01 - The F-16 as it arrives well packed

from Markos at Warbirds-RC | |

02 - The model is double boxed and all

parts are wrapped for protection | |

03 - The HET-RC F-16 Falcon ARF Minifan

480 Jet out of the box | |

04 - The major components of the model. It

is very similar to the HET-RC FA-18 in construction and

covering | |

05 - Front view of cockpit area. The glass

work is very well done | |

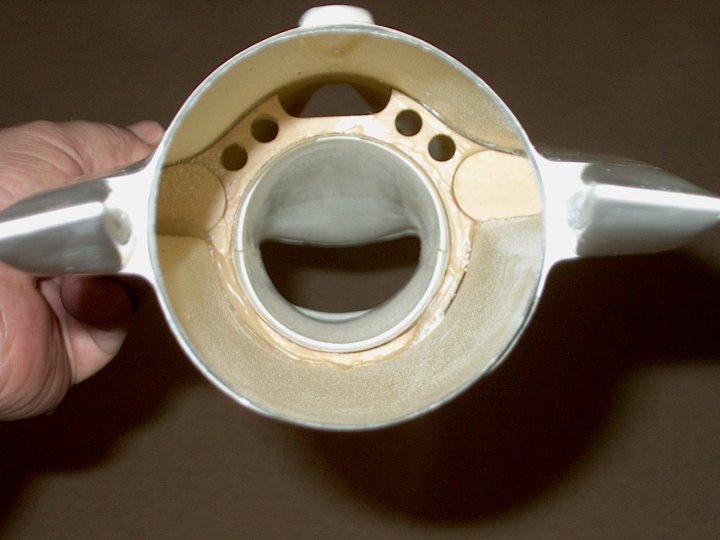

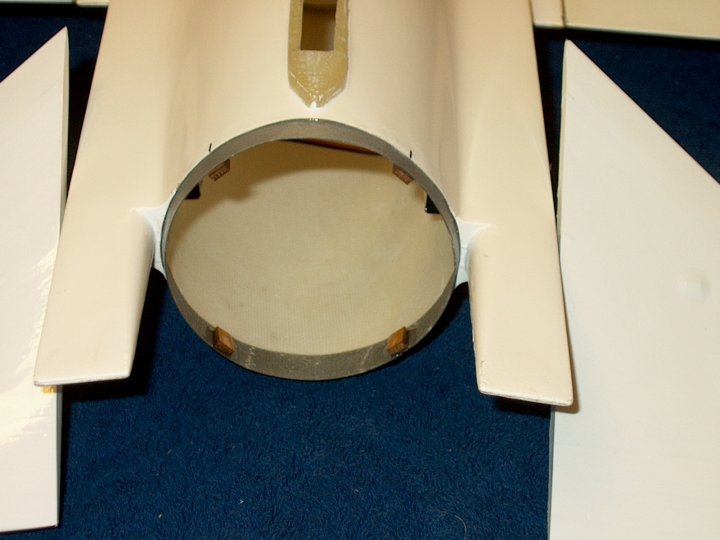

06 - Rear view showing pre-installed

Fiberglass Intake and formers | |

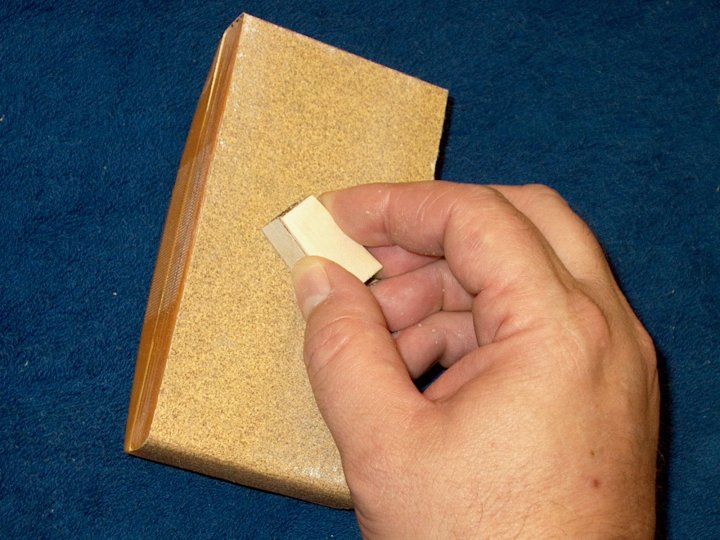

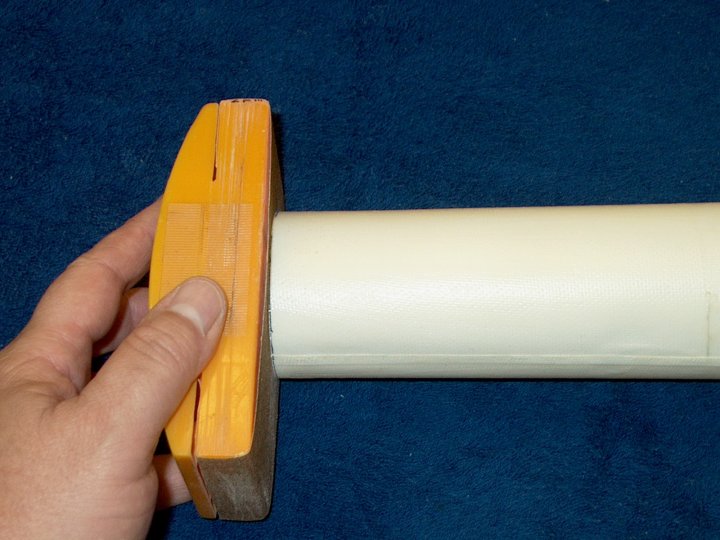

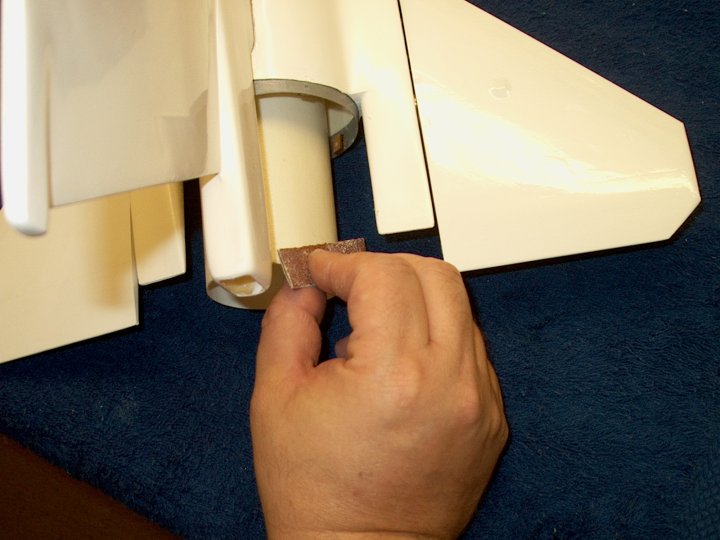

07 - Construction: Sand the wing saddle on

the fuselage for good glue purchase

| |

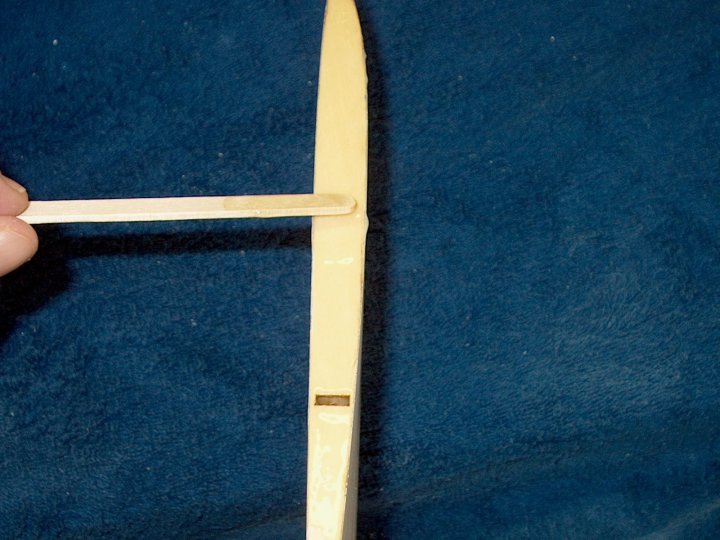

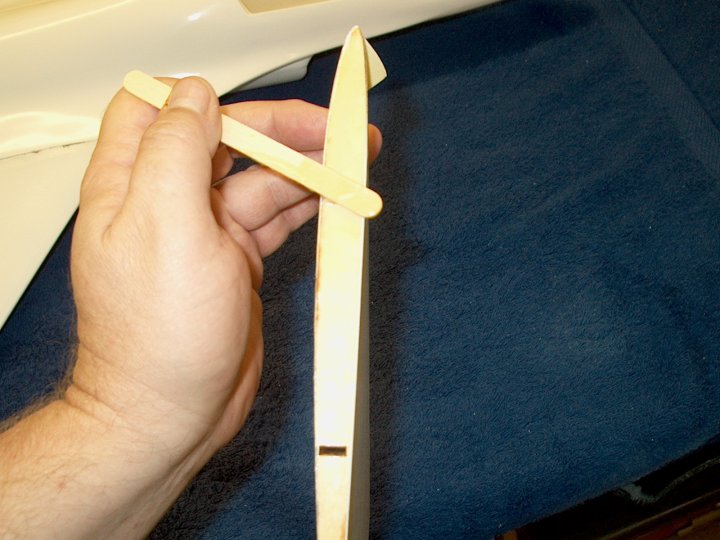

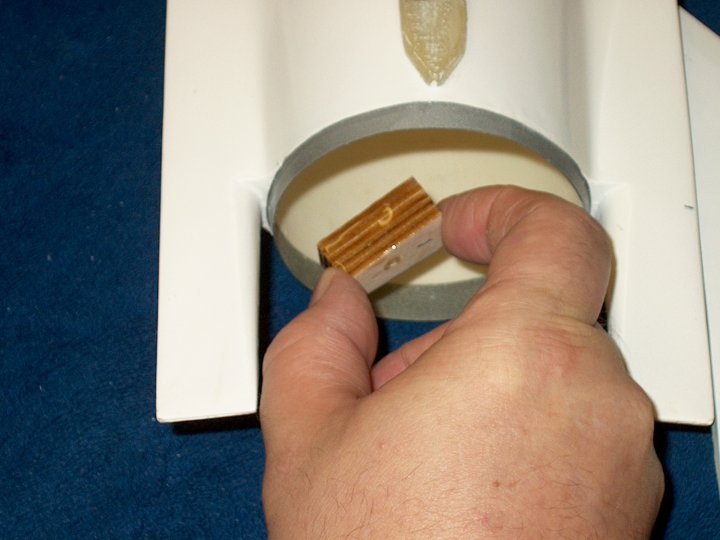

08 - Five Minute Epoxy is applied in the

wing spar hole using a cut down mixing stick to fit the

slot | |

09 - Next, insert a wing spar until it

bottoms out in the slot | |

10 - Spar shown installed

| |

11 - Clean up excess epoxy with some paper

towels and denatured alcohol | |

12 - Spar installation shown

completed | |

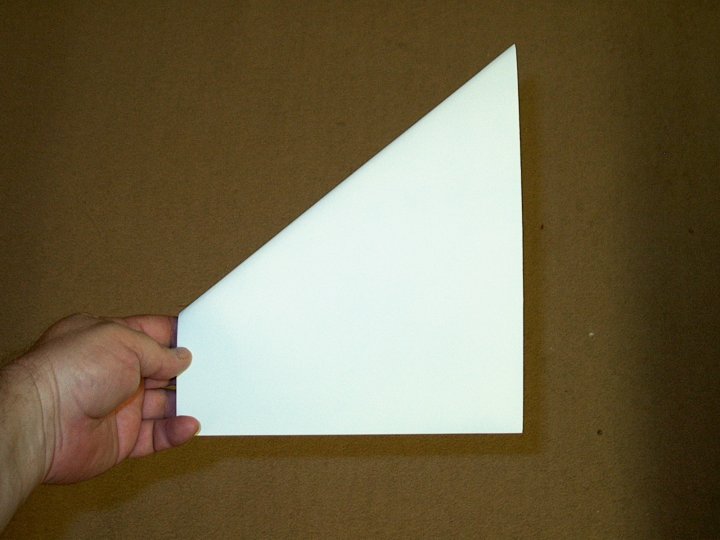

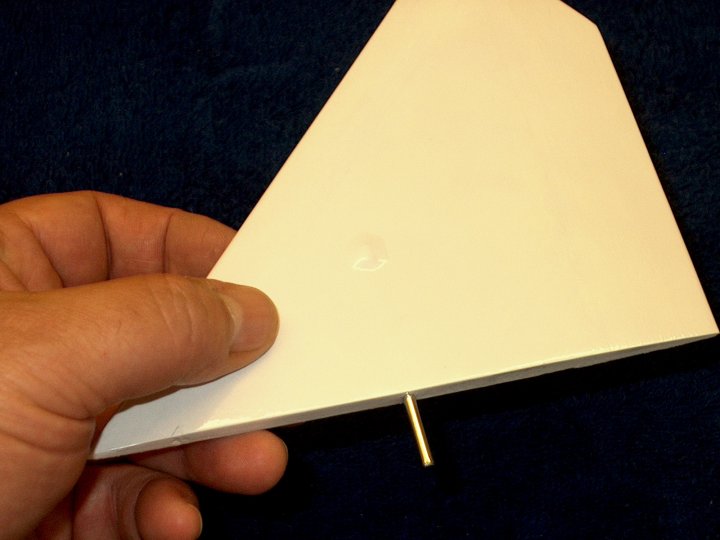

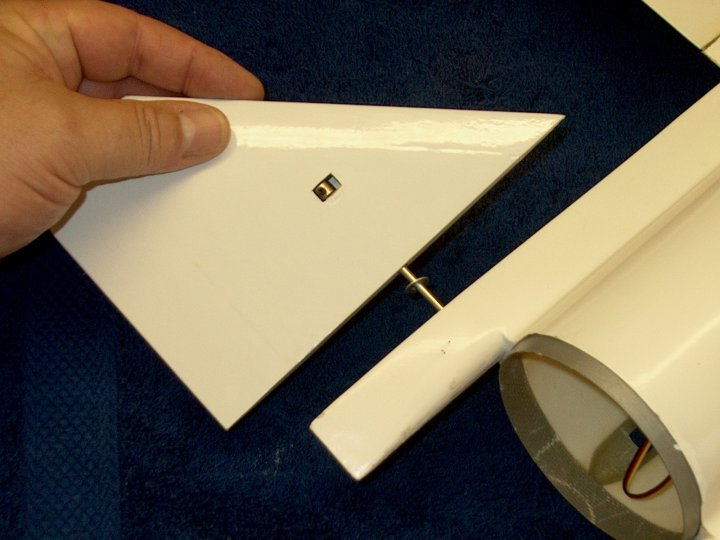

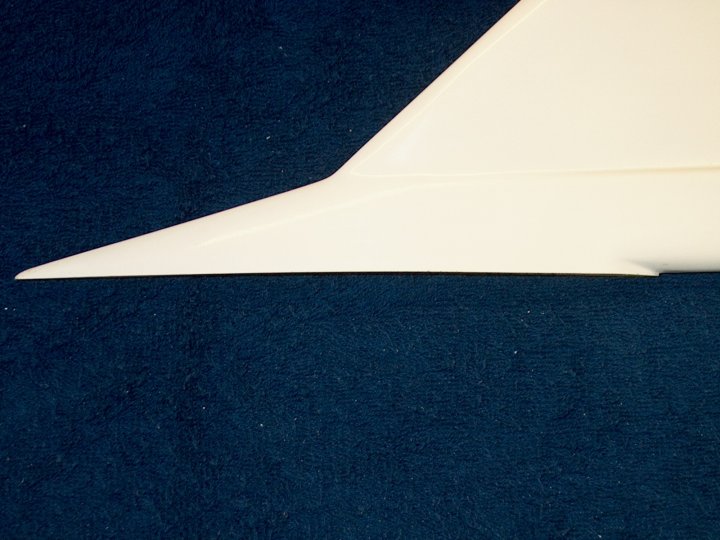

13 - There is a left and right wing. The

side with less curve is the bottom, so mark them "left" and

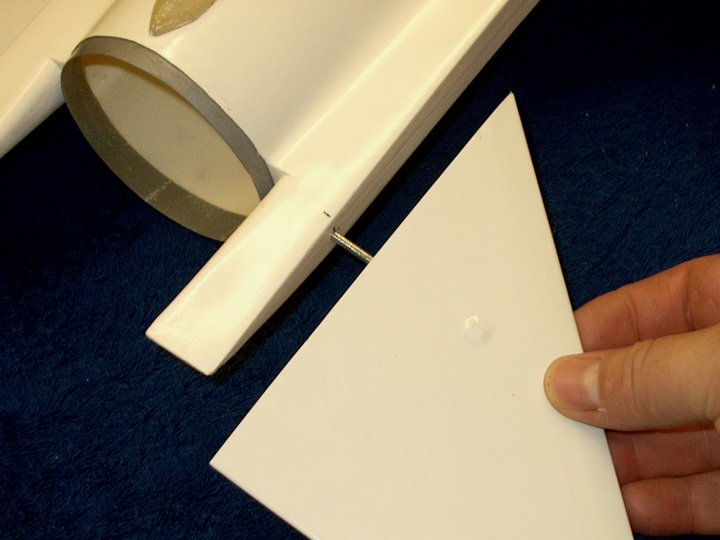

"right" | |

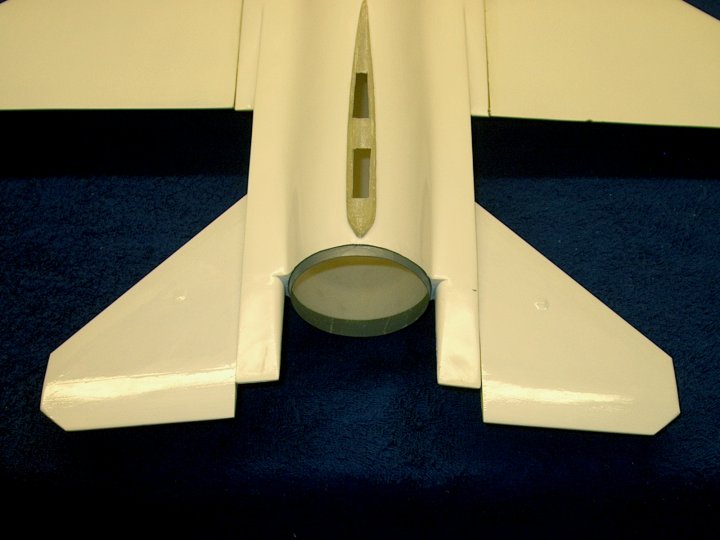

14 - The wing is placed over the spar and

adjusted so it is centered in the rear and the front of the

fuselage. This will adjust the spar to the correct position.

Carefully remove the wing and let the spar glue set

| |

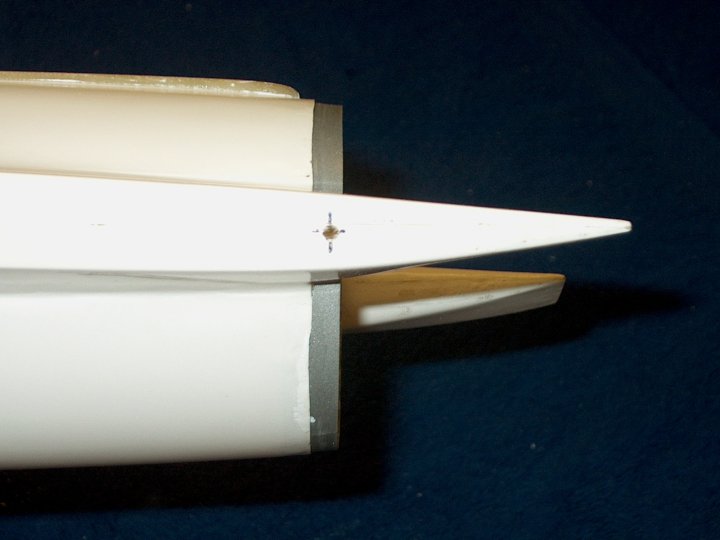

15 - The wing shown installed and flush in

the front of the fuselage shows a gap at the rear. This will

be filled with Epoxy when the wing is mounted

| |

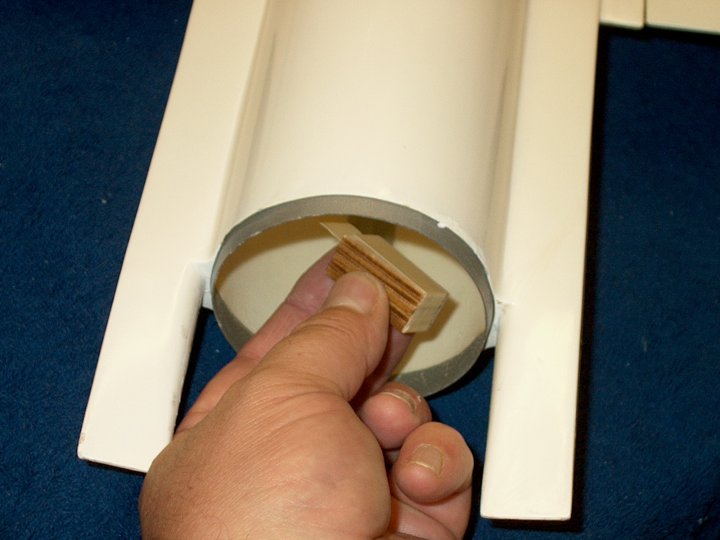

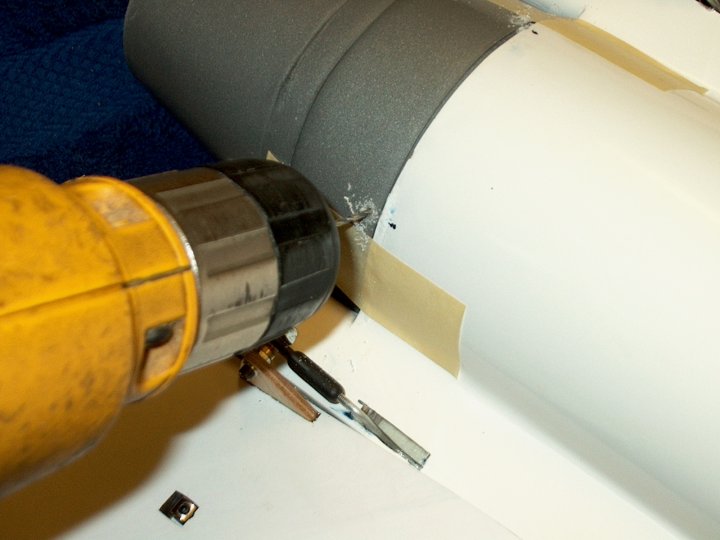

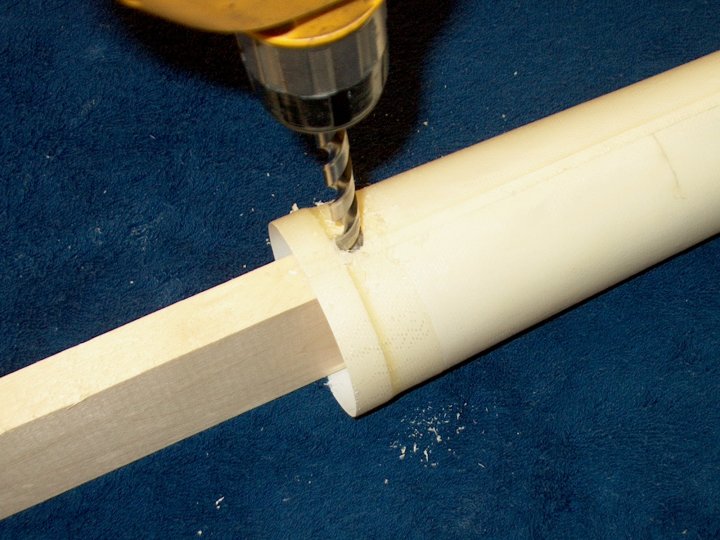

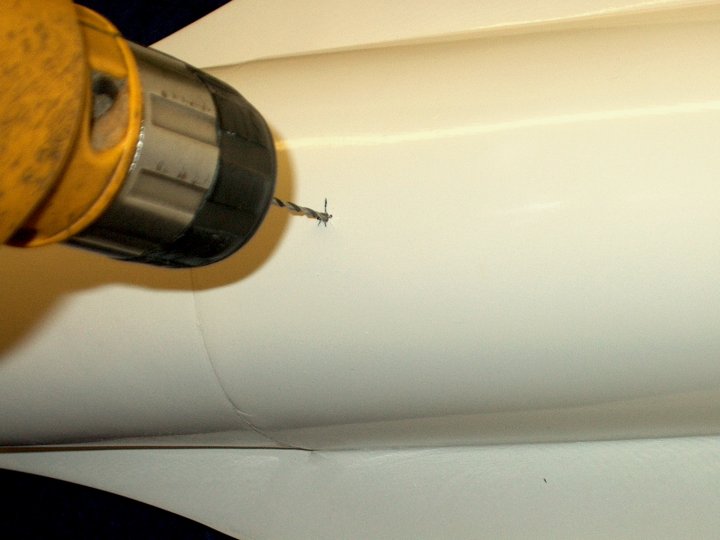

16 - A 1/8" drill bit is used to make some

holes in the fuselage. This will allow the epoxy to create

"rivots" inside the wing saddle for a stronger joint. Lightly

sand after drilling to remove burrs

| |

17 - Fifteen minute Epoxy is applied to

the wing root | |

18 - Fifteen minute Epoxy is applied to

the wing root. | |

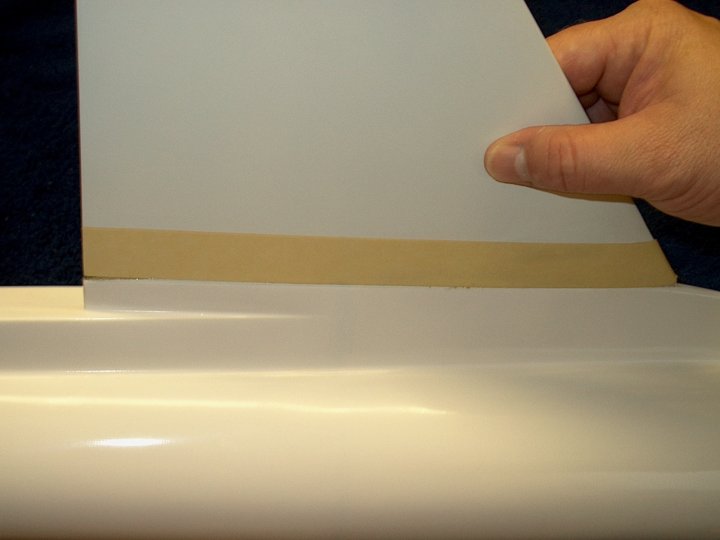

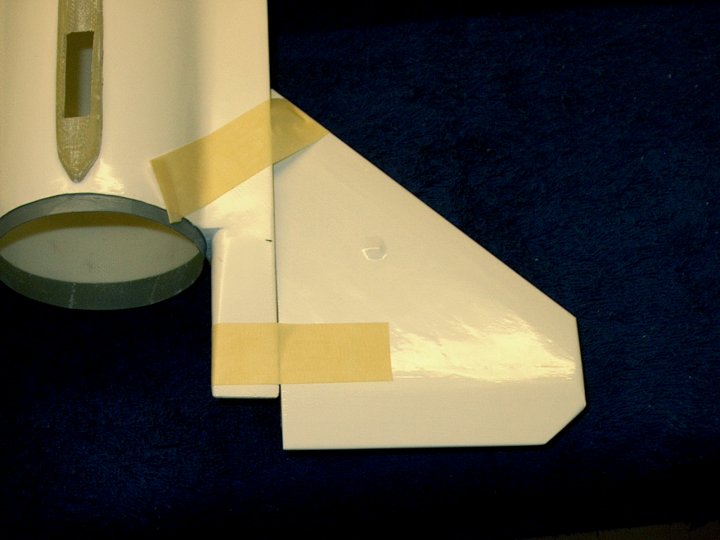

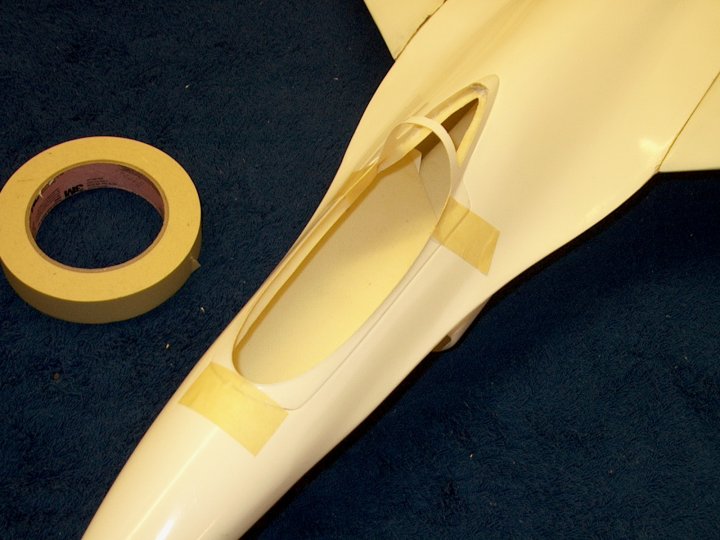

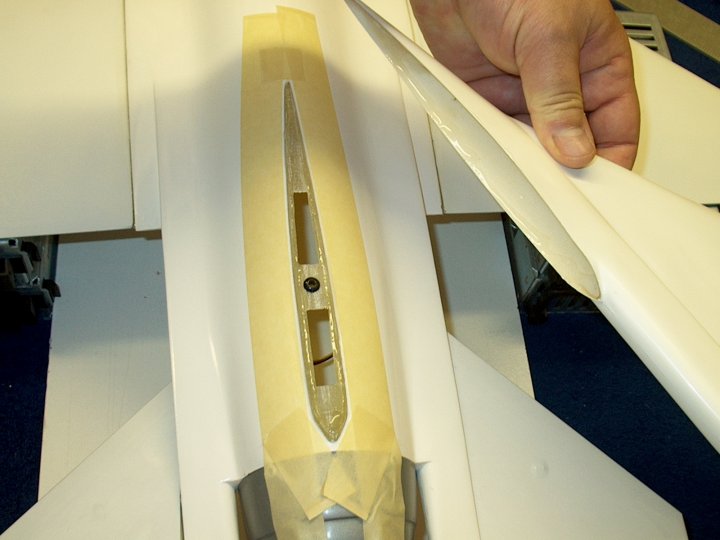

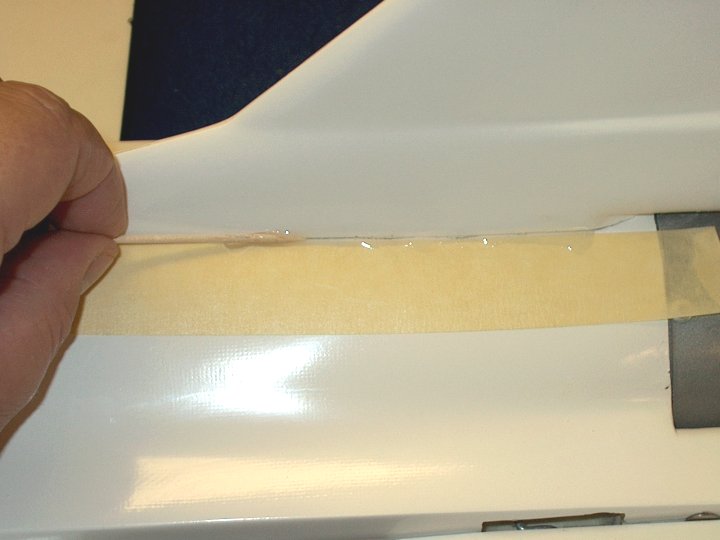

19 - The wing is set in place. If you

fiberglassed your wing, masking tape is used to keep excess

epoxy from adhering to the finished surface. Make sure the

wing is centered and the bottom of the wing is flush with the

root molding of the fuselage. Keeping the bottom of the wing

flush with the bottom of the fuselage will insure correct

incidence without any twist for the wing position.

| |

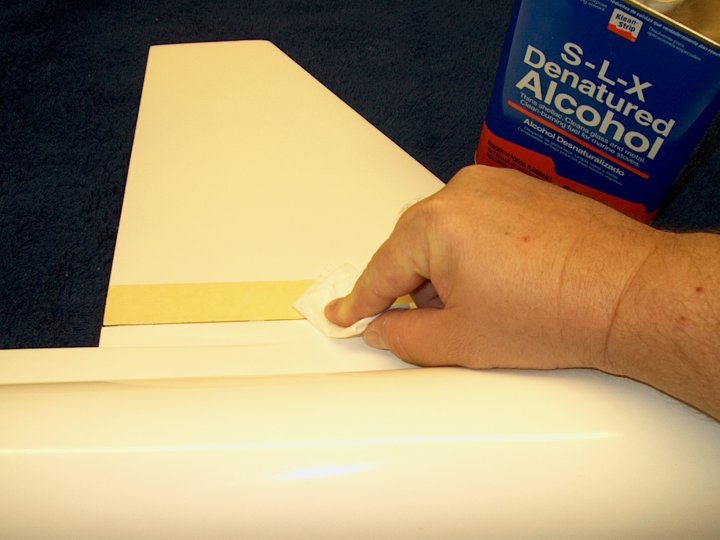

20 - Denatured alcohol is used to remove

the excess epoxy | |

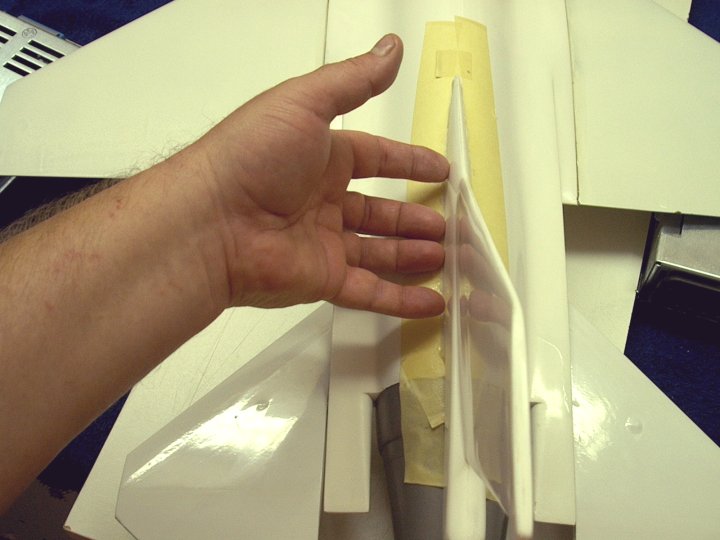

21 - The front of the wing is centered and

held in place with masking tape. The rear is centered and held

in place with a clamp and left to set

| |

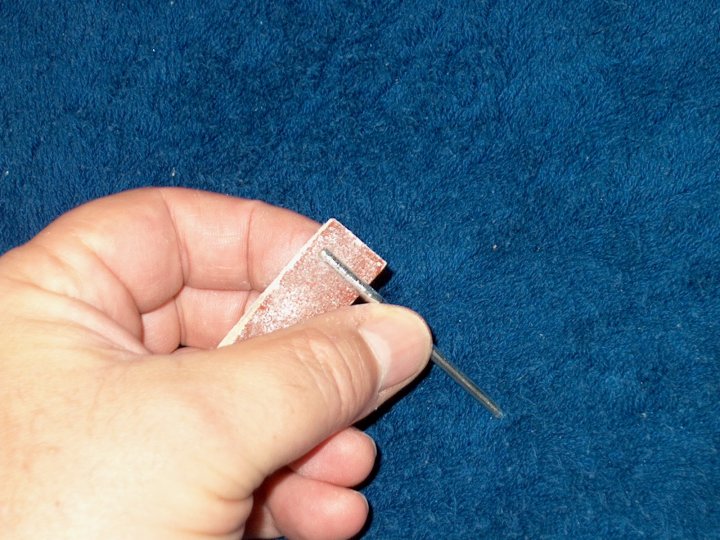

22 - The other wing saddle is sanded for

better glue purchase. A small piece of 60 grit sandpaper makes

quick work of it, but be careful not to oversand

| |

23 - Epoxy is applied to the spar slot

with a cut back mixing stick | |

24 - Epoxy is applied to the spar and the

wing spar is installed until it bottoms out in the slot

| |

25 - Excess glue is cleaned up with

denatured alcohol and a paper towel

| |

26 - Spar is installed

| |

27 - Wing is placed in position and

centered in the front and back to correctly position the spar,

then it is carefully removed before the epoxy sets, then the

spar is drilled for rivot holes | |

28 - Epoxy is applied to the wing

root | |

29 - Next epoxy is applied to the fuselage

wing saddle and spar | |

30 - The wing is installed on the saddle

and centered. Excess epoxy is removed with denatured alcohol

and a paper towel. Then tape is used to keep the front of the

wing centered and the bottom of the wing flush to the fuselage

root while a clamp keeps the rear centered until the epoxy

sets | |

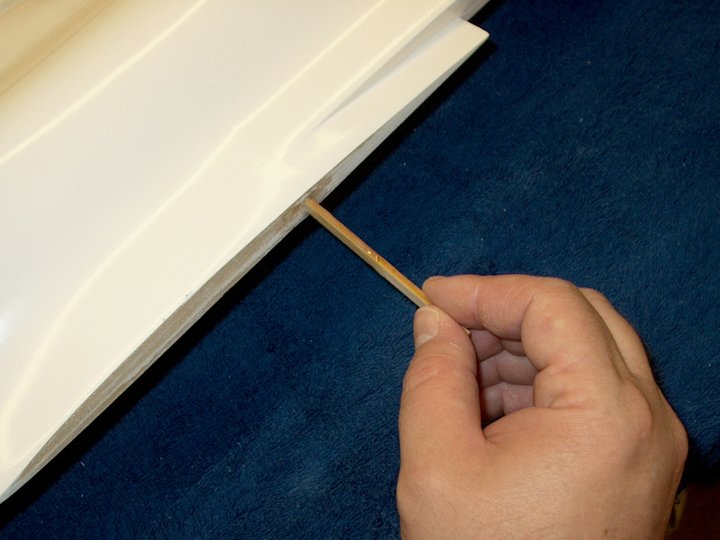

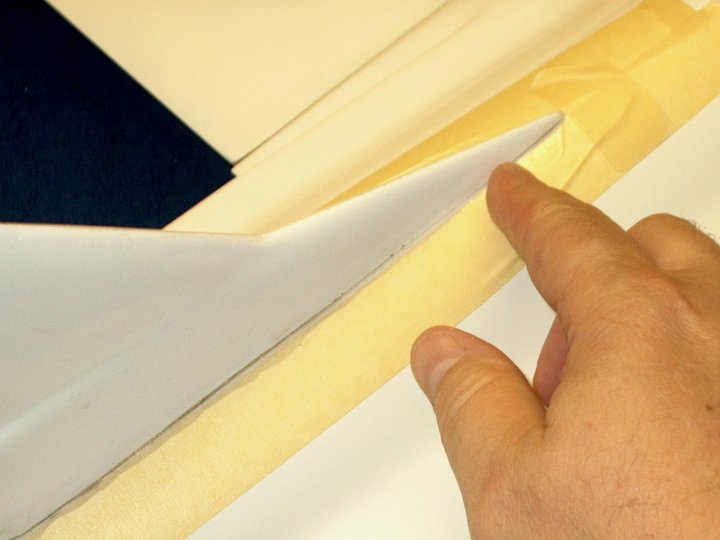

31 - Epoxy is applied to the joint as a

fillet. A toothpick is used to apply it and the tape was place

on the surfaces to catch the overflow

| |

32 - The excess epoxy is wiped off and

overflow lands on the tape | |

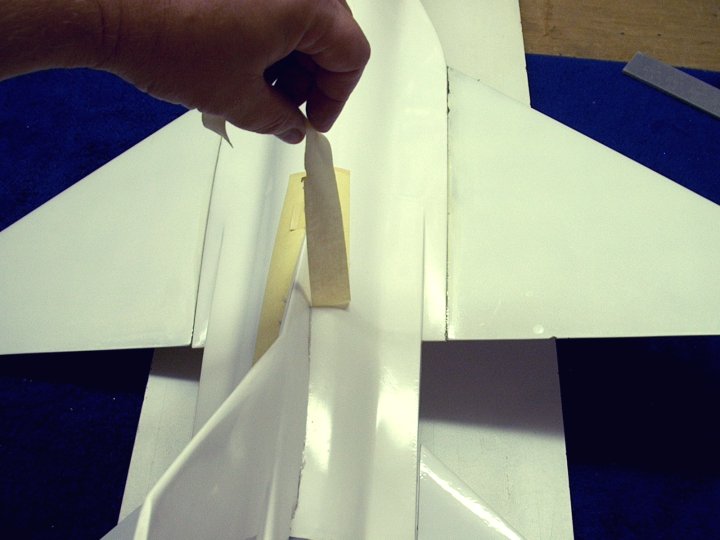

33 - The tape is removed, revealing a

clean joint. Repeat and do the same on the other side of the

model | |

34 - Wings are shown installed on the

fuselage | |

35 - Front view of wing installation shows

wings with a couple of degrees on anhedral. This was due to

the design of the fuselage | |

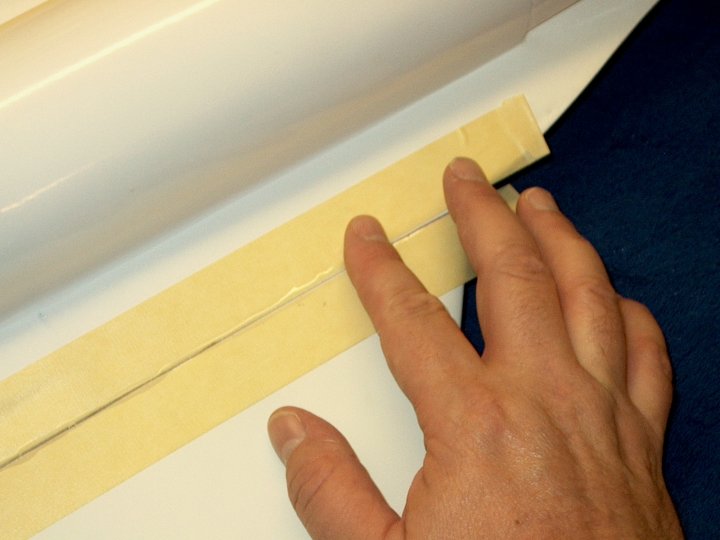

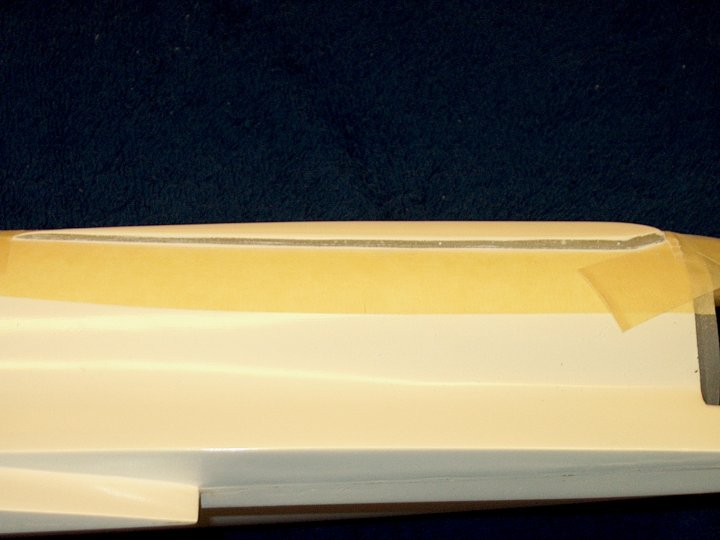

36 - The vertical stabilizer area of the

fuselage is taped off so sandpaper does not mar the

finish | |

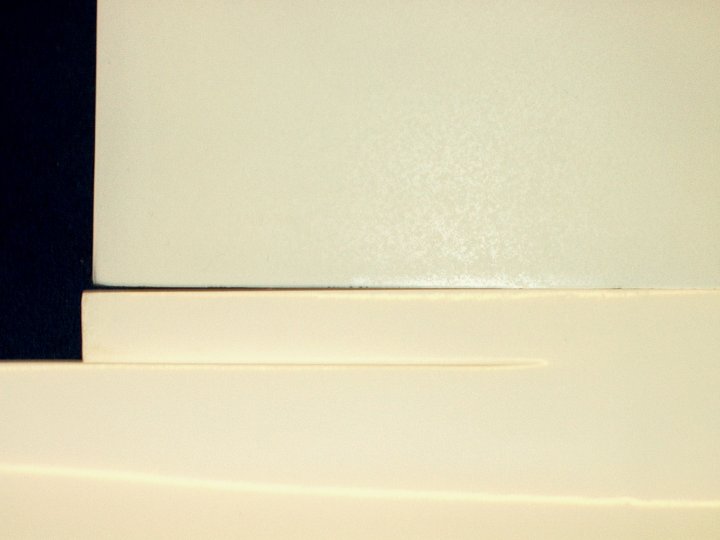

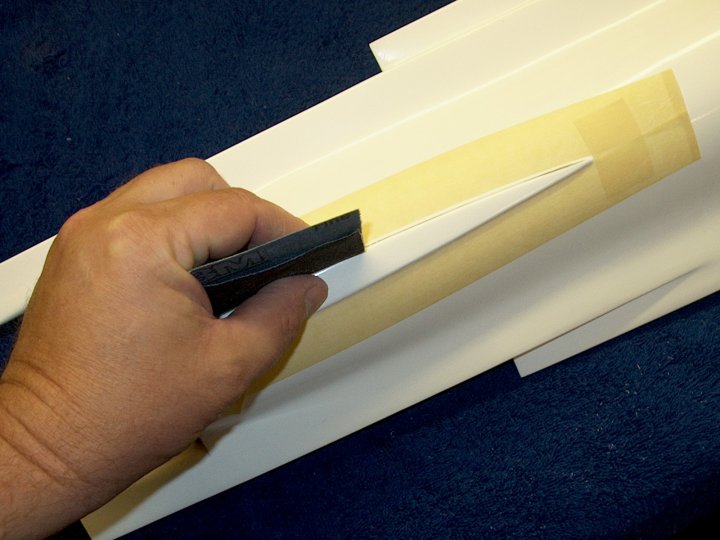

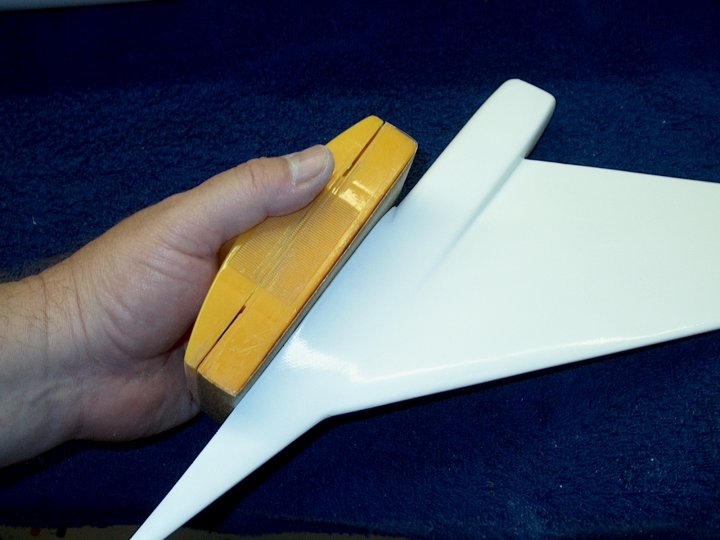

37 - Sand the sides of the saddle with

80-100 grit sandpaper. Be very careful as to not oversand as

you could cut through the glass | |

38 - Side view shows edges sanded and

ready for epoxy | |

39 - The top outside edges were sanded so

any excess glue would adhere well and form an internal fillet.

While it is not necessary, the entire top of the saddle area

was sanded in the pic | |

40 - Stab area sanded. Be careful to not

oversand...if you do, simply apply a coat of epoxy on the

inside area of the fuselage to strengthen

| |

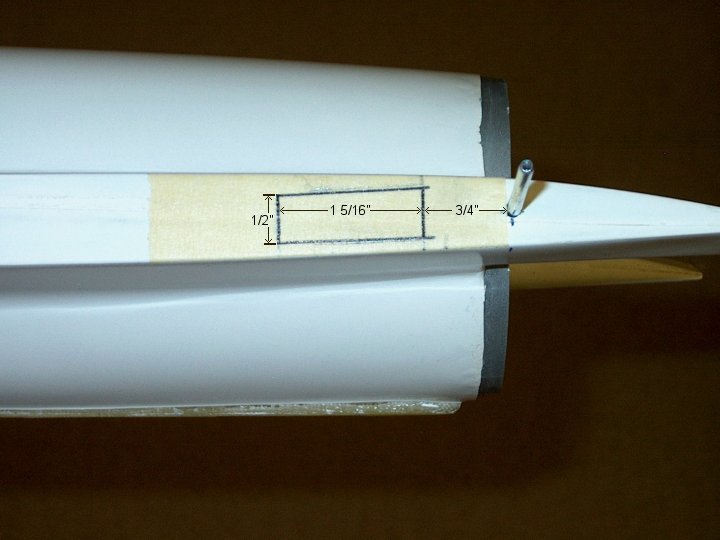

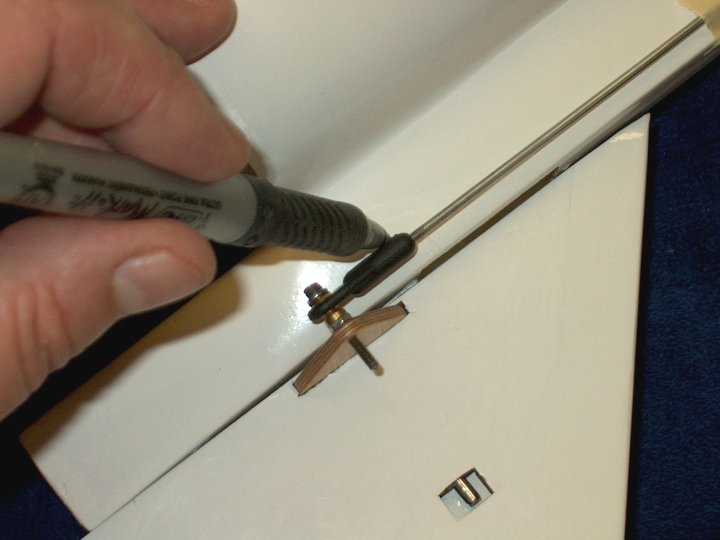

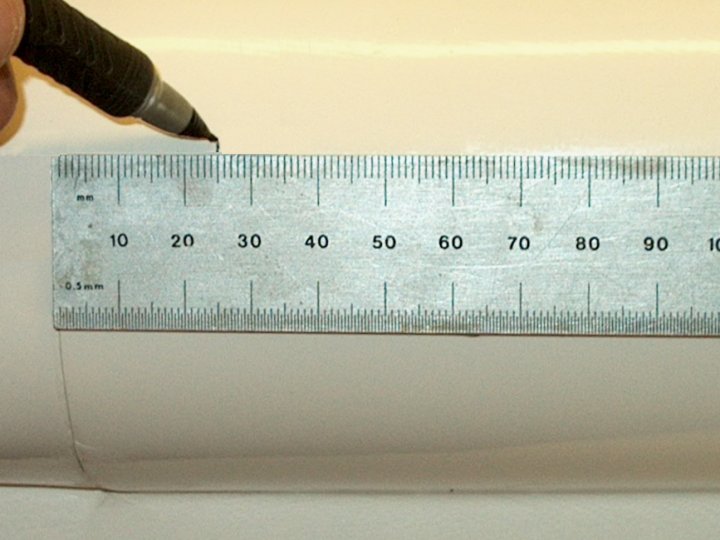

41 - Marks were made in order to cut two 1

1/2" long slots in the vertical stab area that are used for

both cooling and the receiver antenna

| |

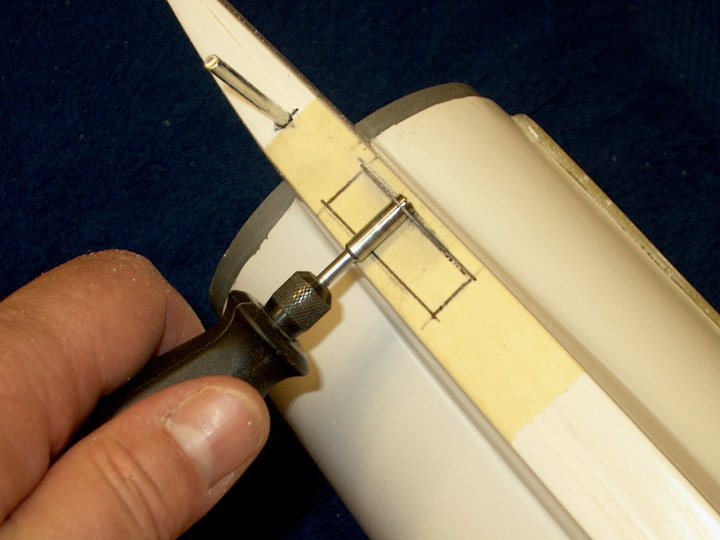

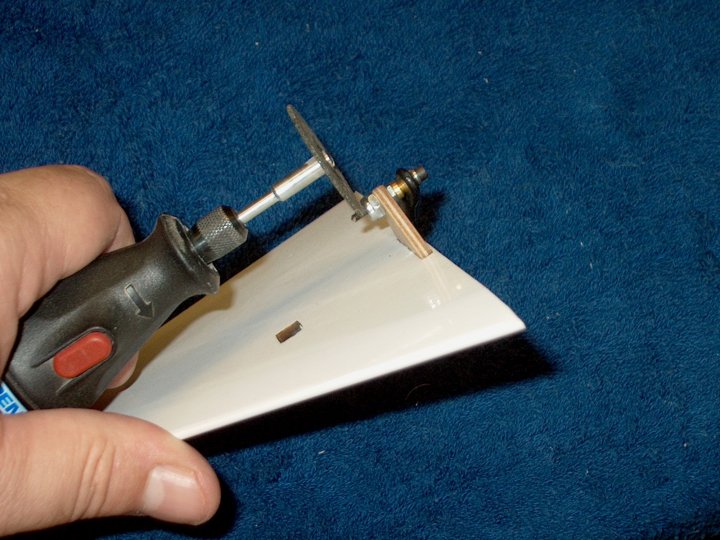

42 - A Dremel with a stone cutting wheel

was used to open the slots | |

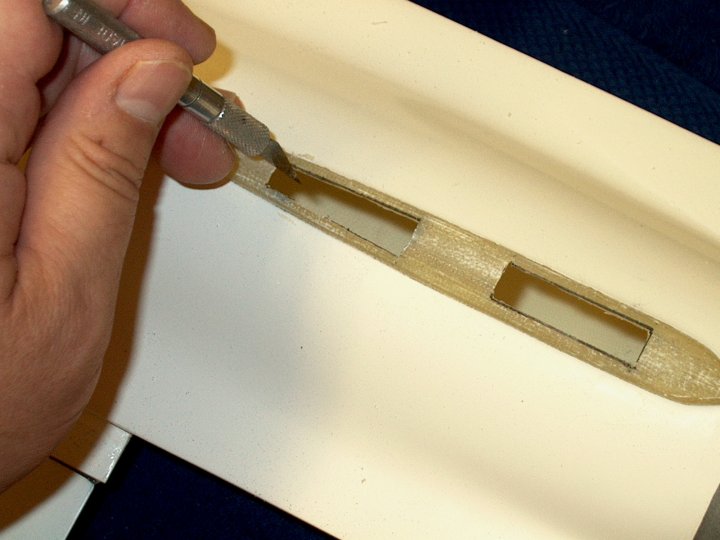

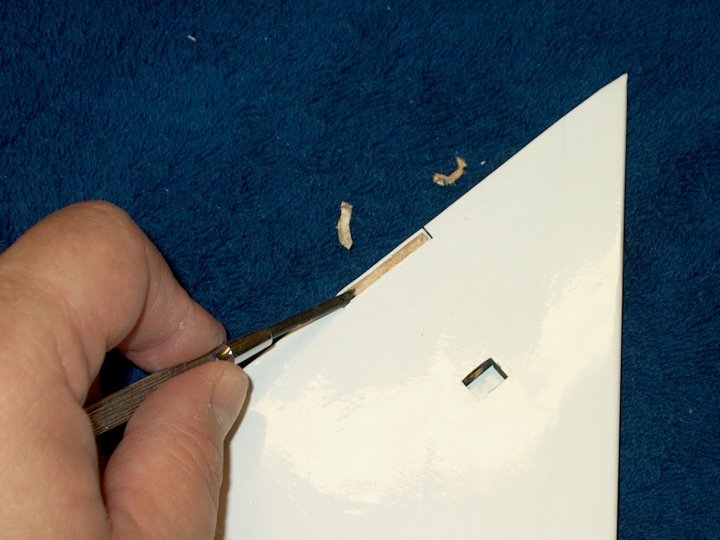

43 - A hobby knife is used to clean the

corners and remove large burrs | |

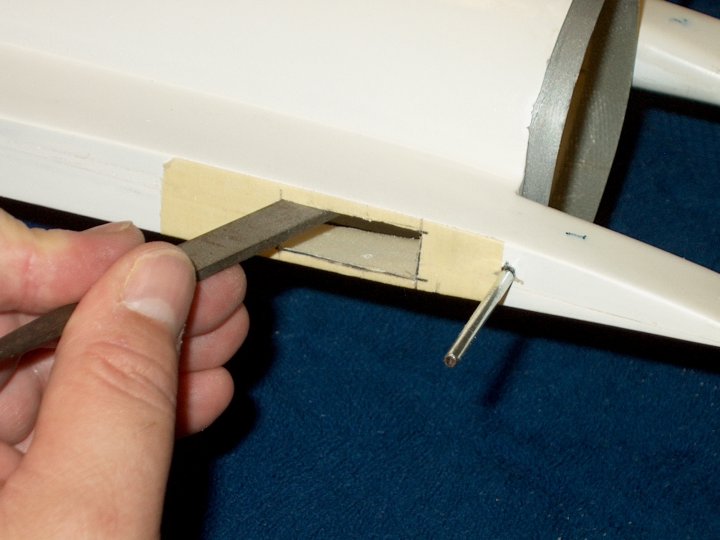

44 - Some 400 grit sandpaper is used to

smooth the edges inside and out | |

45 - The two slots are shown finished.

This completes the Vertical Stab pre-assembly

| |

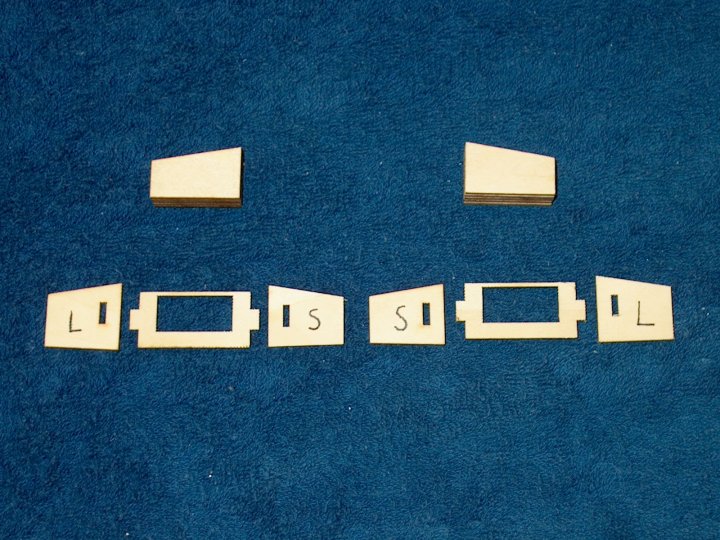

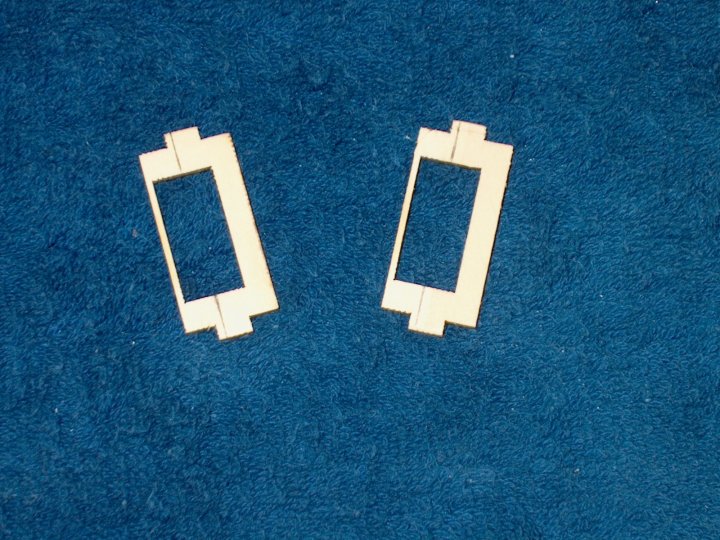

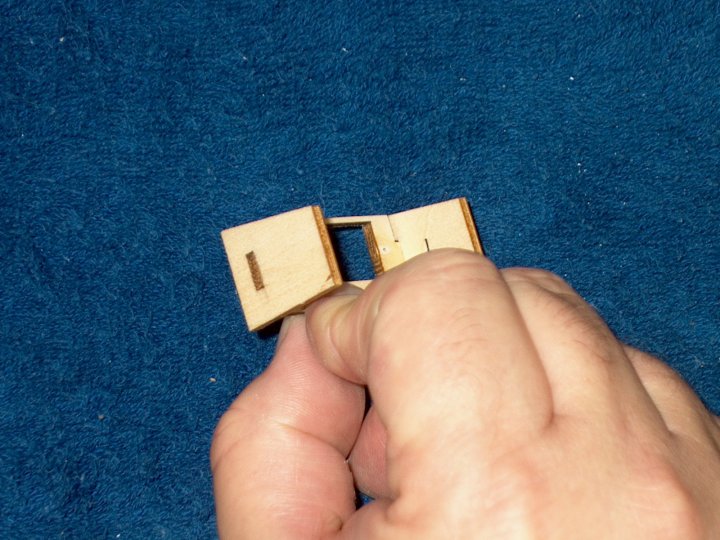

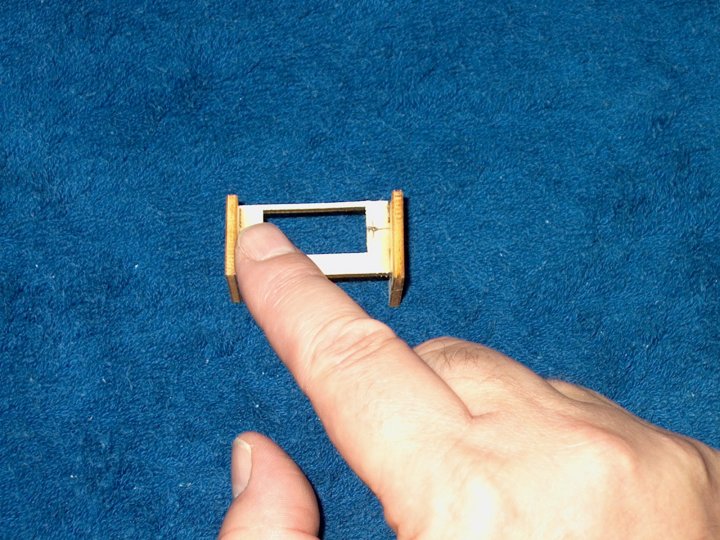

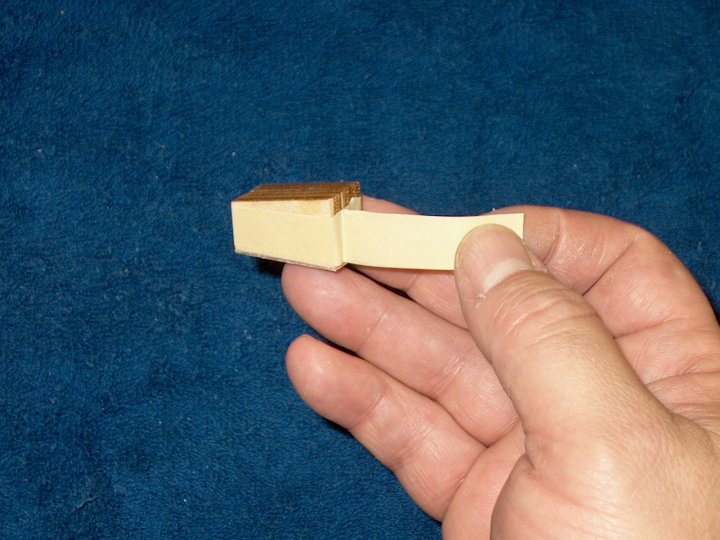

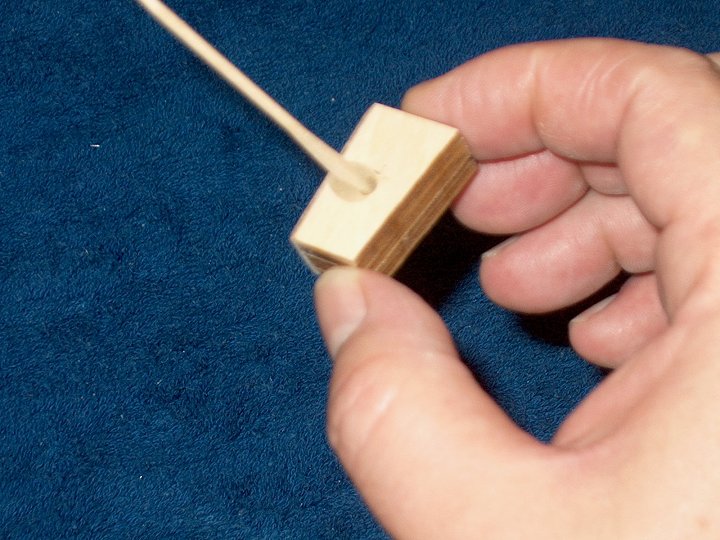

46 - The wood pieces that are needed for

Taileron assembly. Make sure you make two opposite/mirrored

trays, one for the left and one for the right. The side plates

are labeled S for Short and L for Long with the long side

facing the front of the fuselage when installed

| |

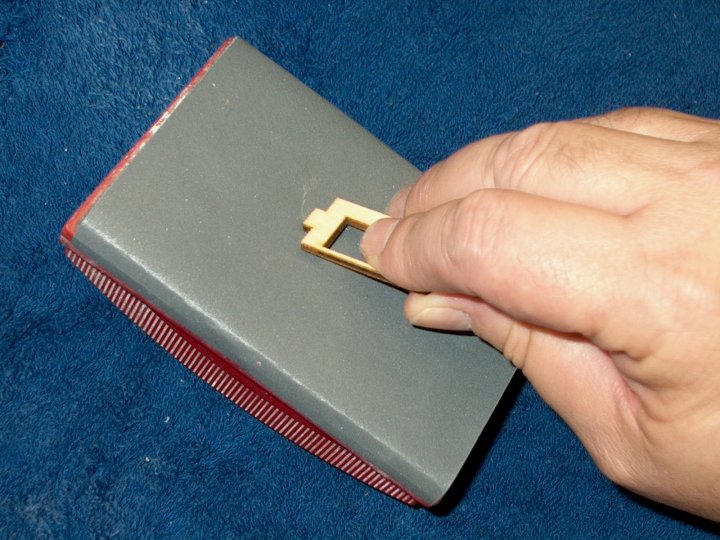

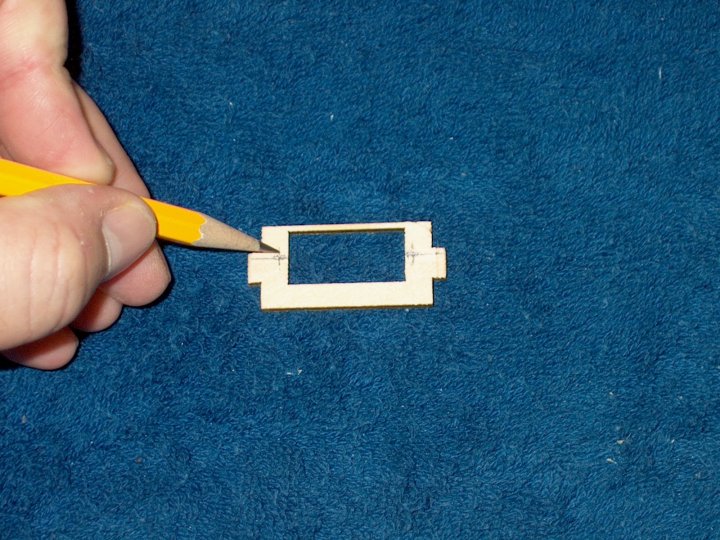

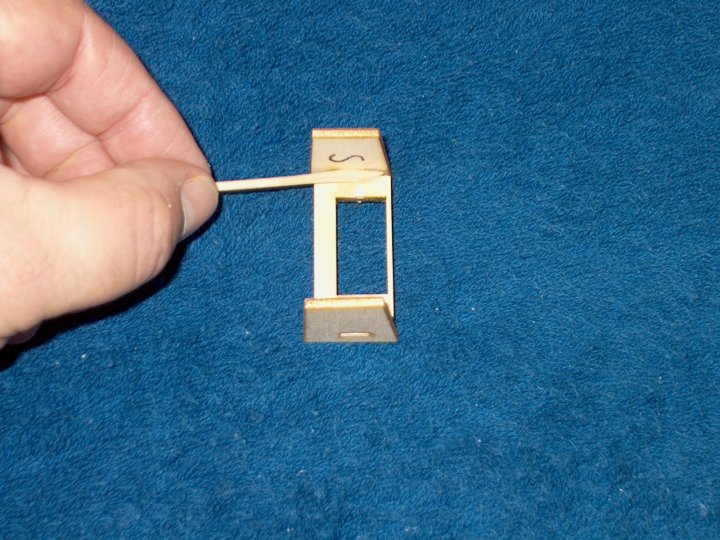

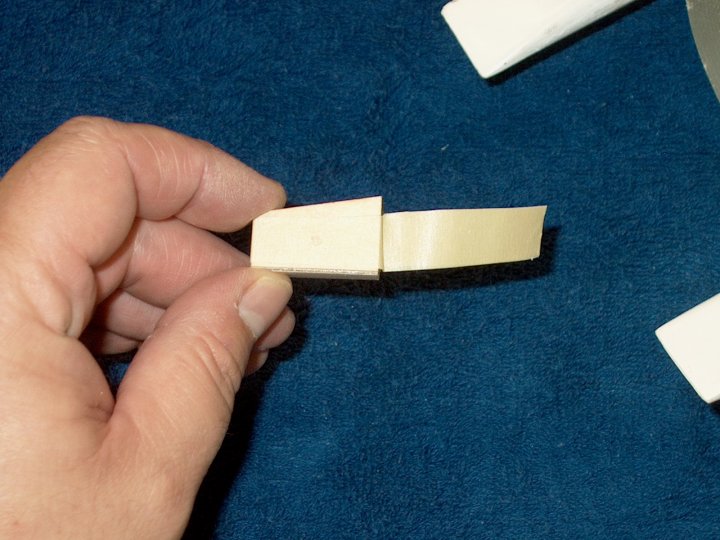

47 - The two ends of both servo trays were

lightly beveled with 400 grit so they could fit in the slots

of the side plates | |

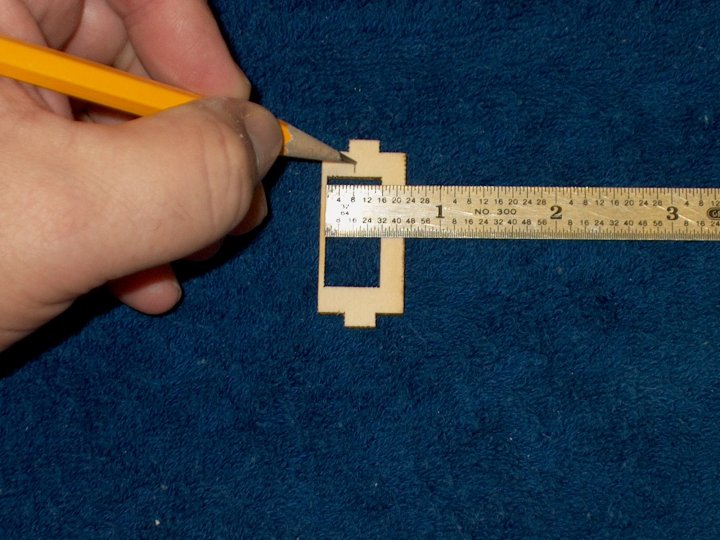

48 - Use a ruler to mark center on the

servo tray | |

49 - Mark both trays with a center line

for your servos | |

50 - The HS65 servos are a perfect fit and

were inserted in their tray to mark for drilling. The was some

play in the tray, so the servo was pushed flush against the

left side, then holes were drawn on both ends. It was then

pushed flush to the right side and marks were made

again | |

51 - You can see the two marks made at

each end. Draw a line between them for a perfect center

| |

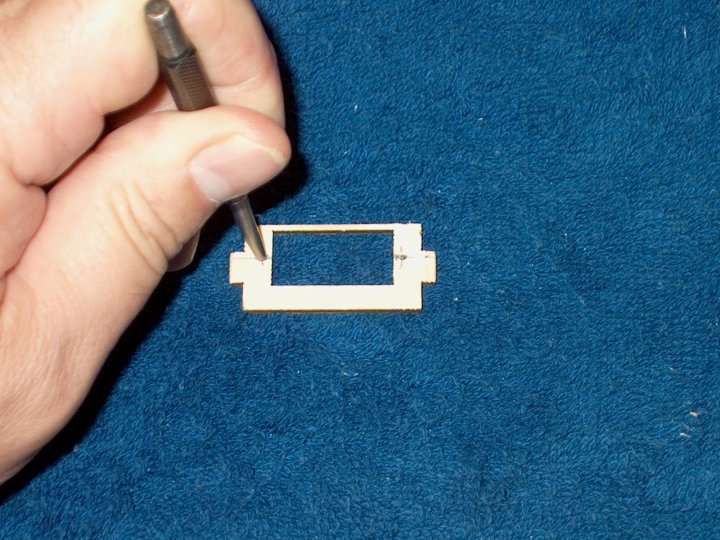

52 - Use a punch to mark where the holes

need to be made | |

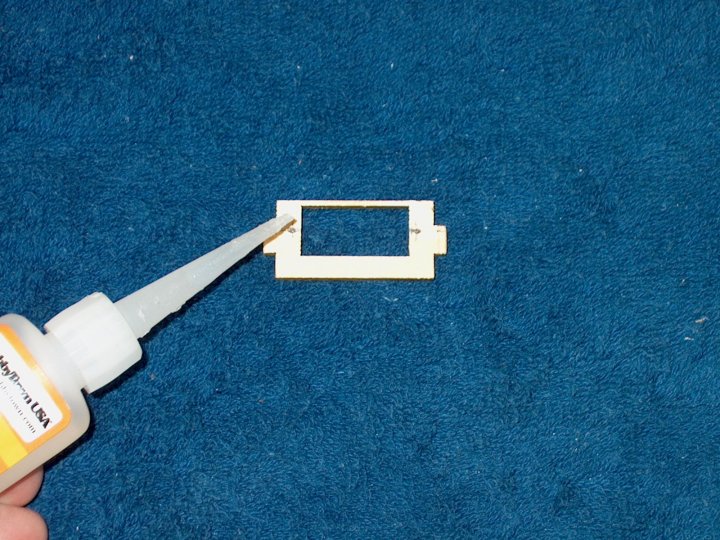

53 - Use thin CA to coat each mounting

hole area on both sides of the tray. This will prevent

cracking and splintering when drilled

| |

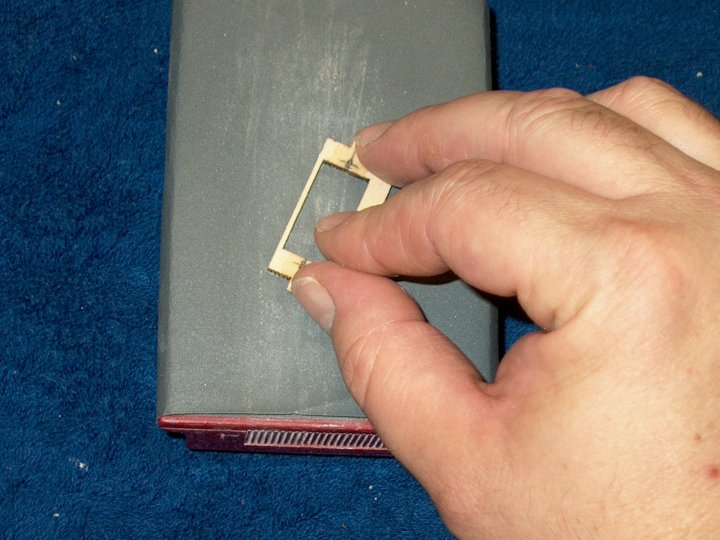

54 - The tray is lightly sanded to smooth

out the CA glue area | |

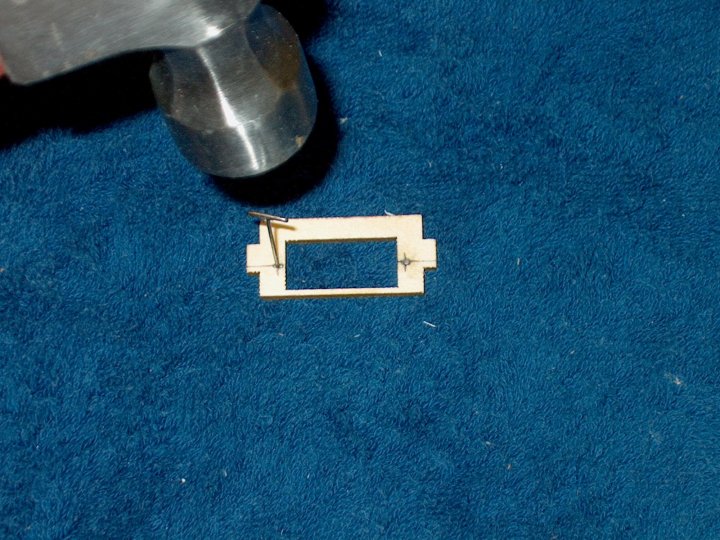

55 - You need a hobby drill smaller than

the standard US 1/16" because the servo mounting screws are so

small, so I found that a medium hobby push pin would work. Use

a hammer and carefully drive it through the tray like a nail,

being careful to keep it straight. Remove the pin and insert

it in the back side of the tray to open the hole a bit

| |

56 - Photo shows the pin driven through

the plate | |

57 - Servo mounting screws are installed

to "cut" threads in the wood | |

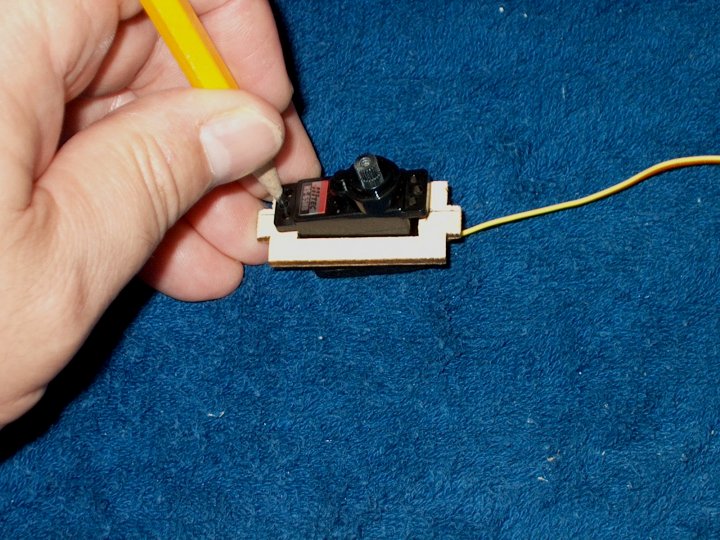

58 - Temporarily install the servo...the

screws should match up with the holes and the servo should be

centered in the tray | |

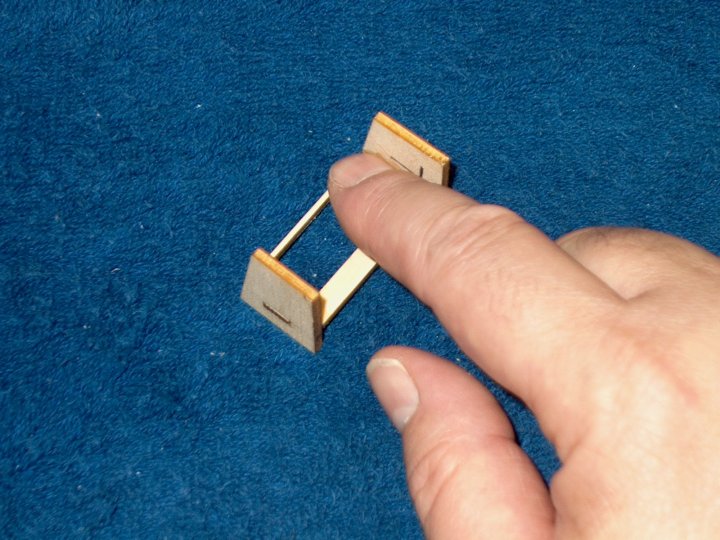

59 - Insert a tray into a side plate. Note

that the thin side of the tray faces upward toward the angled

side of the plate. Do not push in all the way

| |

60 - Install the other end of a tray into

a plate, with the angled side of the plate facing the thin

side of the tray. Be sure to use a short plate on one end and

a long plate on the other end | |

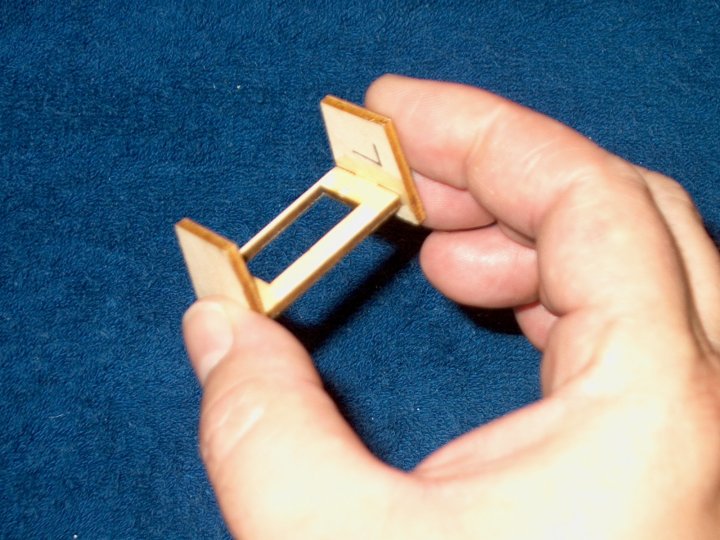

61 - Mix some 5 minute epoxy and use a

toothpick to roll it into the joint at both ends

| |

62 - Squeeze the plates in place and

flush | |

63 - Remove the excess epoxy that could

prevent the servos from sitting flush

| |

64 - Removing the eopxy leaves a very fine

fillet | |

65 - Square up the tray before the epoxy

sets | |

66 - Build the other tray and make sure

you make two opposite "mirrored" trays

| |

67 - Once both trays are completed, add a

fillet of epoxy to the rear for added strength

| |

68 - Remove the excess epoxy so a nice

fillet is made | |

69 - Servo Tray construction completed and

showing fillets at rear side | |

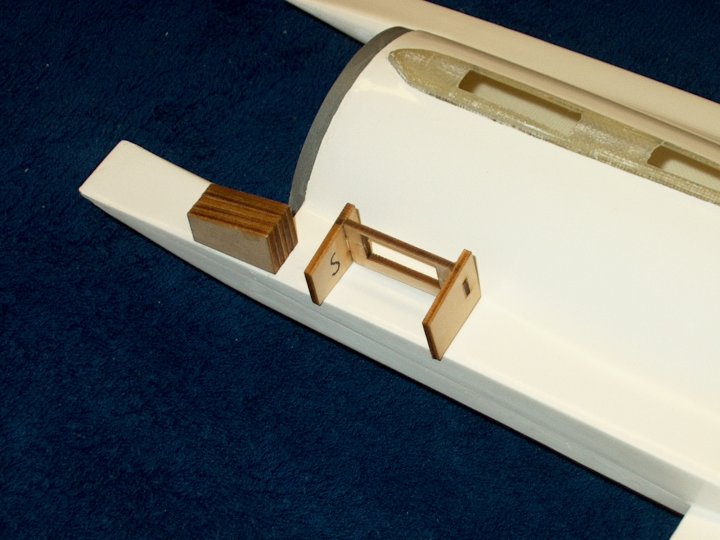

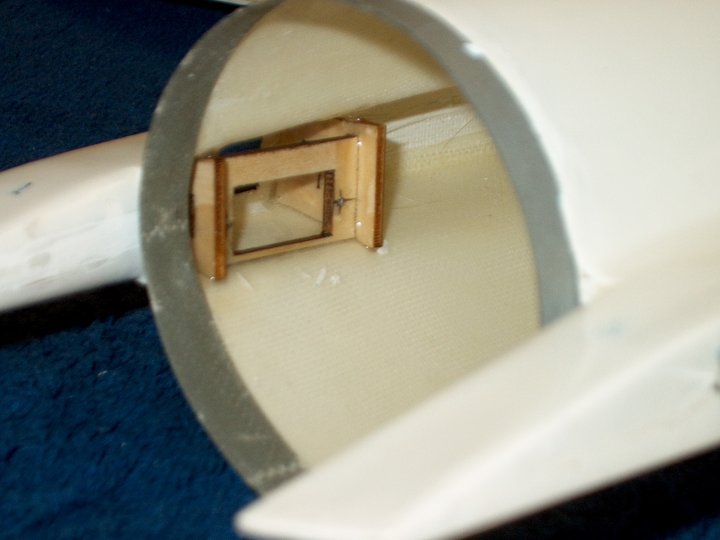

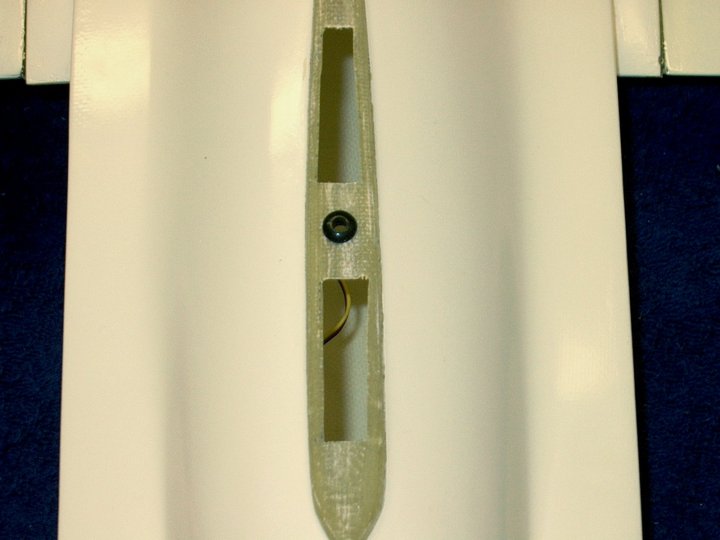

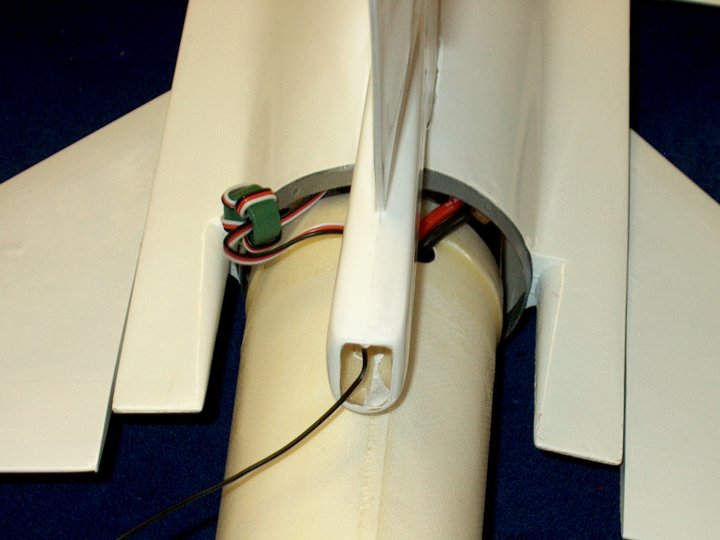

70 - From the top of the fuselage- The

stab block and servo tray are shown near the positions where

they will be installed in the fuselage. Note that the block

tapers rearward and that the tray has the "Shorter" side to

the rear with the thin part of the tray pointing to the top

side of the fuselage | |

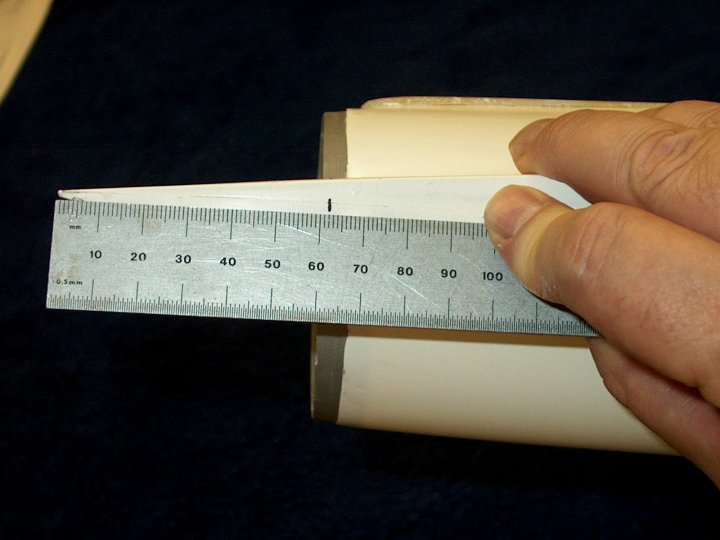

71 - The position for the Horizontal Stab

rods is 62mm from the rear | |

72 - When first installed inside the

fuselage, the blocks were set too far back and not centered

over the mark | |

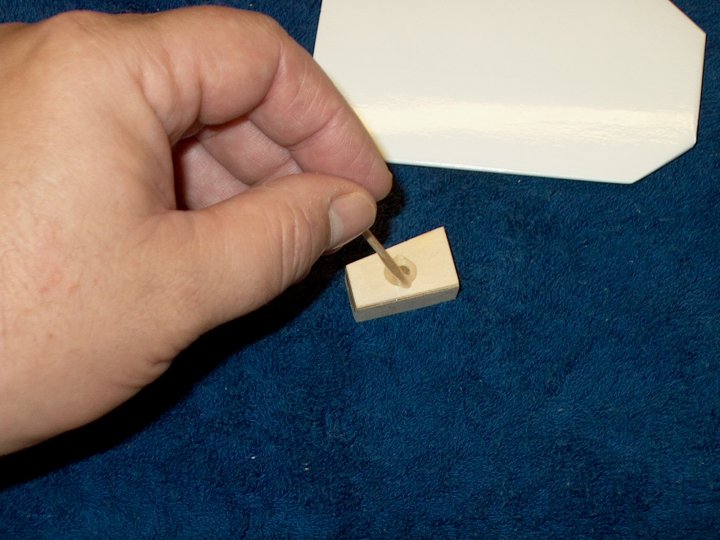

73 - A piece of 1/32" ply was cut as a

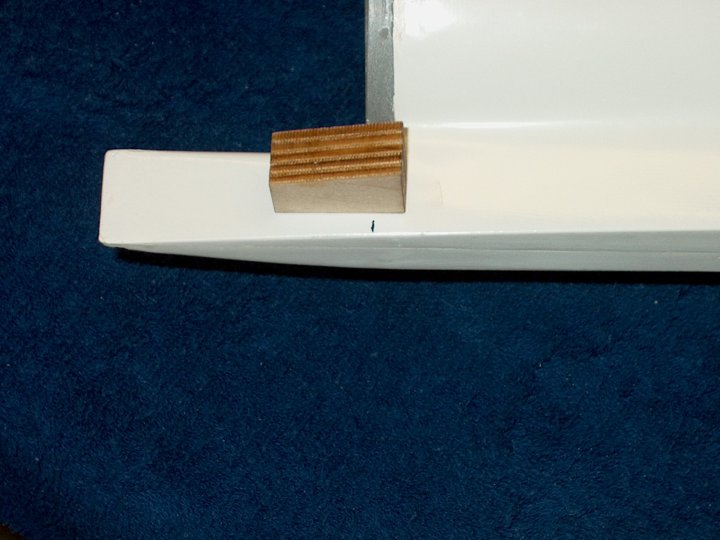

shim to make the block thicker | |

74 - The shim is epoxied to the bottom of

the block | |

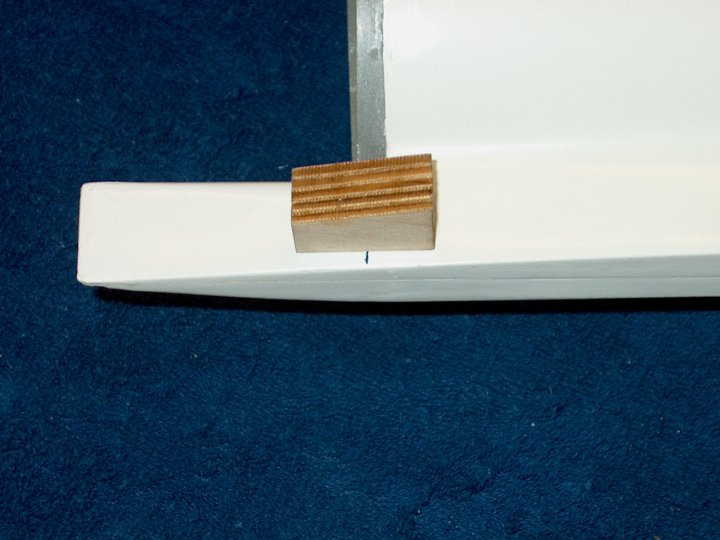

75 - With the addition of the shim, the

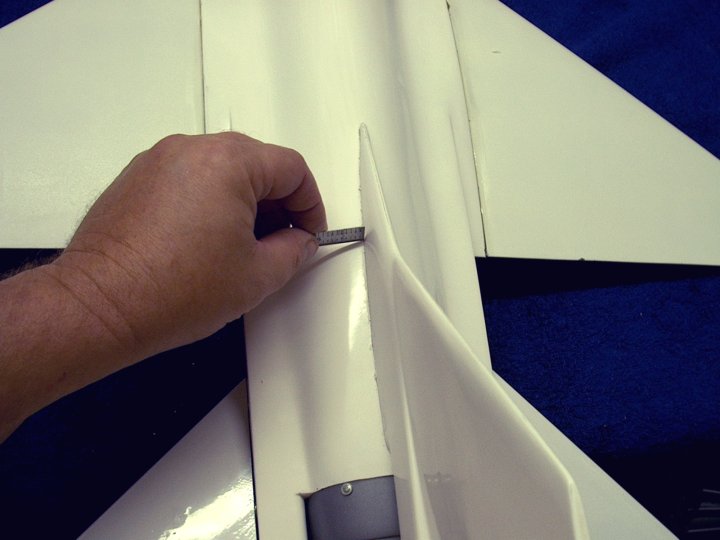

block is inserted and the photo shows where it now would sit

inside the fuselage | |

76 - The second block shim is added using

5 minute epoxy | |

77 - Lightly sand the edges to even out

the shim with the block sides | |

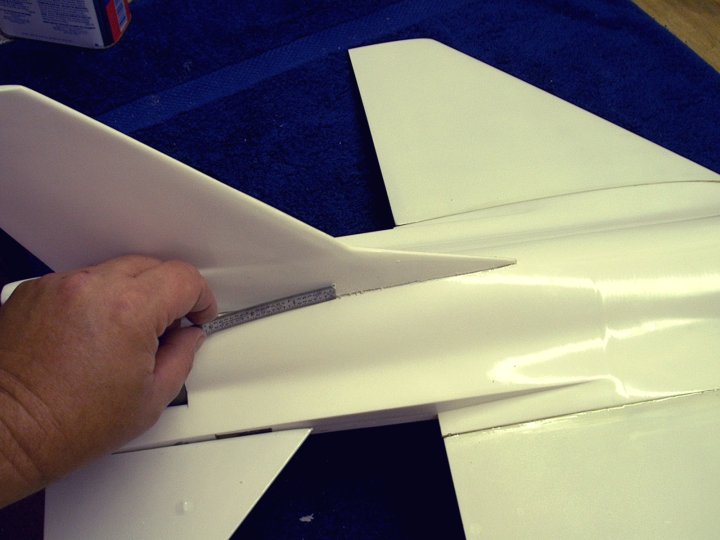

78 - A Warning...the manufacturing process

left some strands of fiberglass that were sharp as needles and

located where the pencil is pointing. If you have these,

carefully break them off inside so you do not get cut

| |

79 - A mark is made on the outside of the

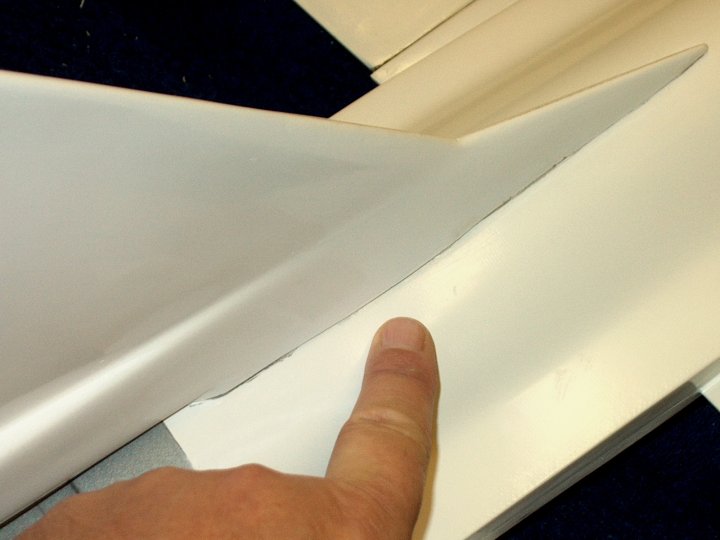

fuselage at 62mm | |

80 - A second horizontal mark is made at

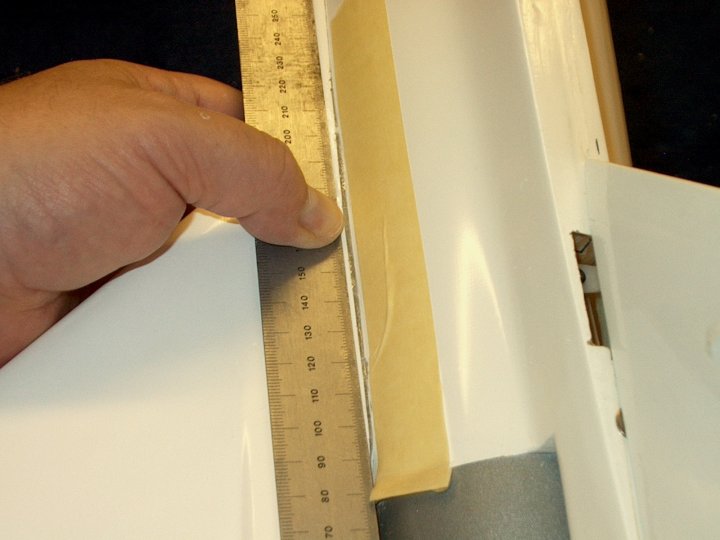

the center of the fuselage | |

81 - A 1/8" Drill is used to open the

holes at the crosshairs. You may want to use a small bit to

make a starter hole first | |

82 - Masking tape is used to wrap around

the block so it can be removed easily later

| |

83 - The block is temporarily installed in

the fuselage | |

84 - Keeping the drill square, make a

small mark on the ply inside but do not drill through

| |

85 - The drill mark is shown centered in

the block | |

86 - The other block is installed and

marked the same way. Use the masking tape tab to easily remove

the block once it is marked | |

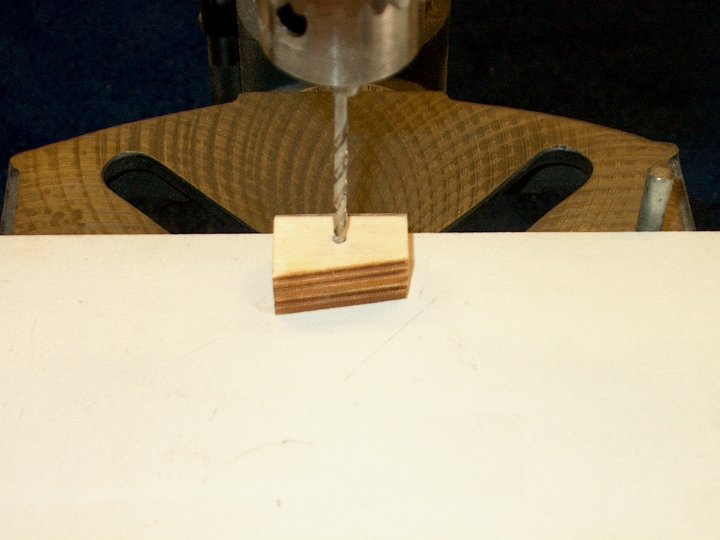

87 - A drill press is used to drill

through the block and keep the hole square

| |

88 - A Hinge drilling jig can also be used

to drill a square hole | |

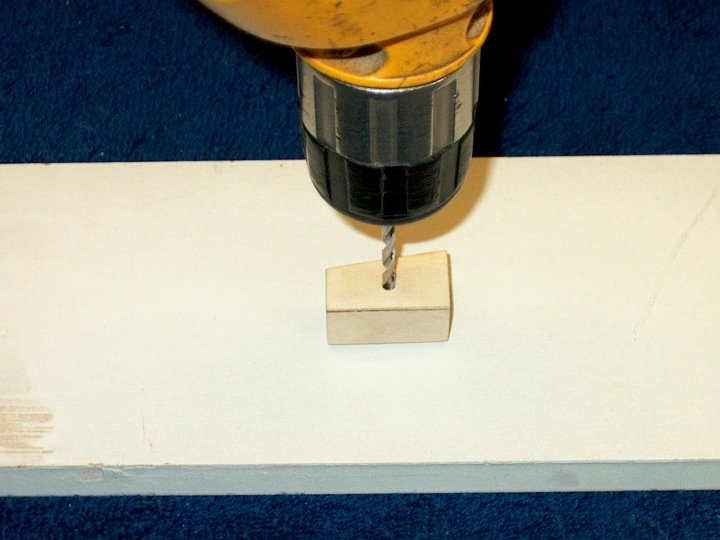

89 - If you do not have a drill press or

hinge jig, the the hole can be carefully drilled by hand. Do a

little at a time making sure the bit stays square both

horizontally and vertically | |

90 - Trial fit the Elevon Rod and use the

drill to open the hole if necessary so the rod moves in and

with little effort | |

91 - Install the block in the fuselage

with the angled side toward the top. Do not glue the block in

place yet | |

92 - Make sure the hole is aligned and

centered on the markers | |

93 - Temorarily install a Elevon rod to

check the angle | |

94 - Rod shown in correct position,

perpendicular to the fuselage where it exits. Note that the

fuselage is molded to include a downward angle on the rod when

compared to the wing...this is normal

| |

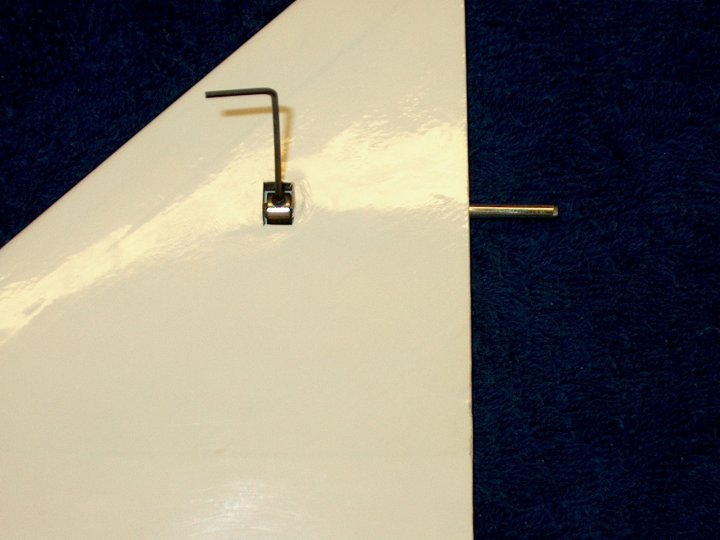

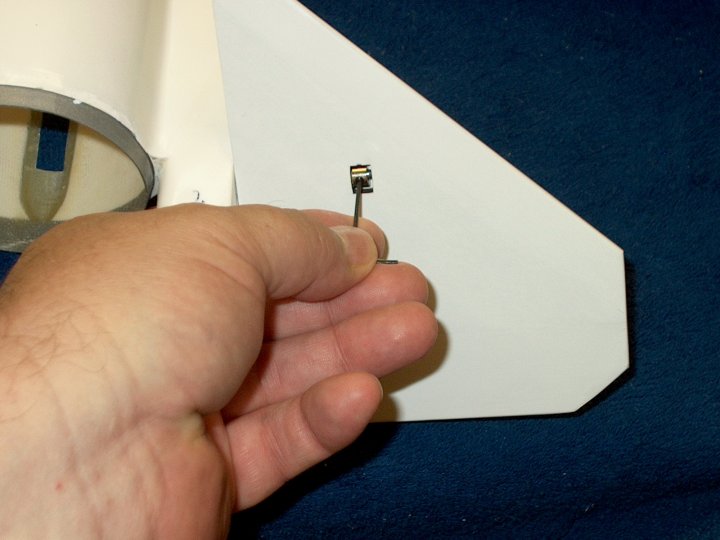

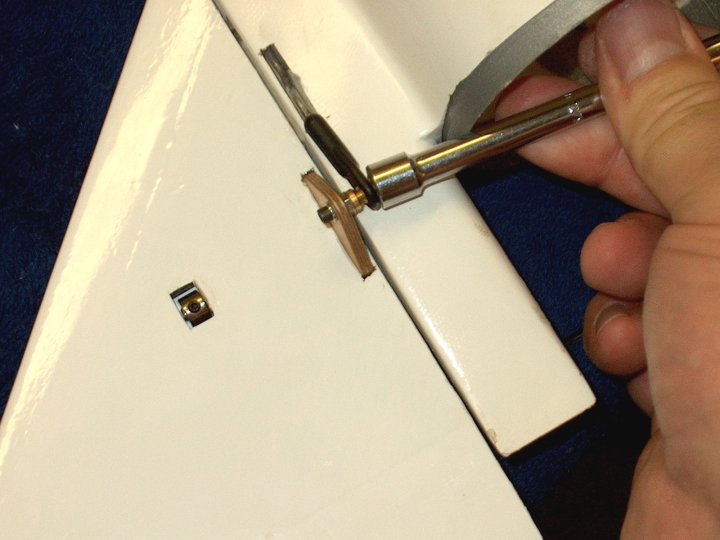

95 - Two 1/8" wheel collars are required

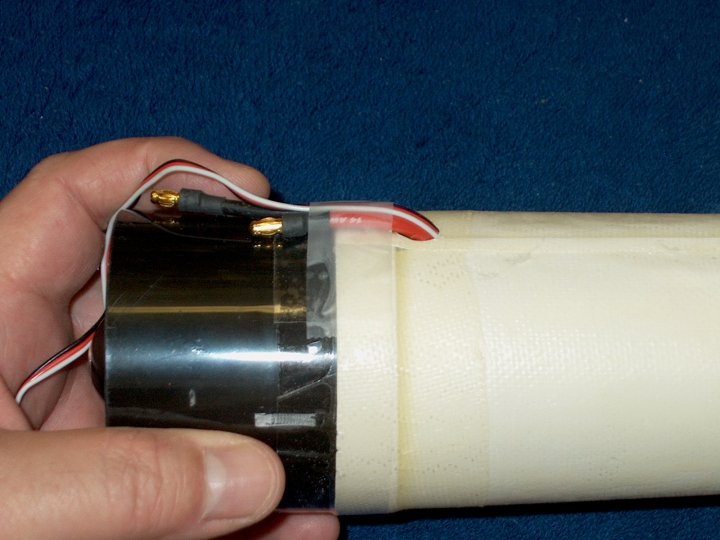

to retain the horizontal stabs. You may have to purchase a set

as they were not in the kit | |

96 - Apply some blue Loktite on the

setscrew for the wheel collar | |

97 - Install the setscrew in the wheel

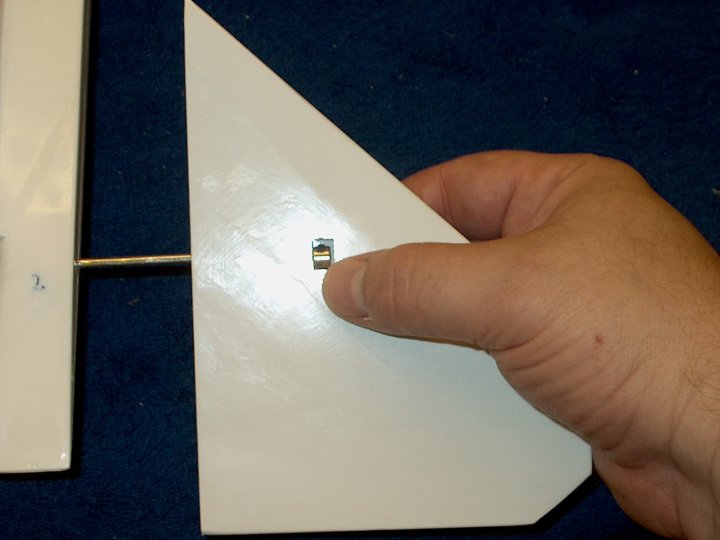

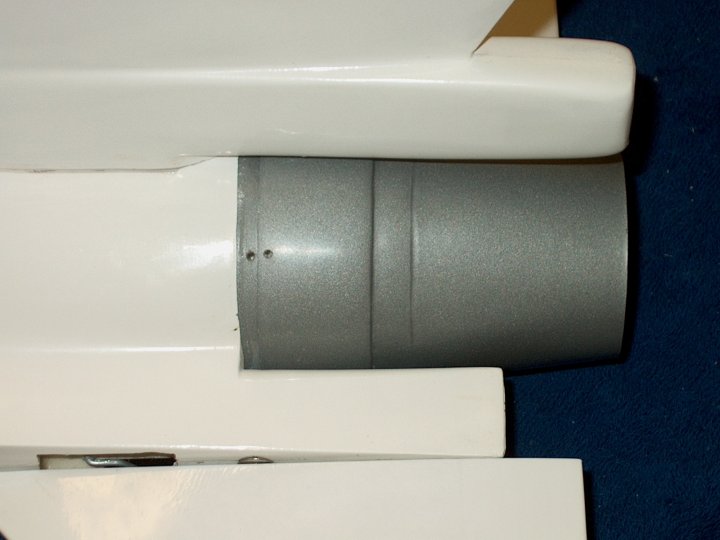

collar | |

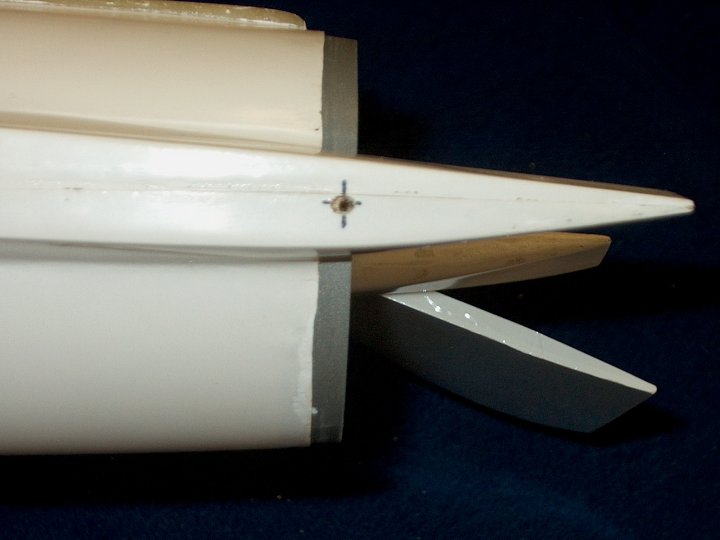

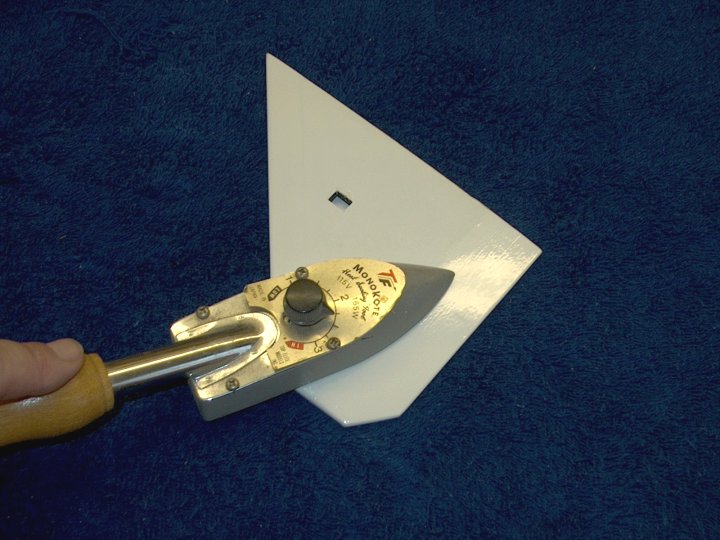

98 - The Horizontal Stabs may need to be

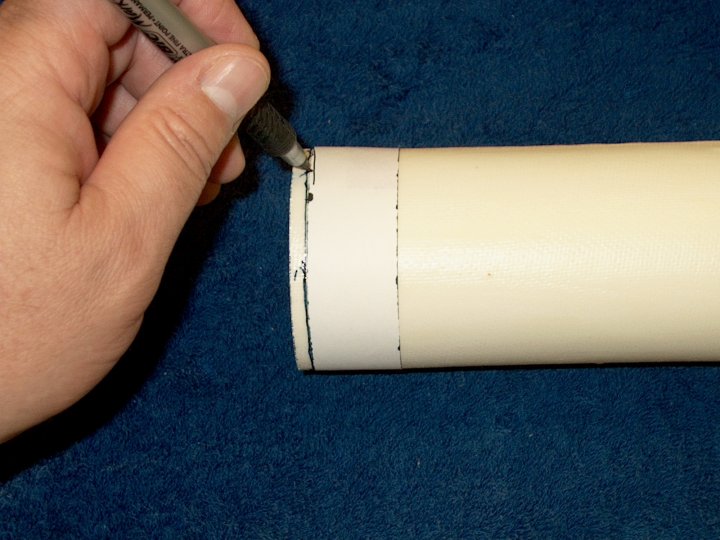

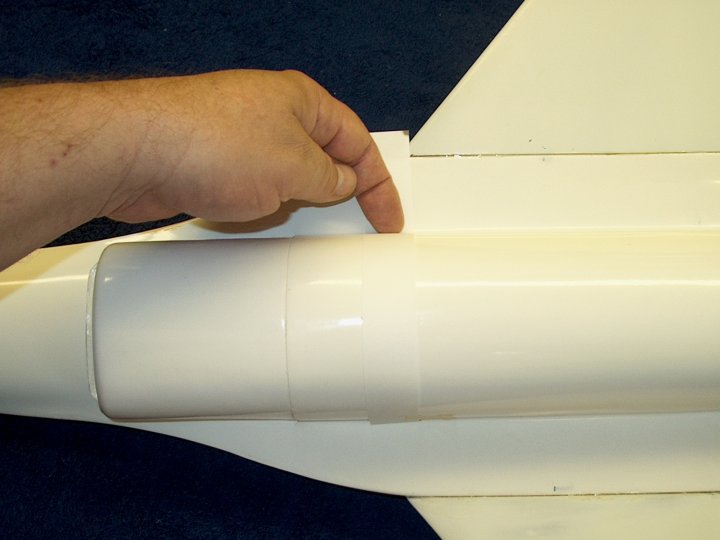

ironed to remove wrinkles | |

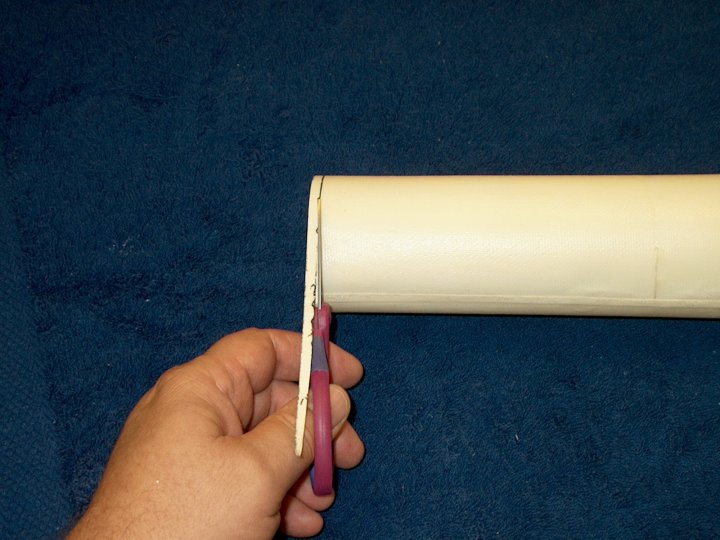

99 - The wheel collar is shown installed

where it is used to mount the stab | |

100 - The wheel collar deforms the top of

the monokote | |

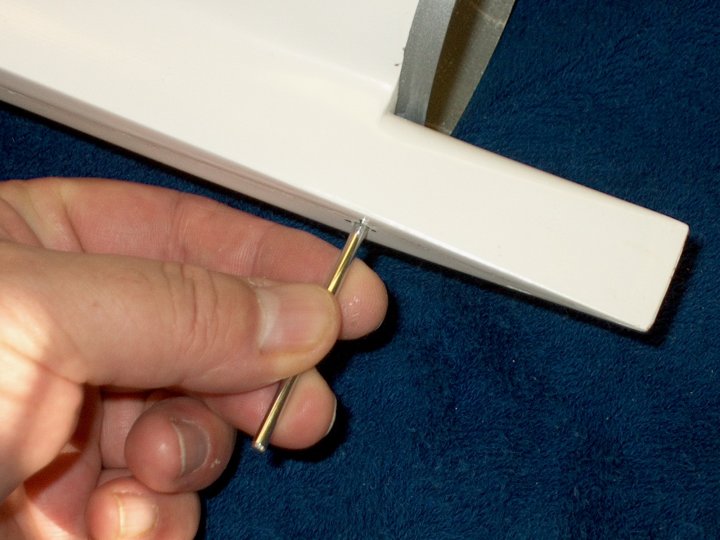

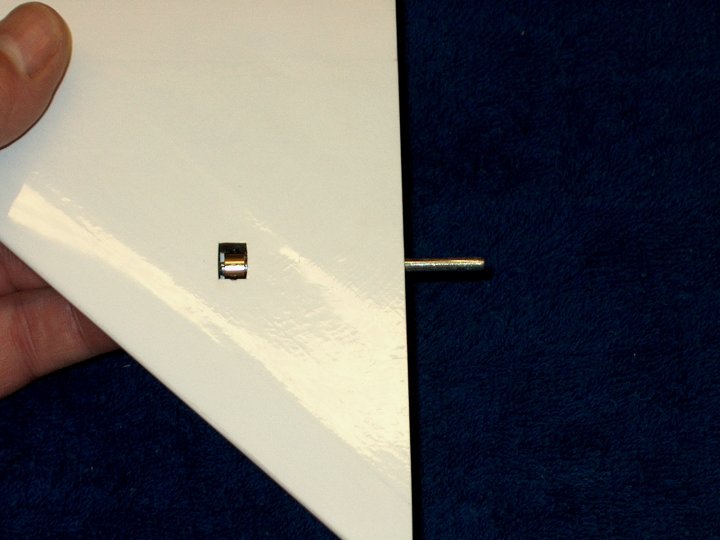

101 - the first 1/2" of the Horizontal

Stab rod is roughed up with 60 grit

| |

102 - Install the rod in the horizontal

stab and lock it in place with the wheel collar. Make sure

that the rod extends past the collar and butts against the

left wall as shown. Also, note that the side of the rod that

was sanded is shown to the right and will be glued into the

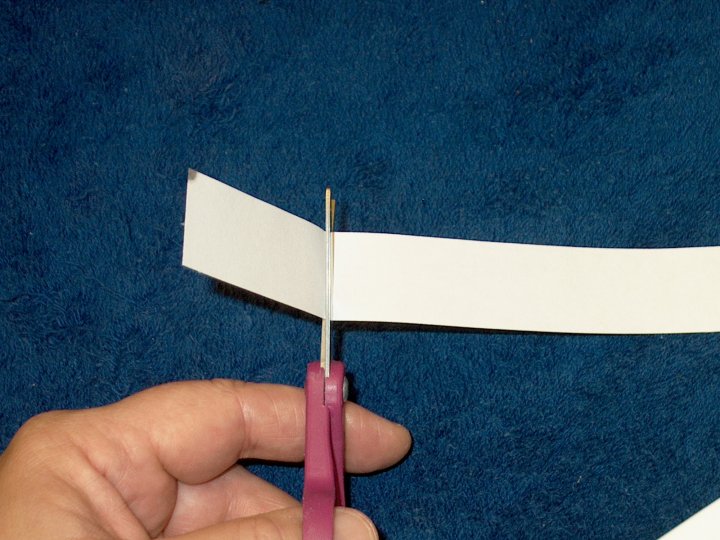

fuselage block | |

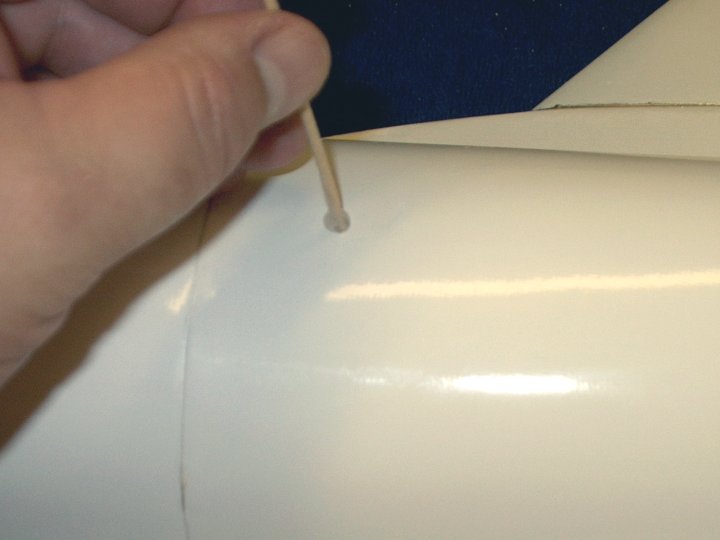

103 - Apply epoxy inside the hole with a

toothpick | |

104 - Apply epoxy to the top and bottom of

the block | |

105 - Install the block in the

fuselage | |

106 - Install the Horizontal stab into the

inner block hole until the root butts against the side of the

fuselage. This will keep the block aligned inside. Put your

finger inside the fuselage and make sure the block is settled

in its location. Hold the stab tight in place with masking

tape | |

107 - Check stab position from the rear to

make sure the angle is aligned with the fuselage trailing

tip | |

108 - Epoxy is applied with a toothpick to

the second block hole | |

109 - Epoxy is applied to the top and

bottom of the block, then it is installed

| |

110 - Horizontal Stab is installed through

the hole and into the block | |

111 - Masking tape is used to hold the

stab flush to the fuselage side. Check your rear angle as you

did with the first stab and make sure it aligns with the

fuselage trailing edge | |

112 - Horizontal Stabs shown installed and

in place | |

113 - The stabs have a slight downward

angle from the rear, which should be even on both sides

| |

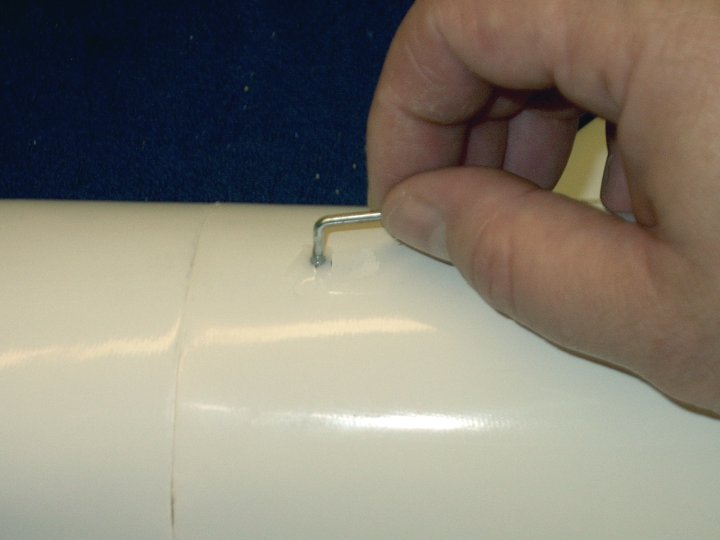

114 - Use a hex wrench to loosen the

retaining wheel collar | |

115 - Remove the stab and wing collar from

the fuselage | |

116 - Horizontal Stab rod installation

completed | |

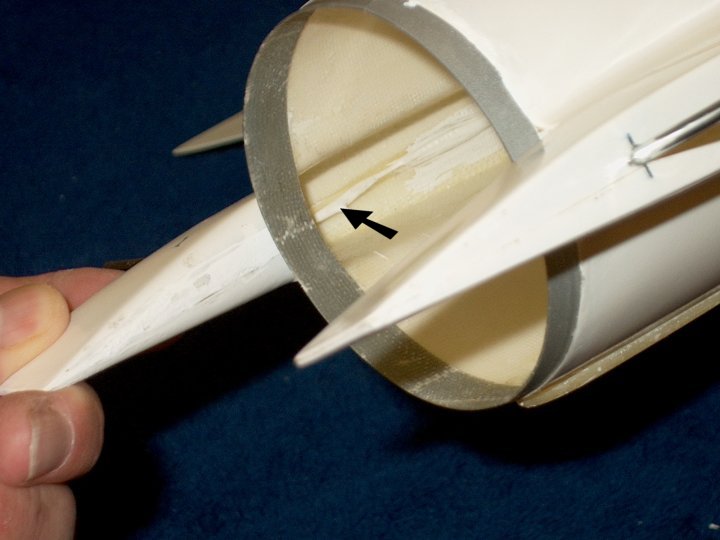

117 - The fuselage halves were assembled

using what appears to be Aeropoxy, as shown by the arrow. This

will prevent the servo trays from seating all the way into the

fuselage area. It cannot be easily reached to be sanded

| |

118 - Masking tape is applied to the side

of the fuselage area and marked for servo cutout

| |

119 - A Dremel with a stone wheel is used

to cut out the opening | |

120 - Opening is shown rough cut. It was

very difficult to cut through the Aeropoxy ridge inside. I

used a pair of 90 degree long nosed pliers to break

through | |

121 - The opening is filed until the servo

can pass through easily | |

122 - The tape is removed from the

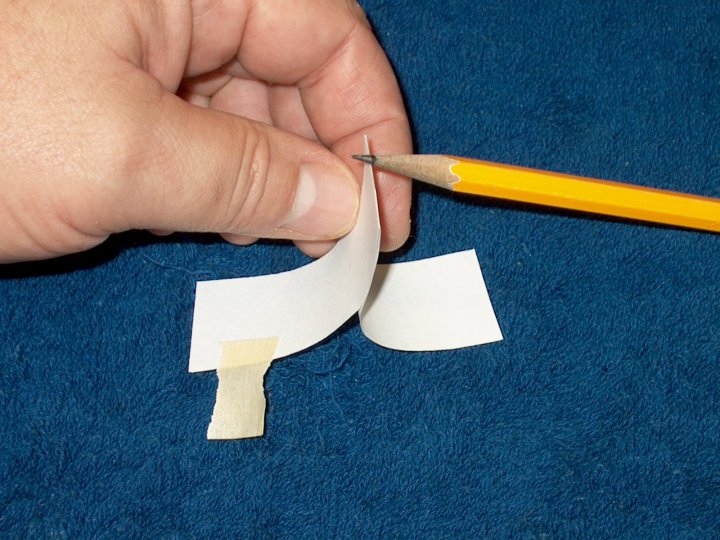

opening | |

123 - The other side is cut with a dremel

and corners are cut with a hobby knife

| |

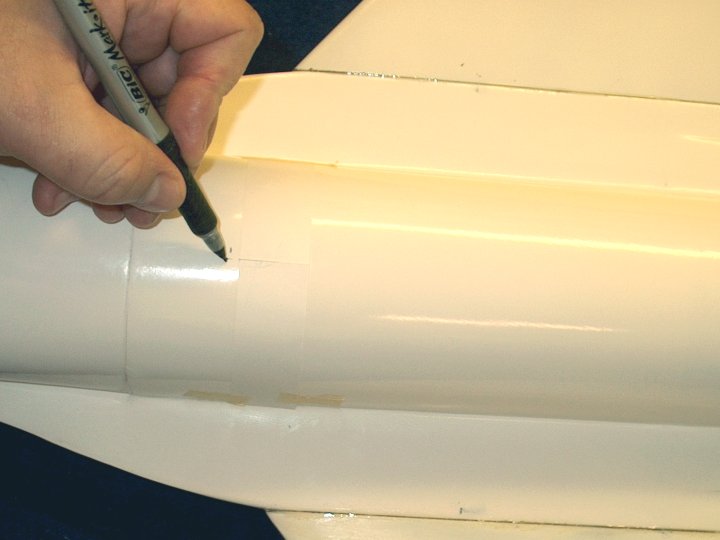

124 - The opening is filed until the servo

can pass through easily | |

125 - A notch is cut in the area where the

Aeropoxy seam hits so the tray will sit flush with the outer

wall | |

126 - A slight bevel was added to the tray

for easier insertion of the servo | |

127 - Epoxy is applied to all edges of the

tray, both top and bottom | |

128 - The tray is inserted into the

fuselage and placed in position | |

129 - The tray is shown set in place; make

sure it is centered over the cutout you made for the servo.

Add fillets of epoxy as necessary | |

130 - The second tray is prepared for

installation | |

131 - The second tray is installed

| |

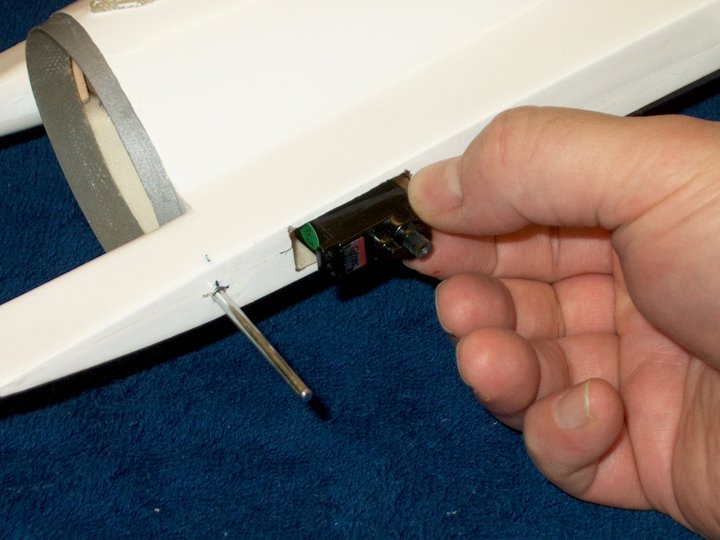

132 - Trial fit a servo into the

tray | |

133 - Servo set in place...do not screw in

place yet | |

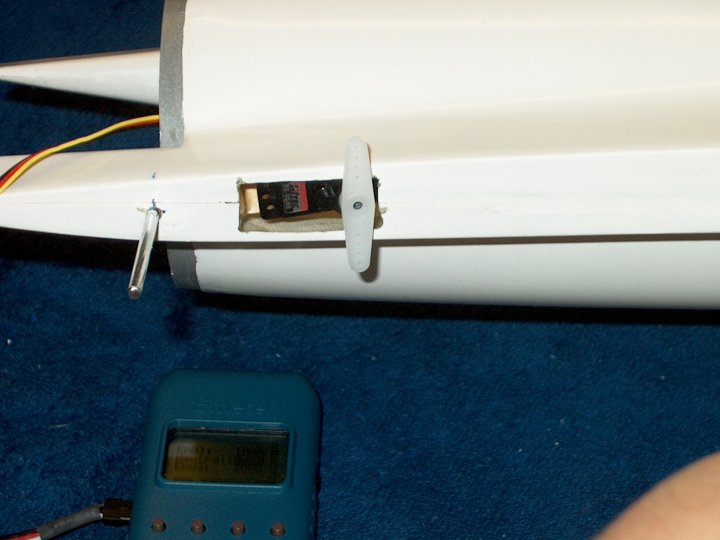

134 - Push the servo out of its tray from

inside and using your radio or a servo tester, center the

servo, then temporarily install the horn

| |

135 - Install horn so it is perpendicular

to the fuselage | |

136 - Remove the upper portion of the horn

and sand to round it out | |

137 - A 1/16" drill bit is used to drill

the hole that is closest to center | |

138 - The horn is cut at the second hole

and rounded as shown | |

139 - Install the sevo horn pointed down

and centered, then use the servo horn retaining screw to

premanently fasten the horn | |

140 - Perform the same steps to the other

servo horn, cutting to length and shaping. Install the horn

pointing downward | |

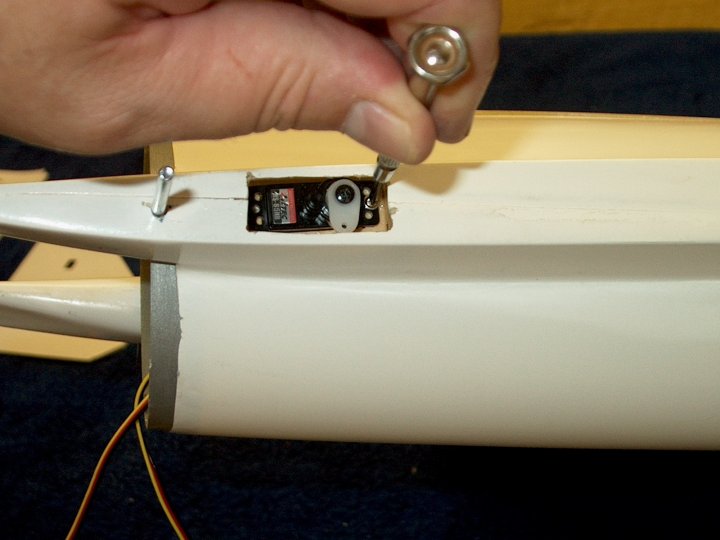

141 - Install the servo horn retaining

screw | |

142 - The servo is mounted in position

using the supplied mounting screws | |

143 - Slide one of the two washers in the

kit over the Stab shaft. This will act like a bearing for the

stab and prevent rubbing on the sides of the fuselage

| |

144 - Install the stab and retaining wheel

collar | |

145 - Holding the stab tight against the

fuselage, tighten the wheel collar | |

146 - Install the other washer, stab and

wheel collar, then tighten | |

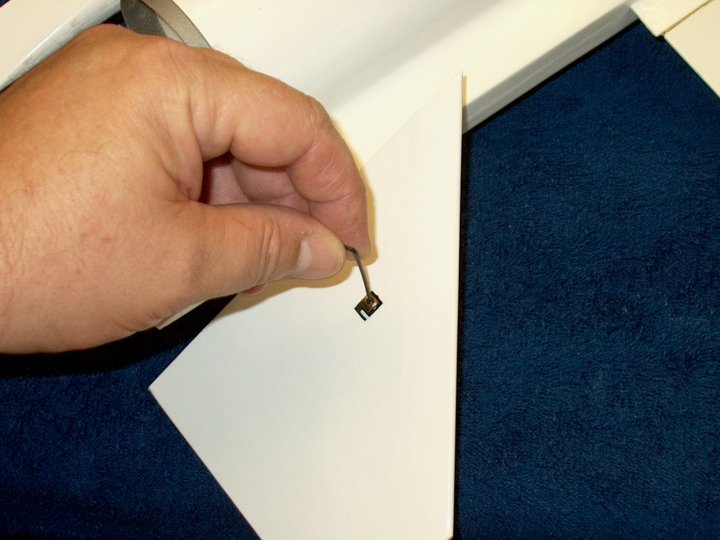

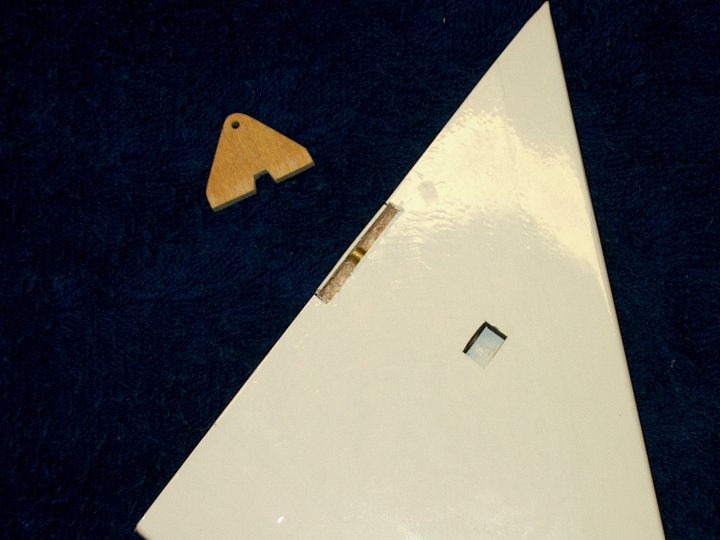

147 - The ply stab horns that come with

the kit are cut wrong, very flimsy and could be dangerous if

installed. Do not use these plywood horns

| |

148 - New horns are cut from 1/8" aircraft

plywood | |

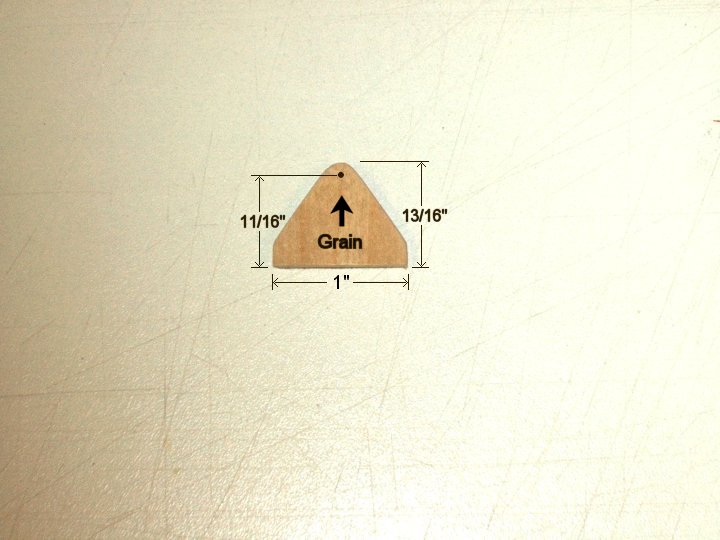

149 - Dimensions and shape of the new

stronger control horn. If you wish to buy them instead, you

can use nylon control horns. Make sure you cut it in the

proper grain direction | |

150 - Shape of old control horn compared

to the new one | |

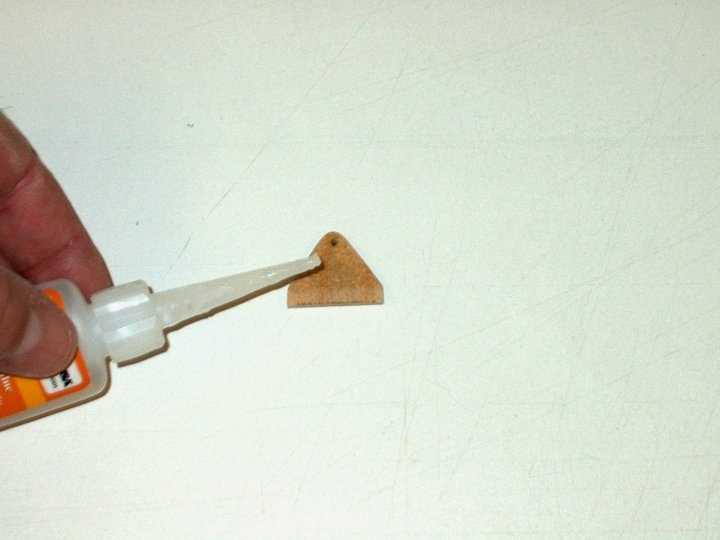

151 - Strengthen the horn by coating it

with thin CA. Do not coat the bottom 3/16" as it will be

epoxied in place | |

152 - Horns are stacked on top of

eachother. A hole is drilled for the pushrod, then a 1/8" hole

is drilled at the bottom center to clear the stab pivot

rod | |

153 - Matched horns are now ready for

final fitting | |

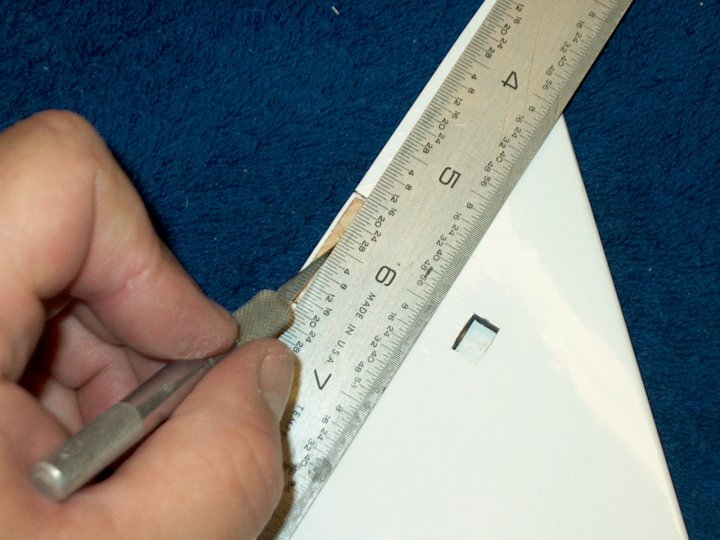

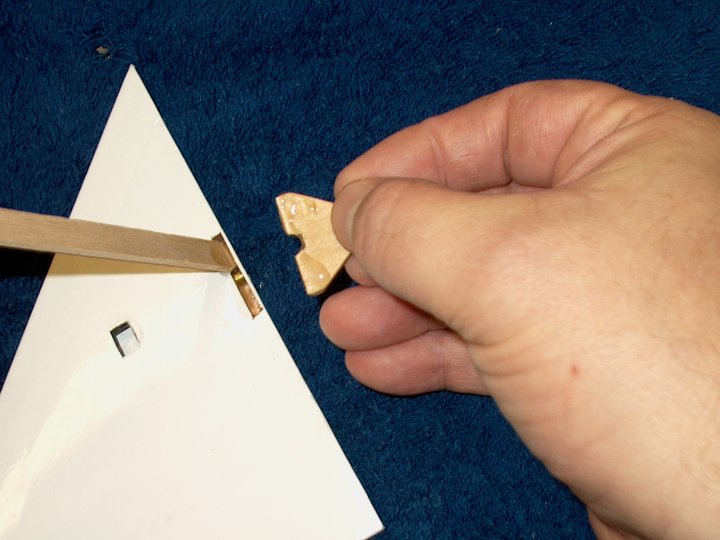

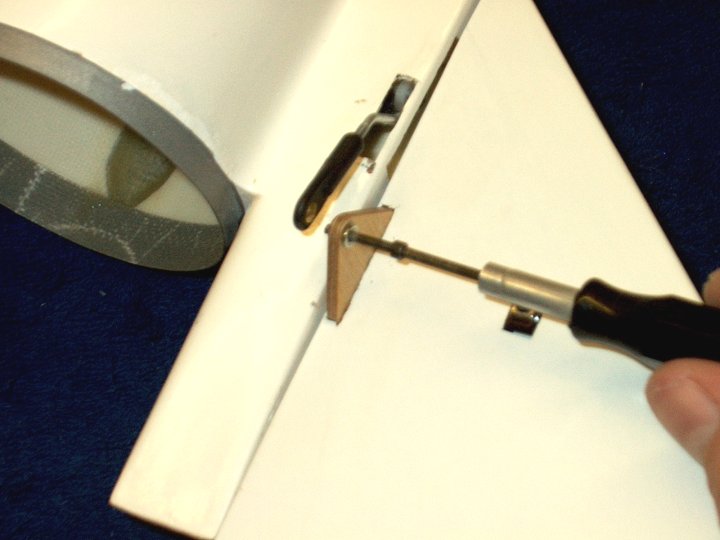

154 - The horn slot is positioned over the

stab rod hole, then the sides are marked to cut to correct

length | |

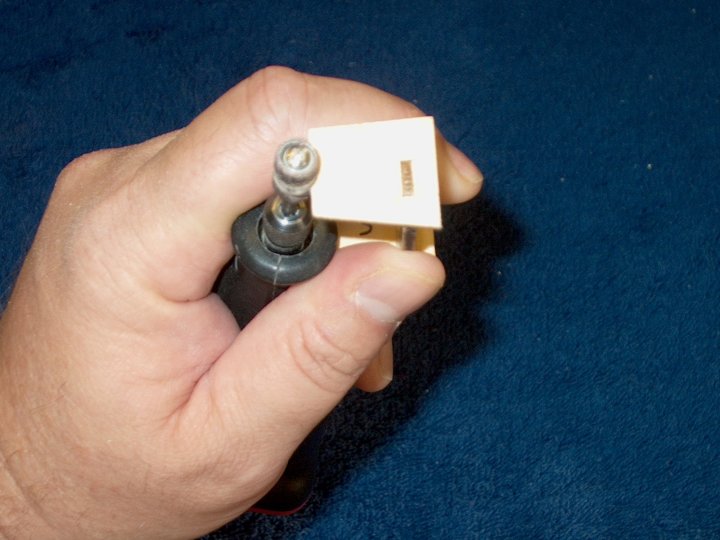

155 - A slot is cut vertically 1/8" wide

and 1/32" from end, just inside the spar cap as shown

| |

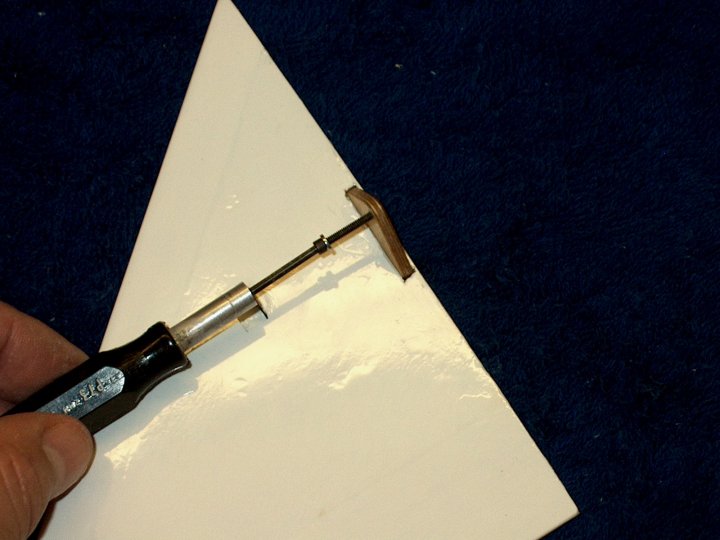

156 - A small flat screwdriver is used to

clean out the slot | |

157 - Slot ready for horn install

| |

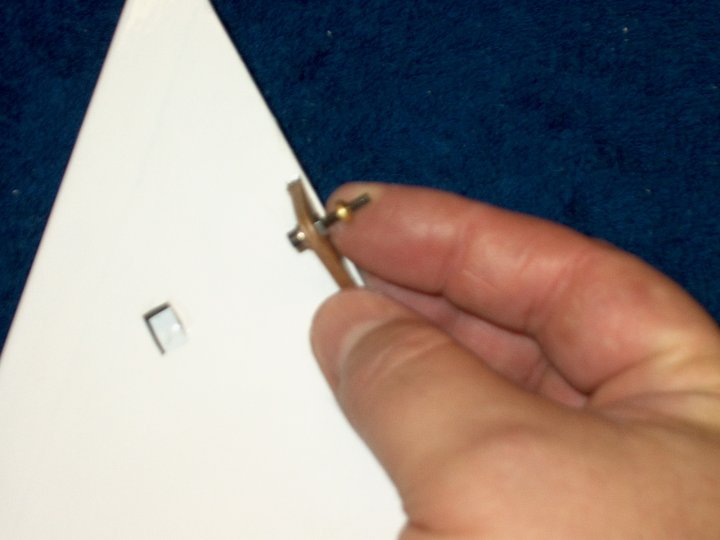

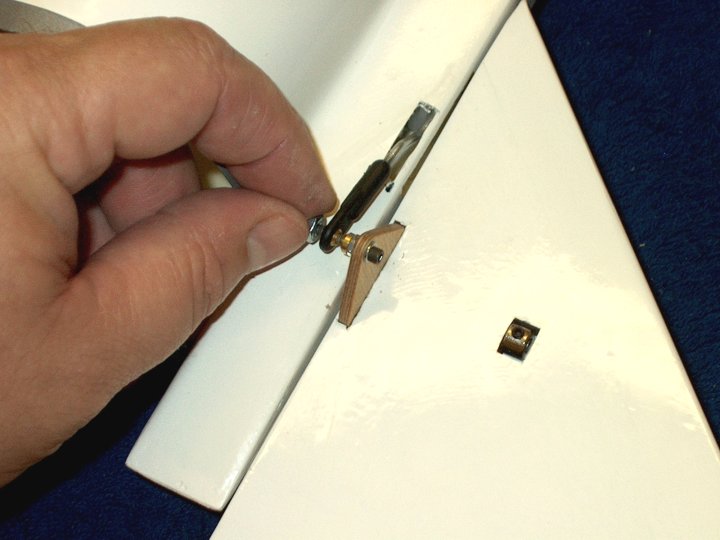

158 - Horn is epoxied in place. Make sure

it stays vertical and does not lean

| |

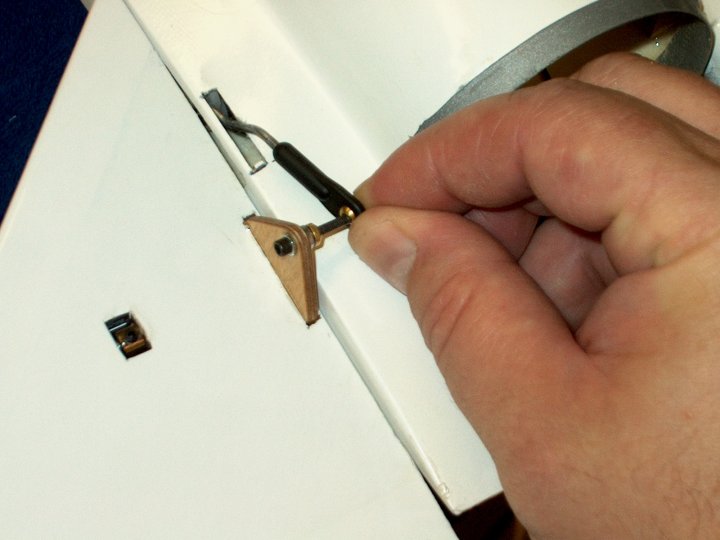

159 - Epoxy is applied and the second

control horn is installed | |

160 - Excess epoxy cleaned up with

denatured alcohol and horn installation is shown

completed | |

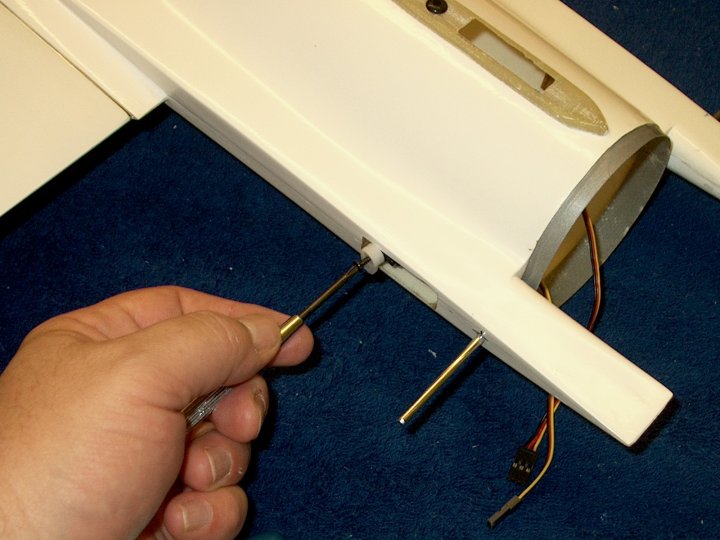

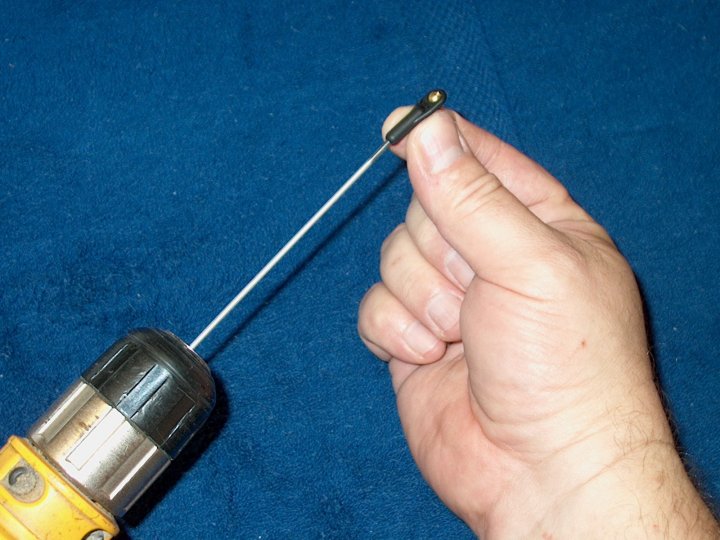

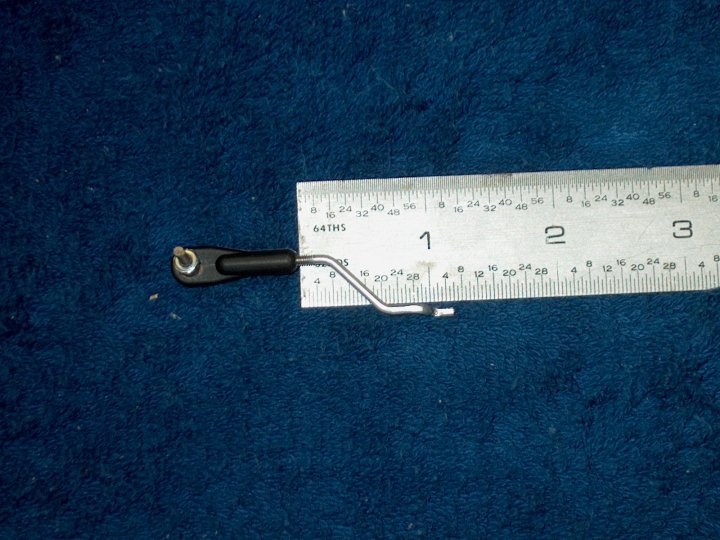

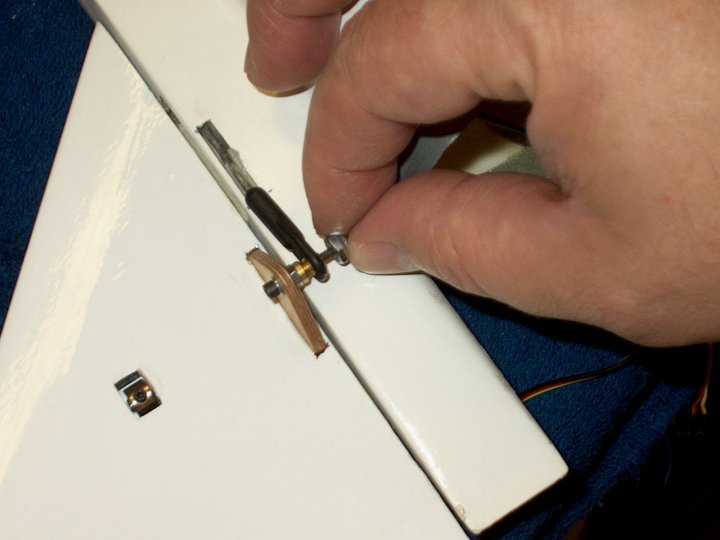

161 - A 12" long piece of 2-56 single end

threaded pushrod is cut to about 4" in length

| |

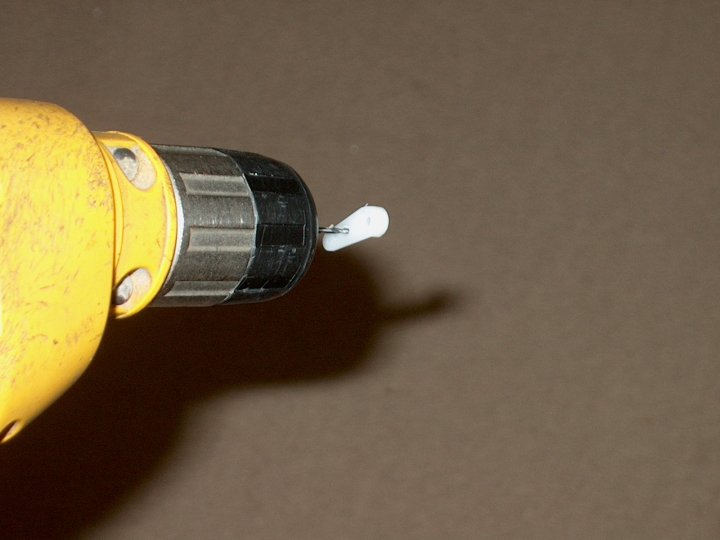

162 - A drill is used to ease the

installation of the rod in the Ball Clevis

| |

163 - The rod is temporarily installed and

a mark is made on the inside for the slot

| |

164 - A mark is made on the outside for

the slot | |

165 - A mark is made on the fuselage 3.5mm

from the bottom front | |

166 - The poshrod is bent as as

shown...make sure you make two opposite pushrods of the same

shape and bend | |

167 - A longer 3/4" bolt had to be used,

so it was cut flush to the nut | |

168 - The rod slot is cut out at the marks

you made. The back part of the slot (the left side) is flush

to the servo tray inner wall and the slot is 7/8" in

length | |

169 - The servo arm screw is

removed | |

170 - Next, the servo arm is

removed | |

171 - The pushrod is fed through the slot

and the servo arm is installed on the Z-Bend

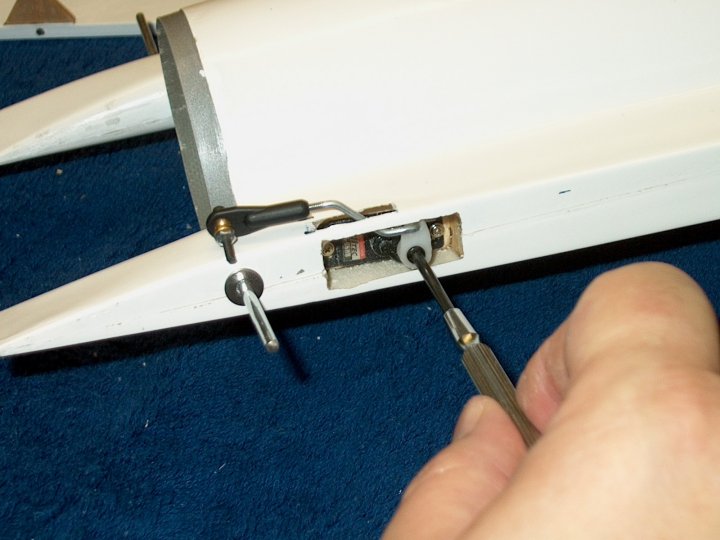

| |

172 - The servo arm and screw are

re-installed. Make sure the arm is placed back in the same

position | |

173 - Servo at center and fin 3.5mm from

bottom mark is shown to the right | |

174 - Full up travel on servo

| |

175 - Full down on servo...pleanty of

travel | |

176 - The slot for the servo pushrod is

cut out on the other side of the fuselage

| |

177 - A hobby knife is used to cut the

short ends | |

178 - Once again, the servo arm is

removed, the pushrod is fed through the slot and the servo arm

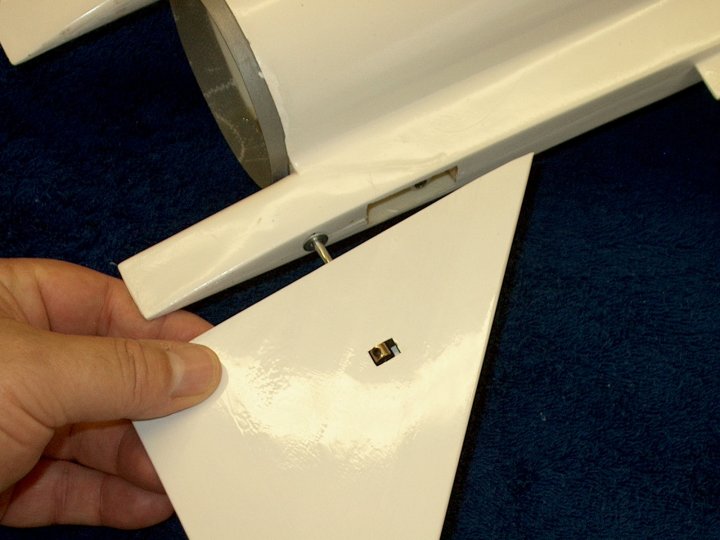

is installed at the Z-Bend | |

179 - Elevon is installed and tightened in

place | |

180 - Final installation of control

arm...the bolt with flat washer is threaded into the control

horn | |

181 - A 2-56 nut is installed to lock the

bolt in place | |

182 - The supplied brass bushing spacer

that comes with the ball clevis is installed

| |

183 - The ball clevis is installed on the

bolt | |

184 - The clevis is retained using a

nylock nut. Note that final assembly shows the nylock nut on

the inside, which allows for easy removal and adjustment of

the clevis | |

185 - Nut is tightened

| |

186 - Pushrod installation on one side

shown completed | |

187 - Bolt is installed in second Elevon

control horn | |

188 - Washer, brass spacer, ball clevis

and nylock nut are installed | |

189 - Pushrod installation

completed | |

190 - The Canopy and supplied wooden dowel

are ready to install | |

191 - Tape the canopy in place so it is

even front and back | |

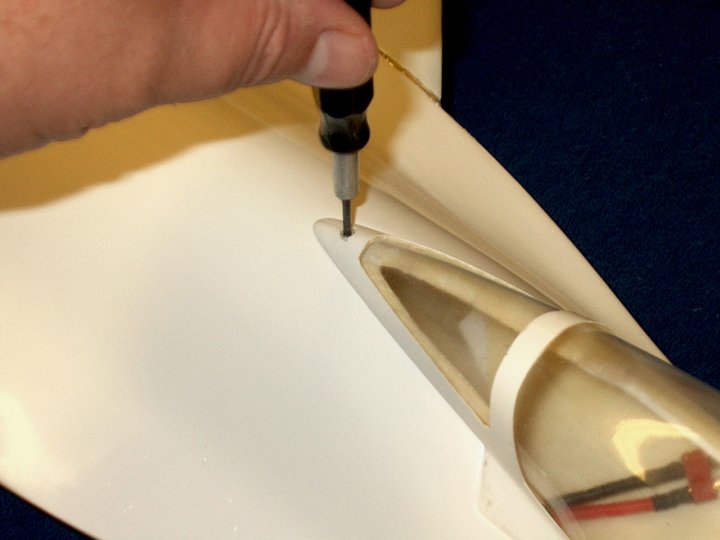

192 - A 1/16" pilot hole is drilled in the

front center | |

193 - The hole is opened up with a 1/8"

drill. It should be centered in the front

| |

194 - Photo shows hole drilled

| |

195 - The wood dowel is rounded at the tip

using 100 grit sandpaper. This will ease installation when in

use | |

196 - Pic shows rounded tip

| |

197 - The dowel is installed in the canopy

frame with rounded end forward | |

198 - Pic shows position of dowel

| |

199 - Epoxy is applied to glue the dowel

in place | |

200 - While the epoxy is still wet,

install the canopy and keep it centered while the glue

sets | |

201 - Tape is used to hold the canopy in

place | |

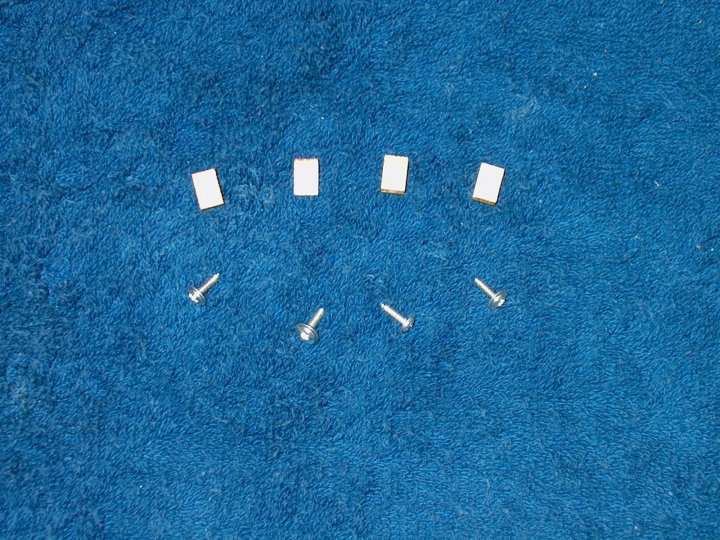

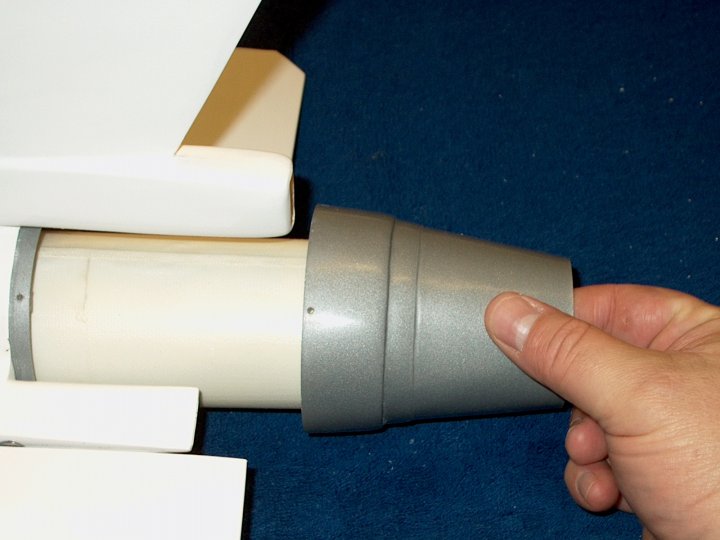

202 - Tailcone Installation: Shown are the

tailcone ply retention plates and screws

| |

203 - Marks are made on the fuselage for

plate location | |

204 - Marks are made inside for the

location of the ply plates | |

205 - Marks are shown...rough up the

inside areas with 60 grit sandpaper

| |

206 - Plywood Plate is installed on a

piece of masking tape and epoxy is applied to the facing

side | |

207 - Plate is positioned over the mark

and held in place with the tape until the glue sets. This is

repeated for all four plates | |

208 - All plates installed and glue is

left to set | |

209 - All plates installed and glue is

left to set | |

210 - All four plates are shown

installed | |

211 - Marks are made again on outside of

fuselage dead center of each plate | |

212 - The tailcone is installed. Place the

best looking side up | |

213 - Masking tape is used to hold the

tailcone in place | |

214 - Holes are drilled, first with a

1/16" bit, then a 3/32" bit | |

215 - A mark is made inside the tailcone

and fuselage to be used as alignment marks when re-installing

the tailcone | |

216 - Easily thread the screws in the

first time as they are cutting threads into the ply plates.

Install them until flush | |

217 - Use denatured alcohol and a paper

towel to remove the marks | |

218 - Tailcone assembly completed

| |

219 - A 1/16" pilot hole is drilled in the

center of the vertical stab area | |

220 - The hole is opened with a 1/4" drill

bit | |

221 - A small rubber grommet is installed

for the antenna wire to pass through

| |

222 - The inside of the vertical stab is

sanded with 60 grit for better glue purchase

| |

223 - The rear is heavily sanded to try

and make it even. The one in the box had a warped bottom cut

to the stab | |

224 - The front also needed sanding but

care was taken as to not take off too much. The Vertical Stab

is ready to install | |

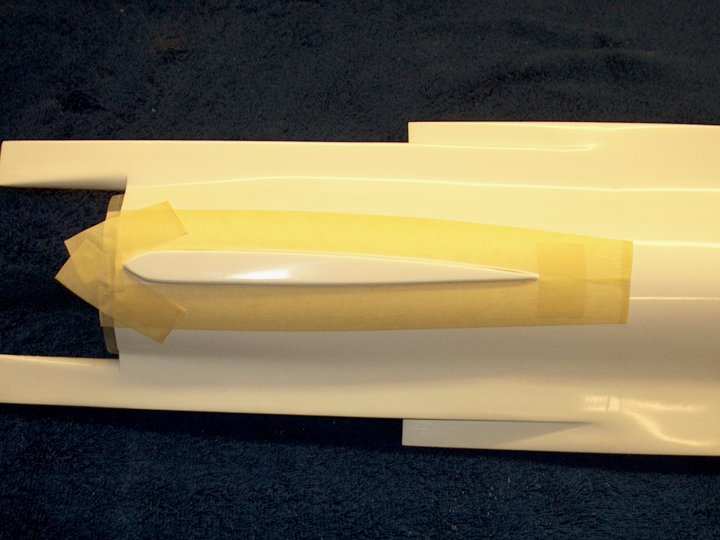

225 - Tape is placed around the vertical

stab area to keep it clean from epoxy

| |

226 - Epoxy is applied to the vertical

stab inside and the fuselage area. Use only 5 minute

epoxy! | |

227 - This is the difficult part. You need

to hold the fin in place while the epoxy sets...this is why

you need to use 5 minute epoxy. Keep plenty of paper towels

and denatured alcohol available, install the fin, squeeze in

the sides, then use an alcohol soaked paper towel to clean up

the excess and hold in place. Make sure the fin remains

vertical. As stated, there is a lot to do, so be sure you know

the steps and have it all planned ahead of time

| |

228 - Once the epoxy sets but is still

soft, remove the masking tape | |

229 - A ruler is used to scrape away any

excess soft epoxy | |

230 - If you plan on painting your model,

you can use fine sandpaper to lightly sand the fin area. Skip

this step if yours is pre-painted | |

231 - The other side is scraped of soft

epoxy | |

232 - A spot in the fin below did not

adhere do to the way the fin was cut

| |

233 - Masking tape was added to minimize

the mess and fresh epoxy was scraped under the seam

| |

234 - The excess epoxy is removed

| |

235 - The side is shown being pushed in to

indicate the spot that did not adhere

| |

236 - A towel with alcohol was used to

clean up the excess epoxy | |

237 - A ruler is used to hold the side

against the molded fuselage former while the epoxy sets

| |

238 - A clamp was used to hold the ruler

in place | |

239 - Vertical Stab installation

completed | |

240 - The Stab should be perpendicular to

the fuselage | |

241 - Tape is once again added to the

fuselage around the stab area | |

242 - A fillet of epoxy is applied with a

toothpick | |

243 - Use your finger to make a nice

fillet around the stab | |

244 - The other side is done

| |

245 - Excess epoxy is removed to form a

small fillet. Remove the tape when finished and before the

epoxy sets | |

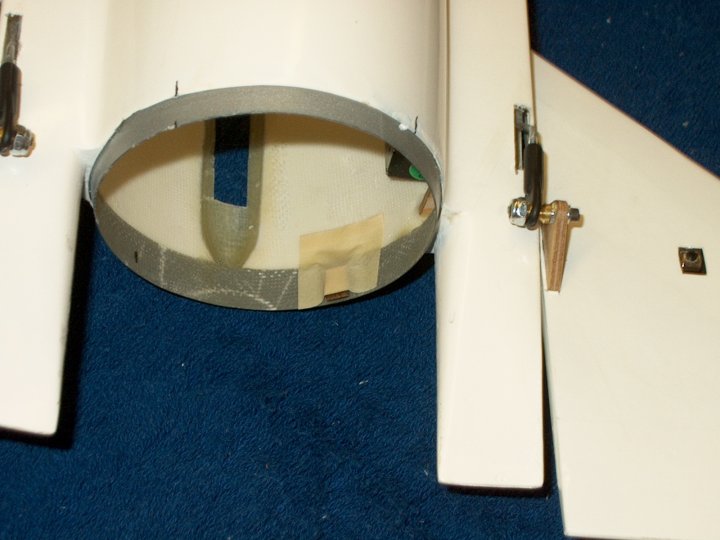

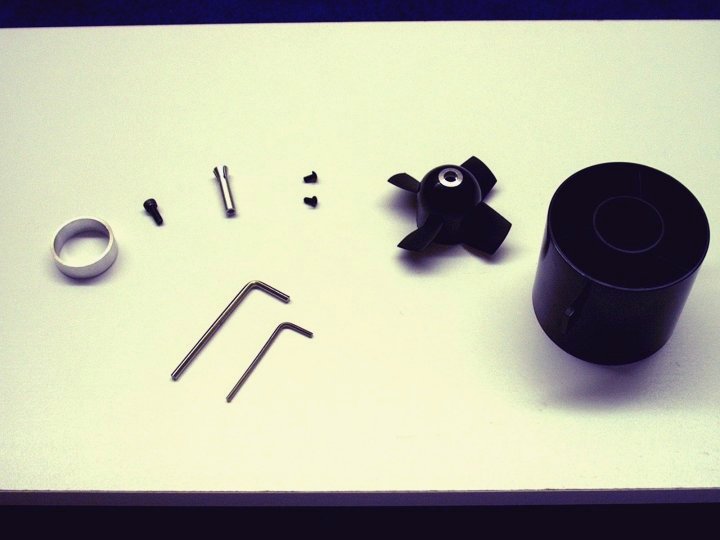

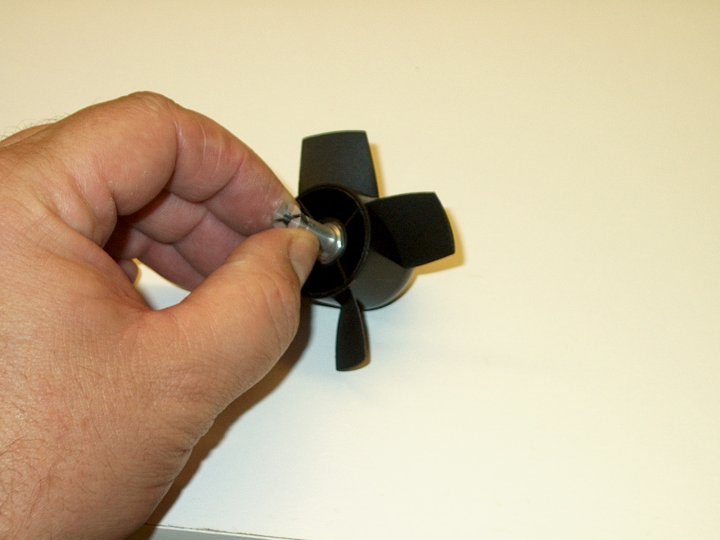

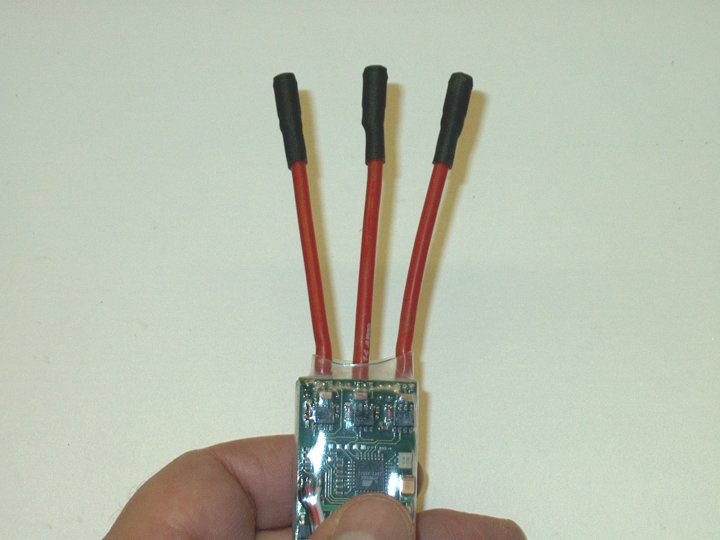

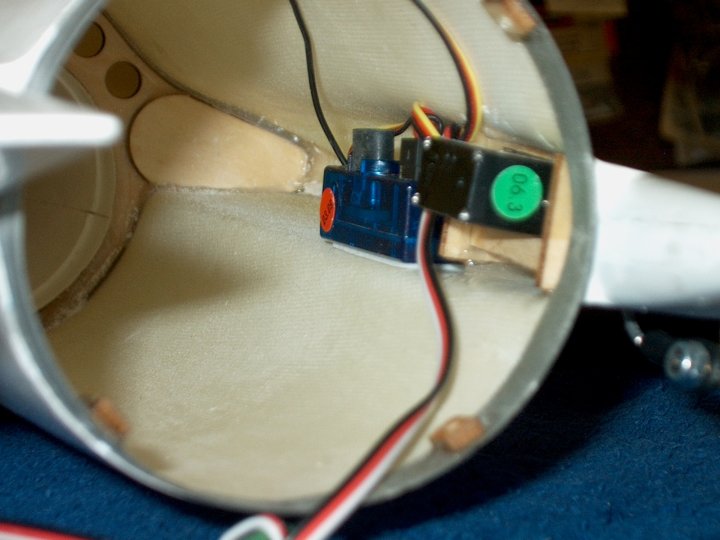

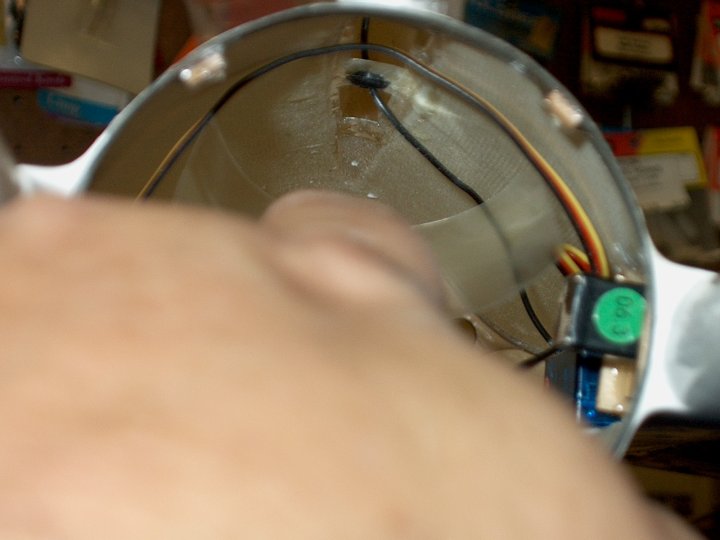

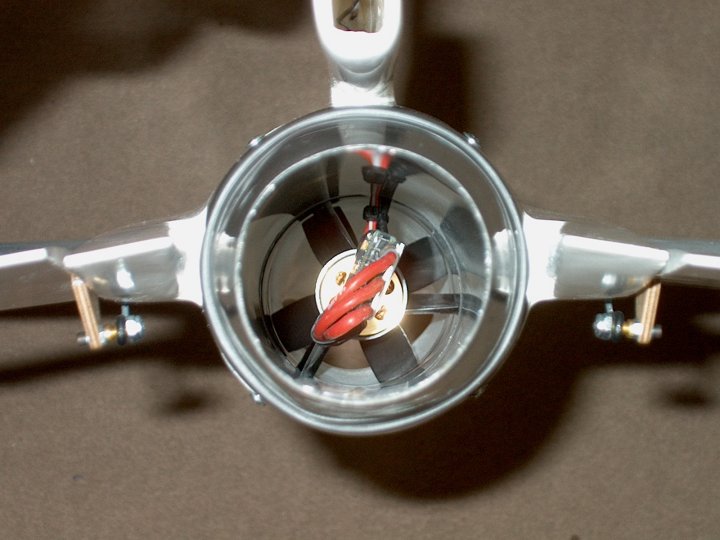

246 - The HET-RC EDF 6904 Minifan

| |

247 - The components of the HET minifan

| |

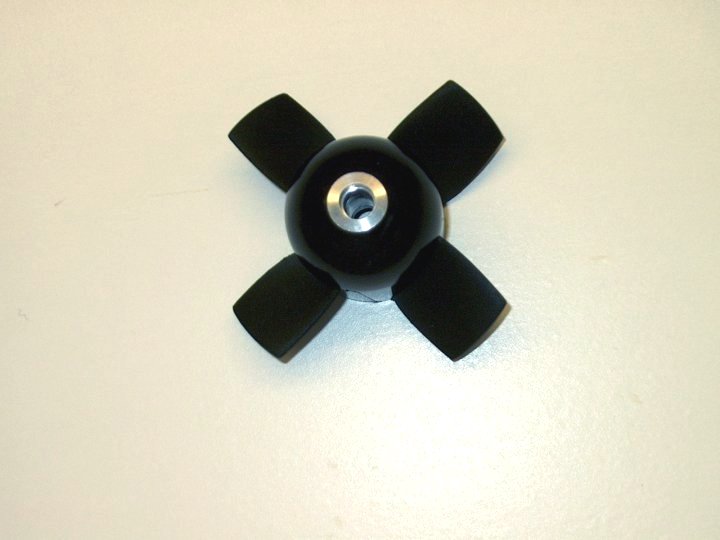

248 - The fan comes with the hub molded

together as one piece | |

249 - A HET-RC 2W motor will be used to

power the model | |

250 - The ring that comes with the fan can

be placed over the rear. Note that the inner lip will insert

into the back of the fan housing. The ring was not used in

this build | |

251 - Motor is test fit in the fan housing

and fit well | |

252 - As you can see, the housing was made

for this motor. Note the two kidney shaped slots in the motor

and the housing | |

253 - The motor is installed with the

slots aligned with the motor. these will help provide some

cooling | |

254 - Some blue Loktite is applied to the

motor threads only and then wiped clean on the surface. Do not

apply Loktite to the bolts as it can touch the sides of the

mounting holes when installed and attack the plastic

| |

255 - The 3mm x 6mm bolts that came with

the fan are installed to retain the motor and tightened using

the supplied allen wrench | |

256 - Photo shows the shaft adapter and

how it fits inside the fan unit | |

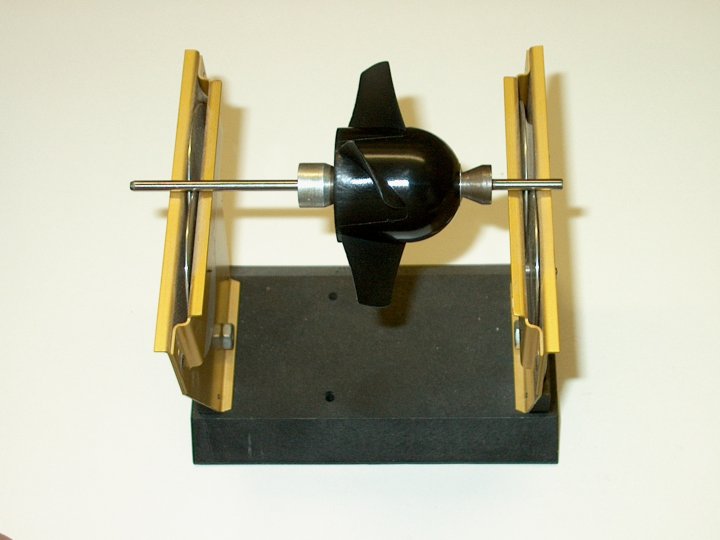

257 - The fan comes pre-balanced but was

still checked to confirm | |

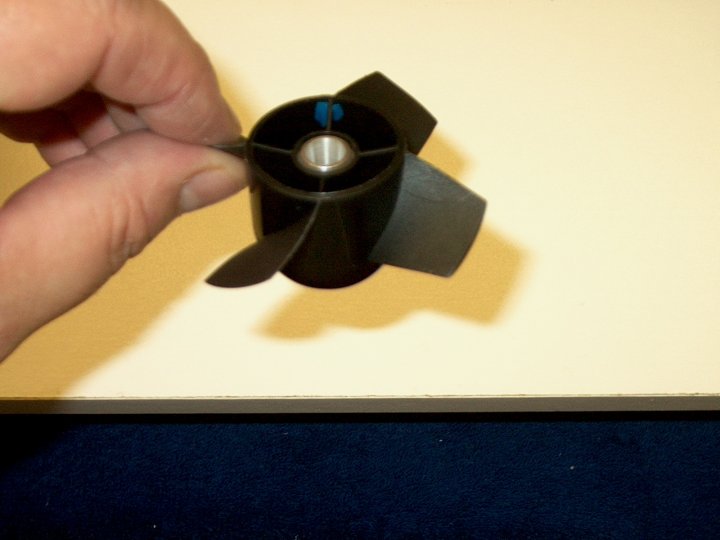

258 - The blue spot shows the area that

was pre balanced at the factory | |

259 - The fan and housing prior to

installation | |

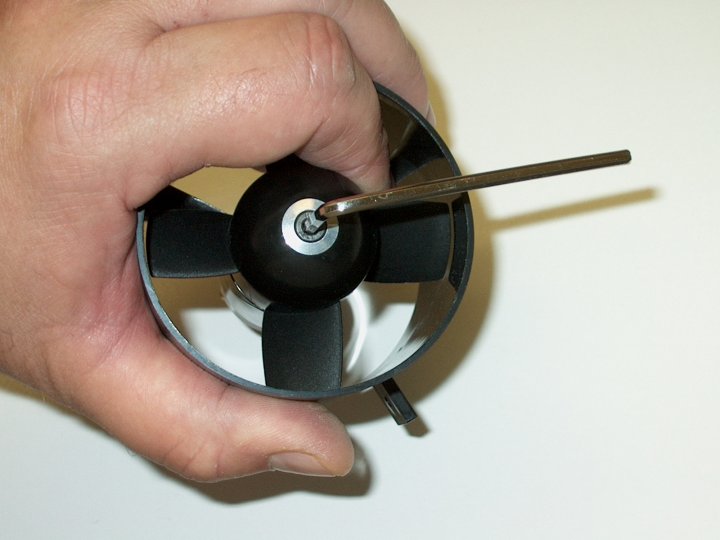

260 - Install the shaft adapter

first | |

261 - Next, install the fan unit

| |

262 - Seat the fan flush for now

| |

263 - Install the front hex bolt that

retains the fan | |

264 - Before tightening, pull the fan unit

away from the rear of the housing as shown by the pencil so it

will not rub | |

265 - Tighten the bolt with the supplied

wrench and check the fan to make sure it is not rubbing on the

housing | |

266 - Make sure the clearance appears even

on all fan blades and check for rubbing

| |

267 - The HET-RC 6904 mini Fan

Assembled | |

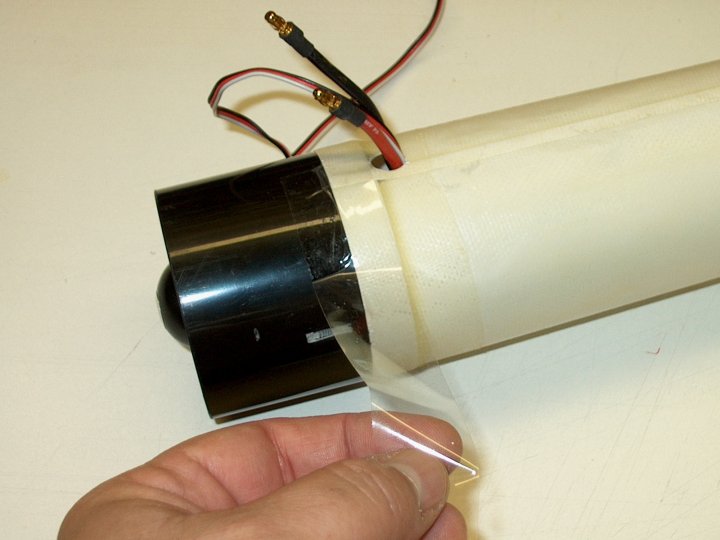

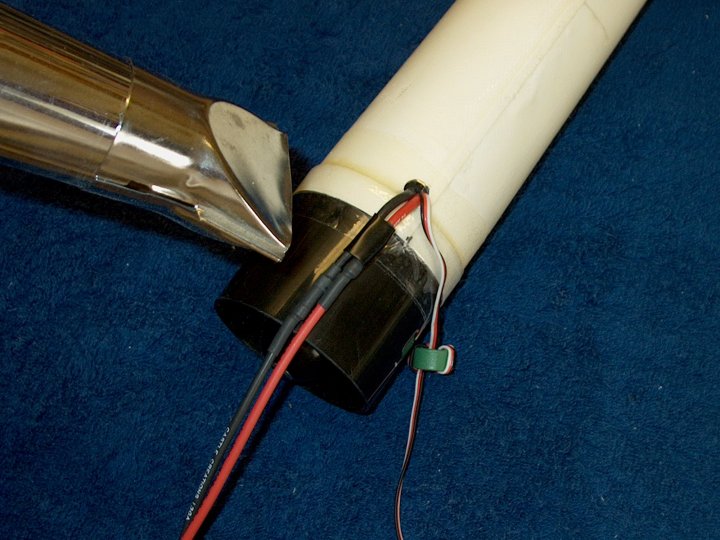

268 - Connectors are soldered to the motor

and ESC. This allows you to swap your motors and ESCs around

easier without taking apart your model

| |

269 - Motor ends of the ESC are covered

with heatshrink to prevent shorts | |

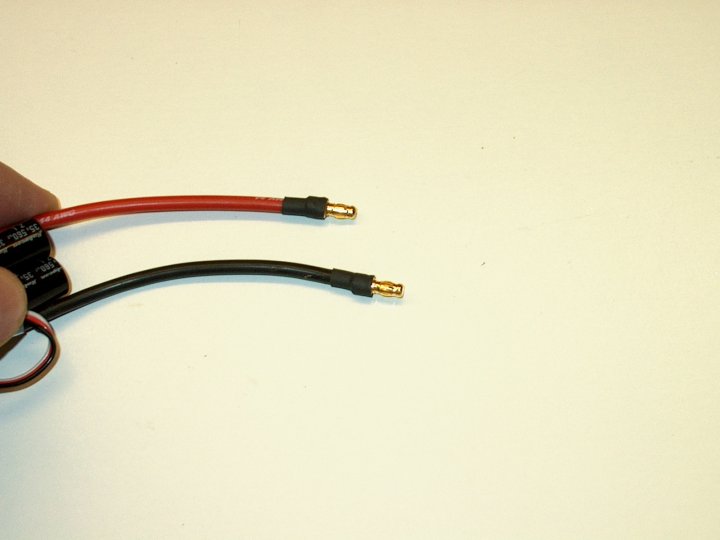

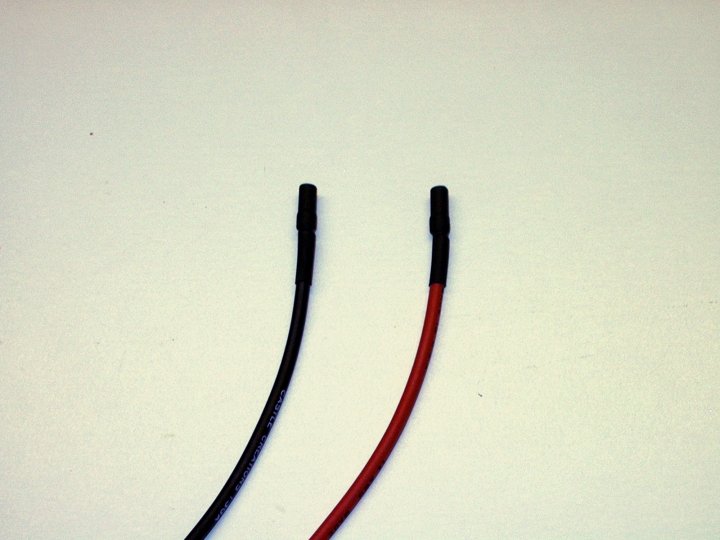

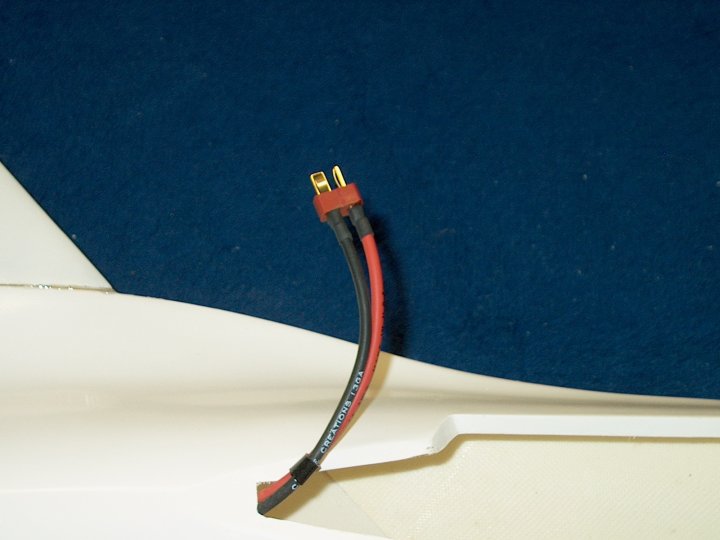

270 - Power wires for the ESC also have

connectors installed | |

271 - Power wires to the battery with

connectors and heatshrink. Always install so the sockets such

as those shown below are coming from the battery source. This

way, no matter where you disconnect down the line, you will

not risk a short like you would if plugs were

substituted | |

272 - Plug in the three wires of your

motor into the ESC sockets. A large piece of heatshrink is

then installed over these wires at the plug asssemblies To

prevent them from coming apart in the air turbulence

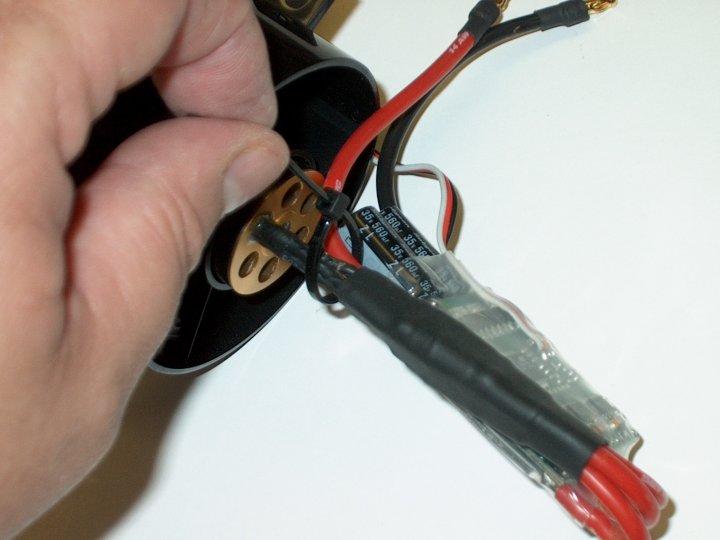

| |

273 - A wire tie is used to secure and

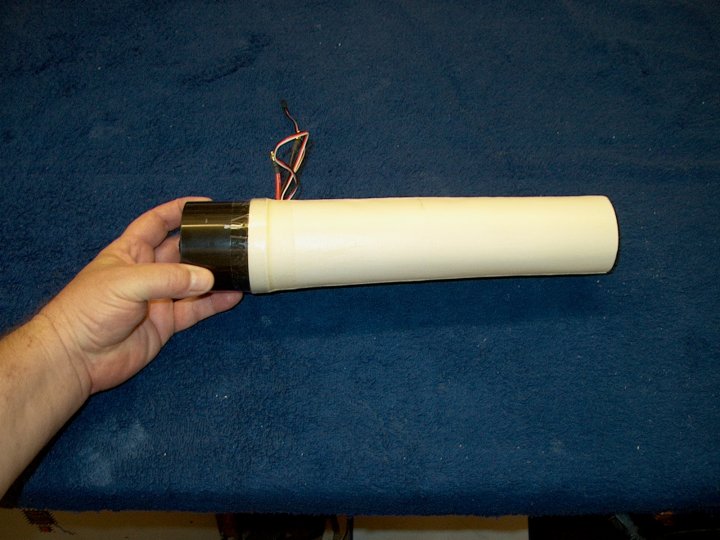

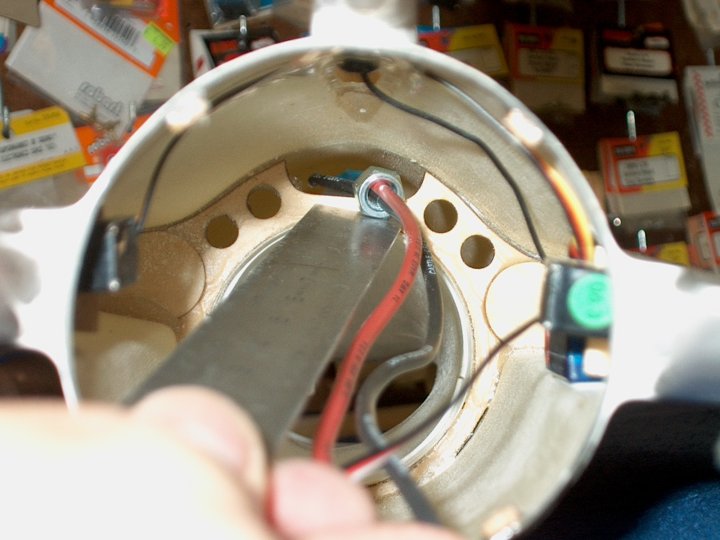

anchor the front of the ESC | |

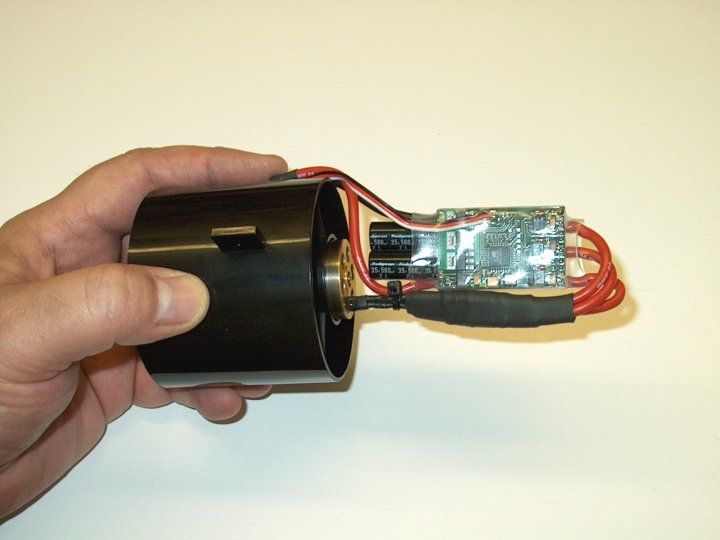

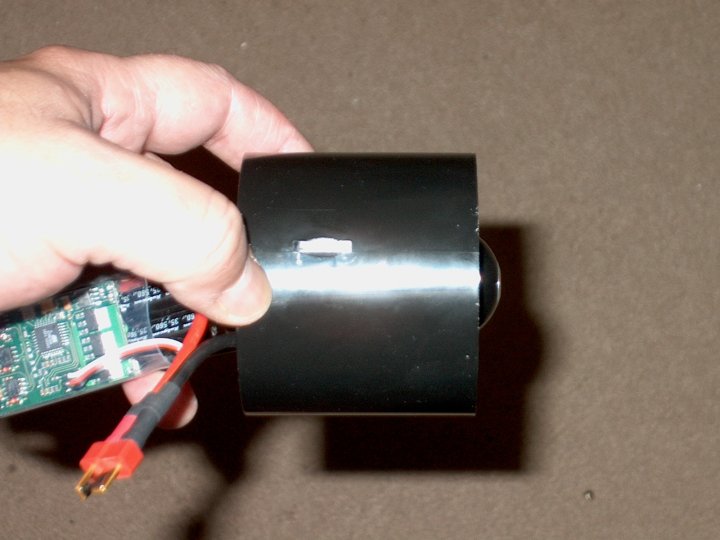

274 - Fan, Motor and ESC assembly

completed and ready to install in the Jet

| |

275 - The instructions call for you to

remove the mounting tabs of the fan as seen in the pic

| |

276 - Tabs have been removed

| |

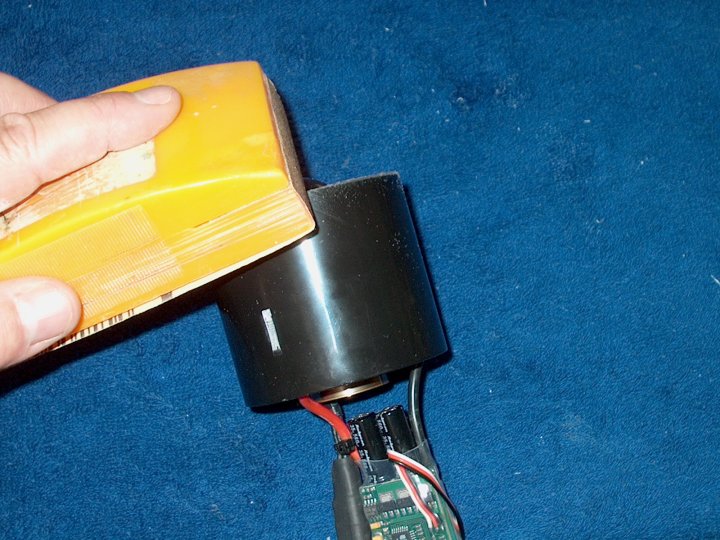

277 - Fine grit sandpaper was wrapped

around a dowel and used to smooth the rough spots in the

fiberglass exhaust duct | |

278 - Exhaust duct after sanding

| |

279 - The outside lip of the fan is sanded

to round the edge and make it easier to install

| |

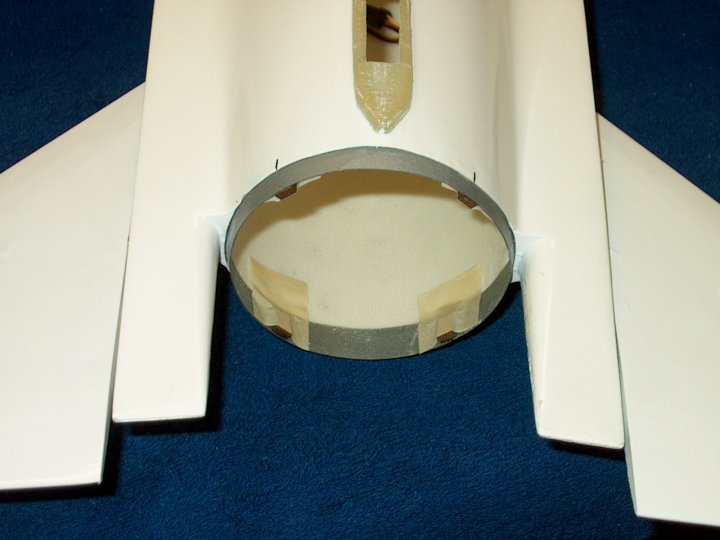

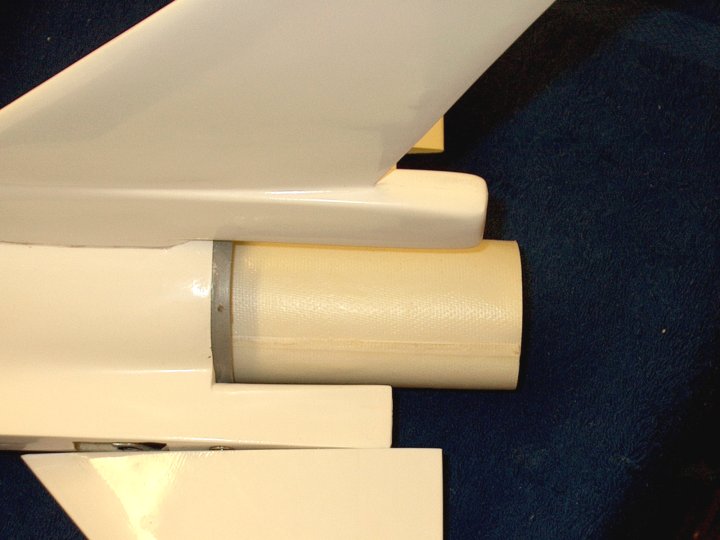

280 - Fiberglass duct is temporarily

installed to the fan assembly | |

281 - A servo had to be loosened so the

fan and duct could pass by from the rear

| |

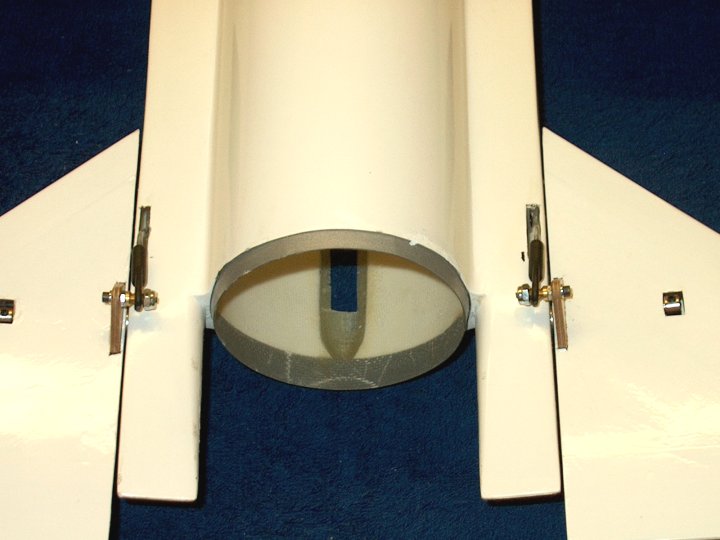

282 - Work the fan past the servos

| |

283 - Insert the fan into the forward

intake duct. It may seem a bit difficult at first to get it to

engage the intake duct. Keeping the bottom of the exhaust duct

low enabled it to slide in better | |

284 - Pic shows duct fully seated in the

intake. It will need to be trimmed to length

| |

285 - Keep the Tailcone centered and

measure the difference between the mounting holes on the

fuselage and the tailcone. This is how far you will need to

trim the exhaust duct | |

286 - A 1" wide strip of paper is wrapped

around the exhaust tube and a mark is made at a distance from

the end that you measured in the previous step

| |

287 - A cutting tool or knife can be used

to trim the exhaust tube. Cut it a bit short of the line so

you can fine sand the excess tube to the line

| |

288 - Sand the tube to the line

| |

289 - Drill a hole in the front of the

tube at the top location | |

290 - Open the hole up to about 3/8" for

your ESC wires to pass | |

291 - The hole should be sanded to remove

sharp areas | |

292 - The ESC wires are passed through the

hole | |

293 - Packing tape is used to fasten the

exhaust tube to the fan assembly | |

294 - Fan and exhaust tube shown with

wires coming from the top. Notice there is a slight upward

angle , which was required to have the exhaust center in the

fuselage rear | |

295 - Tape is used to secure the ESC

wires | |

296 - Temporarily fit the unit in the

fuselage. Make sure the exhaust rear is centered in the

fuselage. If not, remove the unit, loosen the tape on the fan

and re-adjust/tilt slightly until centered

| |

297 - Check the fit of the tailcone. The

Exhaust tube may still need some fine trimming

| |

298 - Make a mark on the exhaust tube

again for final trimming | |

299 - Scissors are used to fine trim the

exhaust tube | |

300 - Check the tailcone fit and make sure

it is flush | |

301 - Check for buckling in the exhaust

tube and sand more if needed. It should be a nice tight

fit | |

302 - Rear exhaust area of the fuselage

shown | |

303 - The inside of the tailcone is

roughed up with 60 grit in the area where the exhaust tube

will touch | |

304 - Lightly rough up the outside of the

exhaust tube | |

305 - Apply a heavy coat of epoxy and

quickly install the tailcone | |

306 - Keep the fuselage vertical so the

epoxy runs down to the exhaust tube joint inside. Quickly

install the screws so the glue sets while the tailcone is in

the correct position | |

307 - Leave the fuselage in a vertical

position until the epoxy sets | |

308 - Once the epoxy has set, remove the

assembly | |

309 - Photo of the completed Fan

Assembly | |

310 - Some additional epoxy was mixed and

poured in the tailcone joint for added strength

| |

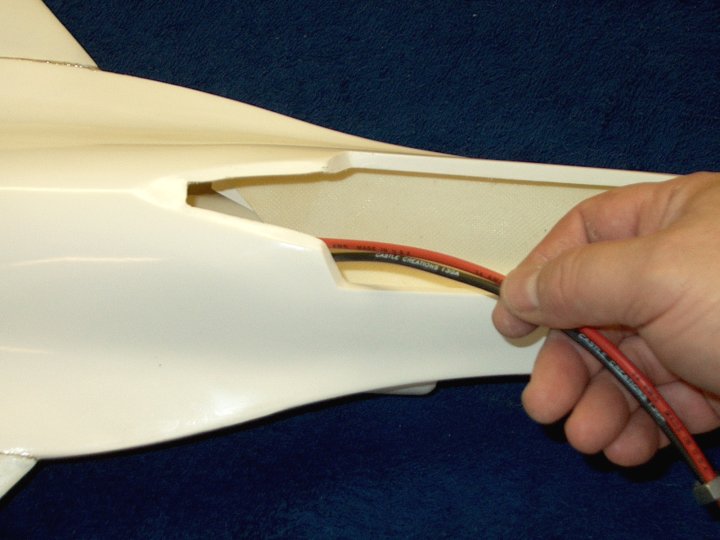

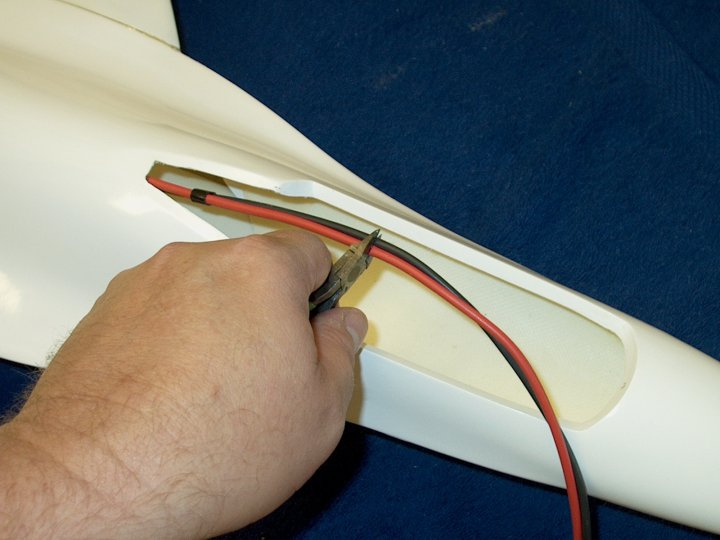

311 - The power wires are installed and

heatshrink is added | |

312 - A couple small slices of heatshrink

are used to dress the cable | |

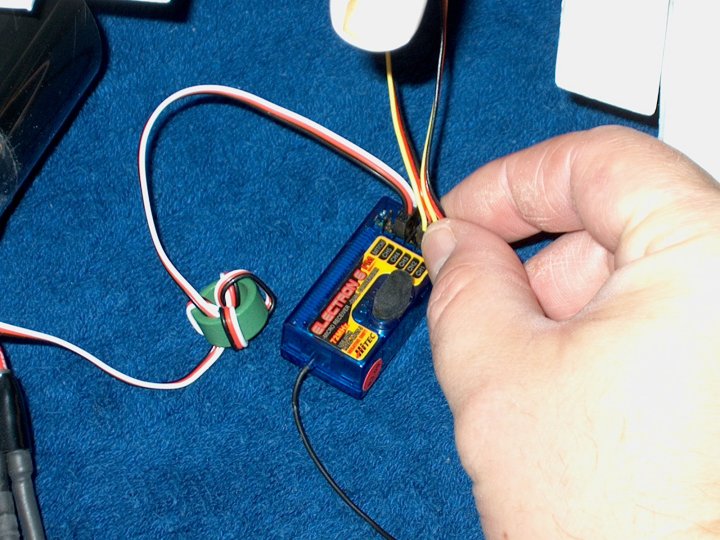

313 - Servo tape is added to the radio

receiver | |

314 - This step is not necessary, but I

added a inner lexan thrust tube as it made for a smoother

walled exhaust, a more even transition to the tailcone and

should provide more efficient airflow

| |

315 - Servo cables are installed in the

receiver | |

316 - The receiver antenna wire is run

through the grommet | |

317 - A nut is taped to the wire to help

with routing | |

318 - The wire nut is installed in the

vertical stab area | |

319 - The nut helps route the wire out the

rear of the vertical stab | |

320 - The receiver is prepared for

installation | |

321 - The receiver is installed on the

right side of the fuselage just in front of the servo tray. It

is a bit tight, but can be reached | |

322 - Receiver installed in place

| |

323 - Tape is used to retain the servo

wire on the other side | |

324 - Tape is shown retaining the servo

wire so it doesn't snag when the fan assembly is

installed | |

325 - A nut is used to help route the

power wires to the front of the fuselage

| |

326 - Install the fan assembly in the

fuselage, taking care to route the wires

| |

327 - Keep removing the slack out of the

power wires during installation | |

328 - Set the fan assembly in the forward

intake | |

329 - Installed the tailcone screws to

hold the fan assembly in place | |

330 - Re-install the screws for the servo

that was loosened | |

331 - Fan Assembly installed in

fuselage | |

332 - Trim the excess length from power

wires | |

333 - An Ultra Plug is installed on the

power wires | |

334 - Power plug installation

completed | |

335 - The canopy is trimmed with a pair of

scissors | |

336 - Trim a little at a time and check

the fit. Leave enough on the sides for gluing

| |

337 - Use epoxy or canopy glue to mount

the canopy to the frame. DO NOT glue the canopy in place if

you plan to paint it | |

338 - Canopy assembly completed

| |

339 - The model comes with magnets for the

canopy, but I opted for a more secure mount. Make sure the

canopy is centered in the rear and drill a 1/16" pilot hole

through the rear of the canopy and into the fuselage

| |

340 - A small piece of wood should be

epoxied under the fuselage area for more grip from the

screw | |

341 - A clamp is used to hold the ply

plate in place until the glue sets | |

342 - Only the top section of the canopy

is opened with a 1/8" drill and a #2 hex screw is used to

secure it | |

343 - A mark is made at 3.5mm from the

bottom of the fuselage and is the center for the Elevons.

Adjust the ball links so that they center at this mark

| |

344 - Elevator up is 11mm from the center

mark. The same applies for Aileron movement

| |

345 - Elevator down is 11mm from the

center mark. The same applies for Aileron movement

| |

346 - The servo openings are covered with

a piece of self stick monokote | |

347 - CG for the model is set at 75mm

behind the wing root. Make sure your model balances before

flying | |

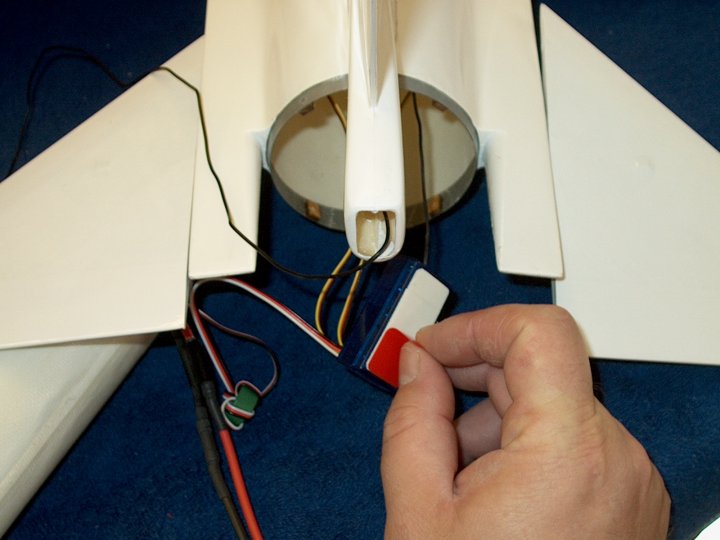

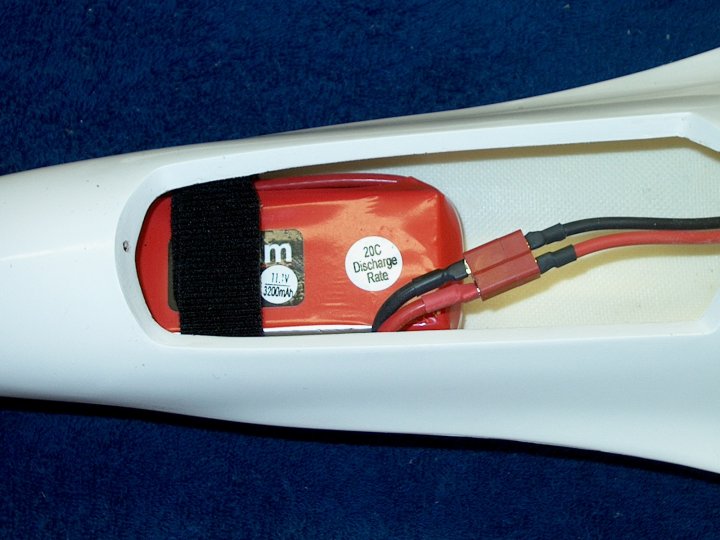

348 - Place your battery in the opening

and install the canopy. Move the battery around until CG is

found. Add a black mark to show the rear location of the

battery for the model to balance at CG. A small strip of

velcro is used to hold the battery in place. Do not use large

strips as you can damage Lipos when removing them

| |

349 - A velcro strap is epoxied to the

bottom of the fuselage and actually retains the battery, while

the small velcro strip prevents it from shifting around

| |

350 - Battery shown installed in

place | |

351 - Battery retention completed

| |

352 - The bungee hook is roughed up with

60 grit at the end that glues into the fuselage

| |

353 - A mark is made 25mm from the intake

seam on the bottom of the fuselage. This is the location of

the ply plate for the bungee hook | |

354 - A 1" strip of paper is anchored with

tape flush to the bottom of the fuselage and shown at the

bottom, then it is creased at the bottom on the other

side | |

355 - The paper is folded back so it is

flush to the bottom of the fuselage

| |

356 - The excess strip is removed

| |

357 - The strip is folded in half, then a

pencil is used to mark it at the fold

| |

358 - The strip of paper is taped to the

fuselage at each end and a mark is made for the hook at the

dead center mark on the paper | |

359 - A hole is drilled at the mark with a

5/64" drill bit | |

360 - A toothpick is used to push epoxy

into the drilled hole | |

361 - The hook is installed as shown and

the excess epoxy is removed | |

362 - Bungee hook shown installed

| |

363 - Make sure the hook is pointing

rearward and let the epoxy set | |

364 - The HET-RC F-16 Falcon from

Warbirds-RC Just add decals and paint(if necessary) and it's

ready to fly! | |

365 - Paint scheme used was for the F-16

Prototype, making it very visible in the air

| |

366 - Rear View showing decal

placement | |

367 - Top View | |

368 - The HET-RC F-16 Falcon EDF Jet

| |

|