The HET-RC F-4 Phantom Twin Minifan EDF as

it comes from Markos at Warbirds-RC

| |

Opening the box reveals a well packed and

rather large model | |

Every that comes with the ARF is shown

| |

The F-4 Phantom assembly

| |

You should use an iron to remove any

wrinkles in the finish | |

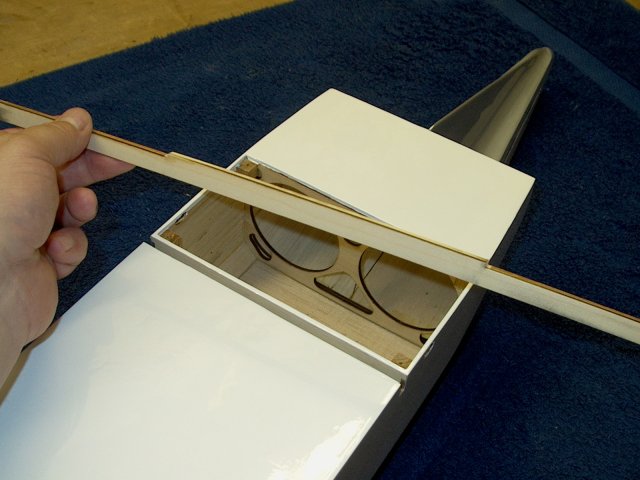

The main spar is the first piece to be

installed | |

Dry fit the spar in place as shown, with

the cut out sides pointing to the bottom side of the

fuselage(pointing up in pic.) Also check for a slight bow in

the spar; if present, install the spar so the outer ends bow

toward the front of the fuselage | |

Epoxy is applied to center of the spar

right up to each notch | |

Apply epoxy to the slot sides where the

spar will be installed | |

Install the spar as shown, noting cutouts

in spar and position so the spar is centered and they are

flush at each side of the fuselage | |

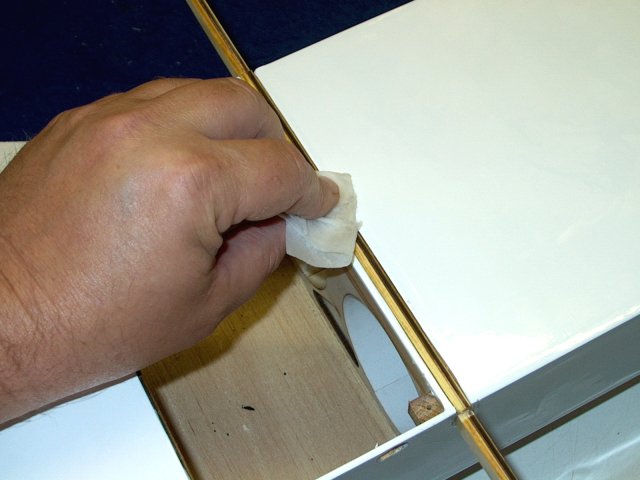

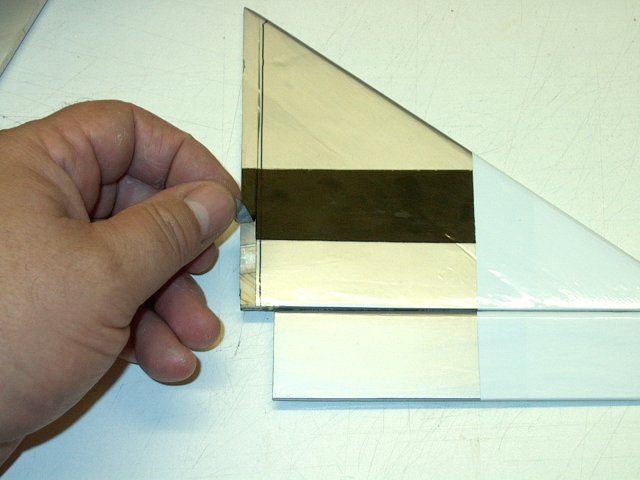

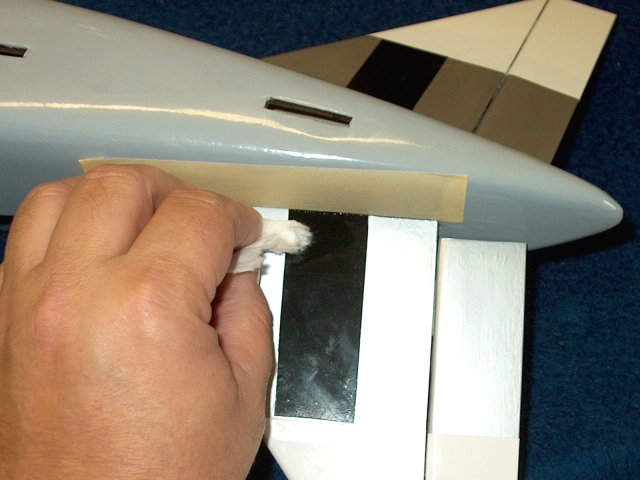

Wiped off any excess epoxy with denatured

alcohol and a paper towel | |

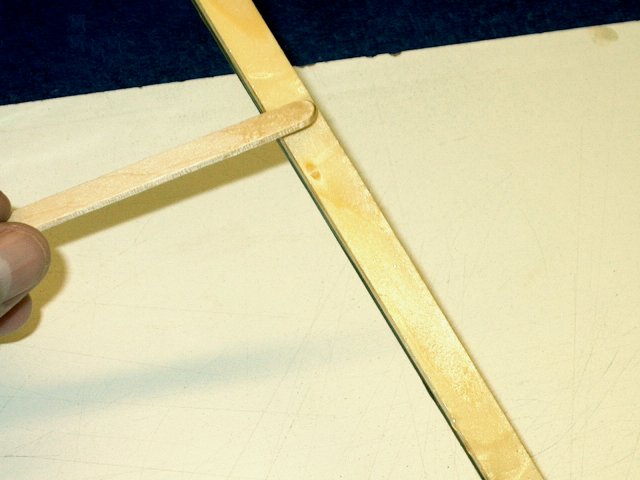

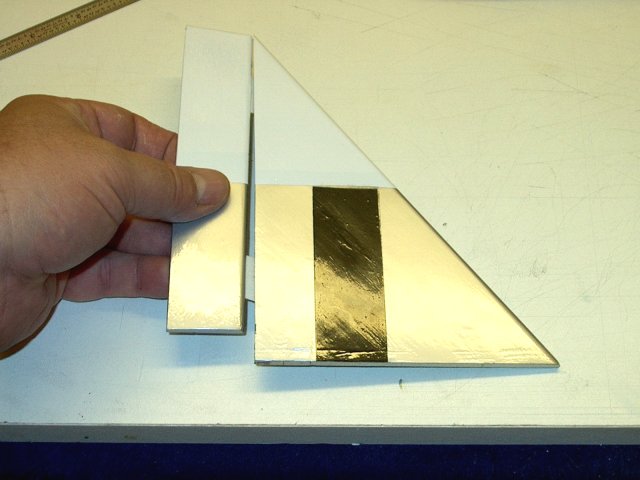

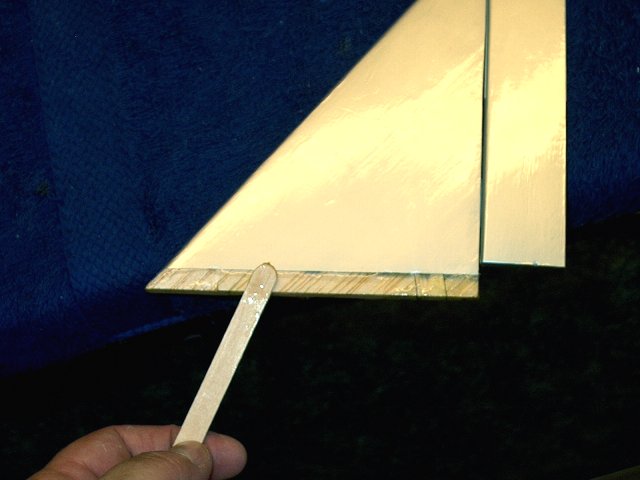

A square is placed across the joint while

the glue is still wet and the spar is pulled up on each side

so it is flush to the bottom of the fuselage

| |

Once the spar is installed correctly, then

centered and adjusted flush, allow the epoxy to set

| |

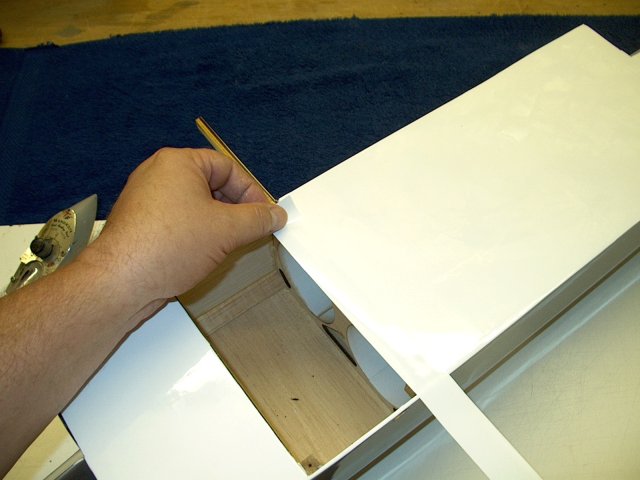

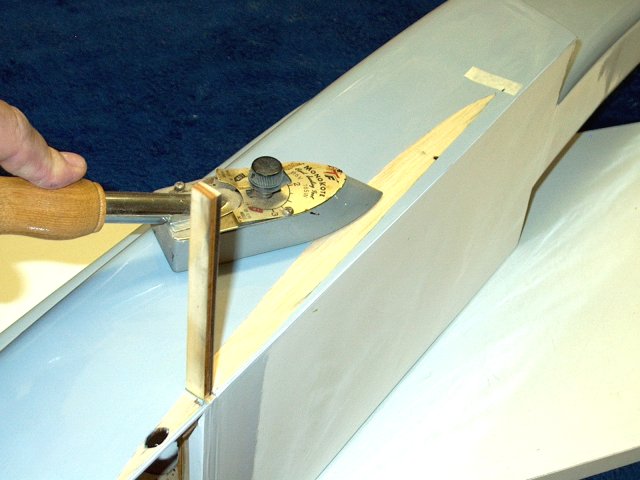

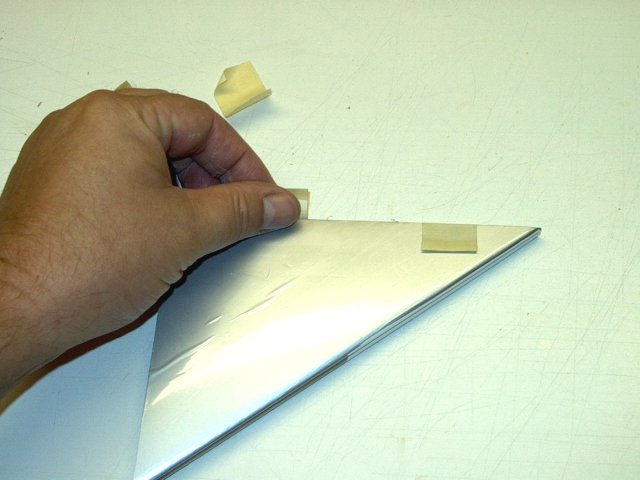

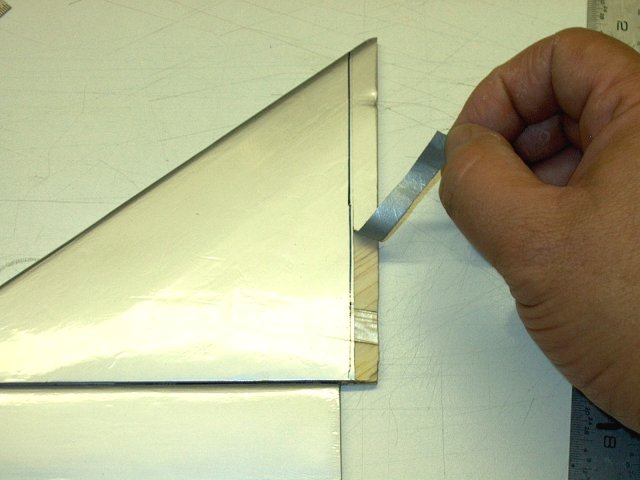

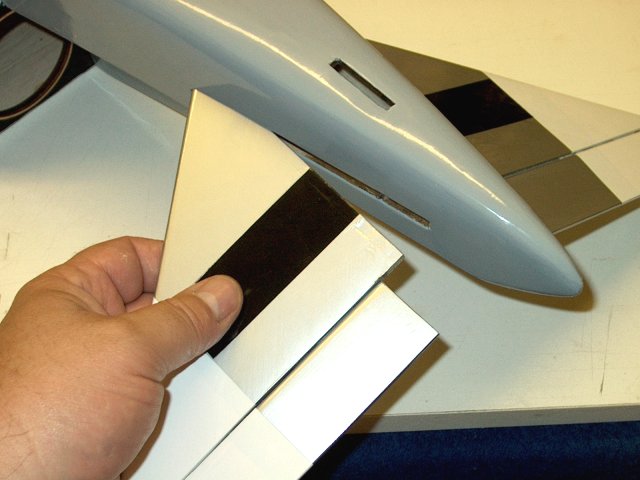

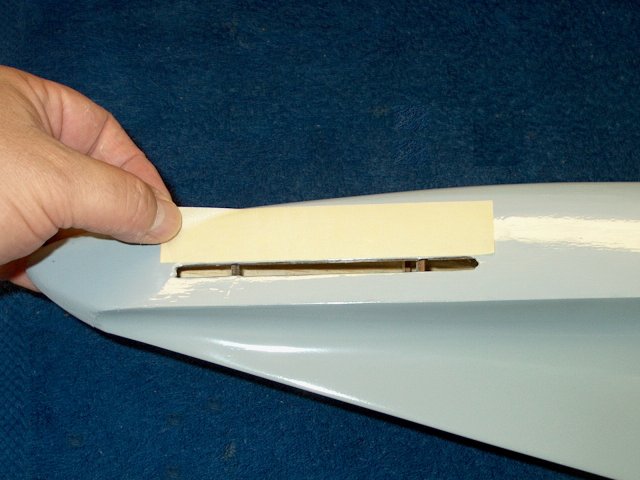

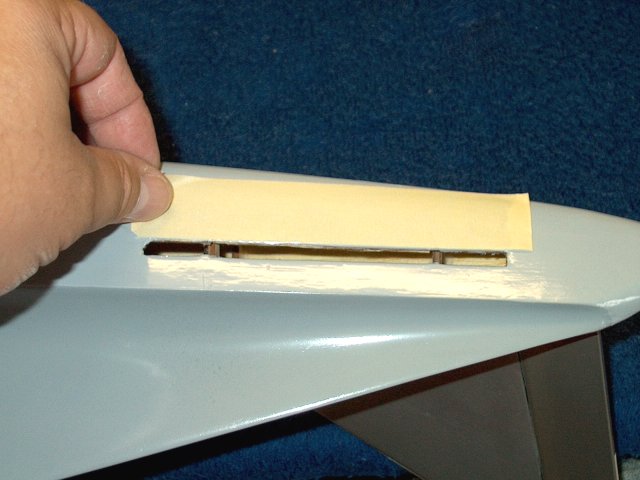

A strip of covering material supplied in

the kit is used to cover the slot. Note that the model was

recovered in the pics to a different color, so the colors may

not match your kit, but the procedures are the same

| |

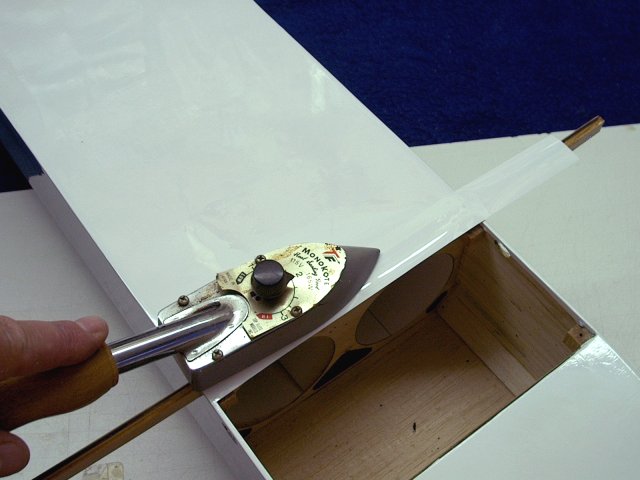

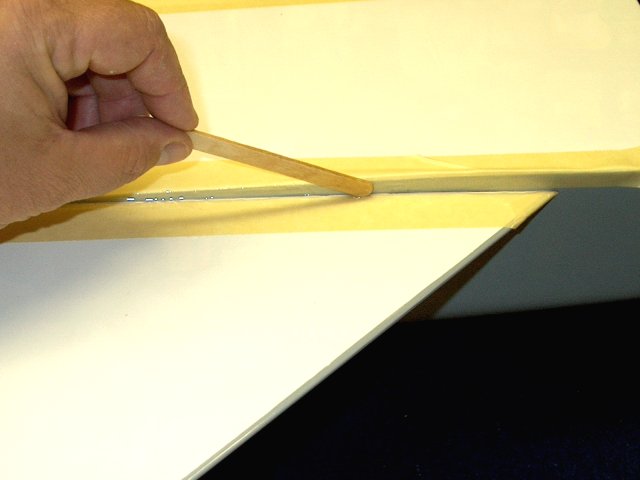

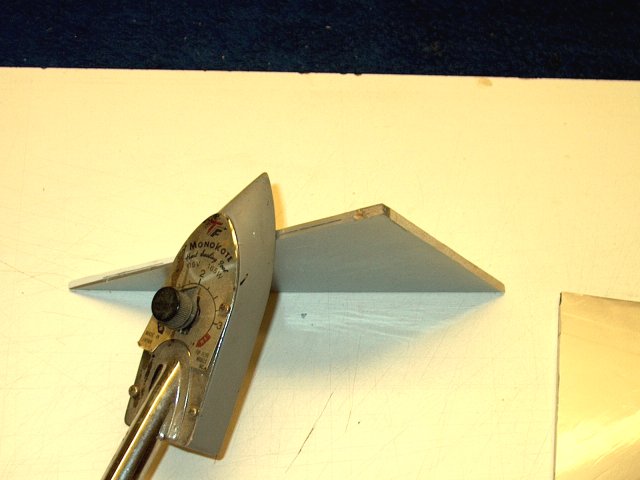

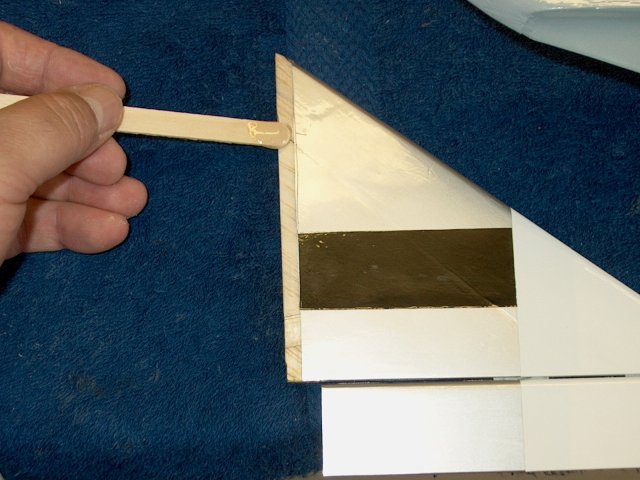

A hobby iron is used to install the strip

of covering | |

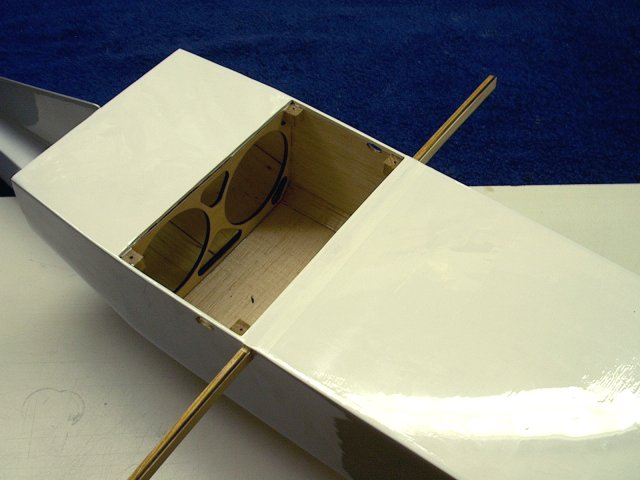

Main Spar assembly is shown completed

| |

Temporarily slide a wing on the spar

| |

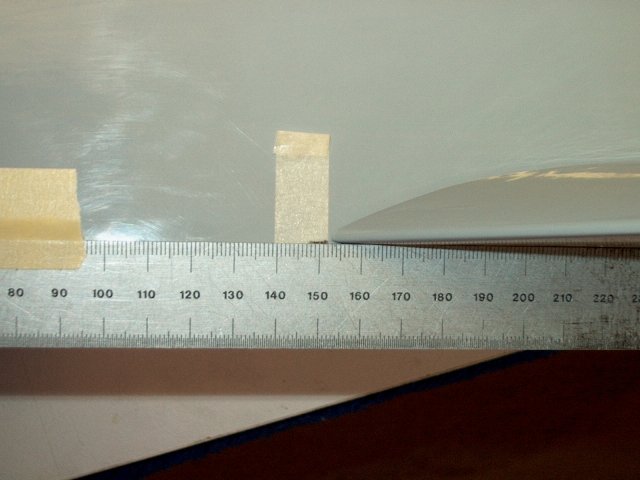

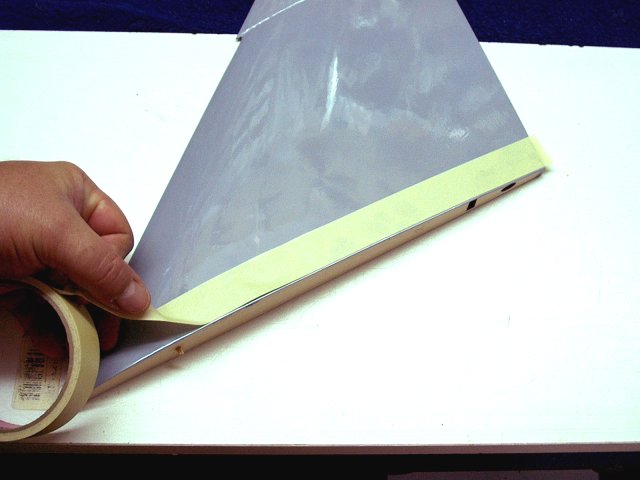

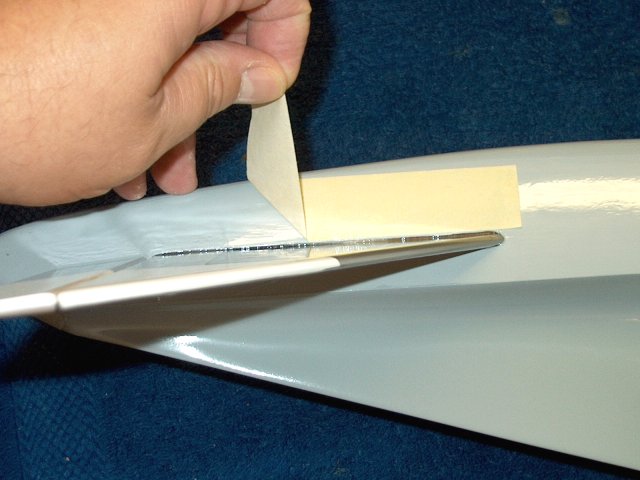

Apply a piece of tape just in front of the

leading edge of the wing | |

Install the other wing and apply another

piece of tape for it | |

Position of tape as shown. Important: For

the next steps, make sure your model is flush against the

bottom of the table. You will need to hang the nose of the

fuselage off the surface as it is lower than the fuselage

bottom and can prevent the fuselage from sitting flush on the

table | |

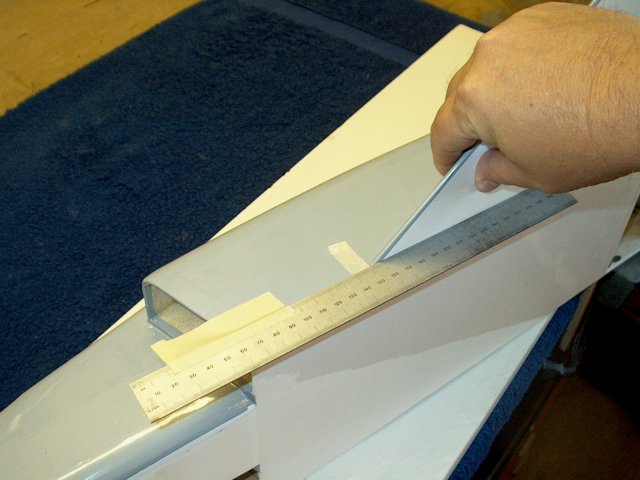

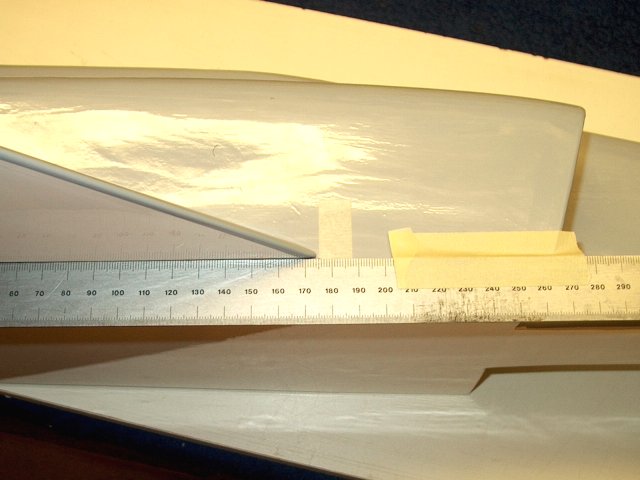

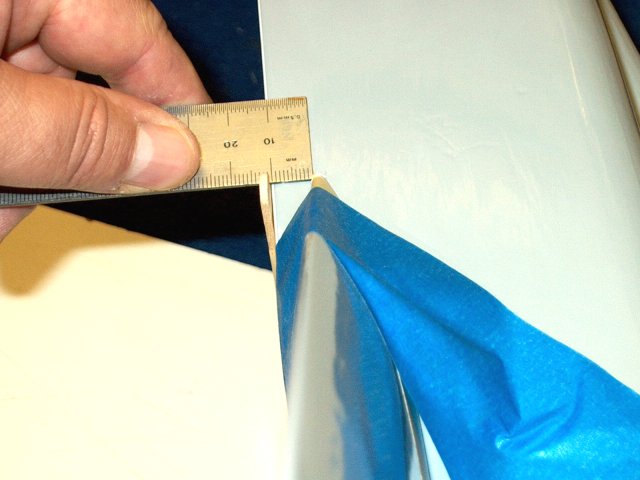

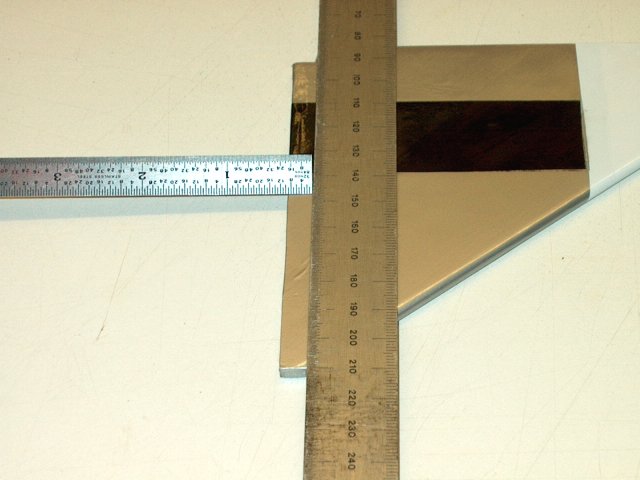

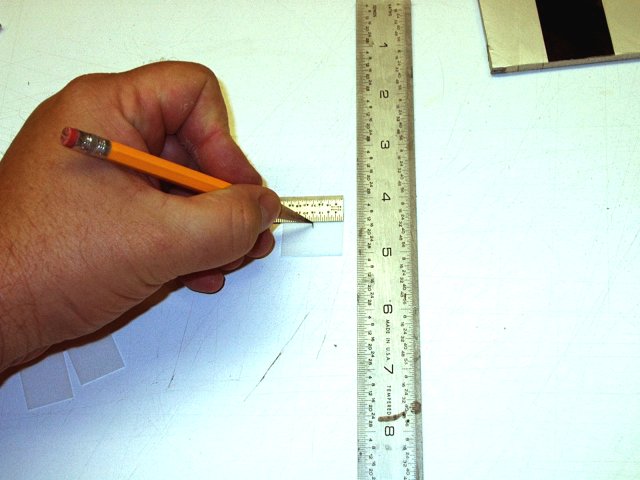

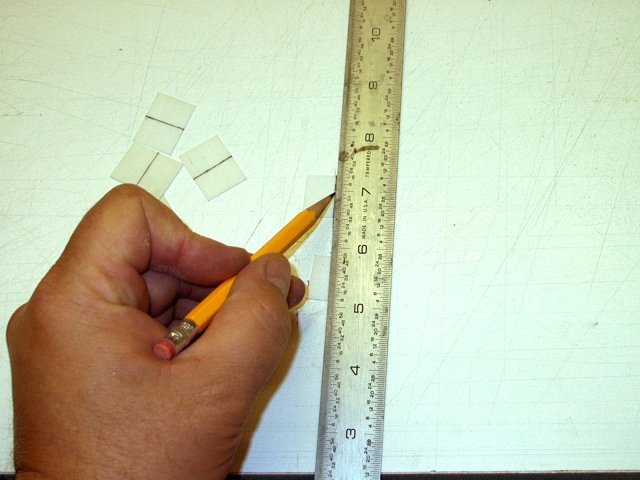

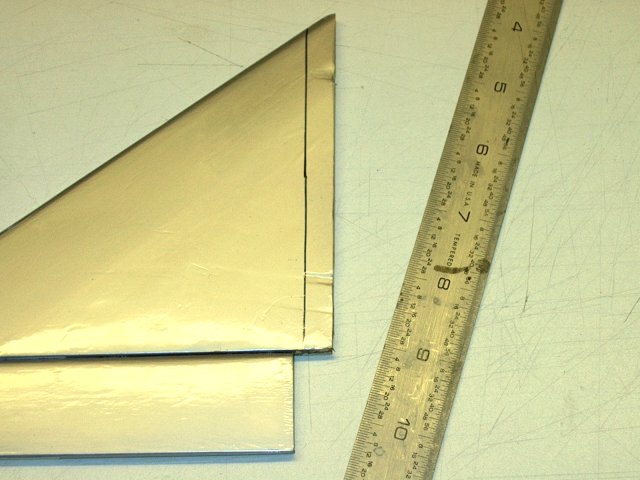

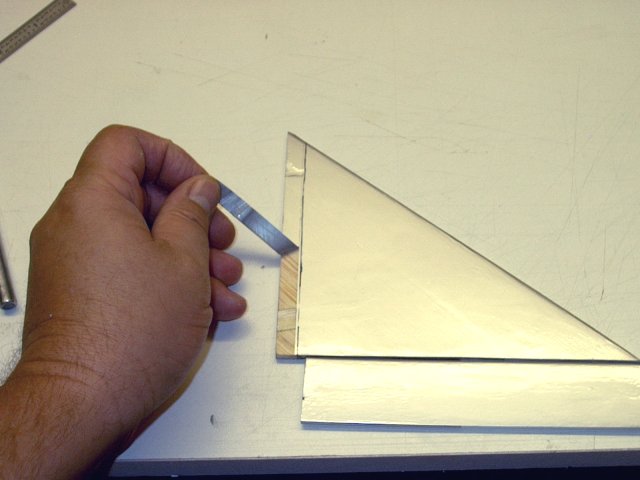

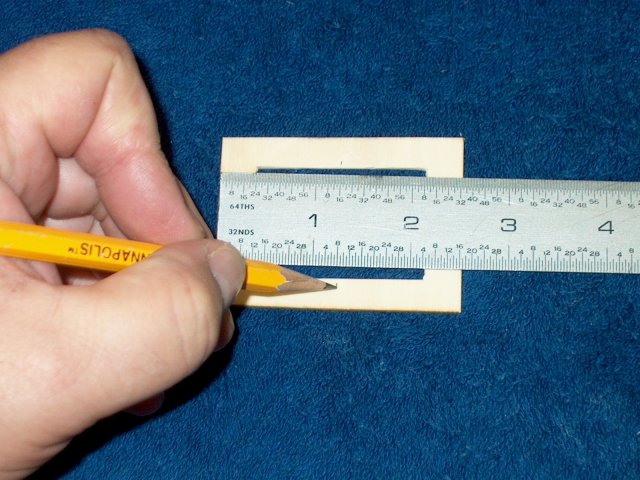

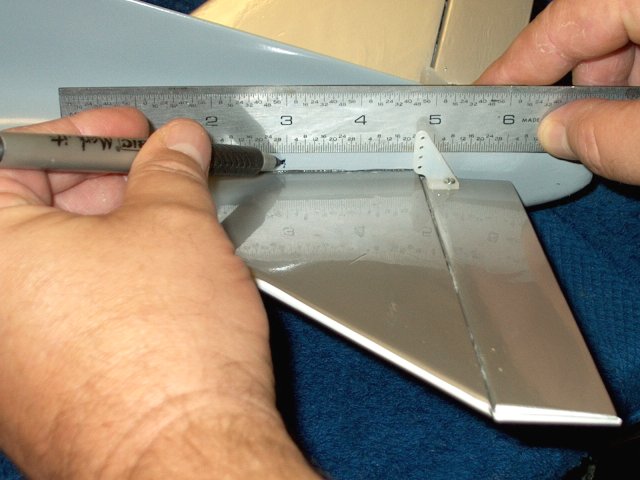

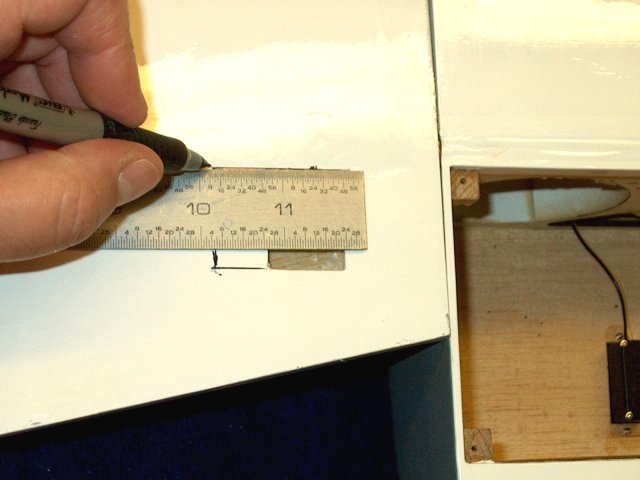

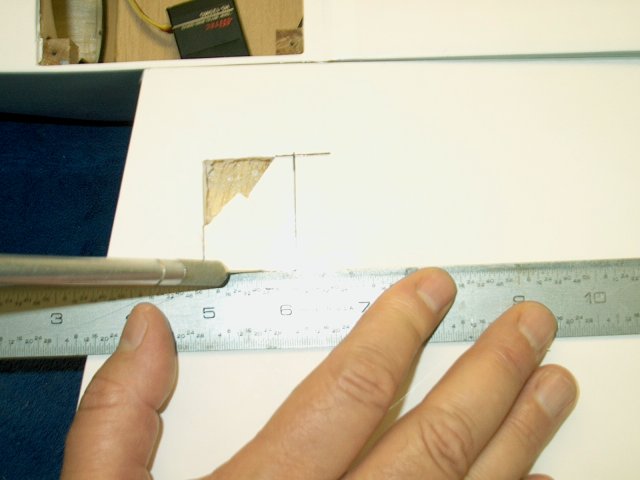

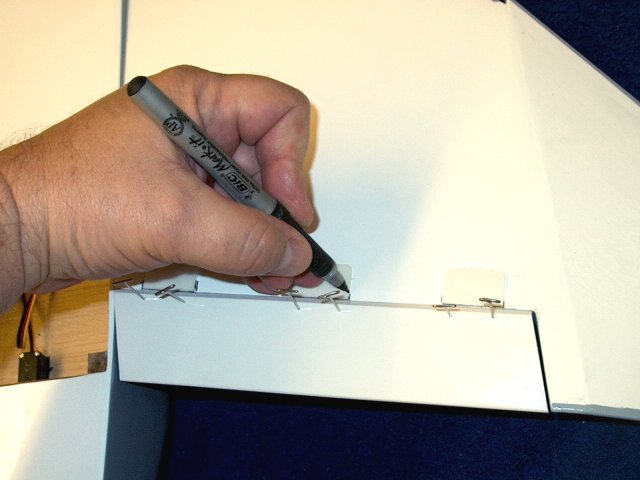

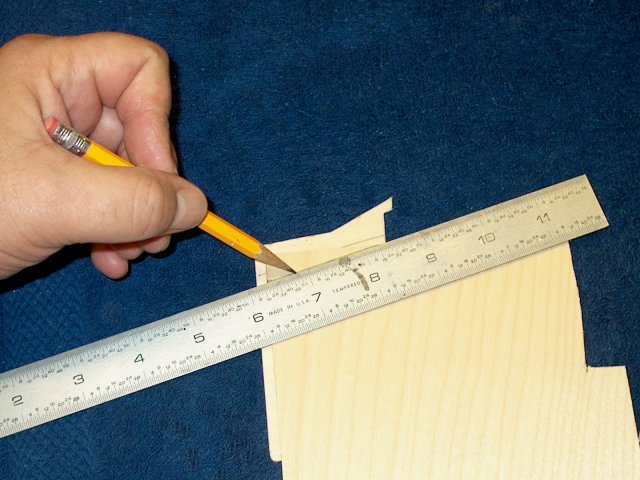

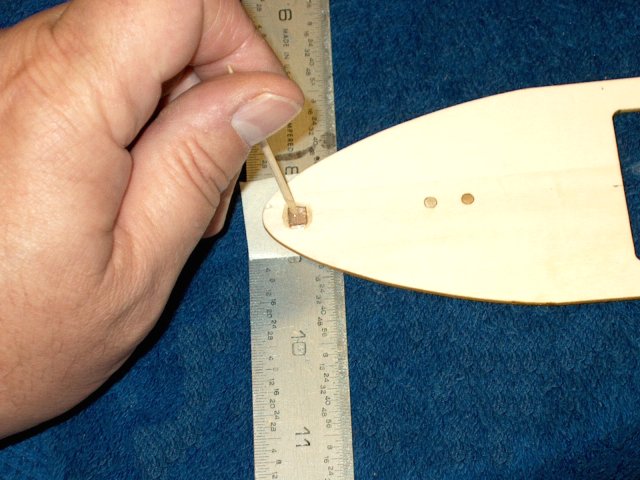

With the fuselage flush against a hard

surface, use a ruler and make a mark on the tape 10mm from the

bottom of the table as shown | |

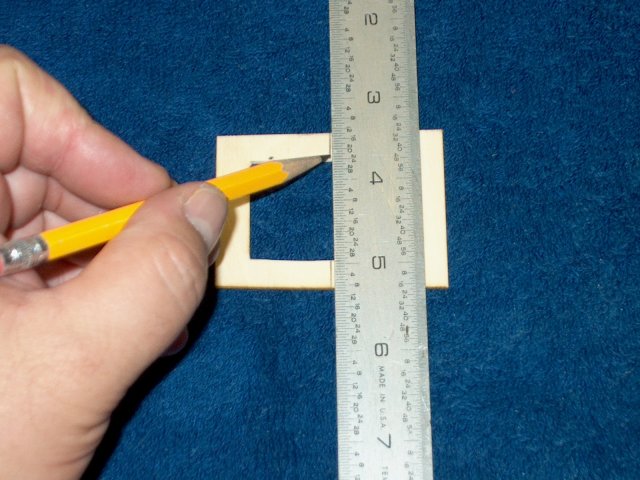

Mark the other tape strip in the same

manner, 10mm up from the surface | |

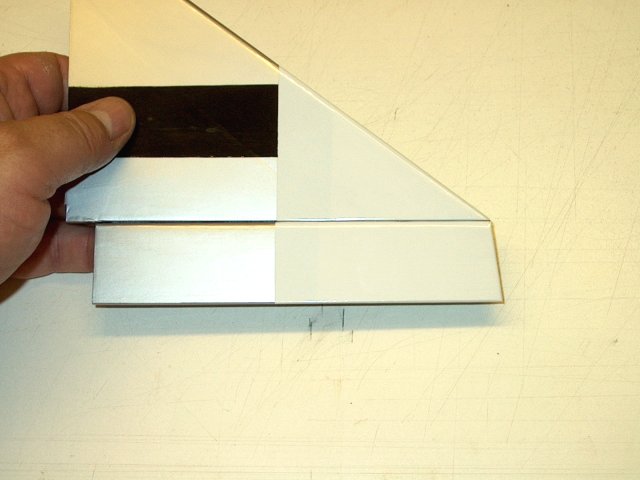

A ruler is used to help align the wing to

the mark. The bottom tip of the wing is at the 10mm position

as shown | |

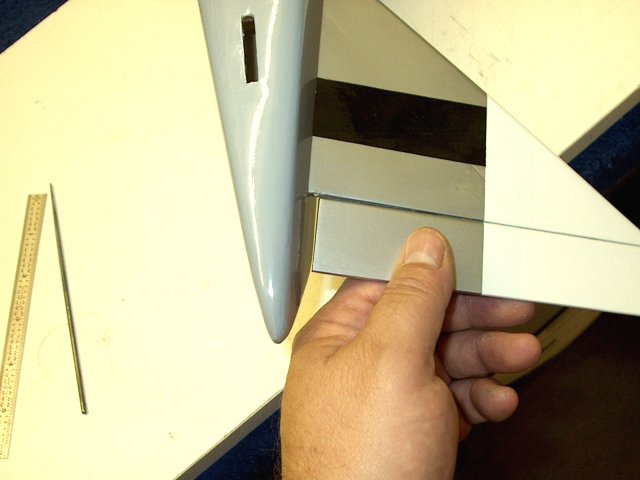

When in position, press the wing down to

make a dimple into the fuselage side, which marks the wood

dowel position on the side of the fuselage

| |

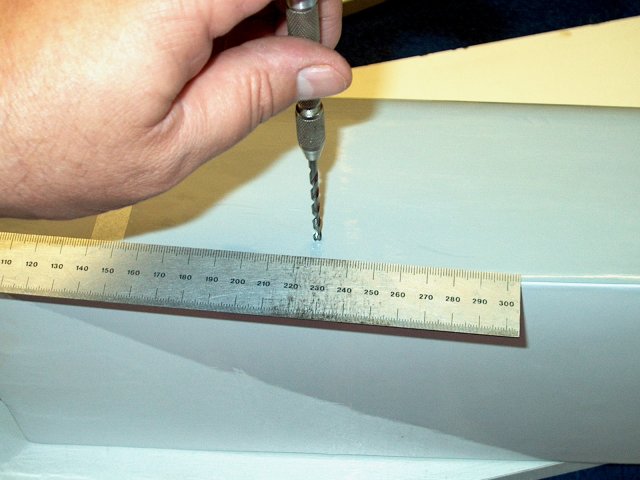

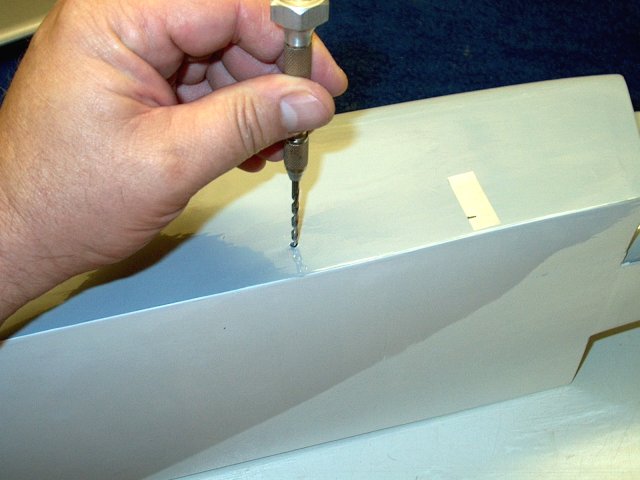

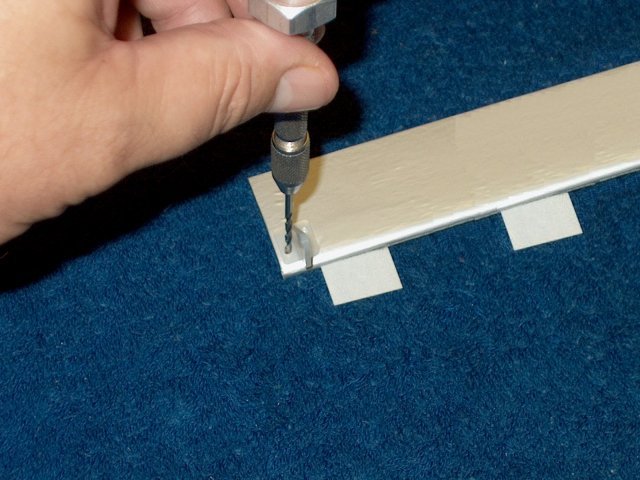

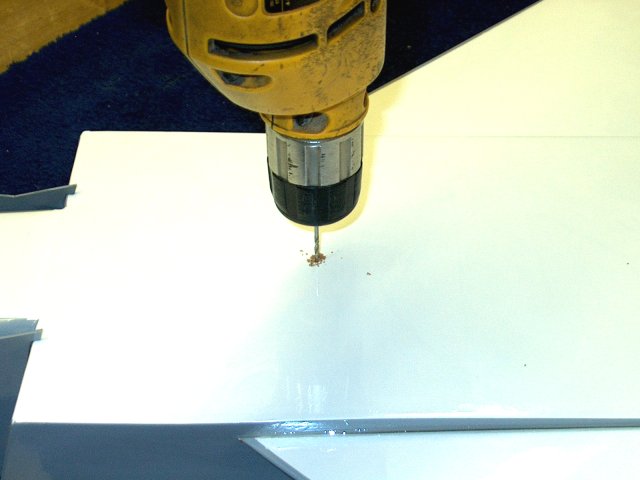

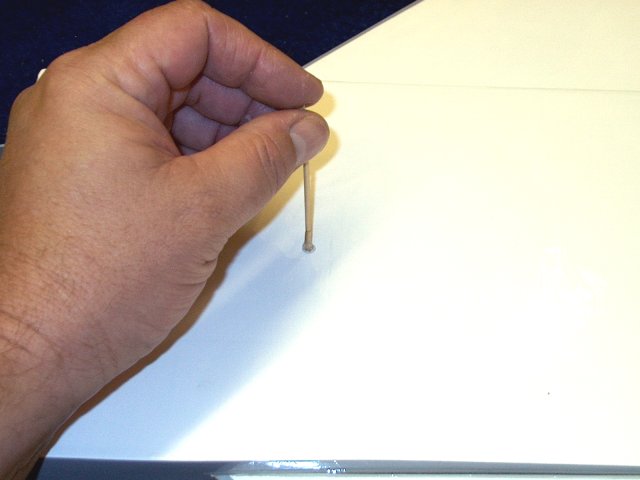

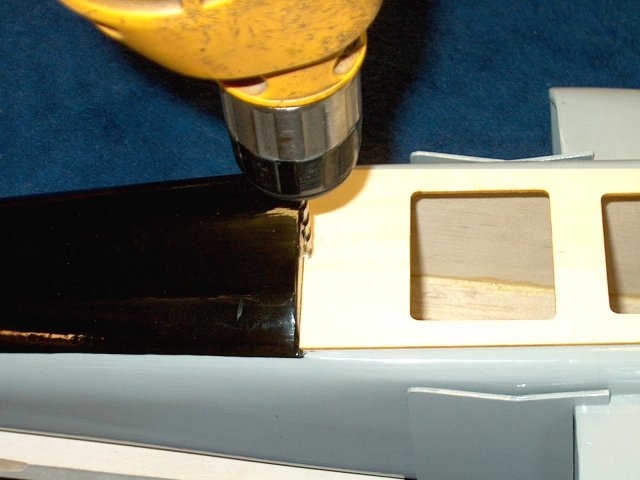

Remove the wing and open the dowel mark

with a 1/8" drill | |

Install the wing and check for a good fit

and correct wing alignment at the 10mm mark

| |

Some overhang of the wing trailing edge

past the bottom of the fuselage is normal

| |

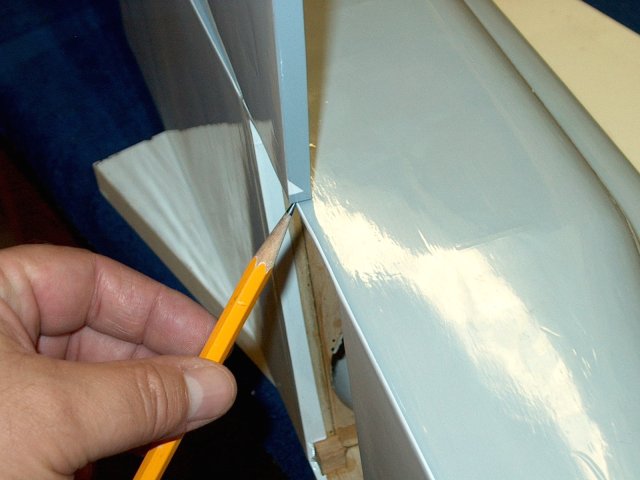

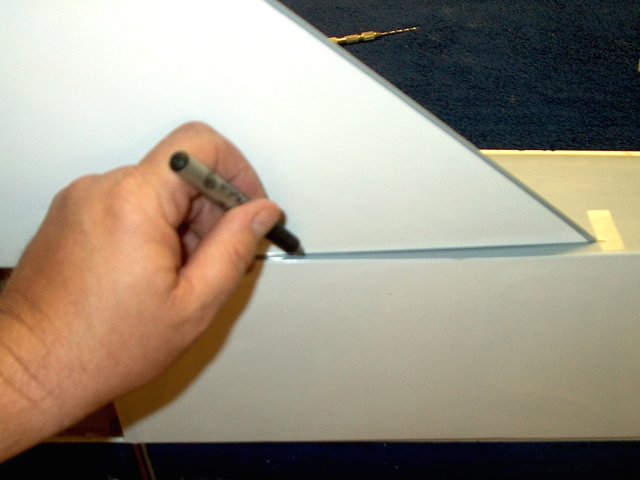

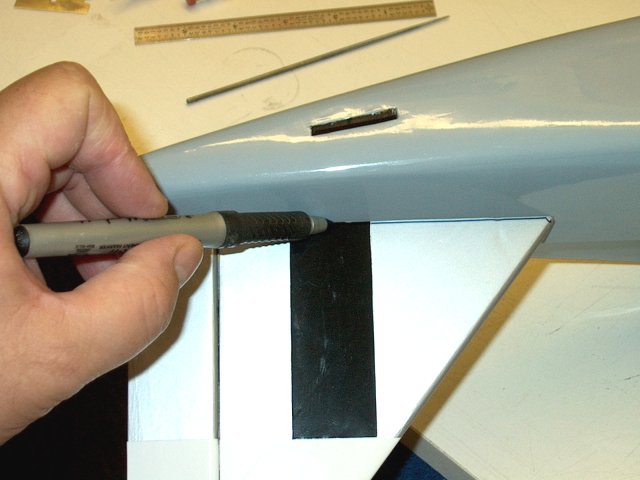

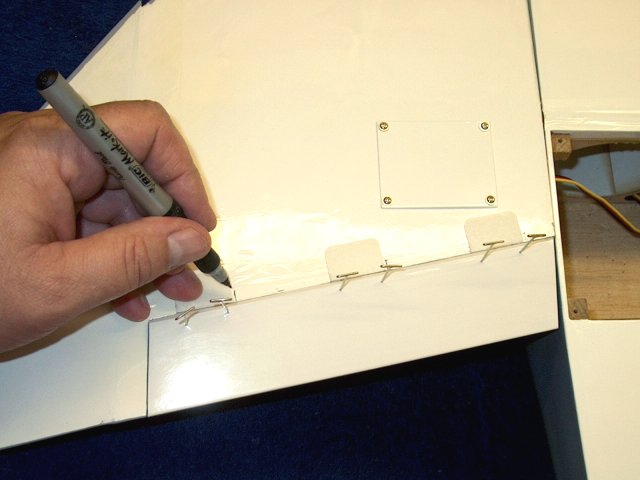

Use a marker and trace the wing root

pattern on to the fuselage | |

Remove the wing to reveal the wing root

pattern | |

Install the other wing and align it, then

press down to mark the dowel position

| |

Remove the wing and drill the hole for the

wing dowel pin | |

Install the wing and check the alignment

| |

Trace the second wing root pattern on the

fuselage | |

Removing the wing shows the root pattern

that was traced | |

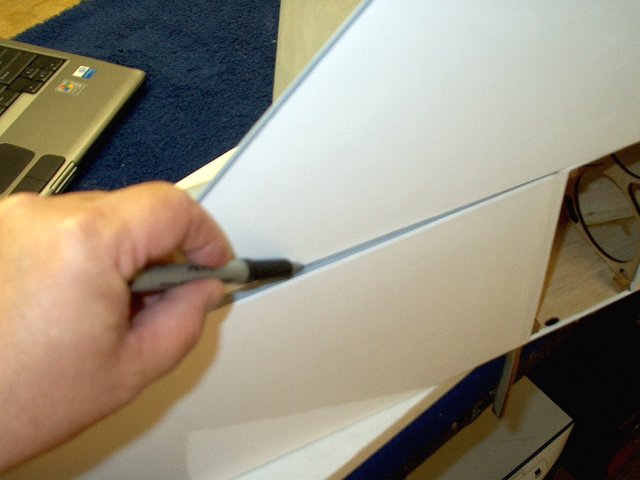

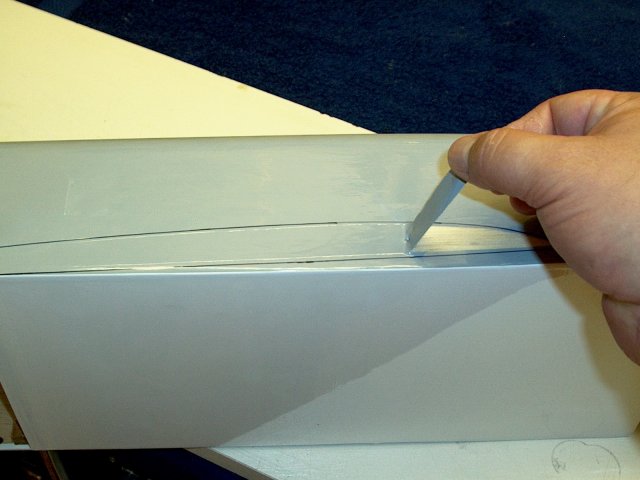

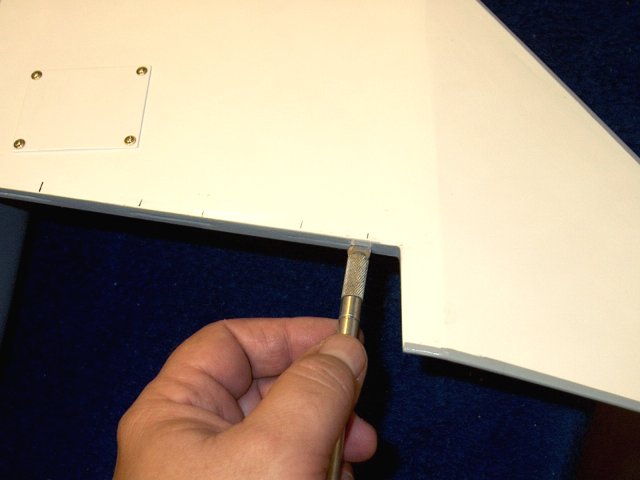

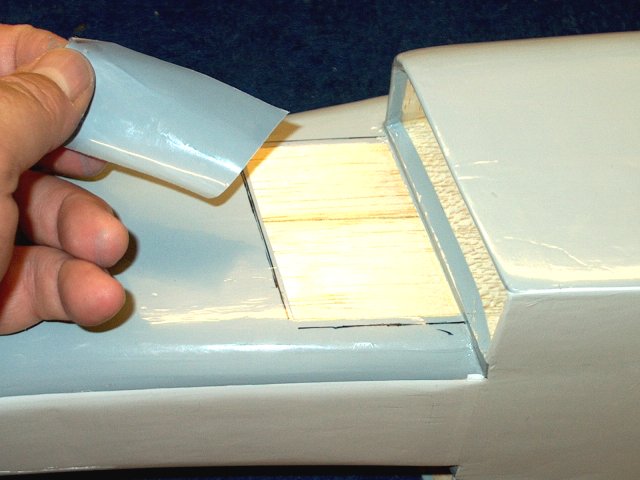

Cut the covering about 3/32" inside the

drawn pattern for the wing | |

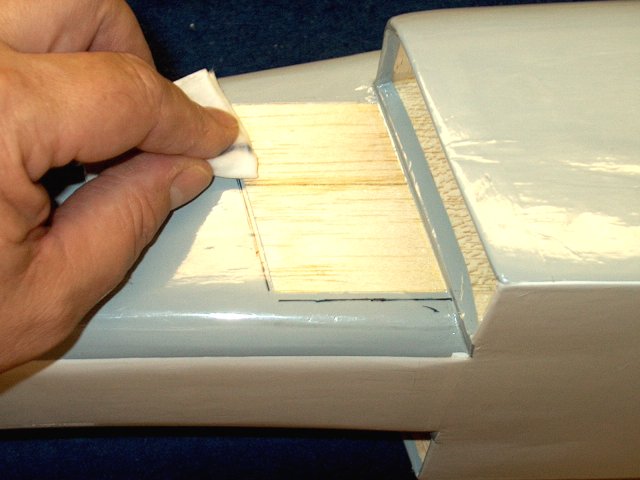

Remove the material as shown

| |

Wing root covering removed

| |

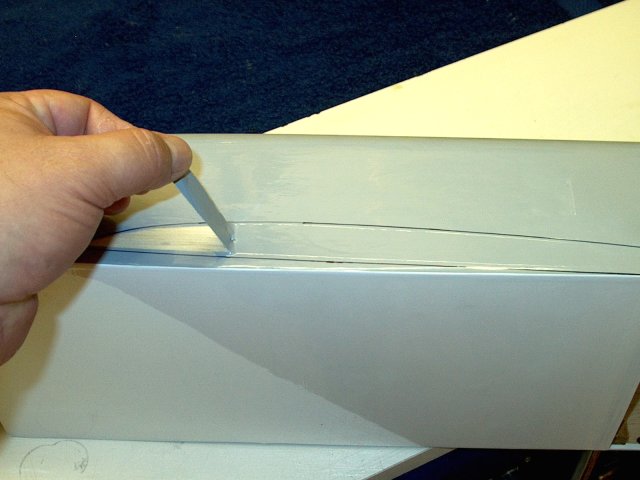

Cut the second wing root area, being

careful not to cut into the wood below

| |

Removed the excess covering

| |

Second wing root is exposed for gluing

| |

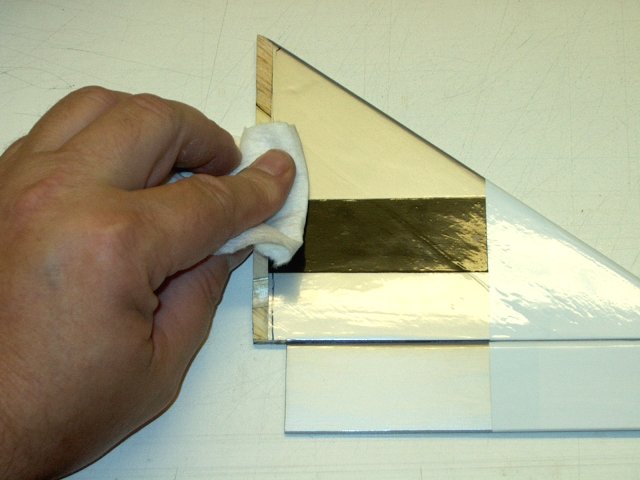

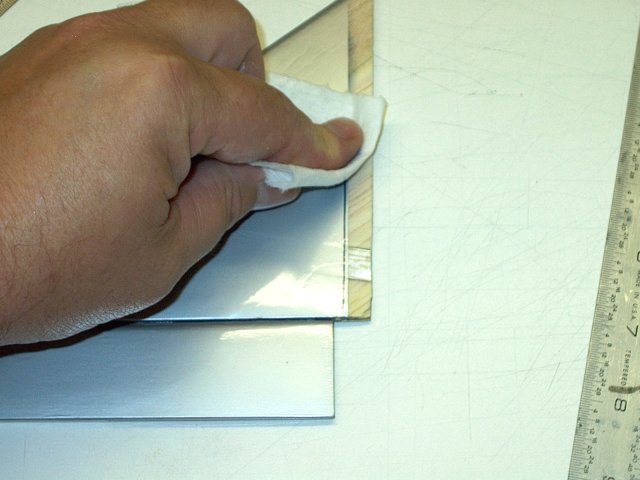

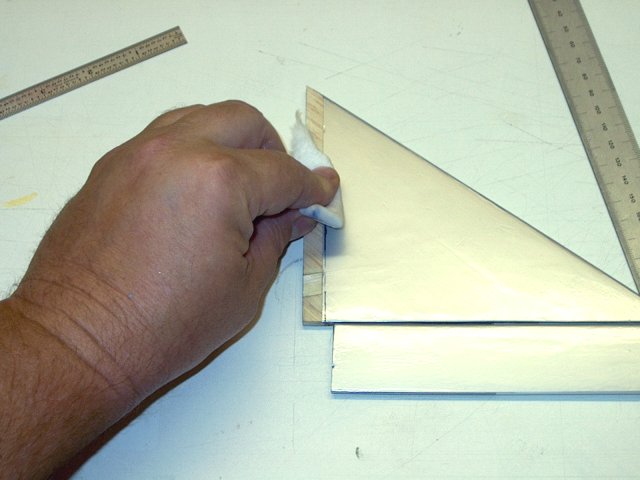

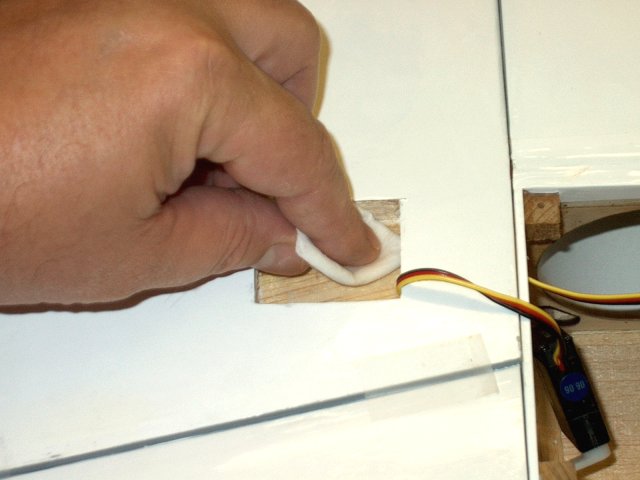

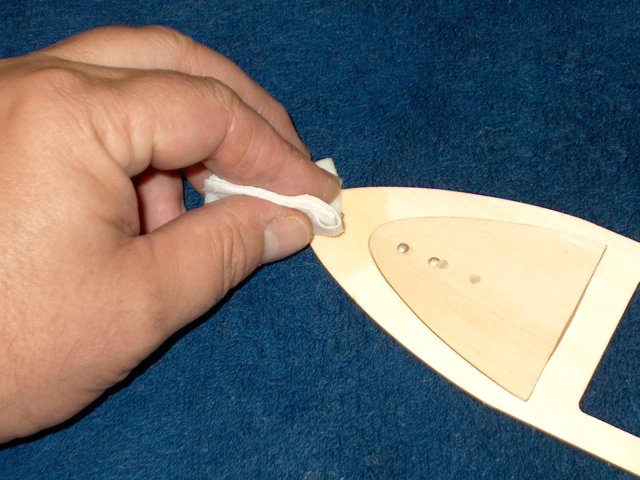

Use a small paper towel and denatured

alcohol to remove the marker lines from the fuselage and wings

| |

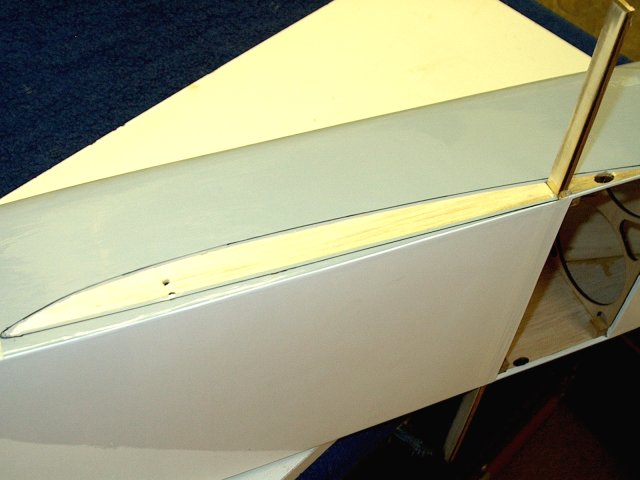

Use an iron to seal the cut area to the

fuselage on both sides | |

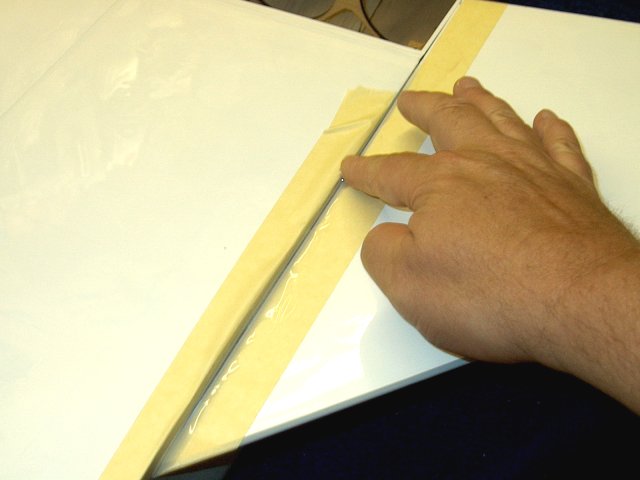

Masking tape is applied 1/16" away from

the inside root of both wings | |

Masking is applied on both sides, top and

bottom. This will aid in cleanup later on

| |

Mix up some 15-30 min epoxy and apply

epoxy liberally to the wing slot for the main spar

| |

Apply epoxy to the entire wing root

| |

Epoxy is then applied to the main spar on

all sides | |

A thin coat of epoxy is applied to the

fuselage wing root area | |

Install the wing on the fuselage

| |

Clean up any excess epoxy with a paper

towel and denatured alcohol | |

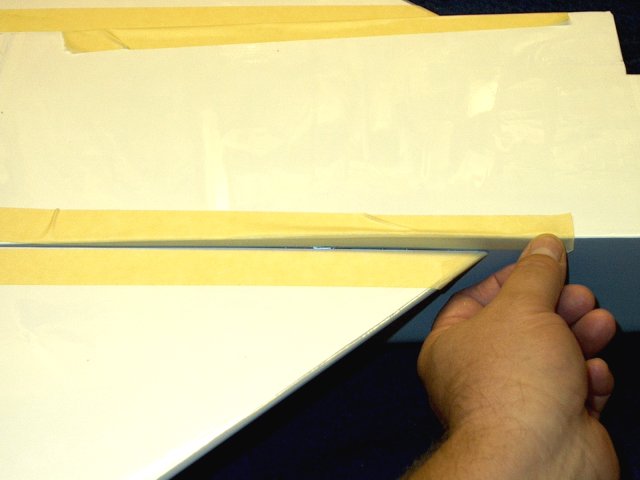

Wing glued in place and waiting for epoxy

to set | |

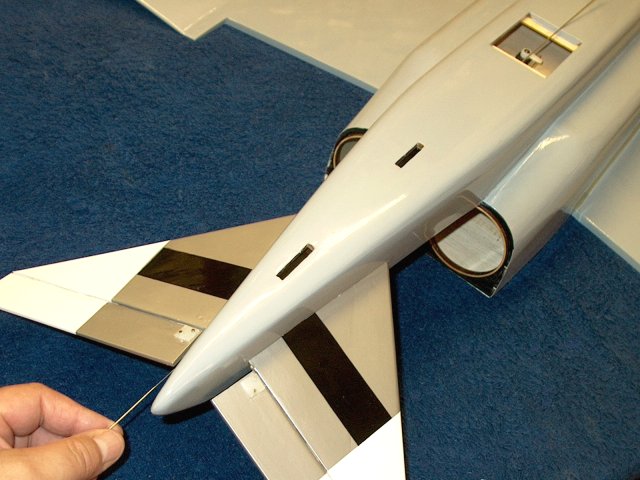

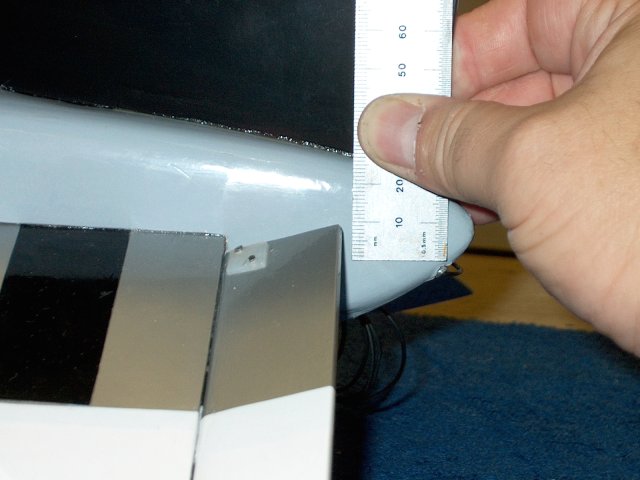

A measurement is taken before the epoxy

sets to insure the leading edge of the wing is 10mm from the

bottom of the fuselage. | |

Mix up some more 15-30 min epoxy and apply

epoxy liberally to the wing slot for the second wing's main

spar | |

Apply epoxy to the root of the second

wing | |

Wing root with epoxy ready to

assemble | |

Next, apply a thick ammount of epoxy to

the main spar | |

Epoxy is also applied to the fuselage wing

root area | |

Install the second wing flush on the

fuselage | |

Clean any extra resin with an alcohol

soaked towel | |

Check alignment for the second wing with a

leading edge of 10mm from the bottom of the fuselage

| |

Second wing installation completed. Allow

some time for the epoxy to set | |

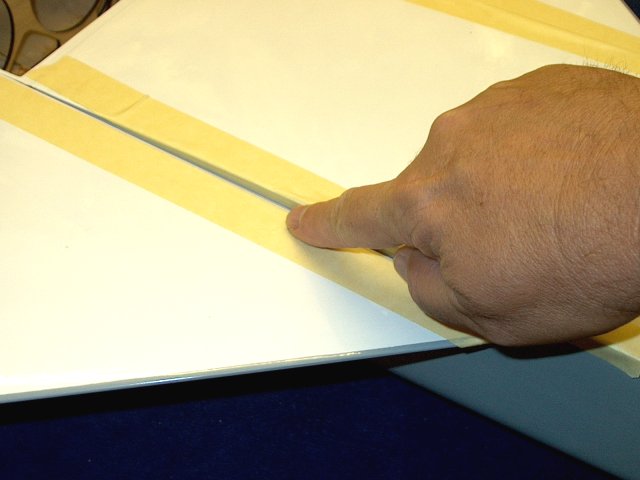

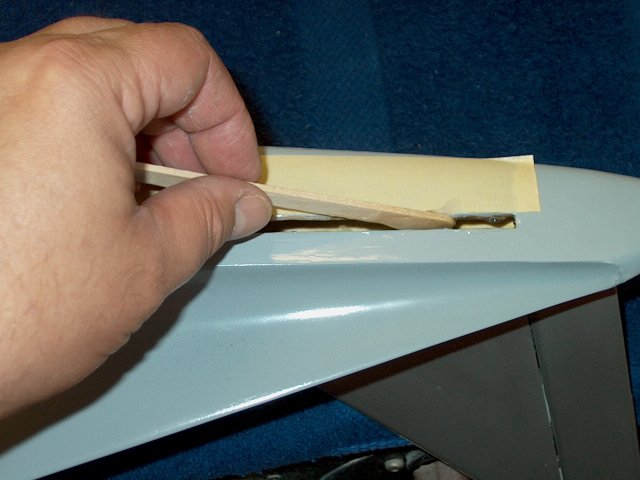

Tape is applied to both surfaces 1/16"

from the joint. This will make cleanup easier later

| |

Epoxy is applied at the joint

| |

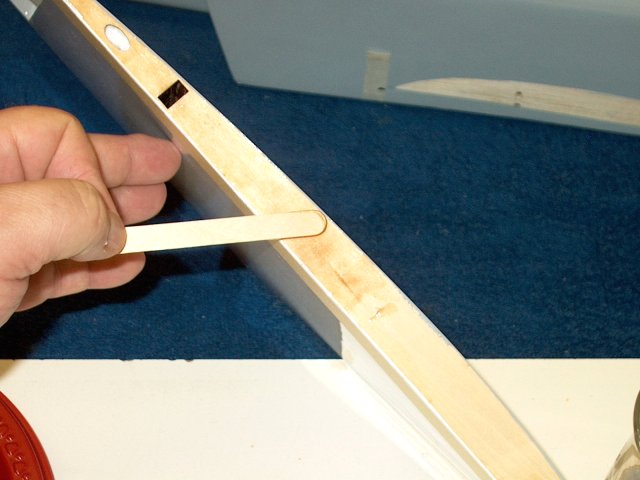

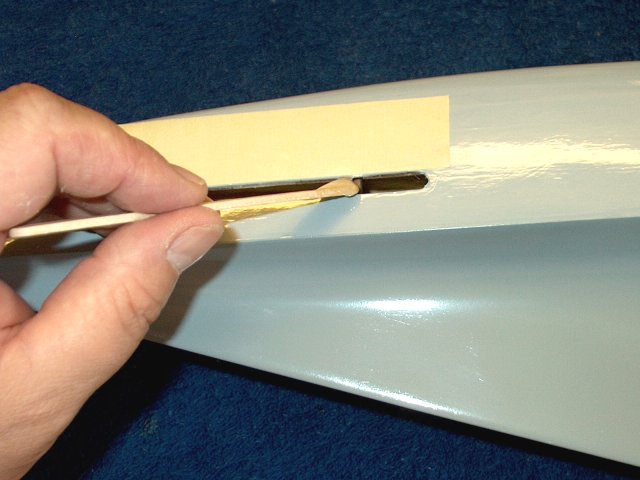

A fillet is made at the joint, removing

the excess epoxy | |

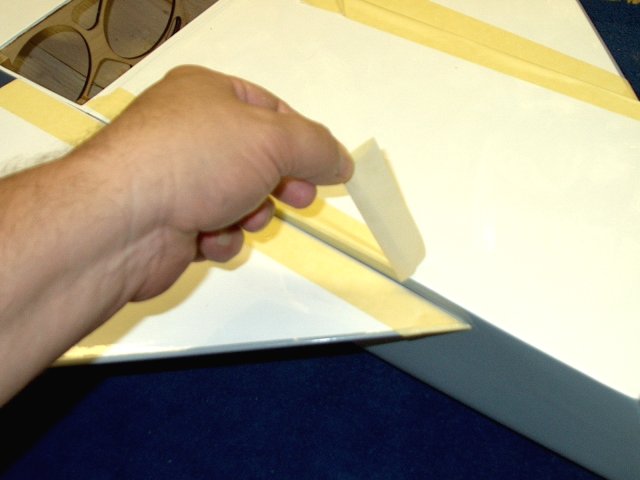

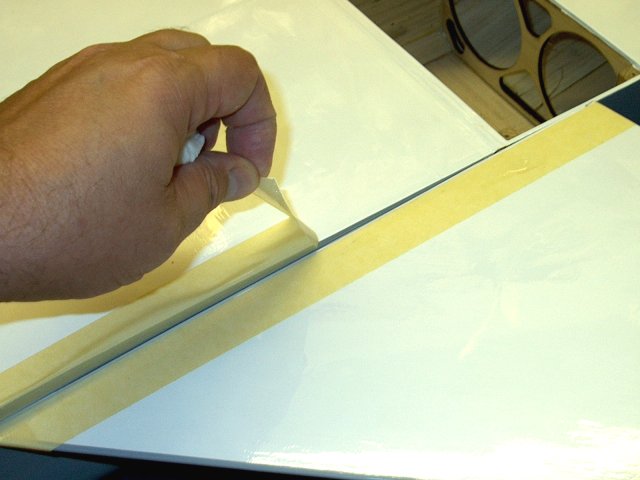

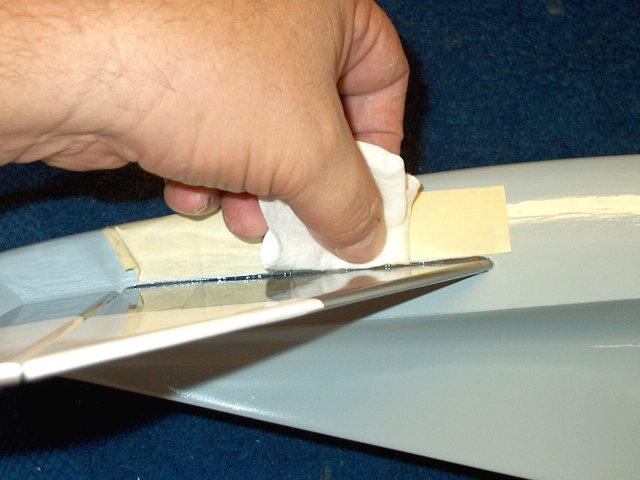

The tape is removed and and additional

cleanup is done with alcohol before the epoxy sets

| |

Epoxy is applied to the other bottom

joint | |

Once again, a fillet is made at the

joint | |

Tape is removed before epoxy sets

| |

The top is done similar to the bottom.

Apply epoxy and make a small fillet at the joint

| |

Clean up any excess with alcohol

| |

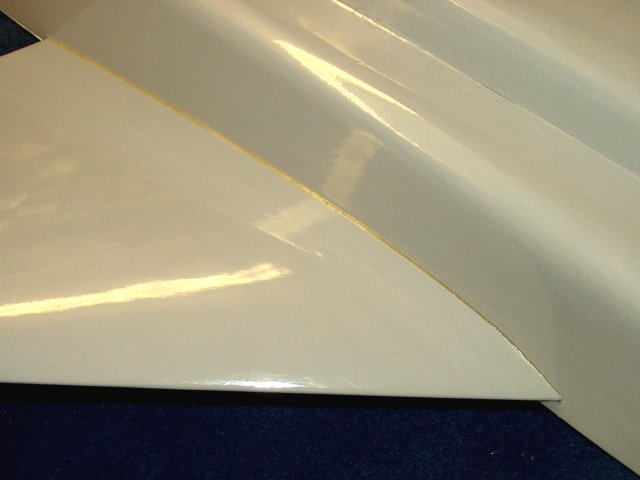

Fillet shown completed and dried

| |

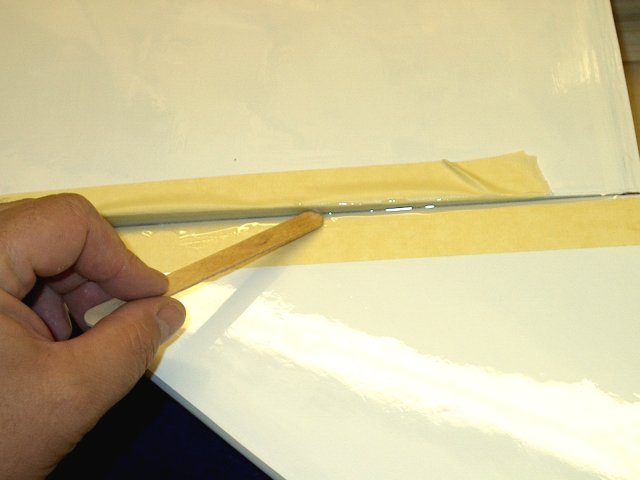

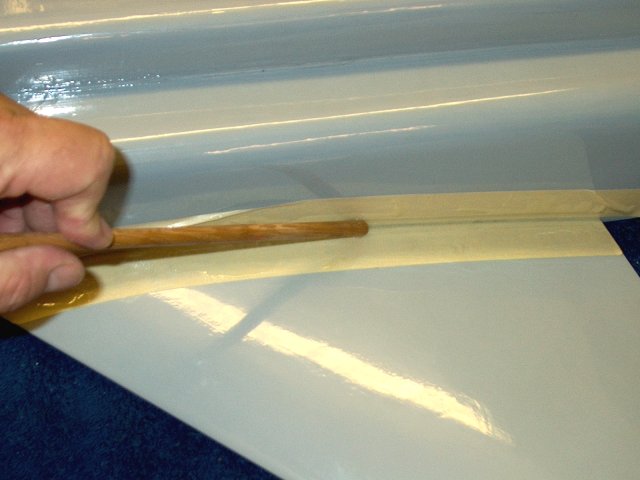

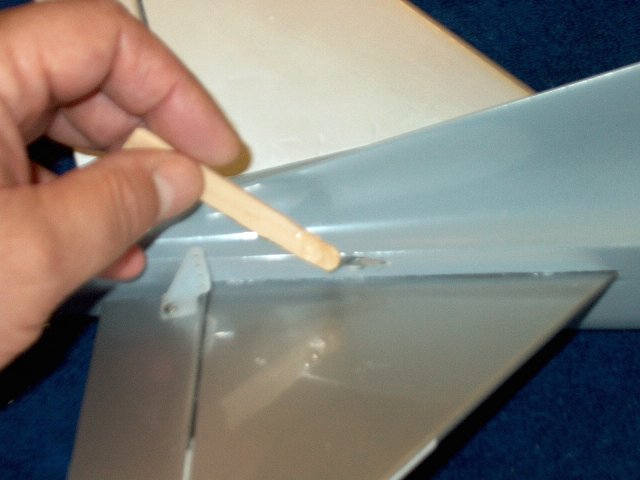

The other wing is done as shown with epoxy

being applied at the joint. A small round stick makes a great

fillet tool and the excess epoxy cleanly spills over on the

tape | |

The tape is removed before the glue

sets | |

The fillet is shown completed

| |

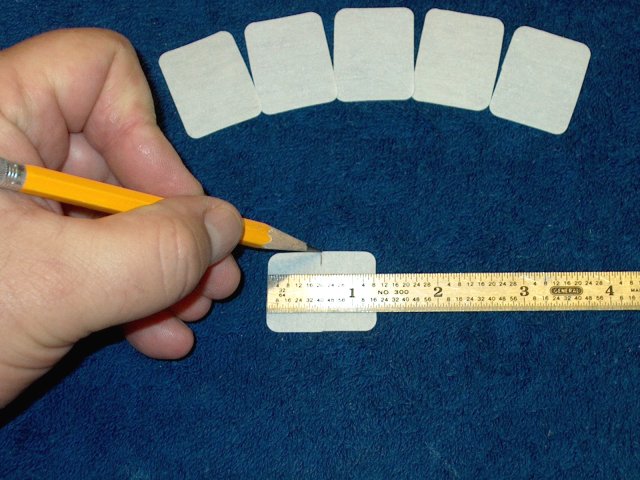

The root end of a horizontal stab is

measured at 9/32" | |

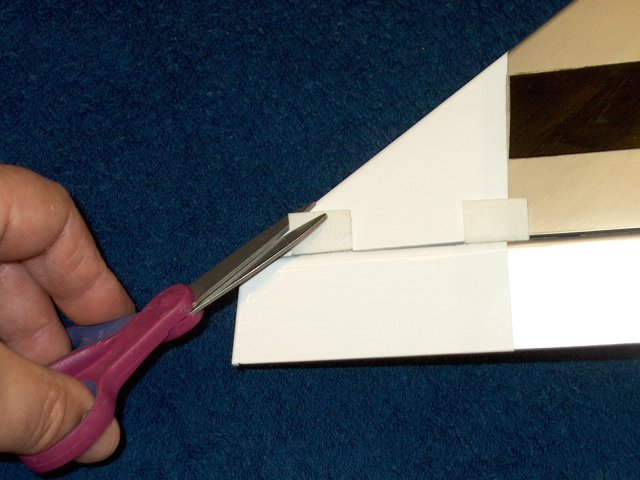

Trim off the excess at the measured

line | |

Stab shown trimmed

| |

Lightly sand the root so it is

square | |

The trailing piece is cut with a

knife | |

Trailing piece shown removed

| |

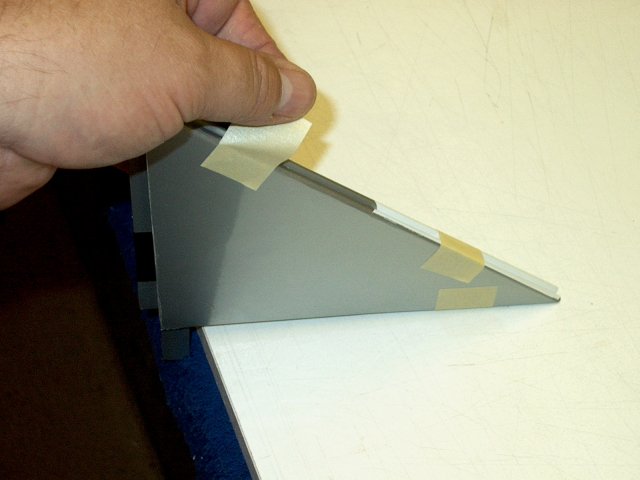

The two stabs are taped together, keeping

the rear and leading edge even | |

The second stab is trimmed using the other

stab for reference | |

Second stab shown trimmed

| |

The trailing tab is removed on the second

stab as shown | |

Remove the tape and lightly sand the root

of the second stab | |

Seal the trailing edge of each stab with

an iron | |

The hinges supplied in the kit were of

poor quality with fabric missing. New Easy Hinges were

substituted | |

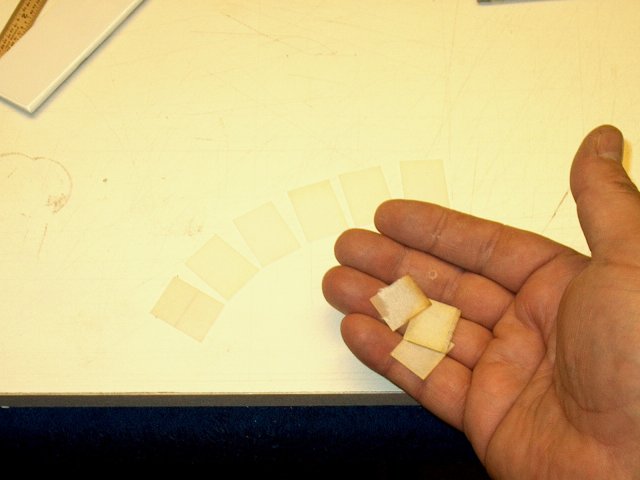

The center point is marked on each

hinge | |

Draw a line down the center of each

hinge | |

Install the hinges to center, opening up

the slots with a knife if needed, then install the

elevators | |

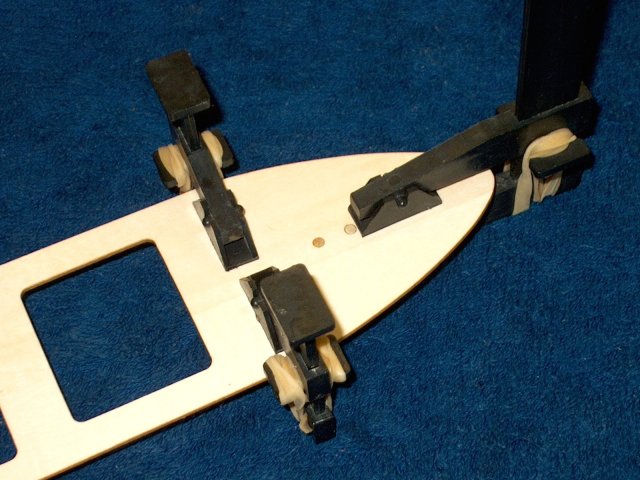

Use a round file to angle the forward slot

on the fuselage | |

Fit the stab in the fuselage, making sure

the forward slot is long enough for the rear to fit

| |

The rear should pivot and just fit in the

slot | |

Down throw will be 10mm, so make sure the

elevator doesn't bind too early when flexed downward

| |

Mark the top of the fin for the fuselage

location | |

Mark the bottom of the fin for the

fuselage location | |

The stab is removed showing the marks that

were made and the material is cut about 1/16" inside of the

line | |

Remove the material from the root

| |

Clean up the line drawn with denatured

alcohol | |

Bottom of the fin showing mark that was

made | |

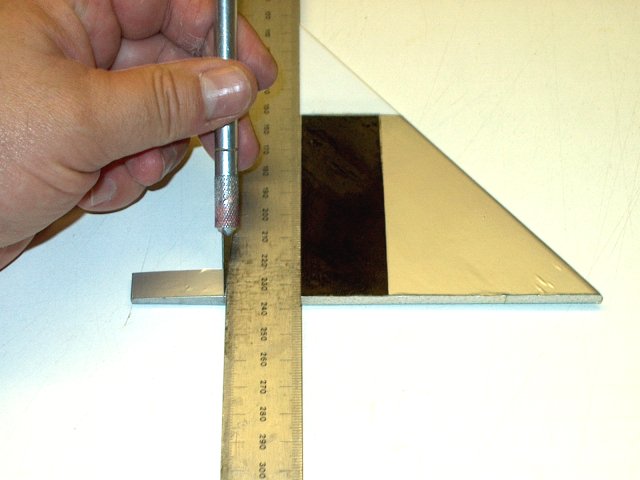

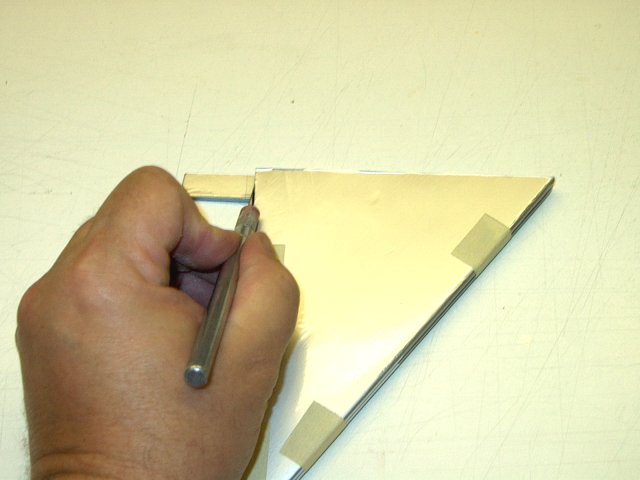

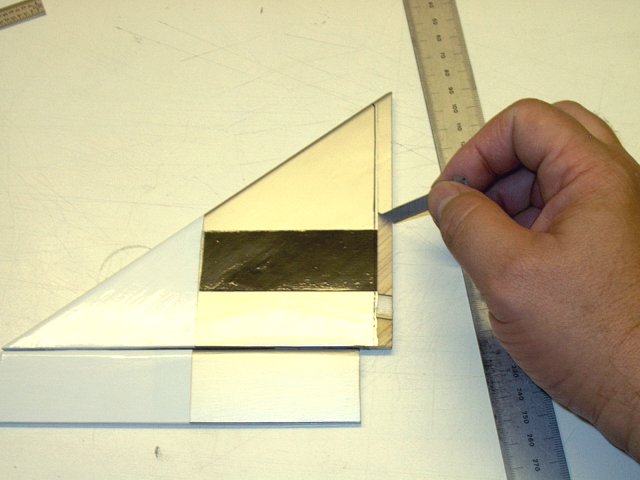

Use a ruler to cut the covering 1/16"

inside of the line | |

Remove the excess covering

| |

Clean up the drawn line with

alcohol | |

Use an iron to seal both sides where the

material was cut | |

Install the stab to check for fit once

more | |

Use the hinges and install an elevator on

the second stab | |

File the front of the slot at an angle and

continue until the stab fits well | |

Draw a line on the top of the stab with a

marker | |

Another line is drawn on the bottom side

of the stab | |

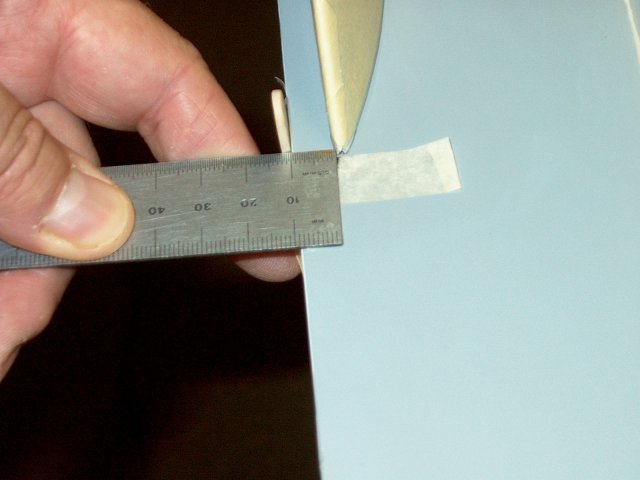

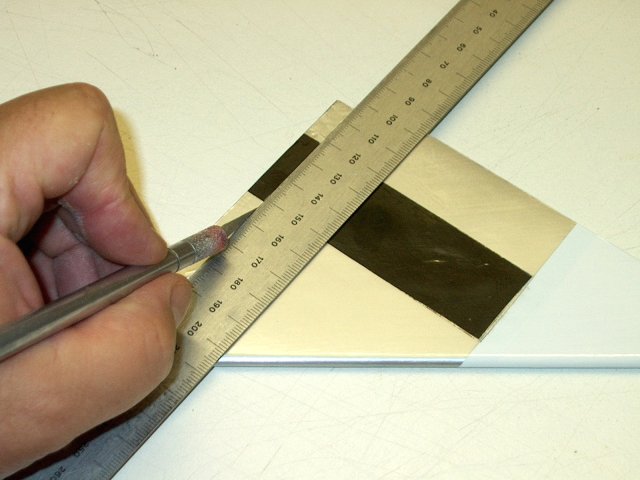

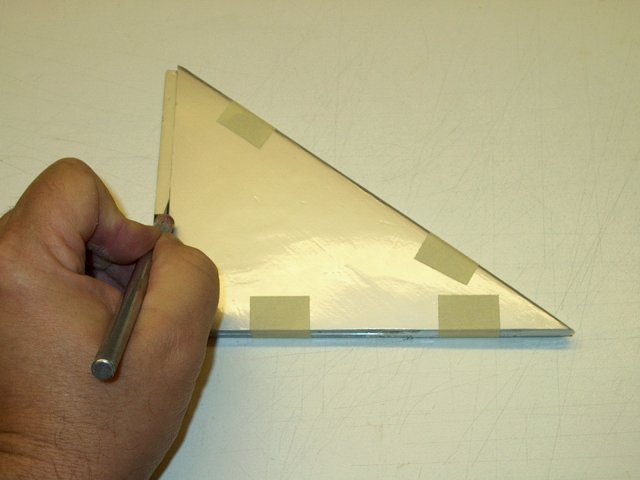

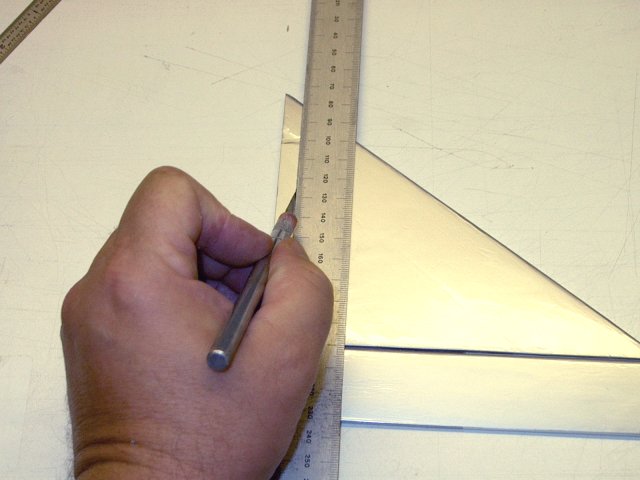

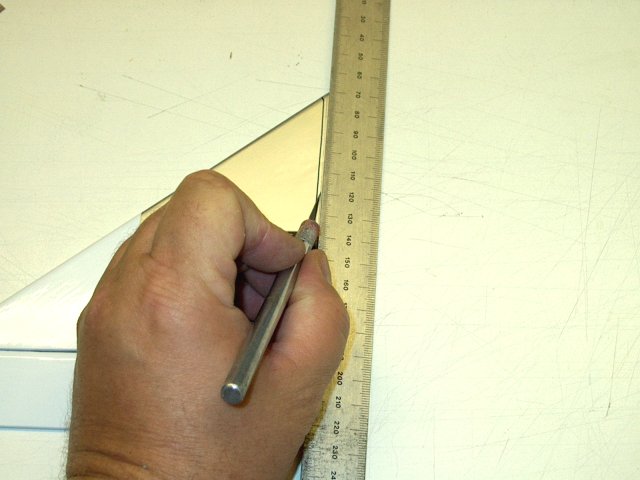

The stab is removed and a ruler is used to

cut about 1/16" inside the drawn line

| |

The ecesss covering is removed

| |

A ruler is used to cut the material on the

top of the stab | |

Excess material is shown removed

| |

Marker lines are cleaned up with

alcohol | |

Seal the covering with an iron, then

install the second stab in the fuselage and check for

fit | |

Tape is applied above the slot to keep the

covering clean when gluing the stab in place

| |

Apply a very thin coat of epoxy to each

side of the stab at set aside to let it soak

| |

Apply epoxy to the top and bottom of the

slot and to the two inside formers | |

Install the stab into the slot. Note that

the stab fits in so it is at a downward angle, which is

normal | |

Clean up any excess epoxy from the joint,

both top and bottom | |

Remove the tape before the glue

sets | |

Prepare the second stab slot with

tape | |

Apply a thin coat of eopxy to both sides

of the stab | |

Apply an ample ammount of epoxy to the top

and bottom of the slot, as well as the two formers

| |

Install the second stab

| |

Remove excess epoxy with alcohol from the

joint on both sides | |

Remove the tape before the epoxy

sets | |

Quickly check alignment by placing the

bottom of the fuselage on a flat surface and measure one stab

as shown | |

Check the other stab and make sure it is

the same distance from the board. prop up one side before the

epoxy sets if necessary so they measure evenly with

eachother | |

Stab installation completed as

shown | |

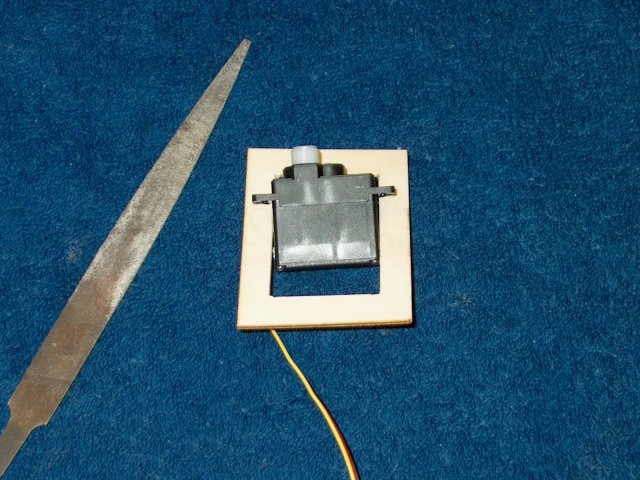

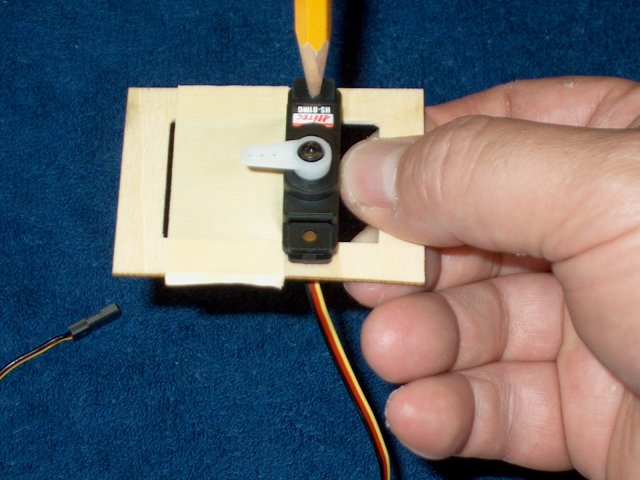

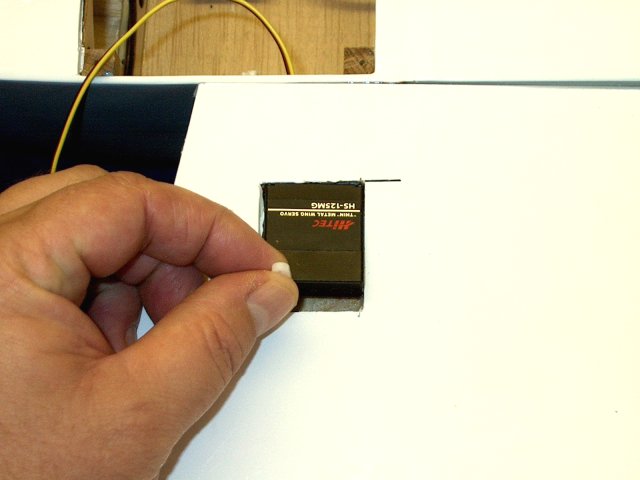

A good quality metal gear servo is used

for the elevator and is shown with the servo tray parts

supplied in the kit | |

Center the servo with a receiver or servo

tester | |

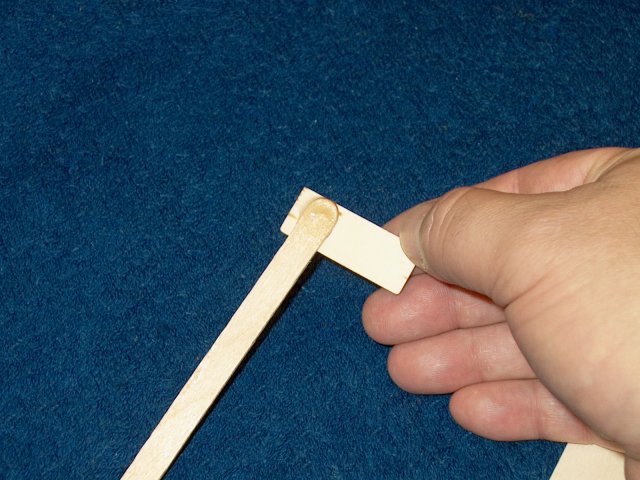

Trim one end of a servo horn as

shown | |

Install the horn on the servo, making sure

it is centered | |

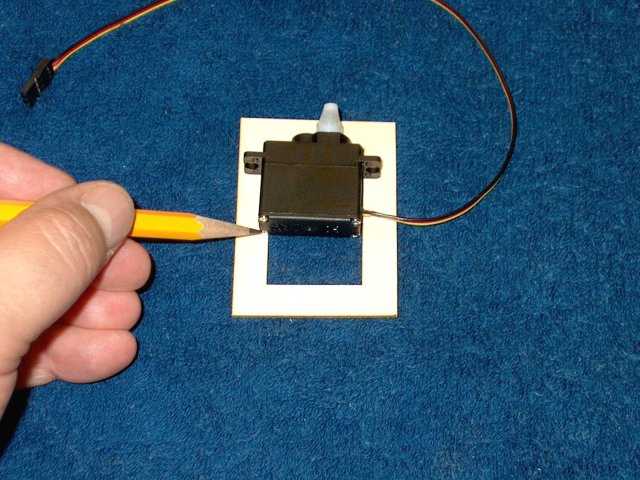

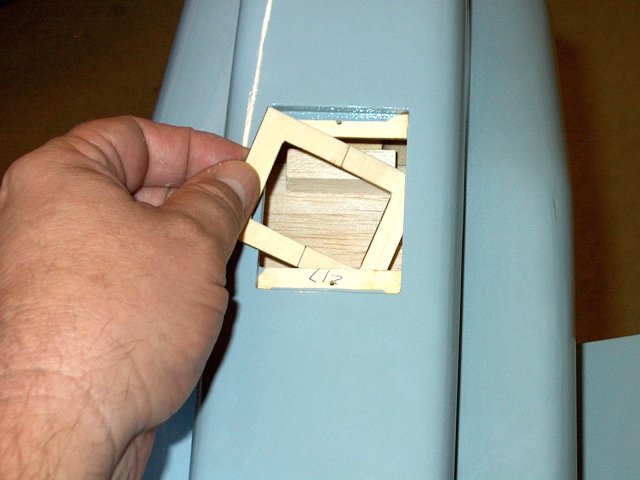

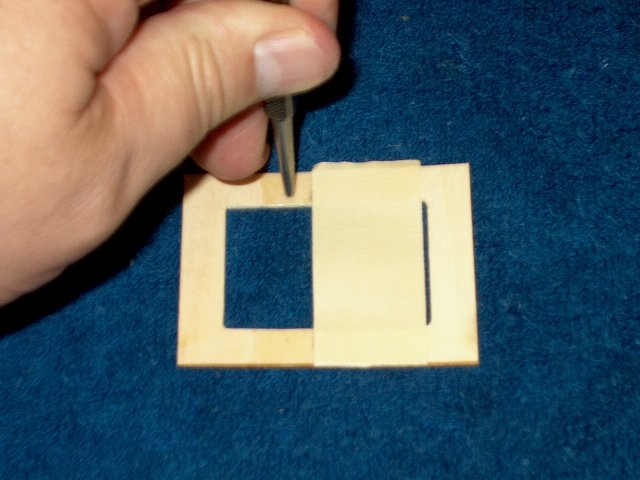

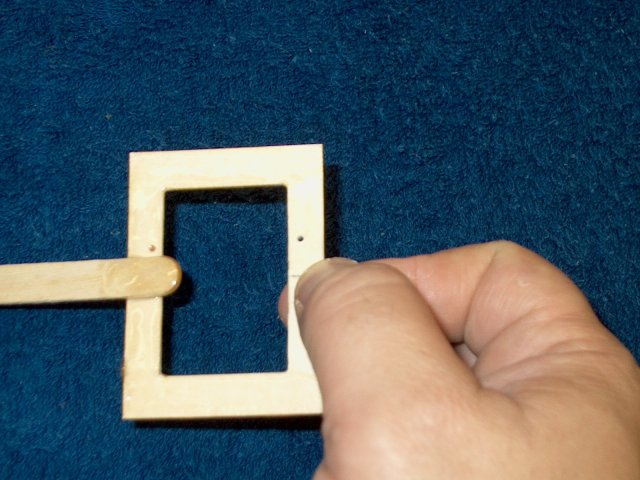

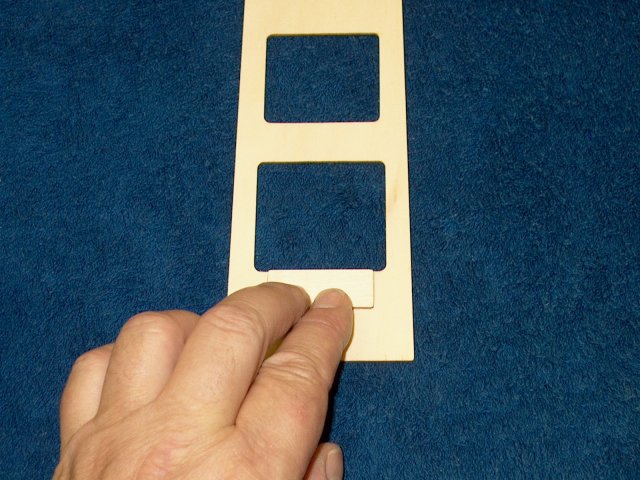

The selected servo is now slightly larger

than the opening in the supplied servo tray. You may have to

enlarge the opening to fit your make of servo

| |

The tray is marked evenly on each side to

widen the opening just enough for the servo to pass

through | |

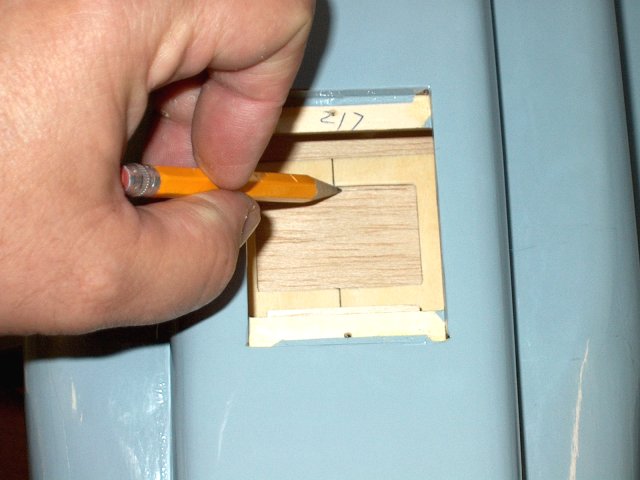

A tool is used to open up the hole. Files

and some light sanding are used to finish the work

| |

The servo should easily fit through the

opening as shown | |

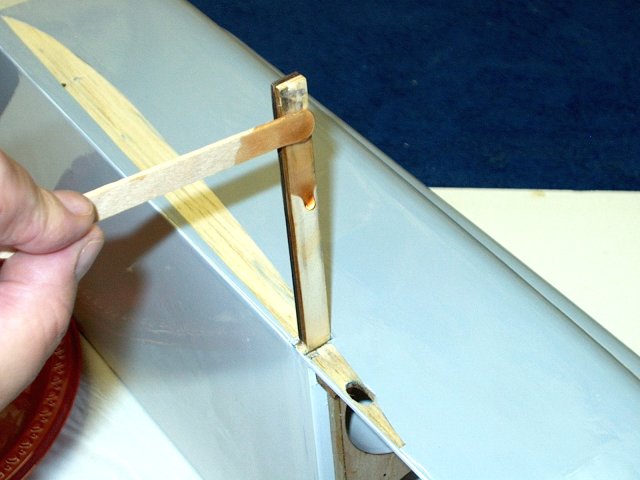

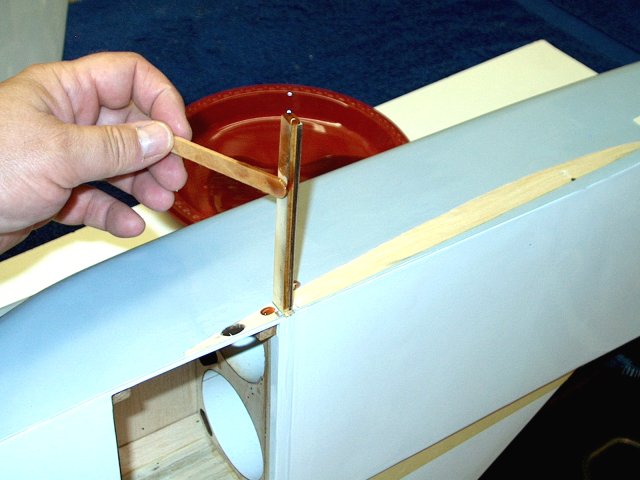

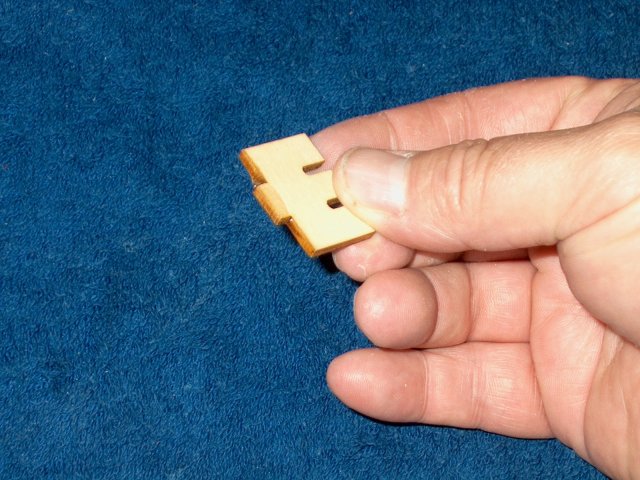

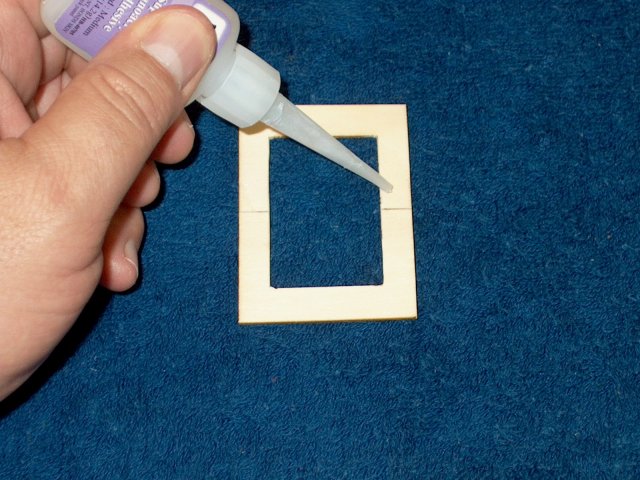

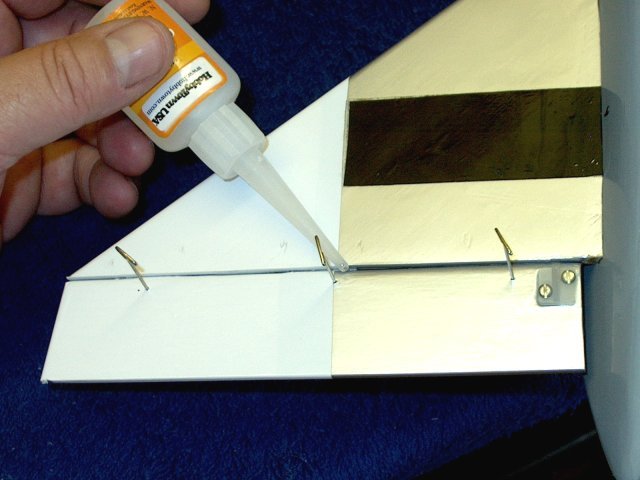

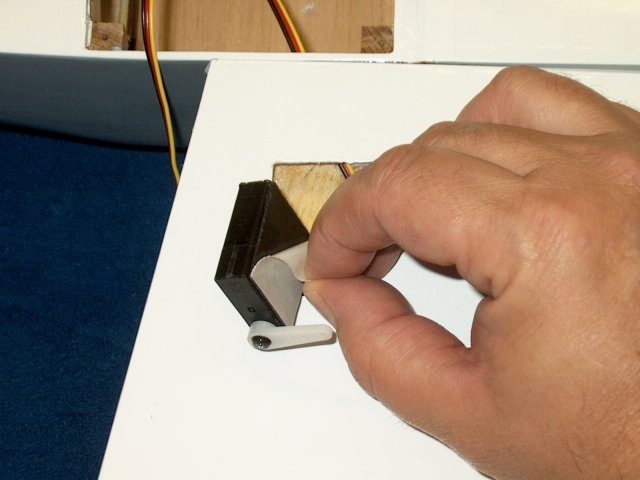

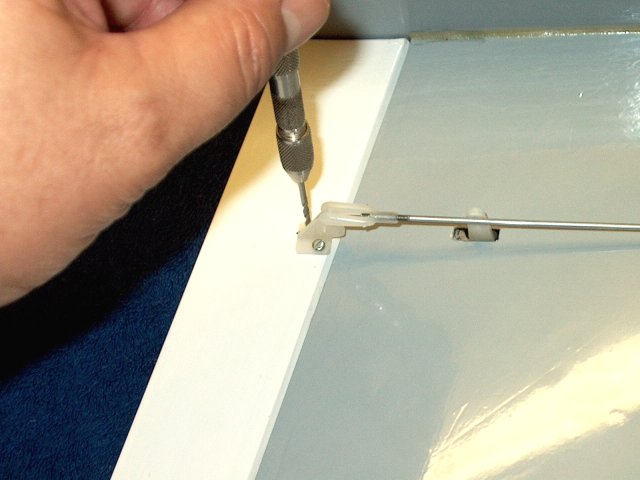

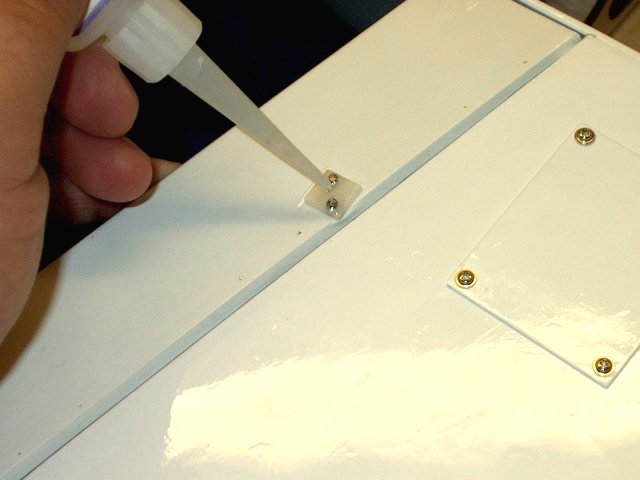

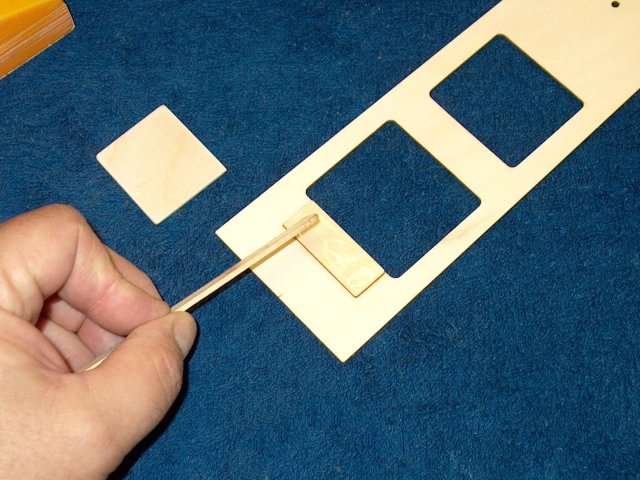

Epoxy is applied to the slot for the

pushrod bracket | |

Epoxy is applied to the vertical section

of the bracket | |

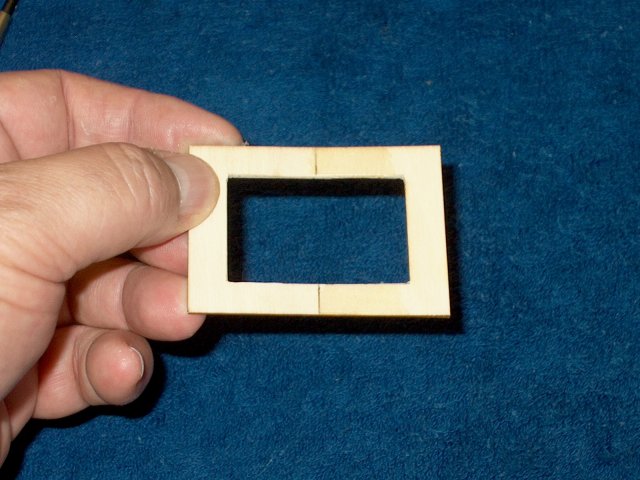

The to pieces are joined until they sit

flush with eachother | |

Some epoxy is added to create a fillet for

strength | |

Make sure the two pieces are perpendicular

to eachother, then set aside while the glue sets

| |

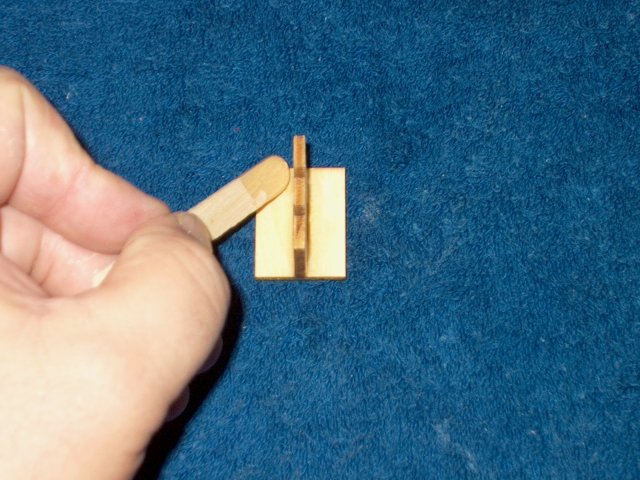

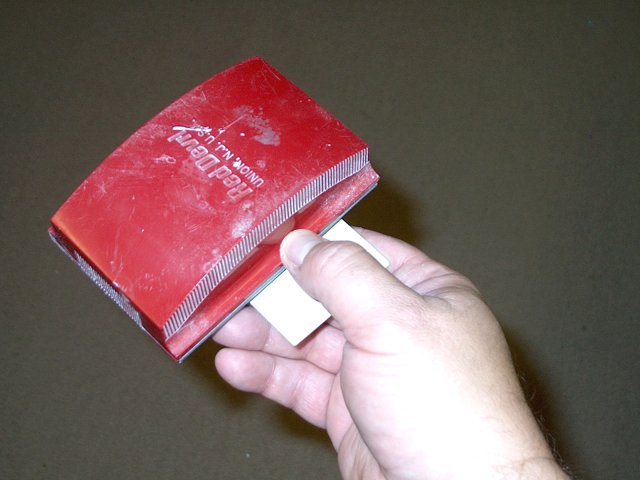

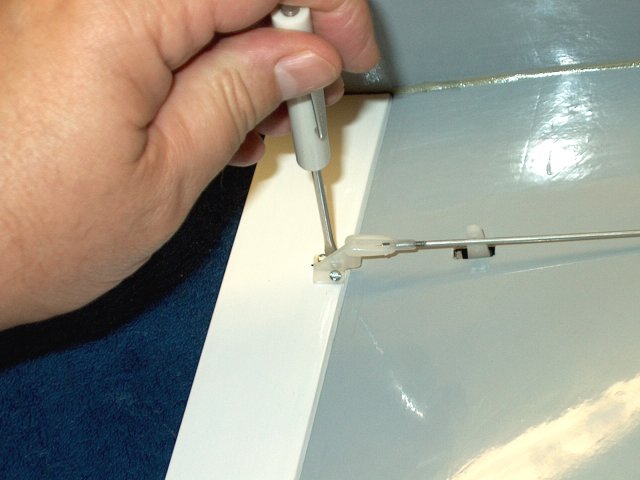

Sand the bottom of the assembly flush with

a sanding block | |

The bottom of the slots are slightly

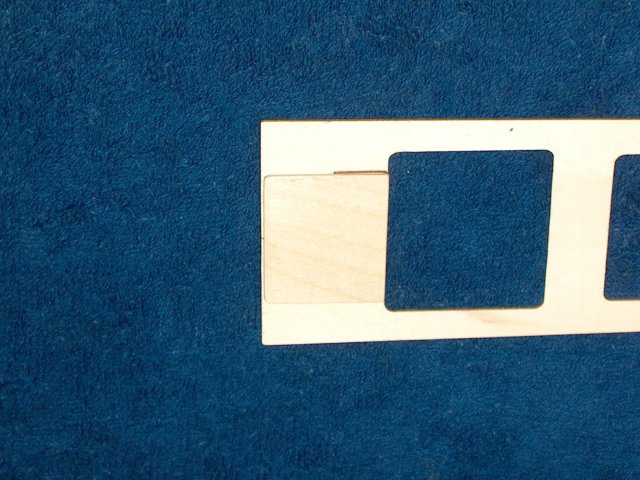

enlarged for the pushrods | |

Test a pushrod sleeve to make sure it fits

well | |

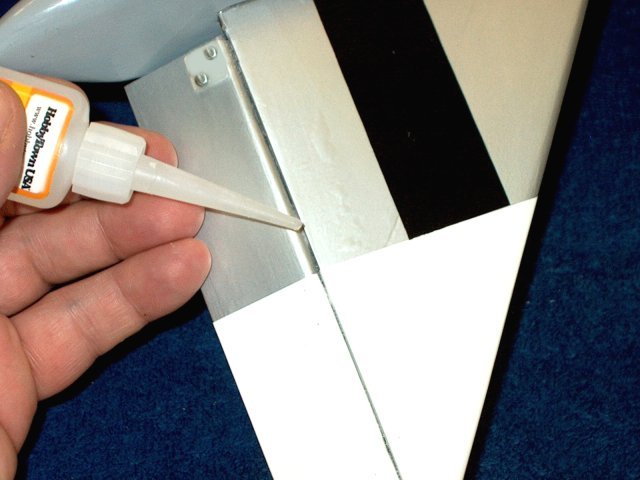

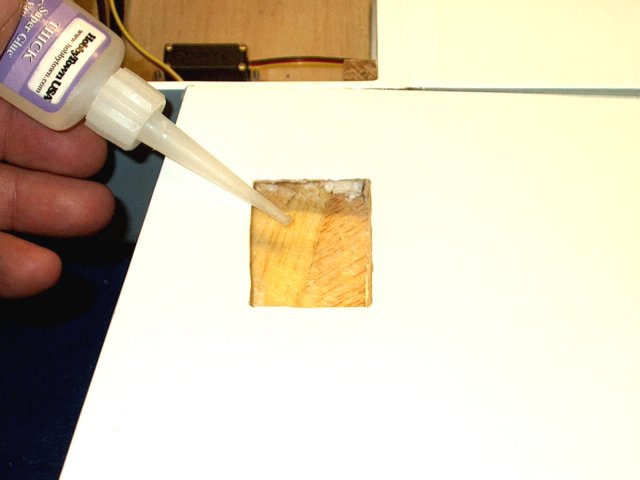

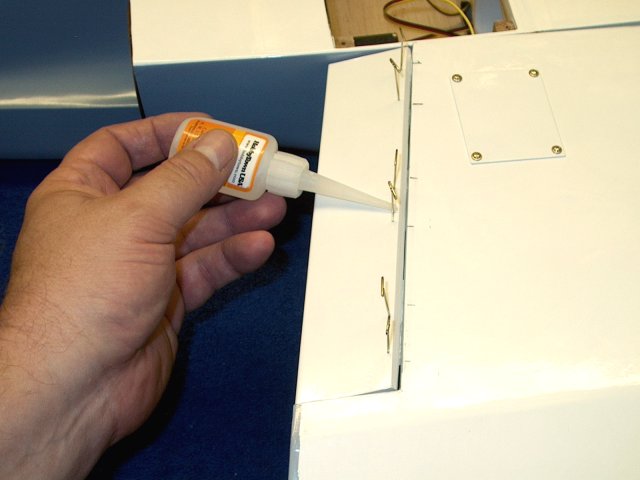

CA is used on the back side to stiffen the

plywood | |

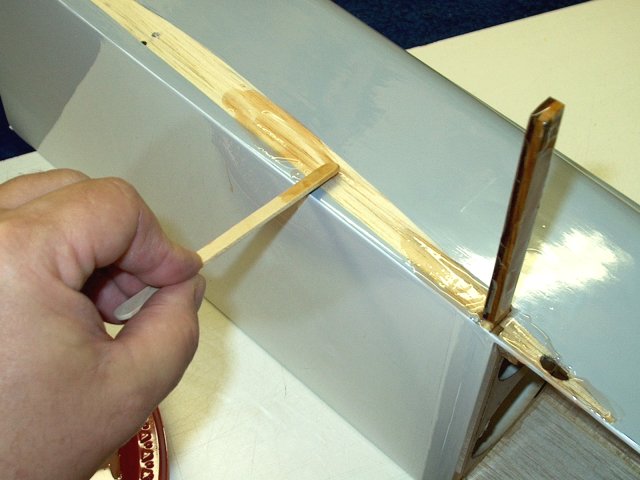

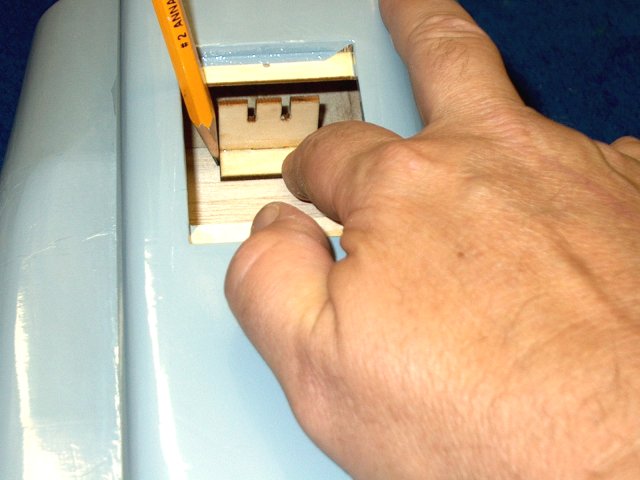

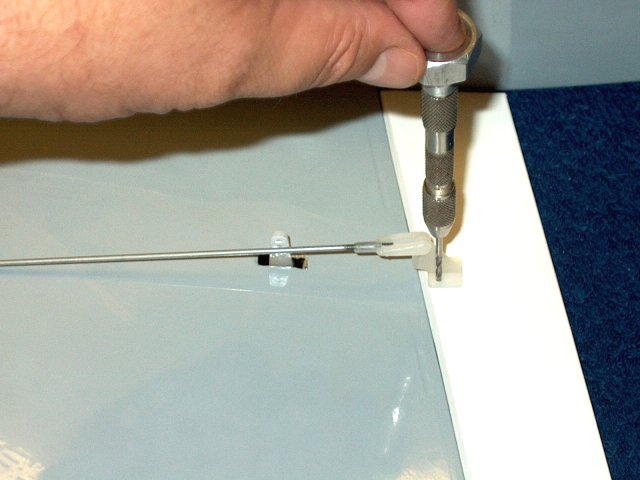

Position the bracket so it is centered in

the rear of the fuselage, just behind the seam in the balsa.

Next, draw an outside line on each side to mark the position

of the tray | |

Lines shown drawn once the bracket is

removed | |

Apply epoxy to the bottom of the

bracket | |

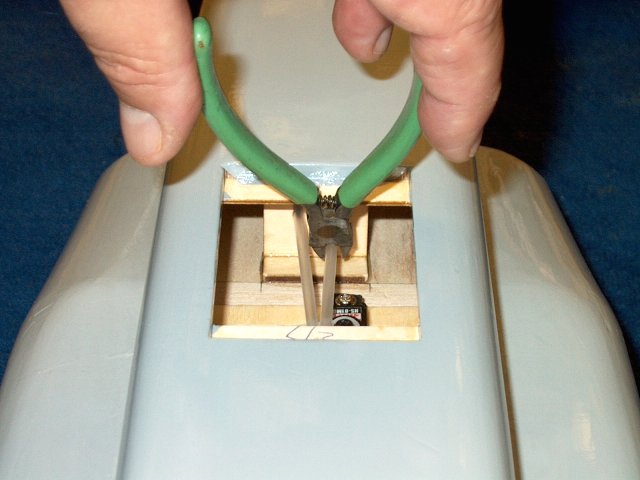

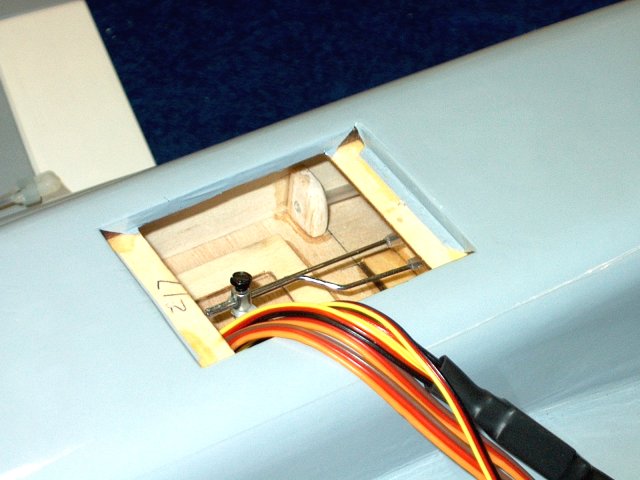

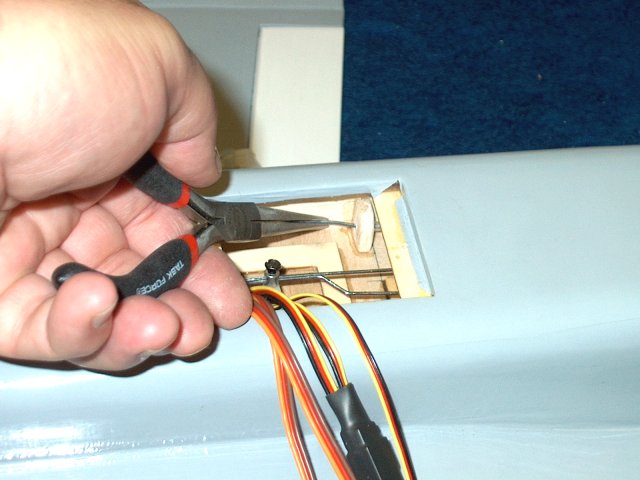

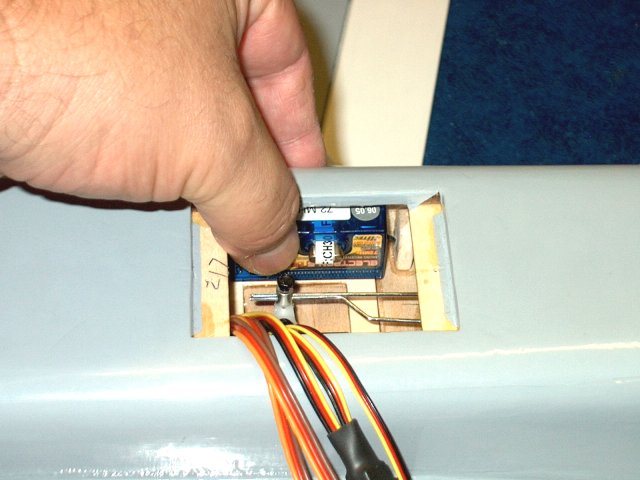

Use some pliers to position the bracket in

the fuselage. | |

Make sure the front is even with the seam

in the balsa floor as shown and that the sides are even with

the marks you made earlier | |

A mark is made for the center of the servo

tray | |

Drawn a line down the center of the tray

through the marks | |

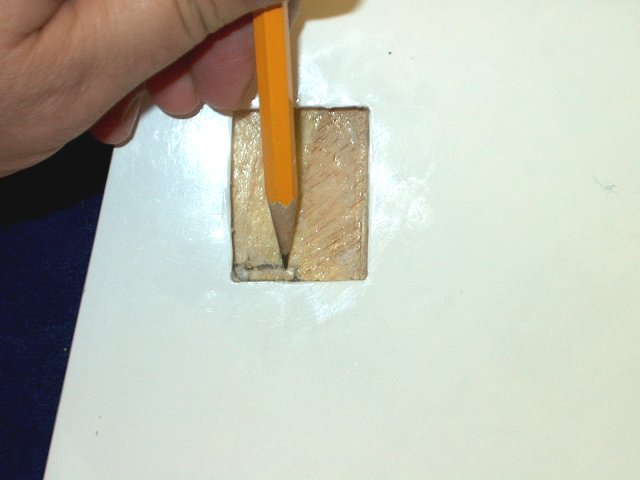

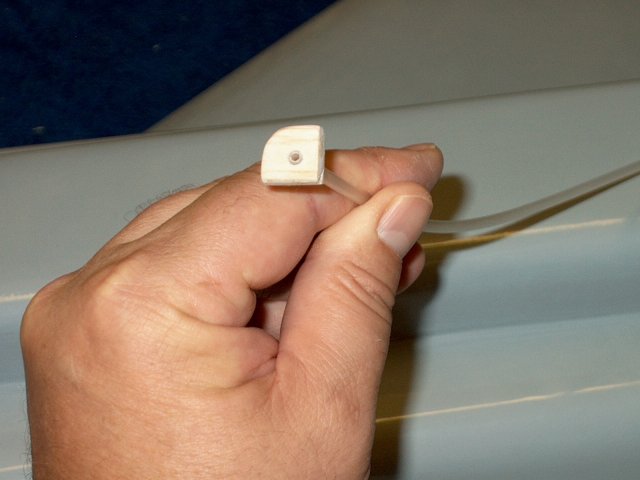

A 1/2" square piece of balsa is inserted

into the fuselage as a spacer | |

The bottom of the block is pushed flush

against the front edge of the pushrod bracket plate

| |

The servo tray is inserted into the

fuselage | |

The servo tray is pushed flush against the

balsa block and centered as shown | |

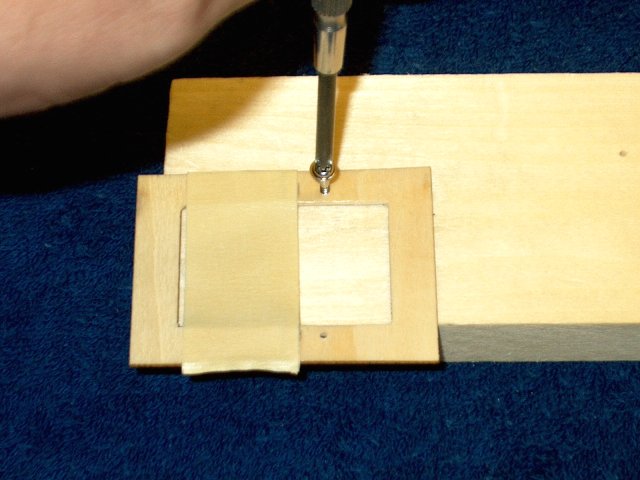

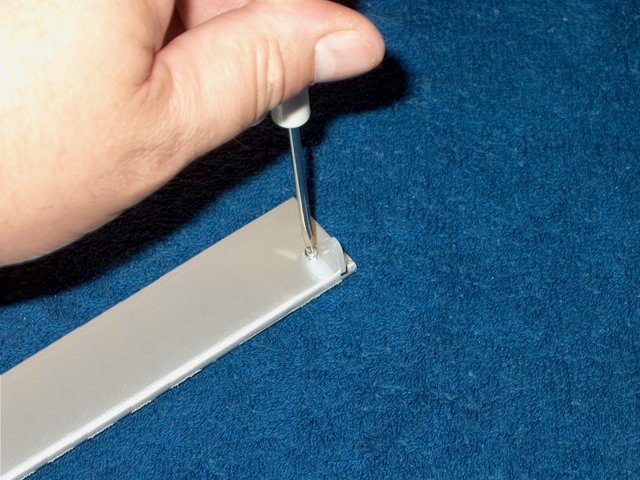

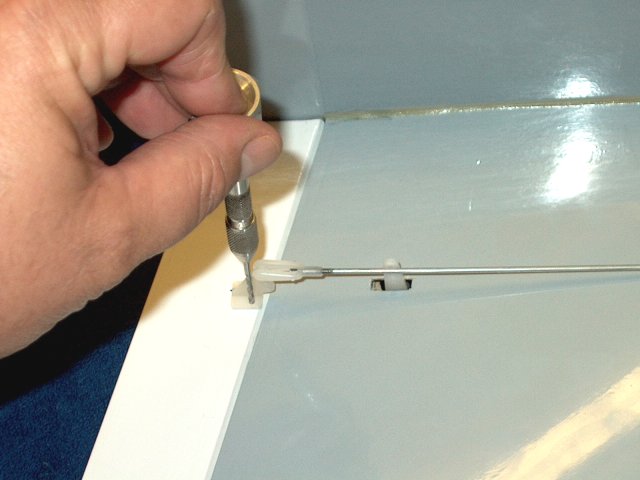

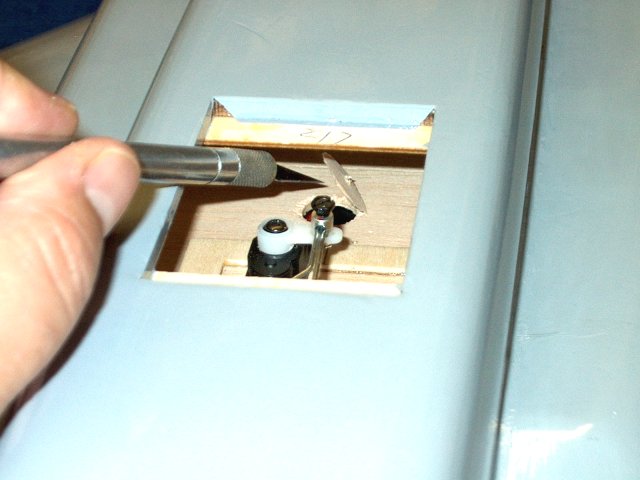

A screwdriver should be inserted to make

sure you have clearance to get to the servo screws that will

be installed | |

Draw an outline of the tray in the floor

of the fuselage | |

remove the tray and seal the top section

with CA where the servo screws will reside

| |

Allow the CA to dry

| |

A mark is made top and bottom 1/8" away

from the centerline on the tray to space the servo so it is

offset from center. This is so the horn will be centered

instead of the servo | |

A couple pieces of tape are stacked across

the offset marks that were just made

| |

Add the grommets to the servo and install

it in the tray. While holding it in place, mark the holes for

the screws. NOTE: While a single servo is used for the

elevators, you can also use dual servos for the

elevators | |

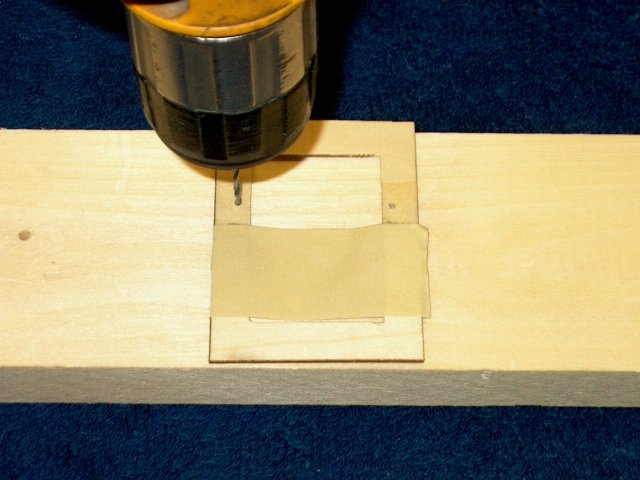

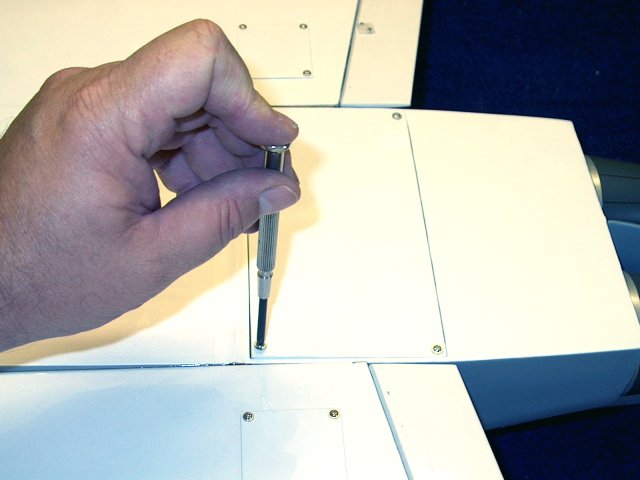

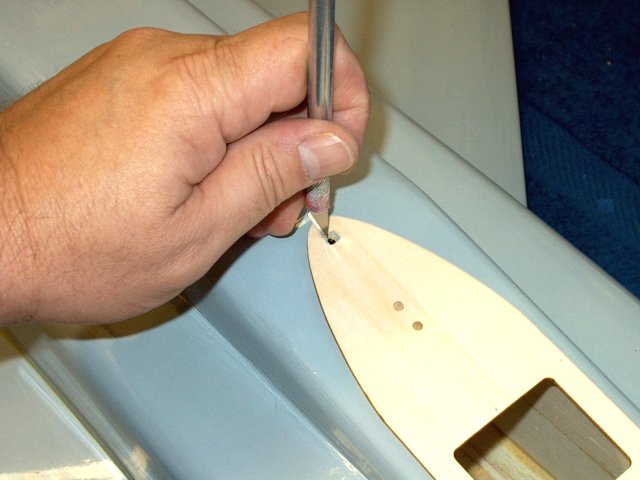

Use a punch to dimple the marks for the

servo screw holes | |

Use a 1/16" drill to make the holes for

the servo screws | |

A screw is used to initially "cut" threads

in the tray | |

Epoxy is applied to the bottom of the

tray | |

Use pliers to ease intallation of the tray

in the fuselage | |

Center the tray over the alignment marks

made on the floor, then press it down in place

| |

The tray had some warping, so a weighted

object is used to hold the tray down flsuh until the epoxy

cures | |

A ruler is placed across the two offset

marks where the tape was placed earlier and a knife is used to

cut the balsa. Make several passes and take your time

| |

A ruler is used to cut the other side,

away from center and 1/2" wide or wide enough for the servo

you are using. note that a single edge razor was installed in

the first slot so the ruler could be pressed flush against it

while cutting the second slot | |

Be sure to cut completely through the

sheeting at the corners as shown, then cut across flush to the

tray and remove the balsa piece | |

A 1/16" drill is used to re-open the screw

holes, which most likely will have some epoxy in them

| |

The fuselage is turned over and CA is

applied to the bottom area around the screw holes to

strengthen them | |

Install the servo in the fuselage

| |

Use the servo screws to permanently mount

the servo in place | |

Servo installation shown completed

| |

Fit three hinges in each of the two

Elevators | |

The horns supplied in the kit were

discarded as they were too thin and flimsy

| |

1/2A horns made for a good substitution

| |

Horn shown in place ...take note of the

hole orientation and note that the horn will be mounted on the

bottom of the elevator | |

Use a 3/32" drill to open the holes in the

balsa. Stiffen the holes with thin CA

|

|

Install the horn on the bottom of each

elevator. Be careful to not over tighten the bolts

| |

Trim and grind the excess thread length

off from the bottom | |

Seal the ends of the bolts on each

elevator with a cap of thick CA so it won't snag or catch

anything while handling | |

The outside hinge requires some trimming

to fit | |

Install the elevator, opening the slots

for the hinges if necessary with a razor, then use thin CA to

glue them in place, Make sure the outer end is flush with the

stab | |

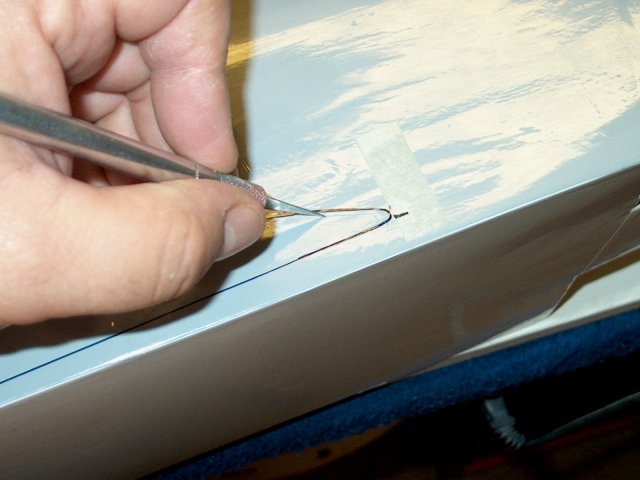

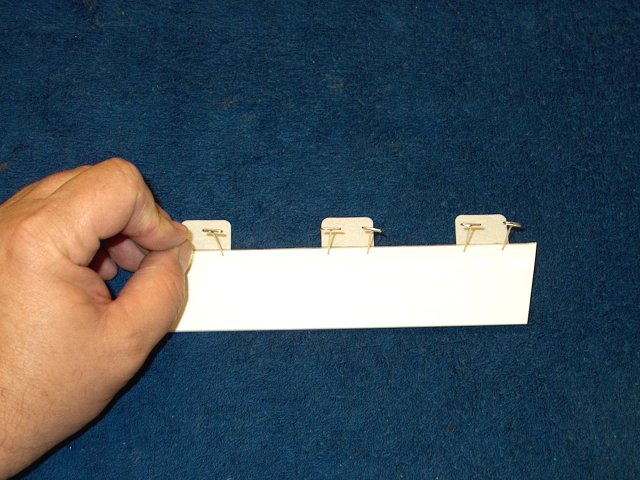

T pins are used to hold the hinges in

place so they do not shift or twist when installed. Apply thin

CA to both sides of the elevator hinges

| |

Install the second elevator the same as

the first | |

Elevator horns shown installed

| |

A piece of tape is applied to the side of

the fuselage and a mark made the same height of the bottom of

the pushrod bracket slot inside | |

Make a mark on the side of the fuselage 3"

from the front root of the stab | |

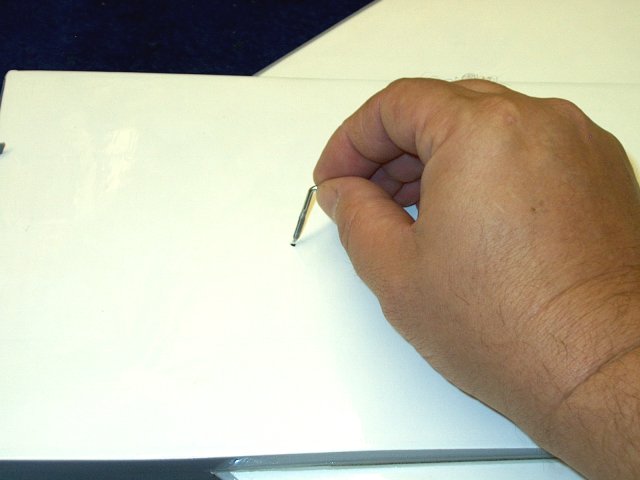

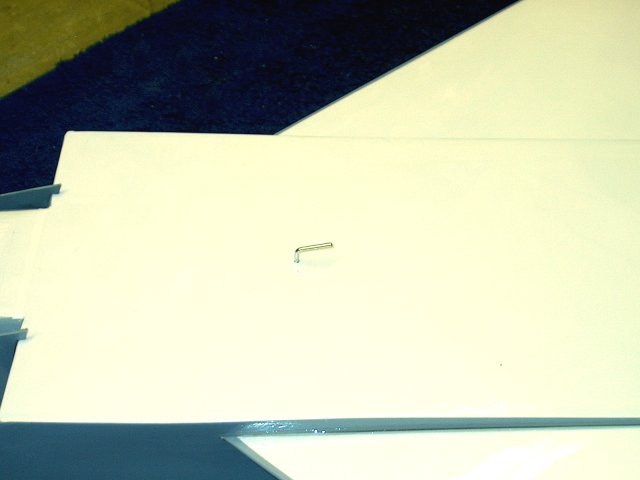

Drill a 1/8" hole at the mark and about

1/16" below the edge of the fuselage as shown

| |

Use a long 1/8" drill bit like a file and

turn it foward, gradually opening the hole at an angle and

pointed slightly down toward the mark on the tape. Slowly

drill a hole internally that is angled down toward the pushrod

bracket | |

Install the pushrod, then slide the

pushrod sleeve over it and work it towards the bracket

inside | |

Remove the steel pushrod and check for

alignment of the sleeve to the horn

| |

Pull the pushrod sleeve through the

bracket as shown | |

Remove the sleeve and use a knife to trim

the excess covering | |

Hole opening completed and the bare balsa

can be touched with some paint to match the fuselage

| |

Re-install the pushrod sleeve from the

front opening | |

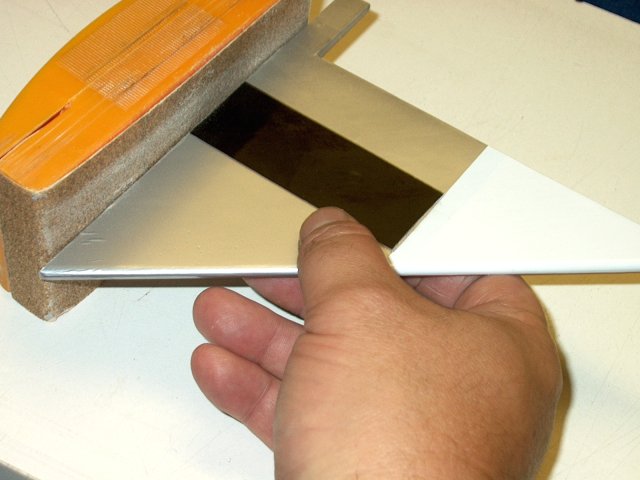

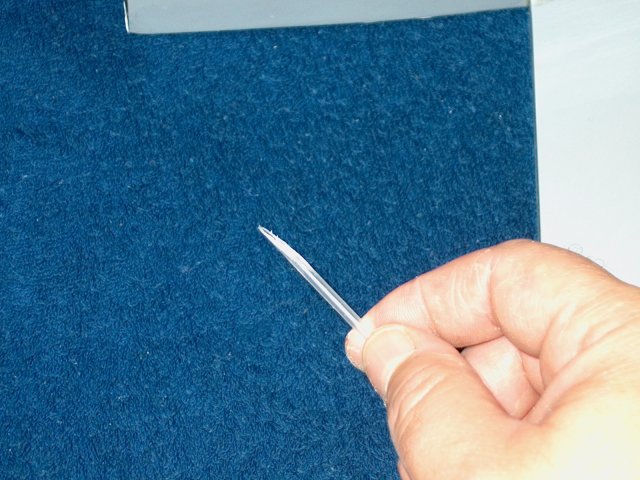

Trim the sleeve so it sits flush with the

fuselage side. IT may be easier and safer to mark it, then

remove it and trim against a hard surface so you don't damage

the fuselage | |

Remove and sand the sleeve to shape, then

clean out the hole for the pushrod | |

Move the plastic sleeve out of the way and

apply some epoxy to the hole, then move the sleeve in

place | |

Remove any extra epoxy with alcohol and

make sure the hole is clean | |

Sleve shown epoxied in place

| |

Measure back 3" from the leading edge of

the second stab | |

Start a 1/8" drill hole about 1 1/6" from

the top edge as shown | |

Turn the bit and use it to file a hole

toward the pushrod bracket that is located by the servo

| |

Install the pushrod from the rear

| |

Sand an angle on the end of the sleeve.

The will lay flush against the rear exit hole

| |

Install the sleeve in the bracket and run

it rearward, using the rod as a guide

| |

Pull the back of the sleeve away and add

some epoxy to the hole, then move the sleeve over the hole and

clean up any excess epoxy | |

Trim the extra length off the front of

each pushrod sleeve as shown | |

Use some epoxy at the base of each sleve

where they pass through the bracket

| |

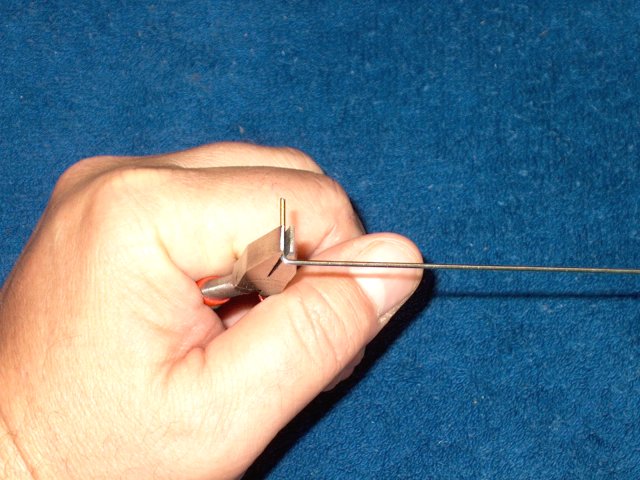

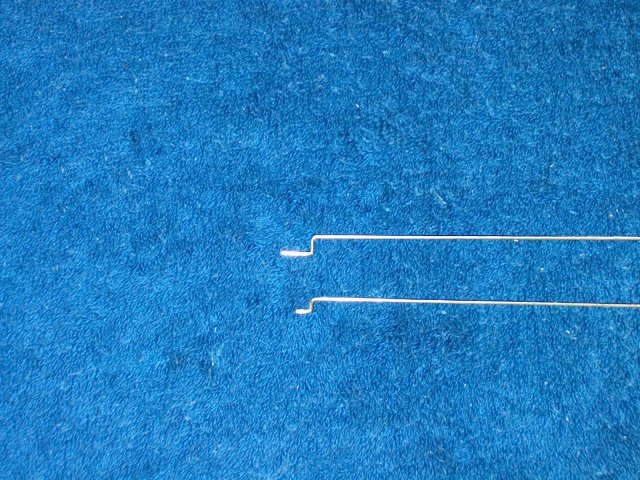

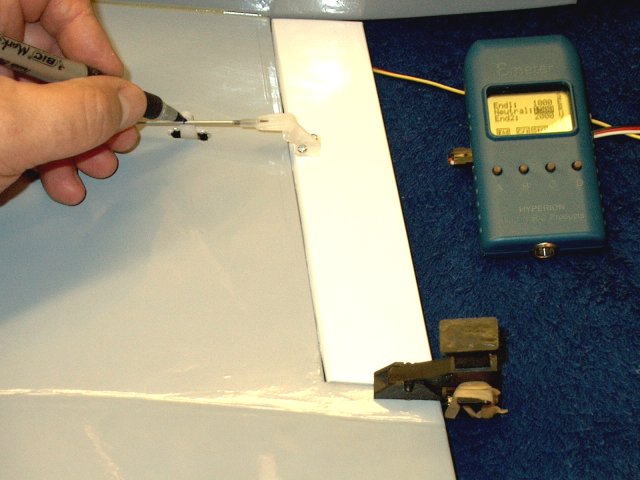

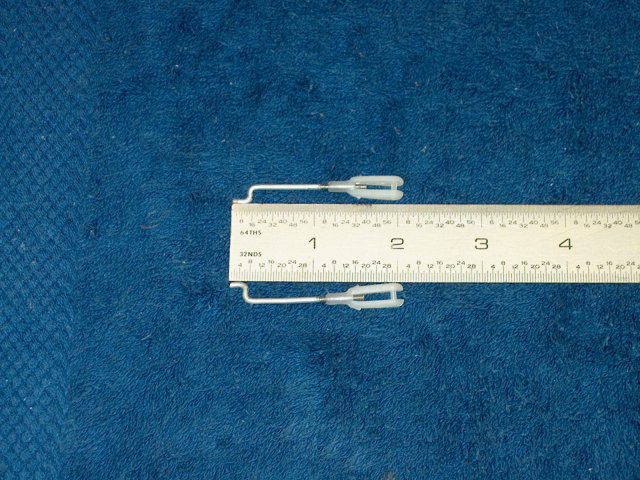

Bend a Z-Bend at the end of two of the

pushrods supplied in the kit | |

The pushrod at the top was supplied in the

kit, but it is too wide, as indicated by its height and this

can cause play. Cut the end off and make a tighter Z-Bend as

shown on the bottom rod | |

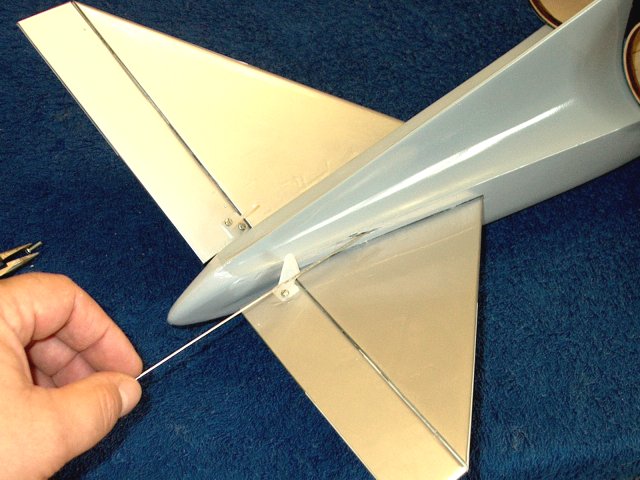

Install a rod from the rear

| |

Loosen one bolt on the horn, then twist it

sideways and install the pushrod in the outside of the

horn | |

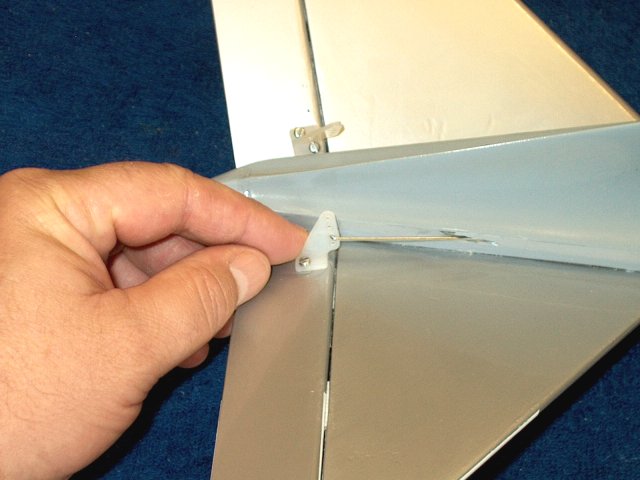

Turn the horn in place and re-install the

screw. Make sure the pushrod is on the outside of the horn as

shown to prevent binding | |

Install the second pushrod in the same

manner as the first, making sure it enters the horn from the

side away form the fuselage | |

Both pushrods are installed in their

correct position as shown | |

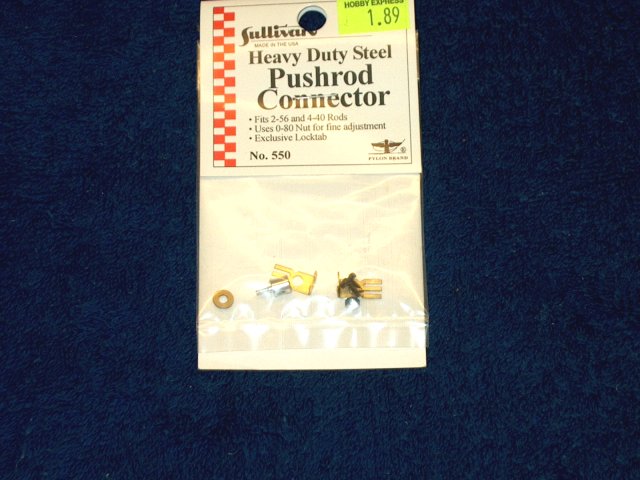

Use the following connector for the

elevator, as it has a wide enough hole and a threaded

base | |

Bend the left side pushrod wire toward the

horn as shown | |

Finish bending the pushrod wire toward the

horn | |

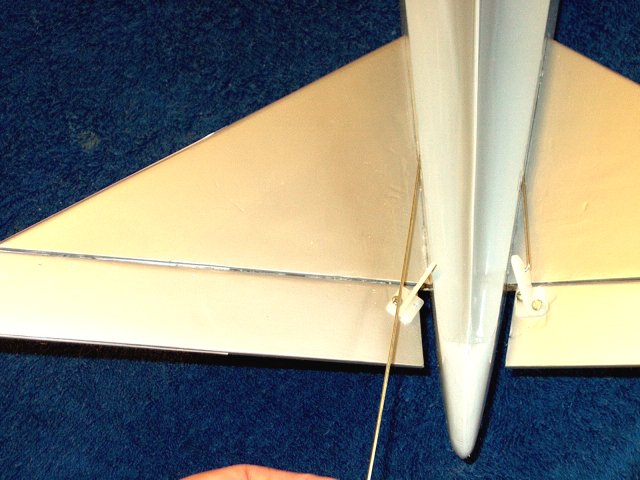

Both wires run parallel to each other and

travel forward, right over the servo horn holes as

shown | |

Use clamps to hold both elevators at

center position | |

Make a mark on each wire for

cutting | |

Cut each wire at the mark, then sand/grind

away any burrs so they pass through the connector

| |

Remove the servo horn

| |

Drill a hole out with a 1/16" drill so the

connector will fit | |

Install the pushrod connector

| |

Use some CA to secure the nut to the

bottom of the connector | |

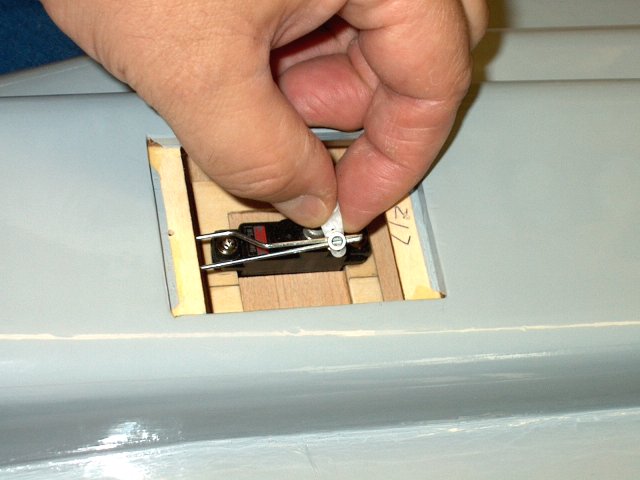

Slide the pushrod connector over both

pushrods as shown. Install the horn on the servo and secure it

with the horn bolt | |

Appy some Loktite to the connector

bolt | |

Install the bolt in the connector and

tighten. This completes the elevator assembly

| |

Install the hatch with the two supplied

screws | |

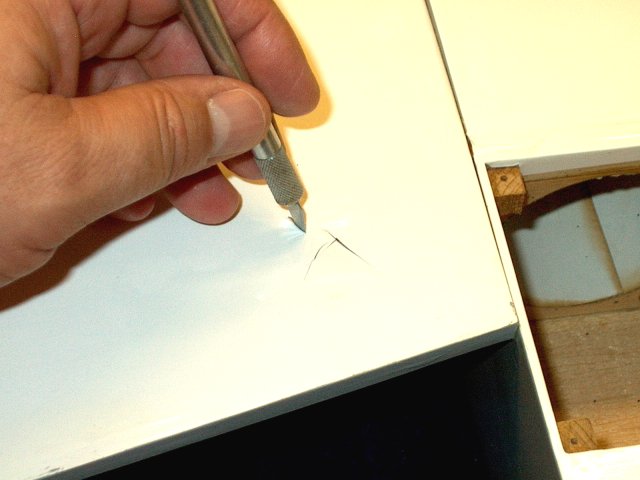

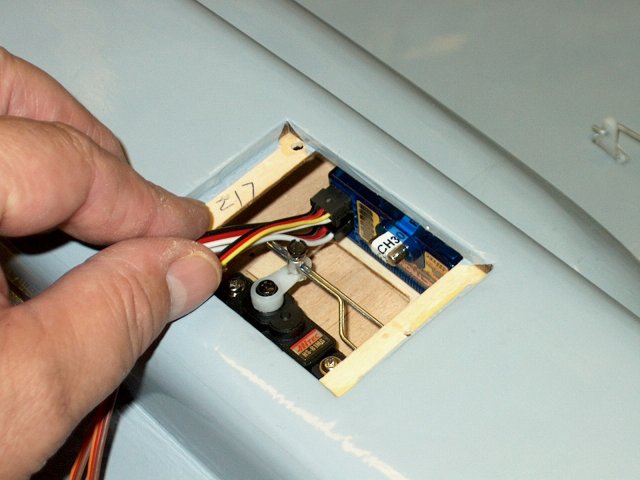

Low profile metal gear wing servos are

used for the ailerons | |

Remove the mounting ears from each of the

two servos | |

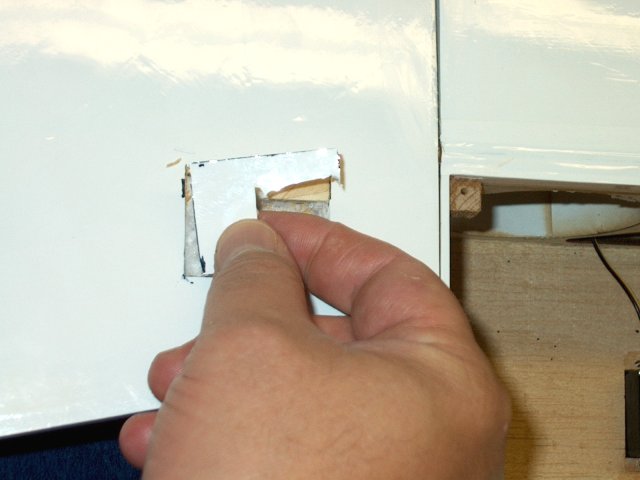

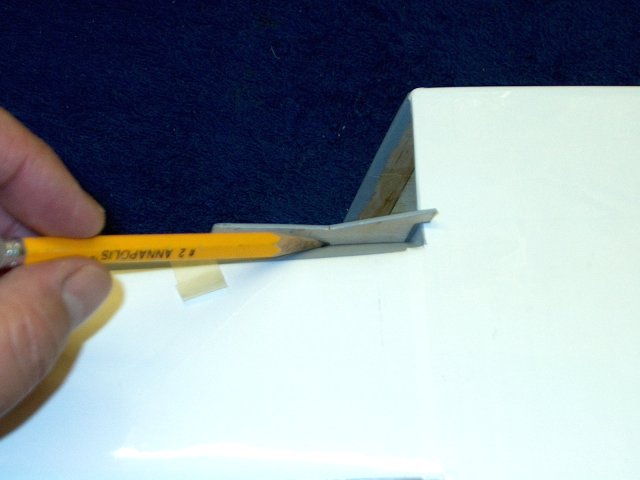

Use a knife and cut into the indented

servo well in the wing area | |

Iron the cloth out of the way on the inner

side and bottom | |

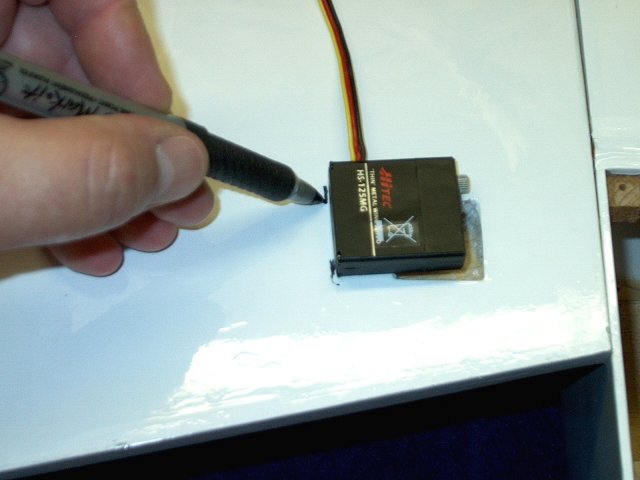

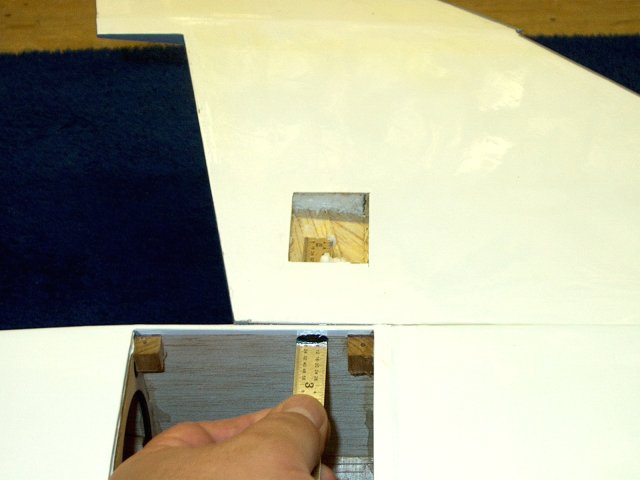

Place the servo over the opening and mark

its size on the wing | |

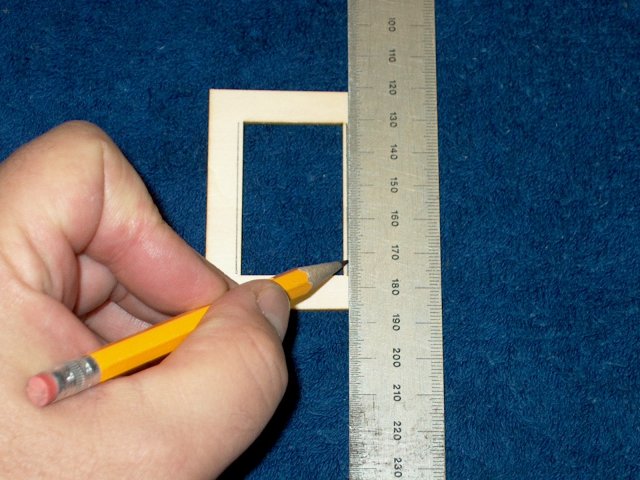

Use a ruler and draw the hole that needs

to be cut for the servo | |

Use a ruler and cut out the wing area at

the marks that were made | |

Remove the pieces that were cut and clean

out the servo well. Lightly sand the balsa bottom of the well

to smooth it out | |

Use a ruler or mixing stick to push out

the foam so the servo wire can be run

| |

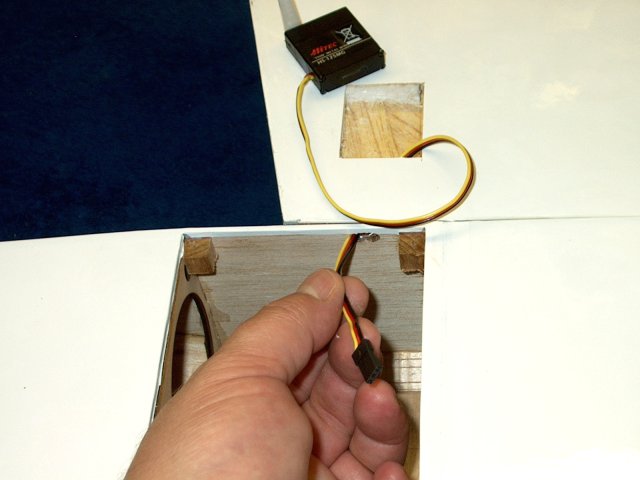

Install the servo wire as shown

| |

Install the servo in the wing well and

trim the opening as necessary for a nice fit

| |

1/2A horns and 2-56 Clevis' were purchased

to replace the parts that were supplied. Once again, do not

use the wood horns in the kit | |

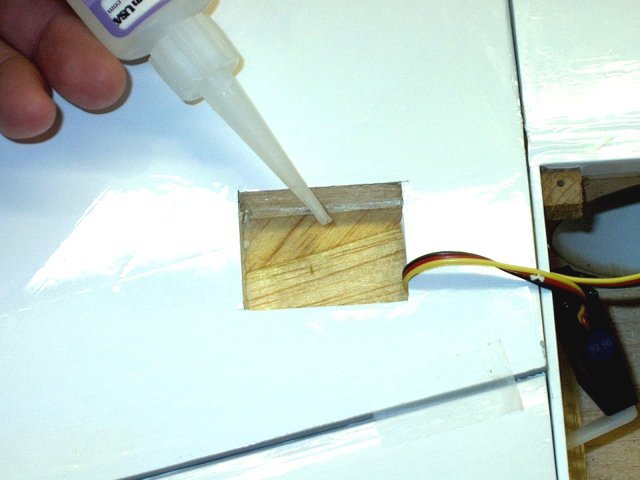

Medium to Thick CA is used to paint a thin

film on the bottom of the servo well in the wing

| |

Once dried, sand the area smooth with 320

grit and clean up the dust with denatured alcohol

| |

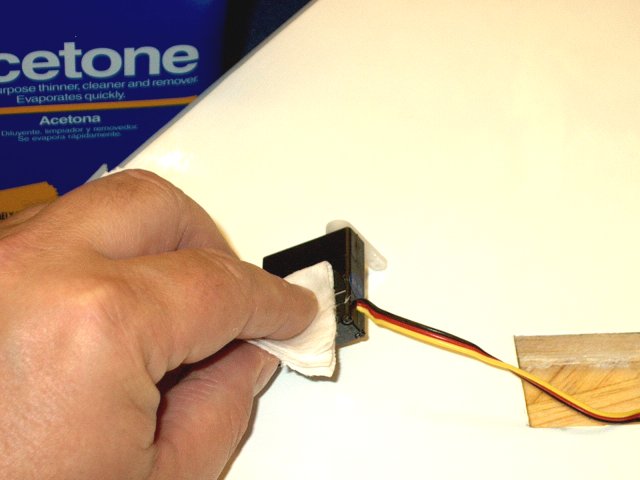

The bottom of the servo is cleaned with

acetone | |

A piece of servo tape is applied to the

bottom of the servo area that was just cleaned. DO NOT REMOVE

the bottom servo tape backing yet | |

The servo is inserted into the well in the

wing and marks are made 1/8" beyond each side of the servo arm

center hub to allow for travel | |

A 3/16" wide slot is cut out for the servo

arm as shown | |

Remove the excess material and

balsa | |

The servo is installed and held in place

with masking tape | |

The servo arm is checked for clearance and

travel. Elongate or widen the slot if necessary

| |

Remove the servo arm, then center the

servo using a tester or your receiver

| |

Install the arm to the center position and

use the servo bolt to hold it in place

| |

Remove the backing from the servo

tape | |

install the servo in the wing well, making

sure to position it correctly. You can hold on to the arm from

the other side while making small adjustments

| |

When centered, press the servo firmly in

place | |

The servo arm should be centered on the

other side of the wing as shown | |

Servo installation is now completed

| |

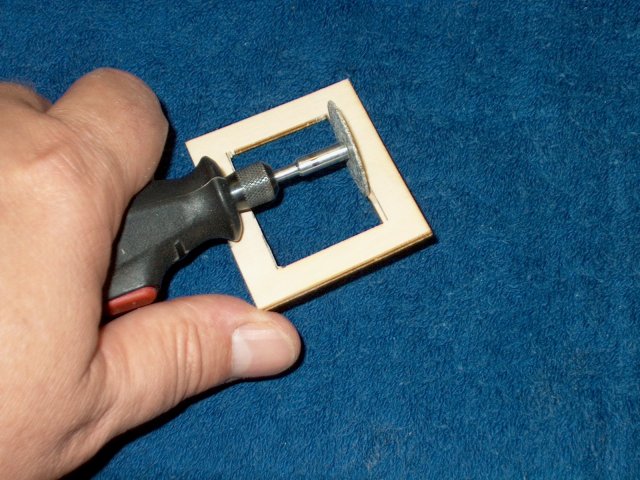

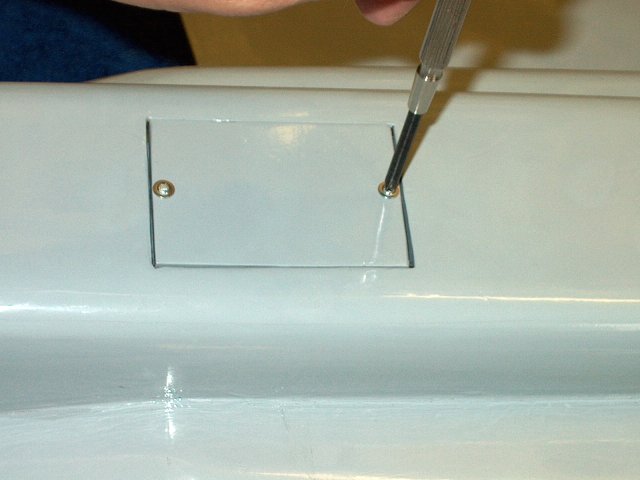

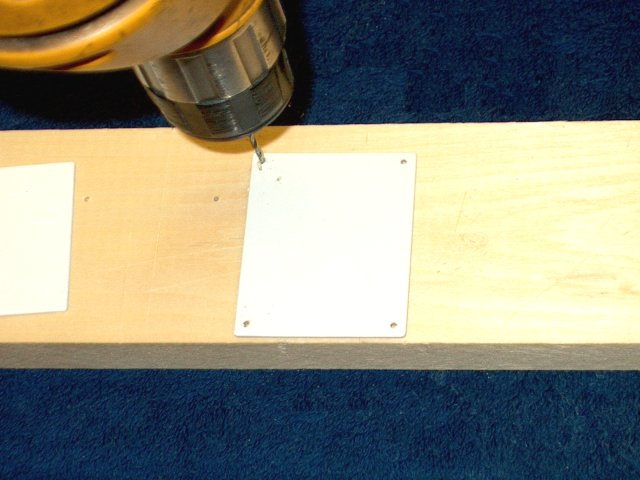

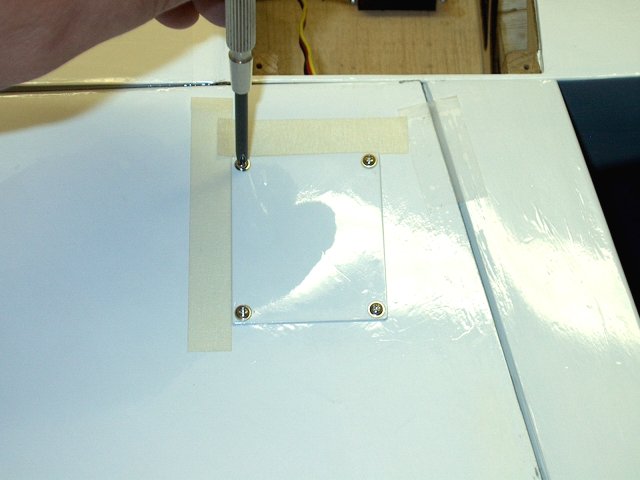

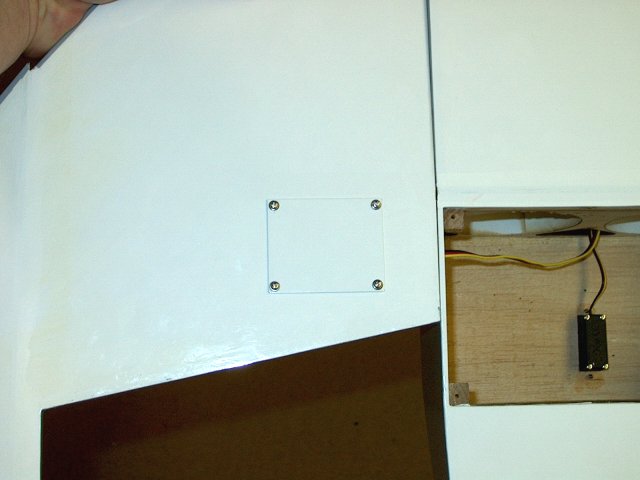

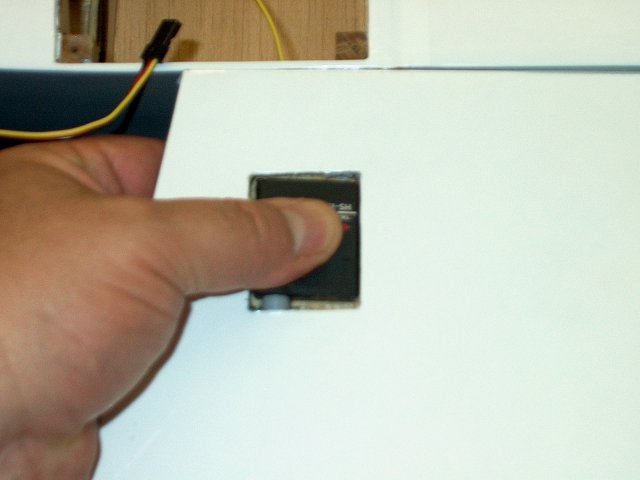

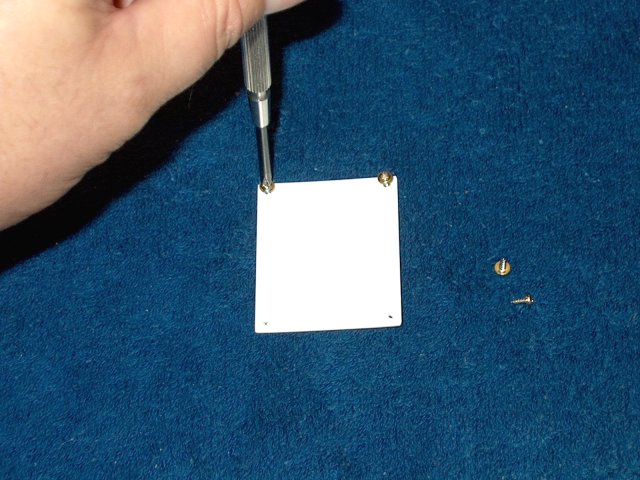

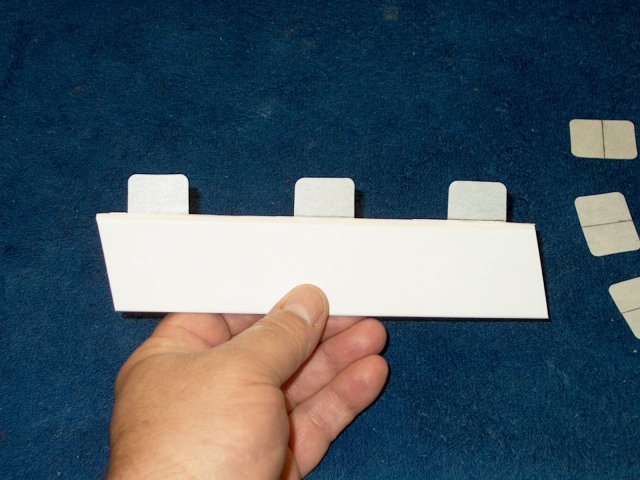

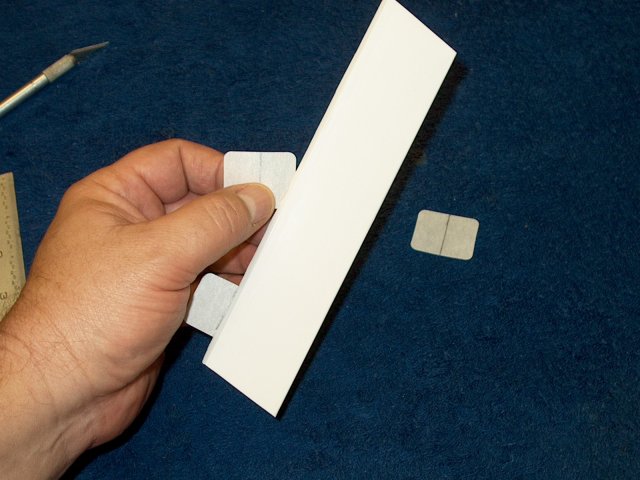

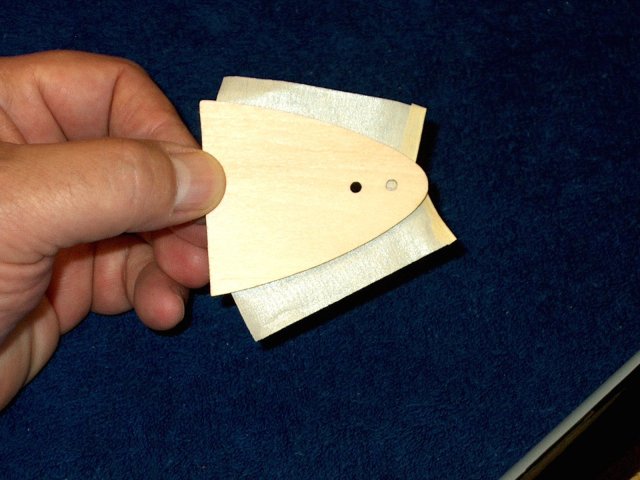

Two servo covers are made from 1/32" ply

and cut to a size of 2 1/8" x 1 3/4". Thin CA is applied to

the corners on both the top and bottom to prevent splintering

when drilled for mounting screws | |

Sand the corners on both sides to a smooth

finish | |

The servo hatch covers are covered with

material to match the bottom of the wing

| |

Make punch marks about 1/8" from each

corner for both servo hatch covers | |

Use a 1/16" drill to open the holes for

the screws | |

Mounting screws included with the servos

are used for the covers and threads are started before

mounting | |

Cover position is marked by centering it

over the hatch and using a piece of tape to help mark

alignment. Do this for both directions

| |

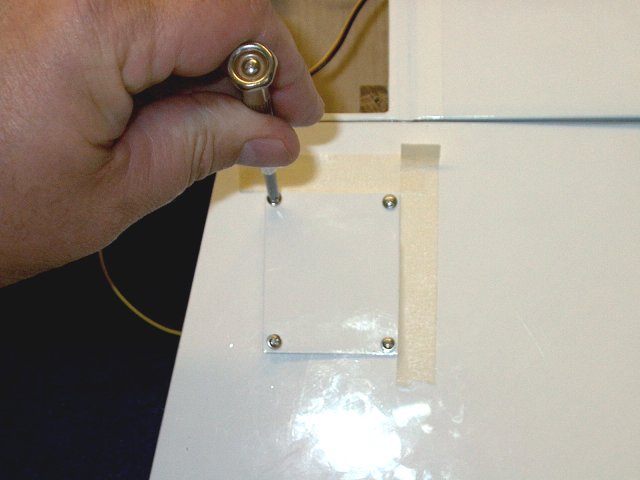

The cover is placed in position, then the

screws are used to tap threads into the balsa. Once completed,

remove the cover and touch each thread in the wing with a drop

of CA to strengthen the hole and allow the CA to dry

| |

Final installation of the Servo Hatch

Cover is shown | |

Another set of 1/2A horns and Clevis' will

be used for the Ailerons | |

The second aileron well is measured and

cut so the servo fits | |

The bottom of the servo well is sanded,

then a mixing stick is used to clear the path for the servo

wires | |

The servo fit is tested, making sure there

is enough clearance for the horn | |

The bottom area is painted wit a thin coat

of CA, then sanded smooth | |

Measurements are drawn for the horn exit

hole, then the hole is cut out with a sharp knife

| |

The servo is centered using a tester or

your receiver. Once centered, install the horn and retaining

washer/bolt | |

Clean the bottom side of the servo with

acetone | |

A piece of servo tape is installed on the

servo | |

The servo tape backing is removed

| |

The servo is installed, making sure the

horn is centered in the slot you cut. Press down to insure a

good bond | |

Install the screws on the second

cover | |

The cover is installed in place over the

servo | |

Aileron servo installation is shown

completed | |

Center marks are drawn on the six very

nice aileron hinges supplied in the kit

| |

Install three hinges in an aileron as

shown | |

Place the aileron over its location and

mark the hinge locations on the fuselage. make sure there is

clearance for free movement on both sides

| |

Open the slots with a knife if

needed | |

Install the Aileron in place. Pins are

used to prevent the hinges from moving during install

| |

Thin CA is applied to permanently mount

the aileron. Make sure there is enough throw without binding

before gluing the hinges in place | |

Excess glue is wiped off and CA is applied

to the hinges from the other side of the wing

| |

Prepare the second Aileron

| |

install the retaining pins

| |

Mark the hinge locations, open them up if

necessary, then install the aileron

| |

Flex the aileron downward to insure ample

throw without binding, then glue the hinges in place on both

sides with thin CA | |

A mark for the Aileron horn is made as

shown. Keep the ruler parallel to the side of the

fuselage | |

A second outer mark was made so the

aileron horn would fit between them

| |

Threads are marked to be shortened on two

2-56 pushrods | |

Pushrods are cut to length as shown

| |

Then end of each pushrod is screwed on the

plastic clevis. A drill makes this go faster

| |

the clevis is locked on the horn

| |

The horn is positioned, then a drill hole

is made | |

A bolt is installed in the first hole to

keep the horn aligned while the second hole is drilled

| |

Both bolts are installed for the horn. Be

sure not to over tighten | |

The excess bolt is cut short on the

underside, then capped with thick CA for safety

| |

The second horn is installed in the same

manner. Note that longer, 3/4" x 2-56 bolts need to be

purchased and used as the ones that came with the clevis' are

too short | |

cap the second set of bolts with a mound

of CA | |

Install a clevis on an Aileron horn, then

center the servo and clamp the Aileron as shown so it is held

to center. Mark the hole location for the z-bend

| |

Make two identical pushrods as

shown | |

Install each pushrod and adjust while the

aileron is clamped to center and the servo is set to center

position | |

Aileron installation shown

completed | |

Nosecone was painted white for a more

scale appearance | |

The rear motor area of the fuselage is

touched up with flat black paint | |

The tailcones were sanded on the outside

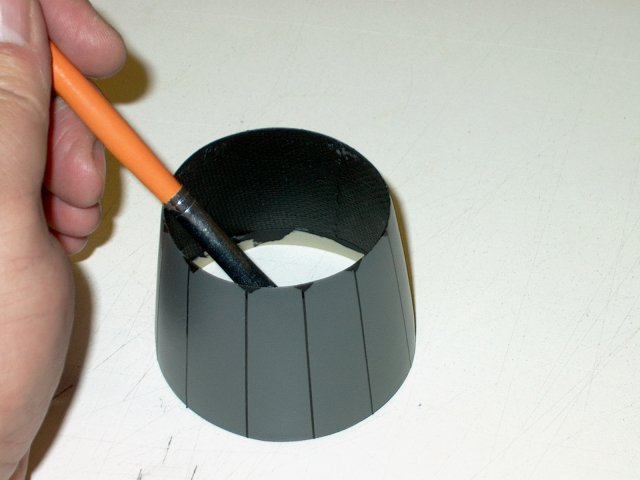

and at each end to smooth them out | |

Each tailcone was painted with flat dark

gray Testors Model Masters spray paint

| |

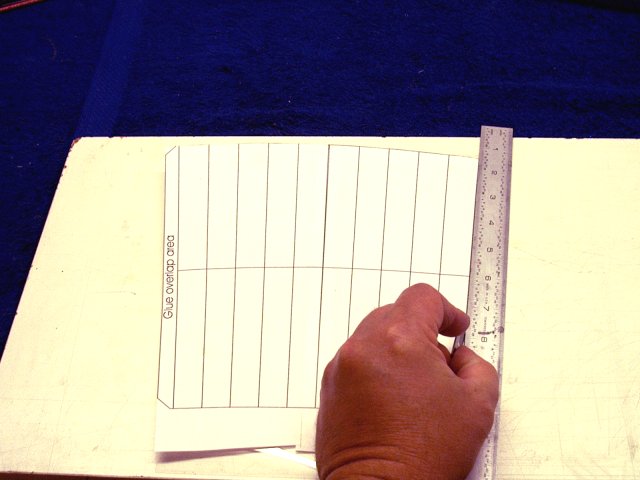

A magazine was used to hold the tailcone,

then a piece of paper was wrapped around and taped. It was

then removed, folded in half and then each half was folded in

thirds and pencil marks were made at all 12 points. It was

then slid back over the magazine as shown

| |

Thin strips of Monokote were cut and

applied, then the ends were trimmed

| |

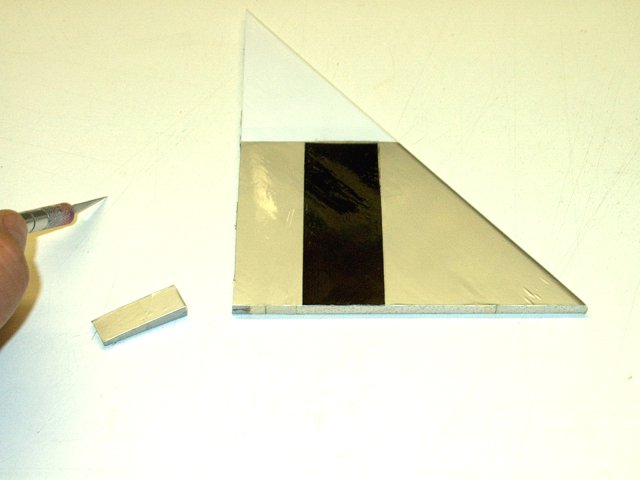

The inside of each tailcone was painted

flat black | |

A section of chrome self stick Monokote

was lightly sanded, then two 1/4" wide strips were cut about

10" long | |

The chrome strips were applied to the

tailcones as shown for a more realistic look

| |

The inside lip of the nosecone is roughed

up with 60 grit sandpaper for better glue adhesion

| |

Tape is used to prevent overspill of glue

that could ruin the finish. Five minute epoxy is applied to

the inside lip of the nosecone | |

The nosecone is installed on the front of

the fuselage and held vertically until the glue set

| |

The inside lip of each tailcone is roughed

up with 60 grit sandpaper for better glue adhesion

| |

Epoxy is applied to the inside of each

tailcone and they are installed as shown

| |

Tailcone installation completed

| |

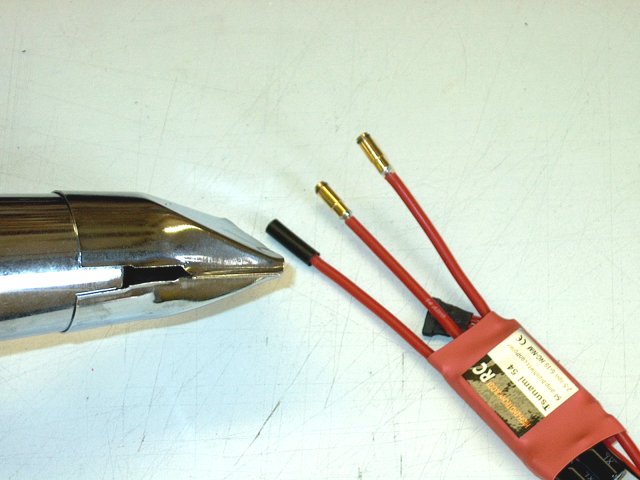

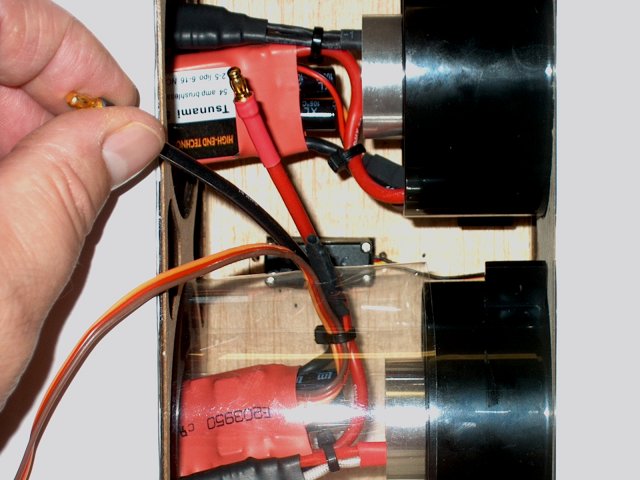

Parts required for each power plant

| |

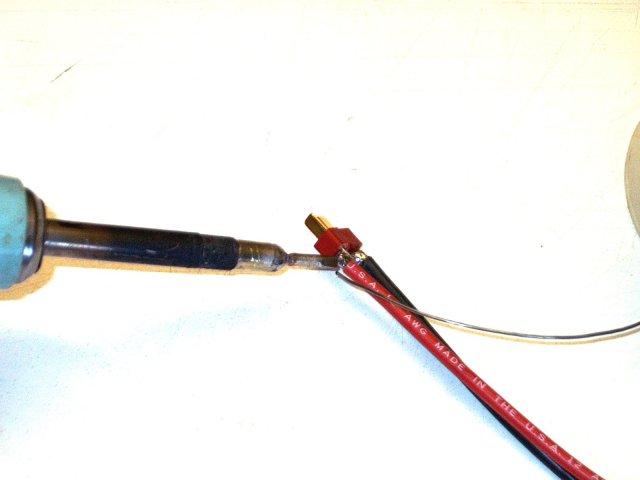

You will be making two power plants, so do

them together. Plugs are soldered to each motor

| |

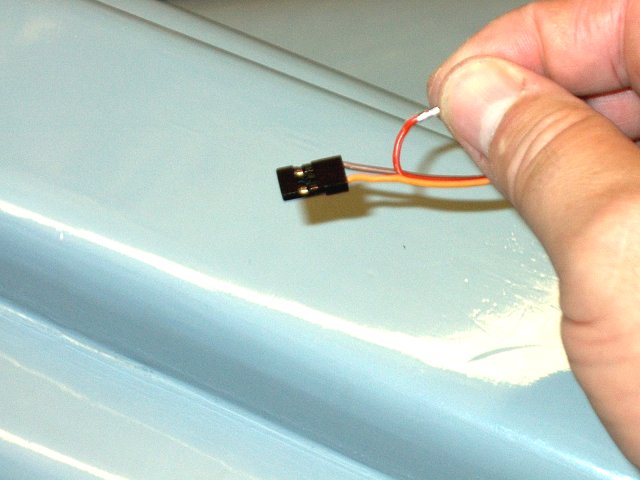

Heatshrink is placed on each wire as

shown | |

Sockets are installed on each ESC

| |

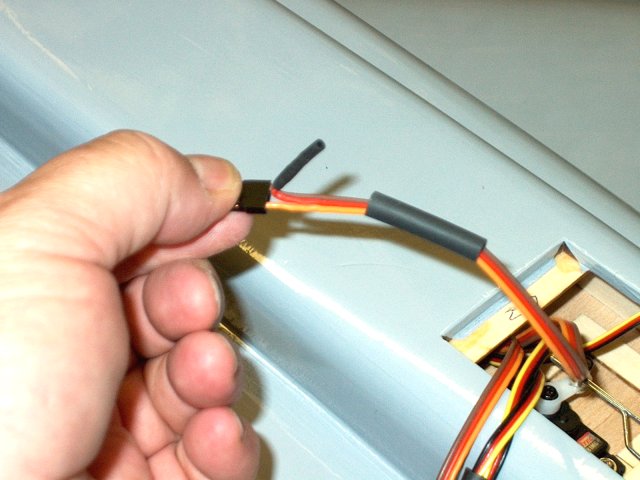

Heatshrink is applied to prevent shorting

of the leads | |

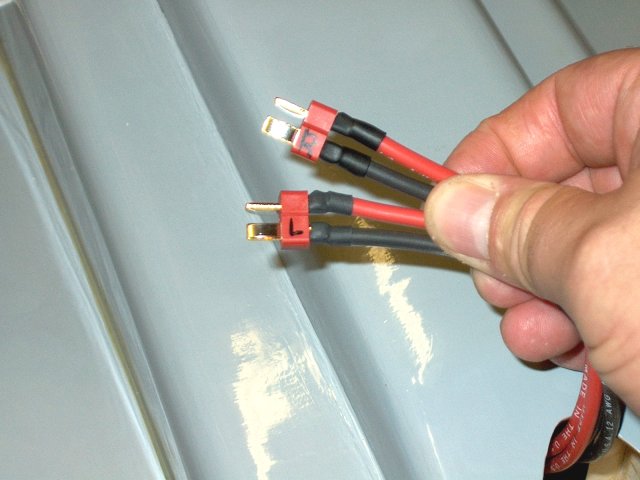

A Power wire is made for each battery

connection, with one end connecting to the ESC, while the

other end has a Deans Ultra plug installed for each

battery | |

Heatshrink is installed on each

plug | |

Two fan units are assembled at the same

time. HET-RC fans were used, so if you use another type of

fan, follow your manufacturer's assembly instructions

| |

Loktite is applied with a toothpick ONLY

to the threads on the motor. DO NOT apply Loktite anywhere it

could come into contact with the fan as it can attack the

plastic in the housing. Never apply Loktite to the bolt

threads | |

Clean up all excess Loktite. Green Loktite

is prefered as it is plastic safe | |

Motor alignment is temporarily

checked | |

The supplied heatsink from the fan unit is

installed on the back of the motor. You may have to heat it

with a torch lighter if the fit is too tight

| |

Install the motor in the fan

assembly | |

Push down on the heatsink so it sits flush

on the back of the motor housing. The inside lip on the

heatsink fits inside the rear of the plastic motor

shroud | |

Tighten the 3.5mm motor mount bolts

| |

The shaft adapter is installed over the

motor shaft | |

Check each fan rotor for balance. HET-RC

fans come pre-balanced, but I had one that was just a bit

off | |

Apply Loktite to the threads of the shaft

adapter | |

The rotor is placed over the shaft

adapter | |

The retaining bolt in installed

| |

Hold the rotor and tighten the shaft

adapter bolt. Make sure the inside back of the fan rotor is

spaced far enough away from the housing so it doesn't bind

when tightened. This completes the Fan Unit assembly

| |

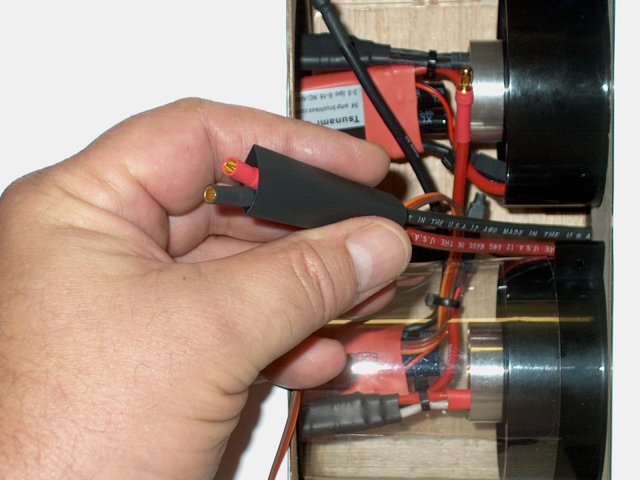

A 1 1/2" long piece of heatshrink is

placed over all three ESC leads | |

The motor is plugged in to the ESC leads

and the heatshrink is used to hold them together

| |

Tie wraps are used to dress the cabling

for each fan unit | |

Both Fan units are shown completed and

ready to install in the fuselage | |

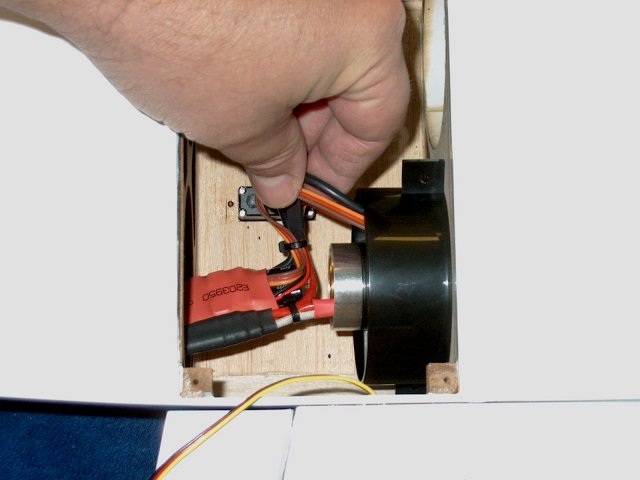

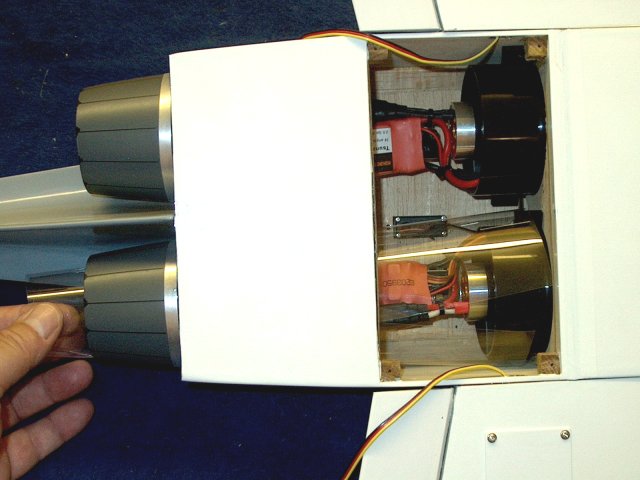

The ESC isinstalled in the rear of the

fuselage so the fan will clear the opening

| |

The fan is installed in the fuselage

intake duct | |

Wires are temporarily run inside the fan

to ease assembly of the exhaust ducts

| |

A thrust tube pattern was printed from the

HET-RC site and used to cut out the pattern for each thrust

tube sheet that was supplied in the kit. The tail was left

extra long so it could be custom fit

| |

The thrust tube shown cut from the

pattern | |

It is inserted through the tailcone to the

fan area | |

Masking tape is used to temporarily hold

it in place tight against the back of the fan and expanded

against the inside of the tailcone at the rear

| |

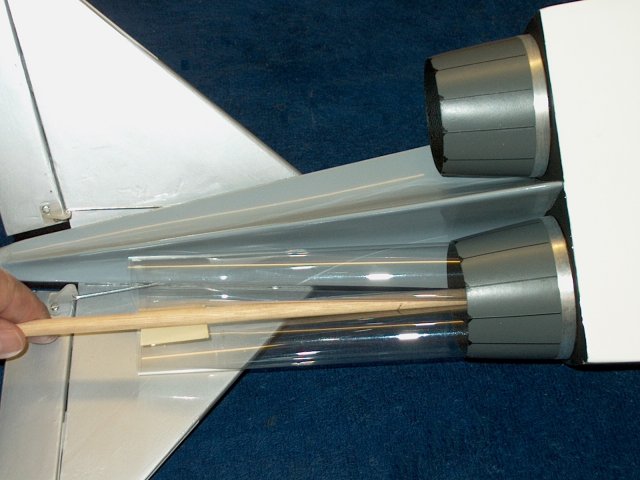

A stick helps fold the tube for easy

extraction | |

1" wide strips of clear packing tape are

used inside and out to permanently seal the seam and a stick

is used to push the tape down on the inside

| |

The thrust rube is inserted in the

fuselage and a mark is made for the location of the ESC

wires | |

The tube is removed and two washers

sandwich the tube and are used as a cutting guide for a wiring

exit hole | |

The thrust tube is inserted back in the

fuselage and the wires are fed through the hole

| |

The thrust tube is then slide on the rear

of the fan unit | |

Power wires Deans Connector end is fed

through the hole to the cockpit area

| |

A piece of heatshrink is slid over the

power wires | |

The power wires are connected to the ESC

connectors | |

A tie wrap is used to align the

connectors, then Heatshrink tubing is installed over the two

connectors | |

A 3/4" piece of packing tape is used to

bond the thrust tube to the rear of the fan shroud

| |

The thrust tube is cut flush to the rear

of the tailcone | |

The second fan thrust tube is built and

installed just as the first | |

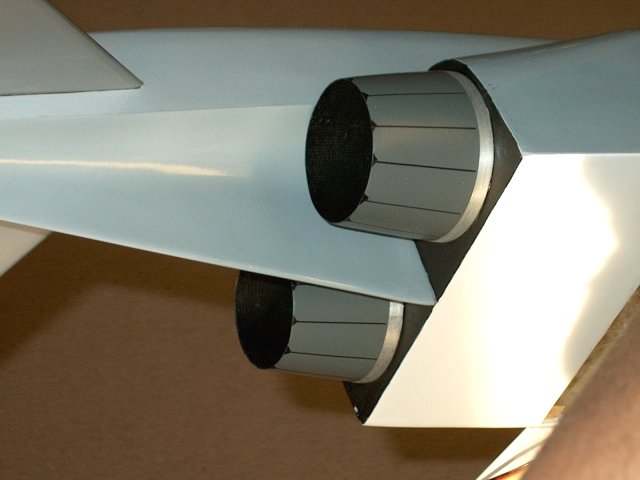

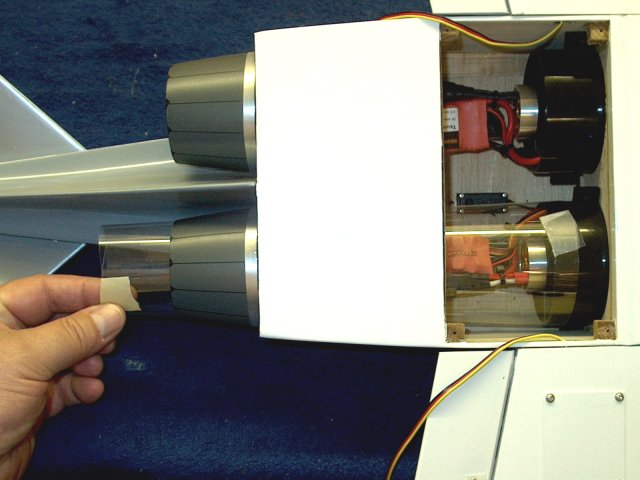

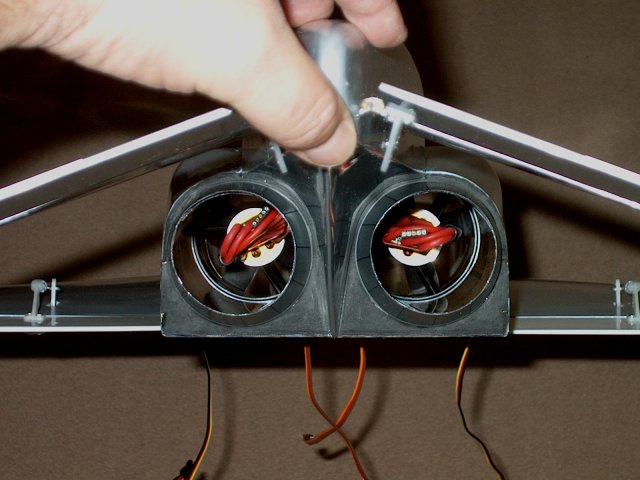

Rear of fuselage showing completed fan

assemblies and thrust tubes | |

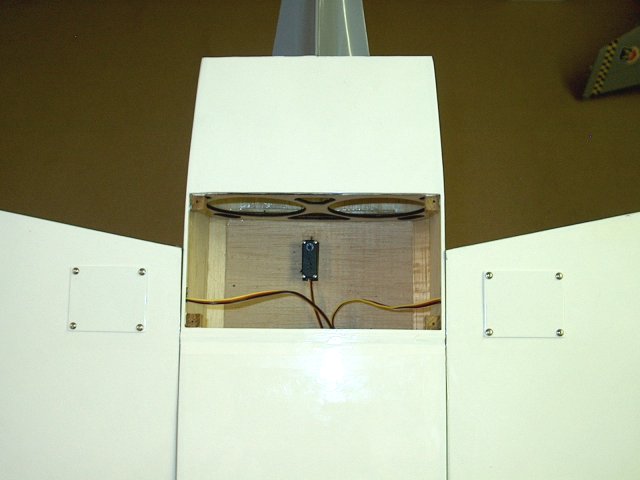

The hatch is temporarily installed to

check for fit | |

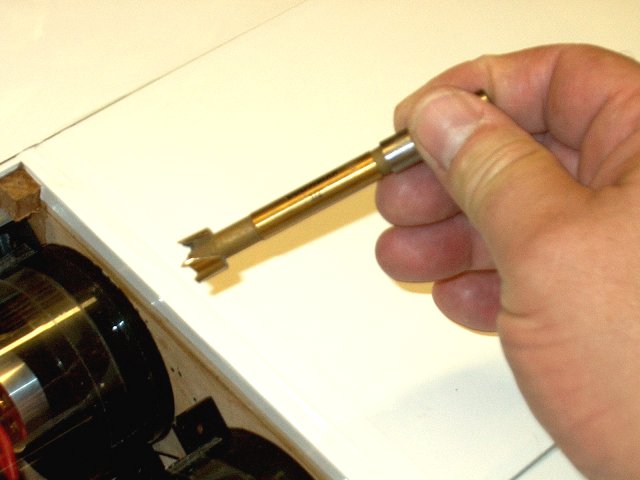

A 1/2" boring bit is used to cut an exit

hole for the servo wires. You can also use a sharp

knife | |

Cut the hole between the fans as

shown | |

Excess balsa cap is removed from the top

side in front of the Elevator servo

| |

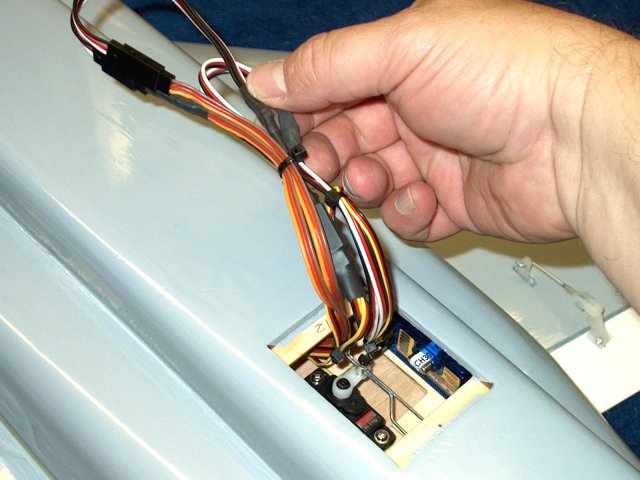

Feed the servo wires through the

hole | |

Clear silicon is used to bond the fan

units in place. It can be cut away if access is ever

needed | |

Fans are now fastened to the

intakes | |

Two balsa strips that are 1" x 3/8" x

3/16" thick were made to support the cover, which was bowed in

the middle | |

Balsa strips are glued in place with CA to

help hold flush the bowed center of the hatch cover

| |

The hatch cover is installed

| |

A tie wrap is used to anchor the bottom

entrance of the servo wires | |

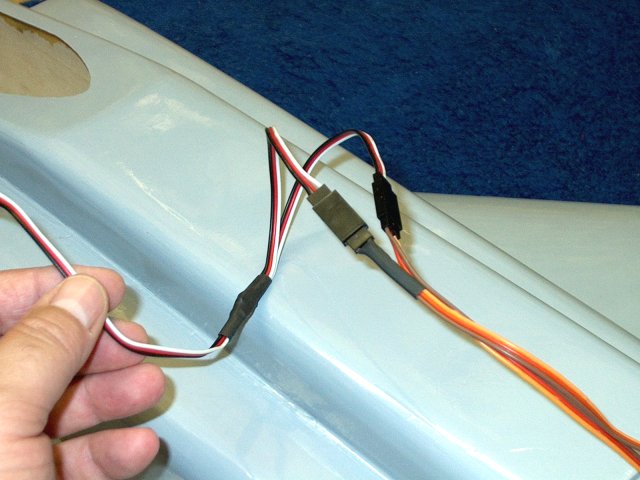

Two "Y" connectors are required, one for

the Aileron servos and one for the ESC's

| |

The two Aileron servo leads are

installed | |

A large piece of heat shrink tubing is

used to prevent the connectors from coming apart

| |

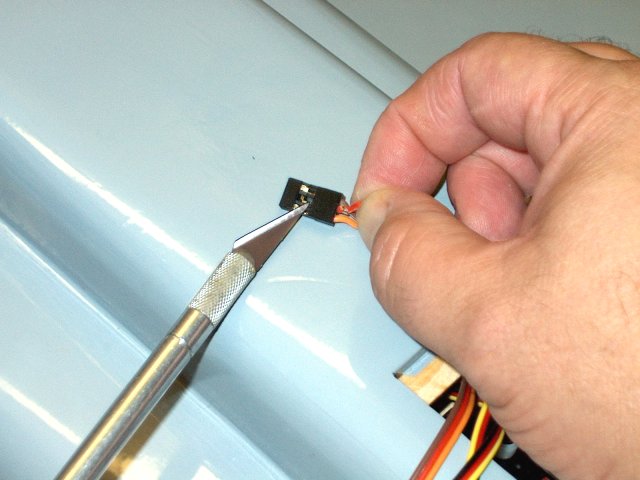

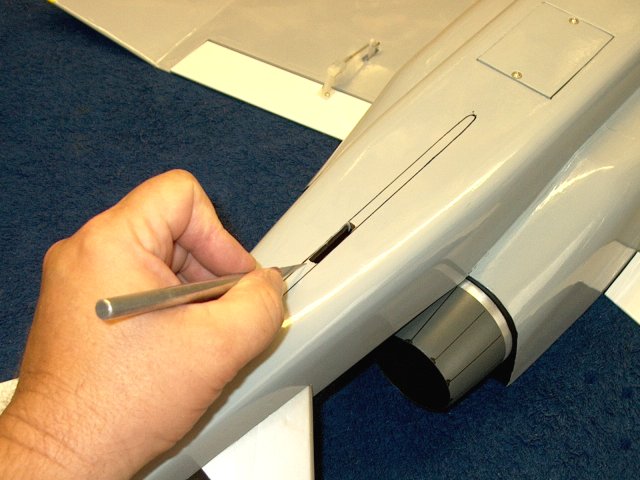

The center red wire lead is removed from

only one of the ESC's as the receiver needs to only be powered

by one ESC. Use a knife as shown to pry up the end of the

plastic clip that is holding in the connector

| |

The red wire has been removed

| |

Heat shrink is used to cover the connector

so it won't snag or become damaged | |

Another piece of heatshrink is used to

dress up the wire | |

Connect both ESC's to the other "Y"

connector | |

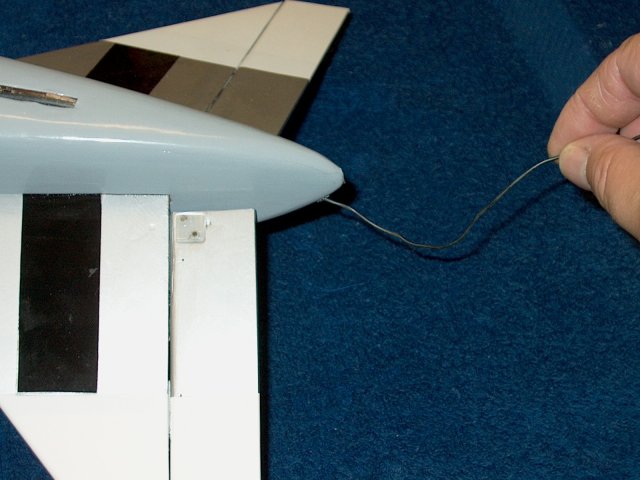

The receiver antenna will exit the bottom

rear of the fuselage, so a small punch is used to mark the

location | |

A 1/8" long drill is used to make a

hole | |

The drill should just exit the rear slot

as shown | |

A wire is used as a guide and the antenna

sleeve is installed | |

Use a screwdriver to push it down and to

the side of the receiver location | |

A small piece of 3/16" thick balsa is cut

to make an anchor for the antenna sleeve and CA is used to

glue it to the sleeve | |

The front of the sleeve is glued in place

with CA as shown | |

The end of the sleeve is cut flush to the

fuselage | |

Baby Powder is used to lubricate the

antenna wire so it slides easily through the sleeve

| |

The wire is fed through until it begins to

exit | |

The antenna wire is then pulled out the

end | |

Two layers of servo tape were applied to

the back of the receiver | |

The receiver was installed in place. Note

that 1/8" of the upper balsa angle in the fuselage needed to

be removed so it would sit flush to the side wall

| |

A 1/8" hole is drilled for a retaining

dowel | |

The servo wires are plugged into the

receiver | |

Wire ties are used to dress the assembly,

then they are fed forward into the fuselage

| |

The retaining dowel is installed as shown,

then cut flush with the top of the shelf. Do not glue the

dowel in place | |

The dowel is used to hold the receiver

servo wires away from the Elevator pushrods

| |

Receiver installation is completed

| |

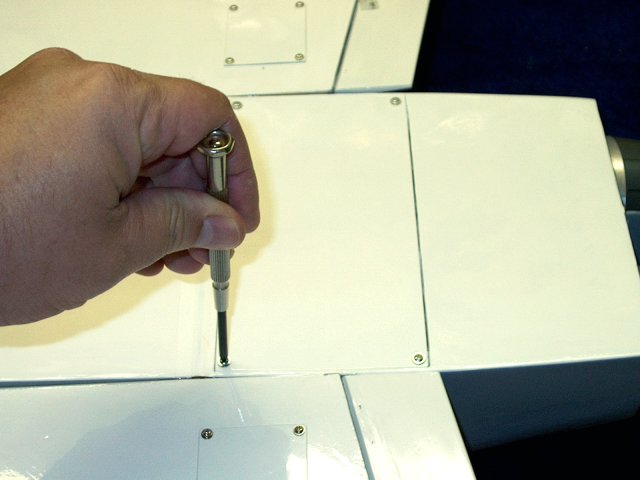

Install the access cover

| |

Label your power connectors for each motor

for easy identification | |

The intake streamers are held in place and

a mark is made on the bottom of each streamer as shown

| |

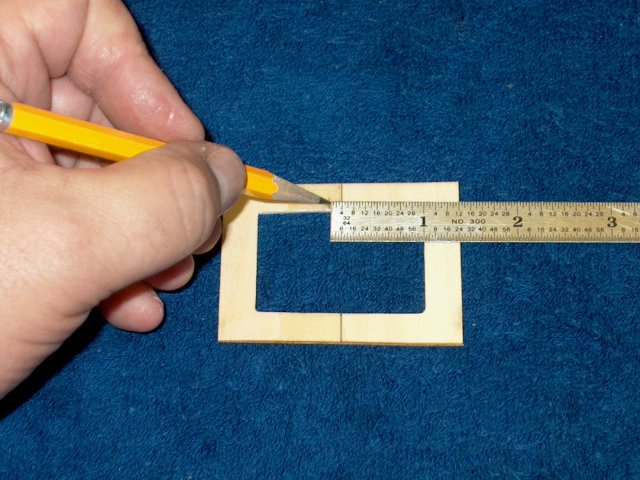

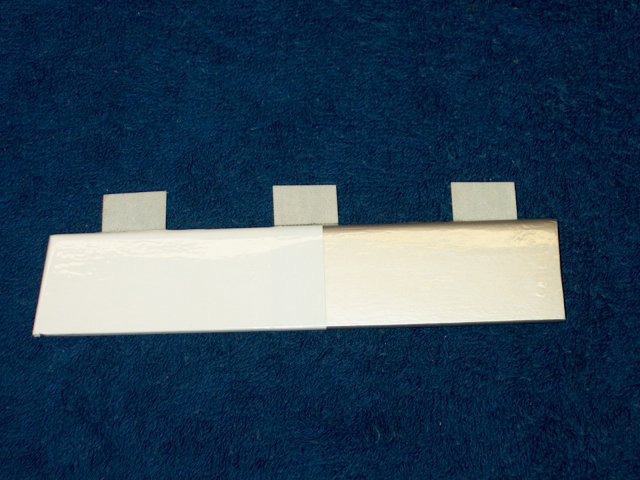

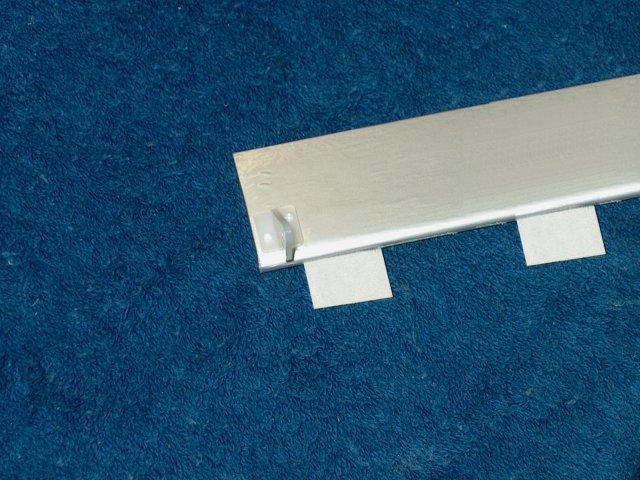

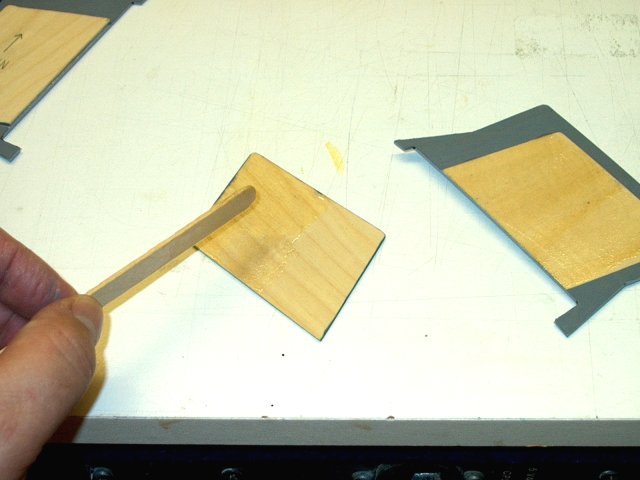

A 1/16" piece of plywood is used to make

some spacer plates | |

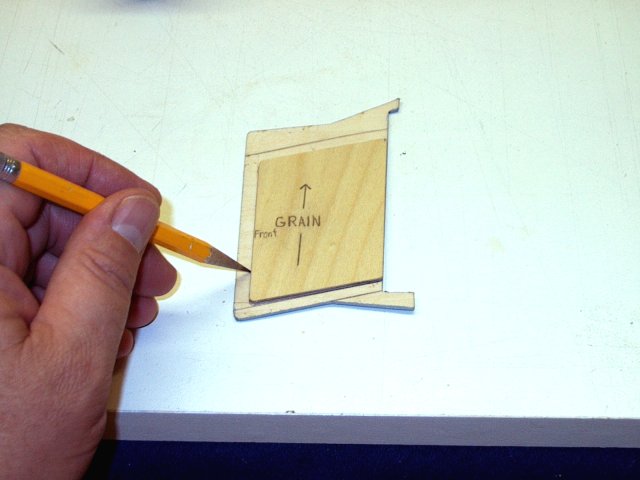

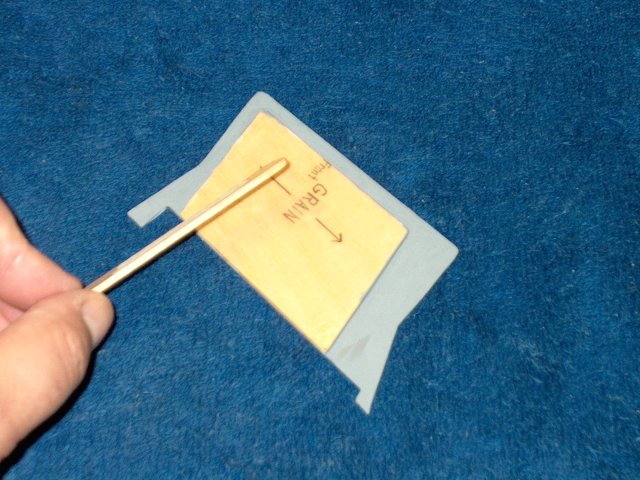

It is important to note the grain

direction. One of the streamers were warped and by using a

cross grain, it will stiffen and straighten them out

| |

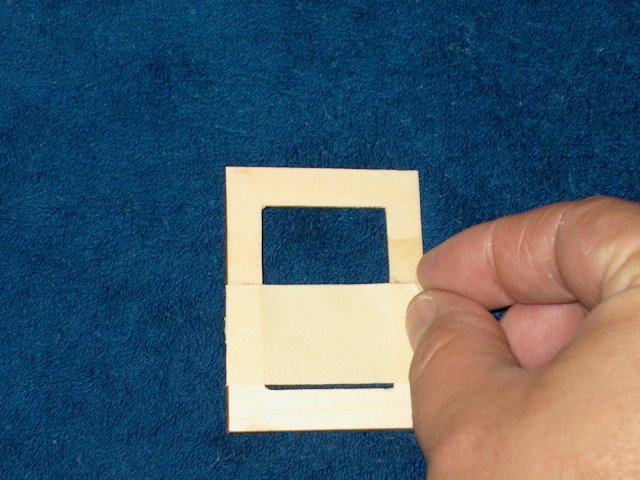

Make two spacer plates as shown. The

spacer plates should be cut 3/16" shorter than the front and

sides of the streamer exposed areas and the rear should sit

flush with the streamer rear | |

The outline of the spacer is drawn on the

streamer. Note the 3/16" clearance on the front (shown left)

and sides | |

Gray paint is used to color the area of

each streamer plate that will be exposed

| |

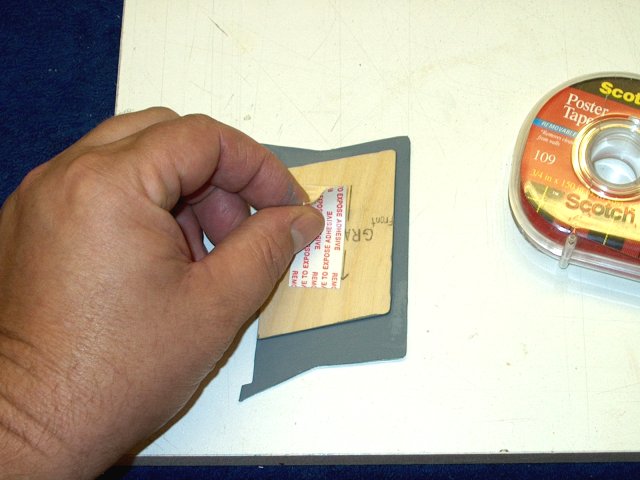

Double sided poster tape is applied to the

spacer. Make sure the spacer plate is in the correct position

as shown | |

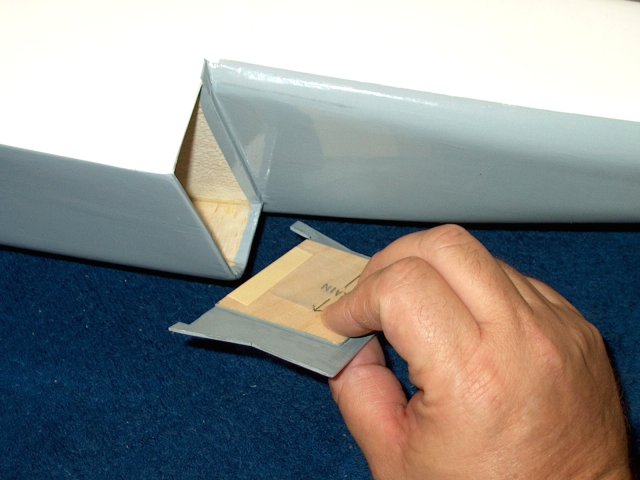

The assembly is held together and

installed in place | |

A marker is used to transfer the outline

of the spacer to the side of the fuselage

| |

Cut about 1/16" inside the line that was

drawn. Be careful to only cut the covering and not the

balsa | |

Remove the excess covering

| |

Draw lines can be cleaned with denatured

alcohol and a paper towel | |

A thin coat of epoxy is applied to each of

the streamers and spacer plates. Be careful to make sure you

are applying epoxy to the correct side of the spacer plate,

which is the side that faces the streamer

| |

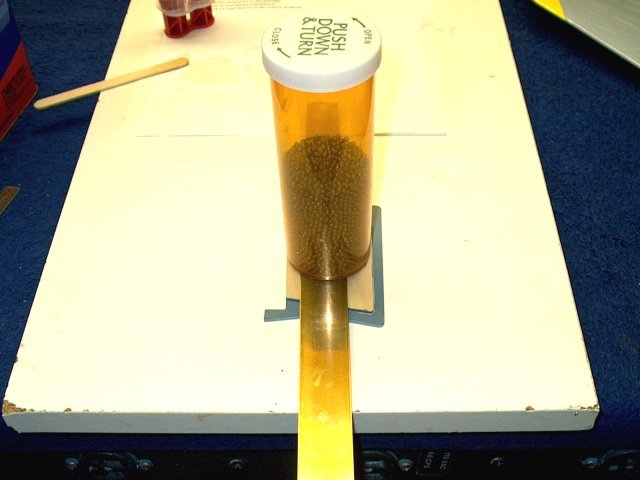

The spacer plate is positioned correctly

on the streamer. The assembly is weighted down while the epoxy

sets; this will help straighten out any warping

| |

Epoxy is applied to the plate

| |

Position the streamer flush sgainst the

intake | |

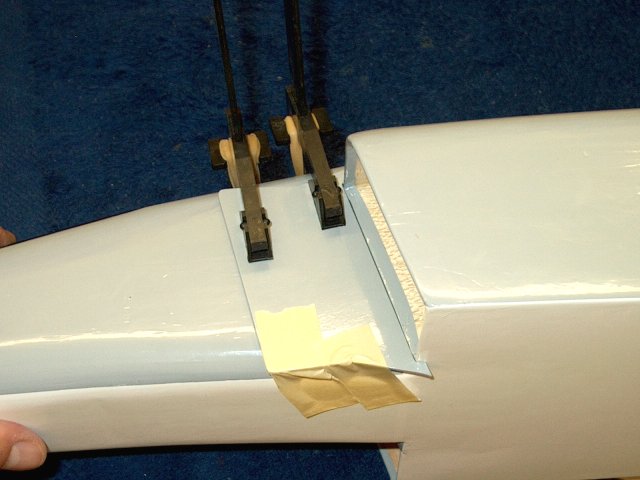

Tape and clamps are used to hold the

streamer in place while the epoxy sets

| |

The other side is completed in the same

manner as the first | |

Streamers shown installed

| |

Use a knife to remove excess covering from

the bottom of the vertical stab | |

Check your stab on a flat board and make

sure it sits flat. Repair any bowing by bending the piece

straight and shrnking with a heat gun

| |

The bottom of the stab may need to be

sanded for a good fit | |

Check for no gaps at the fuselage

joint | |

Install the stab and trace its shape on

the fuselage with a marker | |

Cut the covering inside the pattern line

for the stab | |

Remove the covering from the

fuselage | |

The marker lines can be cleaned up with

denatured alcohol | |

The stab seams are sealed with an

iron | |

Masking tape is applied to the fuselage to

keep it clean of excess epoxy | |

Masking is also appied to both sides of

the stab and it is ready for epoxy | |

15 minute epoxy was used and applied to

the bottom of the vertical stab | |

Epoxy is also applied to the

fuselage | |

Install the stab in place

| |

Excess epoxy is cleaned with

alcohol | |

Use a square to check stab

alignment | |

Remove the tape and clean up any

additional epoxy before it sets | |

Masking can be used to hold the vertical

stab perpendicular to the surface | |

Vertical stab installation shown

completed | |

A T-Pin is pushed through the pin hole in

the towhook hardwood block to locate the hole under the

covering on the outside | |

The hole is drilled with a 5/64"

bit | |

Rough up the side of the towhook that will

be glued. Slightly bend the hook to an outward angle so the

towline will easily drop off | |

A toothpick is used to apply epoxy to the

hole and hook | |

The towhook is installed in the fuselage.

Do not install it too deep; the top of the towhook should just

exit the hardwood block inside | |

Towhook shown installed. Insure it is

pointing straight back | |

Appy epoxy to one side of the small piece

of plywood for the cockpit | |

This plate is installed as shown, with it

centered and the rear flush to the opening in the frame

| |

A second piece shown on the left was cut

from 1/16" ply as wide as the first piece and 1 1/4" long.

Epoxy is applied to the first piece for fastening

| |

The second ply plate is installed flush at

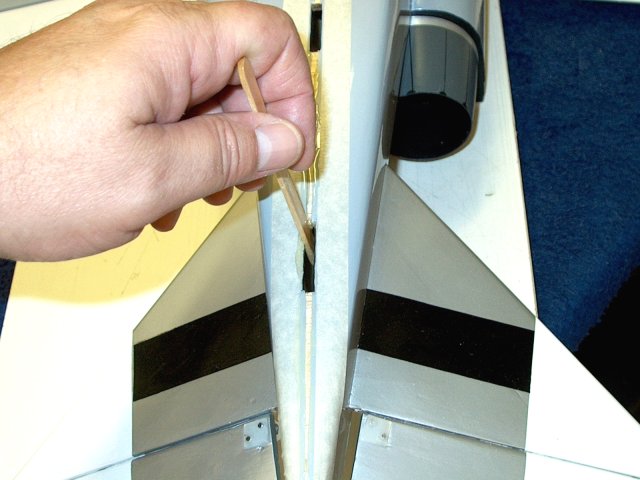

the opening and even with the sides so it can hook under the

front of the fuselage cockpit area | |

Center the shelf with the front of the

fuselage, then mark and drill a 1/8" hole in the center of the

plate as shown | |

Apply epoxy to a 1/8" wooden dowel and

insert it into the hole so it slightly protrudes out the

bottom of the fuselage | |

Once the epoxy sets, space the dowel with

a ruler and cut it flush as shown | |

Open up the hole in the shelf so it is a

slot and fit it to the dowel. This will keep the front of the

cockpit centered when installed | |

Tape is applied to the short cockpit

piece | |

This plate is secured in place as

shown | |

Install the cockpit ply shelf in place and

make sure it is centered in the front and rear, then hold both

rear pieces together with one hand and drill through both

holes with a 1/8" bit | |

Two 1/8" wood dowels are cut about 3/4"

long and inserted in the small plate. Apply epoxy to the small

plate and use the dowels as guides to connect it to the

cockpit shelf | |

The two pieces are clamped together until

the glue sets, then the dowels are cut and sanded flush on

both sides | |

The shelf is hooked in the front and

should drop in place at the rear. Draw a center line at the

rear of the shelf | |

Make a mark with a punch about 3/8" from

the end | |

Use a 3/16" drill and make a hole through

both pieces | |

Remove the shelf and cut the hole to a

rectangle so the magnet is a nice and tight fit

| |

Install the shelf, make sure the front of

it is centered and transfer the rectangle shape to the

fuselage opening | |

A piece of masking tape is applied to the

bottom of the shelf, then epoxy is applied to the edges with a

toothpick. Install the magnet flush to the tape and apply

epoxy to the top to fill the hole. The toothpick can be used

to insure the magnet is pushed down and seated flush with the

tape | |

once the epoxy sets, remove the tape and

clean the bottom exposed surface of the magnet

| |

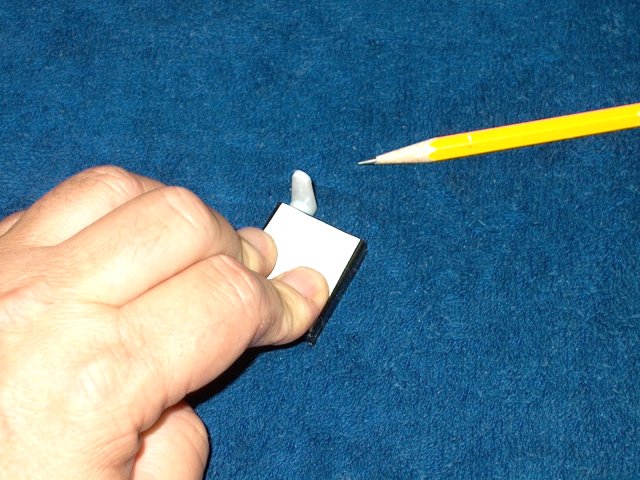

Cut a 1/2" square piece of ply, then apply

epoxy to the ply square and hole in the fuselage. Masking can

be used to hold the ply square in place underneath the hole

inside as shown. Check the magnet direction with the one on

the shelf, then install it in the opening in the correct

direction. The shelf is used to make sure the magnet is flush

to the top of the fuselage | |

The magnet is now installed flush with the

top of the fuselage. Clean up any excess epoxy with

alcohol | |

Tape is a nice tool to use when marking an

outline of the canopy shape for cutting

| |

Cut out the canopy as shown, leaving a

little extra for fitting. Sand the edges and deburr them until

the canopy fits well | |

Install a piece of plastic wrap in the

fuselage area and cut a slot in the plastic for the front hook

so it can engage. Detail the cockpit if you wish before

fastening the canopy. Use canopy glue or clear silicon to

attach the canopy to the cockpit. Masking can be used to hold

the canopy sides to the cockpit. This completes the cockpit

installation | |

Set the Elevator throws for 10mm up and

down | |

Set the Aileron throws for 10mm up and

5mm-10mm down | |

Make balance marks for CG on the fuselage.

CG is at 150mm from the front leading edge if the wing

| |

Make a tray for your battery packs. A thin

ply plate and velcro works well. Position the plate in the

fuselage for good balance with the batteries in place and glue

the tray in the fuselage | |

This completes the basic build of the

HET-RC F-4 Phantom | |

A Detailed Cockpit was built as shown. It

can add some realism to the model | |

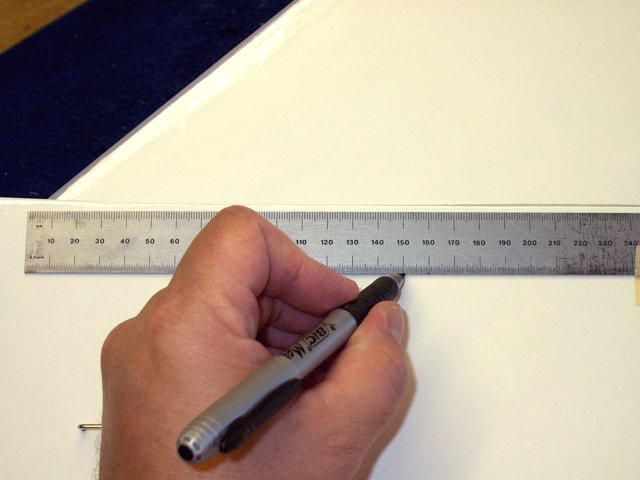

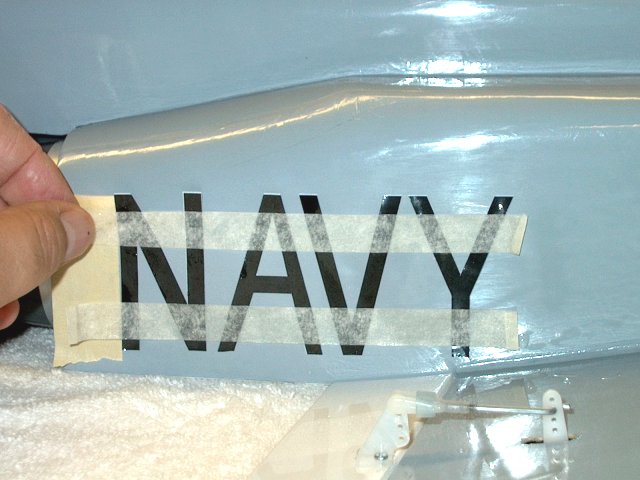

Rulers are used to keep decals aligned

during application | |

Some decals are cut letter by letter for

realism, using masking tape to keep them spaced

correctly | |

Finished front end decals are shown

| |

Top View. The F-4 in the pics was

recovered in Dove Gray Monokote | |

Side View. Once all decals are applied,

Testors Clear Dullcoat paint was used to flat out the Monokote

for a more realistic military look | |

The HET-RC F-4 Phantom Twin Minifan EDF

Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |