1 - The F-20 as it comes in the

box.

|

|

2 - The HET-RC ARF Minifan 480 sized F-20

Tigershark shown out of the box

| |

3 - The major components of the model are shown.

It is very similar to the HET-RC FA-18 in construction and covering

Tigershark.

| |

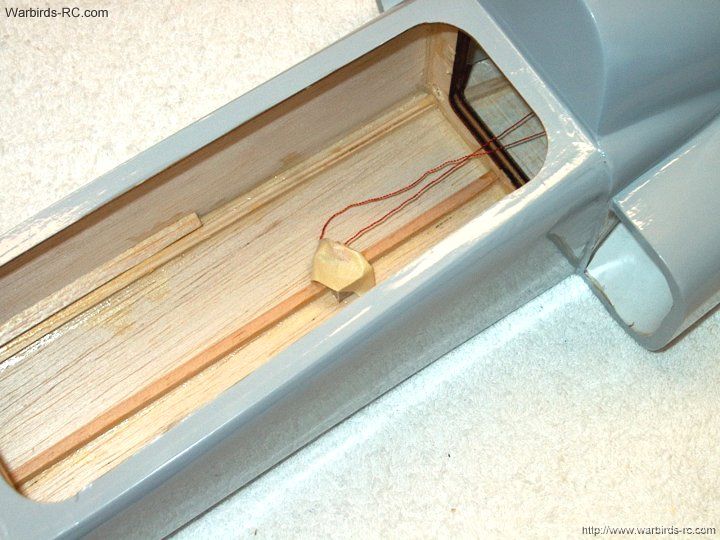

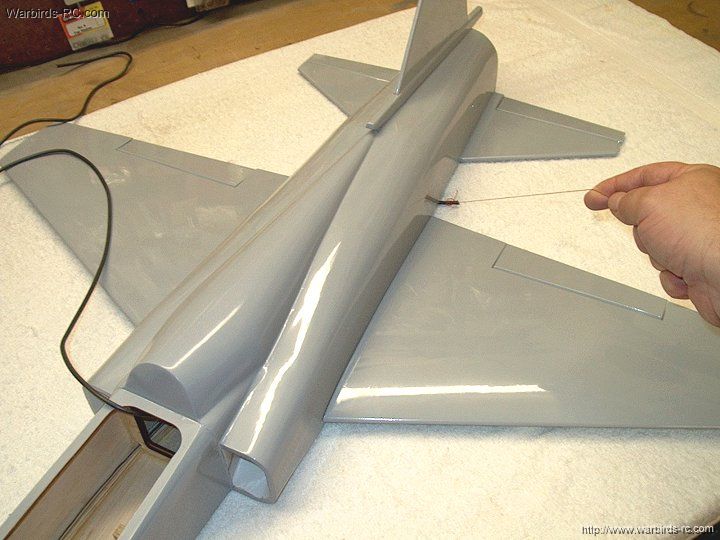

4 - The model comes complete with pre-strung

red cord wire pullers

CG. | |

5 - The Elevator area shows bolt mounts for

easy alignment

| |

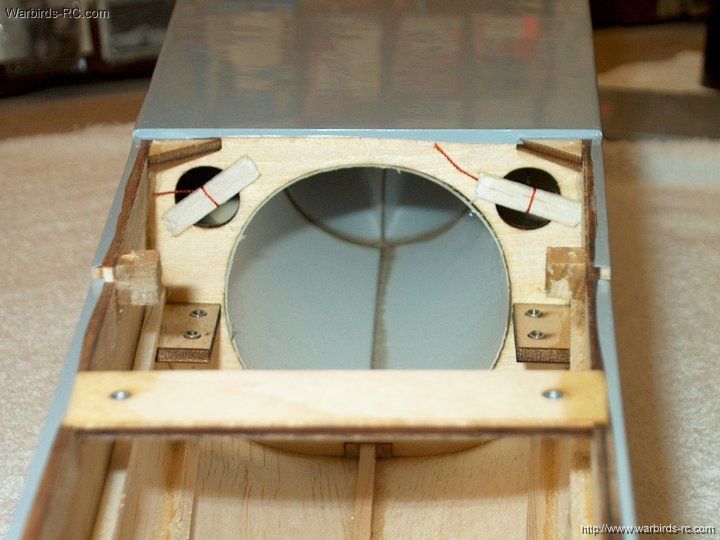

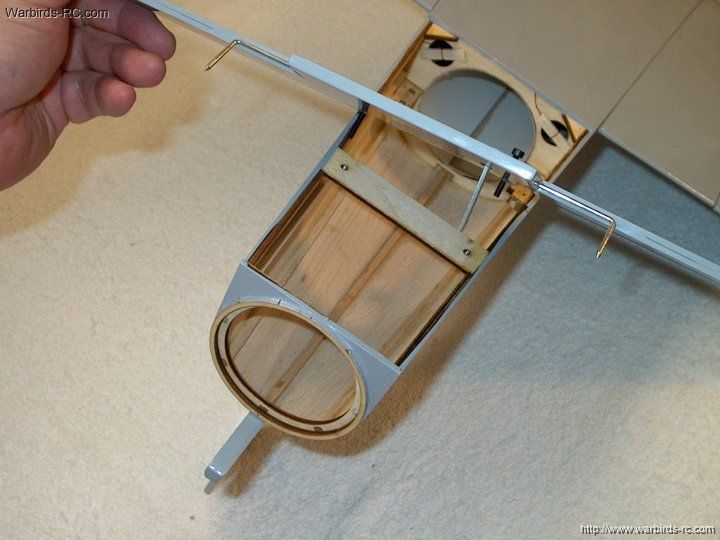

6 - The fan area with blind nuts pre installed

for fan mounts

| |

7 - The other end of the red cord wire pullers.

These ports are used for Aileron servo leads, ESC power wires

and Receiver antenna

| |

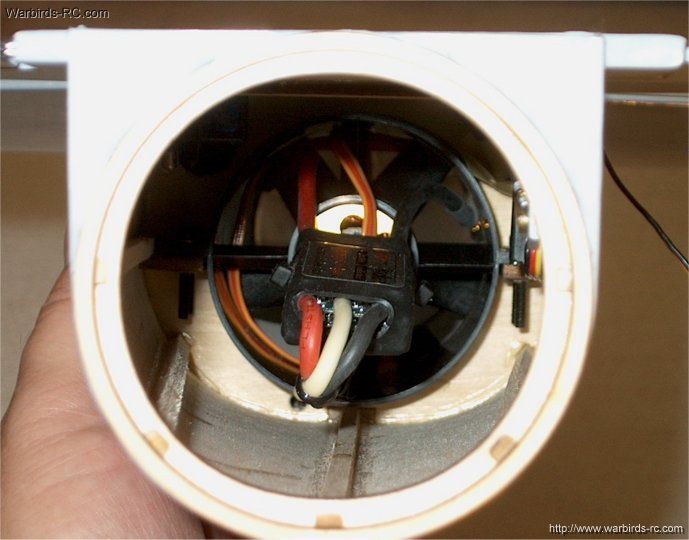

8 - Shown is a view of the ducting area from

the end of the model

| |

9 - Aileron Servo bays come already cut under

the covering

| |

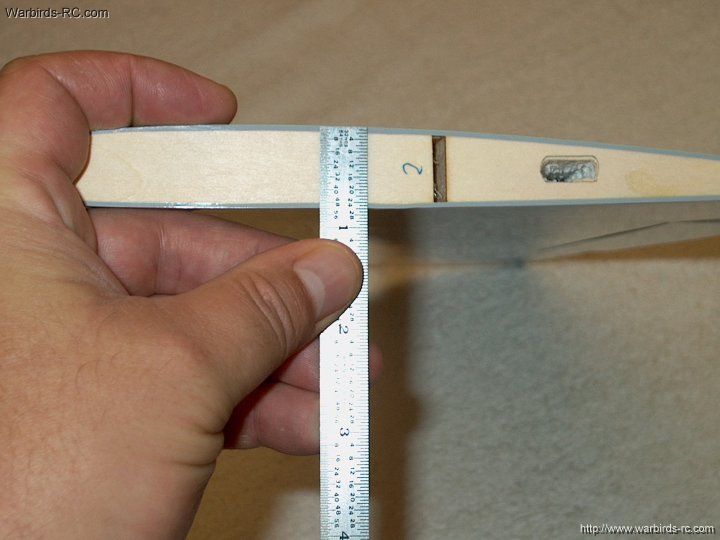

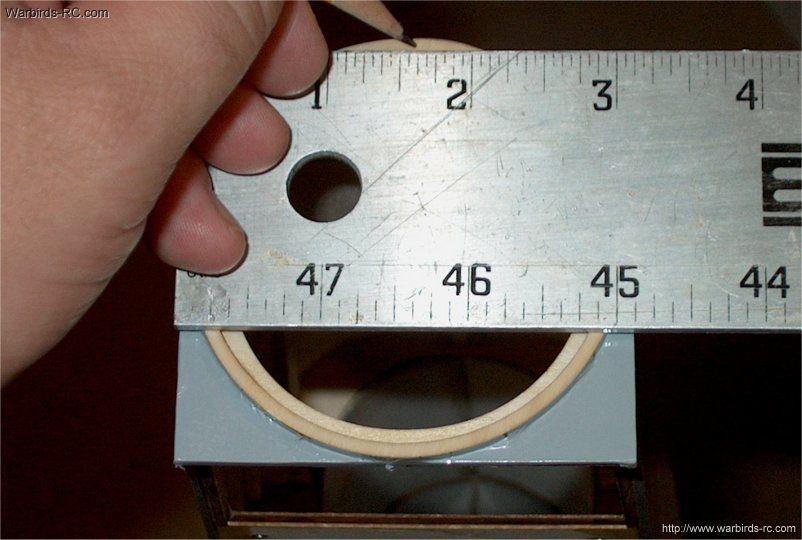

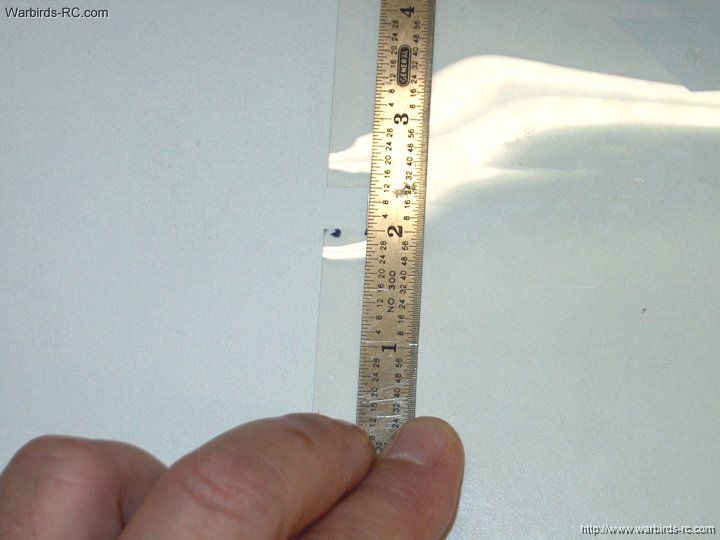

10 - The wing cord is 13/16" thick, which

makes it a good candidate for Retracts

| |

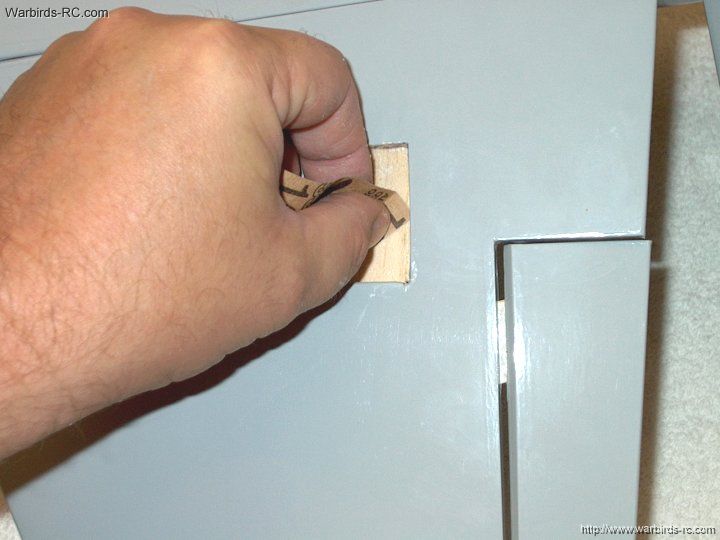

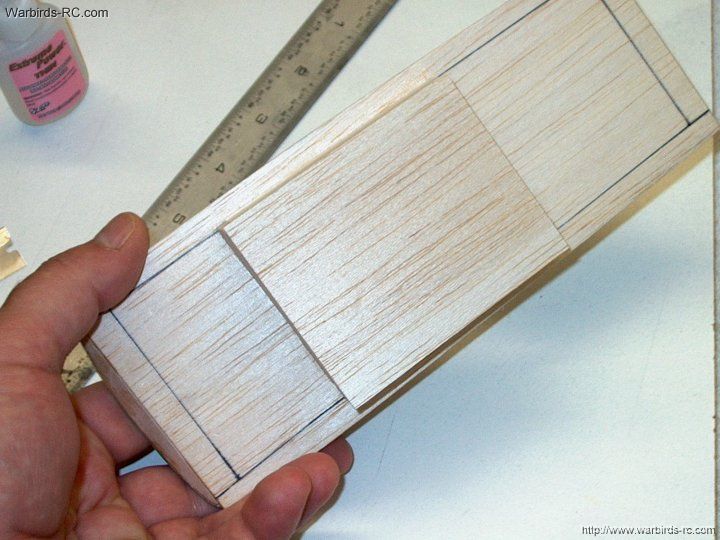

11 - Time to build...Start by trimming

away the covering from the Wing Spar and Aileron Servo holes

| |

12 - Clear the holes of covering

| |

13 - Insert wing spar with the angled edge

facing downward in the fuselage. It is keyed inside so you can't

get it wrong

| |

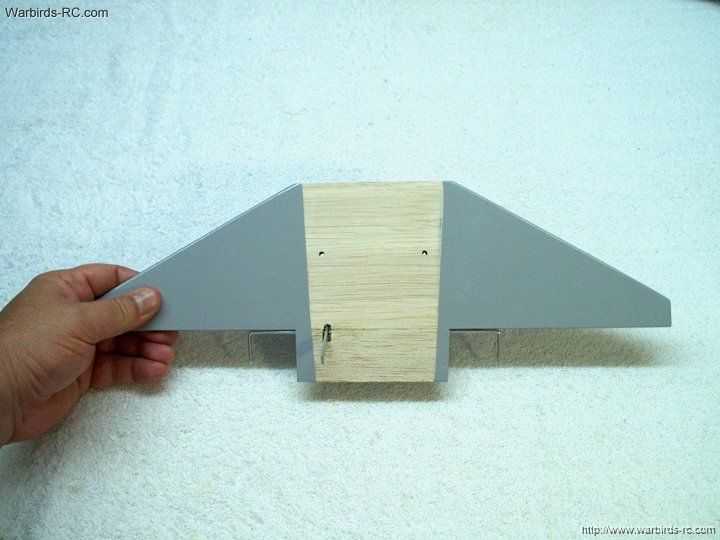

14 - Temporarily install the wing

| |

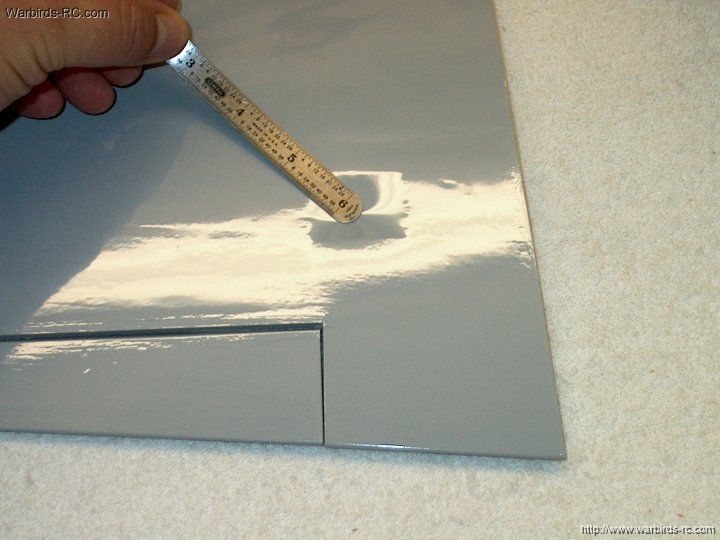

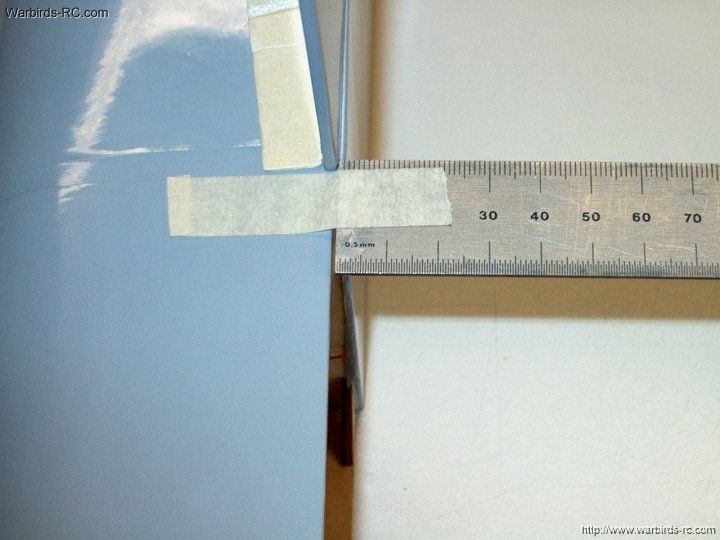

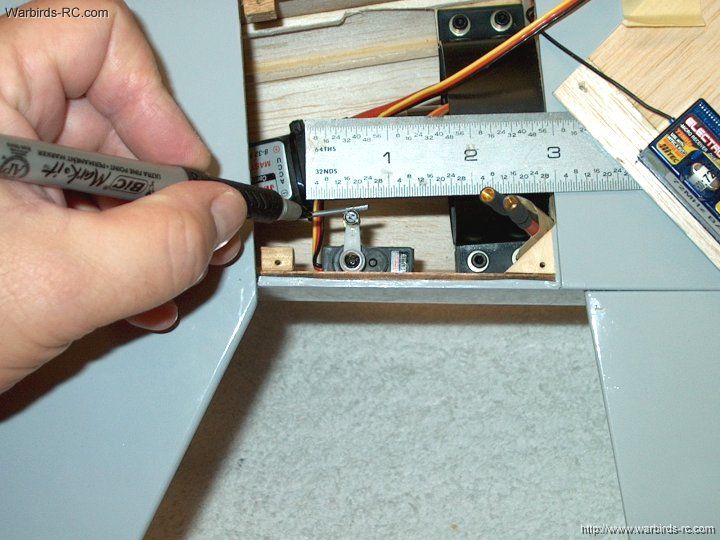

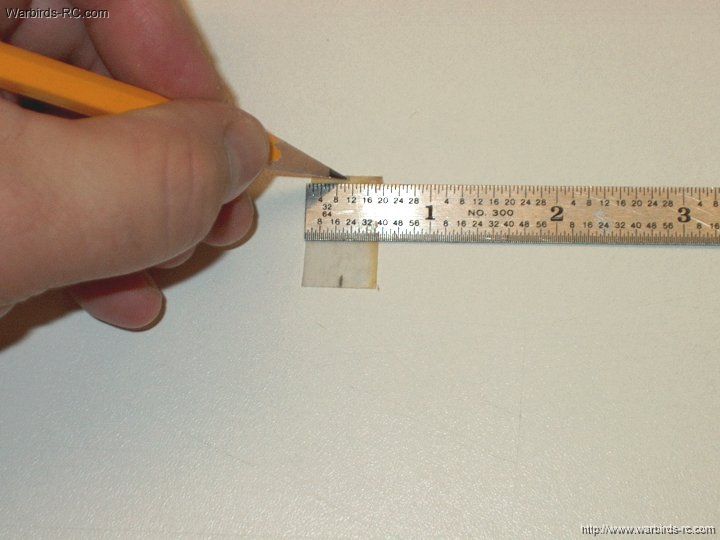

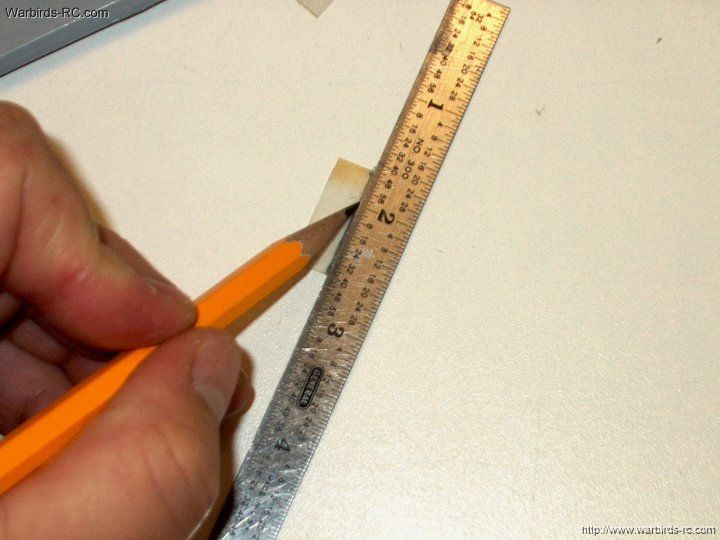

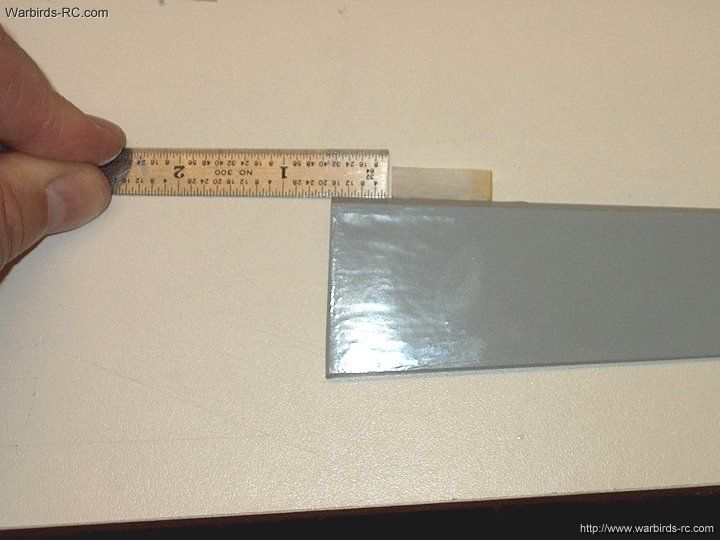

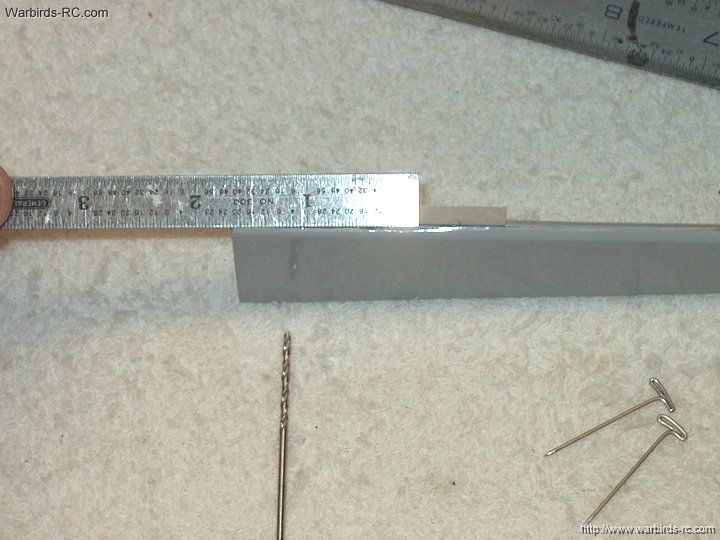

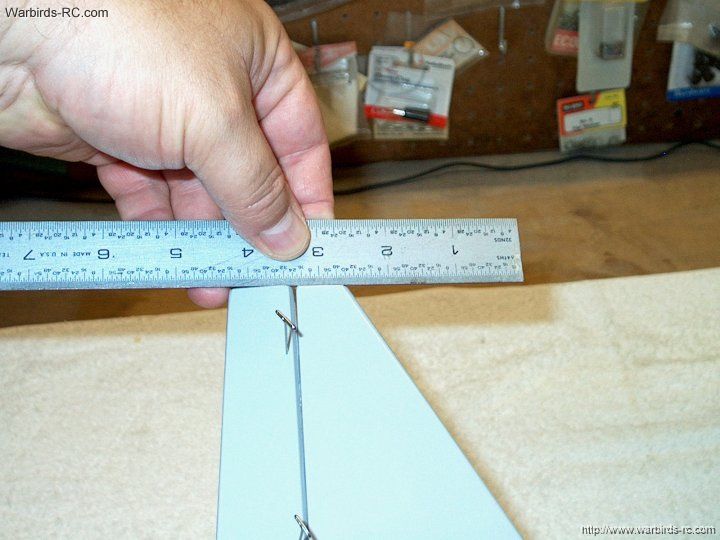

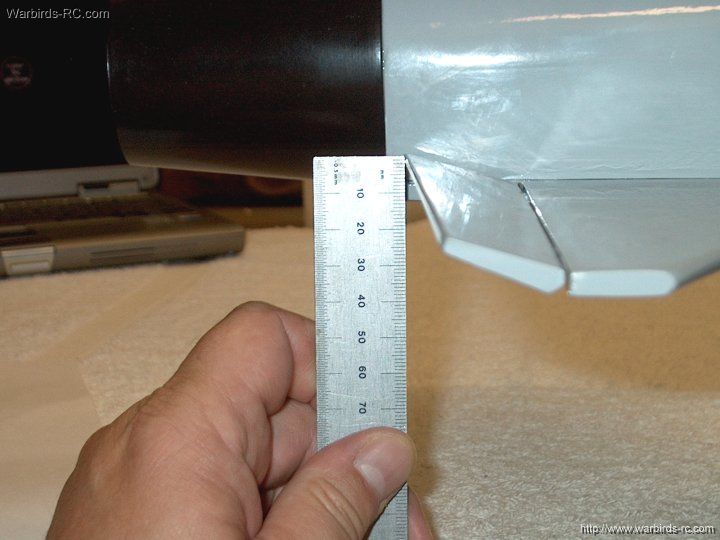

15 - Rig a ruler to measure wing position

| |

16 - Build up a piece of masking tape with

about 4-5 layers. This will be used as an anchor for the wing

root position

| |

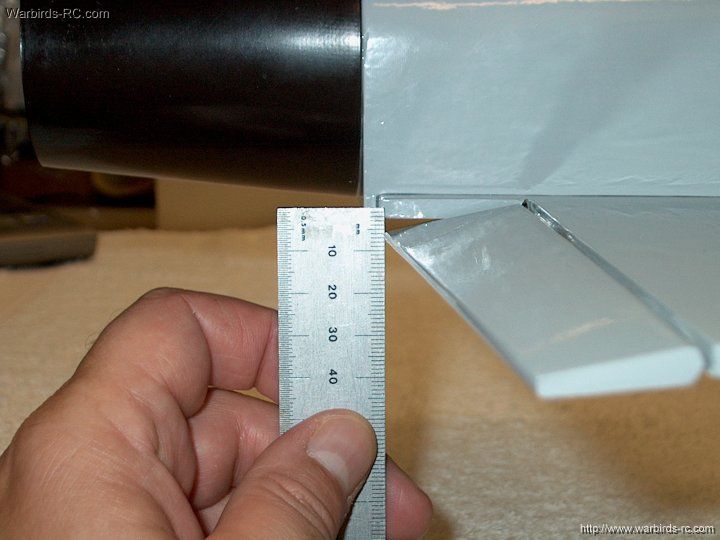

17 - The rear of wing is positioned 1MM from the

bottom of the fuselage. Place some "built up" masking tape

on the side of the fuselage to keep the wing from shifting up (left)

| |

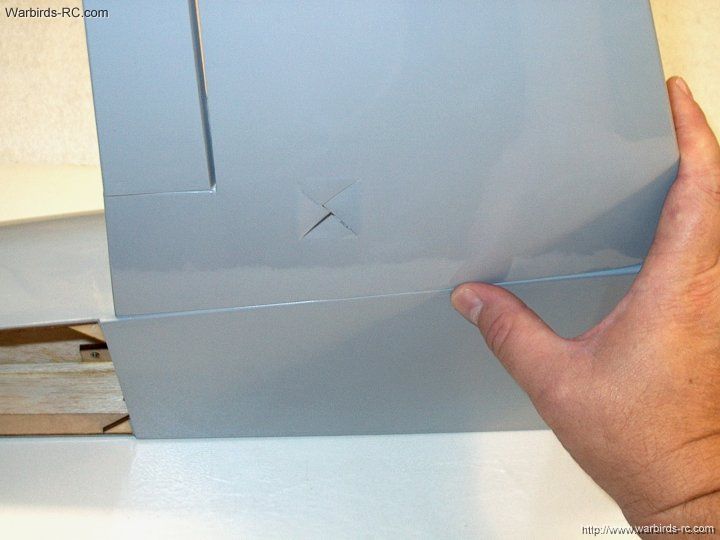

18 - The wing is supposed to be 1mm up from

the fuselage at the rear (left), then flush against the bottom where

it's chord dips (left of thumb) and then it curves upward to a

center of 10mm at leading edge

| |

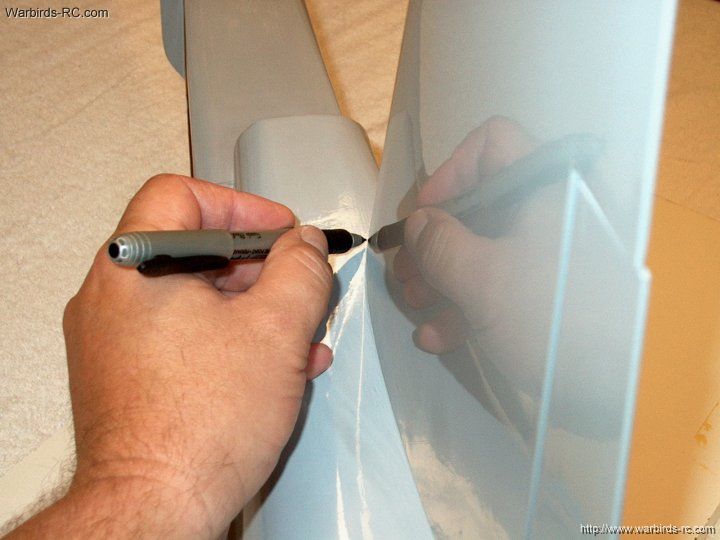

19 - Use a marker to draw the position of

the spar

| |

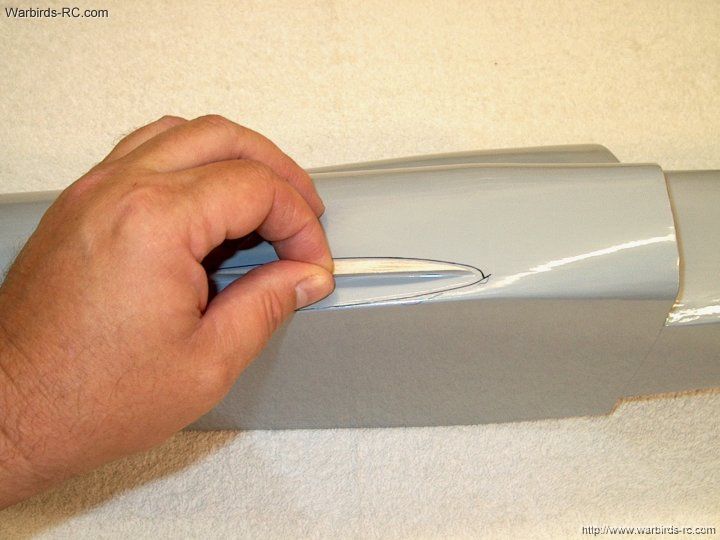

20 - Your wing position should appear

as shown

| |

21 - Cut the covering inside the mark

so the wing can be mounted to the fuselage

| |

22 - Remove the covering

| |

23 - Open up the aileron servo hole

| |

24 - Remove the marker with alcohol

| |

25 - The side should be clean and ready

for wing mounting

| |

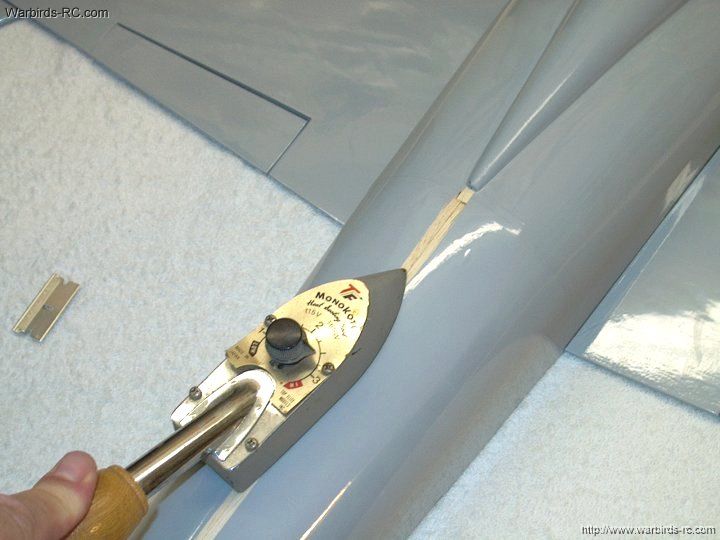

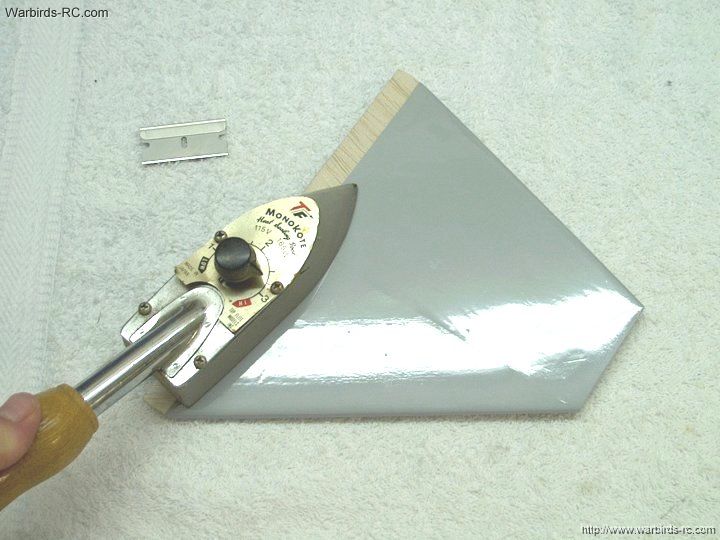

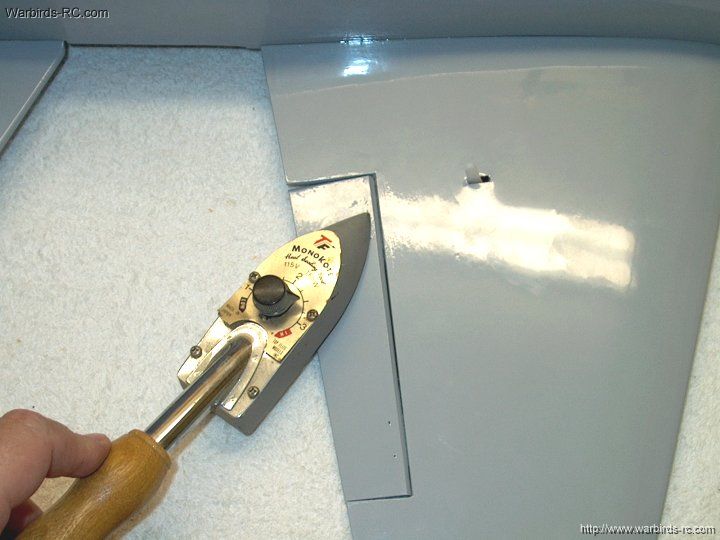

26 - Use an iron to seal the edges of

the covering

| |

27 - Apply epoxy to the exposed area and

wing spar slotted hole

| |

28 - Apply epoxy to the wing root and spar.

Note that due to the much wider wing chord, holes need not be

drilled in the wing

| |

29 - Install the wing on the fuselage

| |

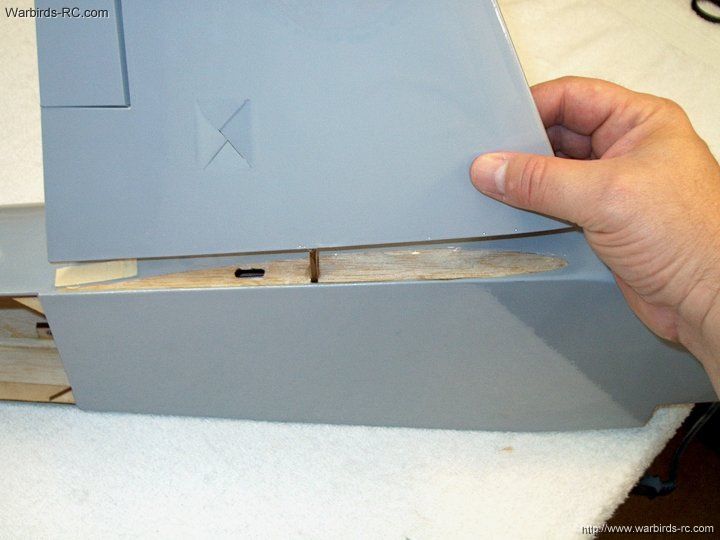

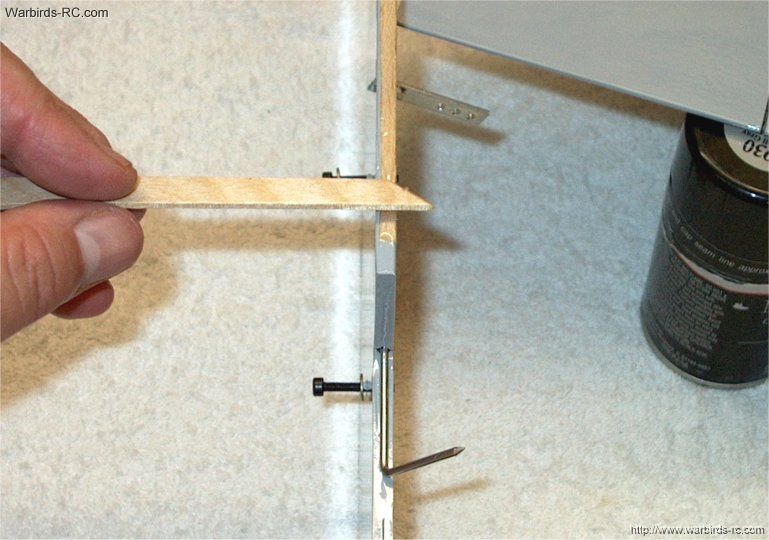

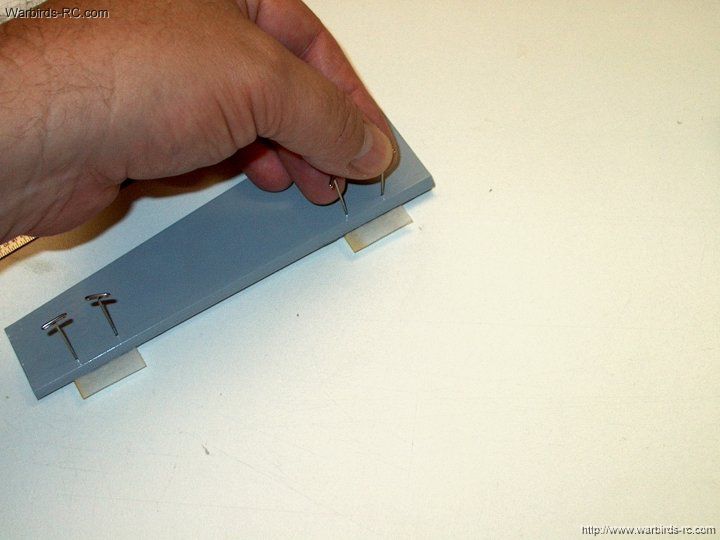

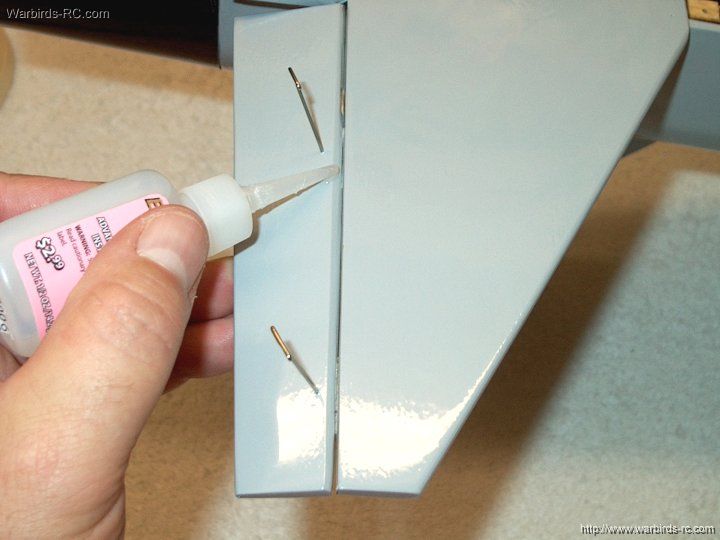

30 - Pin the rear of the wing to hold the

position at 1mm from the bottom and hold it up against the

masking tape jig. Also note the wing is flush to the bottom

of the fuselage near the center. Leave it like this until

the epoxy cures.

| |

31 - Install the wing. The wing

has a slight dihedral, so it is ok if it seems to lean

slightly upward

| |

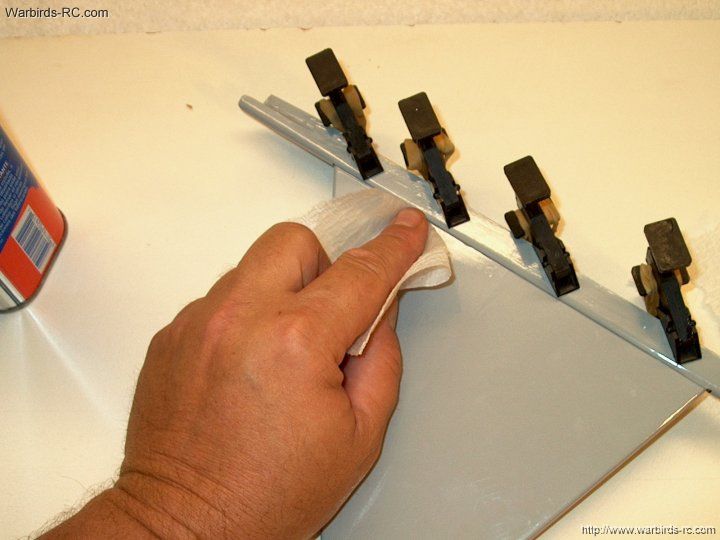

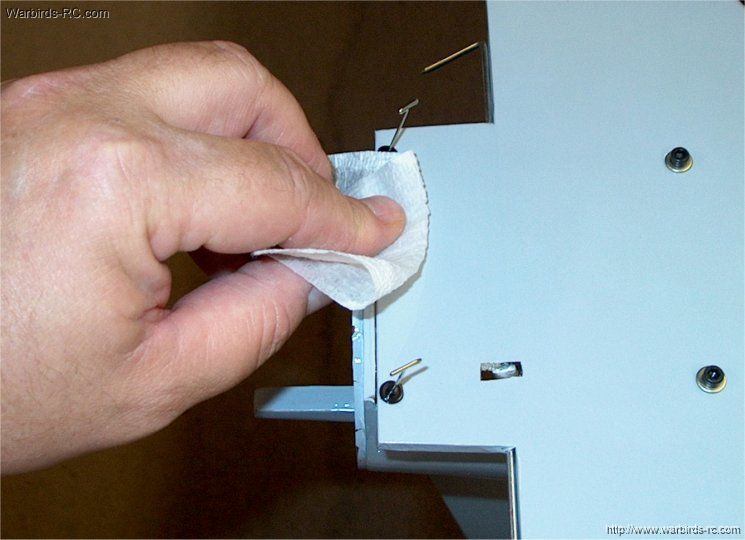

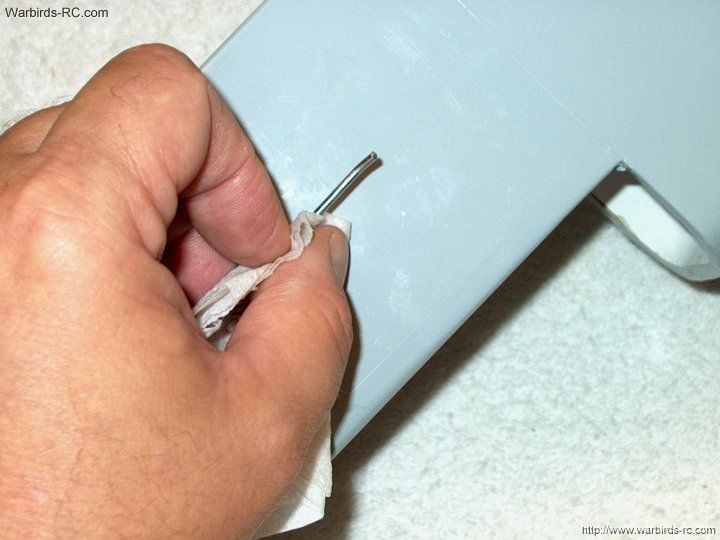

32 - Remove excess epoxy with alcohol

before it sets

| |

33 - Once the wing set, use extra epoxy

to fill any small gaps. Remove the excess with a paper towel

dampened in alcohol

| |

34 - Position the other wing and mark

the chord

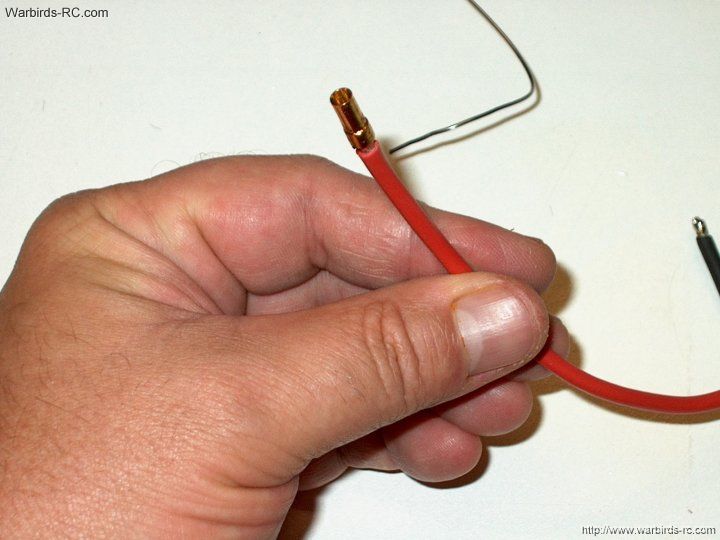

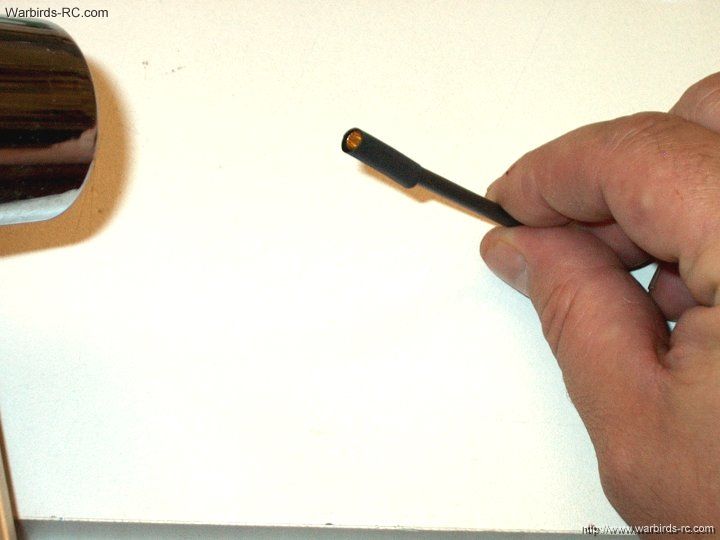

| |

35 - Remove the excess covering

| |

36 - Open up the aileron wire hole and iron

the edges

| |

37 - Apply epoxy to the wing saddle on

the fuselage, as well as the spar

| |

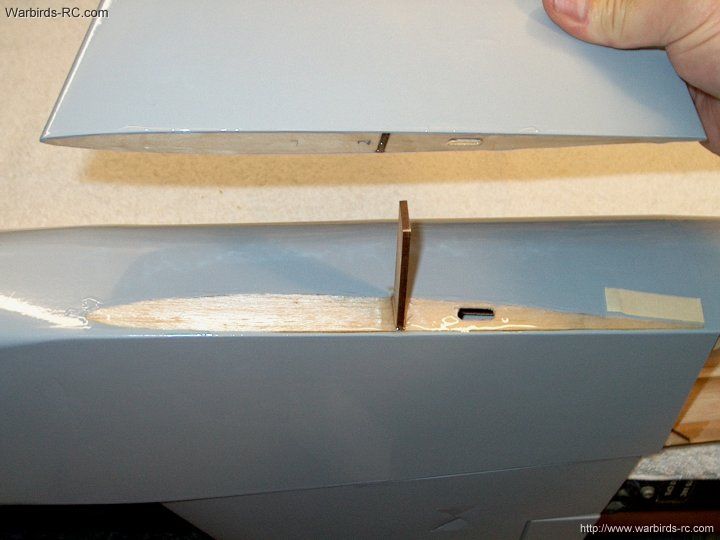

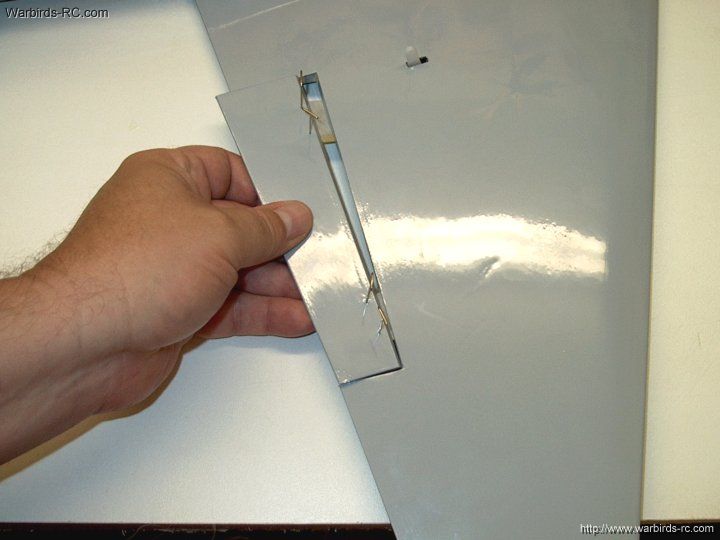

38 - Pin the rear of the wing to hold the

position at 1mm from the bottom and hold it up against the

masking tape jig. Also note the wing is flush to the bottom

of the fuselage near the center. Leave it like this until

the epoxy cures.

| |

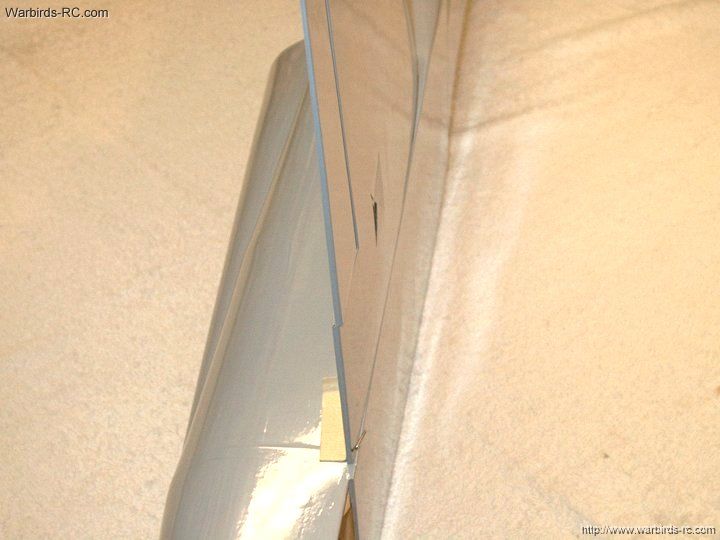

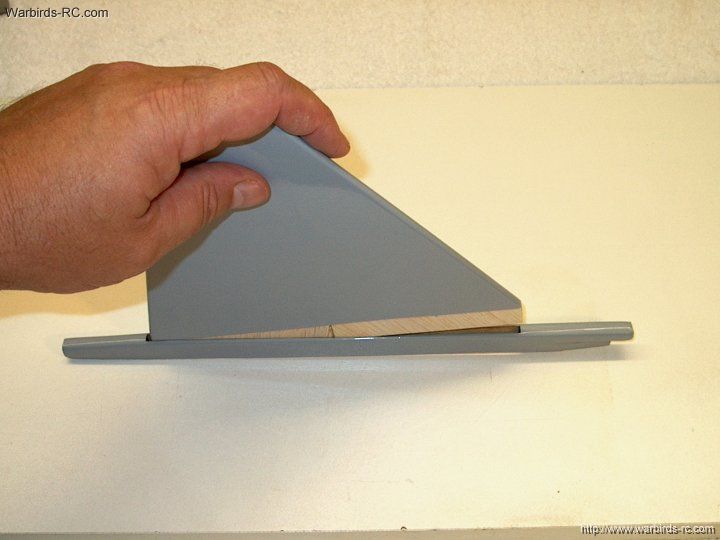

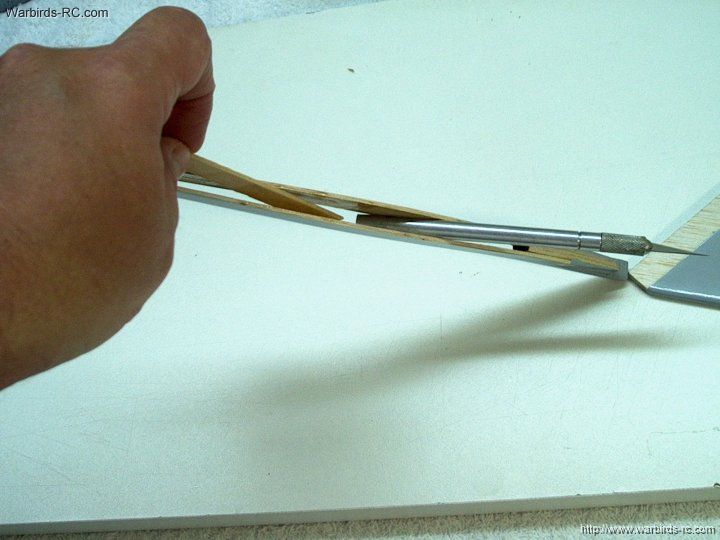

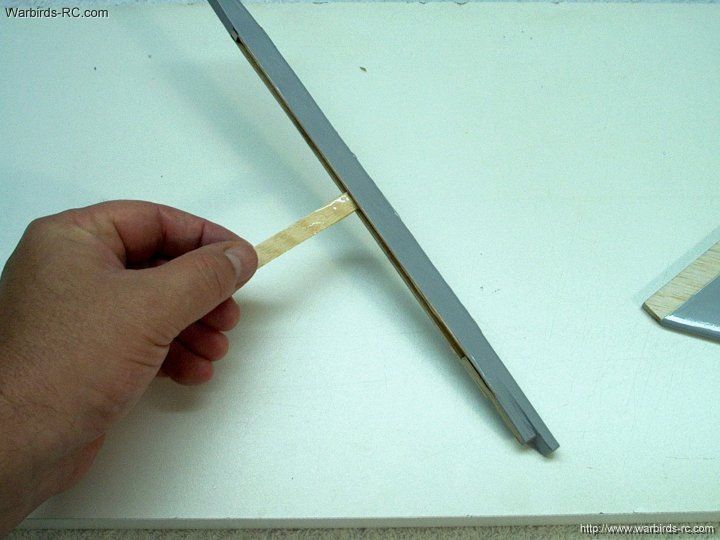

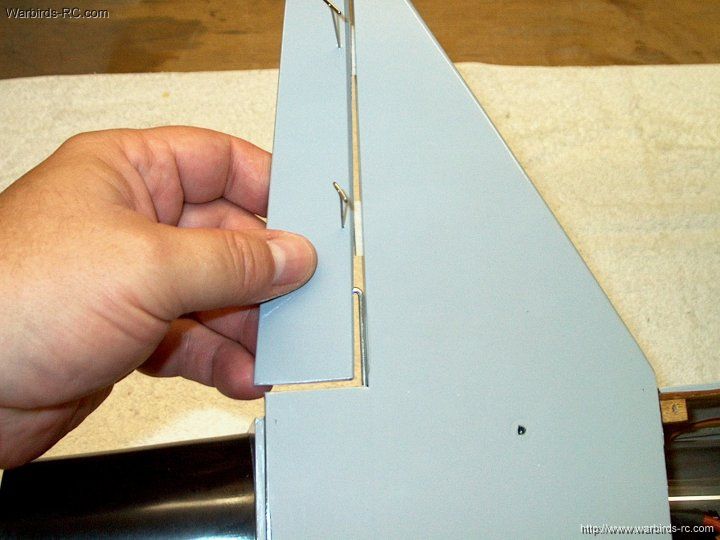

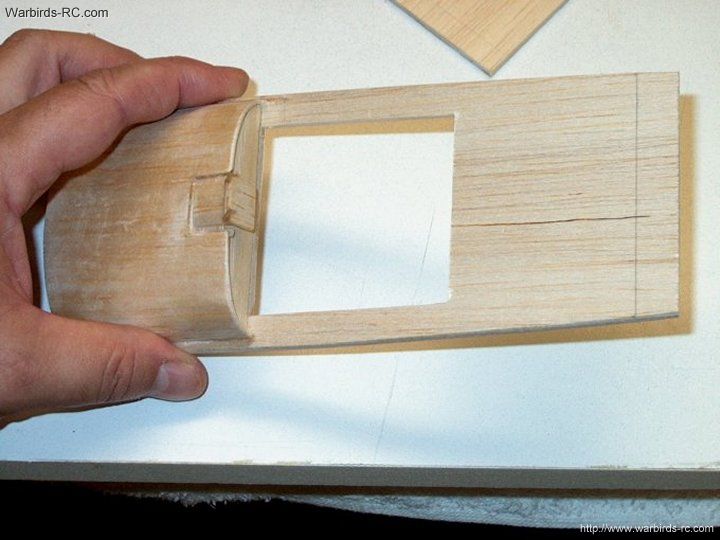

39 - The vertical Stab spar was not

shaped correctly, so trim it to a taper at the forward

section. TIP: you can re-use old pieces of covering removed

from wing chord to cover the re-shaped areas

| |

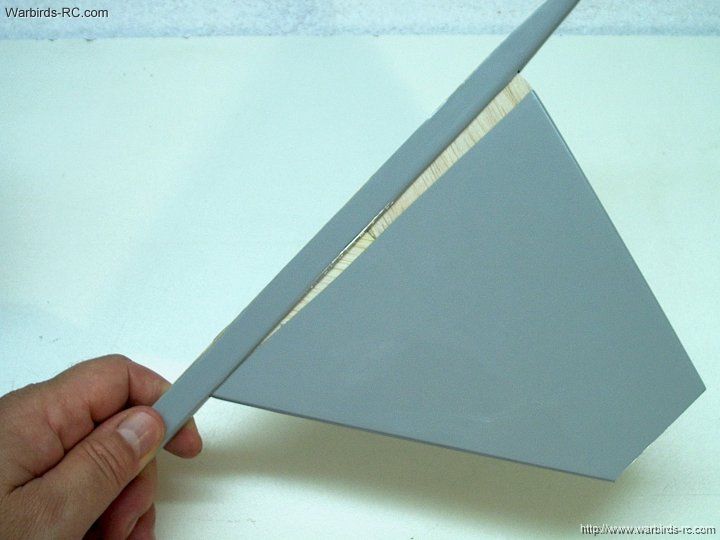

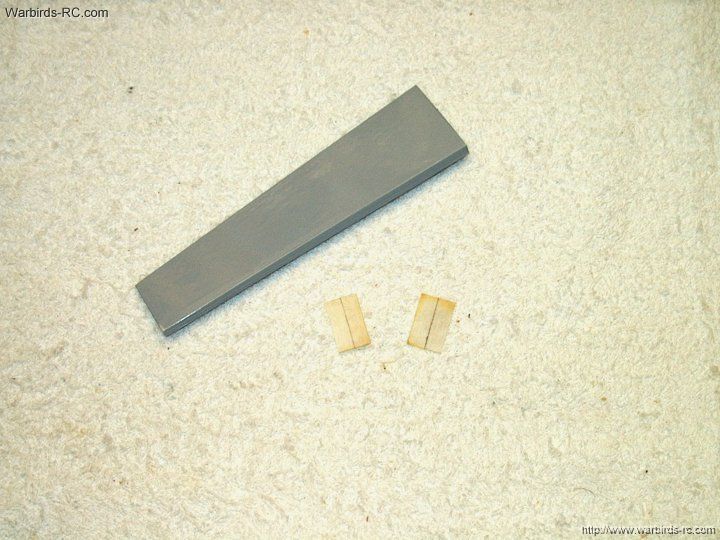

40 - The stab spar is shaped as shown

| |

41 - Mark the top of the fuselage for

vertical stab installation

| |

42 - The mark should appear as shown

| |

43 - Mark the forward section of the

fuselage at the center of the turtle deck

| |

44 - Draw a line from the turtle deck

mark to the rear mark on the fuselage

| |

45 - Your center line should appear as shown

| |

46 - Cut the covering about 1/8" wide

on each side of the center line

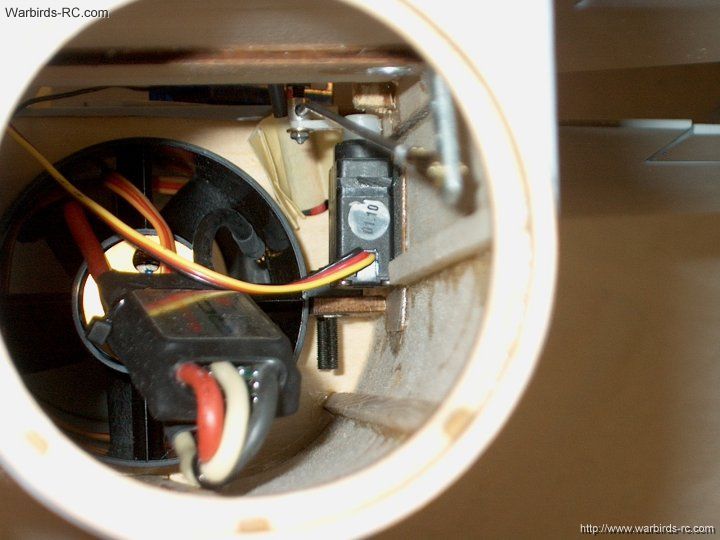

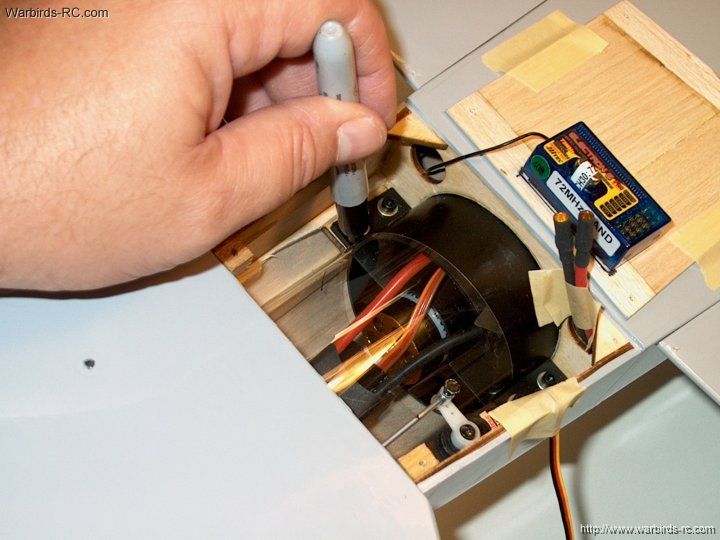

| |

47 - Remove the covering

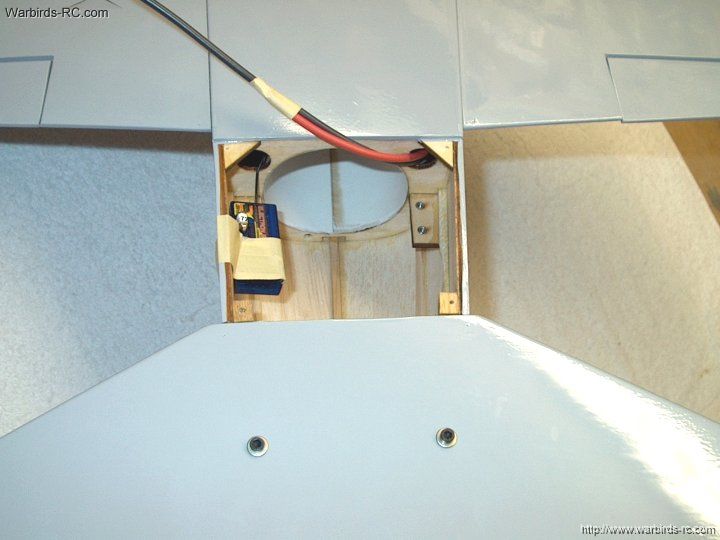

| |

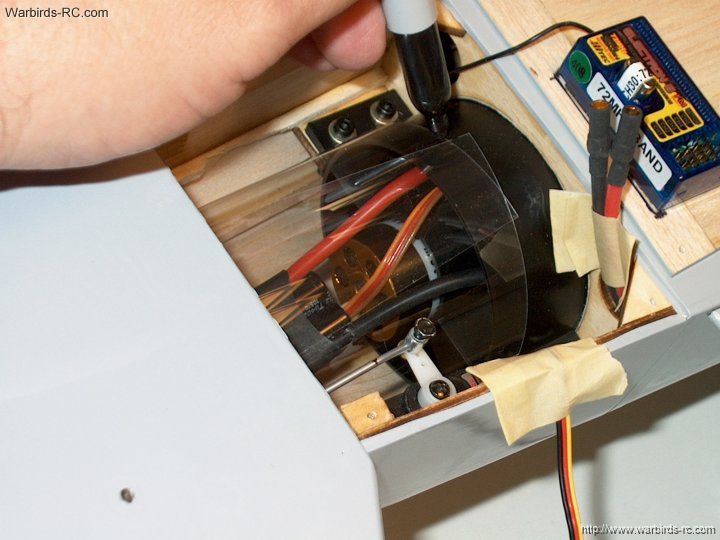

48 - Use an iron to seal the edges

| |

49 - Trim the stab covering 1/2" from

the bottom of the stab

| |

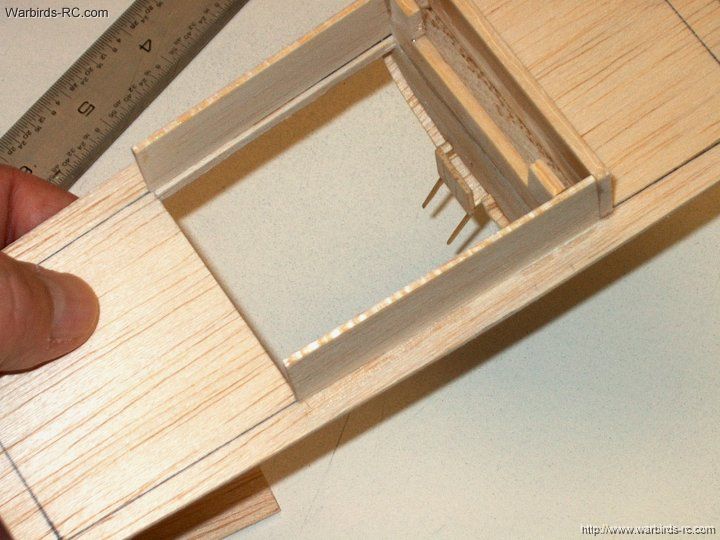

50 - Remove the covering

| |

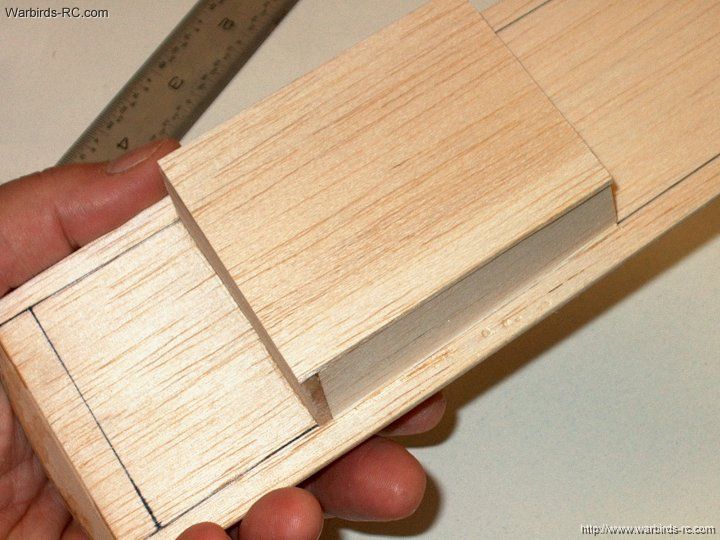

51 - Seal the edges of the covering with an iron

| |

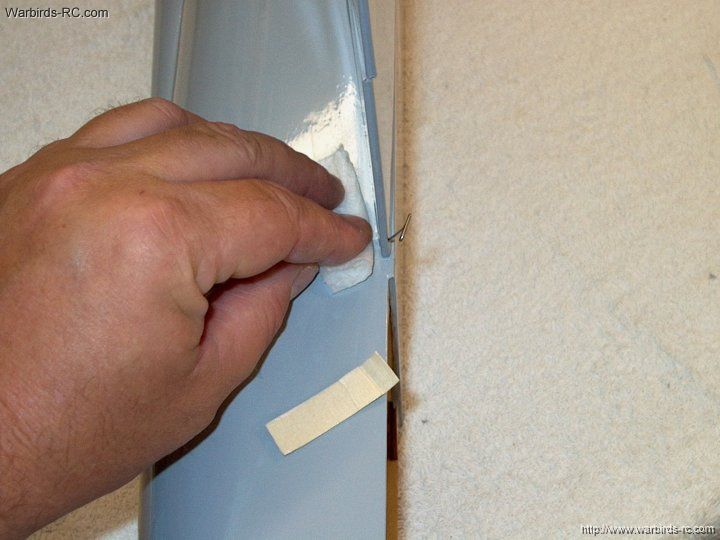

52 - Mark the front of the stab so it is

installed in the proper direction

| |

53 - Test fit the stab in the stake

| |

54 - Use a knife to hold the stake open

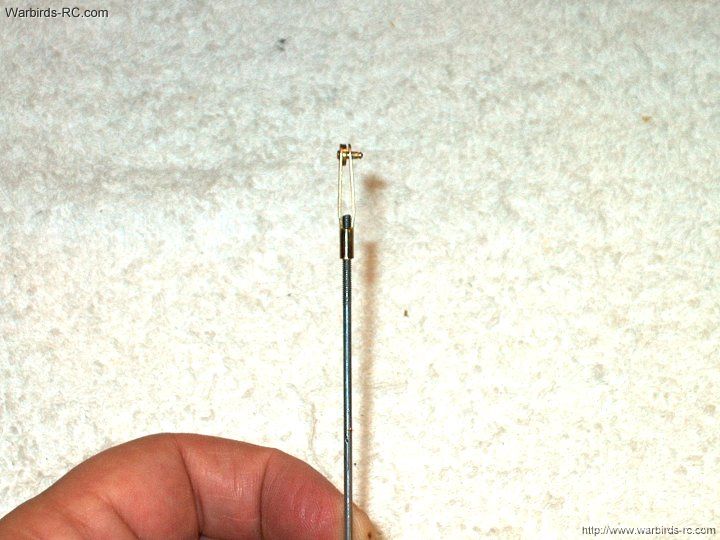

and apply epoxy to the inside of the stake

| |

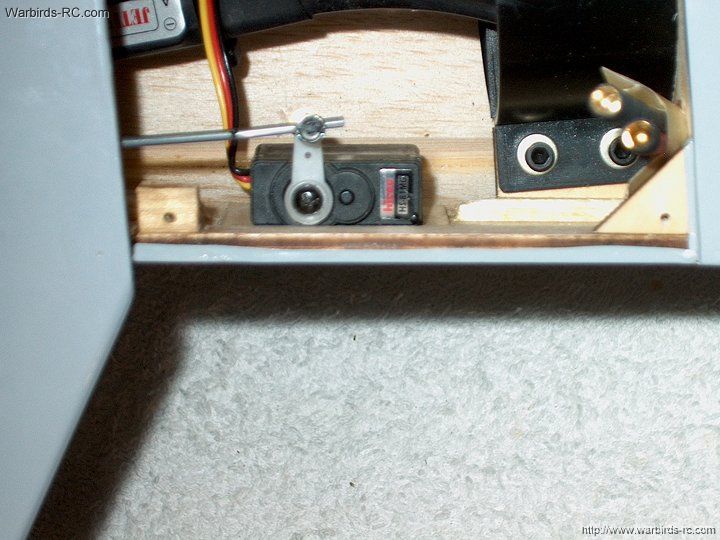

55 - Apply epoxy to the inside of the

stake rather than on the Vertical Stab. This will keep the

upper seam clean and free of glue when the Stab is inserted

| |

56 - Insert the vertical stab into the

stake and position it so it is flush to the bottom of the stake

| |

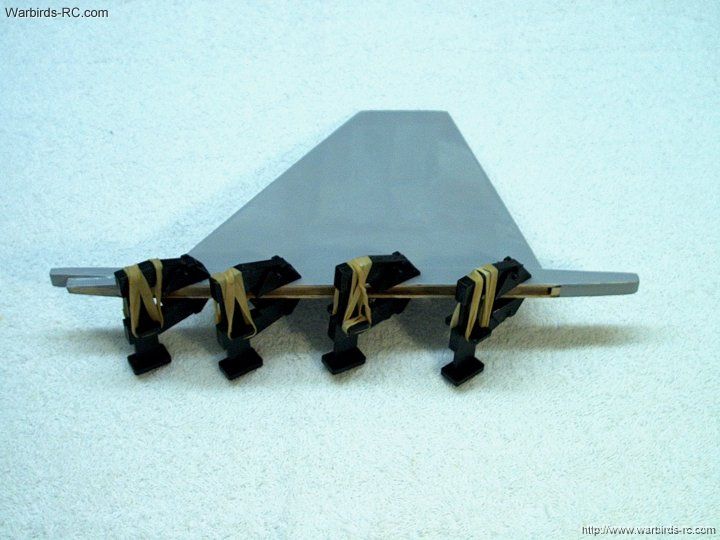

57 - Clamp the stake in place and use

alcohol to clean up the excess epoxy

| |

58 - Allow the epoxy to set and insure

the front stake modification is at the front of the stab

| |

59 - Make a mark at the underside of

the center of the vertical stab

| |

60 - Use pins to help keep the fin

aligned as shown and check the fit

| |

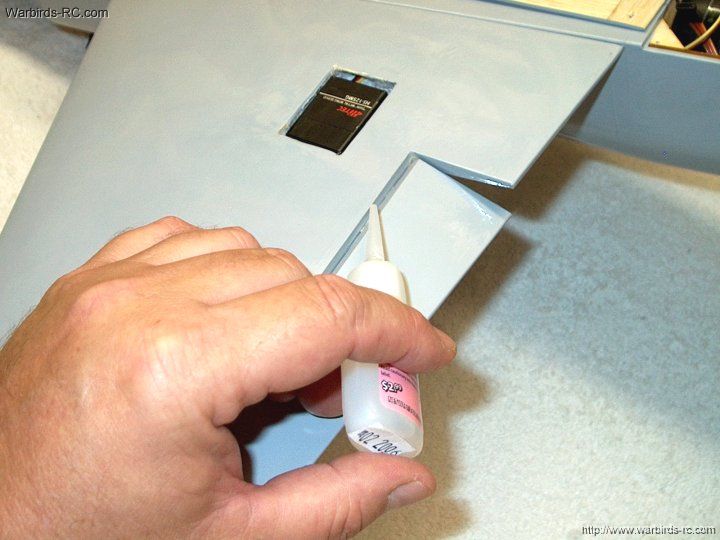

61 - Apply epoxy to the bottom of the

stab and on the fuselage

| |

62 - Place the vertical stab assembly

in position on the fuselage and pin it in place. Use a

square to align the stab perpendicular to the fuselage top

| |

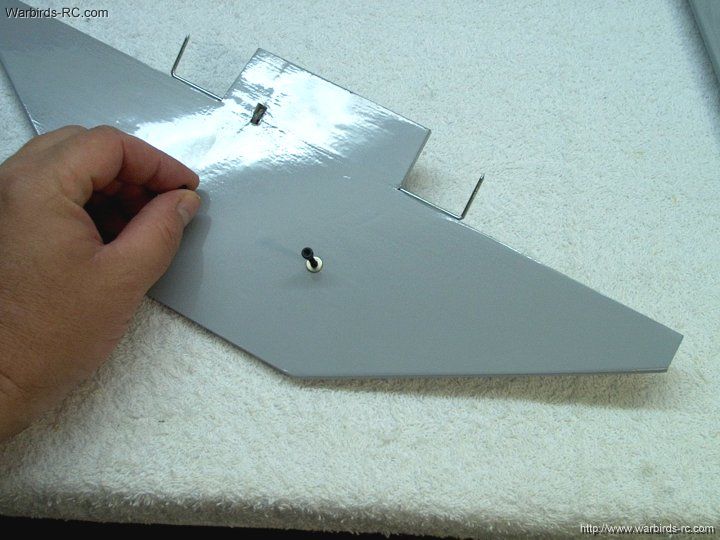

63 - Use a pencil to locate and punch

through the pre-drilled holes in the horizontal stab

| |

64 - Position the stab above its location

| |

65 - Install the supplied bolts into

the stab holes

| |

66 - Temporarily install the horizontal stab

| |

67 - Use a marker to mark the location

of the fuselage sides on the stab

| |

68 - Cut about 1/16" on the inside of

each line

| |

69 - Remove the center covering...SAVE

THIS COVERING! It can be reused to cover Aileron covers

later in the assembly

| |

70 - Remove the marker lines with alcohol

| |

71 - Seal the edges of the covering with an iron

| |

72 - The horizontal stab is ready to install

| |

73 - Trim the excess covering away

from the horizontal stab edges on the bottom of the fuselage

| |

74 - Remove the covering that was trimmed

fromt he top and front of the stab

| |

75 - Seal the edges of the covering

| |

76 - Apply epoxy to the bottom edges of

the fuselage

| |

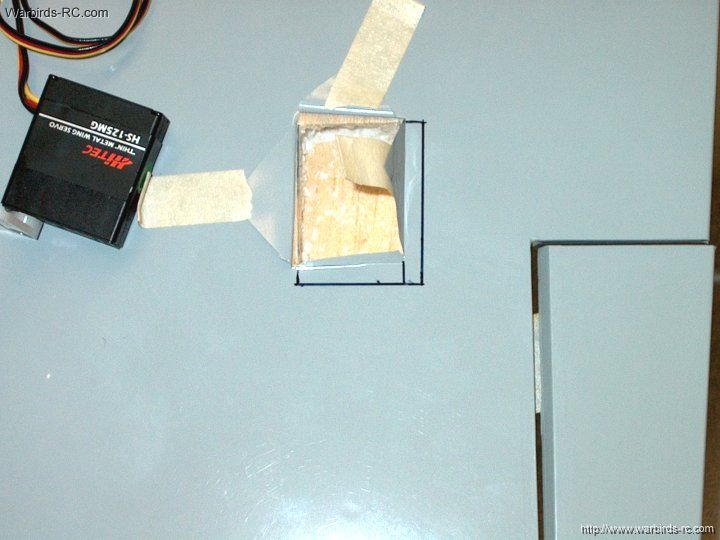

77 - Apply epoxy to the trailing edge

of the horizontal stab

| |

78 - Install the stab on the fuselage

| |

79 - Use the stab bolts to hold it in

place while the epoxy sets. Check alignment of the stab

|

|

80 - Position the stab so it is flush

against the rear lip of the Fuselage, then use pins to hold

the Stab down to the Fuselage edges...this is important...make

sure the fit is flush with no gaps

|

|

81 - Remove excess epoxy from the bottom

| |

82 - Remove epoxy from the fuselage joint

| |

83 - Horizontal stab installation is completed

| |

84 - Drill the fuselage front former for the

antenna tube

| |

85 - Drill a hole in the rear firewall

former for the antenna tube.

| |

86 - The position of the antenna hole is shown

| |

87 - Drill a 1/8" hole in the rear of

the fuselage for the antenna tube

| |

88 - Locate the red pull wires and

tape them out of the way to the bottom of the fuselage

| |

89 - Install the antenna wire tube

from the front

| |

90 - Ties the receiver antenna wire

to a string

| |

91 - Pull the antenna to the front

canopy area using the string | |

92 - slide the antenna tube rearward

over the wire. Mark the front of the tube for trimming | |

93 - Trim the antenna tube to length

| |

94 - Complete the antenna installation

| |

95 - Rough up the inside of the nose

with 60 grit sandpaper

| |

96 - The inside lip should be sanded

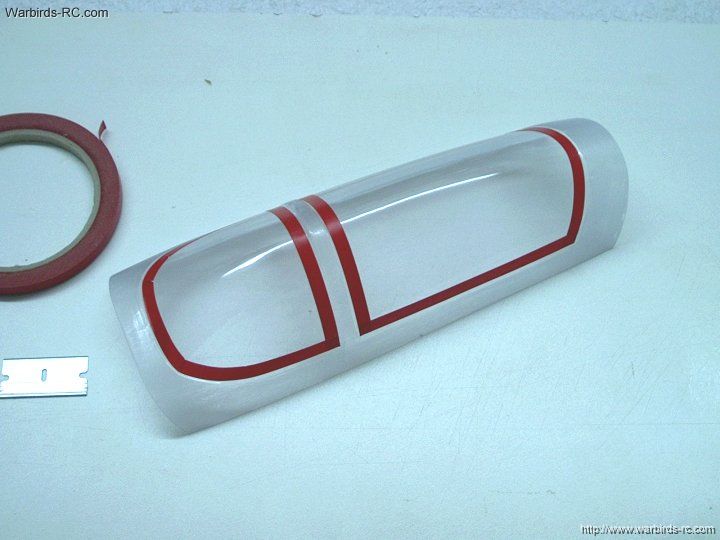

as shown

| |

97 - Apply epoxy to the front edge

of the fuselage

| |

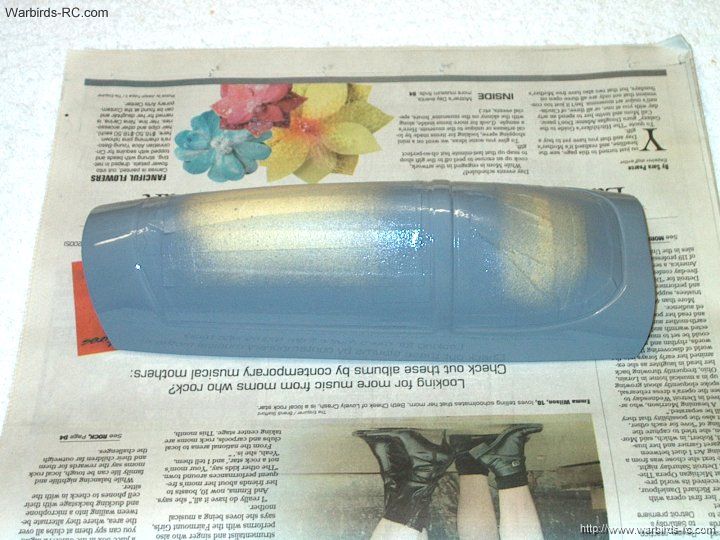

98 - Apply epoxy to the inside lip of

the nose

| |

99 - Install the nose on the front of

the fuselage

| |

100 - Remove any excess epoxy with alcohol

| |

101 - Position the fuselage vertically

until the epoxy sets

| |

102 - The airframe build is completed

| |

103 - Make sure you have all of the

parts you need to complete the electronics

| |

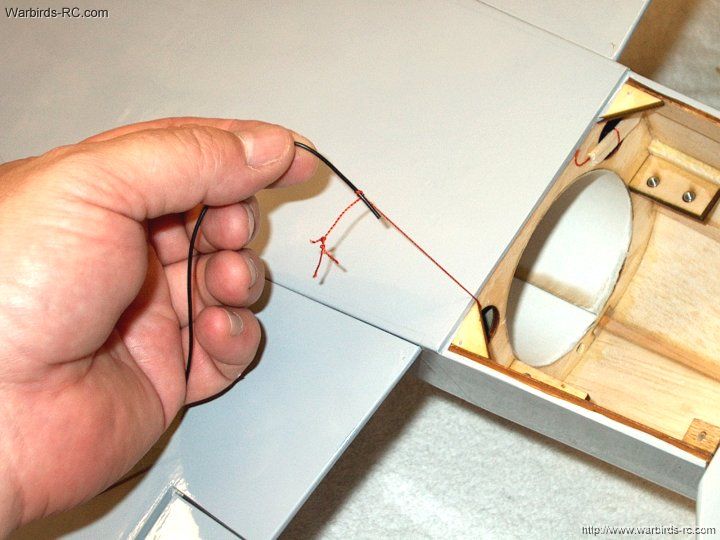

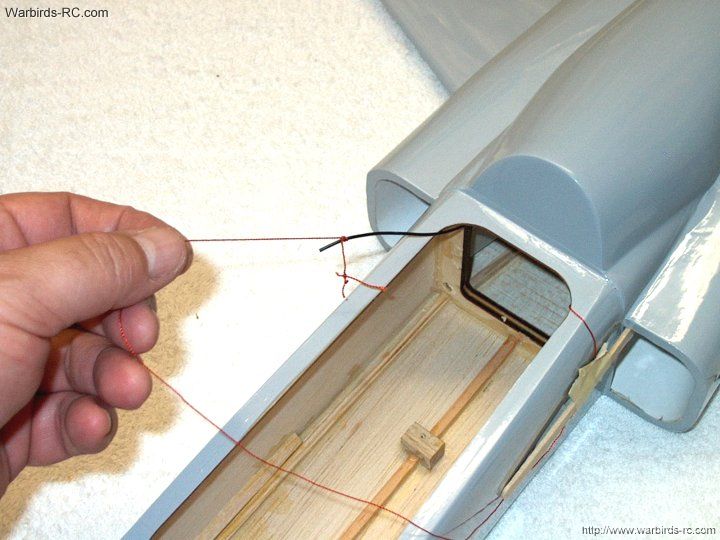

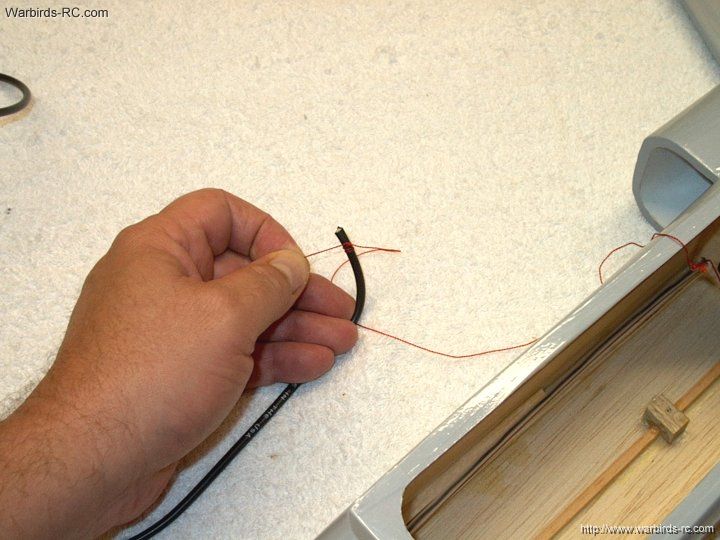

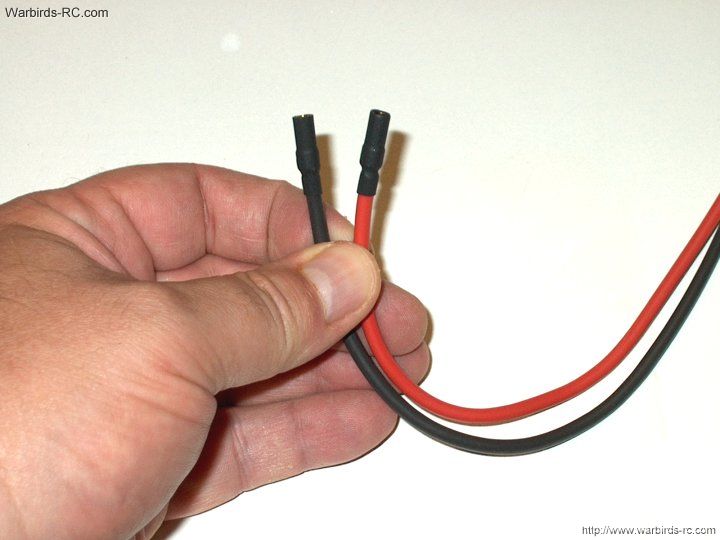

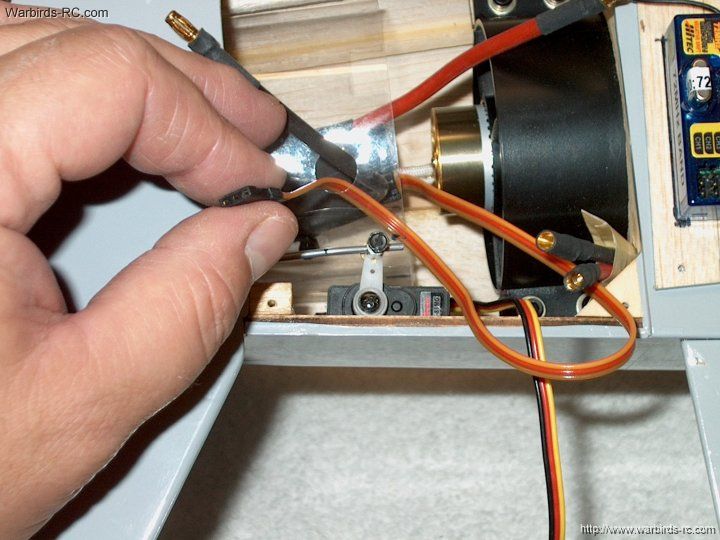

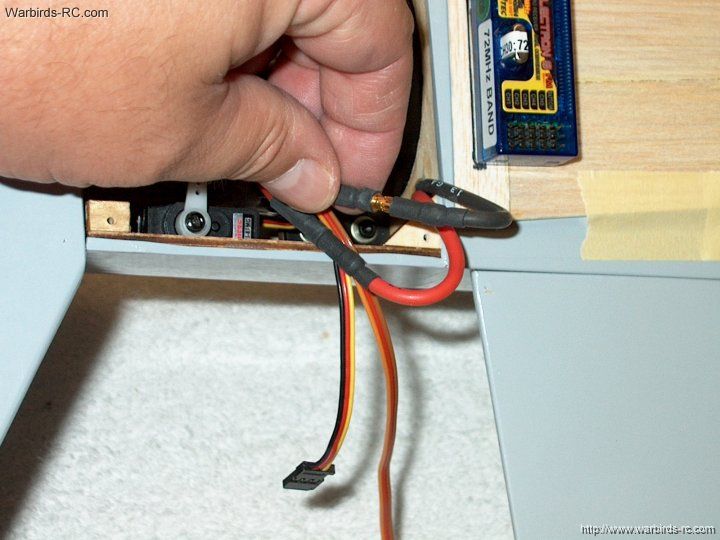

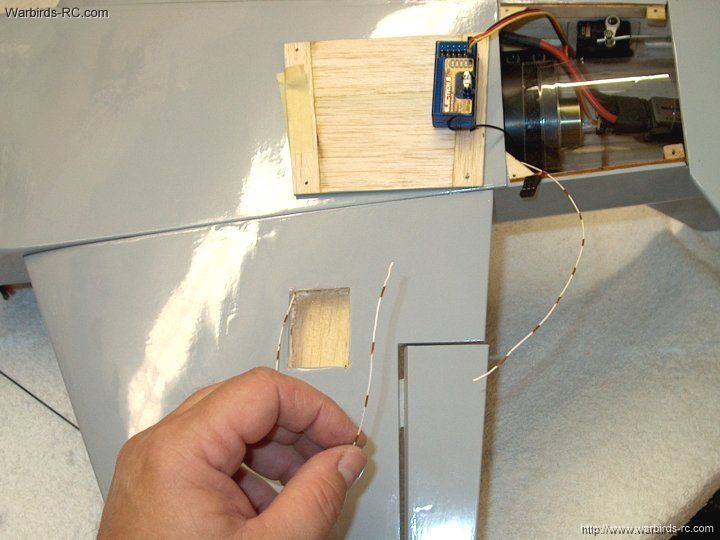

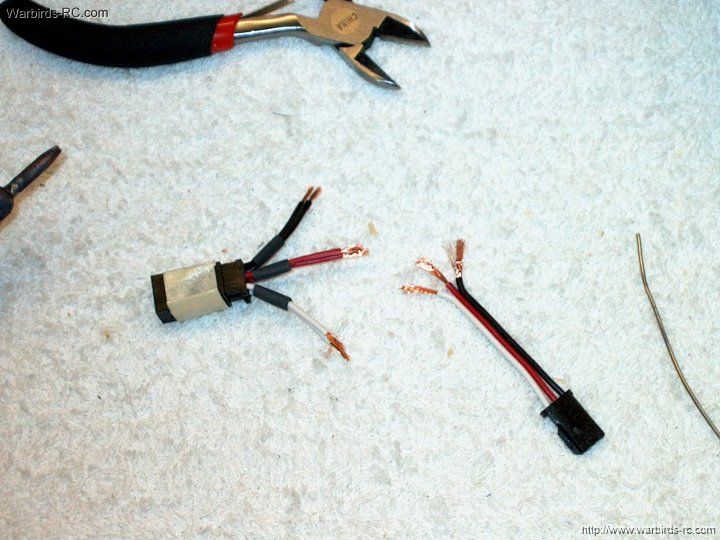

104 - Tie the black wire to the string

| |

105 - Pull the wire to the rear

| |

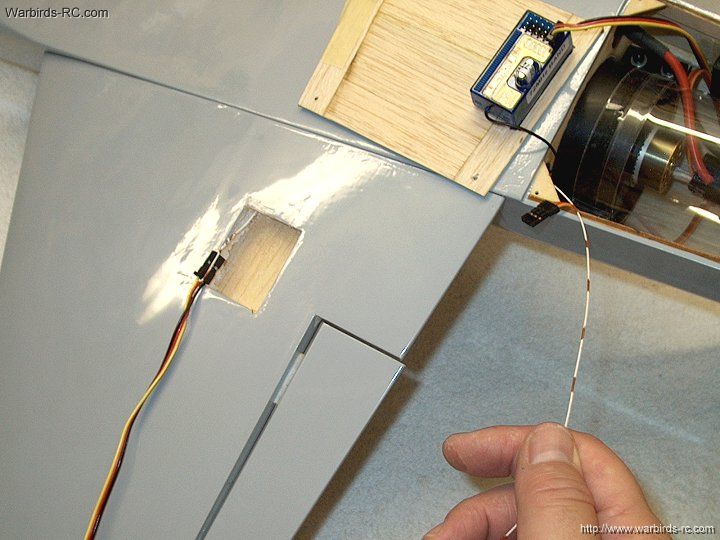

106 - TTape the red wire to the black

and pull them the rest of the way through to the rear

| |

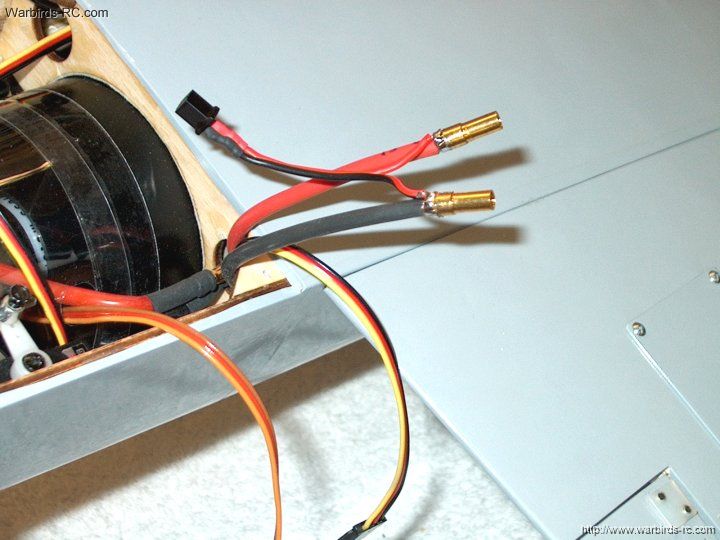

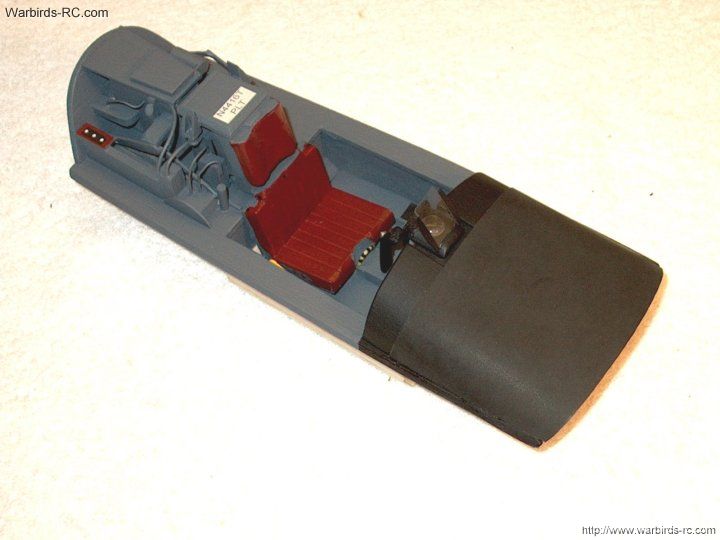

107 - The power wires should exit the

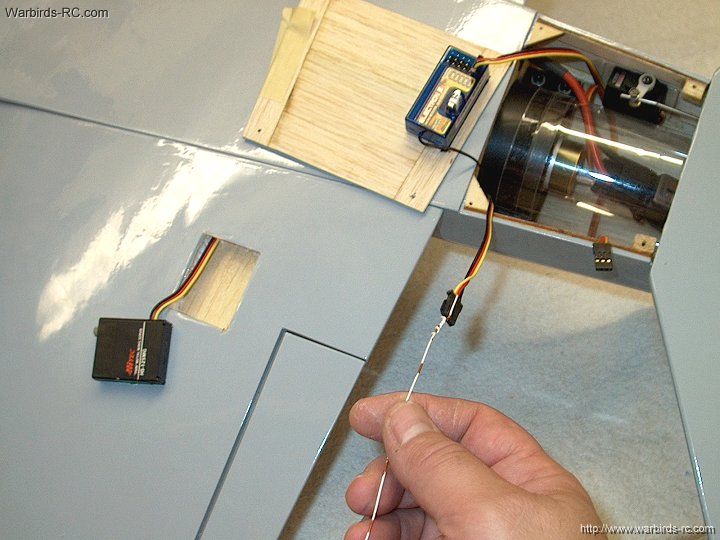

hole as shown

| |

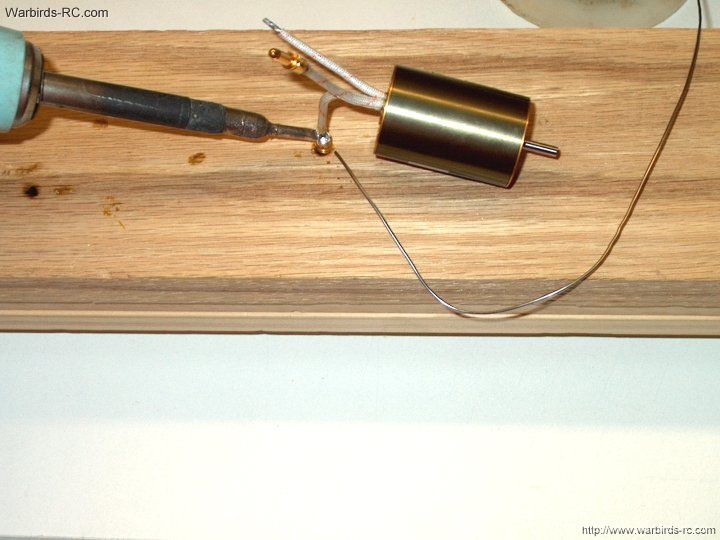

108 - Tin the end of both wires

| |

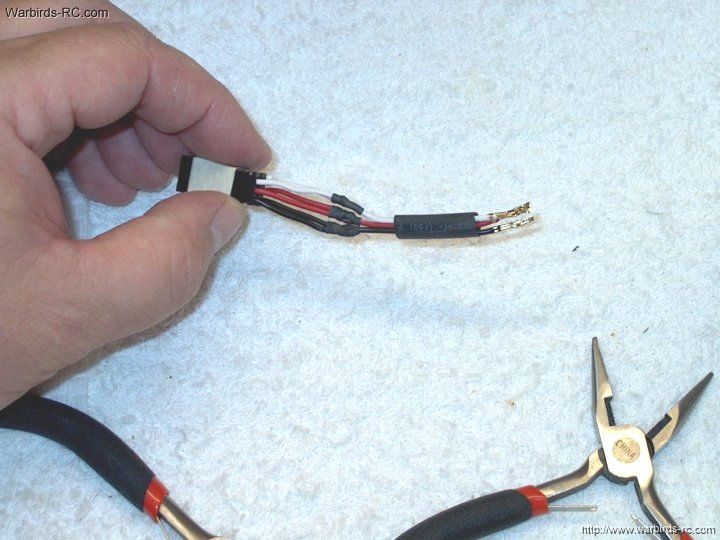

109 - Solder 3.5mm female barrel connectors

to each wire. Always install the sockets on the powered

side so there are no plugs that can short together

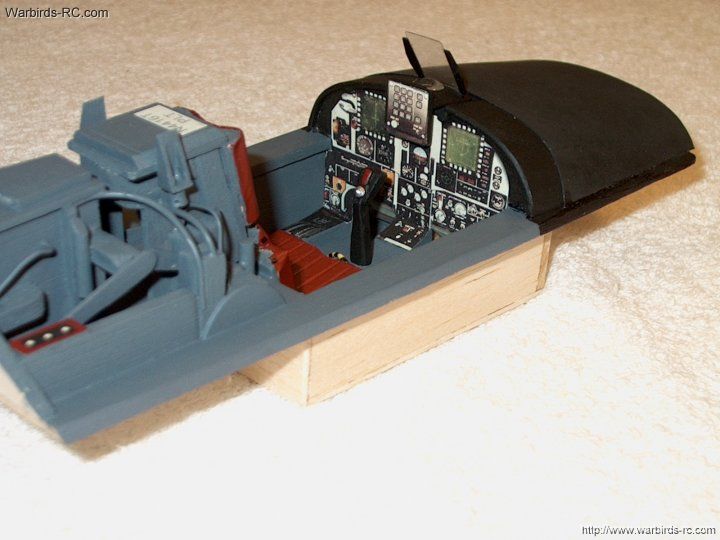

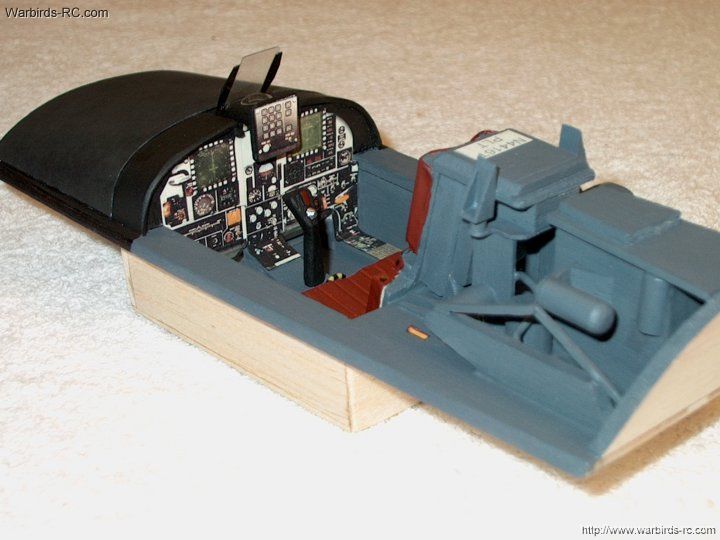

| |

110 - Use heat shrink to cover the sockets

| |

111 - Complete the installation for

both wires

| |

112 - Install 3.5mm female bullet connectors

on the powered side of the ESC and add heat shrink

| |

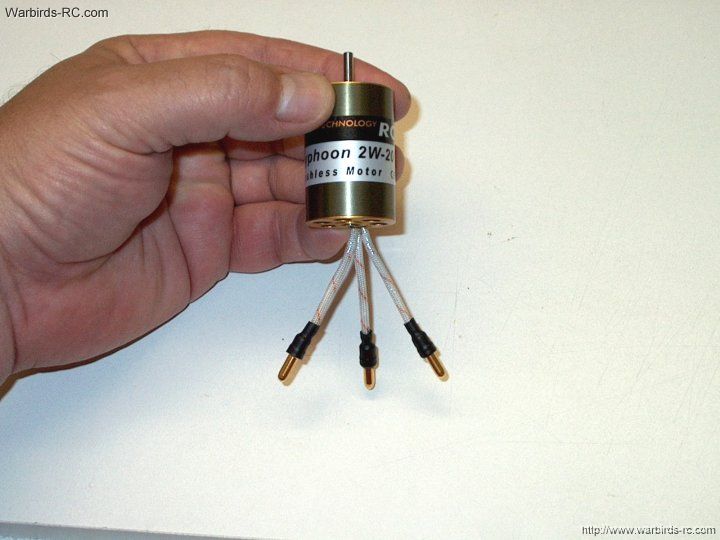

113 - Install male connectors to the motor leads

| |

114 - Apply heat shrink to cover the motor plugs

| |

115 - The motor is shown completed

| |

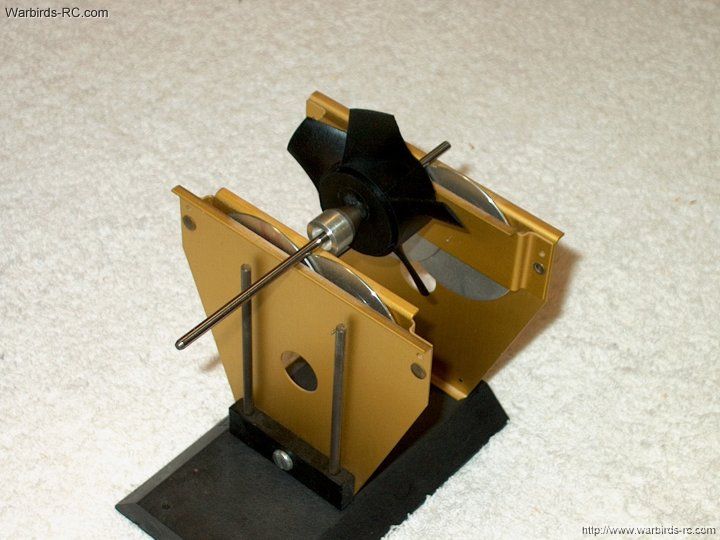

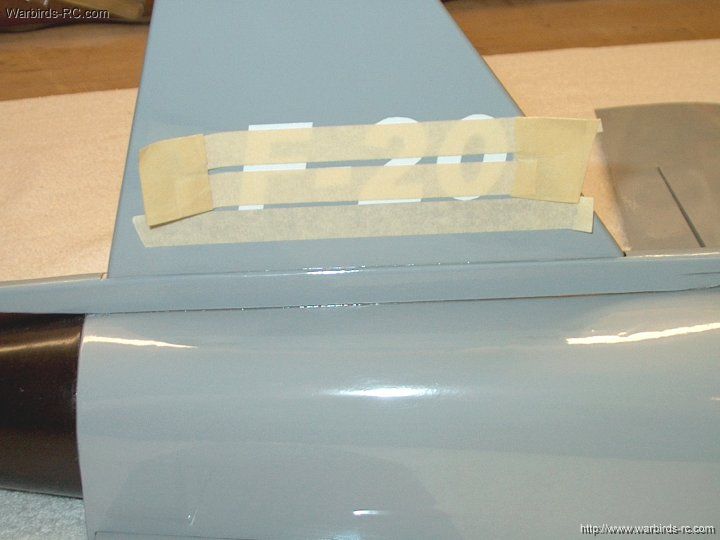

116 - Balance the fan rotor

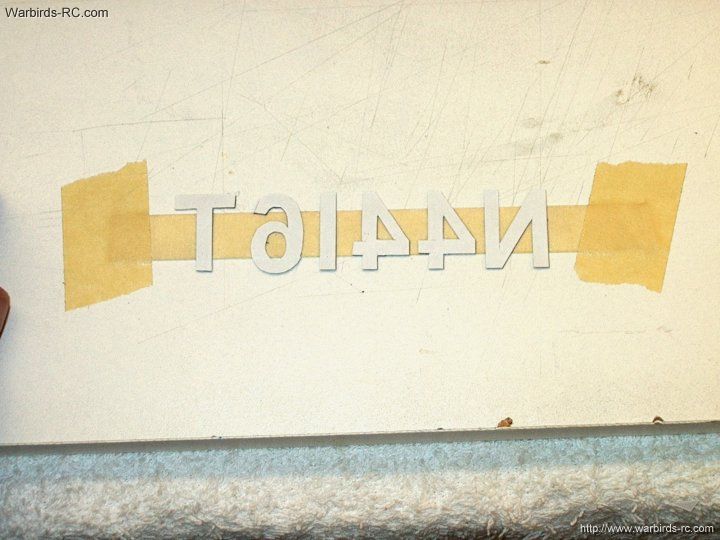

| |

117 - Use 3mm x 6 bolts to mount the motor

| |

118 - Place the shaft adapter on the

motor shaft

| |

119 - Use the supplied set screw to apply

just enough drag to allow the adapter to be moved up and down

the shaft under some pressure

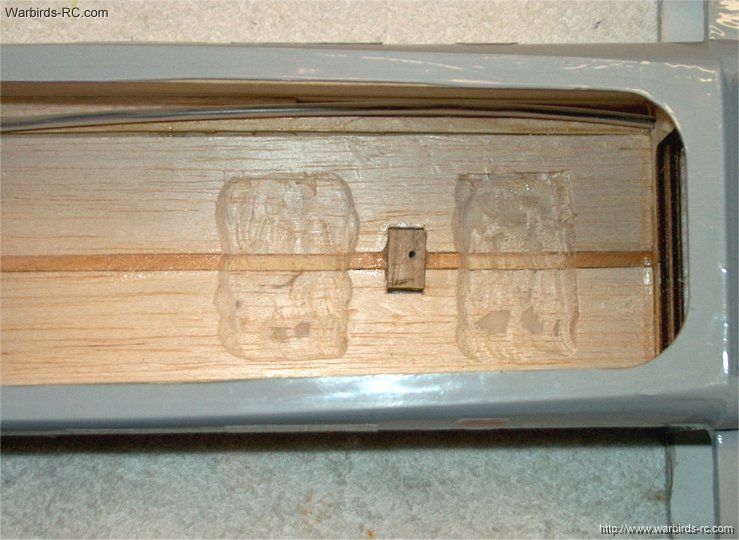

| |

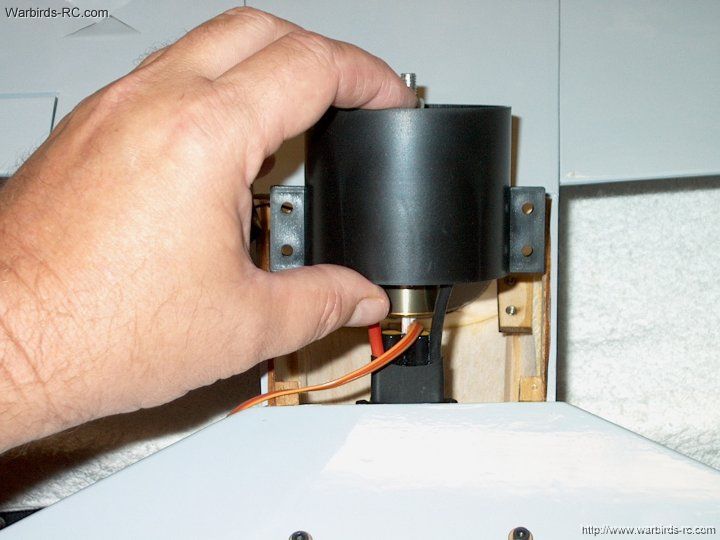

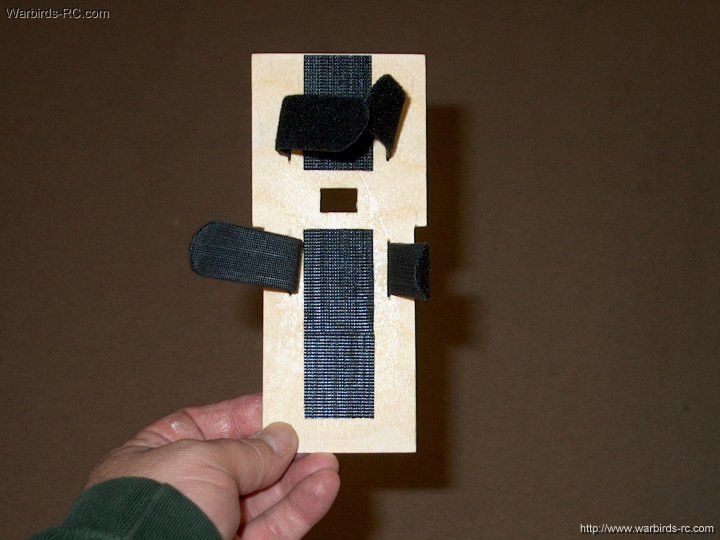

120 - Install the motor in the fan shroud

| |

121 - Temporarily install the 3mm bolts

to hold the motor in place

| |

122 - Install the fan and push down until

the fan bottoms out on the shroud area surrounding the motor

| |

123 - Using your fingers, push against

the fan to keep it bottomed out on the Shaft Adapter. Pull

the Adapter out slightly to give about a 1/16" clearance

between the rear of the fan and the front of the motor housing

at the edges. This spacing will prevent the fan rear from

rubbing against the motor housing

| |

124 - Carefully remove the fan

| |

125 - Remove the motor from the fan

taking care not to disturb the shaft position

| |

126 - Apply Loctite to the set screws

and install them in the shaft adapter

| |

127 - Once the set screws are tightened,

use a Q-Tip to remove any excess Loctite

| |

128 - Apply Locktite to the motor threads

with a toothpick. Never apply Blue Locktite to the bolt threads,

or it can attack the plastic in the shroud. Another solution

is to use "Green" plastic safe Locktite

| |

129 - Install the motor in the fan shroud

| |

130 - Install and tighten the motor screws

| |

131 - Install the fan on the adapter shaft

| |

132 - Install the washer

| |

133 - Install the aluminum nut finger tight

| |

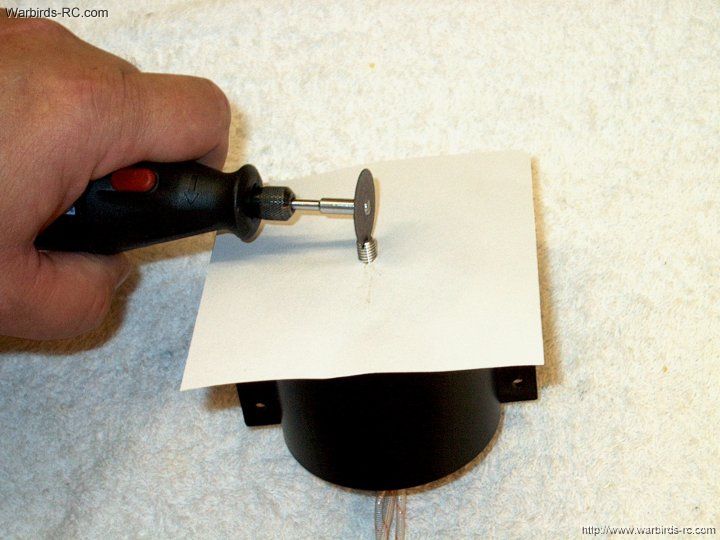

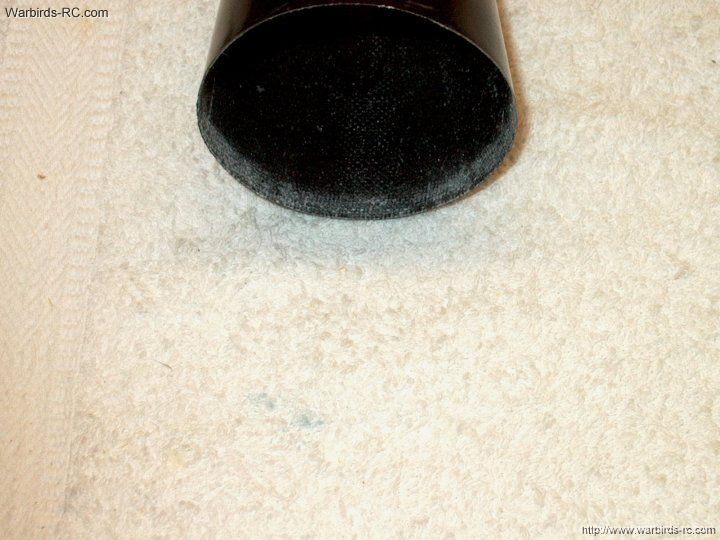

134 - Push the shaft through a piece of

paper, then a slot is cut dead center in the shaft with a

Dremel. The paper is used to keep any filings away from the motor

while cutting

| |

135 - The slot should be cut about 3/16"

deep in the threaded adapter

| |

136 - Use a flat bladed screwdriver

and wrench to tighten the fan nut

| |

137 - The fan assembly is completed

| |

138 - Slide a 2" long piece of heat shrink

over the three motor wires

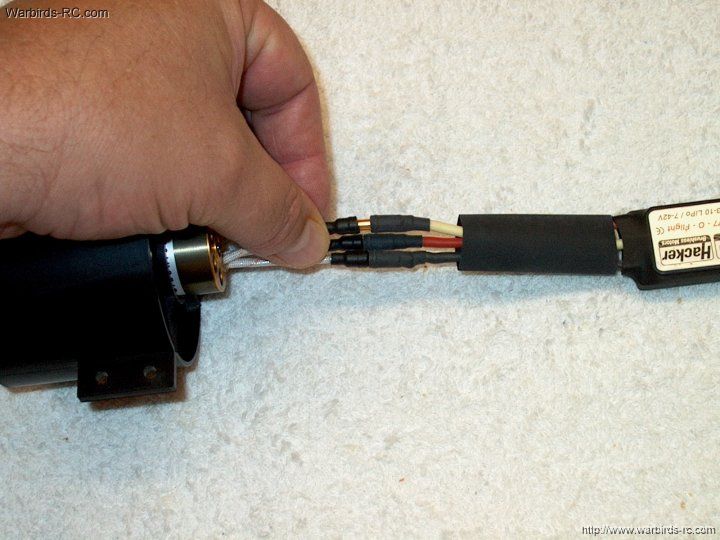

| |

139 - Connect the ESC wires to the motor

| |

140 - Temporarily connect the receiver

and motor and test the fan direction. If it is spinning

the wrong direction, swap any two wires

| |

141 - Once you checked motor direction,

Finish heat shrinking over the connectors to hold them in place

| |

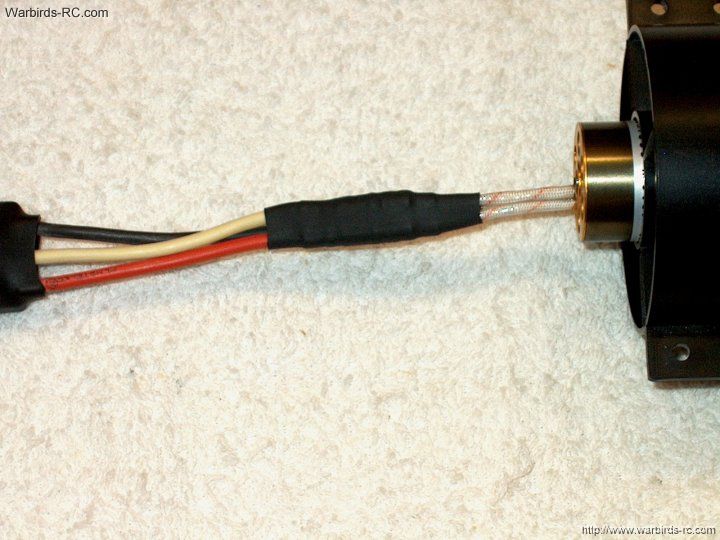

142 - Motor leads should look as shown

| |

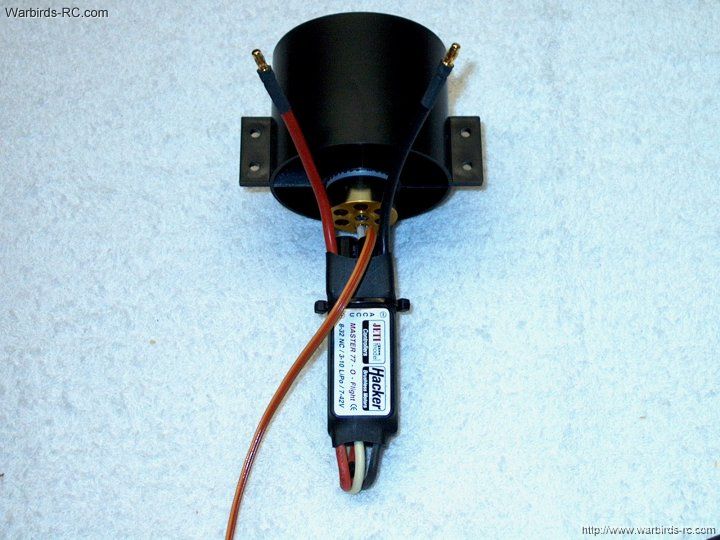

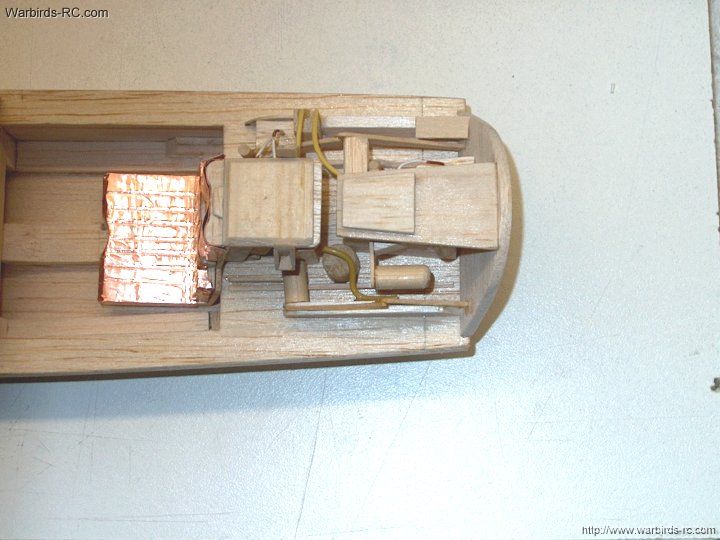

143 - Tie wrap the ESC in place so

the assembly is semi-aerodynamic

| |

144 - A top view of the assembly is shown

| |

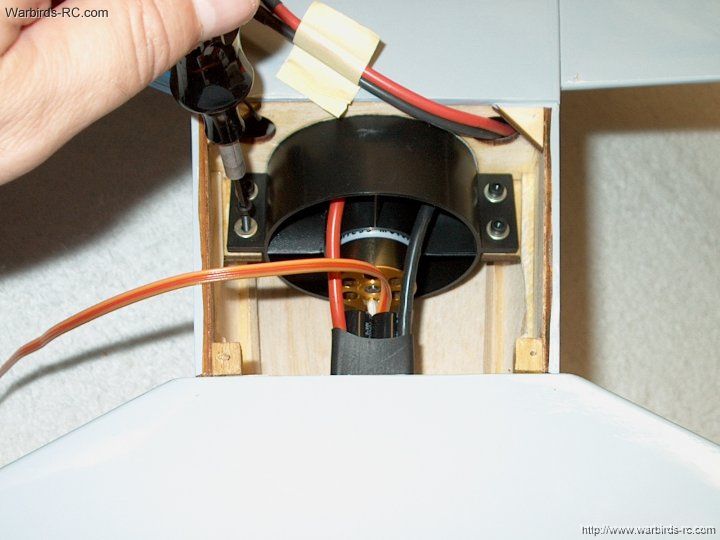

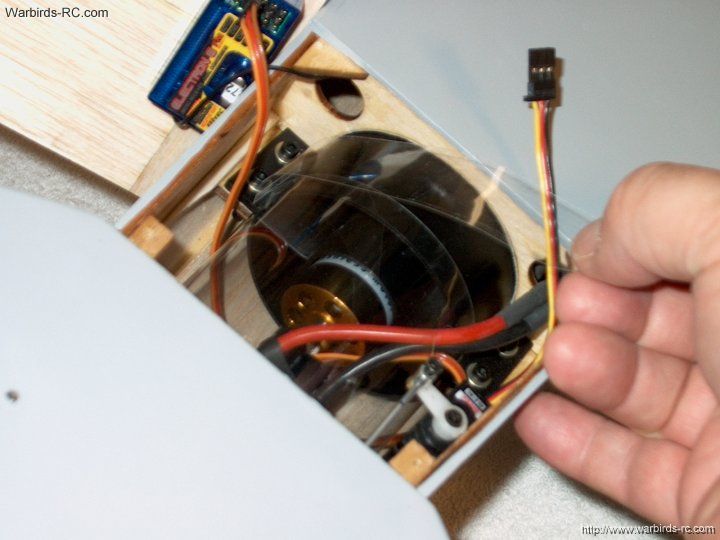

145 - Install the fan assembly in the fuselage

| |

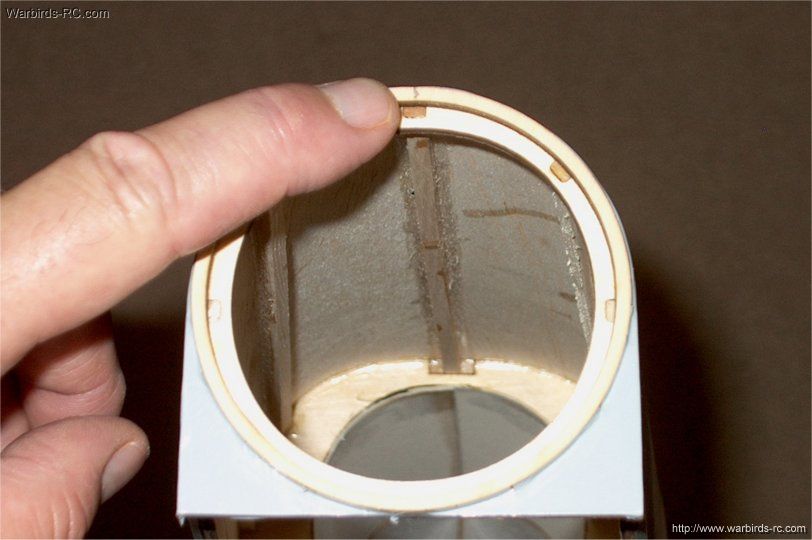

146 - If you have difficulty sliding the

fan into the duct, slightly bell the mouth of the duct with

some fine sandpaper. Pic shows supplied mounting bolts being

installed. Note the inside where balsa was cut away on the

sides so the fan could be installed

|

|

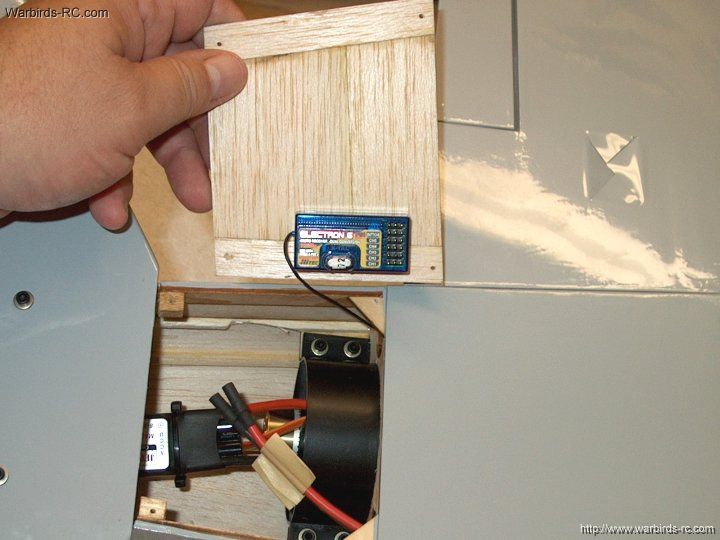

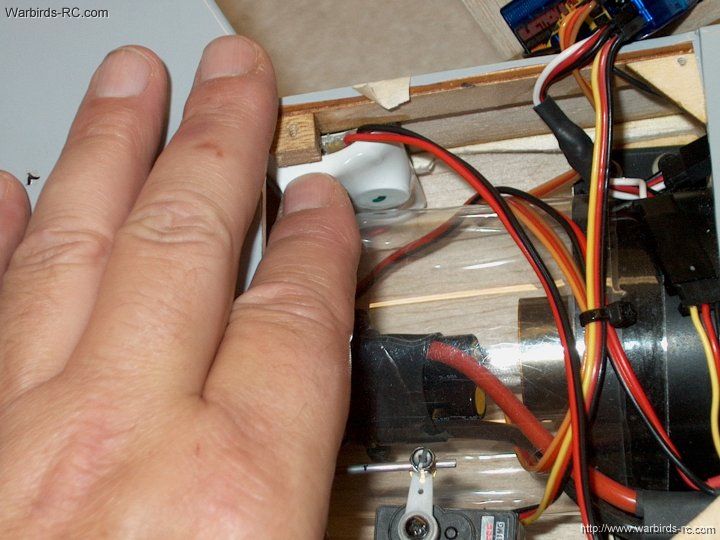

147 - Apply double sided tape to the

bottom of the receiver

|

|

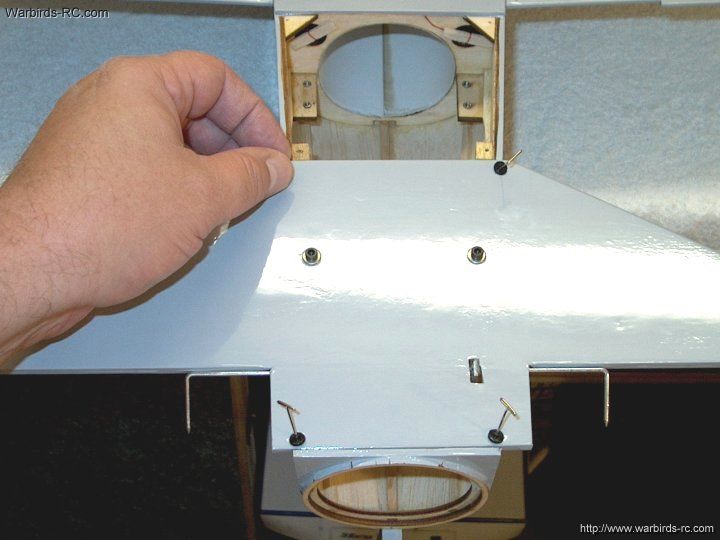

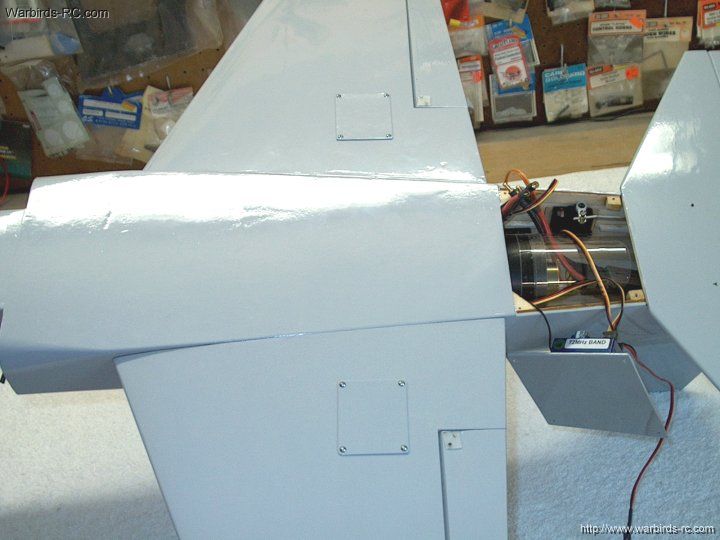

148 - Install the bottom cover plate

with screws, then used a ruler through the rear of the fuselage

to position the receiver and push it down in place. Note that

it has clearance so the Crystal and leads will not interfer

with the duct tube

|

|

149 - Remove the bottom cover screws

|

|

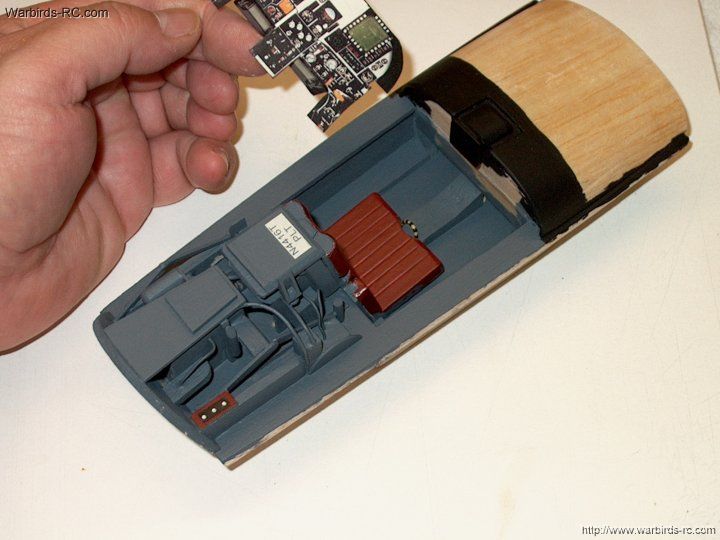

150 - The cover shows receiver placement.

This is a good location as the receiver is not blocking access

to the Fan Assembly

| |

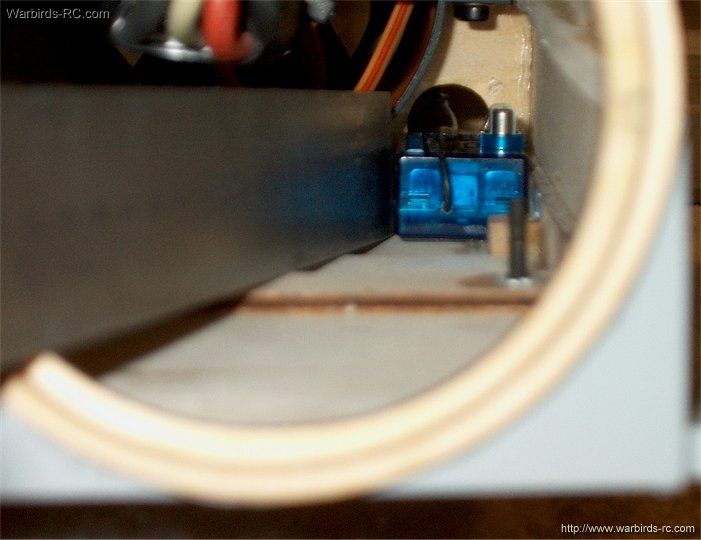

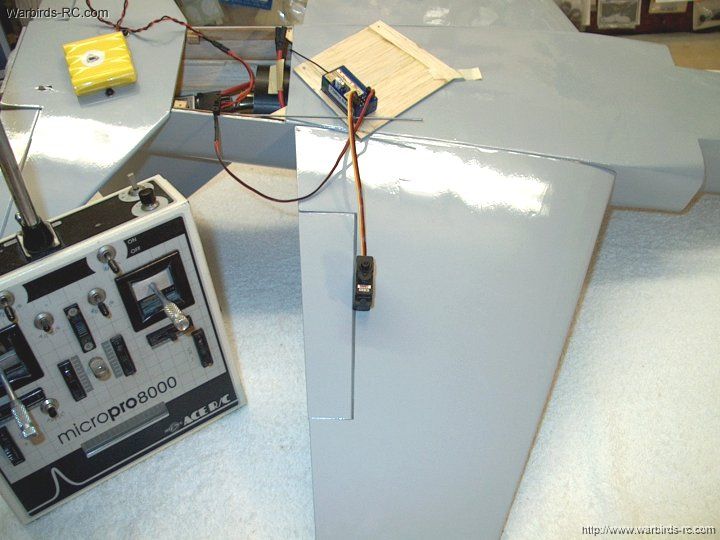

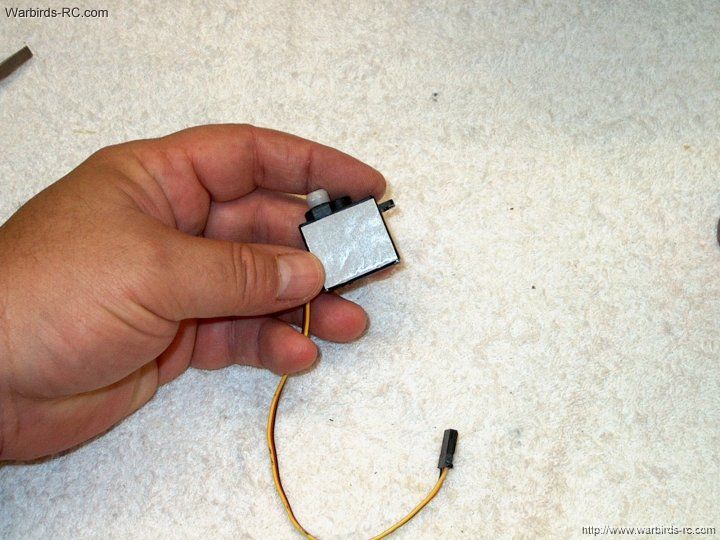

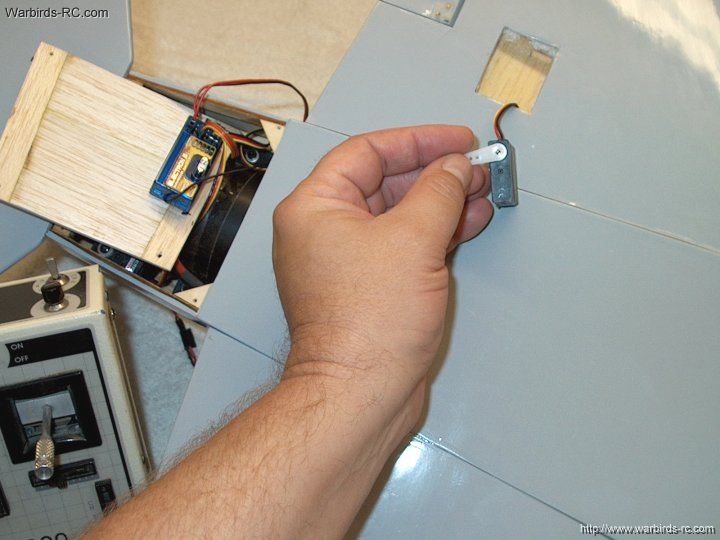

151 - Temporarily connect the HS81

servo to the receiver and turn on the radio to center the servo

| |

152 - Install the servo arm on the servo

| |

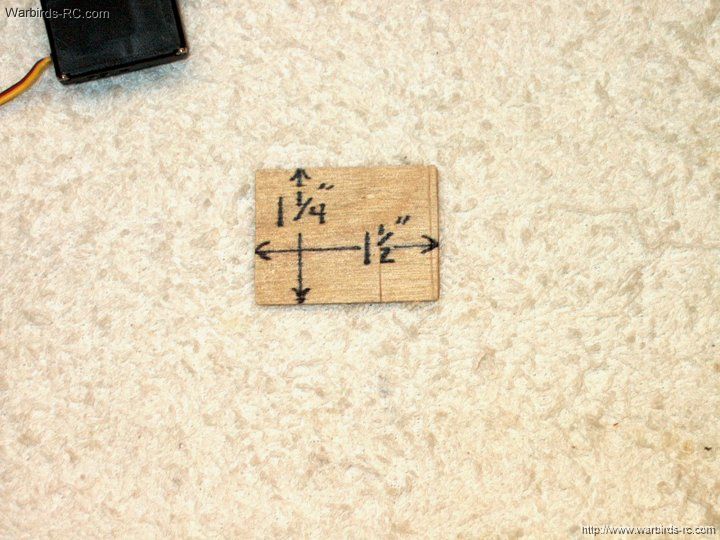

153 - Make a 1/32" thick plate with the

dimensions shown for mounting the elevator servo

| |

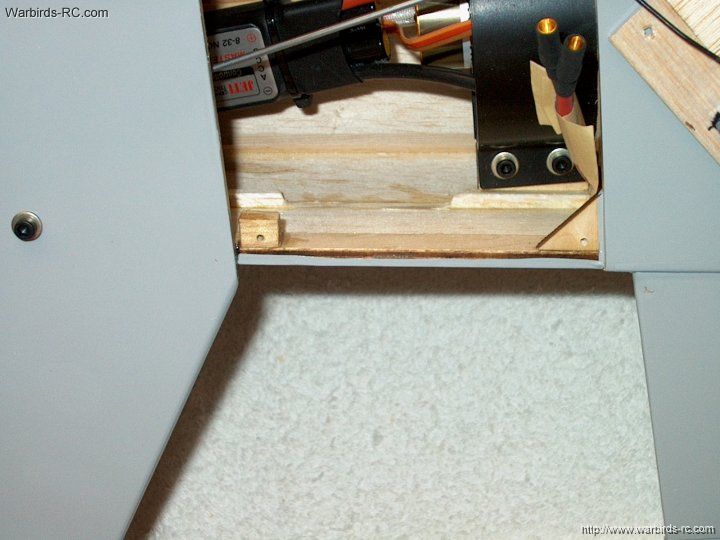

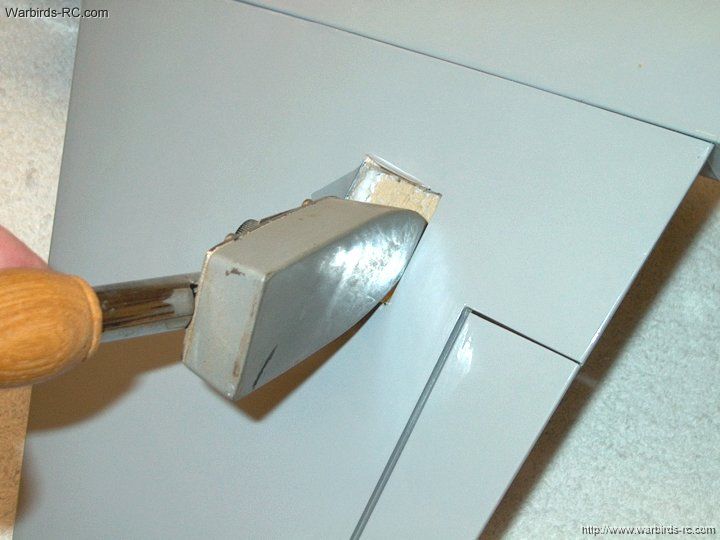

154 - Cut away the wood spar as shown

to make room for the elevator servo

| |

155 - Apply epoxy to the servo plate and

install it in place

| |

156 - Use clamps to hold the plate in

place while epoxy sets. Note the plate edge is about 1/4"

away from the ply supports near the fuselage opening

| |

157 - The plywood plate is shown installed

| |

158 - Coat the plate with thin CA glue

| |

159 - Once the glue is dried, lightly sand

to a "plastic" feel for a good servo tape bond. Be sure to

clean the plate with denatured alcohol before mounting the servo

| |

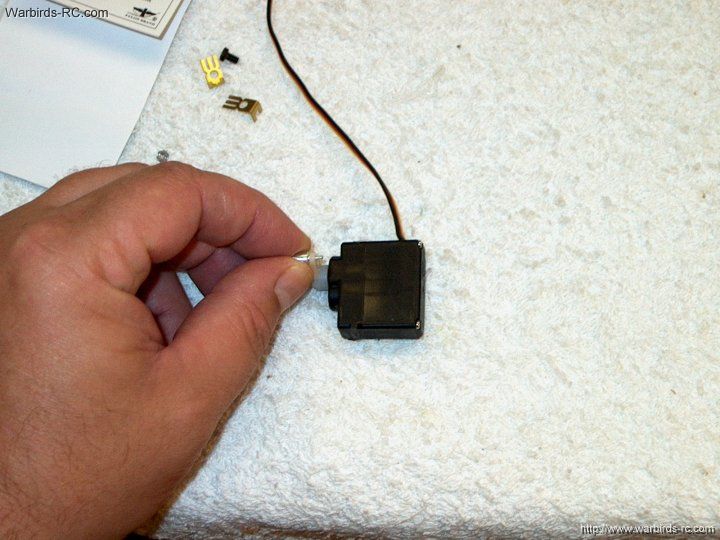

160 - Clean the side of the servo with alcohol

| |

161 - Install double-sided servo tape

on the side of the elevator servo

| |

162 - Drill a 1/16" hole in the servo

arm to open it up for the pushrod

| |

163 - Install a Sullivan Pushrod

Connector #550 on the servo arm

| |

164 - Add a drop of CA on the bottom

threads so the nut will not come loose

| |

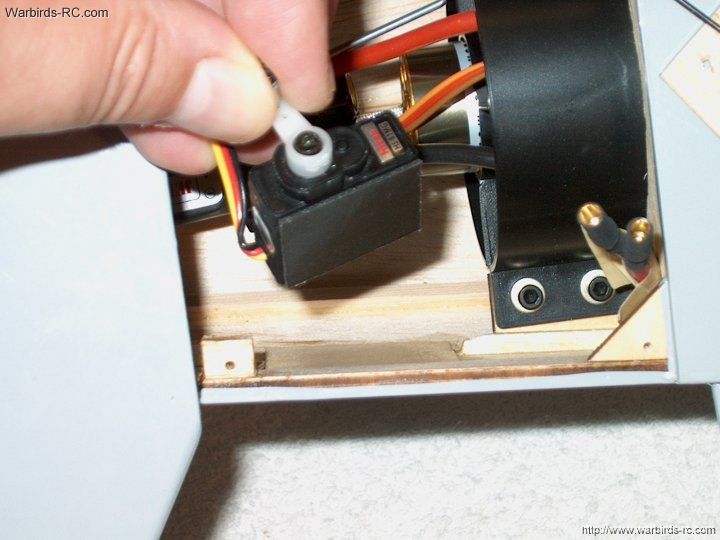

165 - Install the servo in the fuselage

| |

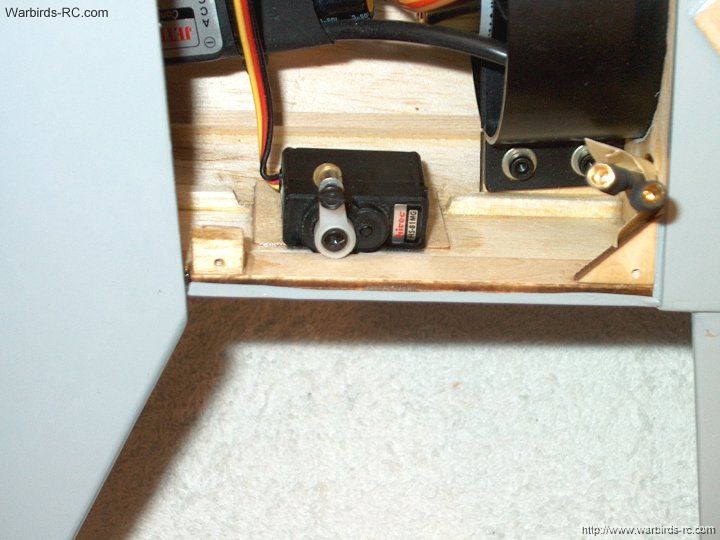

166 - The servo is shown installed

| |

167 - Install a Sullivan Clevis on the

pushrod

| |

168 - Cut down the elevator horn one hole

as it is too long

| |

169 - Install the pushrod on the elevator horn

| |

170 - Mark the pushrod to length

| |

171 - Cut the pushrod at the mark

| |

172 - Make a mark on the pushrod

for bending, 1/2" from the servo arm center

| |

173 - Bend the pushrod to shape

| |

174 - Center the servo and elevators,

then install the pushrod and lock it in place with the screw

| |

175 - The photo shows pushrod clearance

| |

176 - The fuselage rear assembly is

completed and ready for ducting

| |

177 - Temporarily mount the tailcone

| |

178 - Use masking tape to hold it in place

| |

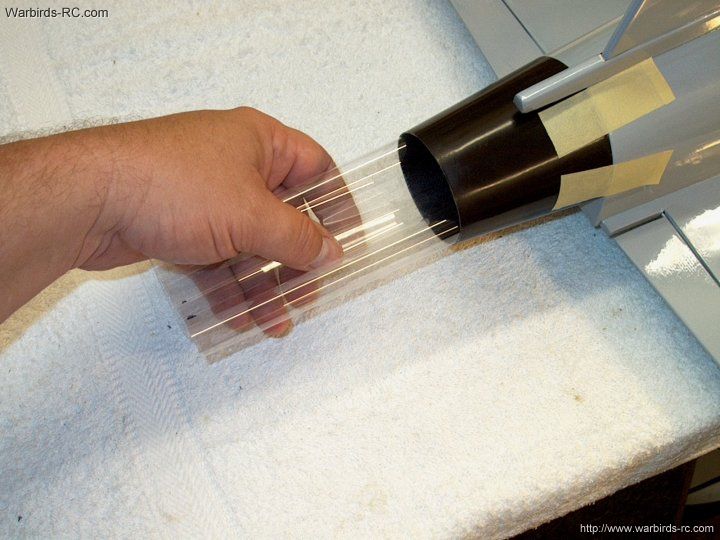

179 - Dura Lar is found at the craft

Hobby Lobby stores and a roll sells for about ten dollars.

I use the heavier .005 mil rolls and it makes excellent ducting

| |

180 - Cut a duct sheet to 12" x 10"

| |

181 - Roll the sheet and install it

in the rear of the fuselage. Push it up against the fan

shroud and mark the shroud mount locations for cutting

| |

182 - Remove 3/8" squares from the sheet

| |

183 - Fit the duct and mark the other side

| |

184 - Cut the second mount out of the sheet

| |

185 - Re-insert the duct over the fan

shroud and make a center mark

| |

186 - The seam should be adjusted so

it is at the top of the fuselage and out of sight

| |

187 - Mark the rear of the duct at the end

| |

188 - Use heavy duty clear packing

tape to assemble the duct sheet

| |

189 - Tape the duct to shape

| |

190 - Fold the duct as shown and install

it in the fuselage | |

191 - A wood dowel can be used to ease

installation

| |

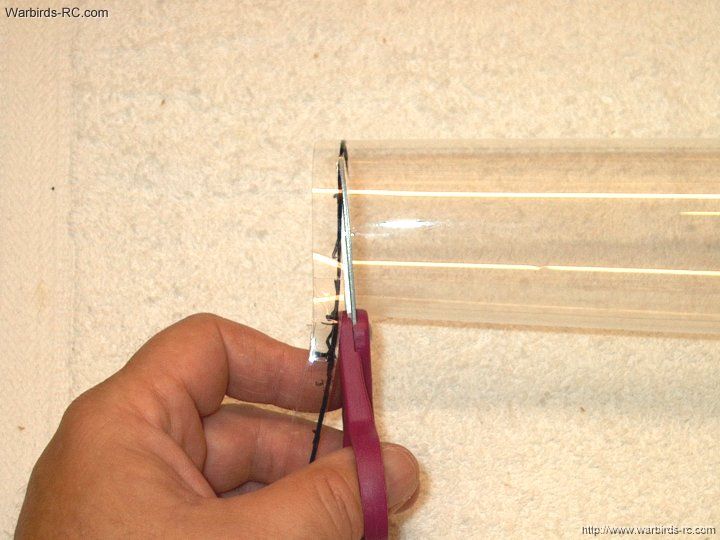

192 - Mark the tail end for cutting

| |

193 - Trim the tail to length

| |

194 - Make a mark on the duct for the ESC wires

| |

195 - Sandwich the duct with a washer

on each side. Holding both washers tight, cut a perfect hole.

3/8" washers were used

| |

196 - Install the duct and feed the

ESC wires through the hole

| |

197 - Plug the ESC wires into the power harness

| |

198 - Cut a 3/4" wide of clear packing

tape and use it to hold the duct to the shroud

| |

199 - The duct should be taped as shown

| |

200 - Install the ESC receiver wire

| |

201 - The duct is shown installed

| |

202 - Remove the tail cone

| |

203 - Rough up the inside of the

tail cone with 60 grit sandpaper

| |

204 - The tailcone should be roughed

up about 1/2" deep in the tailcone

| |

205 - Add epoxy to rear of the fuselage.

As an alternative, you could use clear rtv silicon sealer

in four spots so tailcone could be removed later if ever needed

| |

206 - Apply epoxy to the inside of

the tail cone

| |

207 - Install the tailcone on the

rear of the fuselage and position the fuselage vertically

while the glue sets

| |

208 - Mark the center on each hinge

| |

209 - Draw centerlines down the hinges

| |

210 - Install a hinge 1/2" from the

inside end of each aileron

| |

211 - Use pins to hold the hinges in place

| |

212 - Install an aileron on the wing

| |

213 - Make sure both ends are evenly

spaced from the wing side area

| |

214 - Push the aileron down at least

15mm to allow it to space itdelf from the root

| |

215 - Use thin CA to glue the hinges.

Apply CA from both the top and bottom and immediately

clean up any drops of glue

| |

216 - Remove the pins and iron out the holes

| |

217 - Install the second aileron as the first

| |

218 - Use thin CA to glue in the second

aileron

| |

219 - Install and pin hinges in the elevator

| |

220 - Space a hinge 1/2" from the

control wire

| |

221 - Use pins to hold the hinges in place

| |

222 - Install the elevator

| |

223 - Make sure the tip of the elevator

is flush with the horizontal stab

| |

224 - Push the elevator down at least

15mm to allow it to space itdelf from the root. Glue

the hinge in place

| |

225 - Install hinges in the second elevator

| |

226 - Make sure the elevator is flush

at the end

| |

227 - Apply thin CA to glue the hinges

| |

228 - Cut open the Aileron servo

area in the wing. Open it up id necessary to fit your servo

| |

229 - Use an iron to seal the edges of

the servo bay

| |

230 - Sand the wing sheeting with 100

grit sandpaper

| |

231 - Use thin CA to coat and strengthen

the bay bottom

| |

232 - Use wire or string routed

to the receiver for the aileron wire

| |

233 - Tie the wire to the servo lead

| |

234 - Pull the servo lead to the rear

| |

235 - Cut a horn slot and temporarily

install the aileron. Install a horn to line up with the aileron

| |

236 - Trim off any excess bolt length

| |

237 - Route the second aileron wire

| |

238 - Sand the aileron bay smooth

| |

239 - Connect the aileron to the

receiver and center it

| |

240 - Clean the servo with alcohol

| |

241 - Apply double sided tape to the aileron

| |

242 - Install the servo in th bay

| |

243 - Install the second aileron horn

| |

244 - Make two aileron pushrods to

the dimensions as shown

| |

245 - Install a pushrod on the Aileron

| |

246 - Both pushrods are shown installed

| |

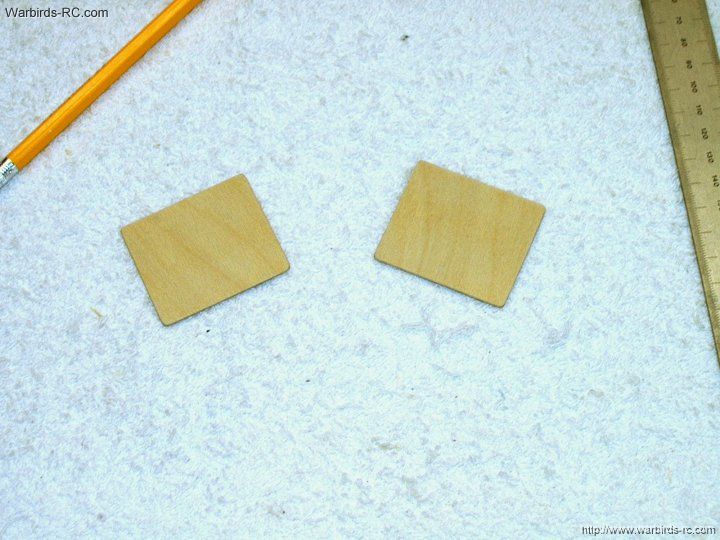

247 - Use some scrap 1/32" ply to make

the servo Aileron bay covers. They should be cut to 2"

x 1 3/4" in size

| |

248 - Apply thin CA to both sides of

each cover ath the ends that will be drilled for mounting

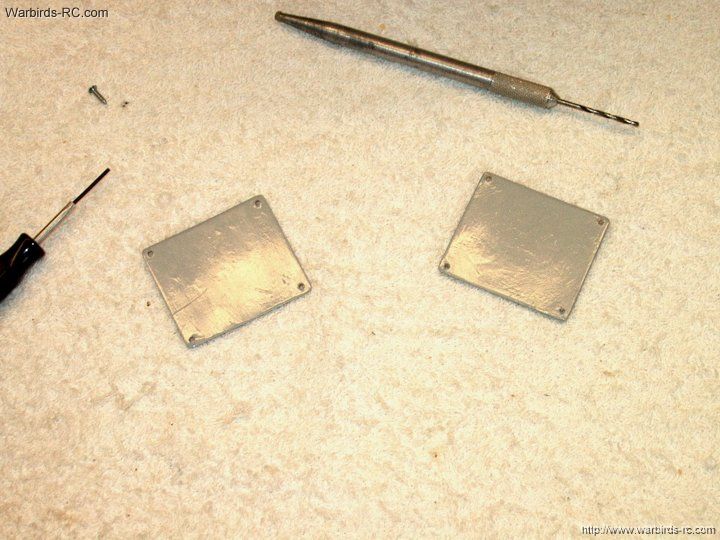

| |

249 - Use the covering you saved from

the horizontal stab to cover the Aileron covers. Both panels

can be covered with the left over scrap

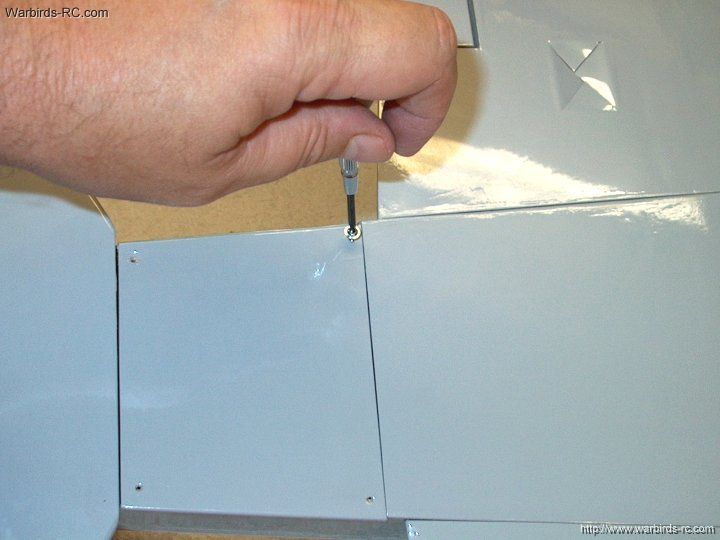

| |

250 - The panels shown covered and

drilled with a 3/32" bit for #2 screws. Drill Matching holes

in the fuselage with a 1/6" drill bit using the panel as

a guide. Reinforce fuselage holes with a couple drops of CyA

| |

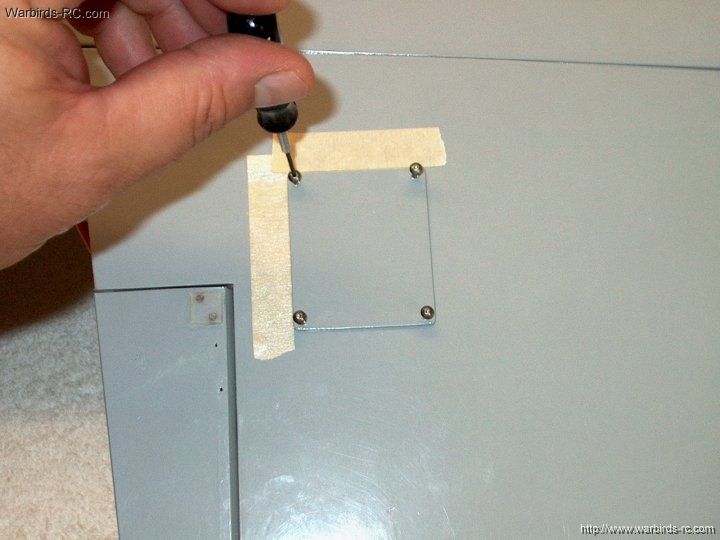

251 - Use button head screws to install

the panels

| |

252 - The second cover panel should be installed

| |

253 - The panel should sit flush to the bottom

| |

254 - Panel installation is now completed

| |

255 - Side view of the panels

| |

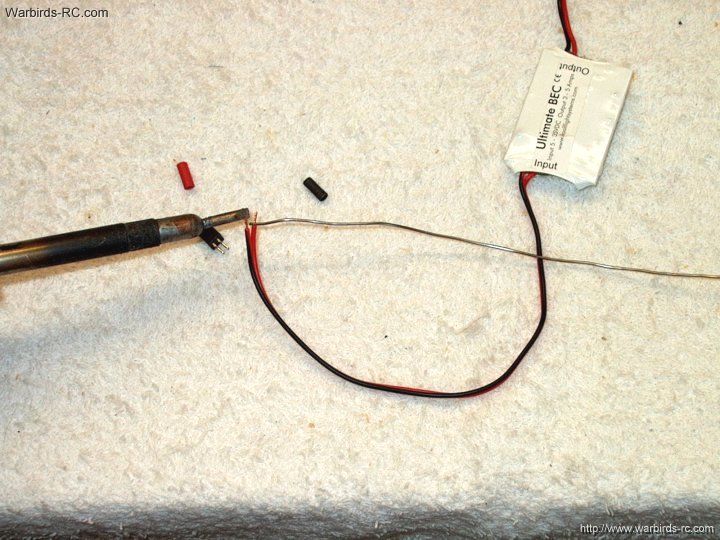

256 - If you plan on using a U-BEC,

installa small set of power wires and micro Deans as shown

| |

257 - Heatshrink the connectors and

connect the main wires, then use heat shrink to cover them

| |

258 - A U-BEC was used, as

my ESC was an Opto version, requiring external power

for the receiver. Solder micro Deans on the U-BEC

| |

259 - Plug in the wire harness and

cover it with heatshrink so it doesn't pull apart

| |

260 - Install double sided, double thick

servo tape for the U-BEC

| |

261 - Install the U-BEC and plug it

in the receiver

| |

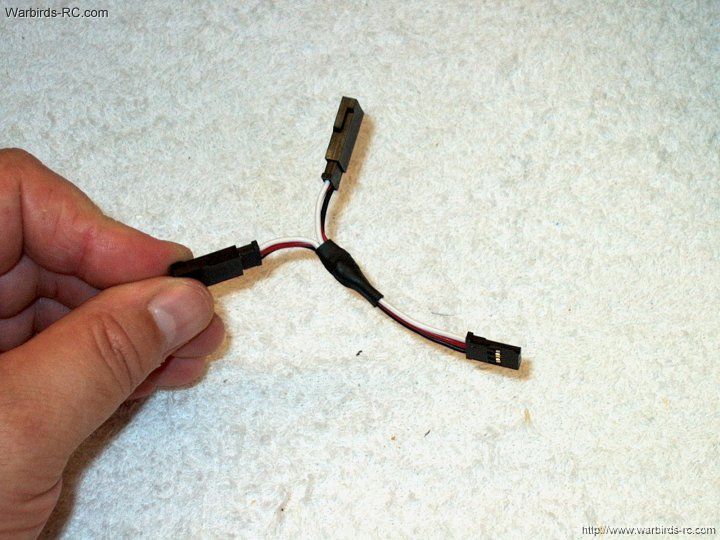

262 - A Y-Connector is required for the

Aileron servo's connection. You can either purchase a

connector or make one as shown

| |

263 - Splice, solder and heat shrink the wires

| |

264 - Cover the center with heat shrink

| |

265 - Install all connectors in the receiver

| |

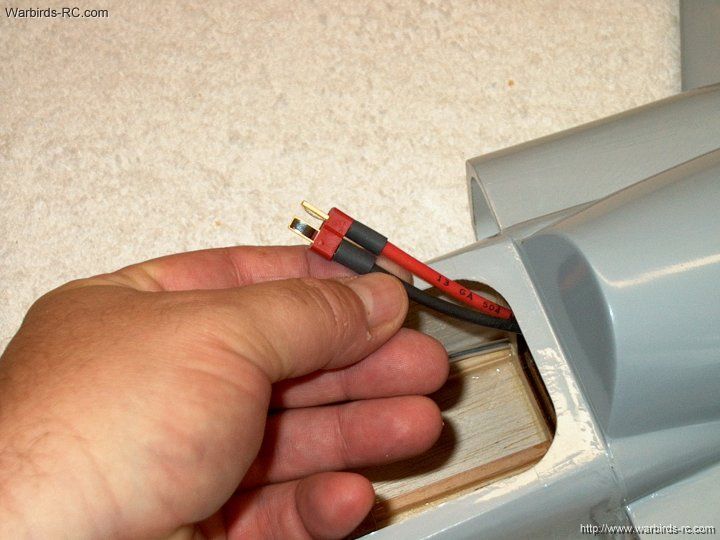

266 - Strip the power wires in the

battery area

| |

267 - Solder a Deans Ultra Connector

to the leads

| |

268 - Push on the heat shrink

| |

269 - Shrink the tubing to complete

the power wiring

| |

270 - I used a Hacker 77 Opto ESC

and programmed it for the HET 2W-20 motor and 4S Lipo

pack. Settings are as follows for the benefit of those

that use this ESC:

Type- AIRPLANE

Controller Type-

M-77-O

Brake- OFF

Timing- 18 DEGREES

Frequency- 16KHZ

Accelleration- MEDIUM

Accumulator Type- Li-Ion/LiPo1

Number of Cells- 4 LiIo/Po Lipo

Cutoff V Per Cell-

3.1

Cut Off- SLOW DOWN

Initial Point- AUTOMATIC

End

Point- AUTOMATIC

Throttle Curve- LINEAR

Rotation-

LEFT

Timing Monitor- ON

| |

271 - Set aileron throws to 12mm

| |

272 - Set elevator throw to 10mm Up

| |

273 - Set elevator throw to 5mm down

| |

274 - Set CG to 67-70mm behind the

root tip of the wing

| |

275 - Trim the ends of the canopy

| |

276 - Mark the bottom lip of the

canopy and trim it

| |

277 - Place the canopy on the center

of the fuselage, even on both sides

| |

278 - Use tape or a marker to evenly

lay a curve on the canopy front, and to mark the sides

and rear for final trimming

| |

279 - Use trim tape to mark the final

shape of the fuselage

| |

280 - Cut the canopy along the inside

of the tape or marker line

| |

281 - Canopy is ready for installation

| |

282 - Canopy is shown fitted to the fuselage

| |

283 - Lightly sand the areas to be

painted to a dull finish

| |

284 - Trim tape the inside window edges

| |

285 - Mask off the window area

| |

286 - Use a couple light coats of paint

| |

287 - Remove the tape from the canopy.

you can screw it on, use velcro or build a cockpit deck

| |

288 - Clean out the bungee hook hole

| |

289 - Rough up the first 1/2" of

the hook

| |

290 - Apply epoxy to the hook hole

with a toothpick and install the hook

| |

291 - Clean up excess epoxy with alcohol

| |

292 - Bungee hook installation is completed

| |

293 - Model with 4S electronics weighs

in around 33oz without batteries

| |

294 - The basic F-20 is shown completed

| |

295 - Hinge the canopy to the side

of the fuselage with masking tape

| |

296 - Use a marker on the inside of

the canopy to make a line showing where it sits flush

to the deck

| |

297 - Trim the canopy on both sides at

the line

| |

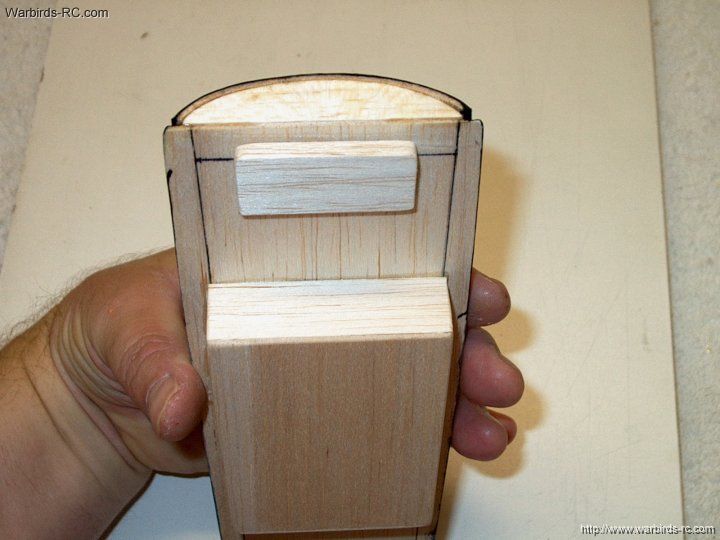

298 - Use a piece of 1/8" balsa for

the cockpit

| |

299 - Carve a piece of balsa for the

front deck

| |

300 - Add a 1/16" thick x 1/2" wide strip of

balsa sheeting to make an overhang for the instrument panel

| |

301 - Remove balsa for the HUD

| |

302 - Make the keypad plate and HUD

rails as shown

| |

303 - Cut a hole for the cockpit area

| |

304 - Use 3/32" balsa to frame up the area.

Be sure it is not too wide and clears the fuselage opening

| |

305 - Add a 1/16" thick balsa floor

| |

306 - Sand the floor flush on all sides

| |

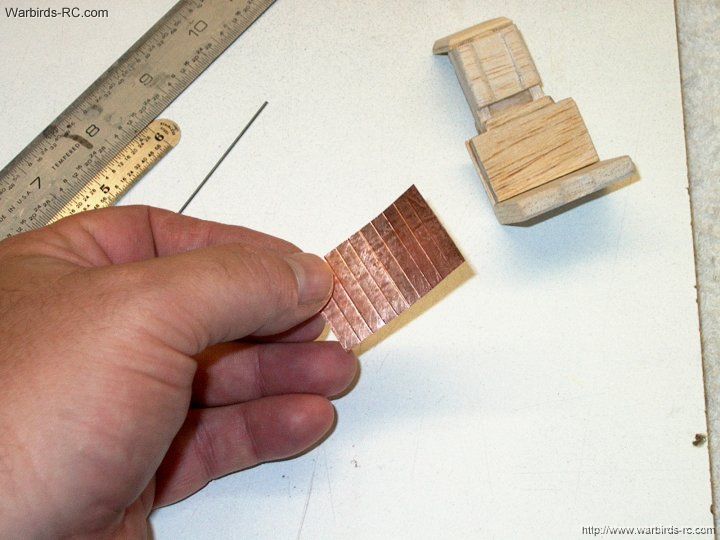

307 - I have a roll of thin, stick

back copper sheeting, 2" wide. Use a similar material

to make a seat cushion . A small thin steel rule can

be used to make cushion marks

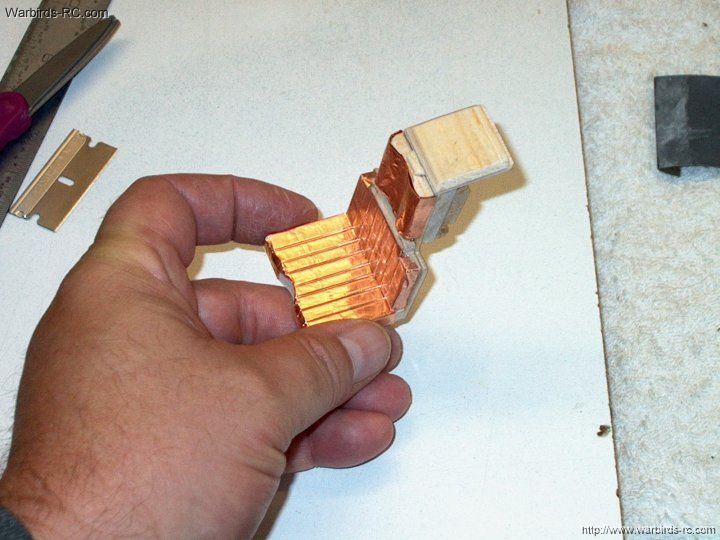

| |

308 - Apply the cushion to the seat

and form it around the corners to shape

| |

309 - Detail the rear of your cockpit area

| |

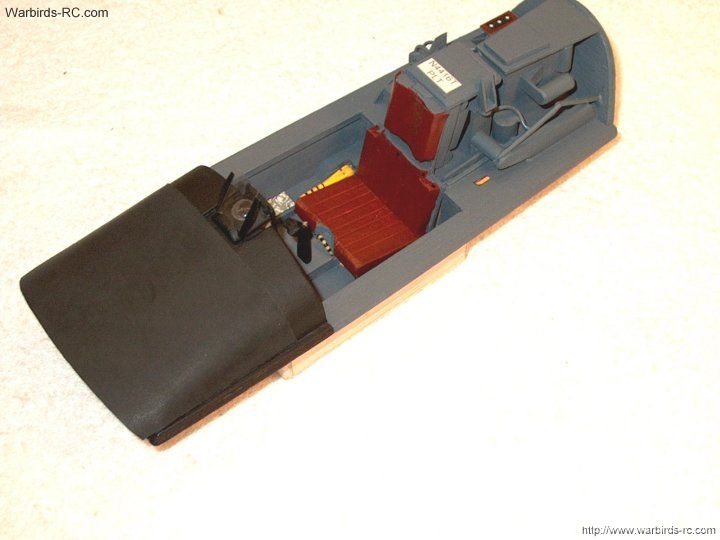

310 - Paint the interior as shown

| |

311 - Make an ejection seat pull from

a piece of yellow wire. Stripe it with paint or a marker

| |

312 - Make a label for the instrument panel

| |

313 - Glue a piece of black card stock from

a department store arts area over the deck as shown

| |

314 - Add a front hook to bottom of the

cockpit. The 1/4" balsa hooks under the front deck of the fuselage

| |

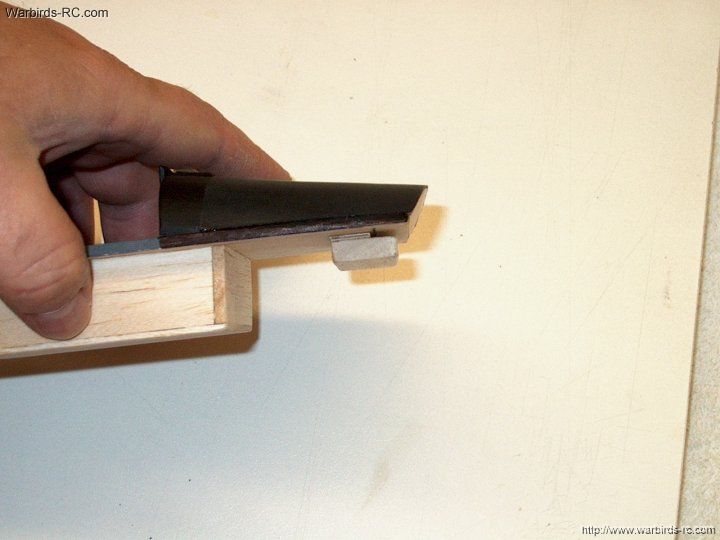

315 - A front view shows the width of

the 1/4" balsa hook

| |

316 - Make a joystick carved to

shape froma balsa stick

| |

317 - Apply your decals to the cockpit area

| |

318 - USe this photo as a reference

when detailing the cockpit

| |

319 - This is a photo of a real F-20

cockpit. Use it to as details as desired

| |

320 - Cockpit Walk Around - Pic 1

| |

321 - Cockpit Walk Around - Pic 2

| |

322 - Cockpit Walk Around - Pic 3

| |

323 - Cockpit Walk Around - Pic 4

| |

324 - Cockpit Walk Around - Pic 5

| |

325 - Cockpit Walk Around - Pic 6

| |

326 - Cockpit Walk Around - Pic 7

| |

327 - Instrument Panel Walk Around - Pic 1

| |

328 - Instrument Panel Walk Around - Pic 1

| |

329 - Instrument Panel Walk Around - Pic 1

| |

330 - Install your cockpit in the fuselage

| |

331 - Rear view of the installed cockpit

| |

332 - Since I didn't have the sheets of

decal printed on clear peal like you will receive from the

mfgr, I had to make my own. Cut the F-20 out and apply it

| |

333 - Use tape to keep individual

letters in alignment

| |

334 - Place masking tape across the

bottom to apply the decals straight and even on both sides

| |

335 - Apply your rear decals as shown

| |

336 - Mask off the top deck and

paint it semi flat black. Flat black tends to crack,

so semi flat is a better choice. You can use a couple

light coats of dull-coat to flatten out the color

| |

337 - Use the cockpit when masking

to insure the tape lines up with the cockpit

| |

338 - Side view shows the cockpit with

paint and decals

| |

339 - Your model should have all

decals applied as shown

| |

340 - The F-20 Tigershark is

shown with detailing completed

| |

341 - The F-20 is huge in size compared to

the HET-RC FA-18

| |

342 - There are many ways to

make a battery tray and this is just one of them. Note

that this method will add about 2 oz in weight. Cut two

1/8" planks of balsa and glue them in on each side of the

center spar to raise the deck. Shorten the The hook block

about 3/32" with a cutting wheel; you can see where the

newly installed balsa planks were carved out to make room

for velcro straps

| |

343 - Make a battery tray from 1/8"

plywood...you could probably shorten the front by 2"

from my pics to save some weight. Velcro is applied to

the battery packs and the plate bottom as shown, while

the straps hold the packs down to the plate

| |

344 - Epoxy the plate in place as shown.

the battery may have to recess into the rear opening for

proper balancing

| |

345 - Carve the former flush for the battery

| |

346 - Apply velcro to your battery | |

347 - I used two 2S Lipos that were

sandwiched to the velcro

| |

348 - Use a Y-connector of you use

2S packs. It is recommend you use sufficient packs for

your power requirements. These Kokam 3200's were rated at 64 amps

| |

349 - Install the battery in place.

Note that if you make one of these trays, it should be

made shorter at the front and extend slightly into

the rear for less weight and better balancing. This one was

a test tray, so it would be different if done again.

Also note the two black lines on each side of the velcro pad

at the bottom. This was a marker to place the packs so CG

would be at 67mm

| |

350 - Top view of the pack is shown

| |

351 - Paint and glue your canopy on

the cockpit using RC-56 canopy glue. Use tape to hold

it in place until the glue sets

| |

352 - Remove the tape and check the fit

| |

353 - Check the balance on your model

| |

354 - The HET-RC F-20 Tigershark EDF Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |