01 - Here's the box...

| |

02 - ... and a couple items I ordered to

make the model fly. | |

03 - Opening the box reveals typical

HET-RC packing, with wings taped inside to prevent damage from

movement. Take your time and carefully pull off all the tape

before removing the components. This will prevent damage that

can be caused if you use a knife. | |

04 - Wings were removed from the inside

panel then the panel was lifted, revealing the airframe, parts

bag, cockpit assembly and thrust tube.

| |

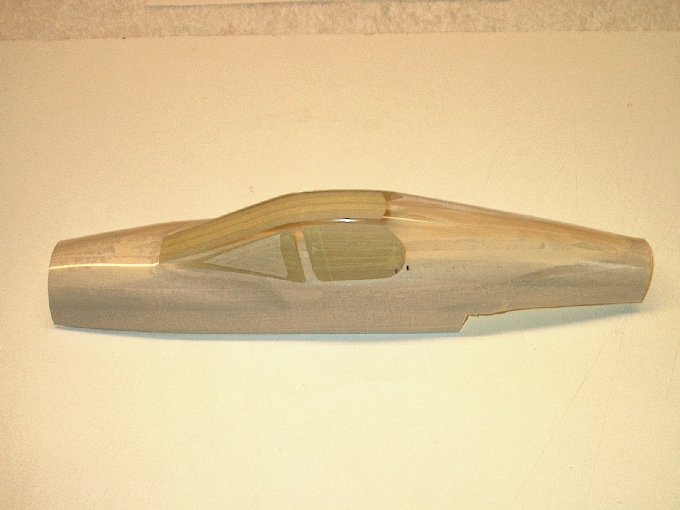

05 - The "F4D Skyray ARF"... this is how

it comes. | |

06 - Tape was carefully and completely

pulled off of each bag and then each item was removed. Pulling

off all the tape first makes sure a piece doesn't accidentally

stick to the covering and damage it.

| |

07 - The major components... top quality

craftsmanship and covering! | |

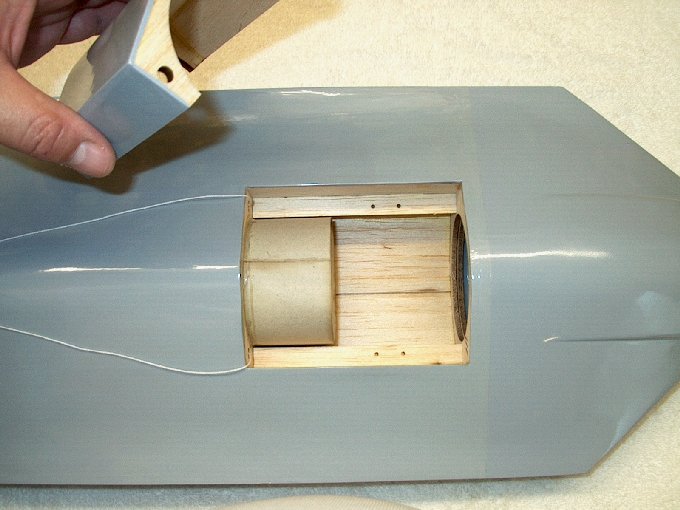

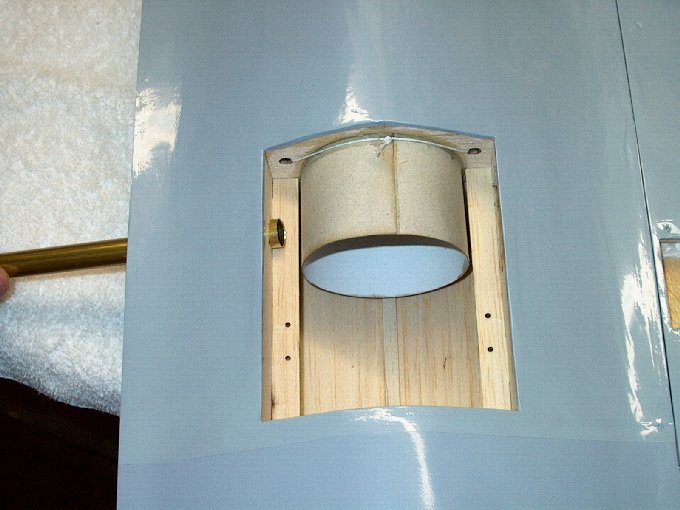

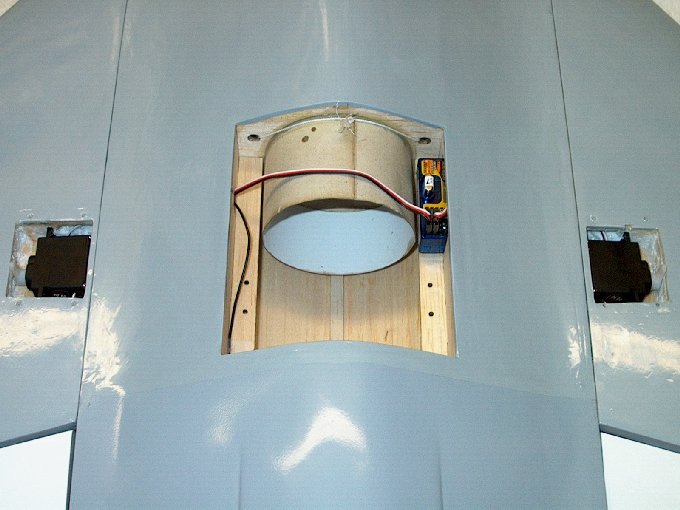

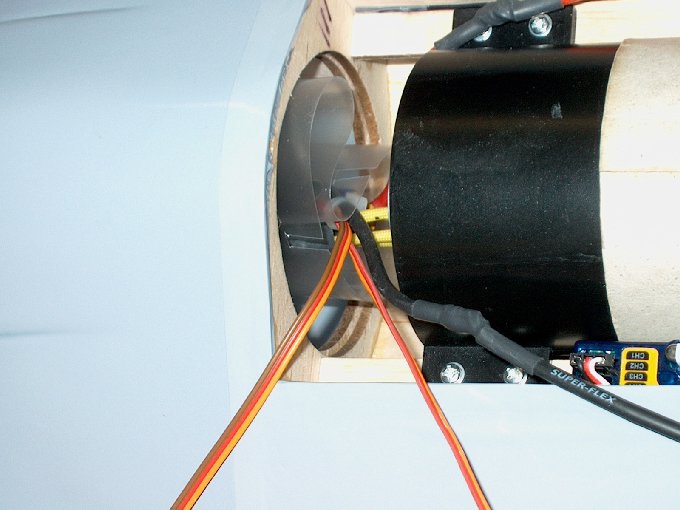

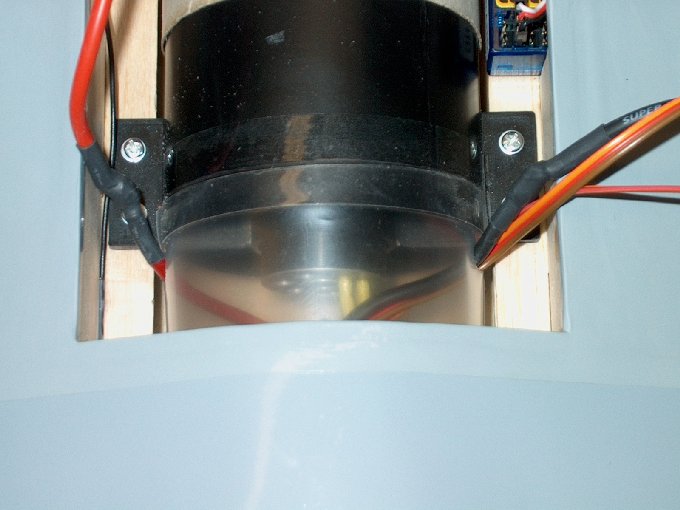

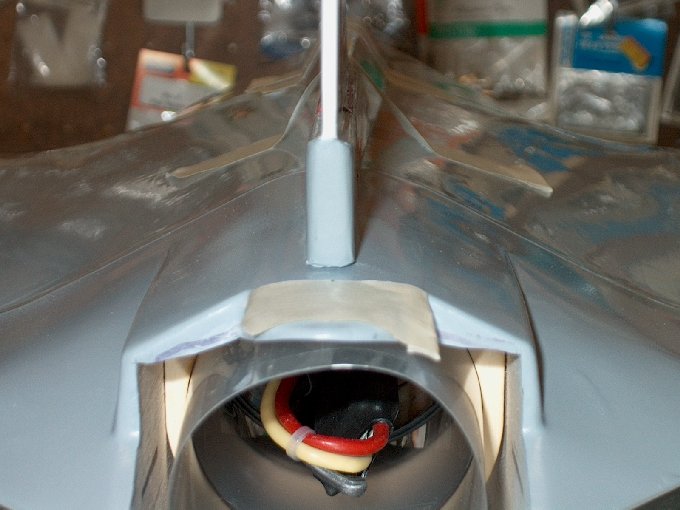

08 - The fan compartment is viewed from

below. | |

09 - HET-RC listened to their customers...

this tow hook location is easy to find!

| |

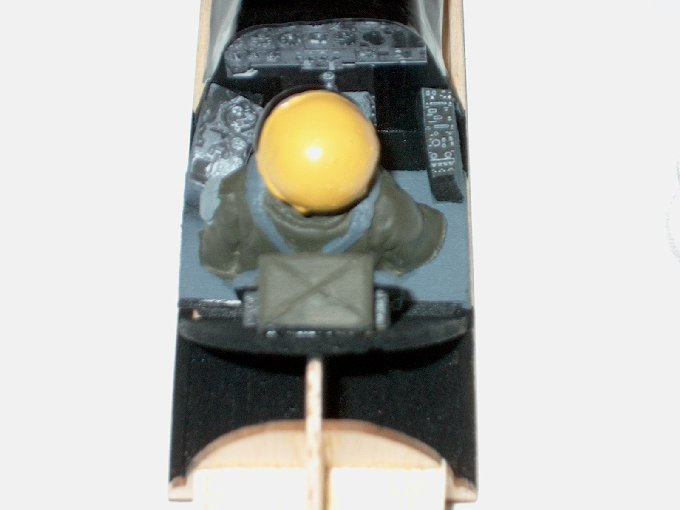

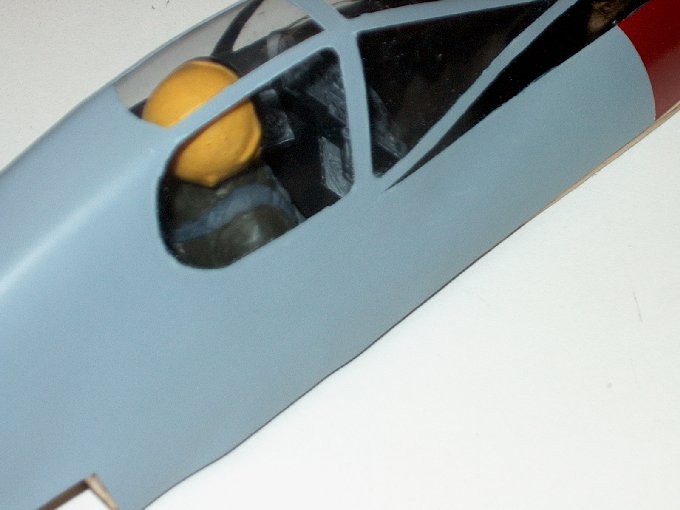

10 - The cockpit assembly. Once again,

improvements were found as the canopy has trim lines well

marked in the molding. | |

11 - The front of the vertical stab had a

small rod protruding. | |

12 - A view underneath reveals this is a

rear canopy latch... a nice touch! | |

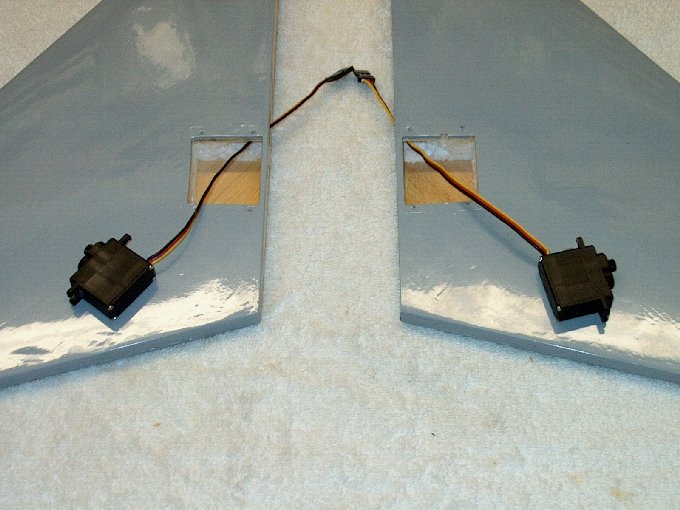

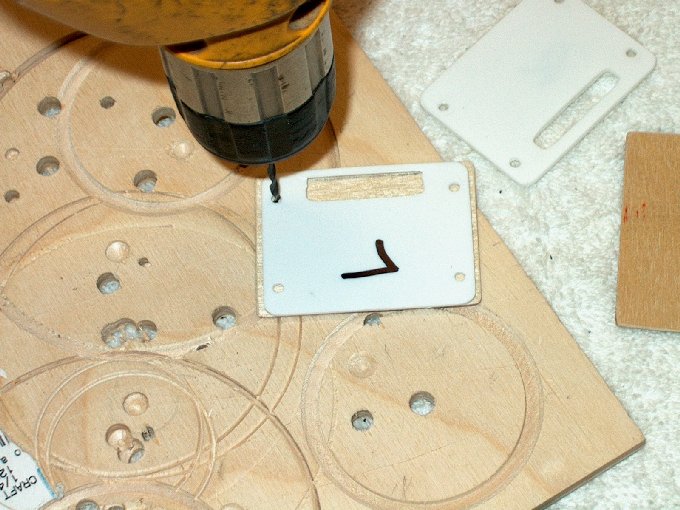

13 - Elevon servo covers are extra thick,

heavy duty plastic. | |

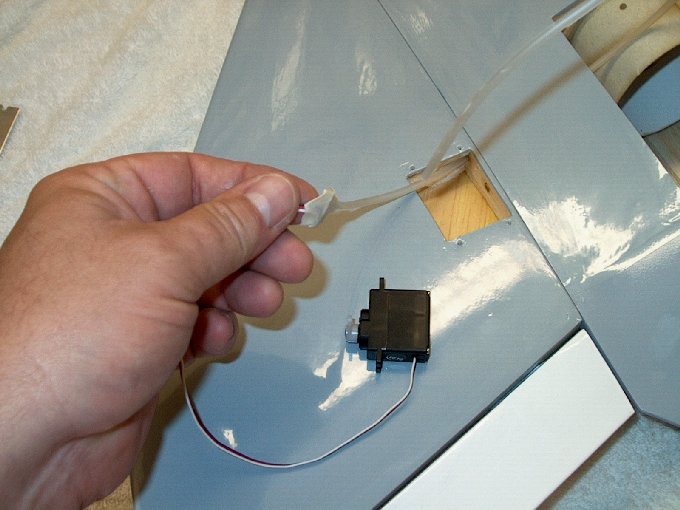

14 - Removing the cover reveals the servo

compartment. | |

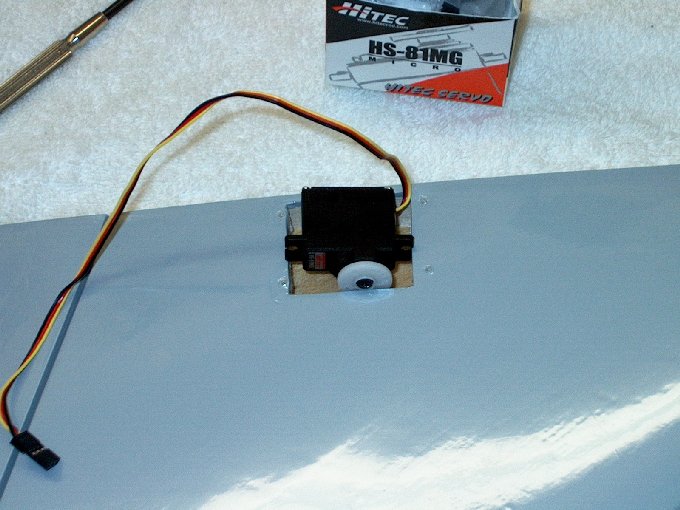

15 - My Hitec HS-81MG Metal Gear servos

will fit, but need a bit of coaxing.

| |

16 - The "bag" of components.

| |

17 - Control surfaces have heavy duty

hinges... they are removed before mounting the wing panels.

| |

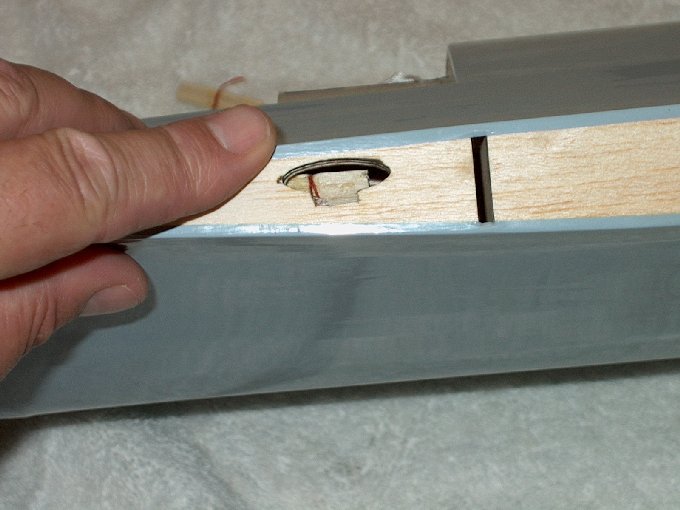

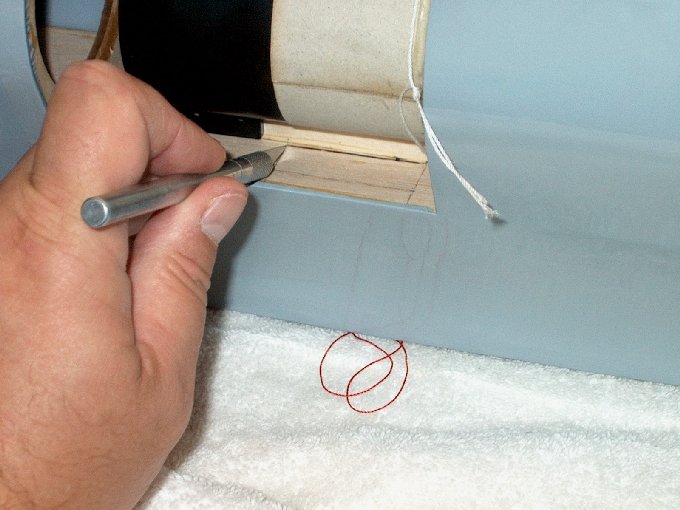

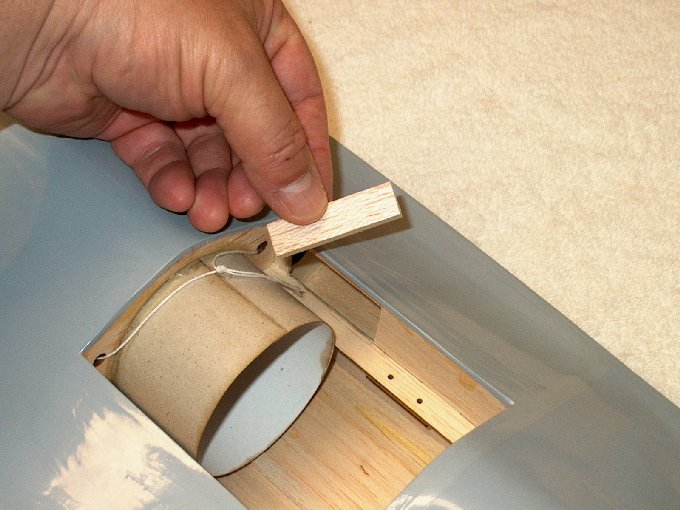

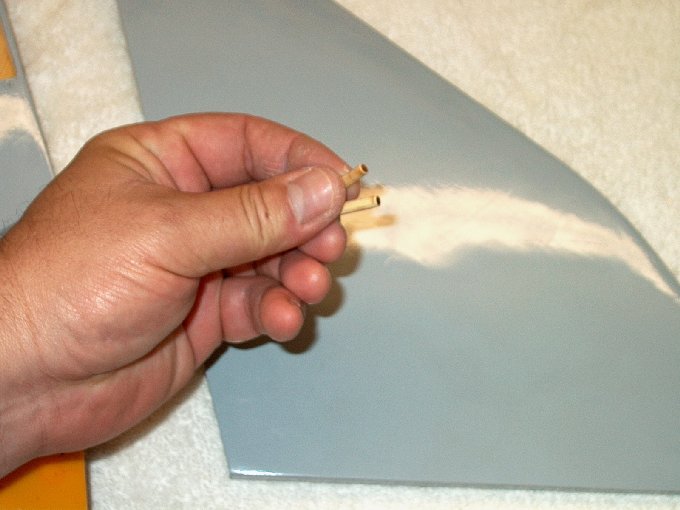

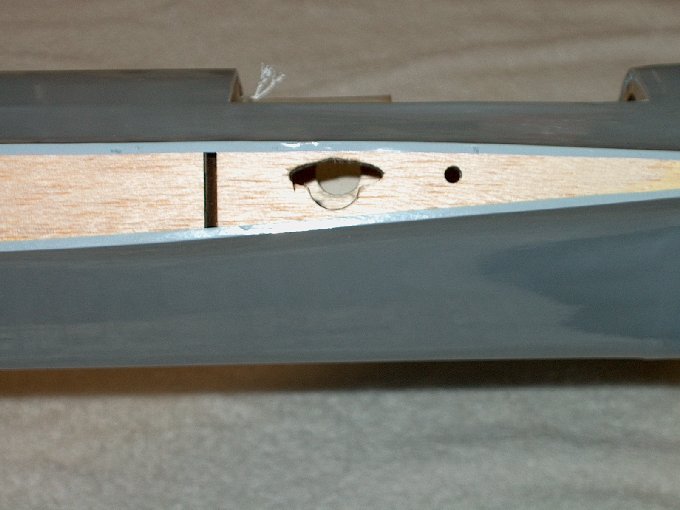

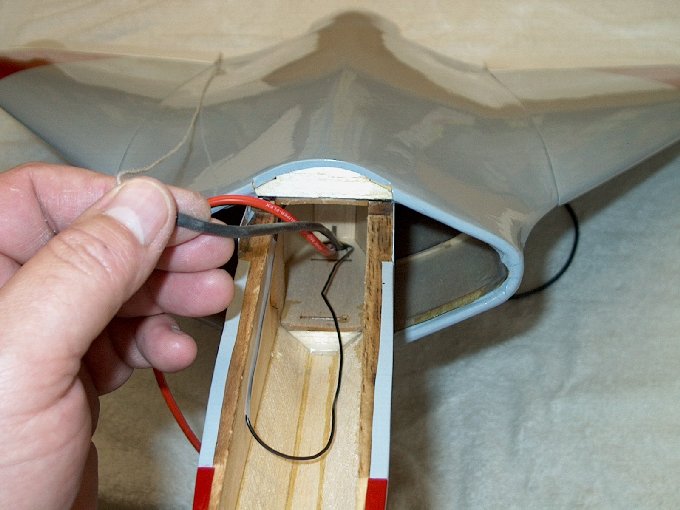

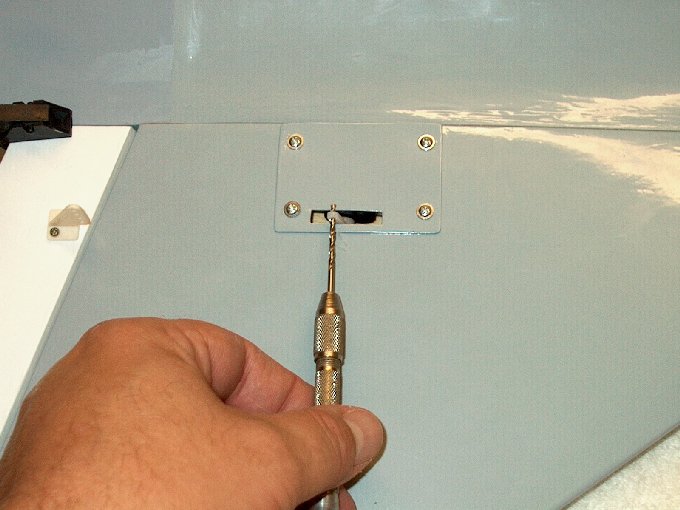

18 - A small slot was extended to remove

the wire pulling thread. | |

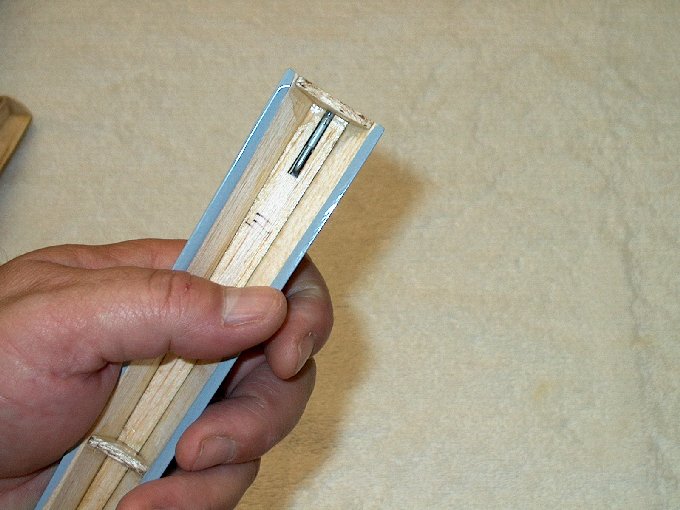

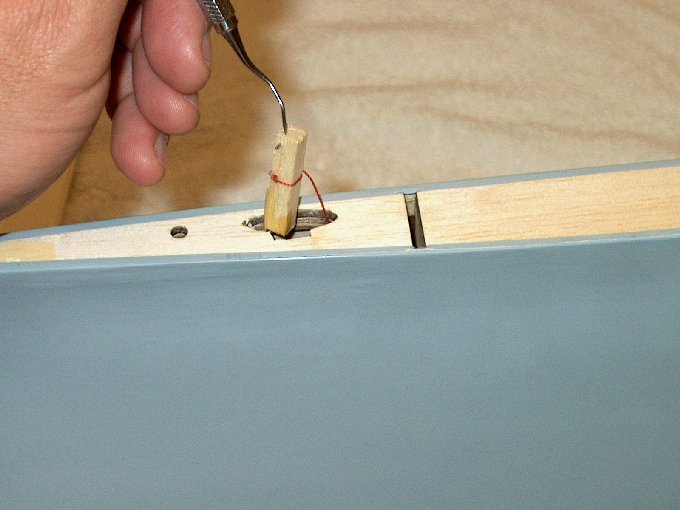

19 - The 1/4" stick has to be

pulled/snapped loose from inside as it is tack-glued in place

during shipment. Once loose, remove it through the enlarged

slot. | |

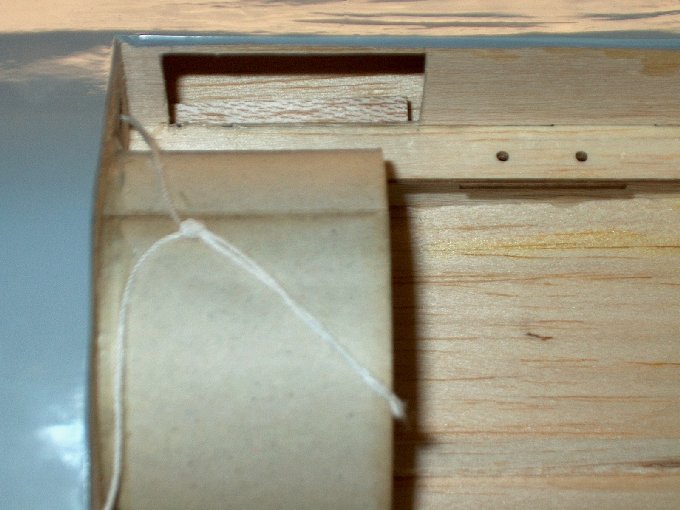

20 - Removing the wire puller thread.

| |

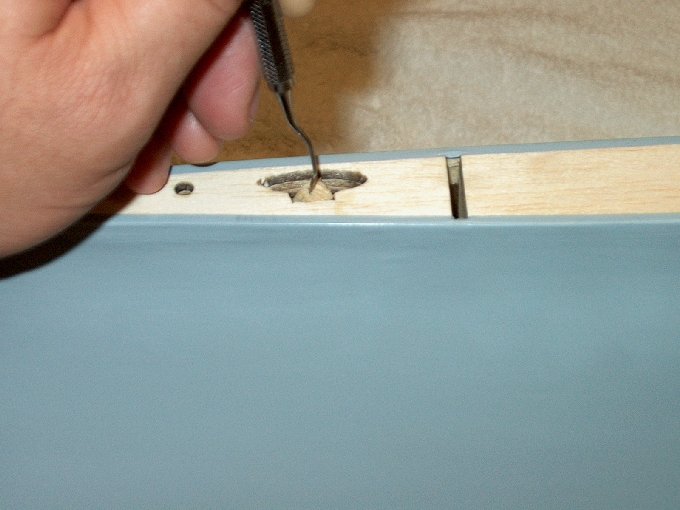

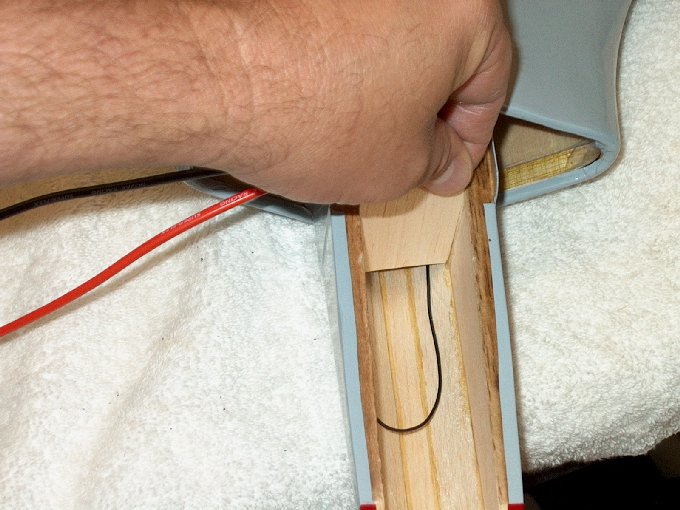

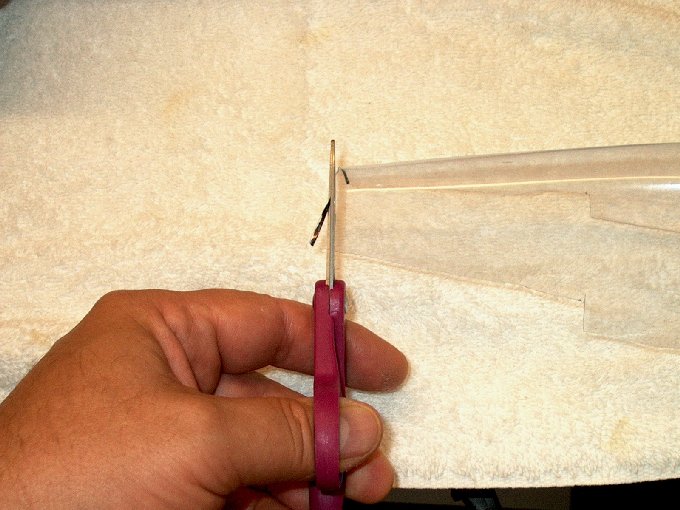

21 - A dental pick or other device was

used to break the stick loose, then used to remove it.

| |

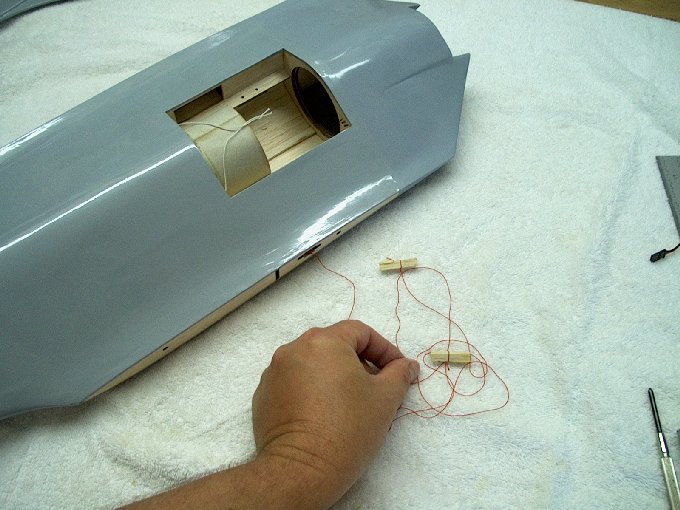

22 - Removing the puller.

| |

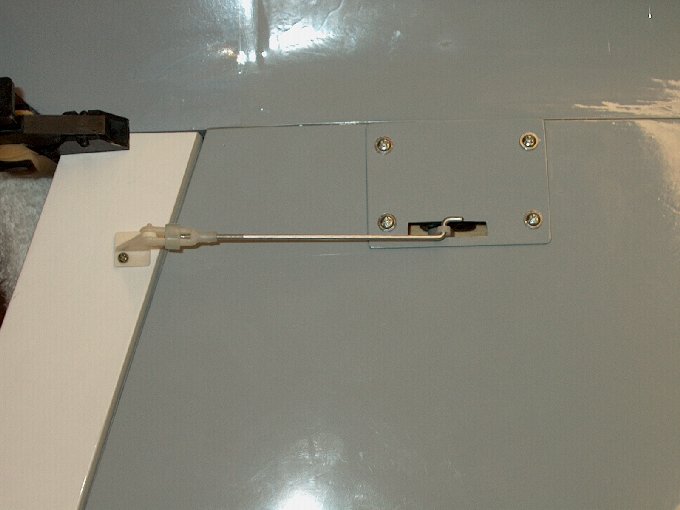

23 - The other end of these strings are

pre-threaded to the front cockpit area of the fuselage by the

factory. They are used to pull the servo extension wires from

the cockpit area through to a servo in each wing.

| |

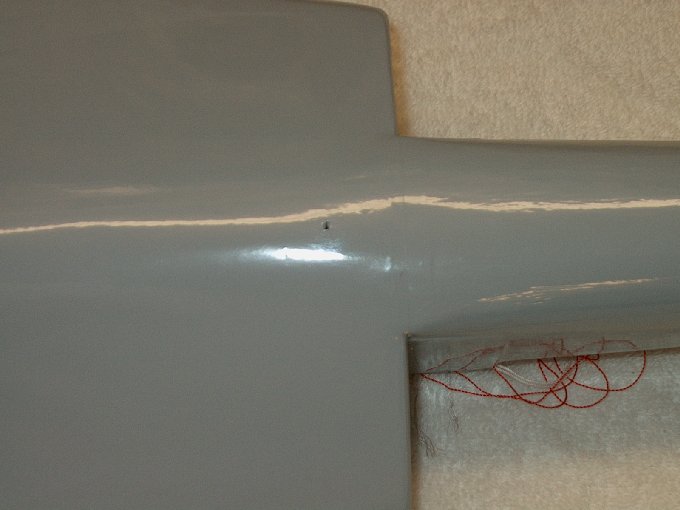

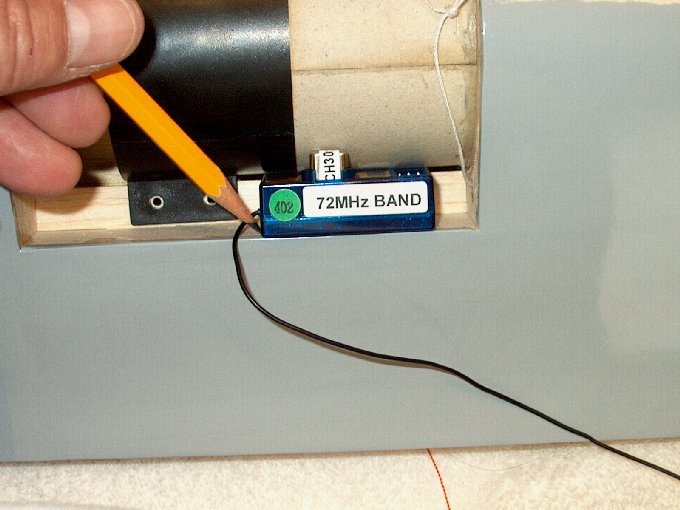

24 - I decided not to mount the receiver

in the cockpit area, so the RED pulling thread was removed.

| |

25 - A dual conversion high quality

receiver is recommended for this model.

| |

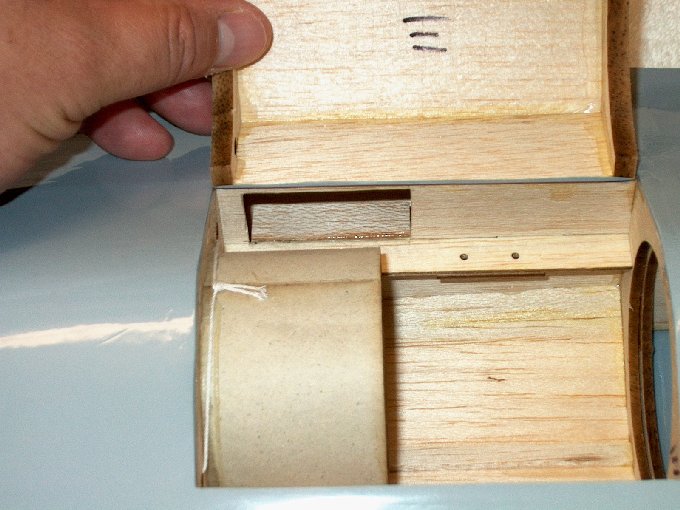

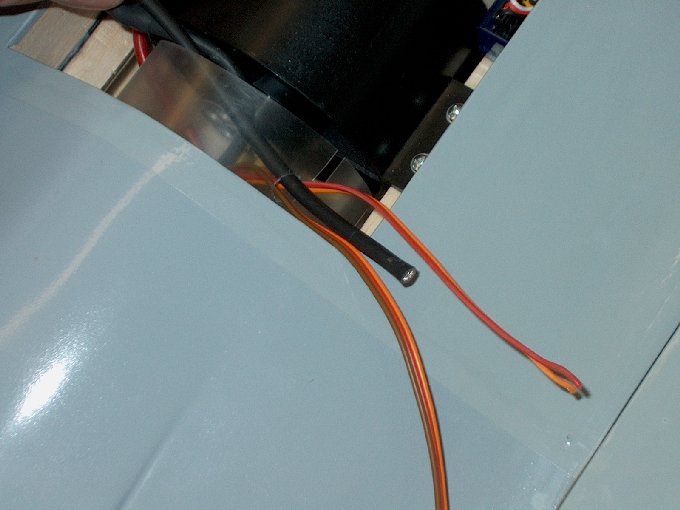

26 - The receiver will be mounted next to

the fan unit, similar to the HET-RC FA-18 Hornet. This will

eliminate the need to route three long servo extensions and

leave more room in the cockpit for batteries.

| |

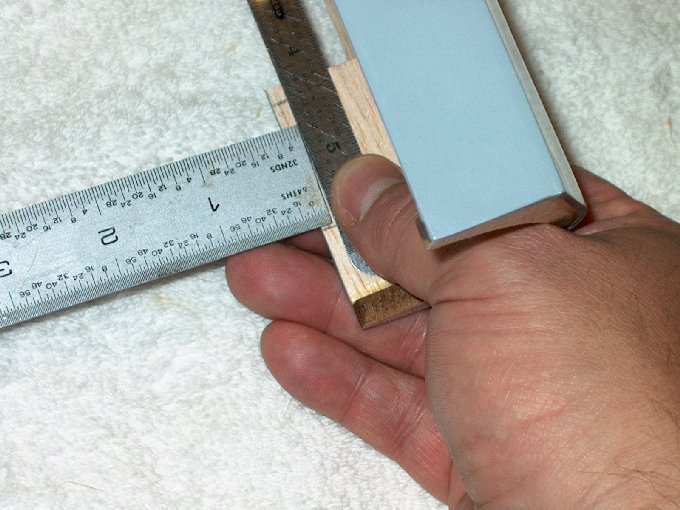

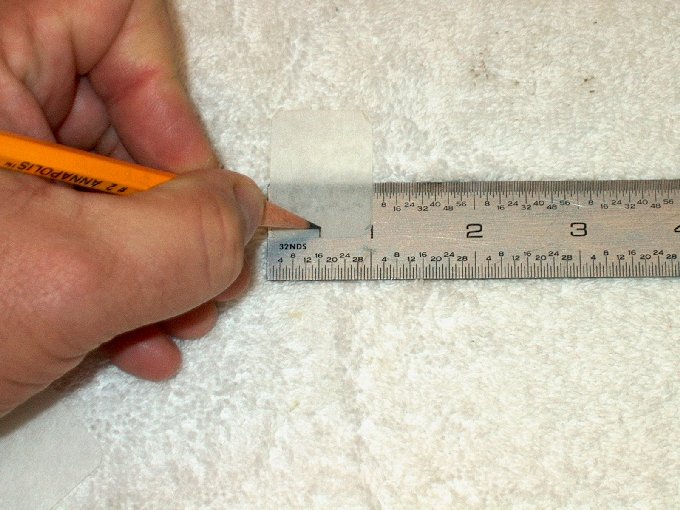

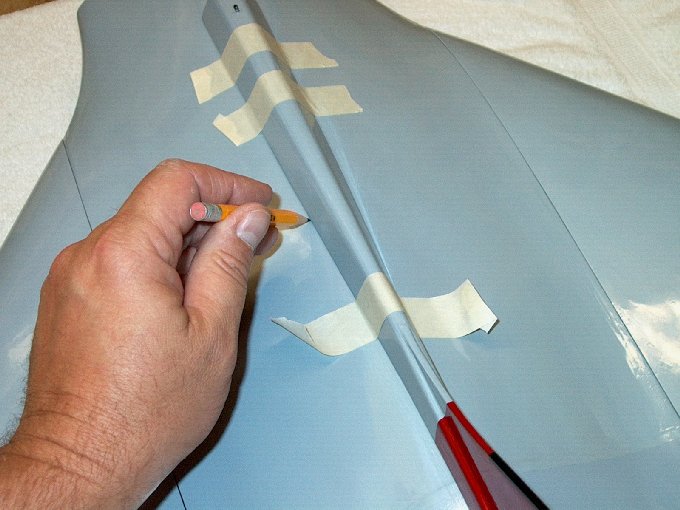

27 - Make a mark 1/4" or more from the

front wall and a second mark for the length of your receiver.

| |

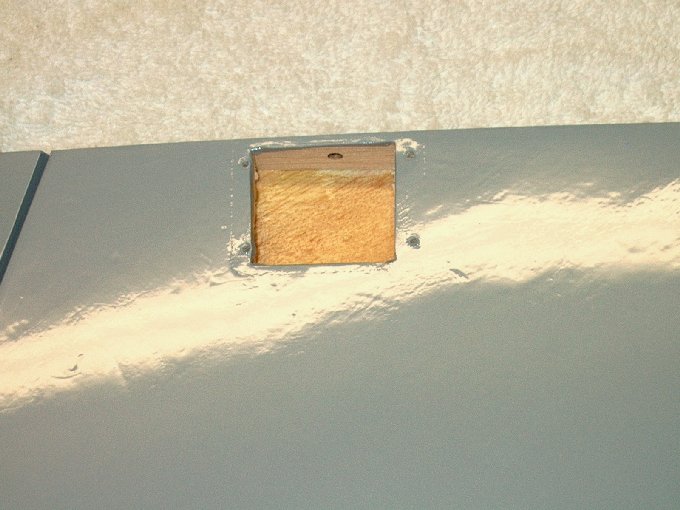

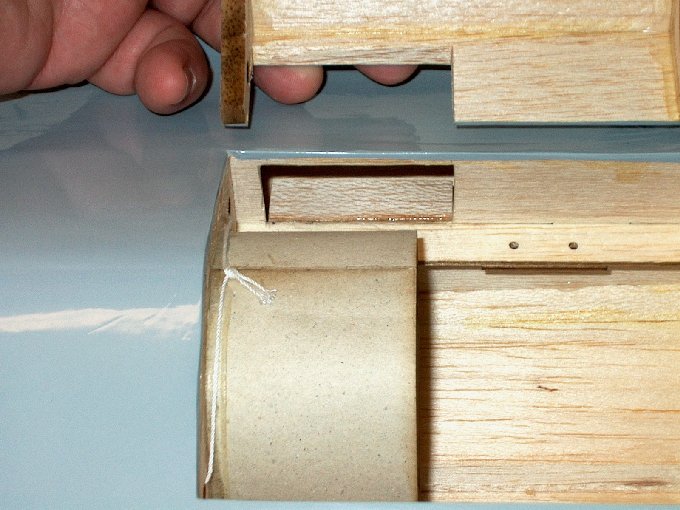

28 - Area that needs to be removed for the

reciever. | |

29 - The location was cut out.

| |

30 - Horizontal cut made.

| |

31 - Receiver area cut out.

| |

32 - Sand the area to fit your receiver.

| |

33 - The Hitec Electron 6 reciever fits

well for a 1 7/8" long hole. | |

34 - A 1/2" square block was cut to extend

the platform for the receiver. | |

35 - A block was inserted...

| |

36 - ... and dropped into place.

| |

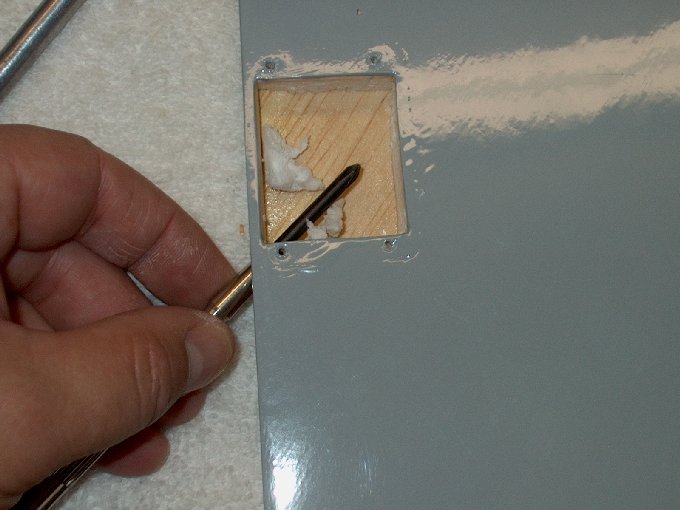

37 - An exacto knife was used to "spear"

the block and hold it in place from the wing servo hold on the

side. | |

38 - Thick CA was applied to the block.

| |

39 - the exacto knife was used to position

the block, making a nice and wide area now for the receiver to

be taped. | |

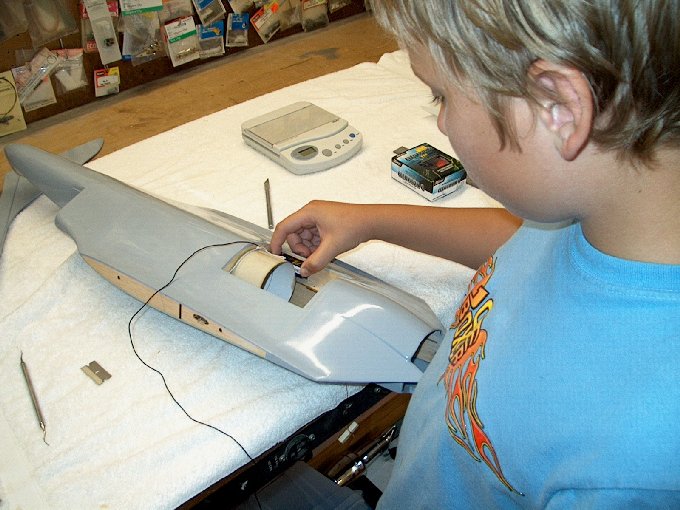

40 - The receiver fits easy enough for a

child to install. | |

41 - The cover will need to be opened so

it fits over the receiver. | |

42 - Cover was marked, then the area was

cut. | |

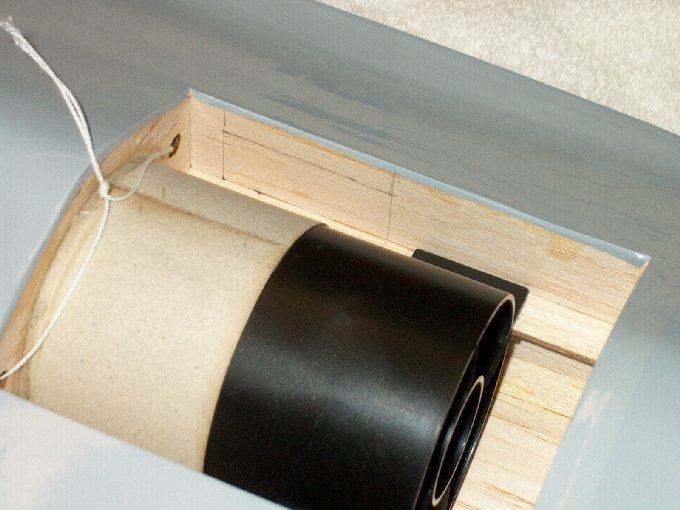

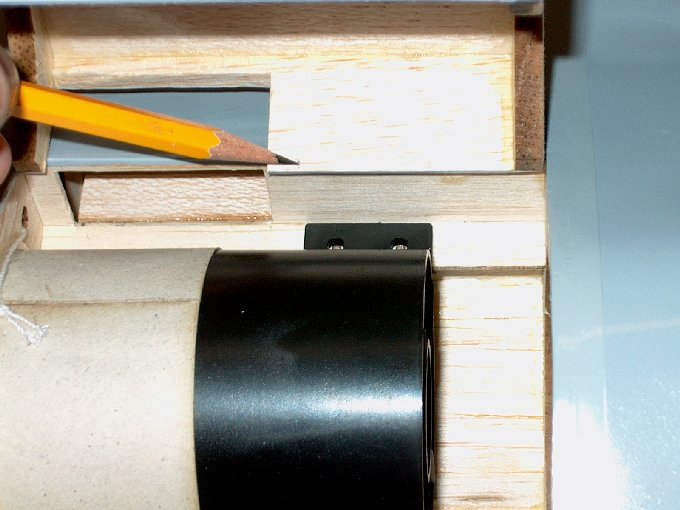

43 - The fan shroud was temporarily

installed to mark mounting areas. | |

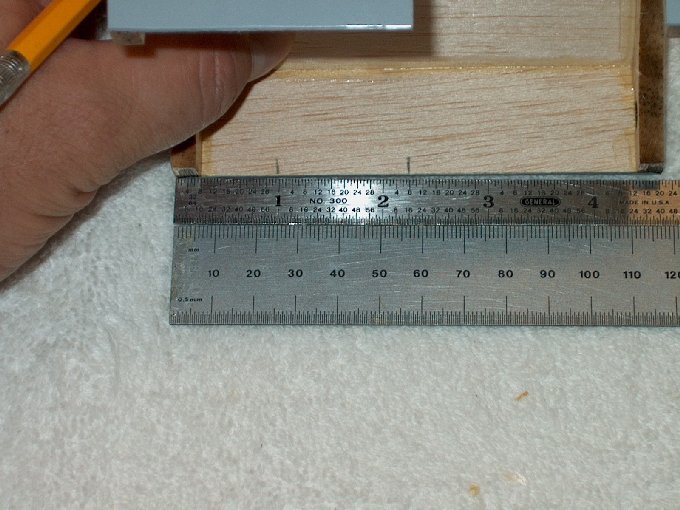

44 - Two marks were made from the rear of

the cover... one mark at 1" and another at 2 1/4".

| |

45 - For our friends overseas, this would

be 25mm and 58mm. | |

46 - The other side of the hatch was

marked. | |

47 - A 1/8" or 3mm wide strip was measured

between the lines. | |

48 - ... and a line was drawn.

| |

49 - This area needs to be

removed in order for the lid to clear the fan shroud mounts.

| |

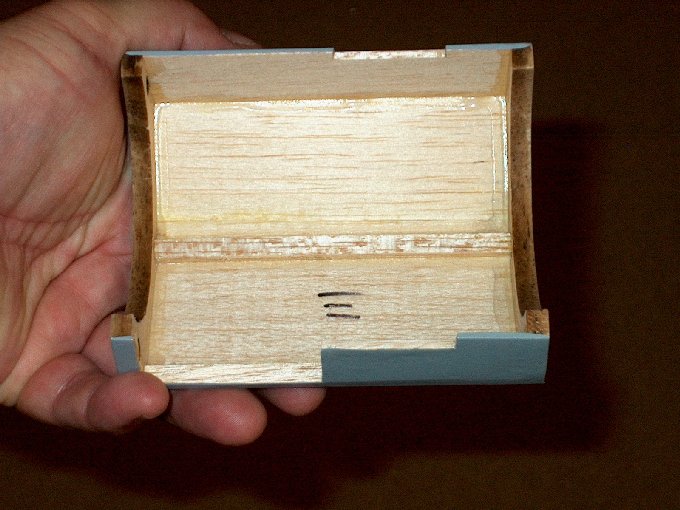

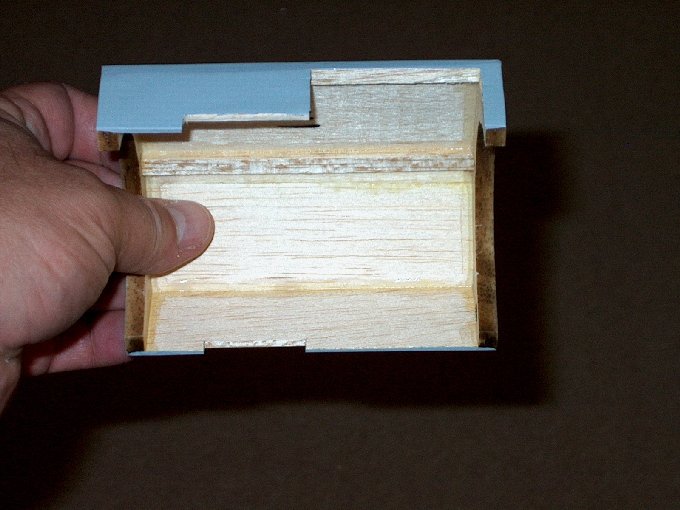

50 - Balsa removed from

both sides. | |

51 - Another view... hatch

is ready to use. | |

52 - Beginning the

build... foam is removed from the wing for servo wires.

| |

53 - The foam was pushed

out. | |

54 - Then the area filed.

| |

55 - Picture showing wires

routed through the wing. | |

56 - Close-up showing wire

routed through foam wing. | |

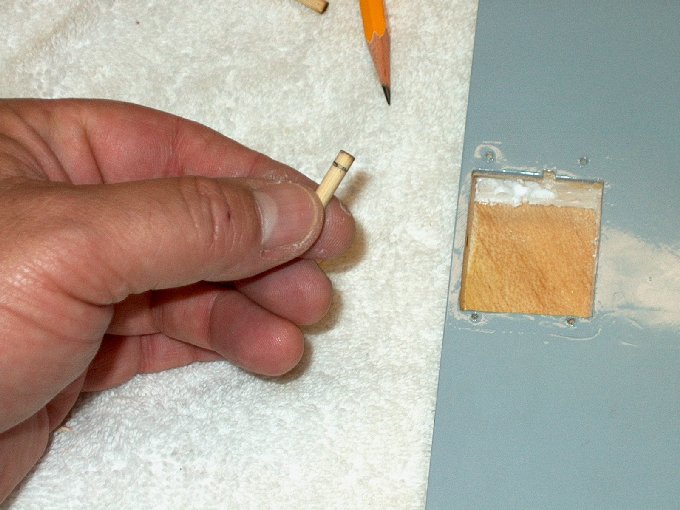

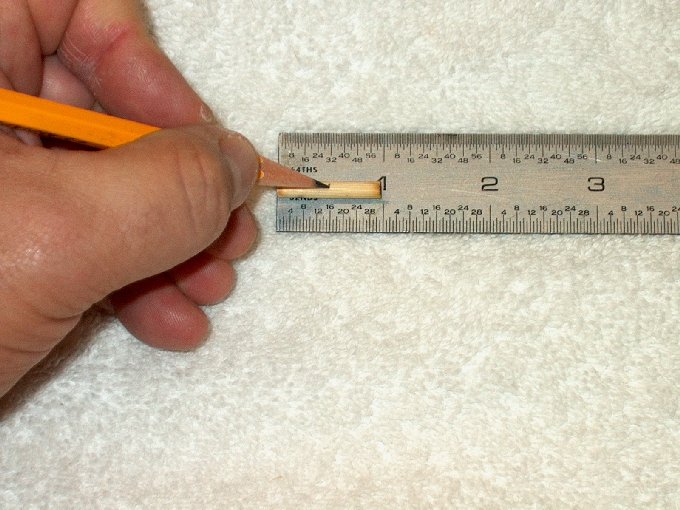

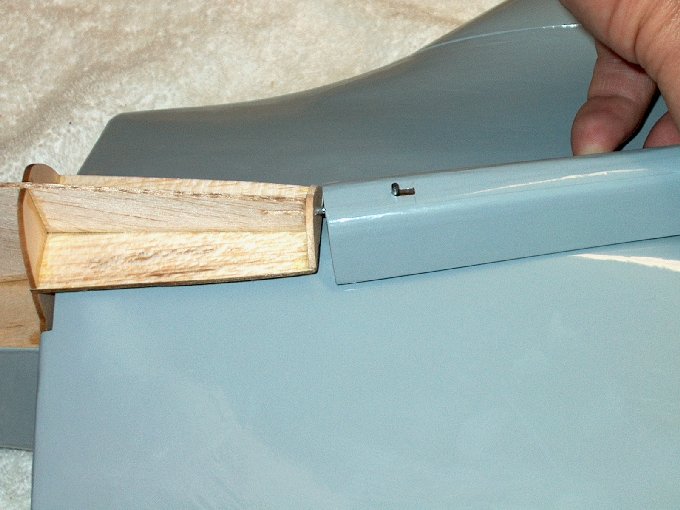

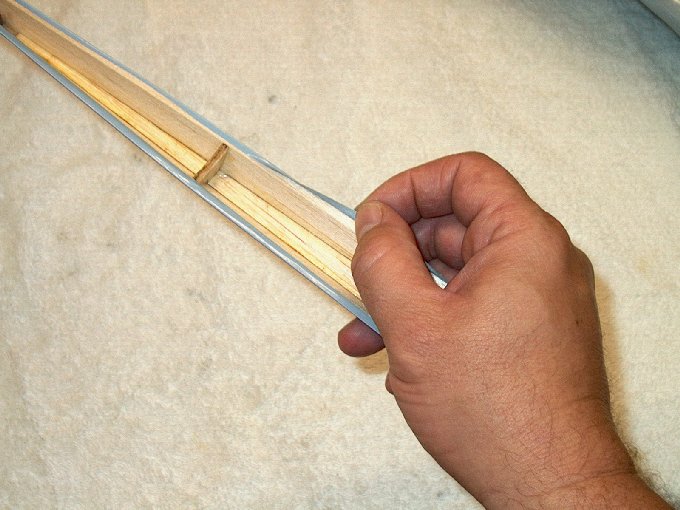

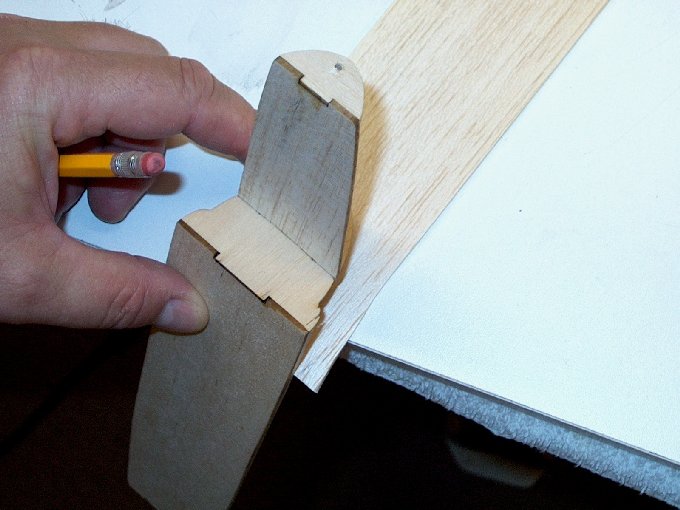

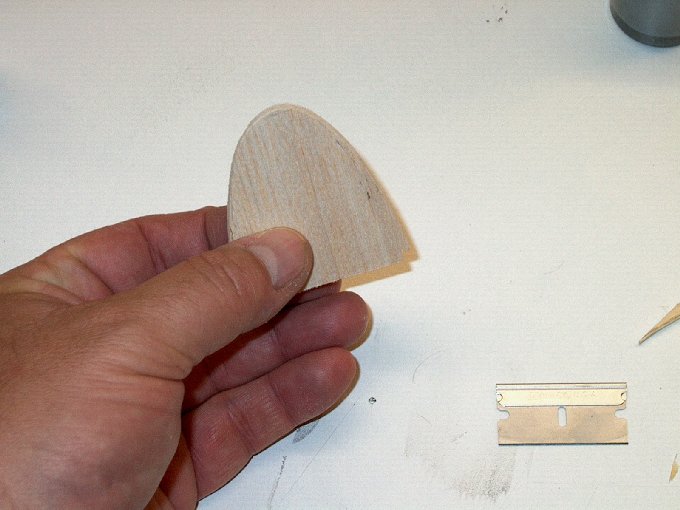

57 - Beveling the edges of

the dowels for easy insertion. | |

58 - End beveled.

| |

59 - both dowels

ready | |

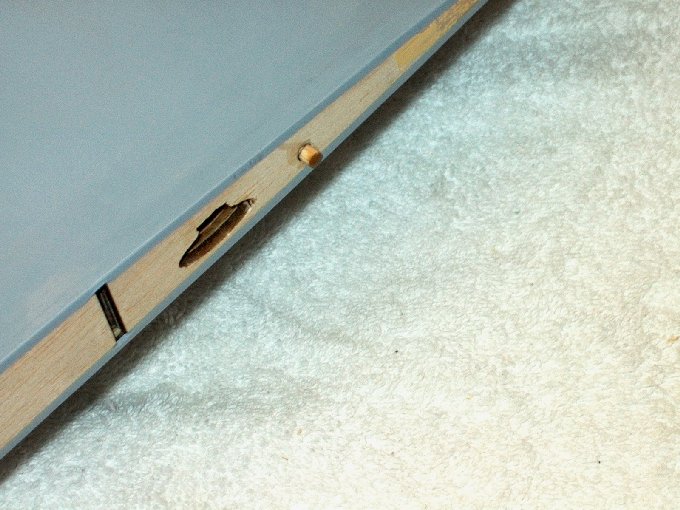

60 - Dowel is inserted so

it is flush with the inside of the wing .

| |

61 - The outside of the

dowel is marked for position. | |

62 - Marked dowel ready to

install. | |

63 - Forward dowel, marked

at 1/2" dead center. | |

64 - Forward dowel

marked. | |

65 - 5 minute epoxy

applied to forward dowel. | |

66 - Forward dowel

inserted in fuselage up to the line that was drawn.

| |

67 - Rear dowel with 5

minute epoxy inserted in fuselage up to the short line.

| |

68 - Excess epoxy was

cleaned up with a paper towel and some denatured alcohol, then

left to set. | |

69 - Mixing up the good

stuff for wing mounting. | |

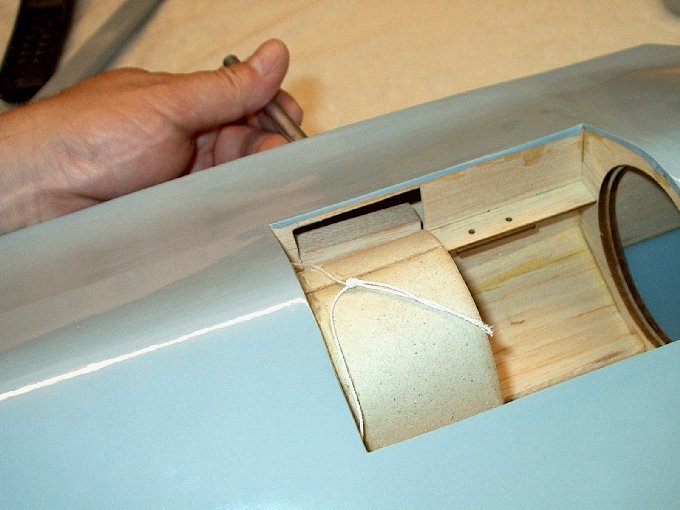

70 - Epoxy applied to wing

spar. | |

71 - Epoxy applied inside

slot, then spar inserted. The spar can go in either way,

making installation easier. | |

72 - Spar will bottom out

inside the fuselage. | |

73 - Applying epoxy to the

fuselage root. | |

74 - Fuselage with epoxy

applied. | |

75 - Epoxy next applied to

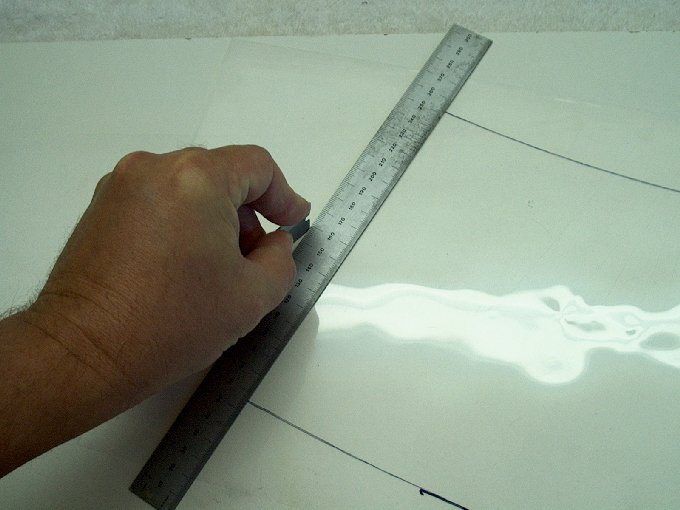

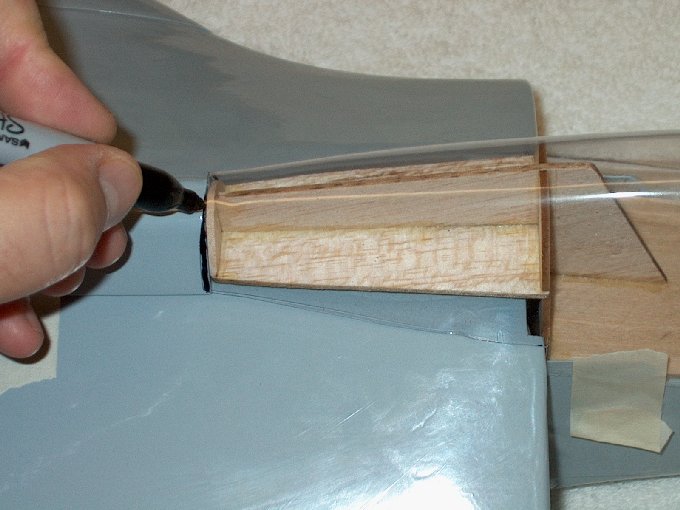

wing spar slot. | |

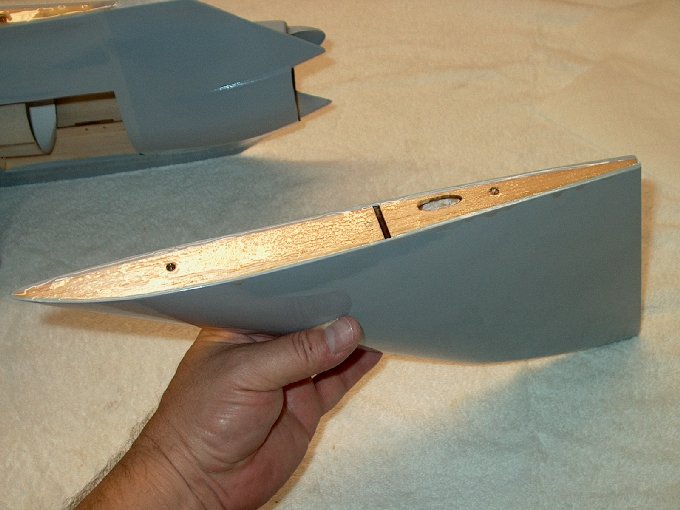

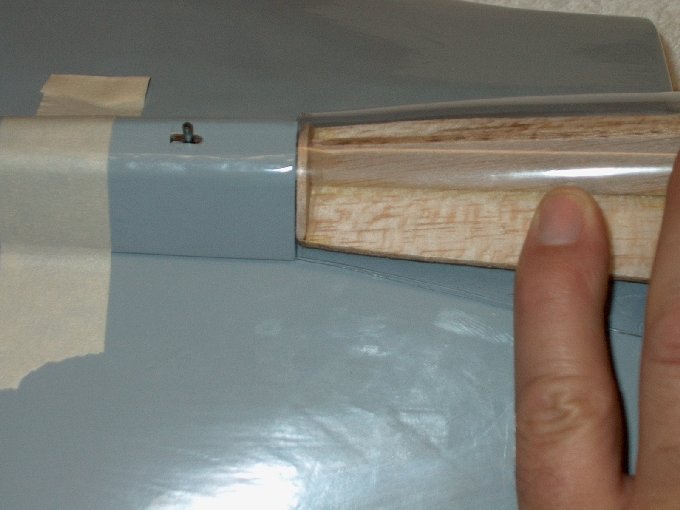

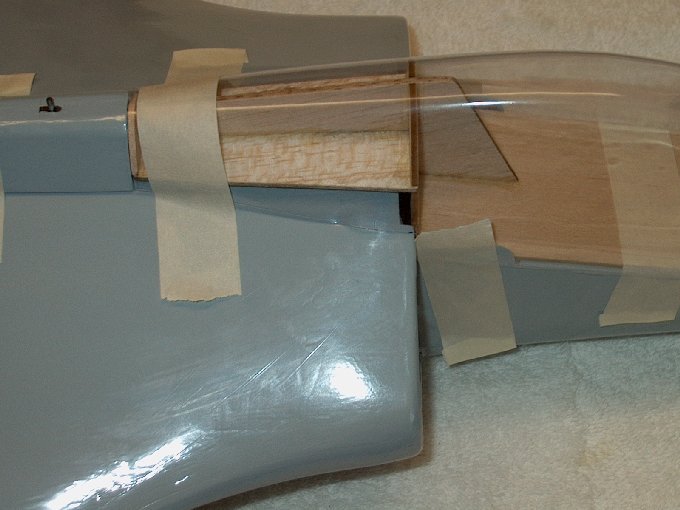

76 - Epoxy applied to entire wing root and

dowel holes. | |

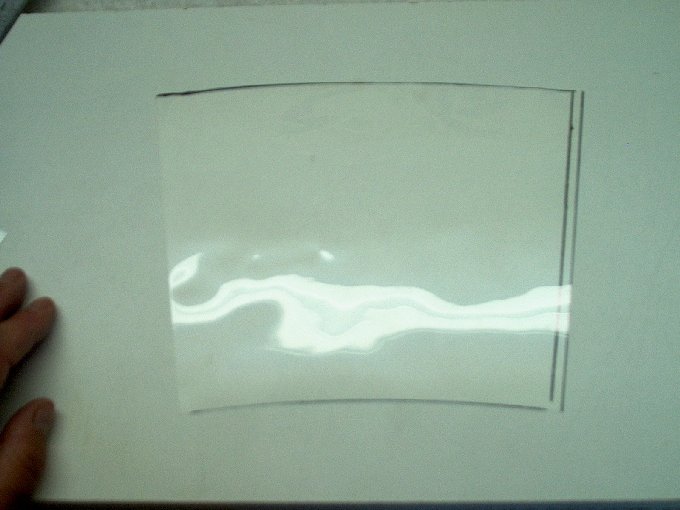

77 - Wing with epoxy ready to install.

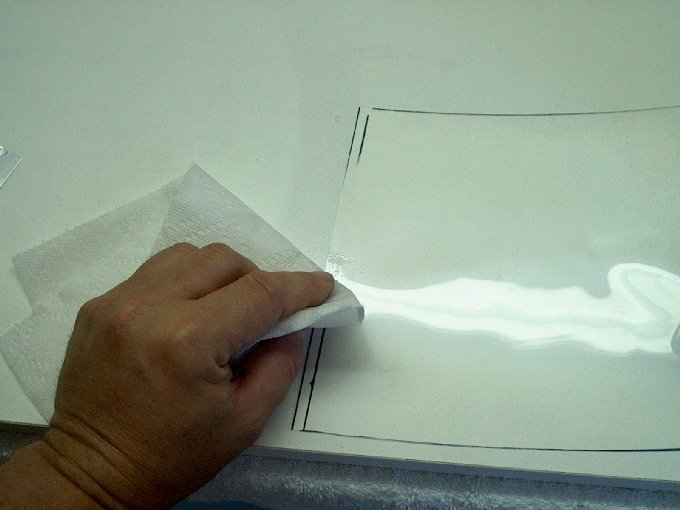

| |

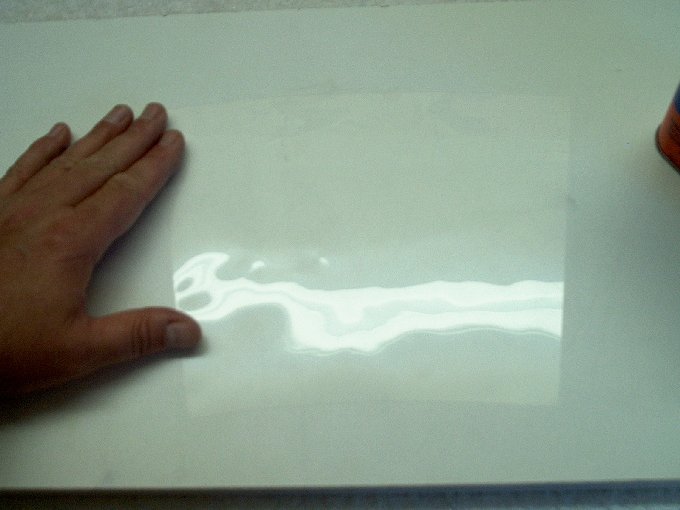

78 - Installing the wing

| |

79 - Wing pressed down until flush.

| |

80 - Excess epoxy was removed with paper

towel soaked in denatured alcohol. | |

81 - Joint cleaned and T-pins used to hold

wing in place. | |

82 - Wing was mounted flush to the top of

the fuselage and a small ridge was evident at the bottom, but

will be fine. | |

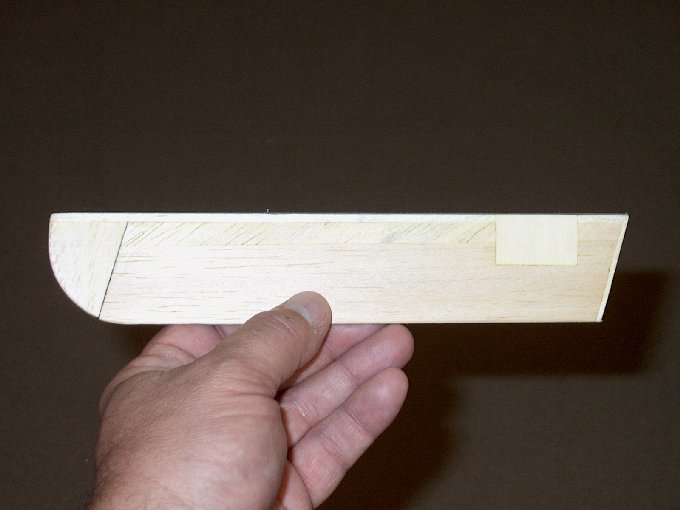

83 - Edge view of

installed and pinned wing. | |

84 - Clean up the excess

epoxy from the servo well. | |

85 - Wing pinned and epoxy

left to set. | |

86 - Wing

installed. | |

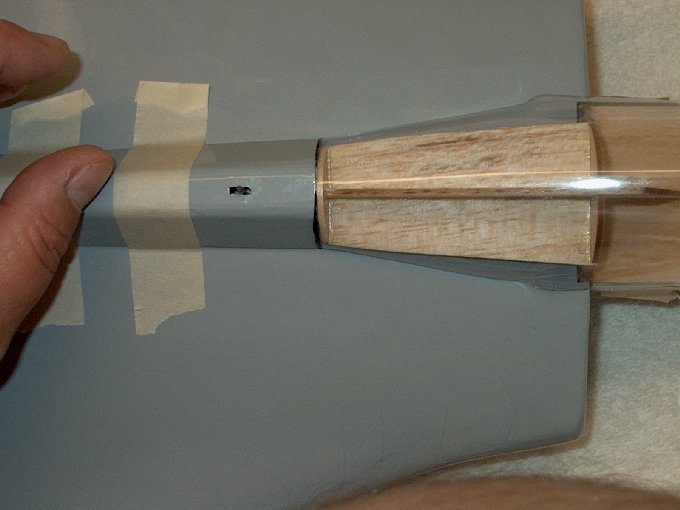

87 - A piece of 1/2" brass

tube is sharpened by shaving the inside with an exacto knife.

| |

88 - Brass tube inserted

through servo access holes. | |

89 - Brass tube is used as

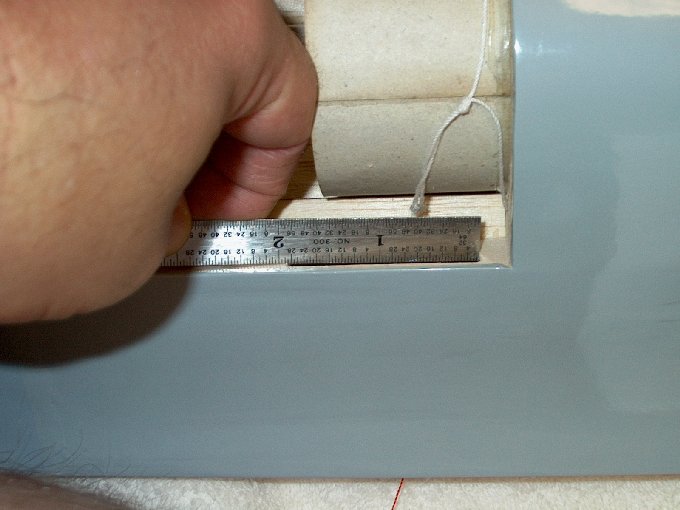

a drill to make a hole for the servo wires.

| |

90 - Tube was angled

upward so it would come out inside just above the horizontal

runner. | |

91 - Tube came out just

above the runner. | |

92 - Hole drilled for

servo wires. | |

93 - Another view... you

can see the fan tube through the holes.

| |

94 - Rear guide dowel

installed in other fuselage root with 5 minute epoxy.

| |

95 - Guide pins installed

and glue is set. | |

96 - Slow cure epoxy

applied to wing root. | |

97 - Second wing installed

just like the first. | |

first. 98 - Epoxy was

cleaned up. | |

99 - Excess epoxy squeezed

out of the top. | |

100 - Wing cleaned up and

pinned just like the first. Then placed aside so epoxy can

set. | |

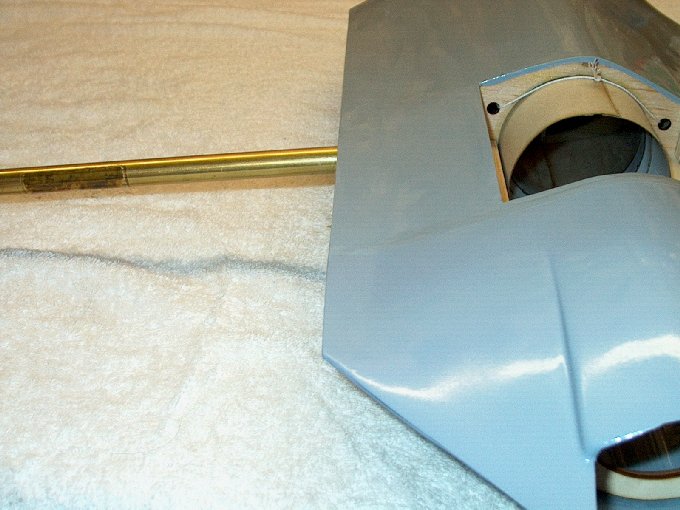

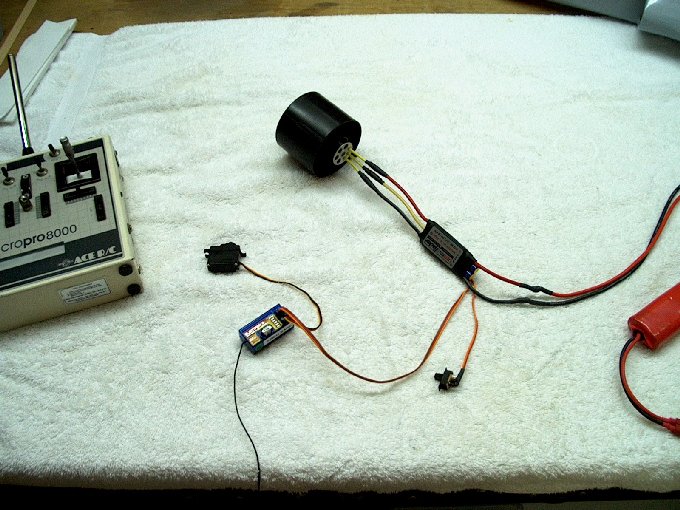

101 - The power plant... a

Wemotec MiniFan 480 and Mega AC 16-15-2.

| |

102 - Torch used to heat

up the adapter so it would slide over the motor shaft. DO NOT

push this adapter all the way on or the back of the fan will

bind against the shroud when installed.

|

|

103 - Set screws installed

with some Loktite. | |

104 - Other set screw

installed... note the shaft base is not against the motor. It

had to be pulled away about 3/16" for fan clearance.

| |

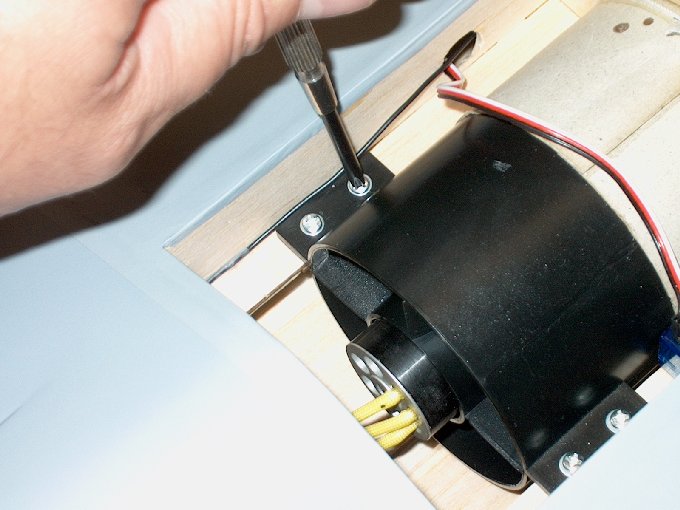

105 - Installing the motor

in the shroud. | |

106 - Motor intalled.

| |

107 - 3mm screws are used

to retain the motor. The fan unit comes with 2.5mm screws, so

you will have to buy 3mm screws if needed.

| |

108 - Fan installed,

followed by washer and nut. | |

109 - Shaft adapter

slotted for screwdriver. | |

110 - Bolt slotted.

| |

111 - With shaft slotted,

a screwdriver can hold the shaft still while the nut is

tightened. | |

112 - Nut

installed. | |

113 - Fan hub installed...

| |

114 - ... and retained

with supplied screw. | |

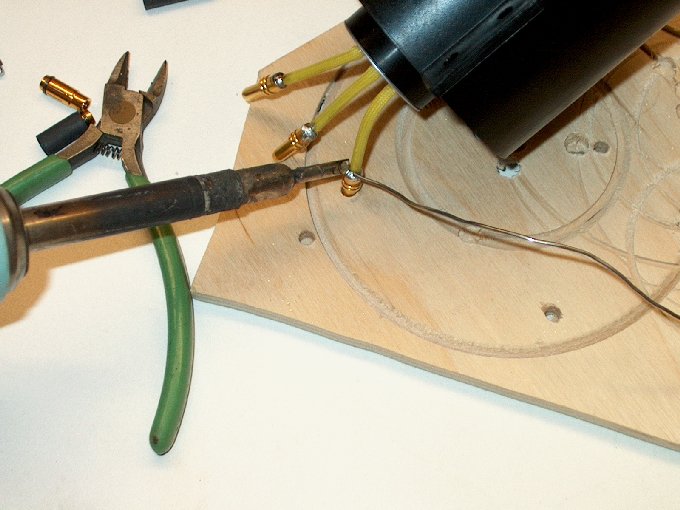

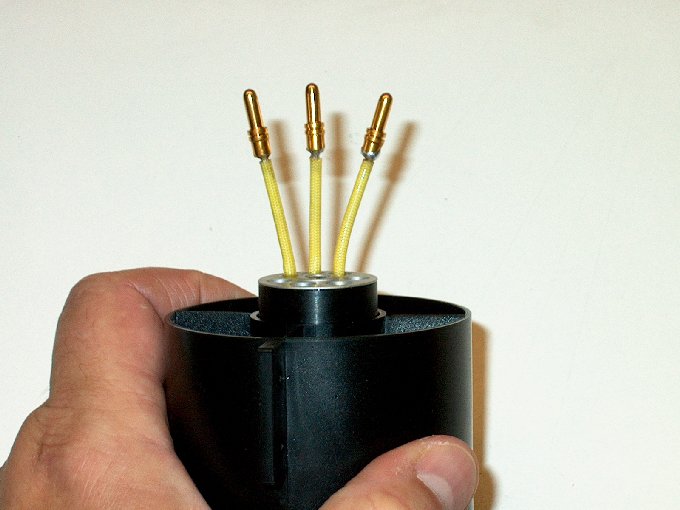

115 - Wiring the motor...

3.5mm connectors added to motor ends.

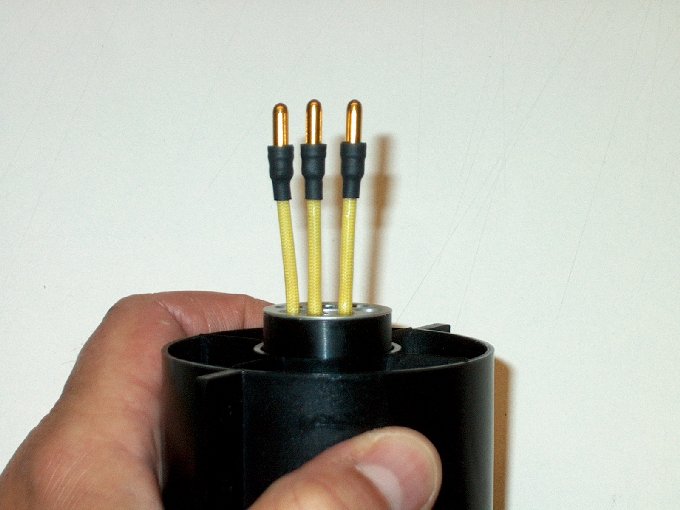

| |

116 - Connectors

installed. | |

117 - Heat shrink

added. | |

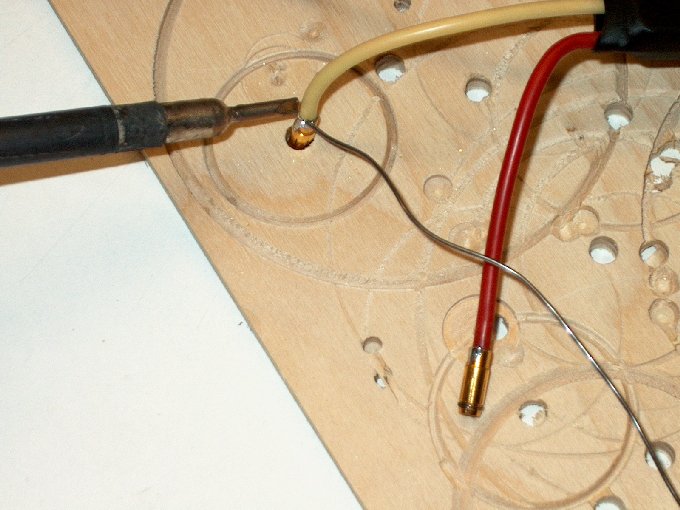

118 - Soldering the

connectors to the electronic speed controller.

| |

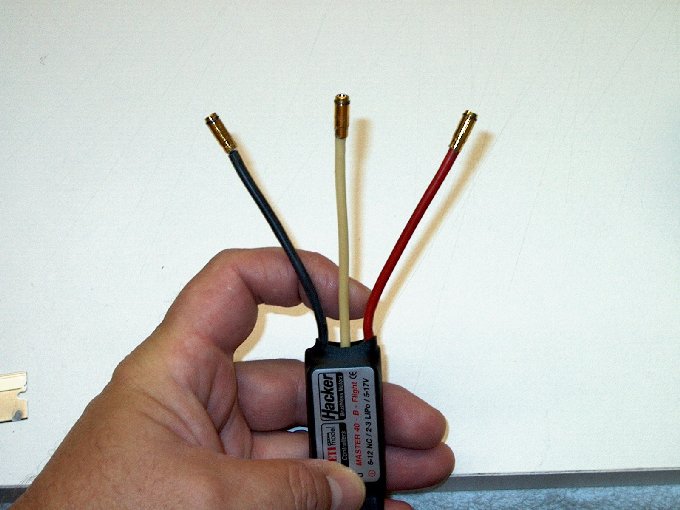

119 - Socket connectors

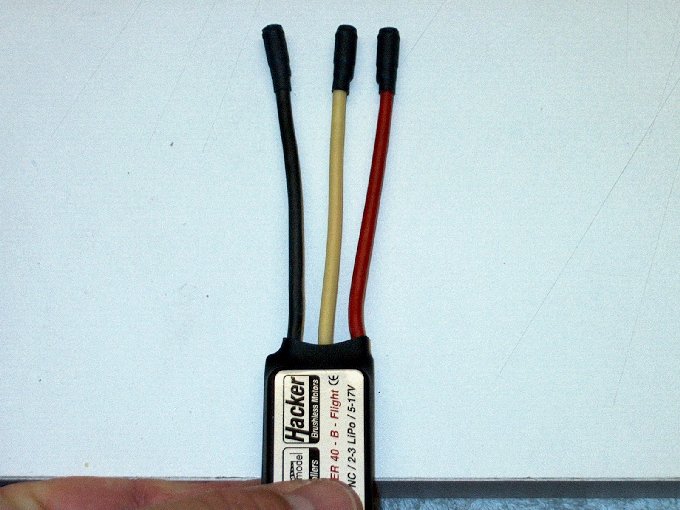

installed. | |

120 - Heat shrink added.

| |

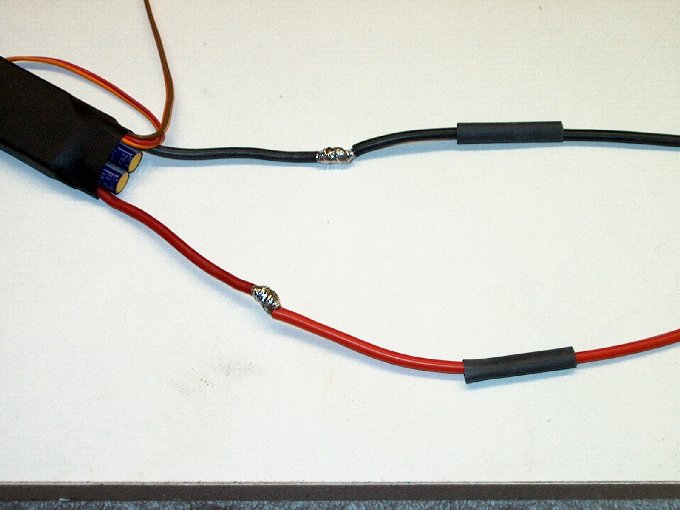

121 - Extended power wires

soldered to the ESC. | |

122 - Assembly wired and

fan balanced prior to installation into airframe.

| |

123 - Wings glued and

model ready for color. | |

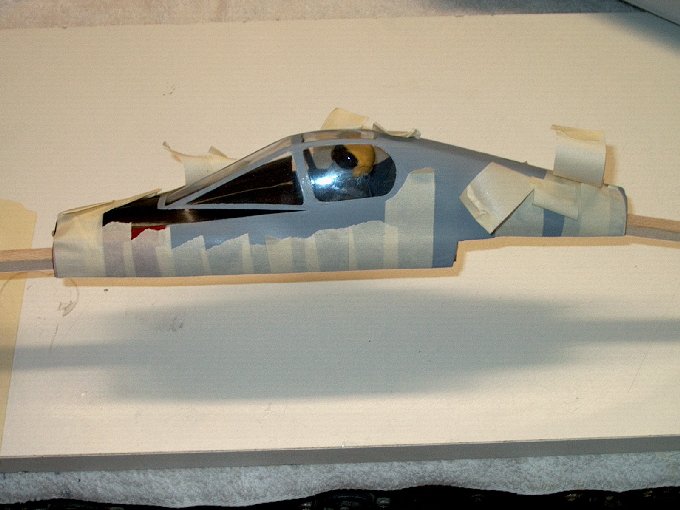

124 - Hinges removed to

mark them. | |

125 - Center lines are

marked down the middle of each hinge

| |

126 - Center lines are

drawn... the lines are drawn up the shorter side, allowing

more surface area to bond when installed.

| |

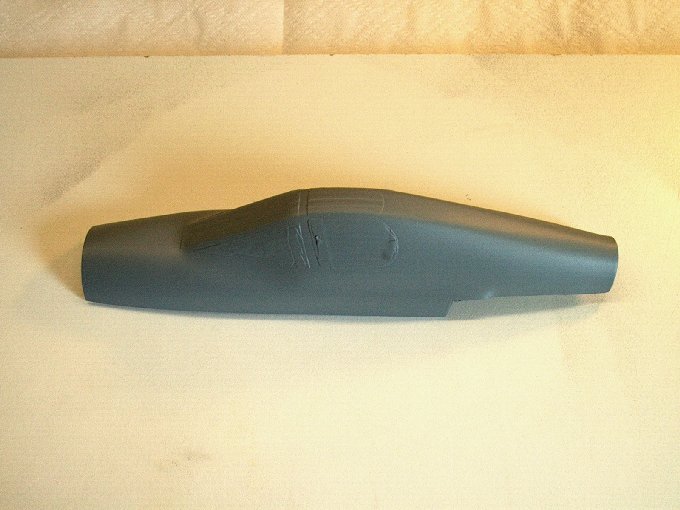

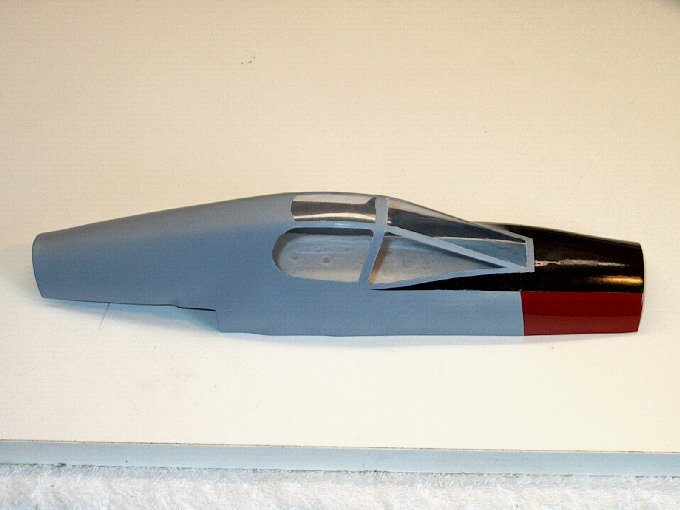

127 - NOTE: THE BUILD

STOPS HERE. The next few steps show my method of dressing up

the model with a bit of color. | |

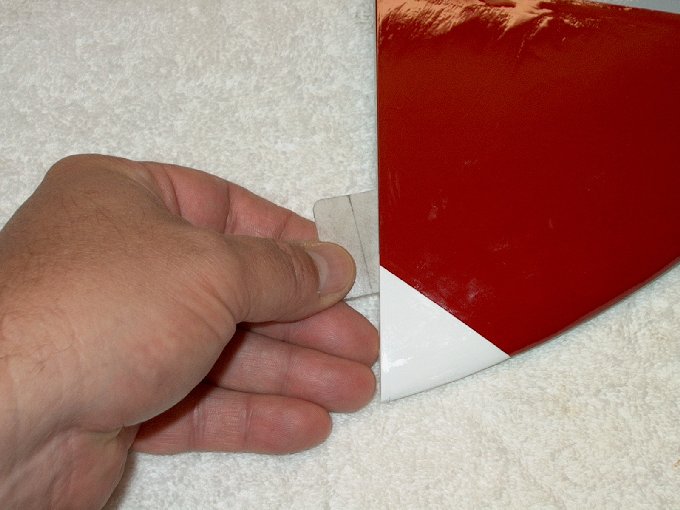

128 - Control surfaces

stripped so I can recover them with white.

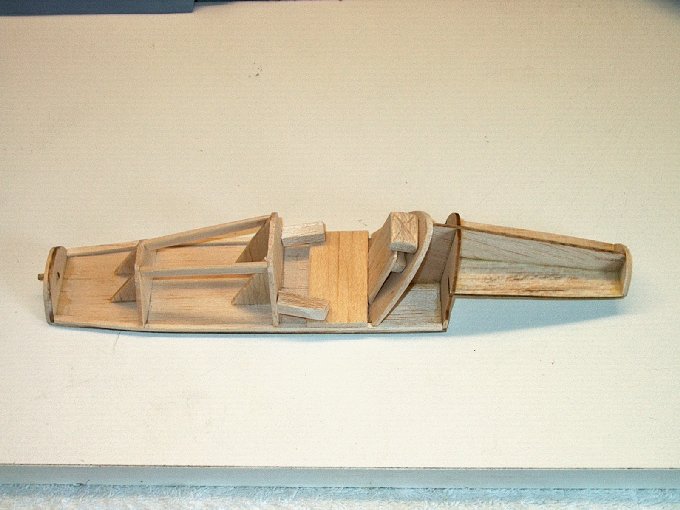

| |

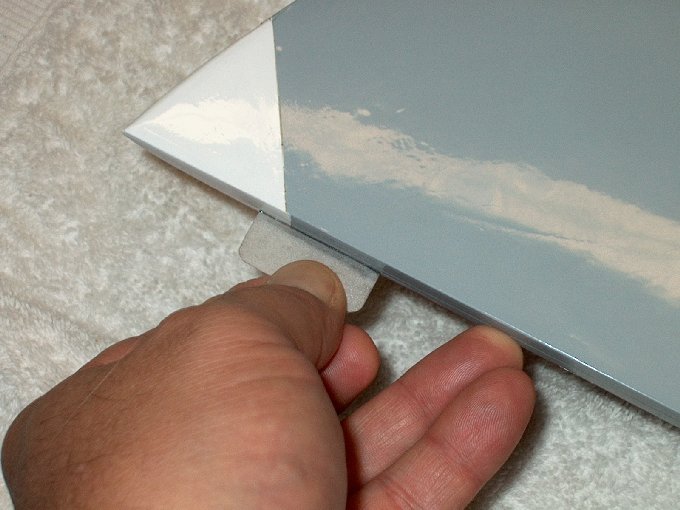

129 - Areas I wanted to

add color to were stripped of the original covering, leaving

1/8" - 3/16" for overlap. | |

130 - A stripped area

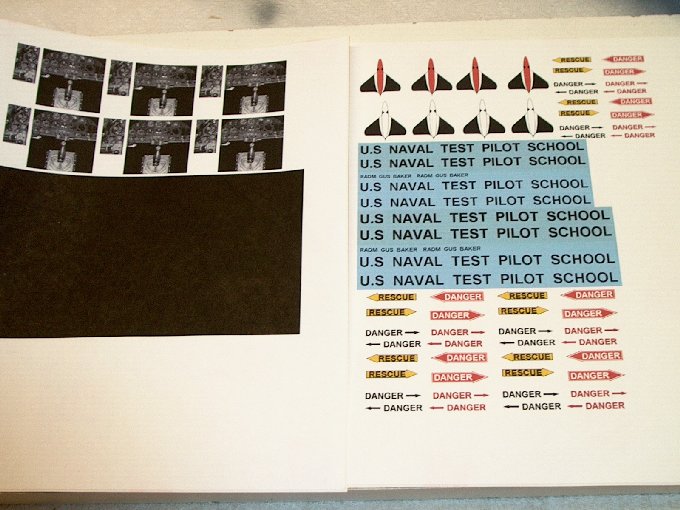

shows some of the quality of build by HET-RC at the

factory. | |

131 - Nose color

applied. | |

132 - Tail is stripped and

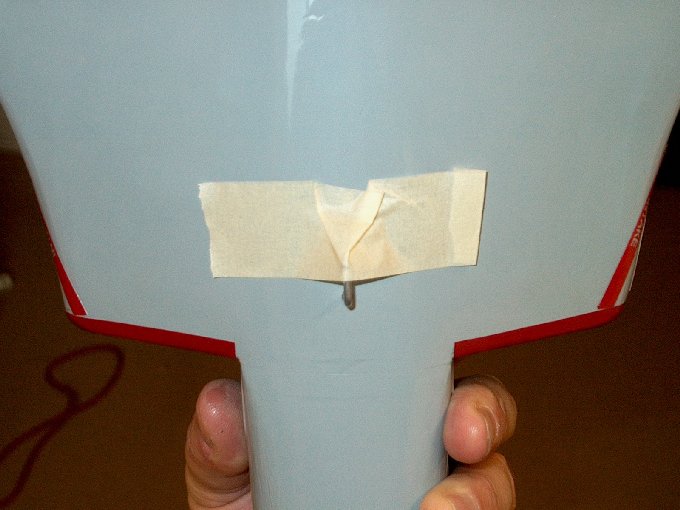

black leading edge added. | |

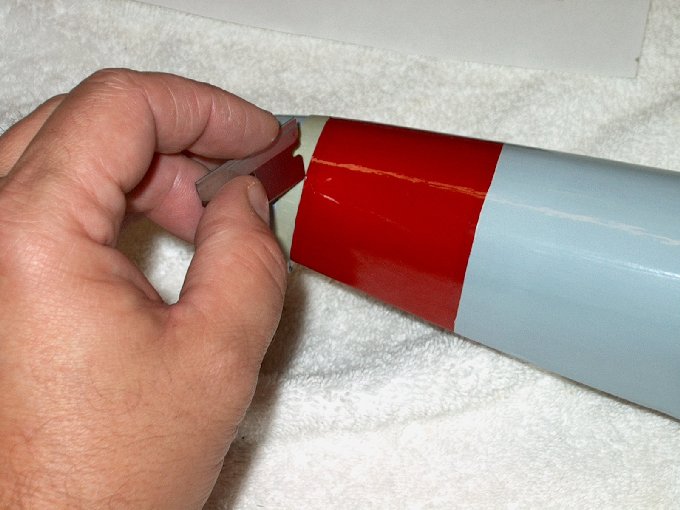

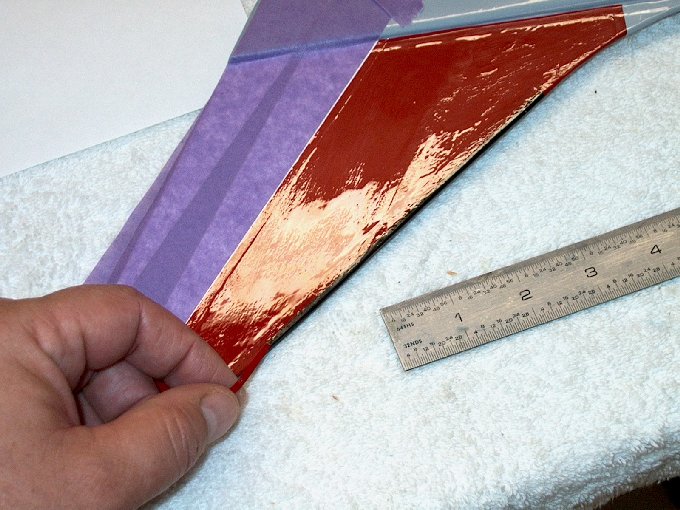

133 - Red added and being

trimmed before cleanup. | |

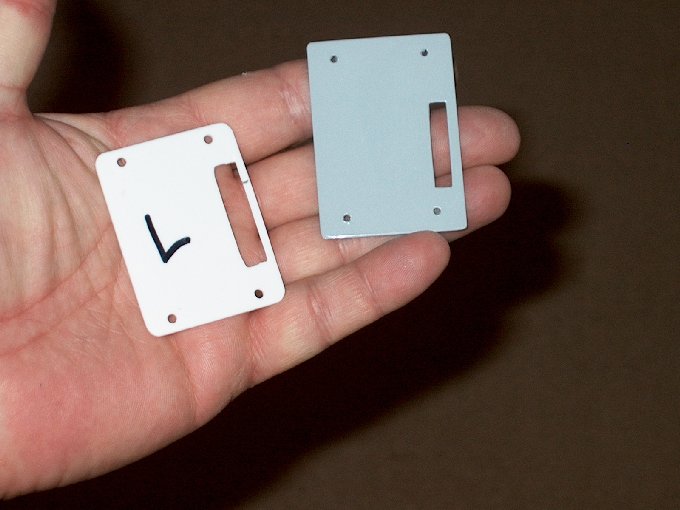

134 - Adding some color to

the vertical stab. | |

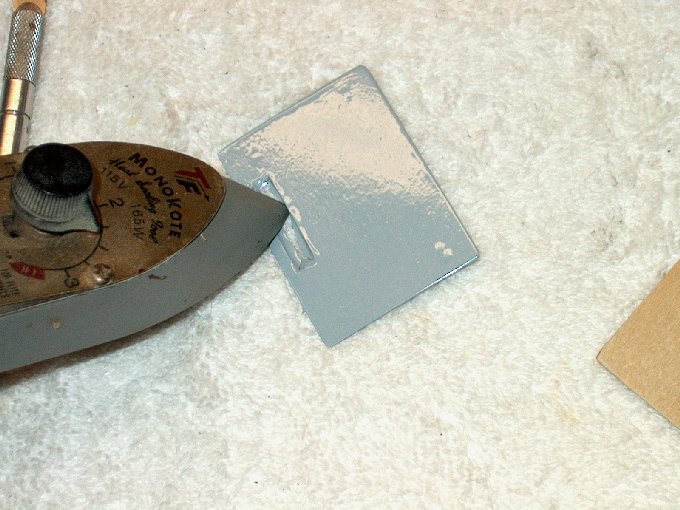

135 - Stab being

ironed. | |

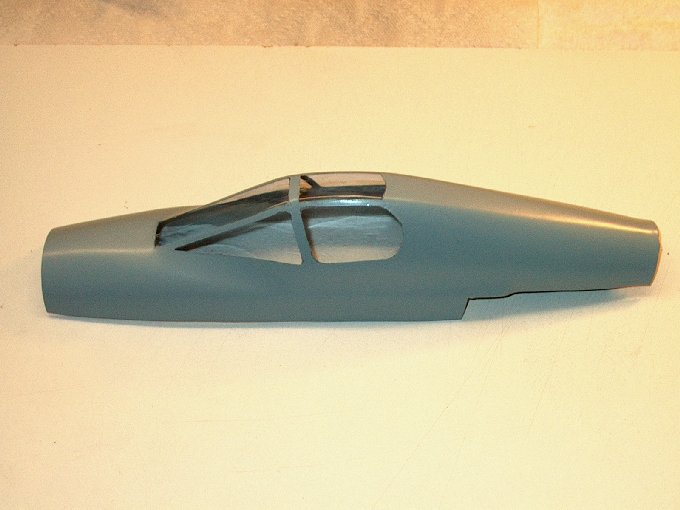

136 - F4D Skyray with the

color scheme I decided to use. | |

137 - Skyray covered in

color... NOTE: THE BUILD WILL CONTINUE FROM HERE

| |

138 - Install a hinge into

the fuselage up to the drawn line. | |

139 - Hinges installed. I

used the control surface to make sure the hinges aligned

correctly. | |

140 - Hinges glued and

tugged to make sure it is in solid.

| |

141 - Hinge glued and

tugged to make sure it is in solid.

| |

142 - Elevon

installed. | |

143 - Other elevon

installed. | |

144 - Make sure it is even

with the wing tip. | |

145 - You should also not

be rubbing the fuselage here at the root.

| |

146 - A piece of masking

tape was marked at center, then 10, 12 and 15mm for down

throw. The stab is designed to throw down only so far.

| |

147 - Holding the stab

with one hand, 5 - 8mm throws are what is called for. I went

to 10 - 12mm so the stab wouldn't bind if pushed a little too

far. | |

148 - Holding the fin

down, thin CA was applied to teach hinge. Make sure the fin is

even with the wing tip because once the CA is applied, it's

too late. | |

149 - Other side of hinge

getting some CA. | |

150 - Hinges glued in

place. | |

151 - This step may not be

necessary for everyone. A 3/32" x 1" x 7/16" piece of ply was

cut from some scrap. | |

152 - Piece glued behind

ply fan mount, extending the mount to the rear former. I plan

on using FAUP's and wanted to make sure I could move the fan

more if needed, so the mount was extended.

| |

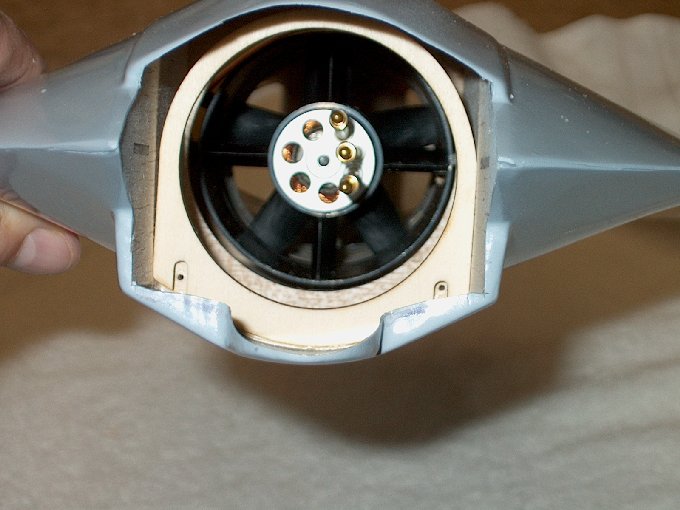

153 - 3/8" Balsa triangle

cut to 2 1/4" long. | |

154 - Triangle glued under

the ply fan mounts for support. This was added because the

stock mount was only supported by the 1/2" wide balsa runner

running from the front to the back. This seemed a bit

weak. | |

155 - With this triangle

piece, the runner is now strong and no longer flexes like it

did earlier. | |

156 - Exacto knife used to

shave the rough edges of the duct work.

| |

157 - Another view, you

can see the rough edges on the plastic.

| |

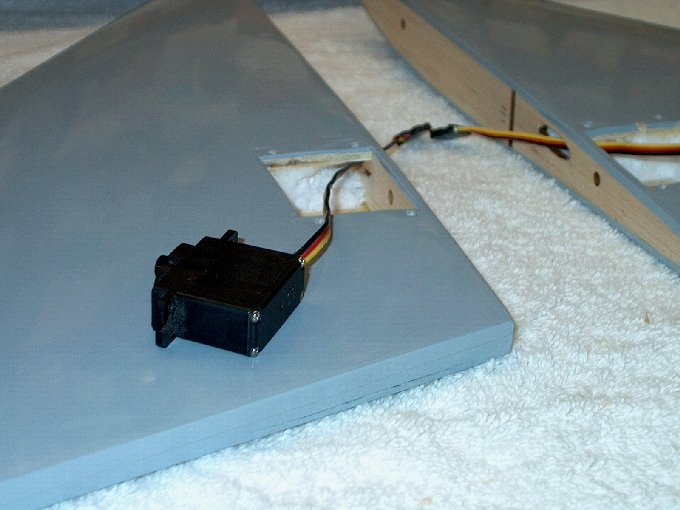

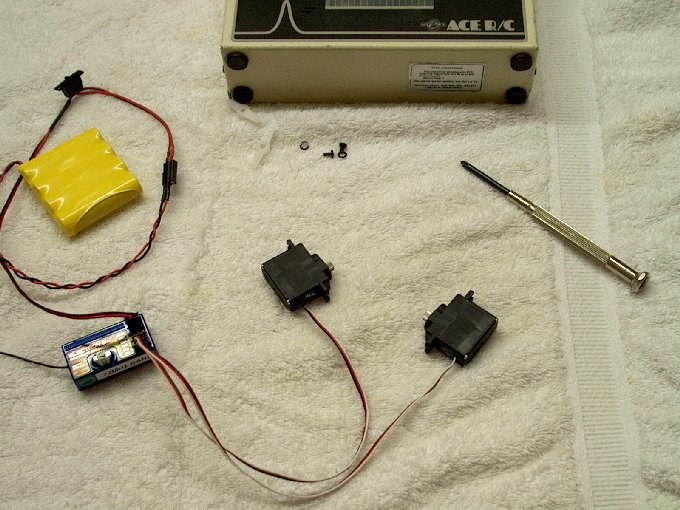

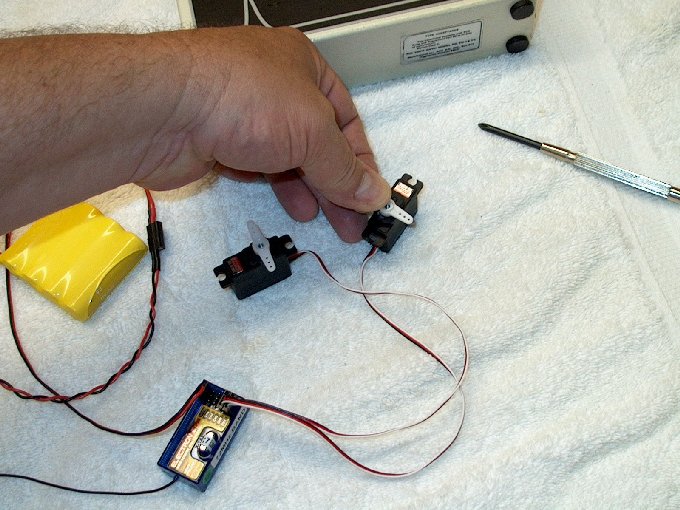

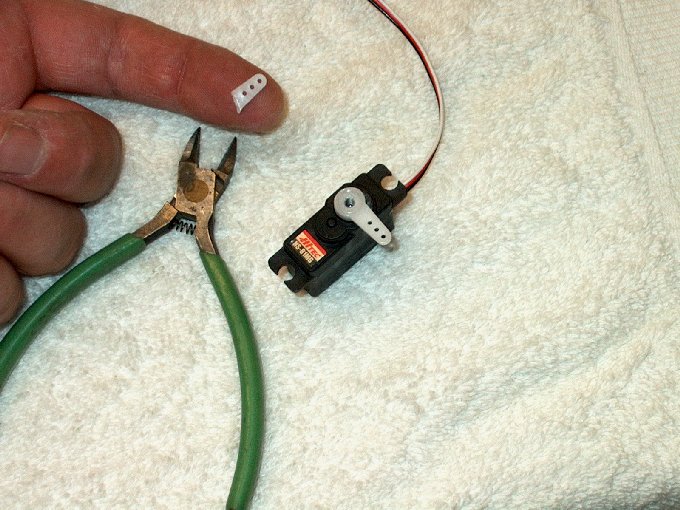

158 - Servos hooked up to

the receiver and both the transmitter and receiver were turned

on so the servos could be centered.

| |

159 - Horns mounted to

servos while they are centered. | |

160 - One end was cut off

the horn. | |

161 - Make sure you do two

opposite servos. | |

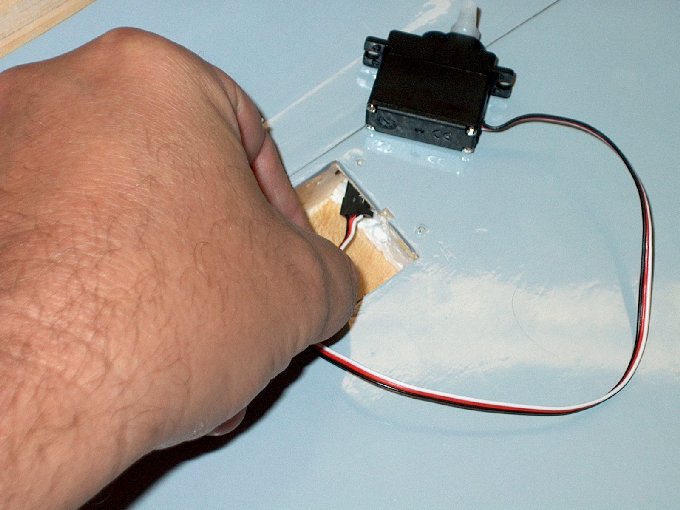

162 - Another view showing

mirrored servos. | |

163 - Servo being

installed in left wing. | |

164 - Servo sitting

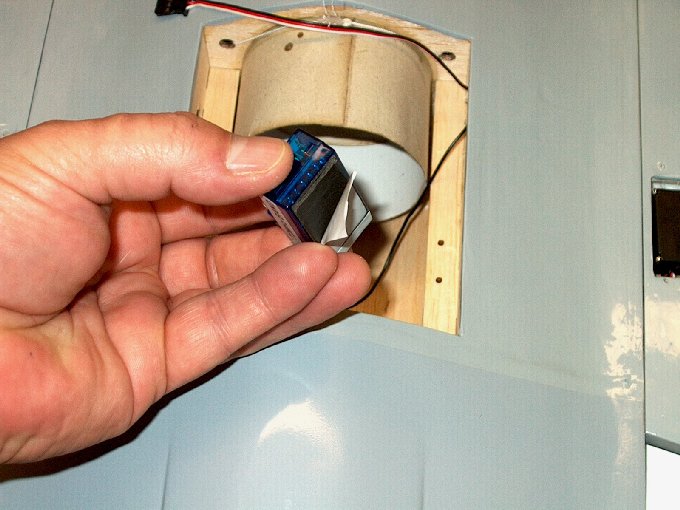

temporarily in place. | |

165 - Servo wire pulled

through receiver opening, then receiver is prepped for

install. | |

166 - Receiver set in

place. | |

167 - Piece of plastic

tube threaded through other wing. | |

168 - Servo wire taped to

plastic rod... | |

169 - ... and wire pulled

through. | |

170 - Servo can be plugged

in without the use of an extender. | |

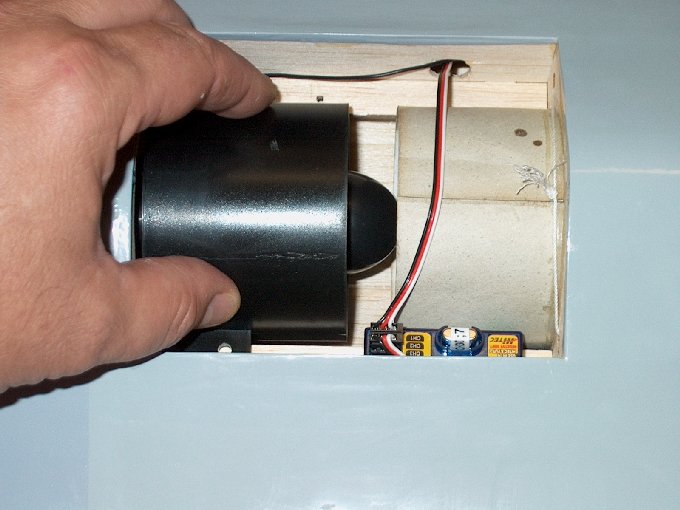

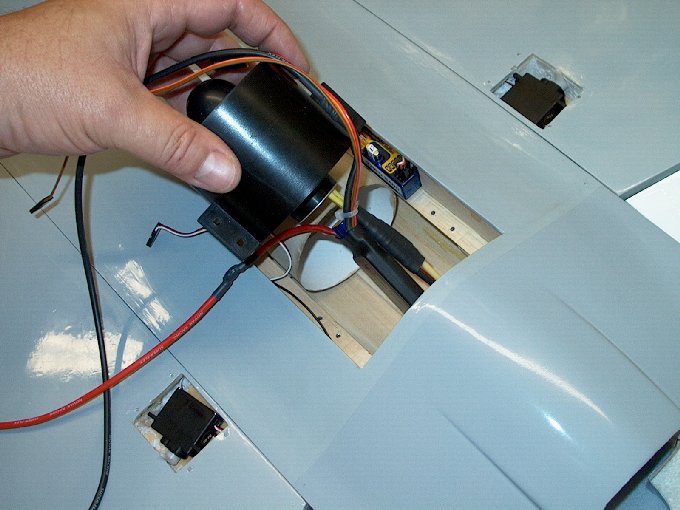

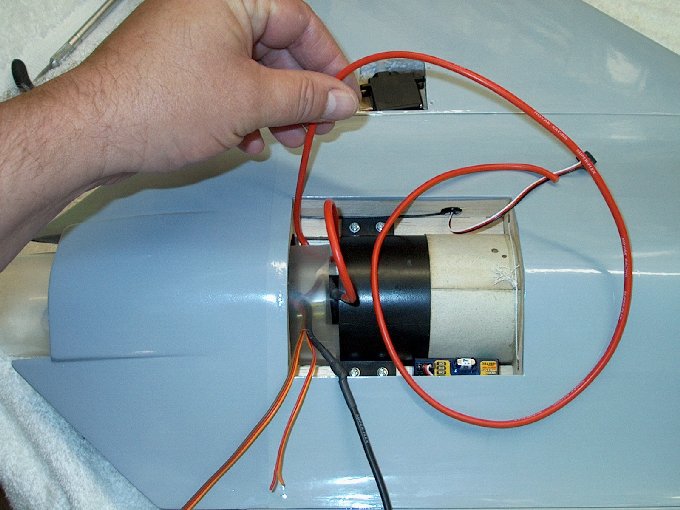

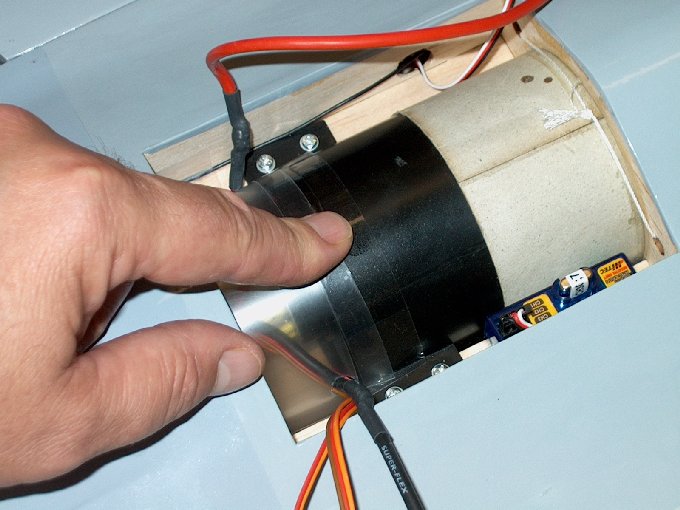

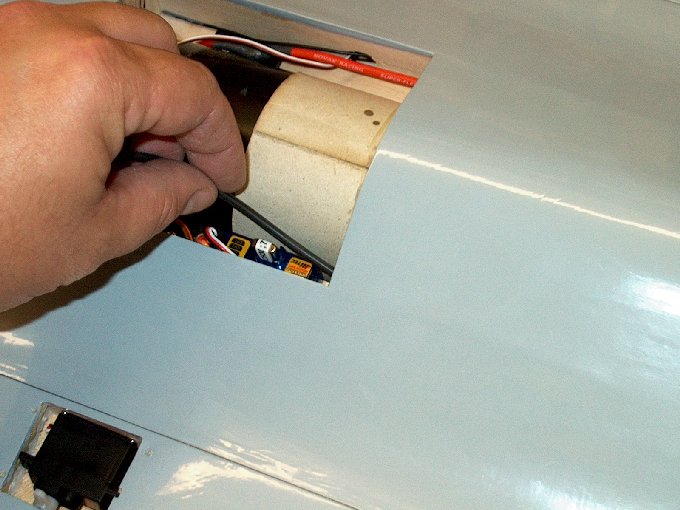

171 - Fan being

installed... you have to bend the cardboard duct down a bit

for the fan to fit. | |

172 - Fan placed in

compartment. | |

173 - Fan unit positioned

over mounting holes. | |

174 - #4 screws and

washers installed. | |

175 - Installing the rear

thrust vector former. | |

176 - The thrust vector

former inserted from the rear. | |

177 - It's pressed flush

against the ply brace behind it. | |

178 - #4 retaining screws

are installed. | |

179 - Thrust vectoring

former install completed. | |

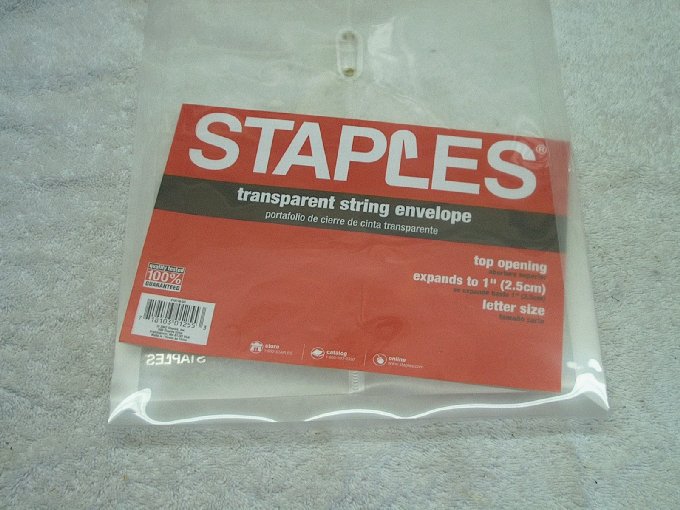

180 - At this point you

can used the supplied paper thrust tube. But I opted to make

my own. | |

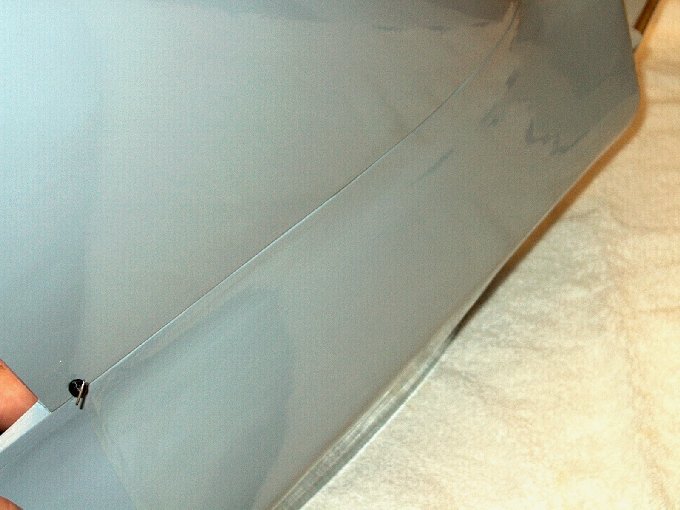

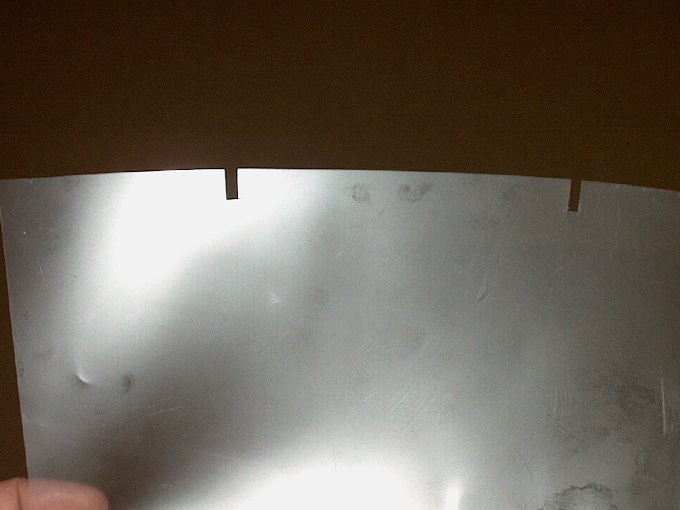

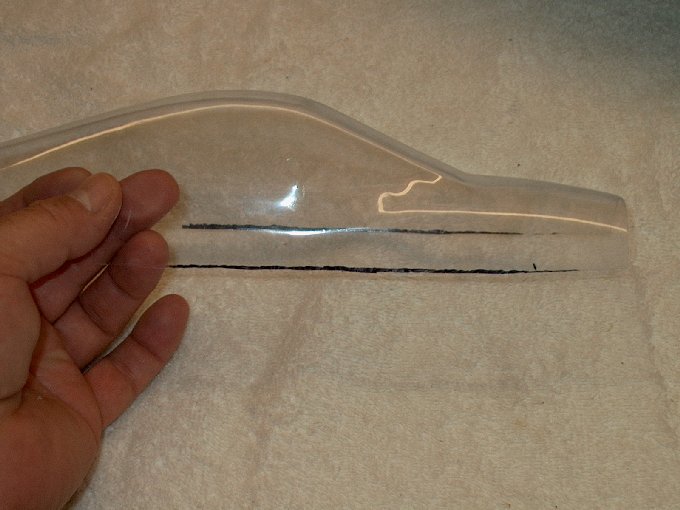

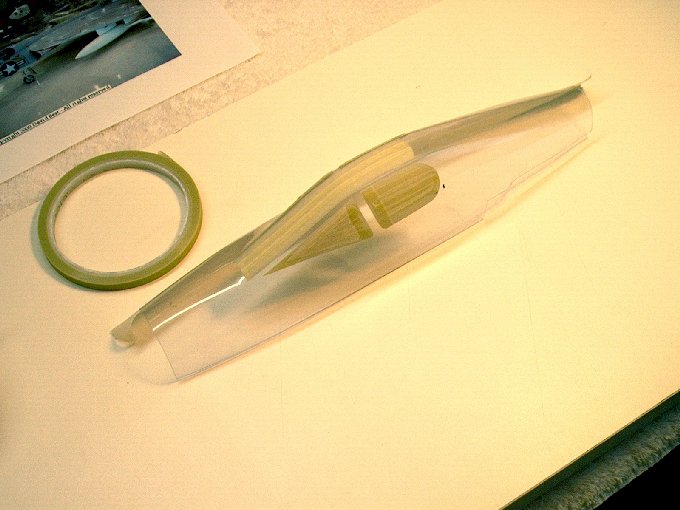

181 - The face of the

plastic folder was removed. | |

182 - This piece will be

used for the thrust tube. | |

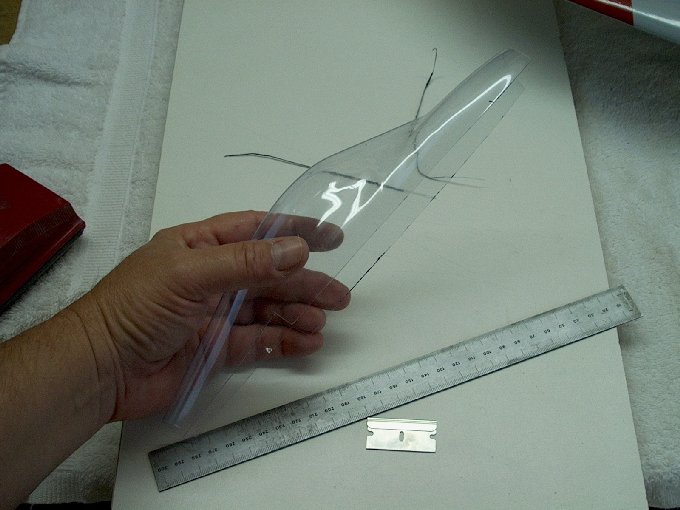

183 - The original tube

was laid flat to draw a pattern. | |

184 - A pattern was dawn

using a marker. | |

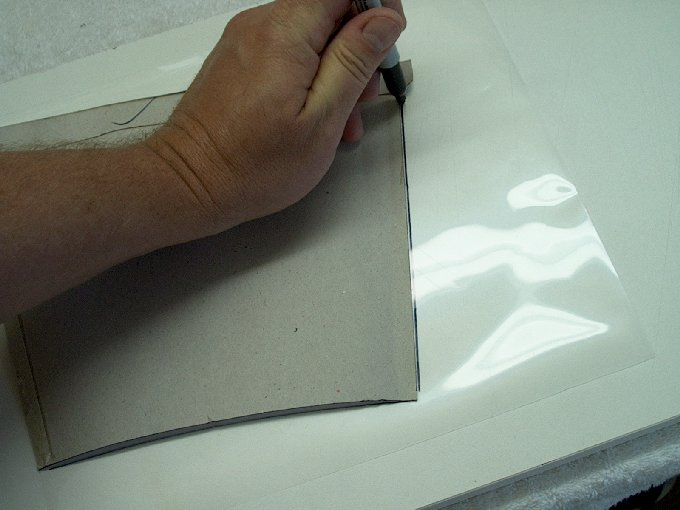

185 - Carefully cut out on

the lines. | |

186 - Thrust tube cut.

| |

187 - The marker was

removed with a paper towel and denatured alcohol.

| |

188 - The trust tube is

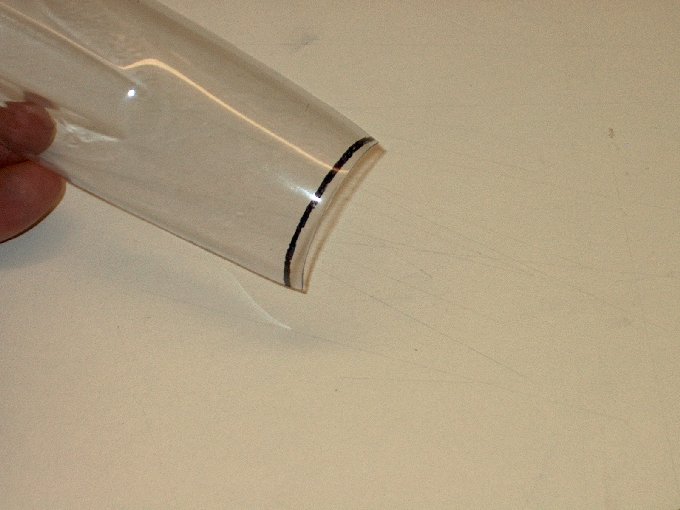

ready to roll. | |

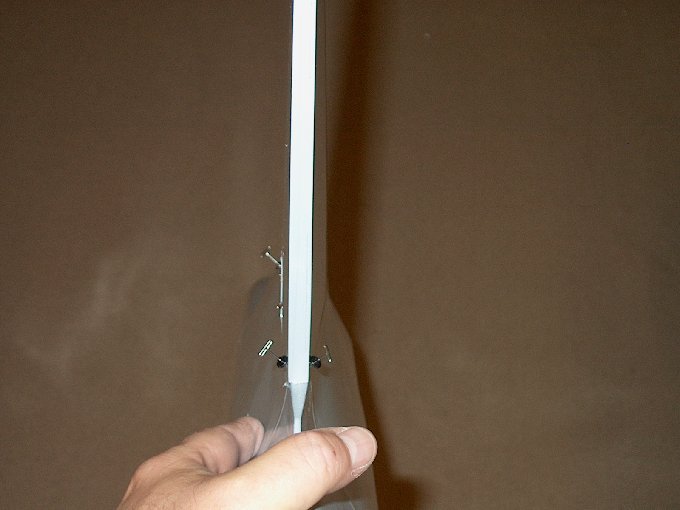

189 - The tube was rolled

up and inserted into place. | |

190 - Notches made at the

front to clear the fan mounts. | |

191 - Tube rolled and

packing tape used to seal the edges. Windex was used to get a

bubble free joint. | |

192 - Thrust tube

completed and ready to install. | |

193 - Inserted the ESC

from rear to connect wires. | |

194 - Wires were hard to

reach so fan was removed and ESC was installed.

| |

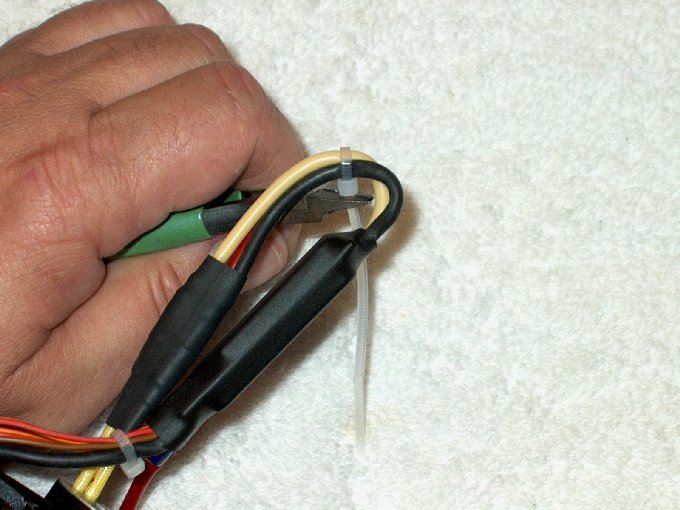

195 - Heat shrink used to

keep the plugs in place. | |

196 - Front of the ESC was

tie wrapped to motor lead. | |

197 - Rear of the ESC

wires tie wrapped to keep them from flying around under

thrust. | |

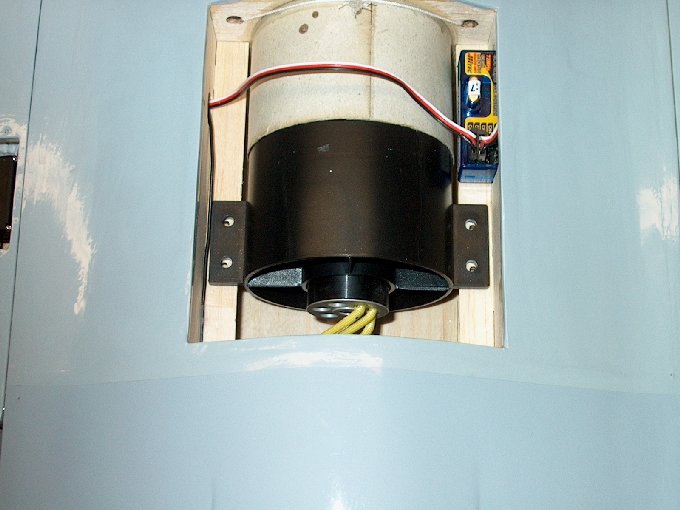

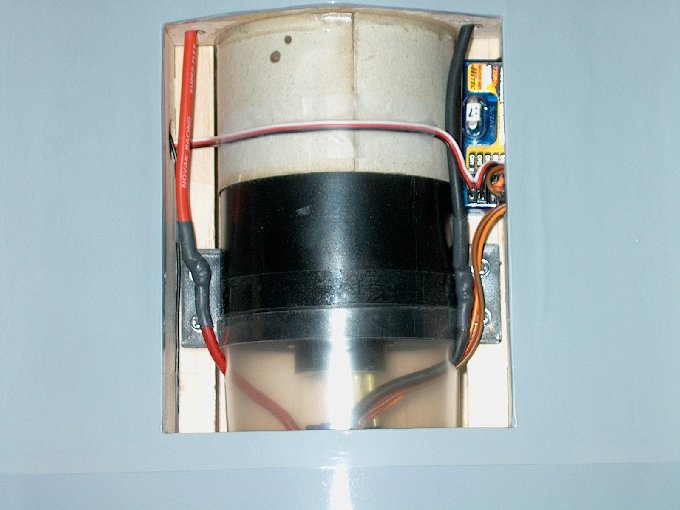

198 - The fan unit with

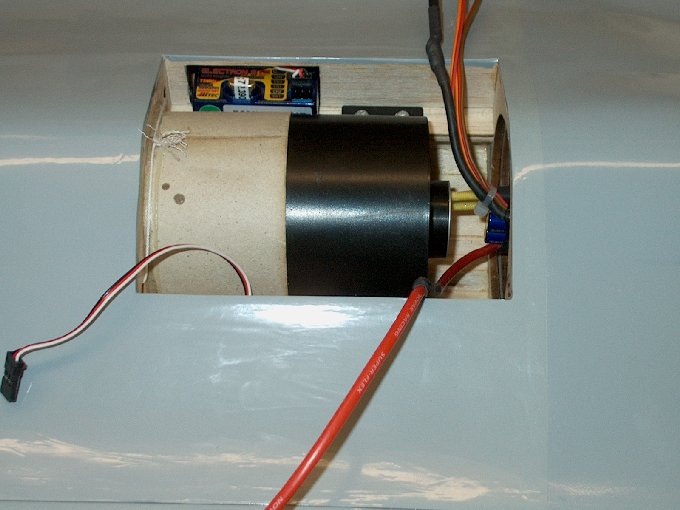

ESC reinstalled. | |

199 - Fan unit bolted back

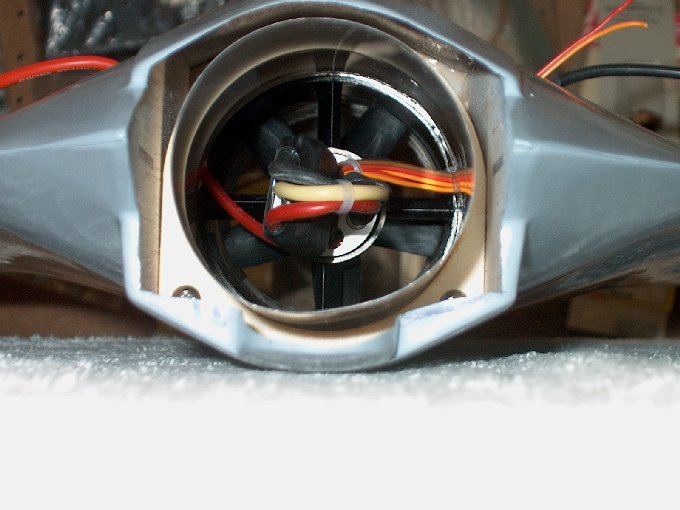

in place. | |

200 - Rear view showing

the ESC in thrust path to keep it cool.

| |

201 - Thrust tube folded

and inserted from rear. | |

202 - The ESC was

maneuvered inside the tube fold. | |

203 - The right side wires

threaded through the punched hole in the tube.

| |

204 - Power wire fed on

the other side. | |

205 - I used this from the

rear like a shoe horn to get the thrust tube on the fan

shroud. | |

206 - Thrust tube slid

forward and has a 3/8" overlap. | |

207 - Packing tape used to

tape the thrust tube to the shroud.

| |

208 - Rear view with

thrust tube installed. | |

209 - Red power wire fed

through first hole using supplied white string.

| |

210 - A piece of lead

glued to other string which fell out. I had to re-thread it

back to the rear. | |

211 - Threading the black

wire. Note that the thread system may work better the other

direction threading from the cockpit rearward, but I already

had soldered my leads to the ESC, so I went this direction.

| |

212 - Pulling the black

wire through. | |

213 - I used a ruler to go

inside above the hole to get pulling leverage upward.

| |

214 - Pulling up got the

wire through the hole... | |

215 - ... and out of the

fuselage. | |

216 - Power wires routed

to battery bay. | |

217 - There is a balsa

plate that is a construction helper during the manufacturing

process. It can be removed from the battery area.

| |

218 - Plate snapped out...

you can see where it was glued. | |

219 - Deans Ultra Plug

soldered to the power wires. | |

220 - Heat shrink applied

and plug is completed. | |

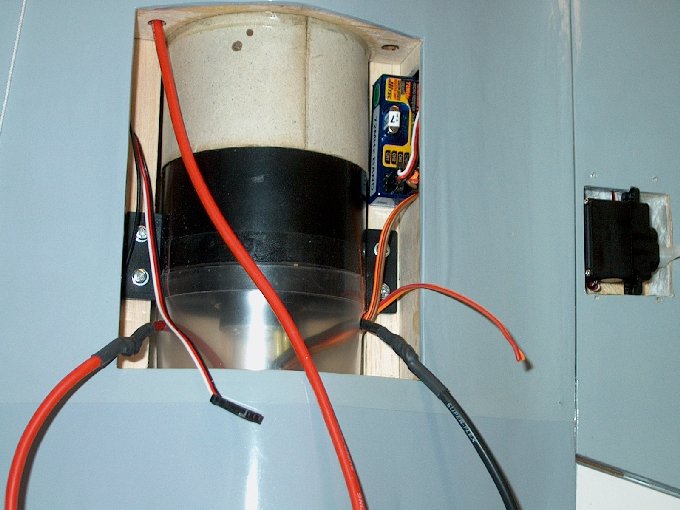

221 - This is the

completed power plant bay. Wires were dressed and Scotch tape

was used to hold down the one servo wire.

| |

222 - Cover was installed

and Scotch tape was used to hold it in place.

| |

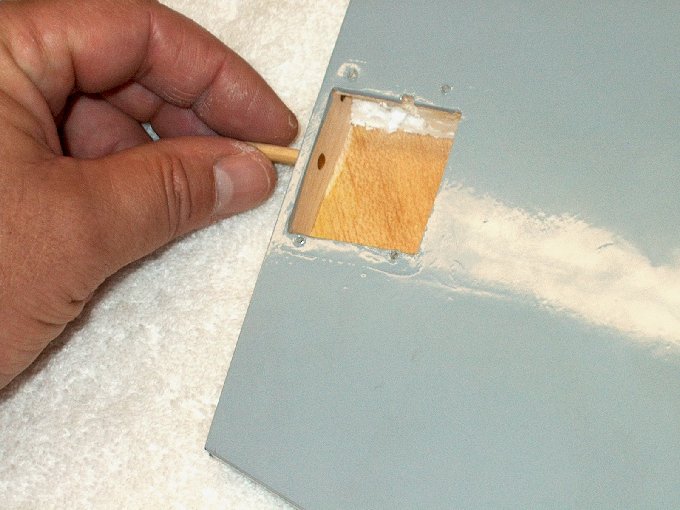

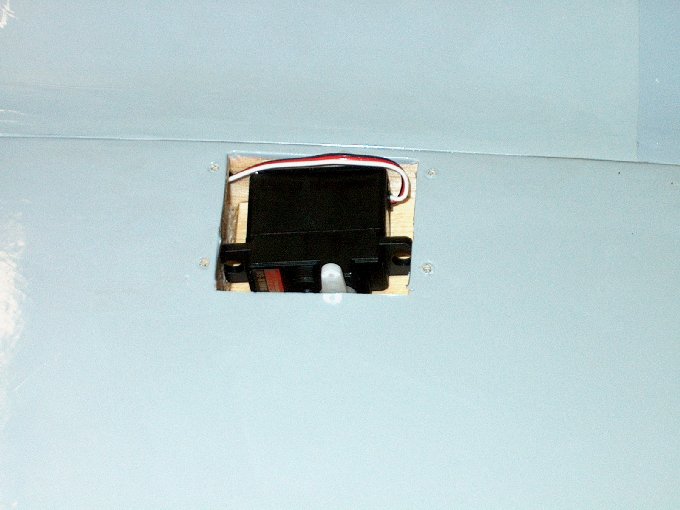

223 - Two 1/8" thick ply

plates were cut from scrap to beef up the servo mounting area.

The photo shows one side being soaked in CA to make a smooth

surface for the servo tape. | |

224 - Two plates cut and

surfaces "plasticoated" with CA and sanded smooth.

| |

225 - Plates installed

with epoxy. | |

226 - Servo test fitted

and clearance is fine. | |

227 - Both servos cleaned

and acetone used prior to adding tape

| |

228 - Double sided servo

mounting tape applied and prepped for installation.

| |

229 - Servo

installed. | |

230 - The next few steps

are not necessary, but I wanted to make some color coordinate

servo hatches. | |

231 - Thin 1/32" ply was

used... original hatch was used as a template.

| |

232 - Some left over

covering was used to cover the plates.

| |

233 - Stock plate on left,

new one on the right. | |

234 - Plate installed with

same supplied screws. | |

235 - Both plates

installed. | |

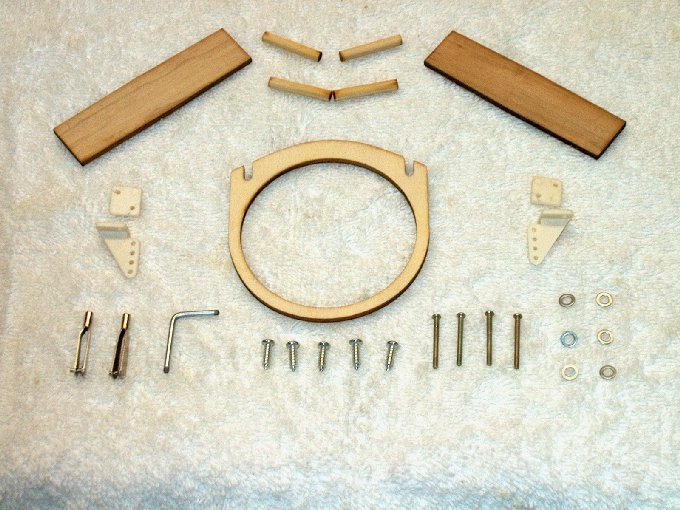

236 - The rest of the

hardware, which will all be used next.

| |

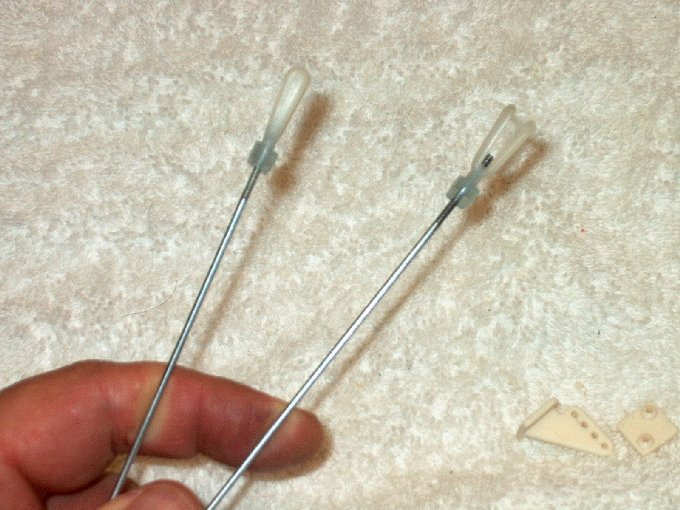

237 - Clevises installed

on rods, along with scrap pieces of fuel line.

| |

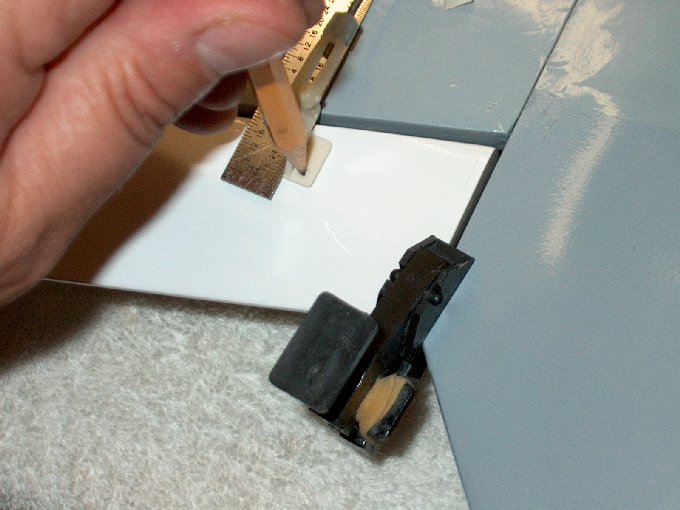

238 - Ruler used for

alignment and first hole marked. | |

239 - Picture shows

alignment for proper elevon horn location.

| |

240 -Elevon

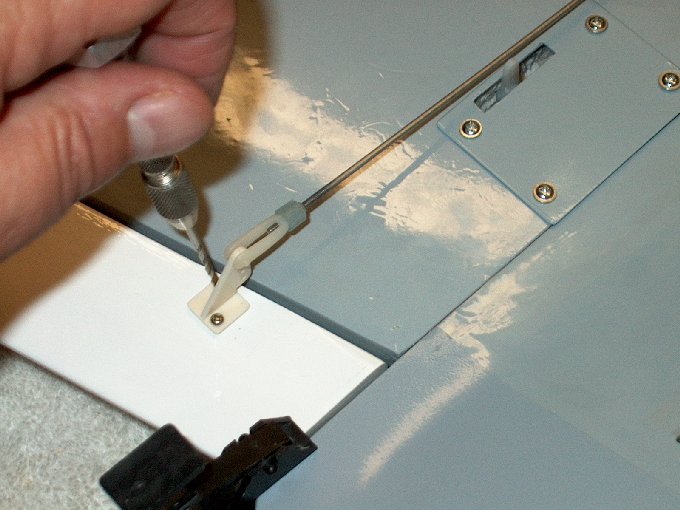

drilled. | |

241 - Bolt added and

second hold drilled. | |

242 - Retainer plate held

on other side as bolts were tightened.

| |

243 - Excess bolt length

cut off. | |

244 - Horn installed.

| |

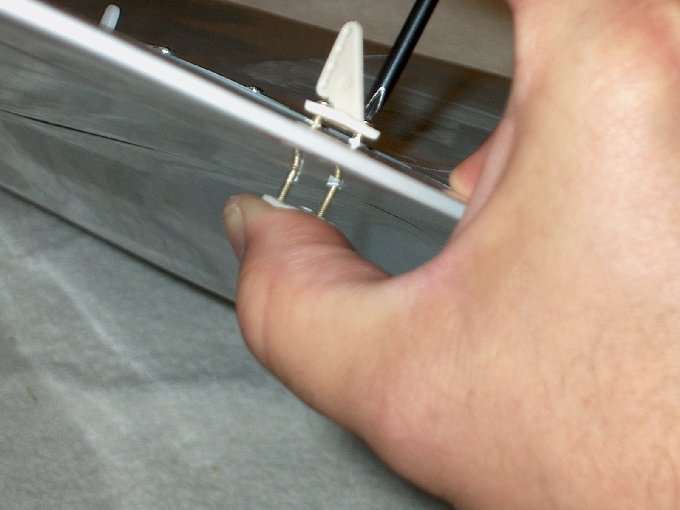

245 - Rod installed...

| |

246 - ... and radio turned

on to center servos. | |

247 - Clamp used to hold

elevon at center. | |

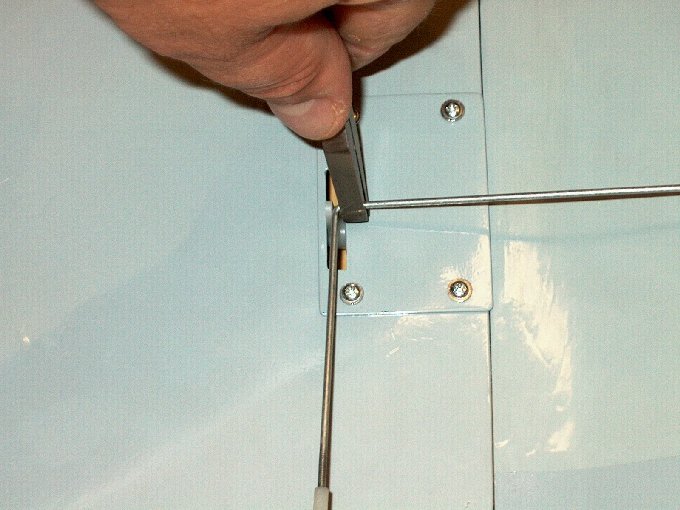

248 - Wire bent at servo

horn. | |

249 - Z-Bend made and wire

installed. | |

250 - Wire made for other

side... note the servo horn holes needed to be drilled a bit.

| |

251 - Other side

installed. | |

252 - Preparing to install

the vertical stab. | |

253 - Cockpit installed

and centered over rear area, then taped to hold it in place.

| |

254 - Hatch latch

extended. | |

255 - Latch installed into

rear of cockpit. | |

256 - Masking placed on

tail, then a mark was made at the center

| |

257 - Trimming the

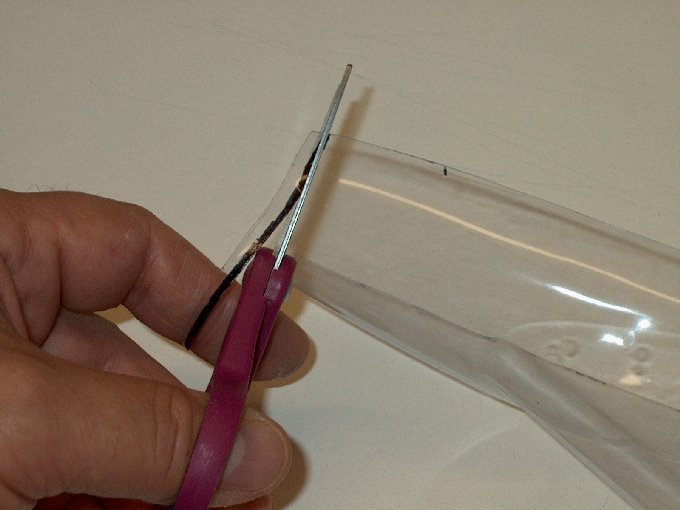

canopy... it has been rough cut with scissors.

| |

258 - Time to fit it to

the cockpit. | |

259 - Permanent marker

used to mark trim lines. | |

260 - Length is marked in

the rear. | |

261 - Top view shows marks

made in rear. | |

262 - Fuselage to nacelle

joint needs some fitting. | |

263 - Nose is too long and

needs trimming. | |

264 - Trimming the rear...

I worked from the rear forward to fit the canopy.

| |

265 - Rear fits

well | |

266 - Next, the sides were

marked to trim to the deck. | |

267 - Rear of the canopy

was anchored with tape. | |

8 - Picture shows side

marked to trim. | |

269 - Sides were trimmed

at the lines. | |

270 - A ruler was used to

steady the cut. | |

271 - Trim

finished. | |

272 - Canopy taped down

again and corner checked for fit once more.

| |

273 - The front of the

canopy marked to trim. | |

274 - Ready to cut.

| |

275 - Trimming the

front... canopy fitting completed. | |

276 - Preparing to epoxy

the vertical stab. Rear of stab centered using mark made on

tape from previous steps. | |

277 - Assembly taped in

place and pencil used to make a mark on the fuselage.

| |

278 - Layers of tape were

stacked up front as a point to but the assembly up against.

Two pins were used to mark sides. | |

279 - Tape that was used

to anchor the front of the vertical stab during canopy

trimming was removed from the front of the stab. The stab was

removed, showing the pencil mark made earlier.

| |

280 - Bottom of stab

needed excess covering removed so epoxy would adhere to the

wood underneath. | |

281 - Holding the razor

like this allowed me to judge the depth and width of the

cut. | |

282 - Excess covering

being removed. | |

283 - Rear also cut away

so it could be epoxied. | |

284 - Area that was

trimmed is ironed back down. | |

285 - Stab ready for

epoxy. | |

286 - Fuselage stab area

ironed down before cutting. | |

287 - Area being trimmed.

| |

288 - Removing the excess

covering. | |

289 - Rear area is plastic

and was roughed up with 100 grit sandpaper for good glue

adhesion. | |

290 - Fuselage ready for

epoxy. The expose area had epoxy applied lightly with a brush.

| |

291 - Epoxy was applied to

the bottom of the vertical stab assembly, then placed flush

against the front tape and pinned in place.

| |

292 - Stab was checked to

be vertical, then excess epoxy was removed.

| |

293 - Stab pinned and

drying. | |

294 - The fin was checked

for vertical alignment once more, then left to set.

| |

295 - Pins removed,

vertical stab assembly is completed.

| |

296 - Canopy washed in hot

soapy water to remove any release agents.

| |

297 - Canopy dried and

ready for paint. | |

298 - Painting the

pilot... sunshield was glazed with epoxy prior to painting it

black. | |

299 - Pilot painted and

ready to fly. | |

300 - Masking the canopy.

| |

301 - Ready to paint.

| |

302 - Canopy primed.

| |

303 - Canopy

painted. | |

304 - Color didn't

match... I spent all day trying to find a matching color and

stripped it twice to repaint. | |

305 - Final paint.

| |

306 - masking removed...

it's going to do ok for now. | |

307 - Working on the

cockpit... the edges were thickened up with another layer of

3/32" balsa. | |

308 - making a cockpit

back. | |

309 - Back made and

shaped. | |

310 - Cockpit back in

place... time now to make a seat. | |

311 - Canopy finally

painted. | |

312 - Detailing the

cockpit. | |

313 - Here is the

framework for the cockpit. | |

314 - A rubber grommet was

epoxied to the dowel, then it was inserted into the figure's

head. The figure could then be attached to the cockpit by

gluing in the dowel at the base with epoxy.

| |

315 - Much of the time

today was spent making some decals that are unique to this

model. | |

316 - Pilot inserted into

the cockpit. | |

317 - View of the other

side. The dash panel is an exact replica taken from a photo of

a real F4D cockpit. It took a couple hours with the Paint Shop

program to do the "Dash". | |

318 - Top view showing

most of the cockpit. | |

319 - View with the canopy

in place. | |

320 - Canopy epoxied to

cockpit with 15 minute epoxy and left to set.

| |

321 - I decided to cover

the intakes with the correct color for my scheme.

| |

322 - Close up of the area

re-covered... not an easy job, but it was a good challenge.

| |

323 - Cockpit epoxied and

finished. | |

324 - Gluing the hook into

place with 15 minute epoxy. | |

325 - Roughing up the tow

hook for good glue adhesion. | |

326 - Gluing the hook into

place with 15 minute epoxy. | |

327 - Tow hook taped with

epoxy. | |

328 - Tow hook

installed. | |

329 - Installing the

battery with velcro. | |

330 - Once the battery was

installed, it needs to be balanced at 100mm from the front of

the wing joint... I made marks with a marker to note the CG

location. | |

331 - Setting the

throws... recommended throws are 5mm up and 5mm down for both

aileron and elevator. | |

332 - I set mine at 8mm up

with 5mm set as low rates. | |

333 - The same goes for

down... set at 8mm with 5mm used for low rates.

| |

334 - Here's a look from

the front. | |

335 - View from the

rear. | |

336 - The left side...

| |

337 - Rights

side... | |

338 - Close up of the

cockpit area. | |

340 - The HET-RC F4D Skyray EDF Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |