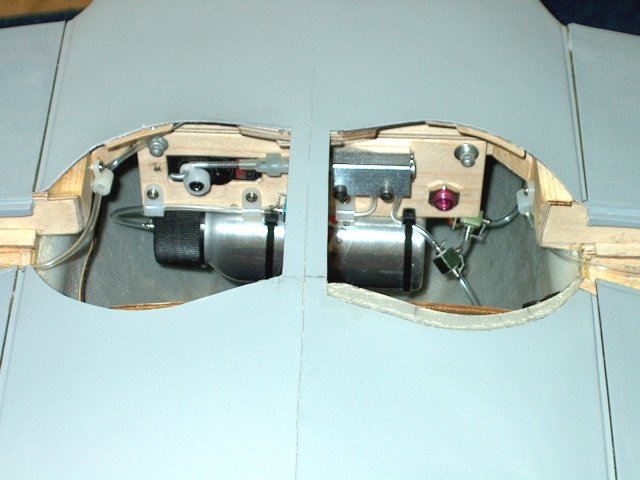

Install the retract units in each

wing | |

Install each strut and wheel into the

retracts | |

Examine the fuselage and look for the rear

seam of the nosewheel plate that is under the fiberglass. It

should appear as a bump in the fuselage. Draw a line about

1/8" behind the pre-installed gear hole, or far enough away so

you don't cut into the stock former

| |

Use a piece of paper aligned at the center

seam to make sure your line is square

| |

Measure 1 1/4" from the center of the seam

in each direction. This will be the location of the sides of

the nosegear hatch | |

Measure and draw lines rearward, making

sure they remain parallel to the center seam. Draw a line at

2" from the front for the rear of the hatch

| |

Draw two lines on the inside 1/2" inward

from the outer lines | |

Measure and draw a line 1/4" from the

front line as shown | |

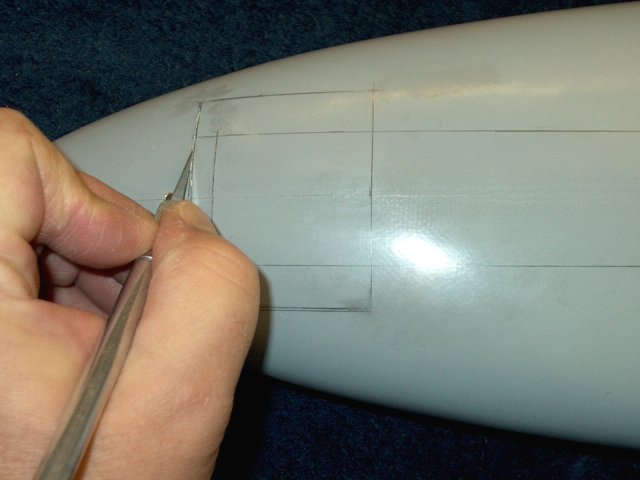

Score and cut the front of the hatch as

shown, taking your time | |

Use a ruler and cut each side outer line

as shown | |

Extend the inner lines rearward on the

fuselage for the main door and back about 6"

| |

Cut the back end as shown. The main door

extends 1/2" into the hatch area. The remaining main door can

be cut to a length of 5 3/4" | |

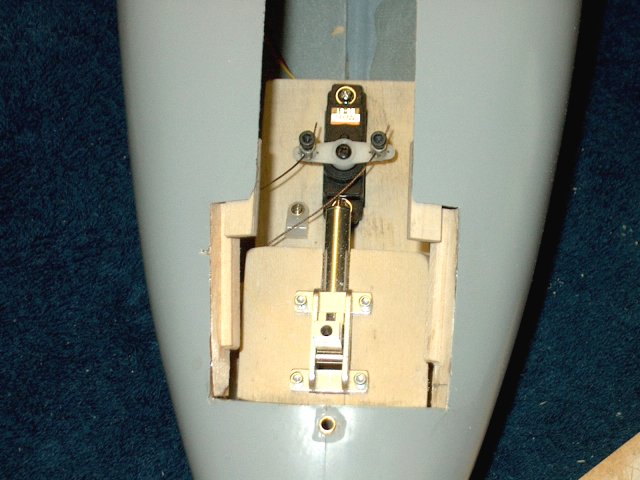

Cut a 1/8" ply Retract Mounting Plate from

the templates | |

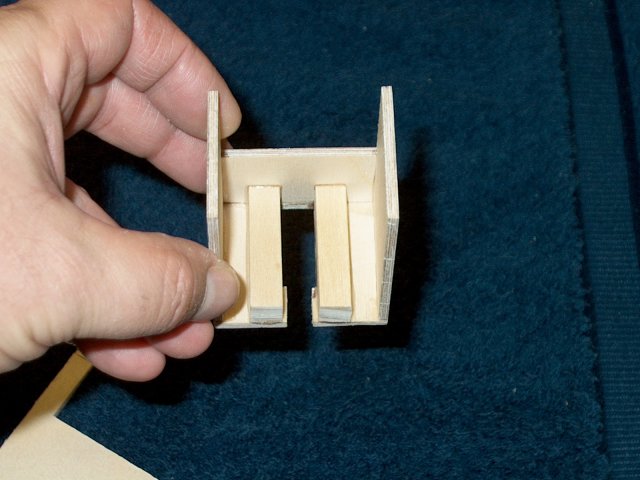

Install a 1/8" ply rear plate as well as

two side plates. While the side plates appear longer in the

pics, they should be 1" wide/tall like the rear. Glue two

strips of 3/8" square hardwood block to add more support for

the mounting screws | |

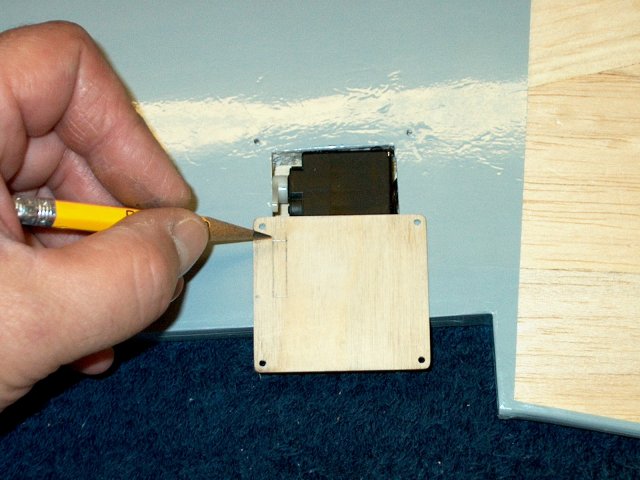

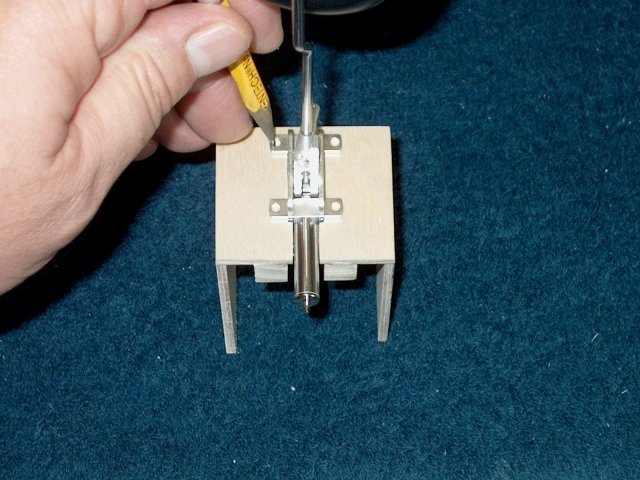

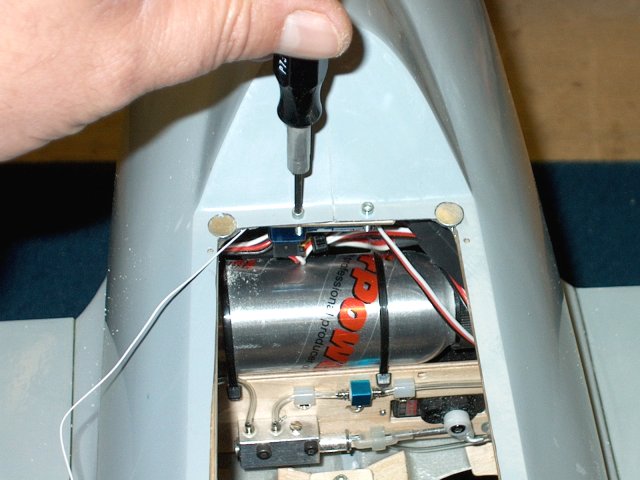

Install the retract and mark the mounting

holes with a pencil, then drill with a small bit

| |

Install #2 x 3/8" long hex head screws to

retain the retract unit | |

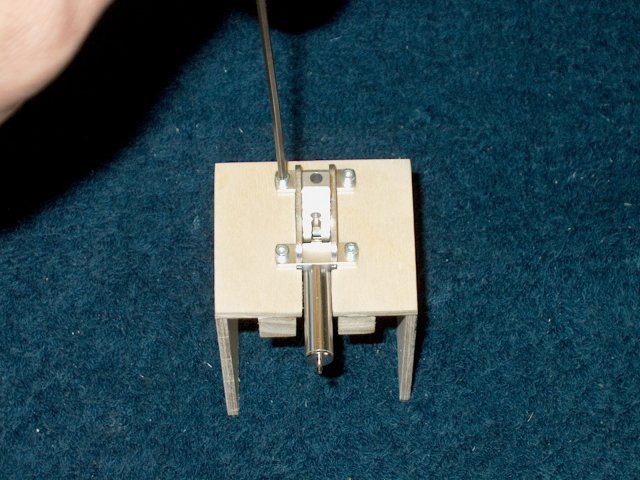

Check the fit of the retract against the

gear plate that came mounted in the fuselage. Additional ply

was added to the back and angled to compensate for the stock

nosegear plate that was mounted crooked

| |

Check your rearward angle on the gear and

sand the back plate as necessary. There should be ample angle

for the rear of the wheel to retract completely, 1/2" or so

past the bottom edge of the fuselage. A cross plate for the

floor is cut from 1/8" ply to fit across the inside of the

fuselage and the retract block sits on this plate. It may take

some time to shape it to fit | |

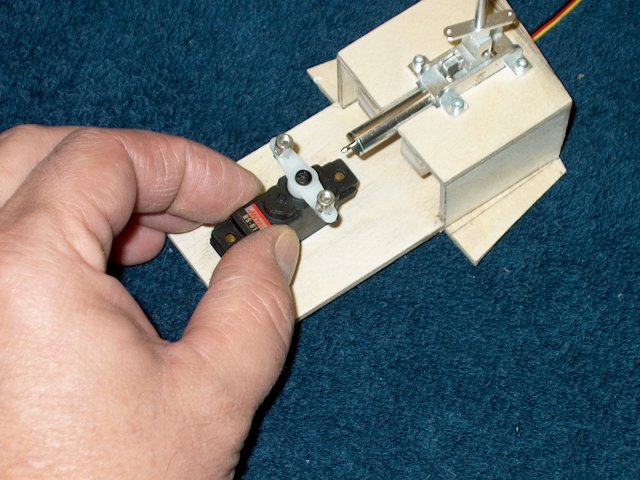

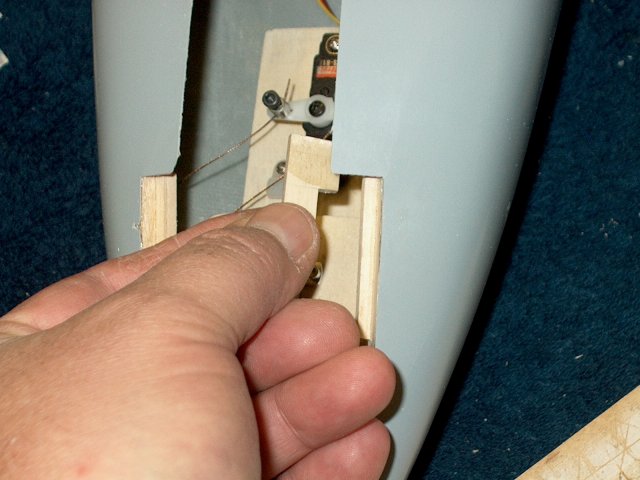

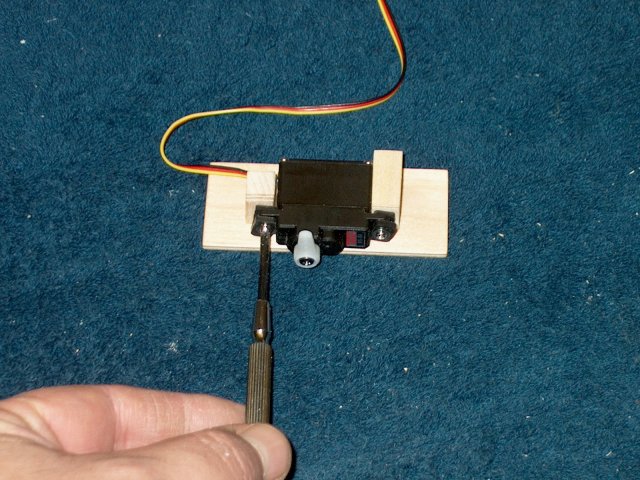

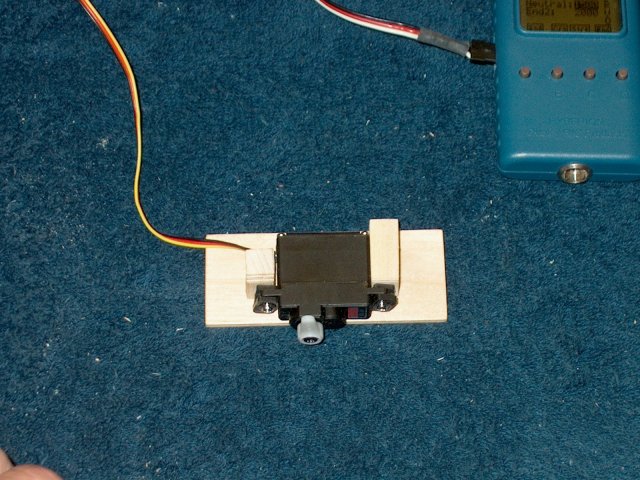

Cut the steering retract servo plate from

the templates. Note that a Hitec HS-81 was used in the

example, so you may need to cut the center hole differently to

fit your servo. Note that the notched sides of the plate

should fit inside the walls of the block

| |

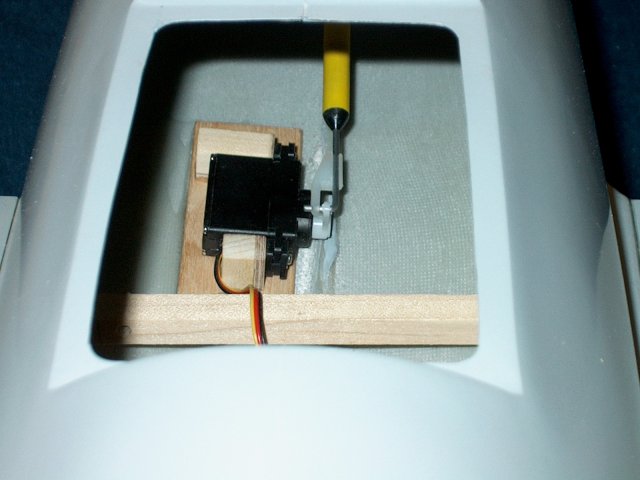

Epoxy the plate to the bottom inside of

the Retract block | |

Apply epoxy to the bottom of the block

assembly. Only apply epoxy in the area as shown

| |

Apply epoxy the the fuselage bottom

plate | |

Glue the two pieces together

| |

A couple of pieces of scrap 1/8" ply can

be cut 3/8" wide by 1" long and glued to the bottom to add

extra grip for the servo mounting screws

| |

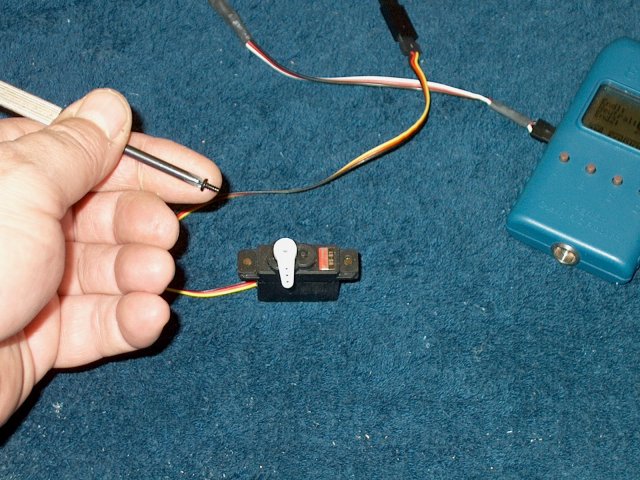

Center your servo using a receiver or

servo tester, then center your horn on the servo and install

the horn screw | |

Install the servo in the plate, making

sure to use the rubber mounting grommets as they will provide

some shock absorbtion for the steering mechanism

| |

Install the mounting screws supplied with

the servo to mount it to the plate | |

Install two Sullivan #550 pushrod

connectors in the second hole from each end of the horn. Apply

Loktite to the lockdown holes, then install the bolts

| |

Use a tailwheel wiring kit, slide a crimp

over the wire and then run the wire through the end of the

steering arm. Note the arm thin center shaft is on the

bottom | |

Thread the wire per instructions through

the crimp tube | |

Crimp and then trim the excess from the

wire. Repeat the installation for the other side of the

aluminum steering arm | |

Install the landing gear strut, then run

the wires through the servo connectors. Center, then tighten

the wires with the pushrod connector bolts and trim so there

is about 1/4" wire extending past each connector

| |

Check the functionality that the steering

wires will colapse in the up position, then check that they

are not too tight to lock down. If the gear doesn't lock down,

your wires are too tight. They should be taught, but not

tight. Adjust if necessary | |

Sand to round the corners of the block so

the wires do not snag on them during operation

| |

Instsall a 3/32" aileron horn bracket as

shown to help with the air hose routing

| |

Apply epoxy to the back plate and bottom

edges of the cross plate | |

Install the retract assembly against the

bottom floor and rear stock gear plate. Make sure the gear is

centered and not angled left or right

| |

Cover the block with masking, then apply

an epoxy/glass mil mix along the edges of the cross plate as

shown | |

The servo plate should be receeded into

the fuselage at least 3/4" | |

A custom length of 1/8" strut wire was

used to make the extra long nosegear strut. A drill and dremel

were used to cut down the 1/8" wire diameter to 3mm so it

would fit the retract. Narrow about 1" of wire from the

end | |

Insure the retract and steering arm can

fit the wire without being too loose or binding

| |

Use the stock retract wire to mark the

notch location | |

make sure the mark is drawn completely

around the wire | |

Use a dremel with cutting wheel to notch

the wire while spinning it in a drill. Use a file and

sandpaper to smooth the notch, using the drill to spin it like

a lathe. Check the assembly in the retract

| |

Make a mark at 1" from the other end of

the gear, then bend a right angle. A vise was used, but you

need to grind a slight round edge on the vise before hammering

the bend, otherwise the wire will crack from bending against a

sharp surface | |

Shape the gear to the template

| |

Slide a 1/8" id brass sleeve over the end

of the strut | |

Install the wheel, then the collar. Make

sure the wheel spins freely and doesn't bind

| |

Install the strut in the retract. Check

for rotation/turning without binding while the retension screw

holds the strut in place | |

Colapse the retract. It should clear the

rear of the main door | |

Use a sanding drum to remove the glue seam

left from manufacturing | |

Lightly sand the edges of the opening

smooth with fine sandpaper | |

Position and trace the nose opening curve

to a piece of 1/8" or 1/4" ply as shown

| |

The ply piece must be 1/4" thick. If you

used 1/8" ply as in the photos, make another piece

| |

Laminate the two 1/8" pieces together with

epoxy | |

Check the fit and adjust as

necessary | |

Use a 1/8" drill and drill a hole as

shown, through the 1/4" ply and into the stock ply former in

the nose | |

Use a wood dowel to hold the drilled

section in place and drill a second hole

| |

Cut two pieces of 1/8" dowel to a length

of 1/2", round the tips, then epoxy them in the holes

| |

Insert the ply plate and dowels into the

front of the nose. Use a piece of sotch tape between the joint

to catch glue overspill. Apply epoxy to the ply top and glue

both halves of the fiberglass hatch to the wood. Use tape to

hold it in shape until the glue sets

| |

Use a scrap piece of 1/8" ply to begin

framing in the opening | |

Put a piece of 1/4 angle balsa across the

back, then sand to shape | |

Apply epoxy to the 1/8" ply edge and angle

stock, then epoxy in place | |

Frame in the edges of the hatch with 1/8"

square ply as shown | |

Build and glue a second frame piece for

the opposite side of the fuselage. glue, then clamp in

place | |

Use smal 1/8" square pieces of basswood to

finish framing the inside of the hatch as shown

| |

Disgard the fiberglass pieces of small

door you had and cut one from 1/32" ply. Cut, sand and shape a

piece of 1/4" thick hardwood for the rear

| |

Frame in the inside of the door with 1/8"

x 1/16" pieces of basswood on the sides and 1/8" ply on the

front. Be sure to keep the curve in the door

| |

Cut to shorten the door stop tabs as

shown | |

Set the door in the opening and tape in

place. Small Robart pin hinges are used for door

mounting | |

Use a drill and make two holes into the

door for the hinges | |

As the hinges need to recess 1/8" inside

the top panel, cut 1/8" square openings for them. Drill

downward from this position so the pin hinges use the body of

the door plate as a good anchor to bond

| |

Check the fit of the hinges and clean up

the holes | |

Apply epoxy through the holes in the

hatch | |

Install the hinges in the hatch and dry

fit them to the door. Check for alignment and ease of movement

befor the glue sets | |

Trim the protruding hinges flush with the

hatch as shown | |

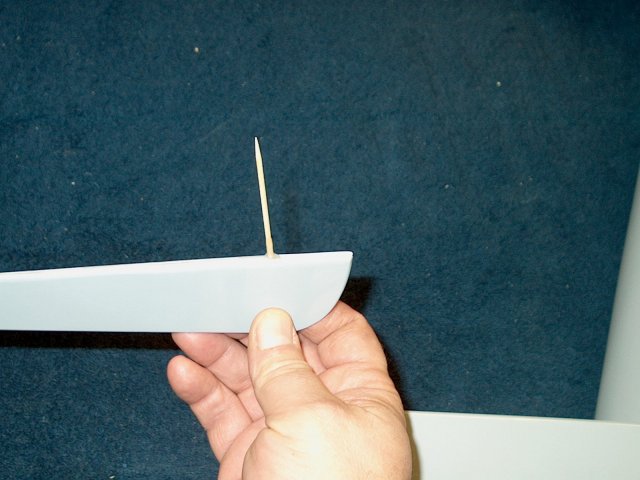

Use a toothpick to apply epoxy to the

holes in the small door | |

Install the door

| |

Position the door and check for free

movement before the epoxy sets | |

Trim the hinges flush as shown

| |

Cut two hatch mounts from the templates to

shape | |

Epoxy one of the mount plates in

place | |

Epoxy the other mount plate in the

fuselage | |

Install the hatch, then make marks at the

center of each end | |

Use a small drill to drill holes through

the hatch and the ply hatch mounts. Use #2 button head screws

to retain the hatch | |

Cut a piece of 1/16" x 3/8" wide ply to a

length so it fits inside the small door. Use a saw as shown to

cut only halfway through, so the surface is slotted

| |

Use sone .020" wire to make the shape as

shown. Cut two slots for the "L" shapes to fit

| |

Epoxy a piece of scrap 1/32" ply to hold

the wires in the slots | |

Bend the wire at an angle as shown

| |

Apply epoxy to the bottom of the

mount | |

Epoxy the wire and mount into the end of

the door as shown | |

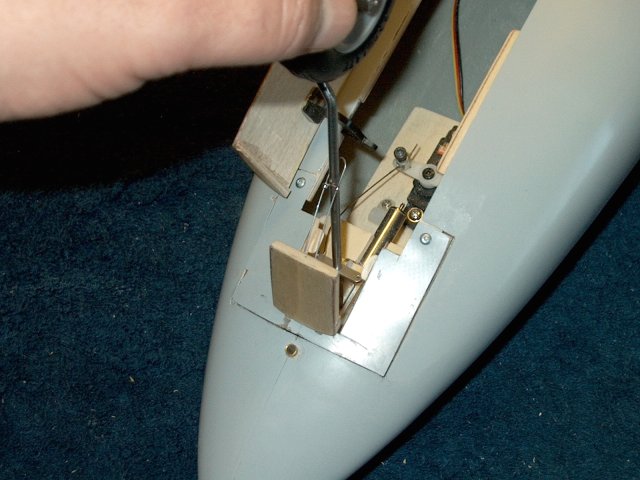

Twist a piece of solid copper wire around

the loop as shown, with the twists on the away side of the

loop | |

Solder the wire in place. the wire will be

used by the strut to "open" the door

| |

Install the strut and check the motion of

the door. The wire loop can be bet up or down to adjust so the

door just closes at full retraction

| |

Check opening of the door; it should not

bind when the retract is in full down position

| |

Cut a piece of 1/8" ply to fit the width

of the large door opening | |

Shape the ply piece to match the curve of

the hatch/small door | |

Cut two pieces of 1/64" ply so they are

oversized on all sides by about 1/4"

| |

Tape the door opening to catch epoxy

spillover and tape one end of the two ply pieces

| |

Open the pieces like a book, then apply a

film of epoxy to both pieces. Fold them together and press out

as much epoxy as you can | |

Tape the door to the opening, overlapping

the sides and rear. Slightly overlap the front at the

hatch/small door. Allow the epoxy to set halfway (5-10 mins

for 5 min epoxy) | |

Teh door can be bent and shaped while

still curing and semi soft. Trim the sides and back end so it

fits the opening. Flex or shape it as necessary. It should

have a slight curve at the front, as well as a slope

| |

Cut the outer door hinge mounts from 1/8"

ply and 1/32" ply | |

Slot the two ends of the ply, 3/32"

outward from the corners so a piece of small pushrod can fit

the slot | |

Laminate the two pieces together with

epoxy, then run the rod through the slots before the epoxy

cures to clean out the holes | |

Make two door inner hinges from plywood.

On the left is a 1/32" ply cap piece that is epoxied to cover

the slotted piece on the right. The right piece has a 1/32"

base piece, a 1/16" x 1/16" end edge piece on the far side and

a 1/32" x 1/4" wide piece on the left. Assemble the

hinge | |

Glue the hinge in place on the outside

edge of the door as shown, with the thin spacer closest to the

edge. Cap the assembly and clean up any excess glue. Make sure

the slot is clean all the way through

| |

The door is slotted just over 1/8" so the

Outer Hinge clears | |

Door assembly connected to the Outer

Hinge | |

Make a hinge pin from 2-56 pushrod so it

extends completely through and past the other end by at least

1/8" | |

Apply epoxy to the Outer Hinge and install

in the fuselage | |

Clamp the assembly down and make sure the

hinge is flush with the edge of the fuselage

| |

Install the door with the pin from the

front. You may have to flex the door until it clears the

opening. Note how wide the front outer hinge is...there is a

3/4" long piece of 1/8" wide Carbon Fiber rod under the narrow

hinge to help support it and prevent breakage

| |

Make a 1/8" x 1/8" horn from ply using

1/16" ply to elevate the bottom | |

Epoxy the ply horn in place as

shown | |

Bend a small piece of fine music wire to

the shape below | |

Install the wire through the ply horn,

then curved down and use a screw to hold it in place. The door

should now be able to "spring" open and closed. Squeeze the

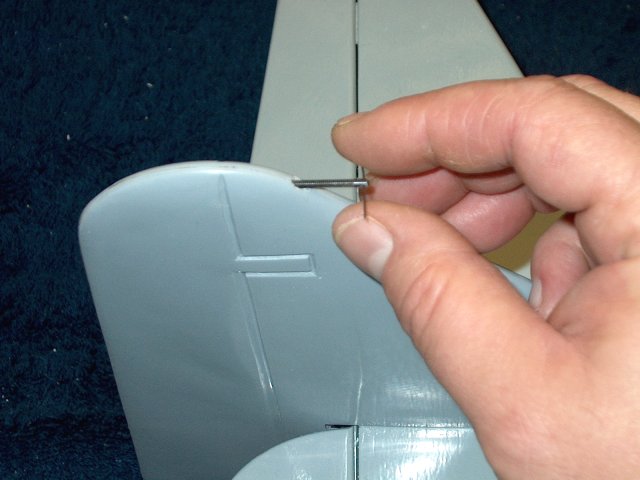

bend closer if the tension is too much, as the door should

snap shut without a hard slam | |

Round a piece of 3/8" square hardwood 1/2"

long is off at the top into a half-moon shape. A 3/32" hole is

drilled through the center | |

Epoxy the piece to the frame under the

outer side as shown. Note the position

| |

Tie a knot in one end of a piece of heavy

round elastic cord, then run it through the hole as

shown | |

Make a wood block from 1/8" ply with a

1/32" top cover. Drill a 3/16" hole in the center of the 1/8"

square and drill a 1/16" hole in the center of the 1/32"

square. Install the Sullivan #550 connector through the small

hole, install the nut and glue the two pieces together. Glue

the assembly in position as shown in the pic. Note the

position of the elastic cord | |

Adjust the length of the cord until the

door closes completely and has little or no slack inside, then

lock it down with a set screw. Turn the model carefully

upright and if adjusted properly, the gear should fall out of

the door under its own weight and lock down. Adjust as

necessary the door tension and cord position. This completes

the retract unit assmebly for the nosegear

| |

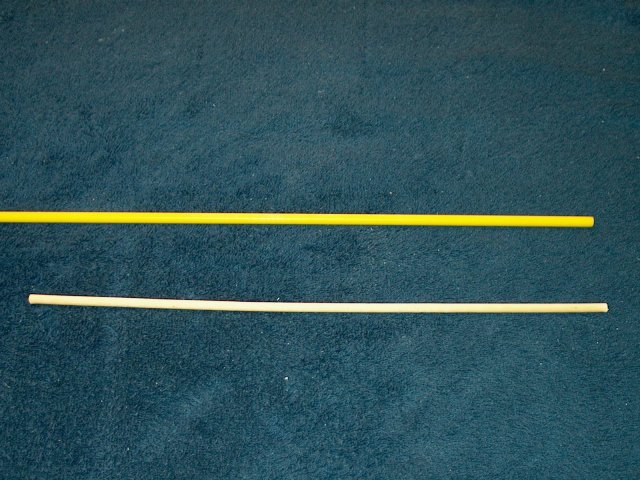

The supplied wood dowel used for the

Elevator pushrod was warped, so a fiberglass pushrod was

subtituted. Cut the rod to 15 1/2" long

| |

Drill one end of the rodper instructions

supplied with the glass pushrod | |

Install a 2-56 pushrod with a right angle

bend through the pushrod cap and outward, then epoxy the black

cap in the pushrod | |

Repeat for the other end and install the

2-56 pushrod | |

Bend a right angle at 1" from the end of

one side, then install the clip as shown

| |

Center the rear of the Stab in the tail,

then mark each side | |

Adjust the front of the stab until both

sides are equally spaced | |

Draw the location of the stab

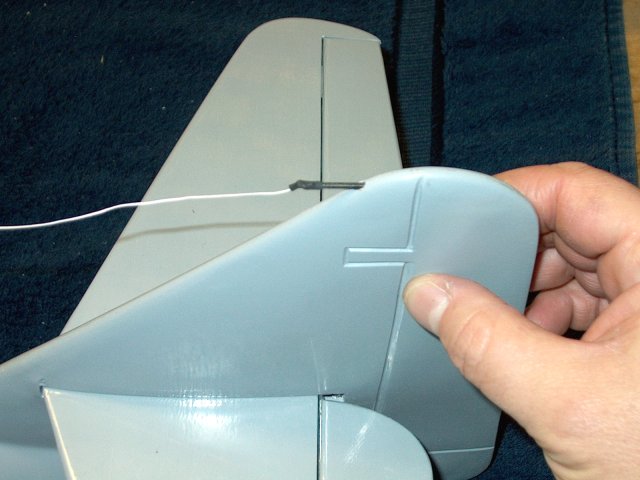

| |

Us a razor to cut and remove the covering

just inside the vertical stab location. Remove covering from

both the top and bottom of the stab

| |

Use an iron to seal the seam where your

cuts were made | |

Clean out the rear inside of the stab so

it doesn't bind on the Elevator pushrod

| |

Slightly round the center of the Elevator

control assembly with a dremel so it will not snag inside the

vertical stab | |

Make a bend as shown in the center horn

and install the pushrod connector. Test fit the assembly and

make sure it is centered when installed in the vertical stab.

If not, make the bend shallower until there is no rubbing and

the rods appear centered | |

Install the Elevator control assembly into

the fuselage as shown | |

Rotate the control rods so the horn is

visible in the large hole below the slot

| |

Measure and make marks on the rod at the

stab so the assembly can be evenly centered during permanent

installation | |

Install and center the stab on the marks

you made. Clean up the marks, then use thin CA on the top and

bottom seams to glue the stab to the fuselage. Believe it or

not, thin CA works great here | |

Use an iron to seal the seams on each

elevator. Slice the end down the center where the metal rod

will install, then use the iron to make a divot for the

rod | |

Draw a center line down each of the four

hinges | |

Install the hinges in place up to the

center lines | |

Apply epoxy to each elevator rod hole with

a toothpick | |

Quickly install the elevator over the

control rod and hinges. Clean up excess epoxy, then check

movement and centering of hinges and apply thin CA to the top

and bottom of each hinge to secure in place

| |

You should be able to find the elevator

pushrod connector through the hole. Install the pushrod and

clamp it down in the connector. I substituted a 3mm set screw

for the bolt that was supplied | |

Make an Elevator servo plate from scrap

1/8" ply and 3/8" square hardwood stick

| |

Trim away one side of the servo arm, then

use a receiver or servo tester to center your servo and

install the arm as shown | |

Install the servo on the board with servo

tape, then fit and epoxy the two hardwood blocks on the sides

of the servo | |

Install servo mounting hardware, grommets

and finally mounting screws to secure it in place

| |

Drill out the end hole in the arm so the

2-56 rod will fit | |

Center the servo once again before final

installation | |

Rough up the area for the servo plate

inside the bottom rear of the fuselage

| |

Apply epoxy to the bottom of the plate and

glue in place, making sure the servo arm is located near the

pushrod | |

Clamp the elevators even with the

horizontal stab, then install the pushrod on the servo arm,

loosen the rear set screw and adjust as needed

| |

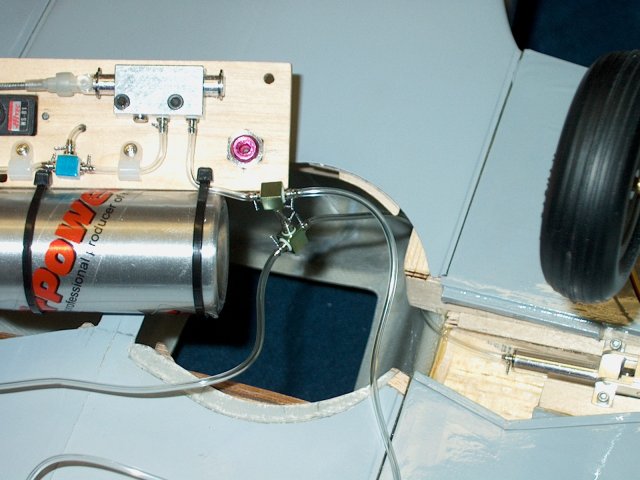

Finish installing the air hose for the

retracts | |

A clamp is made for the forward

hose | |

Install the hose clamp as shown for the

front wheel assembly | |

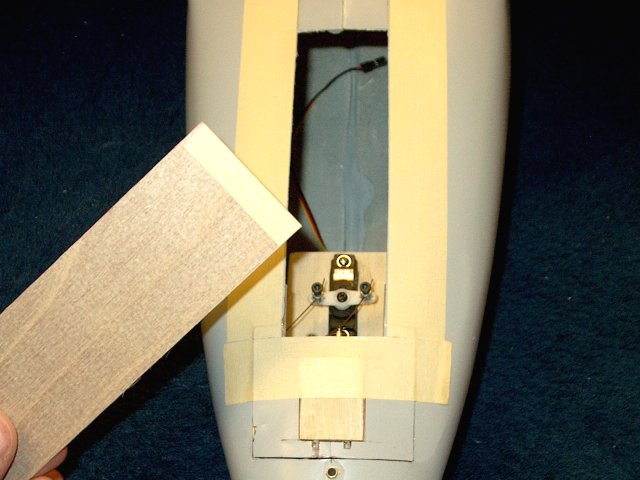

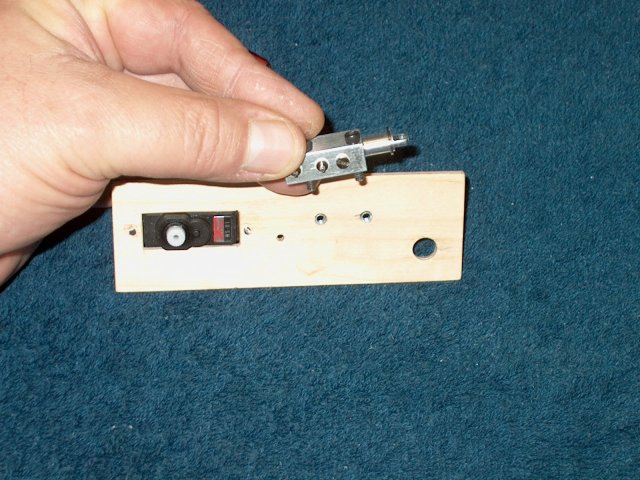

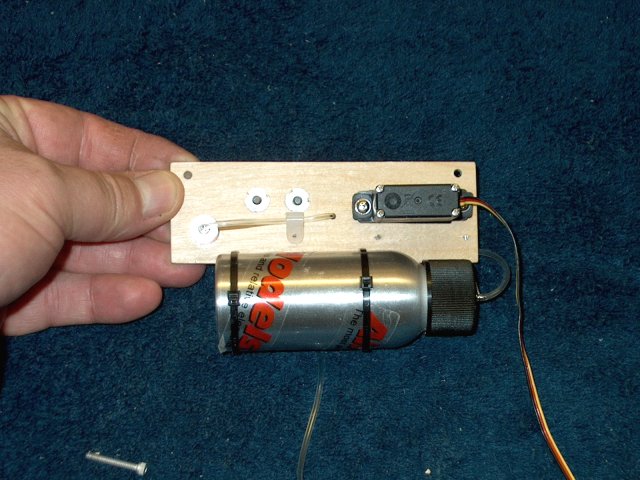

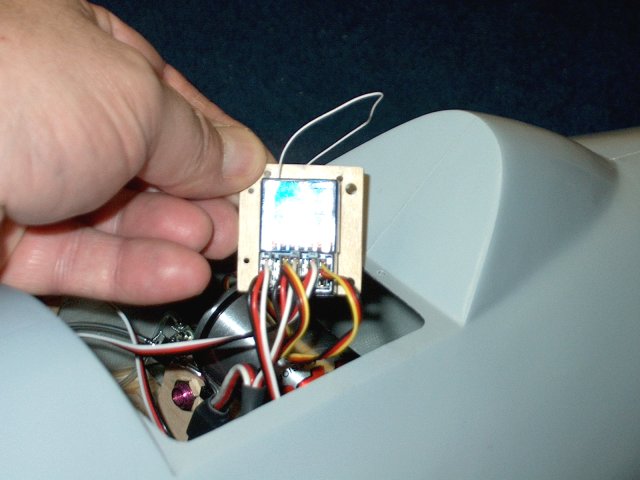

A 1/8" ply Retract Control Panel is built

from the templates | |

Install all parts on the panel

| |

The panel should appear as shown. The

bottom stick is made from 3/8" hardwood and 4-40 blind nuts

are installed to mount the panel in he fudelage

| |

Rear view of panel

| |

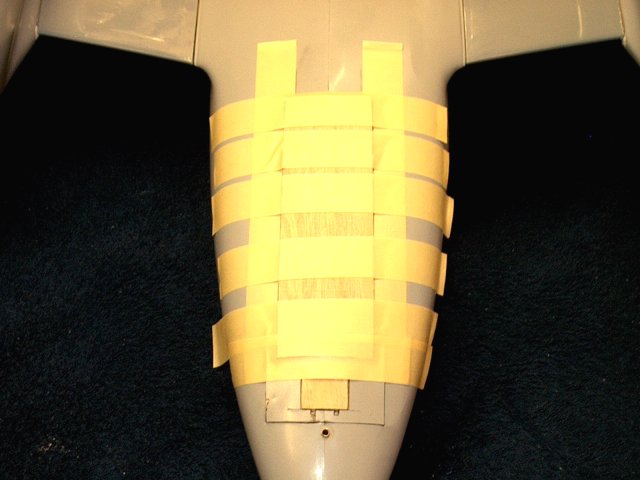

Install the hardwood stick in place as

shown with epoxy, then cut small wedges and epoxy them in the

corners for support | |

Connect the hoses to the supplied "T"

fittings supplied in the retract kit

| |

The Retract Control Panel can be mounted

in place with two 4-40 x 1" bolts as shown

| |

Install the air hose in the front retract

assembly | |

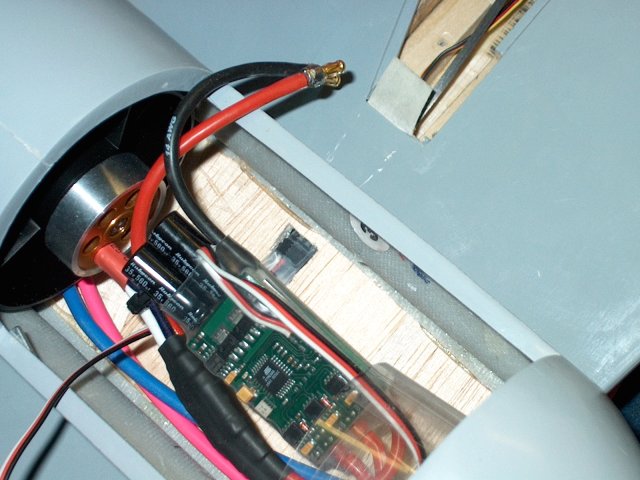

Build your fan units following the

instructions supplied witht he fans, or go to

www.warbirds-rc.com in the "Research Center" for step-by step

instructions on assembling the most common fan

assmeblies | |

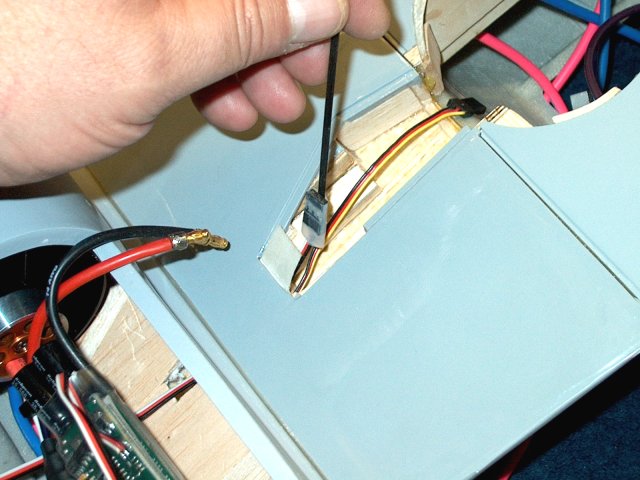

Elongate the opening for the power wires

to make it easier to run | |

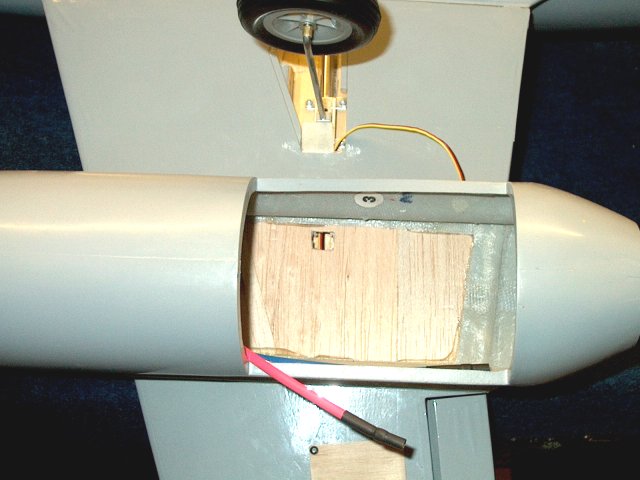

Install the power wires from the inside of

the fuselage | |

Pull them out of the hole in the wing as

shown | |

Solder the connectors for your ESC to the

wires | |

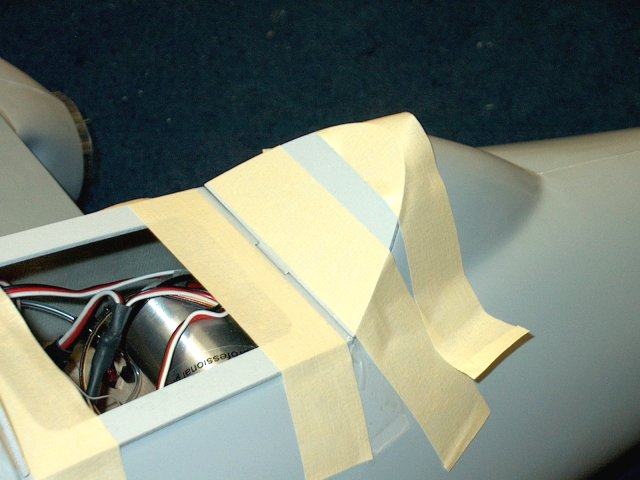

Cut a 1/2" square opening along the

aileron servo wire run as shown. Be careful to only cut

through the balsa and not the servo wire

| |

Use some layers of tape to build up the

front end of each fan for a tight fit into the intake

tube | |

Check the fit of the fan in the

intake | |

Install the exhaust ducting and tape in

place once fitted to the fan and exit hole

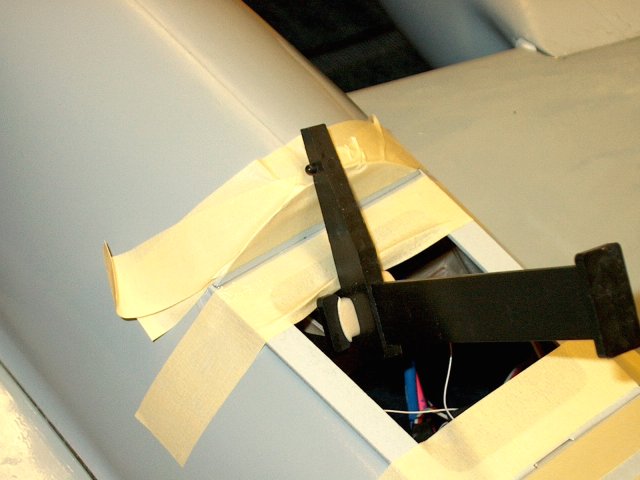

| |

Use clear packing tape and a burnishing

tool to finish the exhaust tube | |

Make a mark on the thrust tube for the ESC

wires | |

Use two washers to sandwich the duct and

cut out the hole for the wires | |

Use a flat piece of carbon fiber or a

small wire and run it from the retract area where the aileron

servo wire exits through the hole you cut earlier

| |

Tape the ESC radio wires to the rod and

carefully pull it through the hole | |

Run the power wires and ESC servo wires

through the hole in the exhaust tube. Install the power wires

on the ESC and use heatshrink to hold them

| |

Slide the exhaust tube over the rear of

the fan | |

Install heavy clear packing tape to fasten

the tube to the fan | |

Use a razor to remove the excess exhaust

tube from the rear | |

Install four "L" shaped wires in the botom

of each motor hatch as shown | |

Some light sanding on the nacelle may be

necessary for the wires to clear. The wires are bet slightly

outward as a safety catch in case the magnetic retension

fails | |

Cover is installed in the motor

opening | |

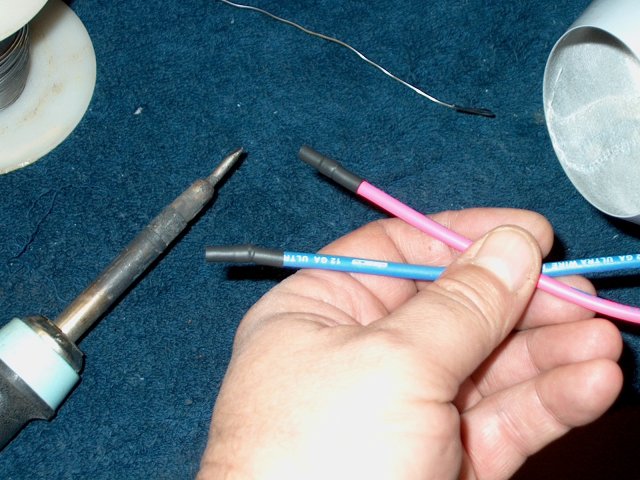

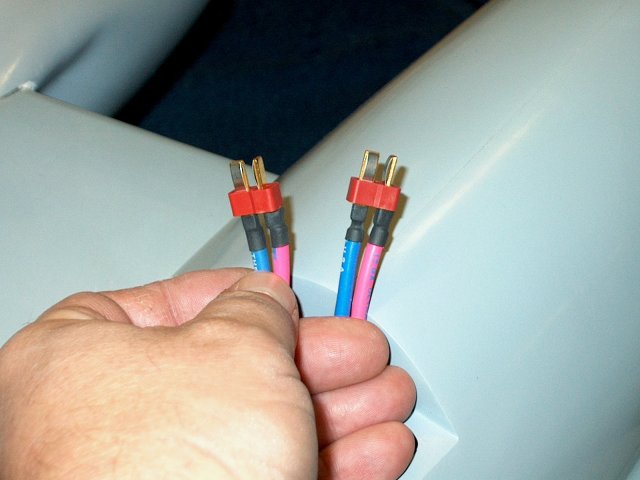

Solder Deans connectors tot he power wires

in the fuselage. Two batteries are used, one for each motor

assembly. | |

Add the heatshrink to the wires to protect

the Deans Ultra Conmectors | |

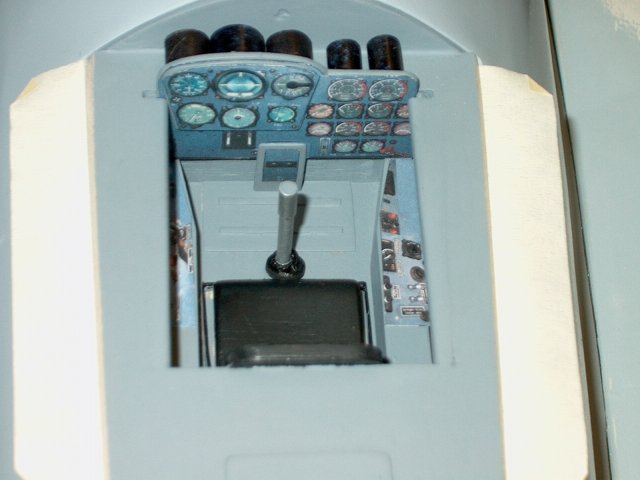

Cover the front and rear cockpit area with

plastic | |

Install the cockpit floor and tape it in

place so it is centered, then epoxy the rear plate supplied in

the kit to the cockpit floor. Tape in place until the glue

dries | |

Epoxy the front plate in place. A clamp is

used to hold it while the epoxy sets

| |

Remove the cockpit assembly and sand the

bottom to a smooth finish | |

Cut two pieces of 1/8" thick ply about

1/4" wide and the length of the cockpit. The will be used as

stiffeners along the outer sides of the fuselage cockpit area

to remove bowing in the fiberglass. Epoxy the sticks in place

under each side lip | |

Install the cockpit and tape in place,

then drill a 1/8" center hole as shown in the front cockpit

plate | |

Epoxy the supplied wooden dowel in place

and check for fit | |

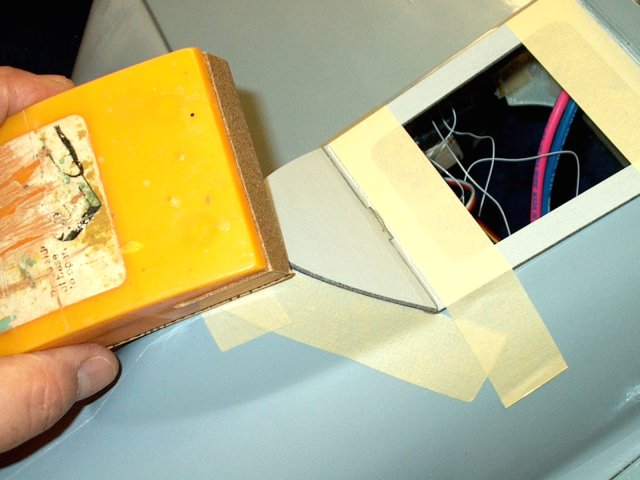

Install the cockpit, then tape it centered

in place and use a sanding block to shape the rear ply.

Masking tape in installed on the fuselage to prevent

scratching of the surface from the sandpaper

| |

Drill two holes in the corners for the

cockpit magnets, then transfer the hole locations to the

fuselage | |

Use a dremel to remove the fiberglass but

do not cut through the sidewall ply stiffeners as they will

support the bottom of the magnets | |

Apply epoxy tot he fuselage locations and

glue in the magnets | |

Apply clear tape across the bottom of the

cockpit, under the holes | |

Check polarity on the magnets against the

ones glued in the fuselage, then epoxy the in the cockpit

floor as shown | |

Drill two 5/64" holes , one in each corner

of the cockpit floor as shown to help with alignment. Glue two

pieces of 2-56 pushrod in the cockpit wood as alignment

pins | |

A piece of 1/8" balsa is used as a base

floor covering and is glued to the cockpit area

| |

Install a 12" servo extender and

heatshrink the connection so it cannot come apart

| |

Cut a board to fit the receiver with 1/4"

overlap on all sides | |

Plug the servo wires in the receiver, then

dress and tie wrap the wires. Drill two plate mounting holes

along the front edge and through the fuselage

| |

Use some #2 screws to install the receiver

plate behind the cockpit | |

Coat the top of the screw heards with lead

from a pencil. Install the cockpit and press down on the

screws to transfer the hole locations to the cockpit

bottom | |

Drill out each hole so it clears the head

of the respective screw | |

Rough cut out the canopy with

scissors | |

Trim the canopy to fit, but be sure not to

trim too much, especially on the forward sides as they need to

cover the Cockpit floor | |

Now is a good time to build a scale

cockpit if you wish | |

Apply masking tape along the bottom edges

of the cockpit as shown | |

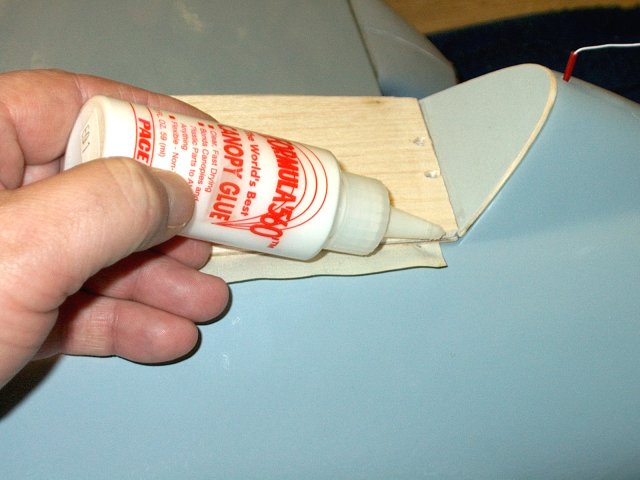

Install the cockpit on the fuselage, then

apply RC-56 canopy glue along both side edges

| |

Install the canopy and fold the tape

upwards to hold it in place while the glue dries. You can tape

down the front of the canopy to make sure it is flush with the

front of the fuselage hump | |

Antenna installation can vary depending on

your radio. Shown is a method to install a semi-scale antenna.

Drill a hole in the vertical stab using a 5/64" bit

| |

Once through, angle the drill forward and

drill again through the stab. The first hole will allow the

bit to remain in place and not slip while drilling

| |

Install one of the tailwheel wire rods

from the tailwheel kit you used to wire the nosegear steering

assembly. A piece of wie installed through the hole helps with

the turning | |

Drill a hole just behind the canopy and

install a 1 1/2" long plastic tube from a WD40 oil can spray

tube. Make sure your antenna can fit through the tube. The

antenna for the Berg receiver fits perfectly

| |

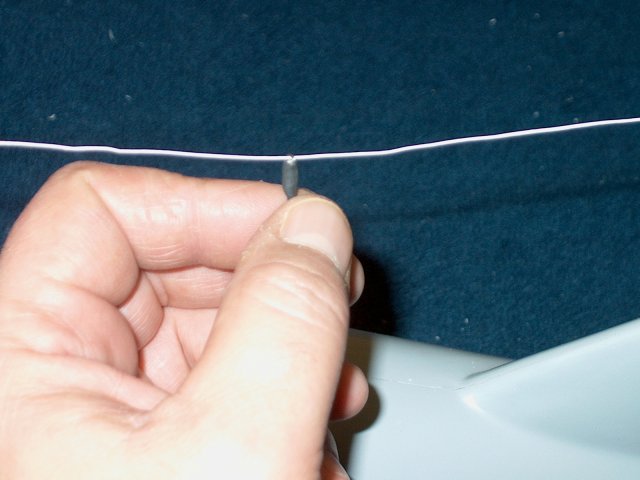

Run your antenna through the fuselage,

then through a tensioner shown in the next photo and tie it

through the rod hole and cover it with a small piece of

heatshrink | |

slide the tensioner in place. it is made

from a small wire, looped and sodered, then glued to a small

diameter elastic string. Heatshrink covers the assembly

| |

Build a string mount from 5/16" dowel.

coat in in CA, then sand and Drill a 1/16" hole down through

the dowel. Drill a 3/32" hole in the side and tapit, then

install a 4-40 set screw. Drill the bottom of the tube with a

3/32" bit about 1/8" deep, then install a piece of aluminum

3/32" OD tubing as a mount, making sure id does not sit so

deep that it blocks the setscrew. Drill a hole in the fuselage

for the tube, then epoxy the assembly in place. Install the

eleastic through the top hole and down through the tube into

the inside of the fuselage, adjust the tension and lock down

the set screw | |

Cut a piece of 1/64" ply and epoxy it in

place as shown, applying epoxy only to the hinge

| |

Tape the area with stick side up under the

hinge and ply, then apply epoxy to the top side of the

hinge | |

Install and position the door, then fold

the tape up to hold it in place | |

Tilt the door up and clamp the area while

the epoxy sets. Repeat this procedure for the second

door | |

IF you plan on using a BEC, install it per

instructions. Apply servo tape to the bottom and stick the BEC

unit to an upper side walll in the cockpit area. Dress the

wires and tie wrap them as necessary

| |

Install a battery, then turn on your radio

and receiver. Set Elevator travel to 8mm up and down

| |

Set Aileron travel to 8mm up and 6-8mm

down | |

CG is located 85mm from the leading edge

of the wing root. Mark the location on each wing so you can

check CG in the field | |

The door closing wire is bent to work as

shown. Adjust the wire so the door closes and does not hang on

the wire | |

A wood block is cut and drilled through

the top through the front of the bar at two locations for the

inner fuselage door tensioning wires. It is glued in place as

shown, then fine .020" wire is cut and routed to the door

tubes as shown. These doors work similarly to the main

nosegear door, so that they spring open and closed

| |

The batteries are installed in the very

front sides of the model. Start by sanding the area for a

velcro strap | |

Cut four 10" long pieces of Velcro strap.

This is the double sides strap with cloth on one side and

hooks on the other | |

Apply a thick coat of epoxy and fiberglass

mil to the strap 2" from one end and about 3" long

| |

Slide the strap in place with the front

edge just behind the rear of the steering servo tray. The glue

holds the strap to the floor and side wall. Do not glue past

the inner ply reinforcement and trim off any excess so the

door can close | |

At the rear, take a second strap and wrap

it around a 4S battery. Apply a industrial self stick 1" wide

strip of velcro hook to the bottom and side of the strap as

shown. Install it in the fuselage from the cockpit, then when

it is in place, remove the battey and lake sure the velcro is

seated. Repeat these steps for the other battery

| |

The batteries are installed from the

cockpit, moved forward and strapped in place from the

nosewheel opening, then the rear straps are installed

| |

Air Power RA-260 Retracts shown in the

down position | |

The photo shows how the wheel closes the

inner fuselage door on the mains | |

Gear is shown in the retracted

position | |

Side view showing a slight nose high

stance of the ME-262 | |

Front view showing the Air Power Retracts

and landing gear | |

The HET-RC ME-262 twin EDF Jet with

Airpower RA-260 Retracts from Warbirds-RC. The main assembly

is completed and the model is ready to be painted in your

choice of color schemes | |

Paint your model in a color scheme of your

choice | |

A two tone leopard scheme was used for the

build model | |

Detail your cockpit as desired

| |

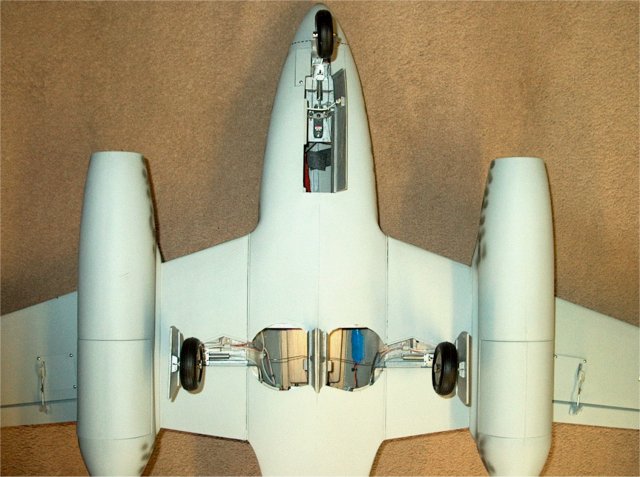

ME-262 Top View

| |

ME-262 Side View

| |

ME-262 Forward View

| |

ME-262 Front View of Gear

| |

ME-262 Side View of Gear

| |

ME-262 Gear Down

| |

ME-262 Gear Up | |

ME-262 Side Profile

| |

The HET-RC ME-262 Swallow Twin EDF Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

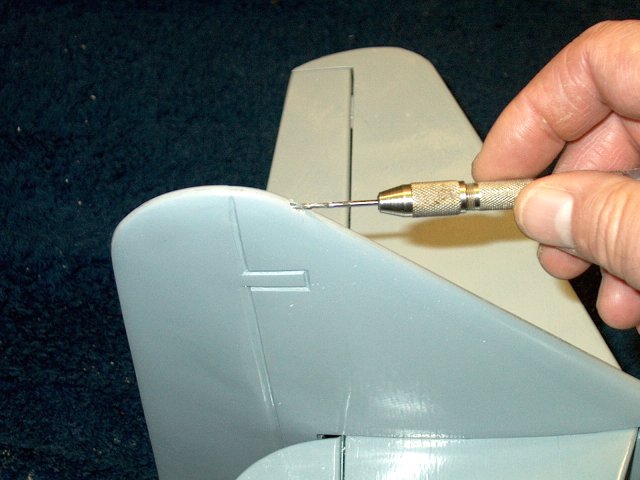

| |