The HET-RC F-104 Starfighter Minifan EDF

as it comes from Markos at Warbirds-RC

| |

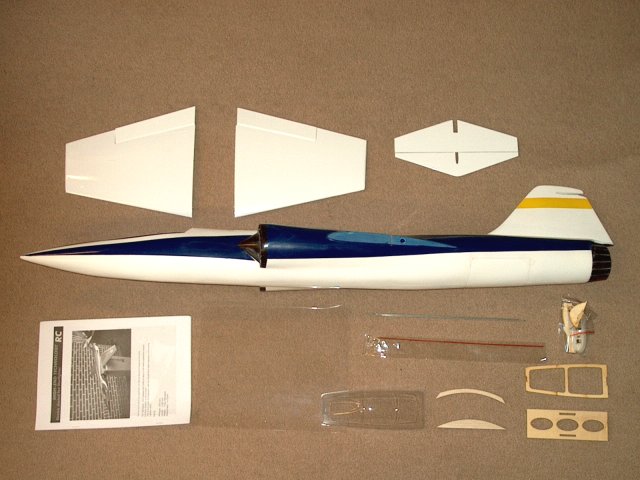

Opening the box reveals a well packed and

rather long model | |

Every that comes with the ARF is shown

| |

Shown is a closeup of the wood and

hardware included with the kit | |

The F-104 Starfighter fuselage

assembly | |

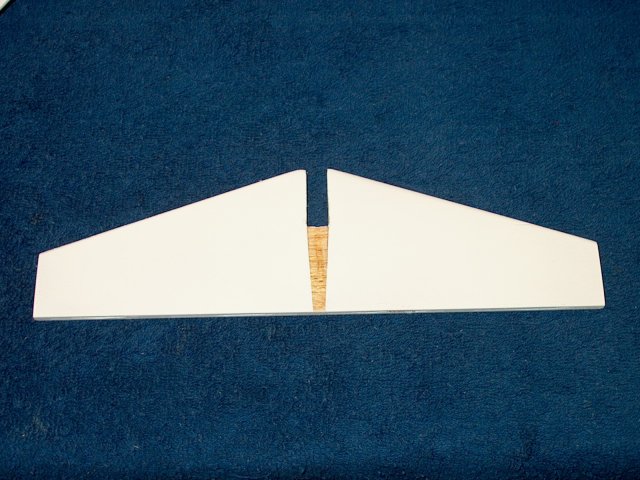

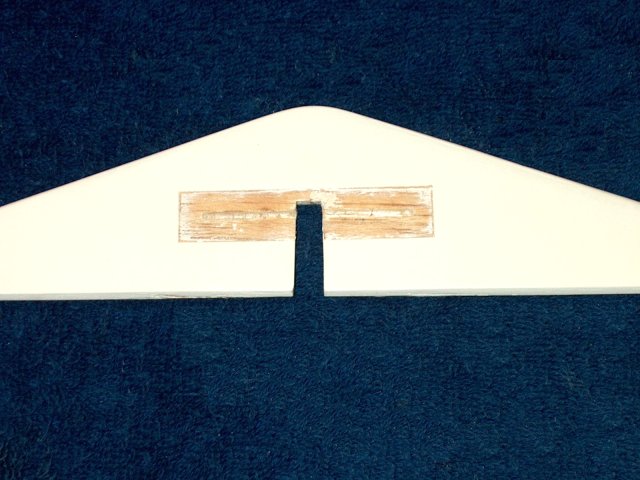

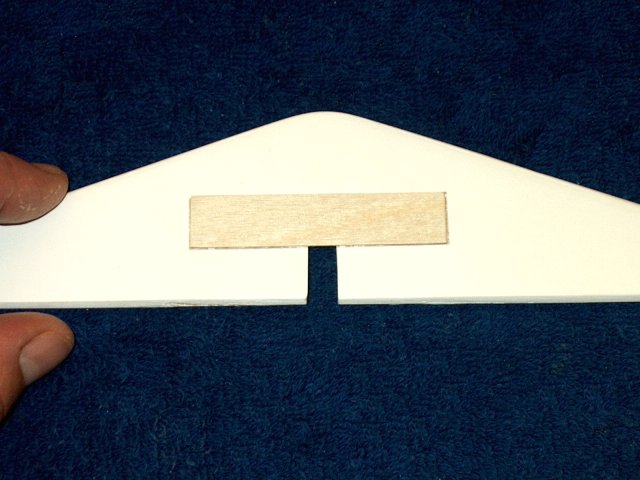

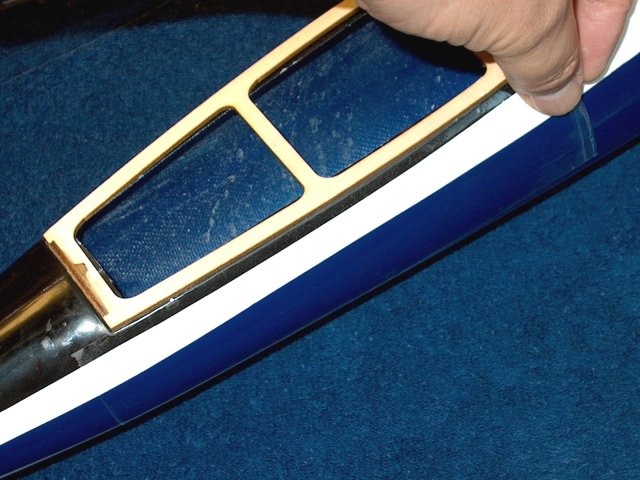

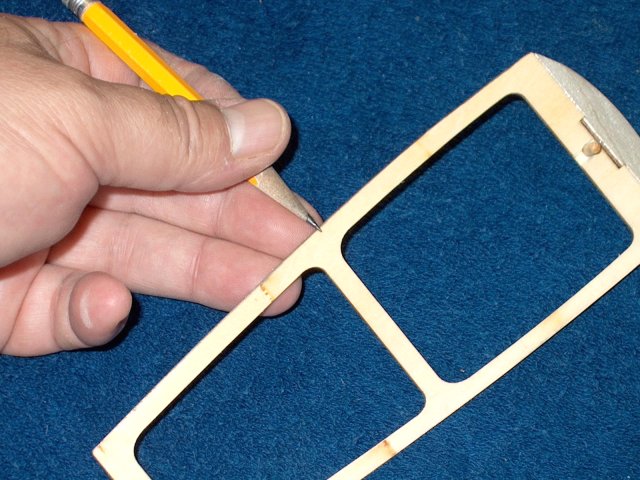

Mark a Left and Right main spar and

install them in each slot in the fuselage

| |

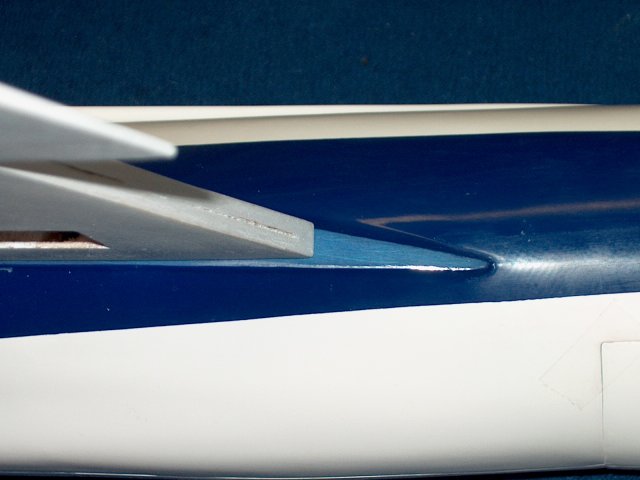

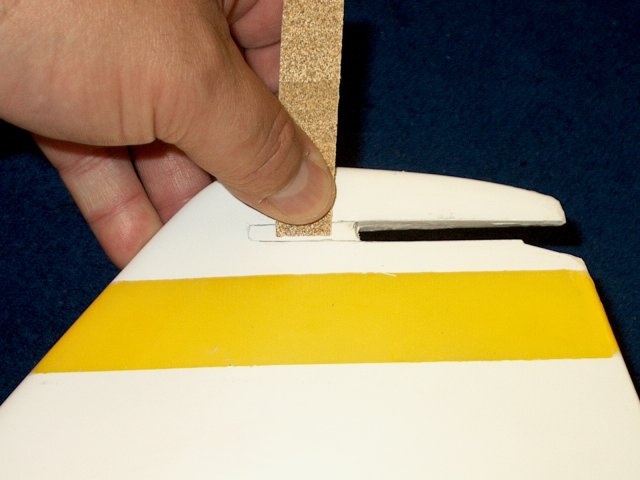

Install each wing and check that it is

fully seated on the wing saddle. If it will not seat flush

against the fuselage, sand the fuselage side of the spar, then

take a little off the end of the spar until the wing sits

flush | |

With each wing installed, check the

trailing edge for alignment and proper incidence. One wing was

off in this kit and needed adjusted

| |

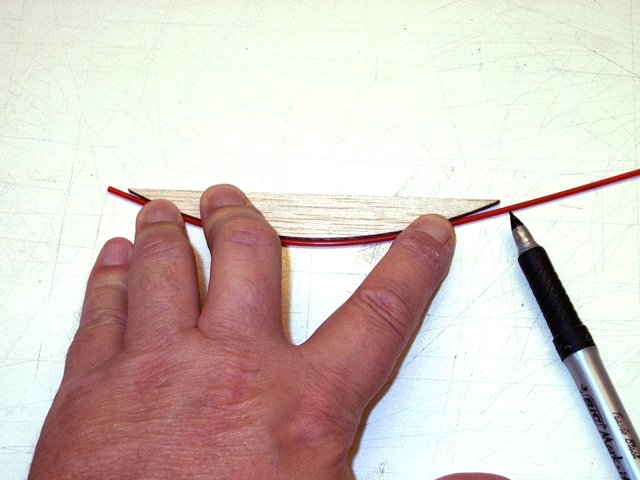

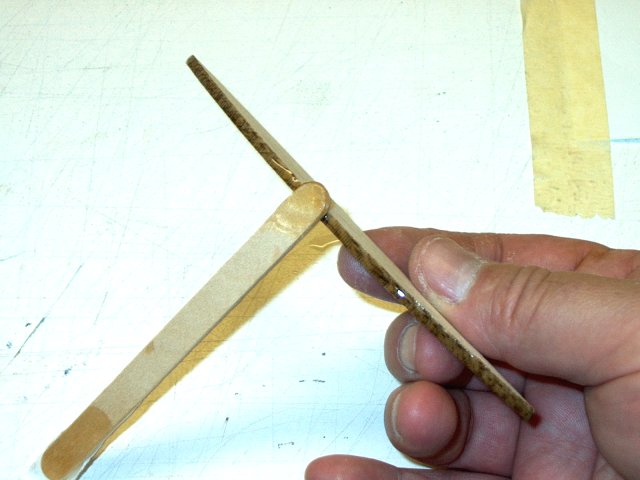

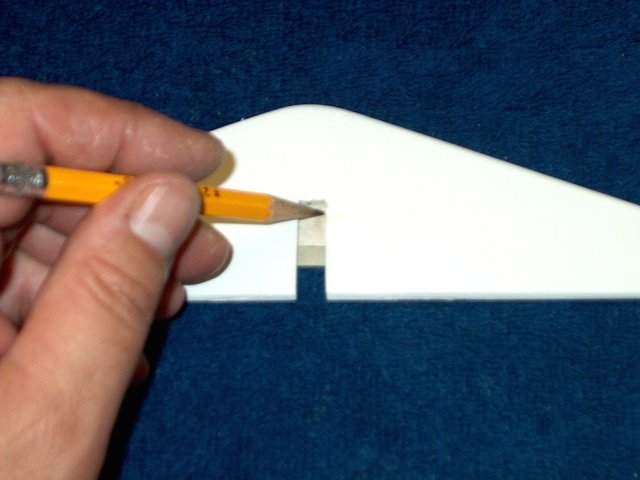

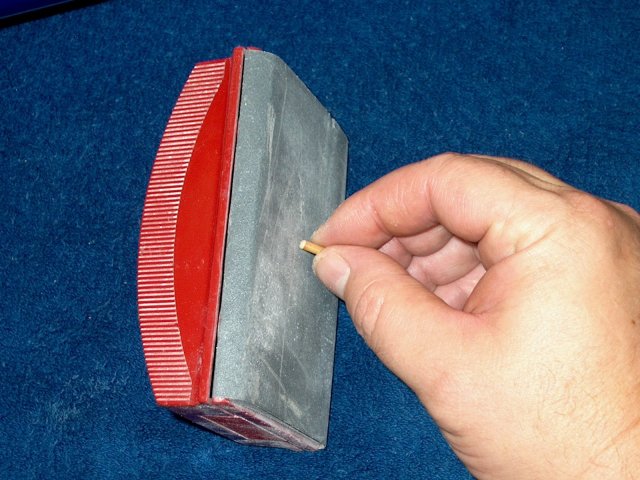

When sanding the spar, make sure you sand

only enough on the inside so that it remains centered from top

to bottom in the slot, then perform the remaining sanding at

the tip. Use a sanding block to keep each end straight or the

wing can rock in its position | |

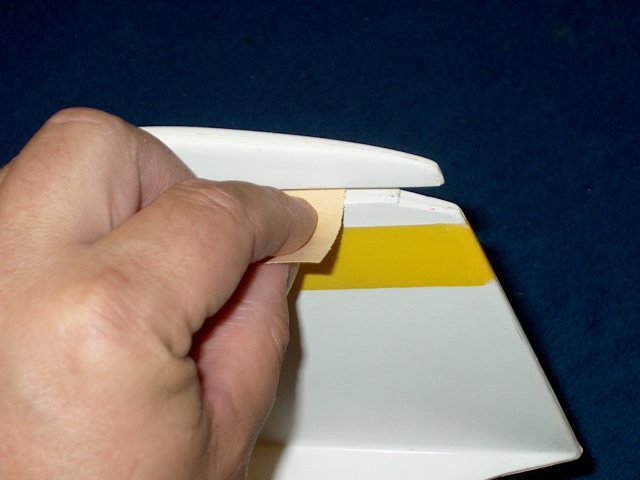

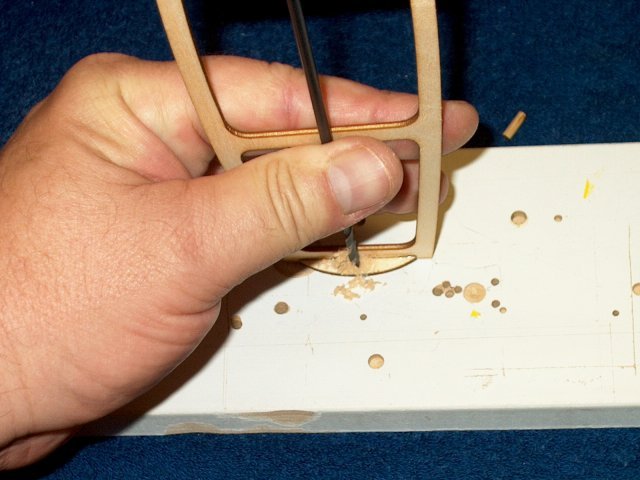

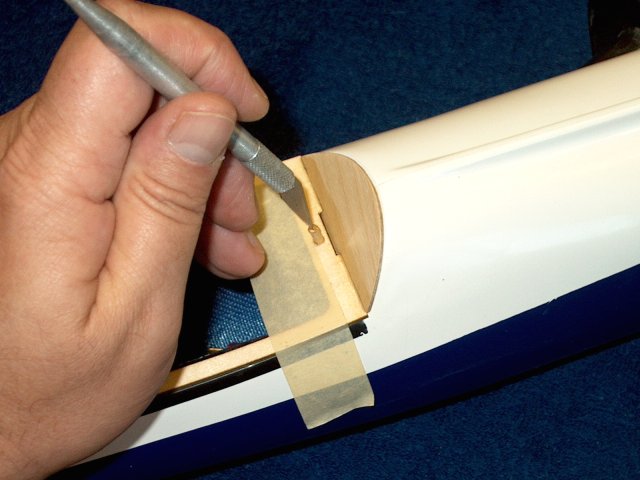

To adjust the wing, use a small round file

to elongate the wing dowel pin hole in the fuselage. Remove a

little at a time and check alignment. Continue to elongate

until the rear of the wing is centered and runs evenly across

the top and bottom of the fuselage wing saddle

| |

A properly aligned wing is shown

| |

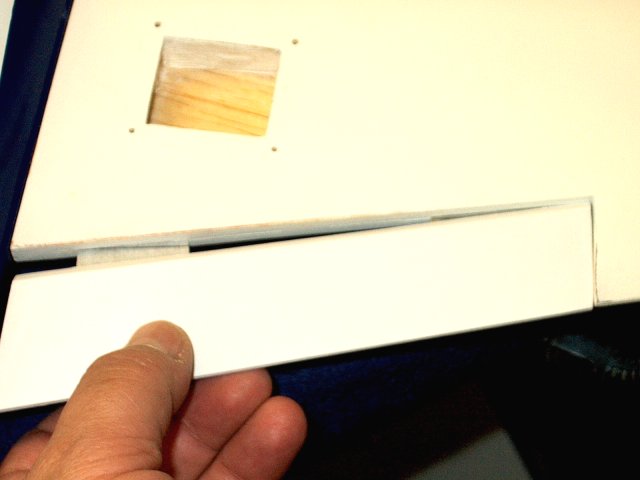

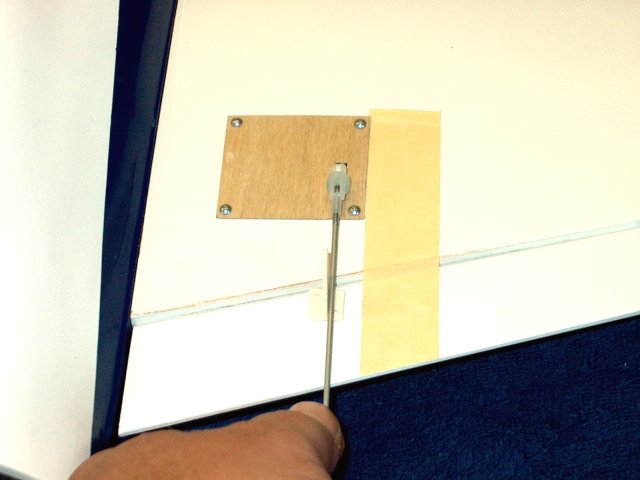

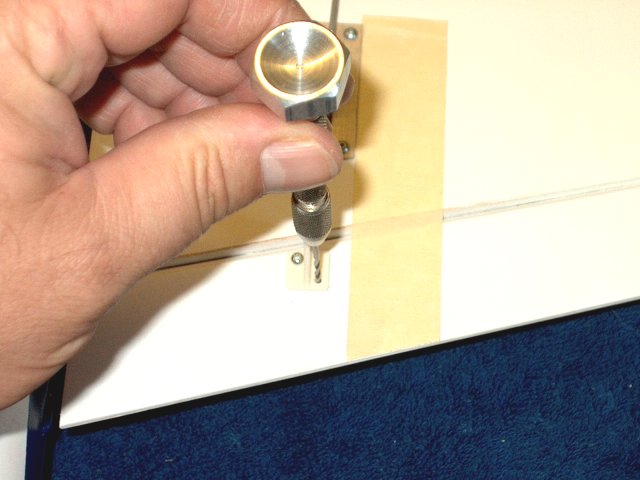

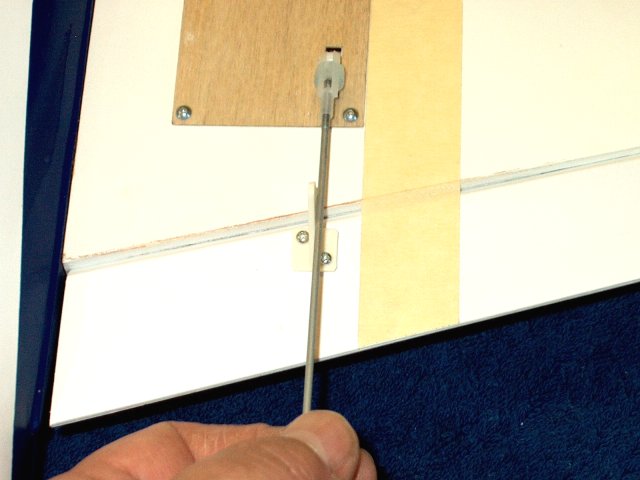

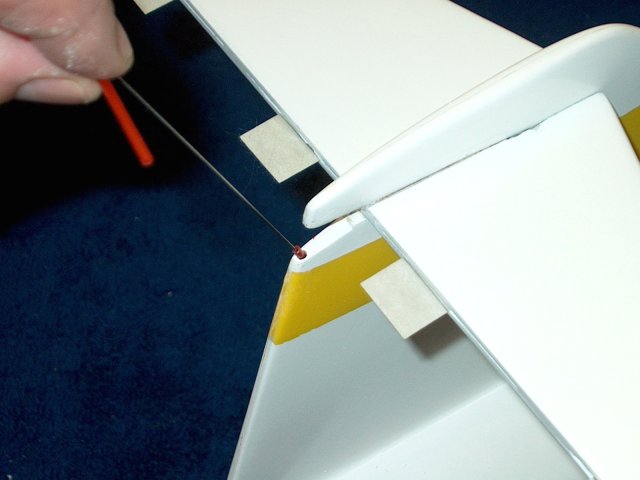

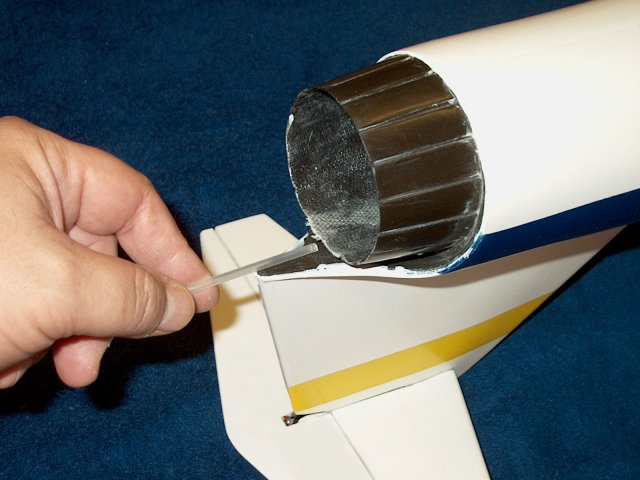

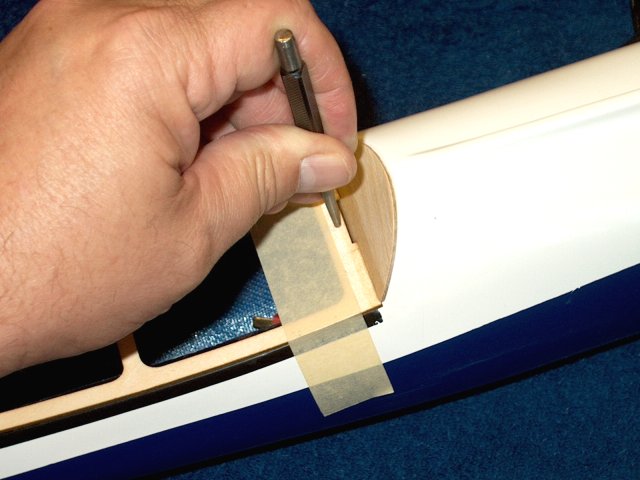

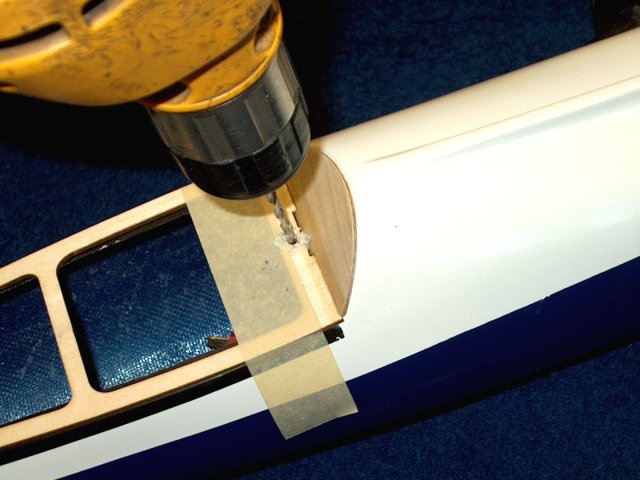

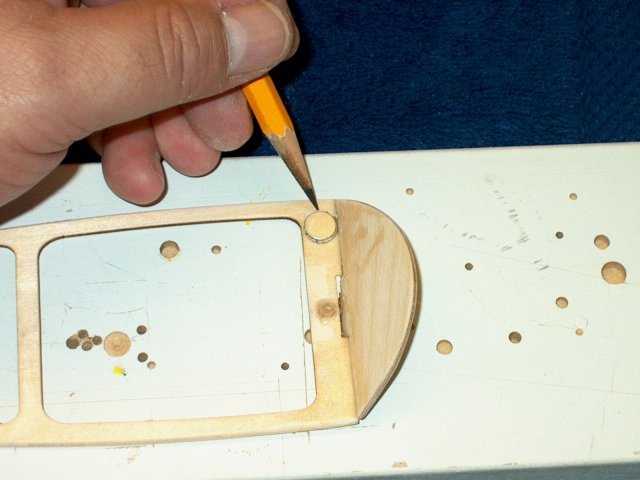

To tighten the dowel in the new hole,

drill a small hole above or below the wing depending on which

side you had to sand the slot | |

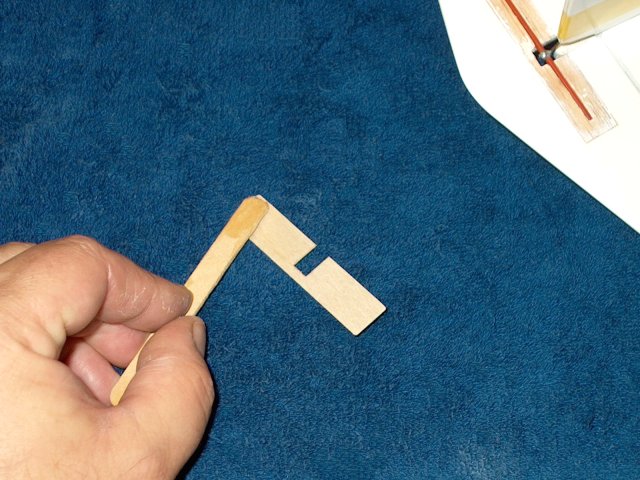

A toothpick is added and allows a snug fit

of the dowel pin into the elongated fuselage dowel pin

hole | |

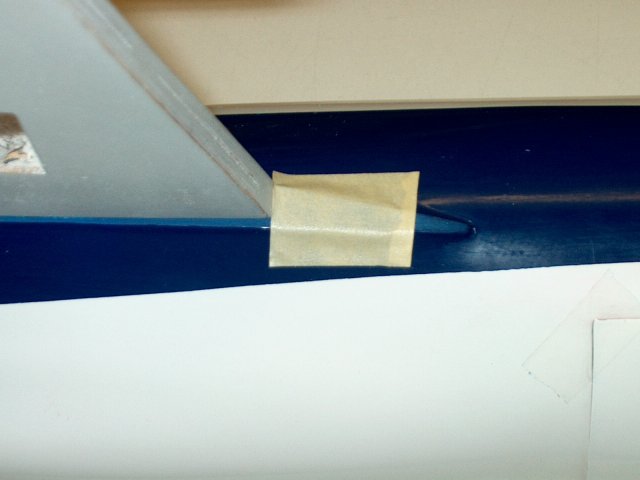

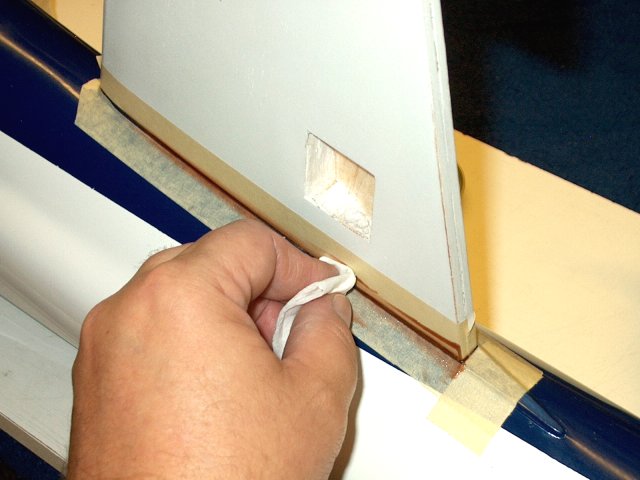

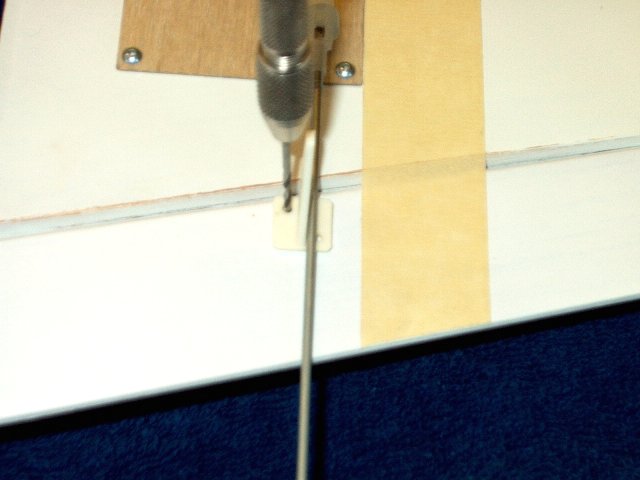

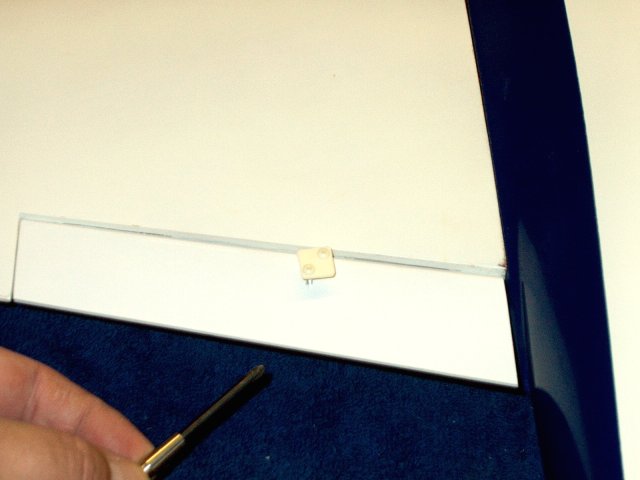

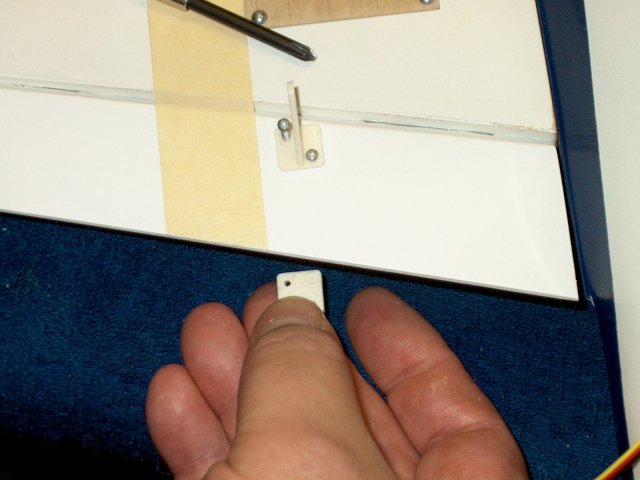

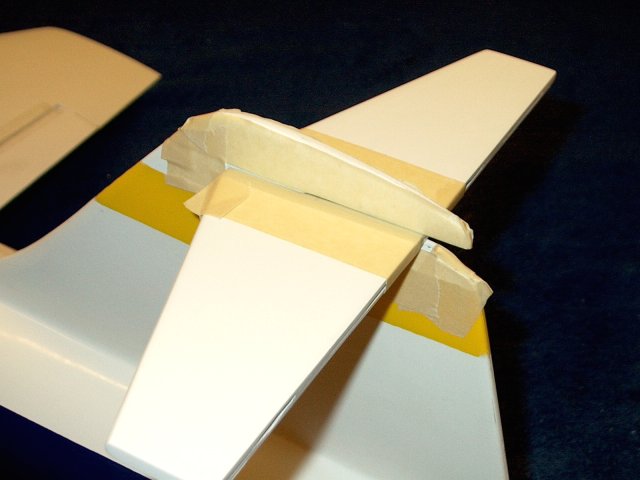

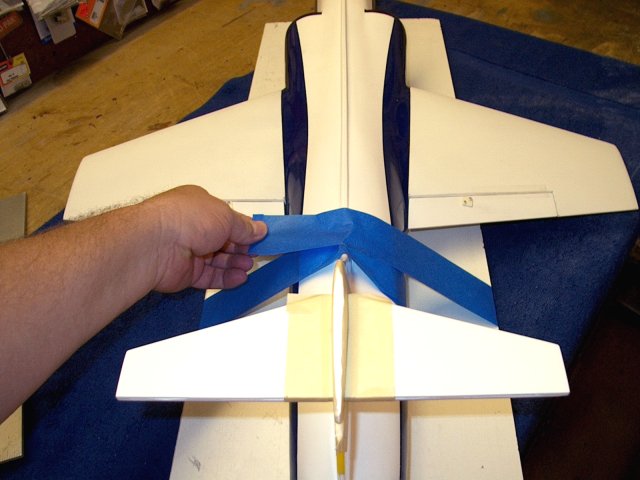

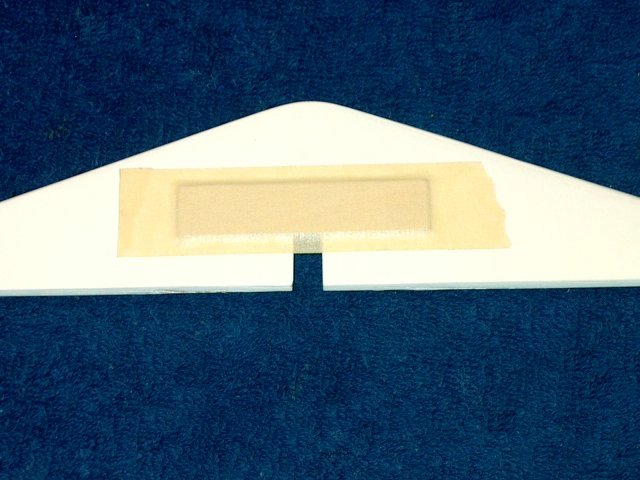

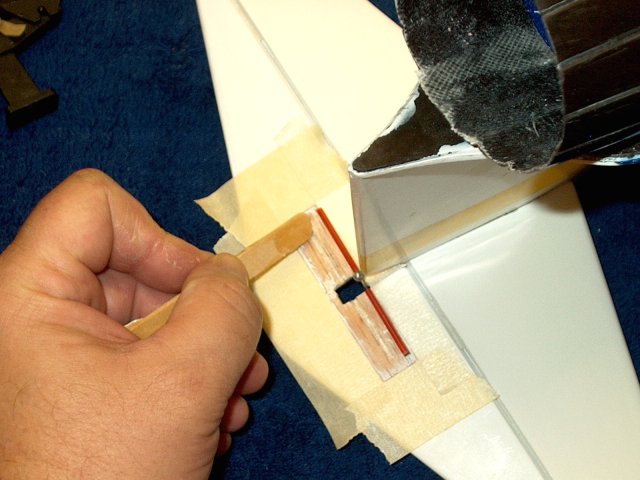

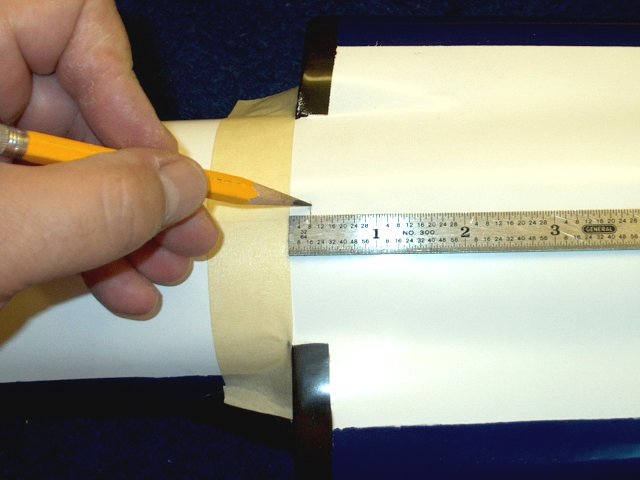

With the wing installed, apply some

masking tape even with the rear of the wing

| |

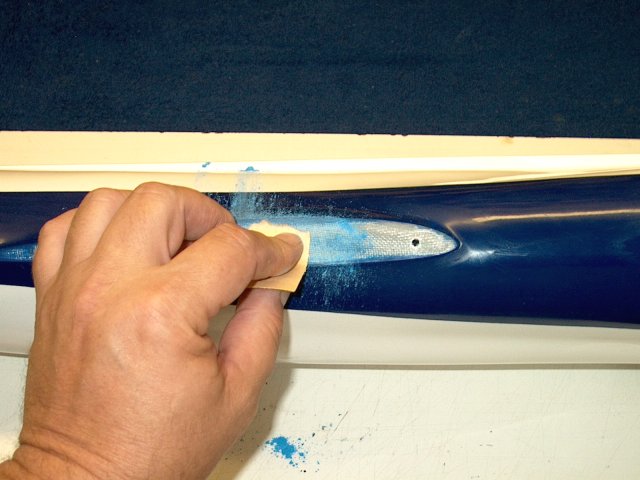

Sand this area up to the tape to remove

paint and allow for better glue purchase

| |

The rest of the wing saddle is sanded with

60-100 grit. Be careful not to remove too much, which will

weaken the saddle | |

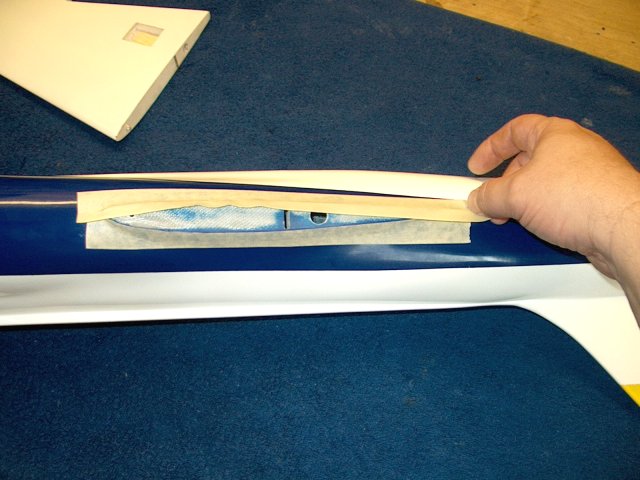

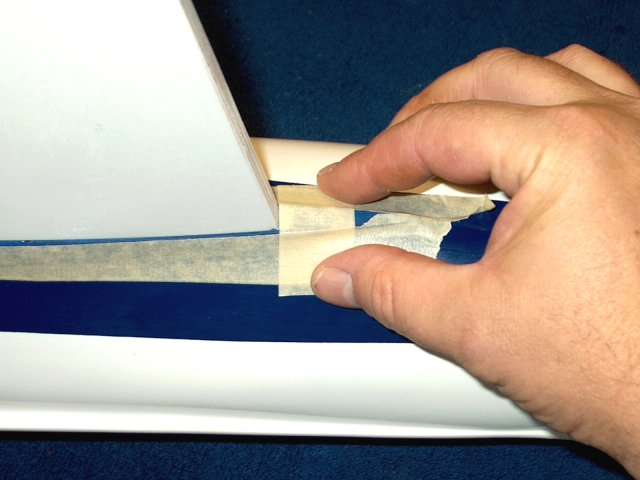

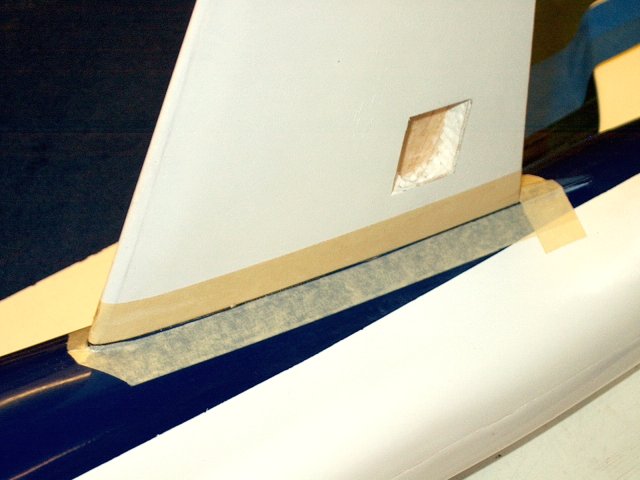

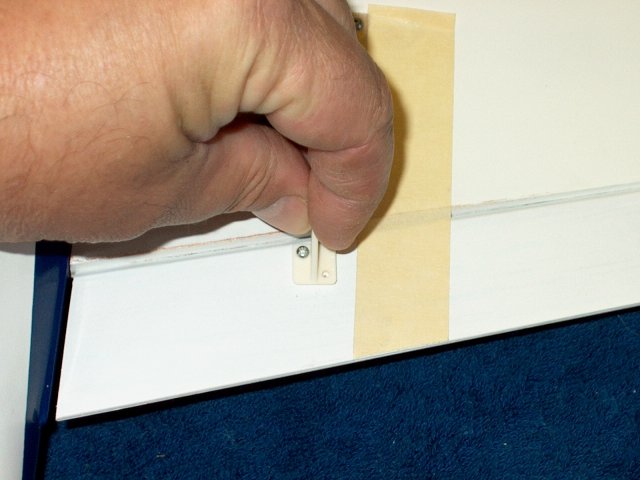

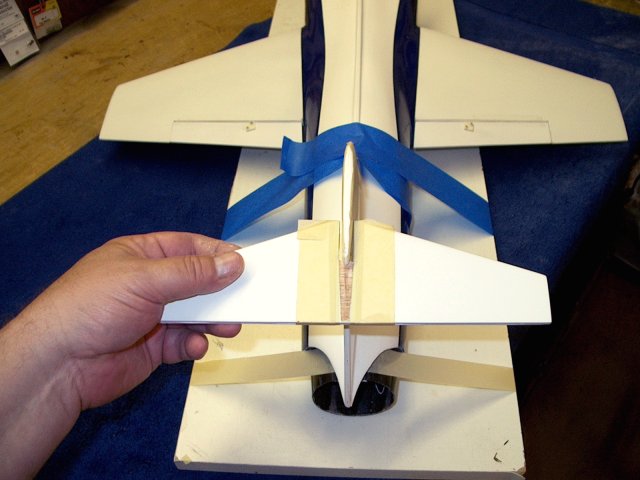

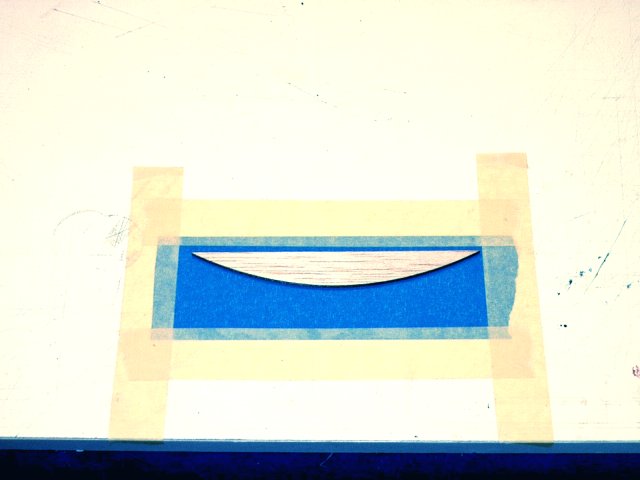

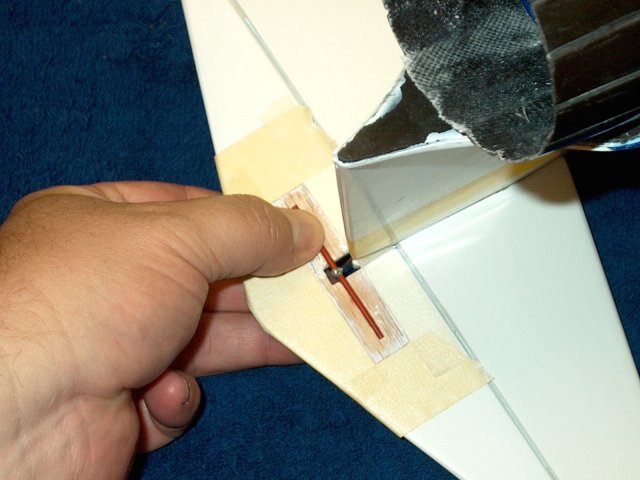

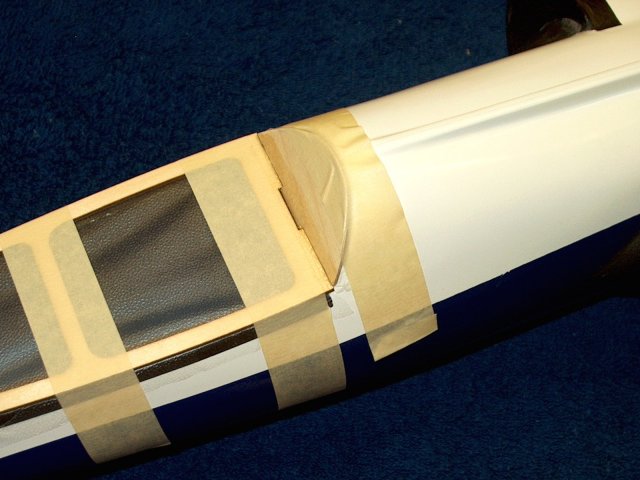

Masking tape is applied around the wing

saddles for both wings | |

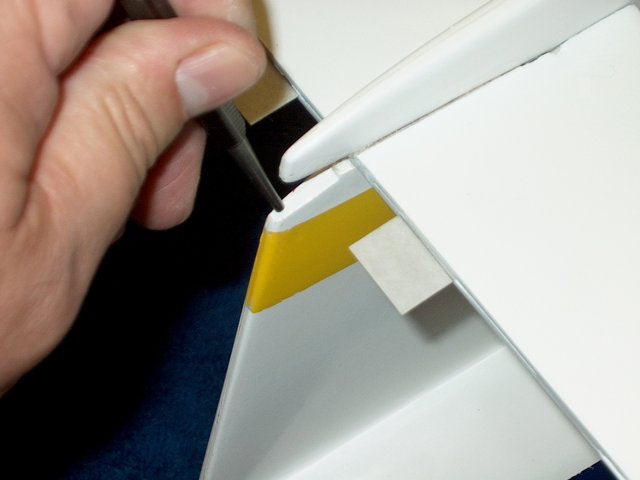

Trim the tape flush to the gluing surface

of the wing saddle | |

Add a fresh piece of masking even with the

rear of each wing | |

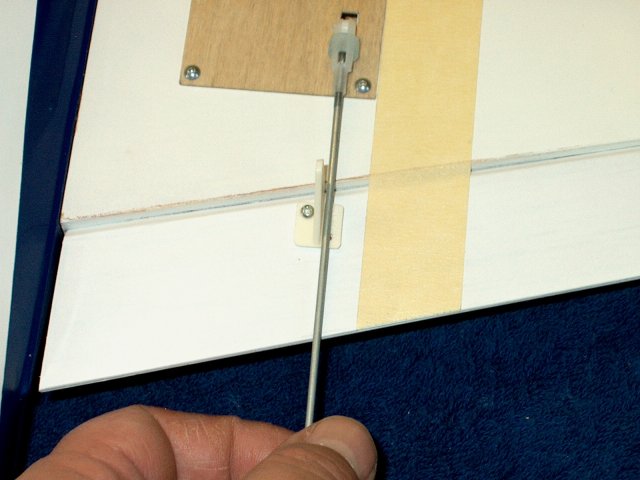

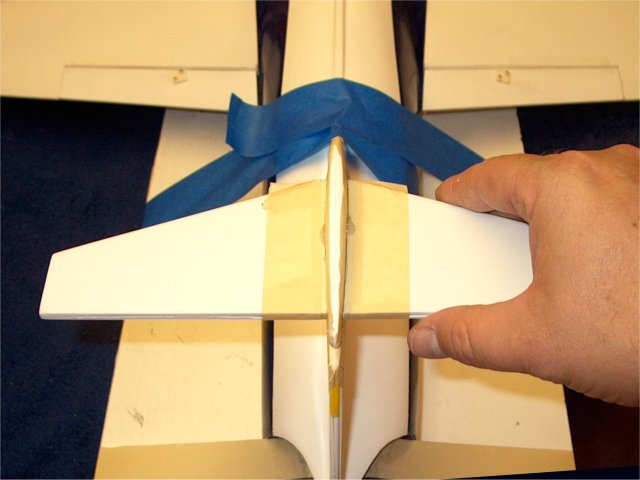

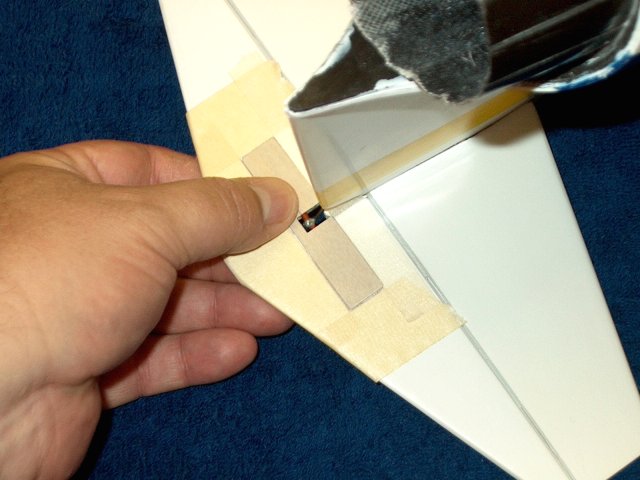

The wing area is shown ready for

epoxy | |

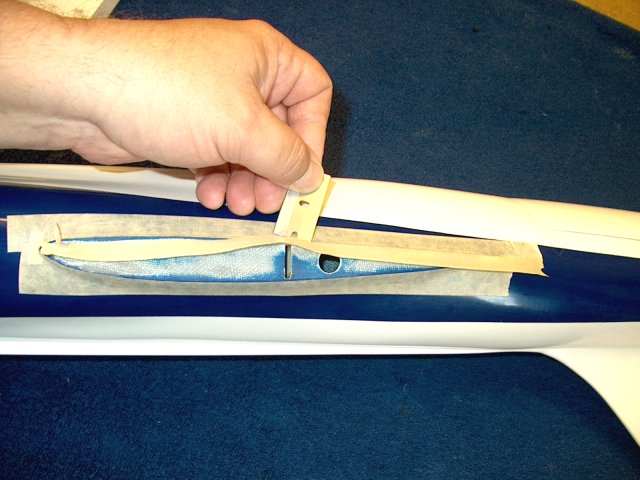

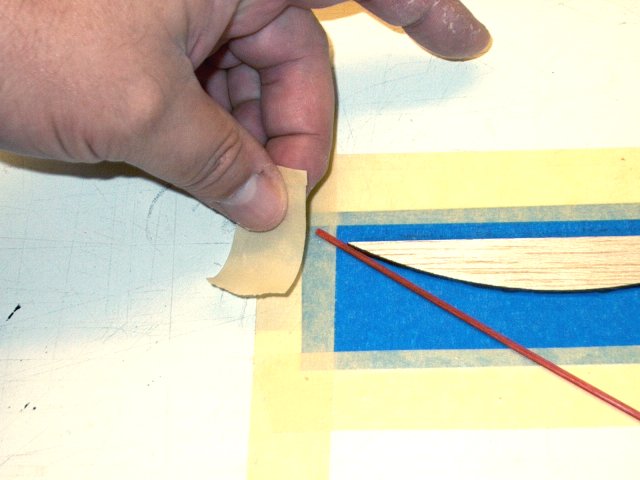

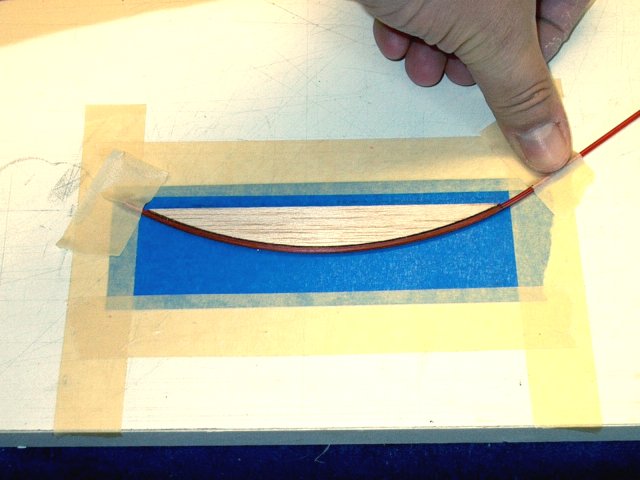

Apply masking tape flush to the end of

each wing. This will catch any epoxy spill over and keep the

wings clean | |

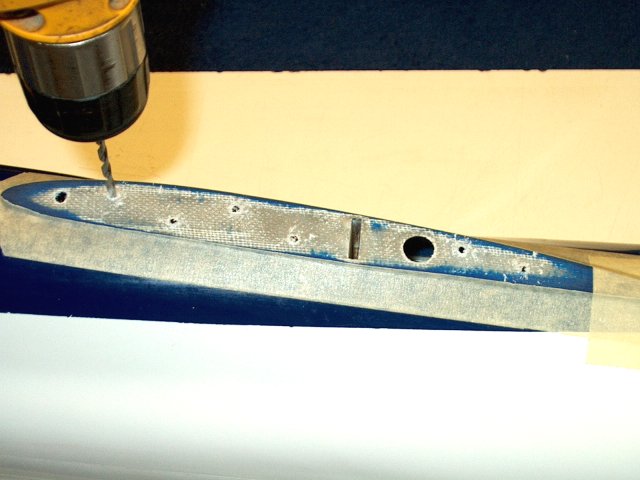

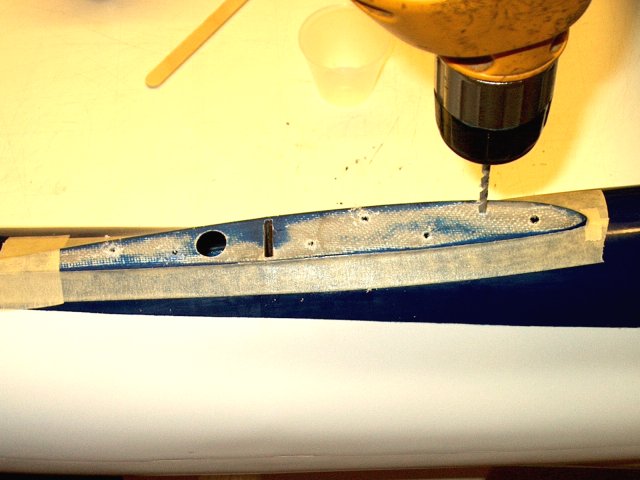

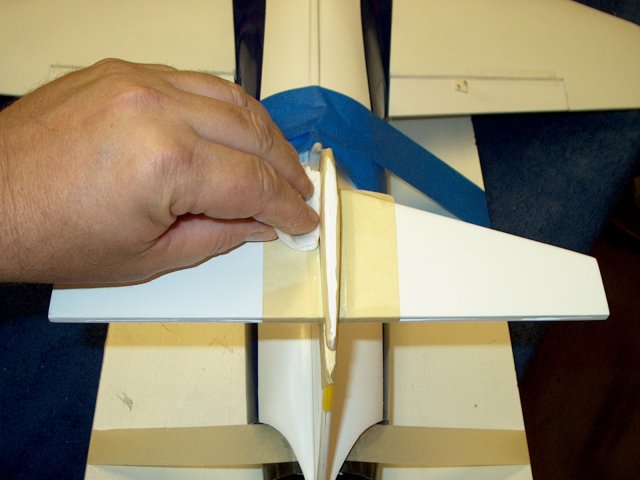

Drill some 1/8" holes in each wing saddle,

spaced about an inch apart and inside the glue area. This will

allow rivots to form and add strength to the joint

| |

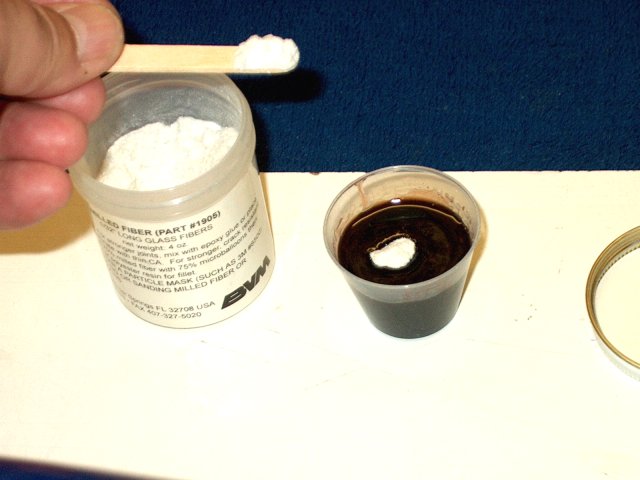

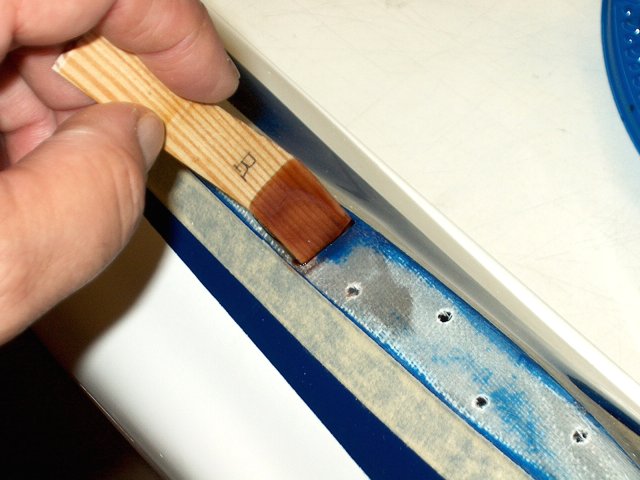

Mix some epoxy and set some of the mix

aside, then add some fiberglass mil to thicken the remaining

solution. Fifteen minute epoxy was used for each wing

installation | |

Apply the regular epoxy to the wing spar

slot in one wing | |

Apply epoxy to the spar in the area that

will be inserted into the wing | |

Install the spar in the wing and clean up

the remaining epoxy. Note that the epoxy may "hydraulic" in

the hole, so push and pull the spar a few times to work it in

so it is seated flush | |

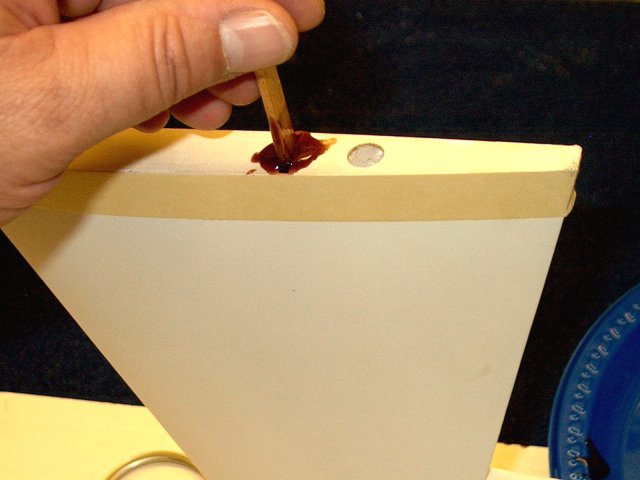

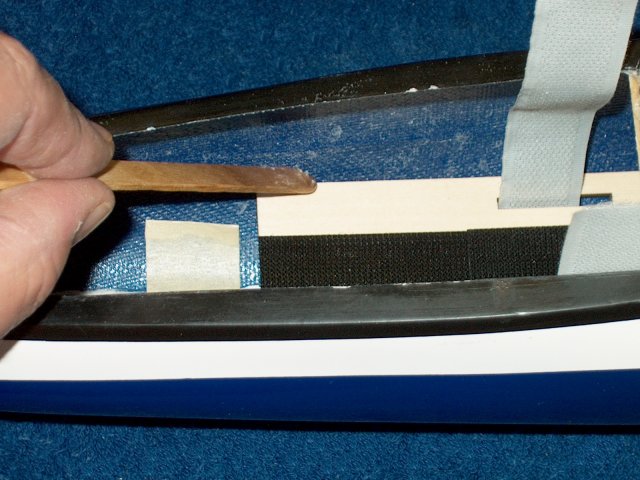

Use a stick to apply the thickened epoxy

mix to the wing saddle | |

Apply regular epoxy to the exposed spar

area | |

Apply regular epoxy to the wing spar

area | |

Apply regular epoxy to the remainder of

the wing in a thin film so it will soak into the spar

| |

Install the wing on the spar and flush to

the fuselage | |

Use denatured alcohol and paper towels to

remove excess epoxy | |

Wing is shown installed. Allow some time

for the epoxy to set | |

Drill holes in the second wing saddle as

shown | |

Install regular epoxy in the wing spar

slot on the fuselage | |

Apply regular epoxy to the spar and

install as shown. Make sure it hydraulics and bottoms out so

it sits flush inside the fuselage, then clean off the

excess | |

Apply thickened epoxy to the remaining

wing saddle | |

Use a stick to apply regular epoxy to the

exposed wing spar | |

Apply regular epoxy to the wing spar slot

and wing spar as shown | |

Install the second wing on the

fuselage | |

Remove excess epoxy with alcohol and paper

towels | |

Allow the epoxy on the second wing to

set | |

Remove the tape from each fuselage saddle

and wing | |

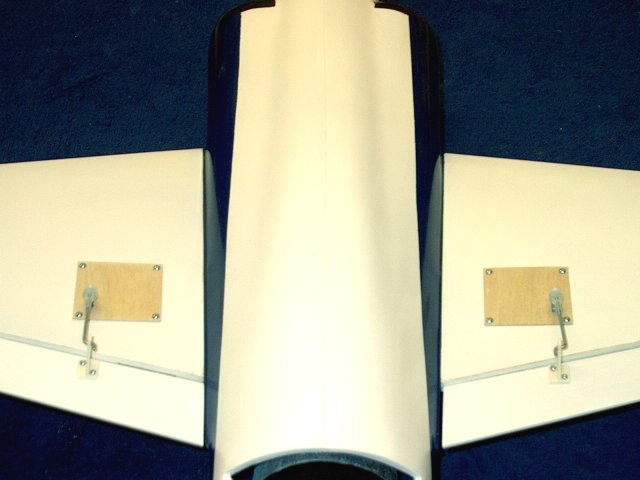

Wing installation shown completed

| |

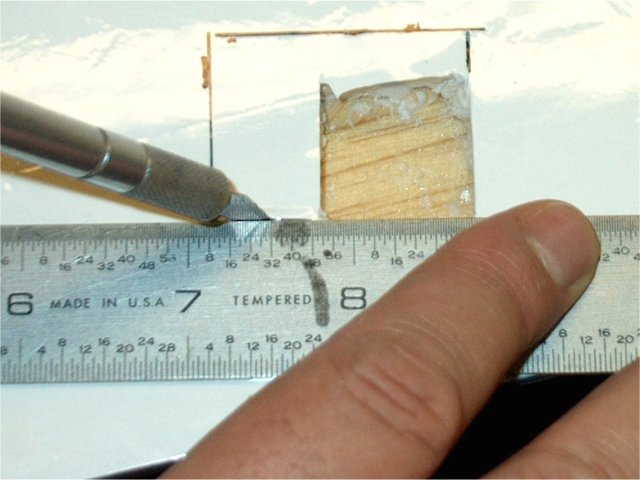

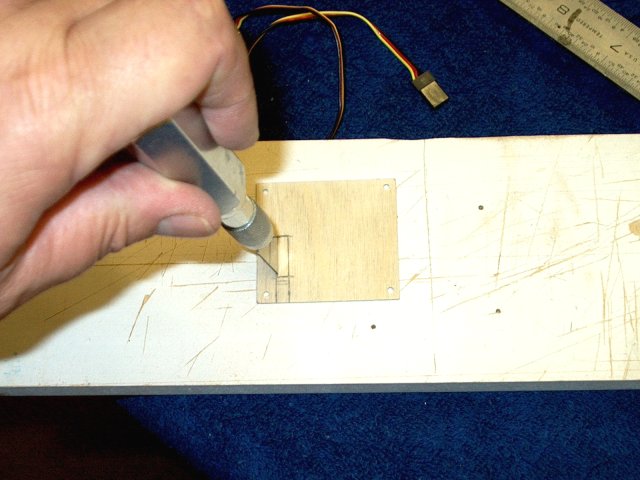

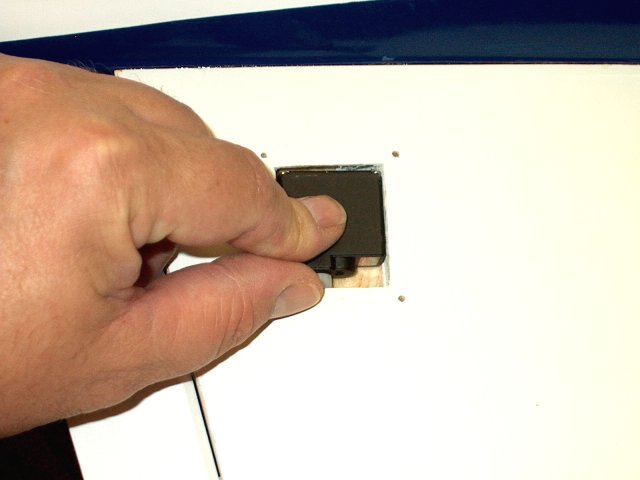

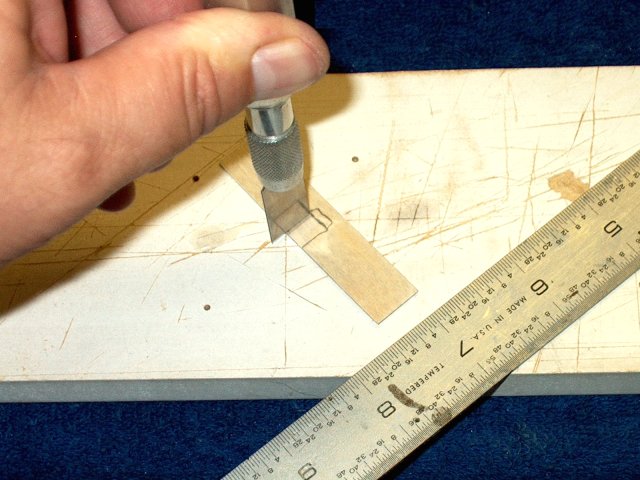

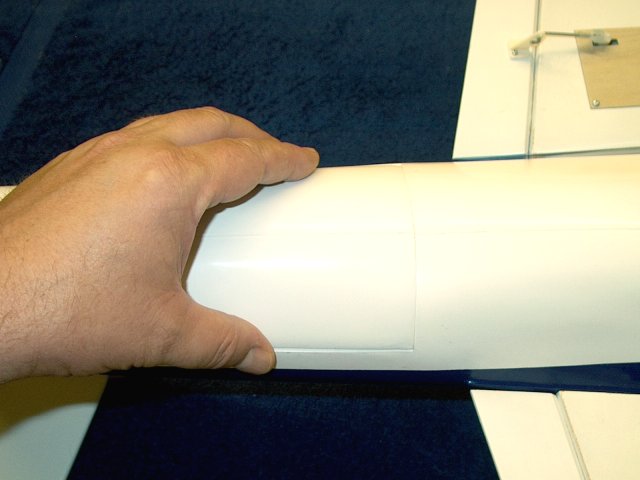

Construction begins with wing preparation

and installation. Remove the tabs from your servo and place it

over each opening. Mark the outer shape and enlarge the

opening width | |

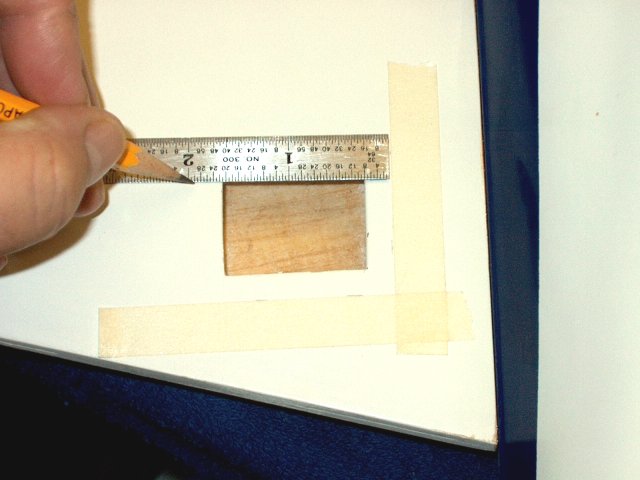

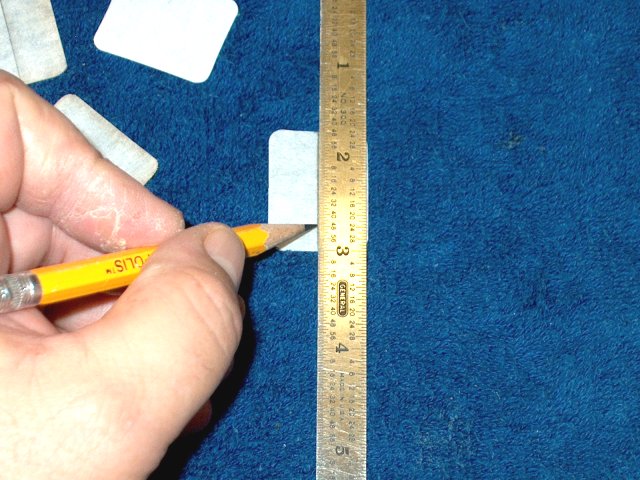

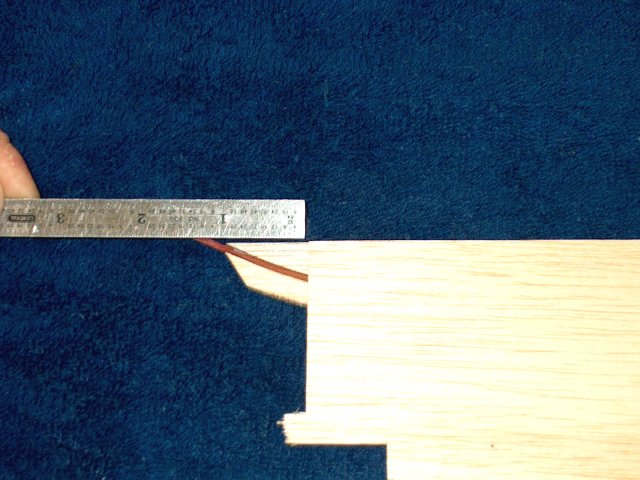

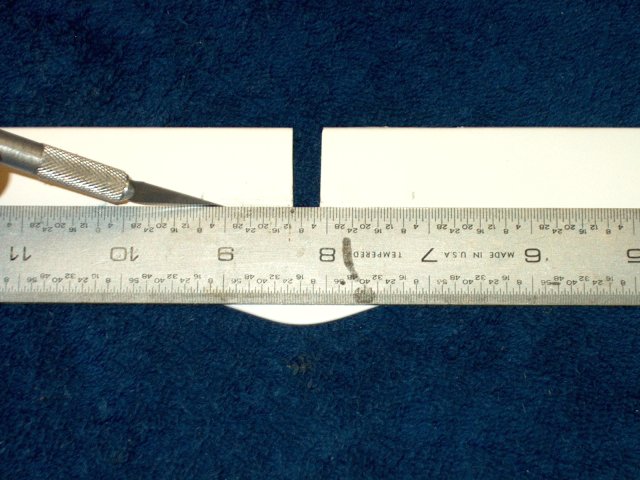

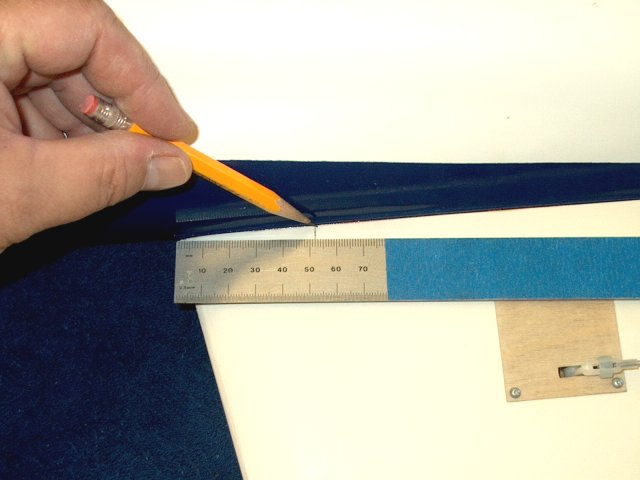

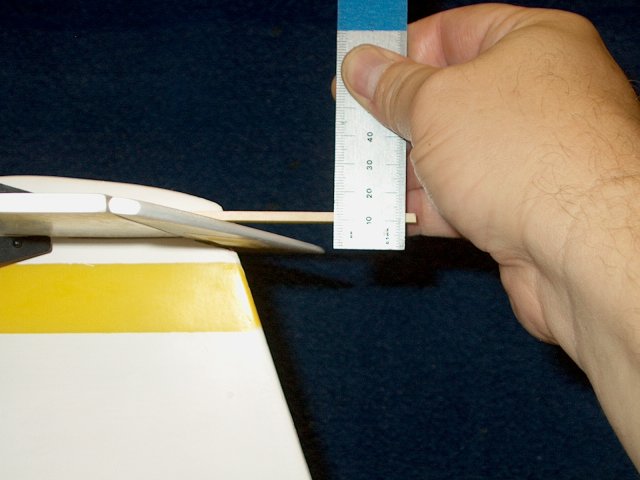

Measure the opening of the servo well and

add 1/4" overhang to each of the four sides

| |

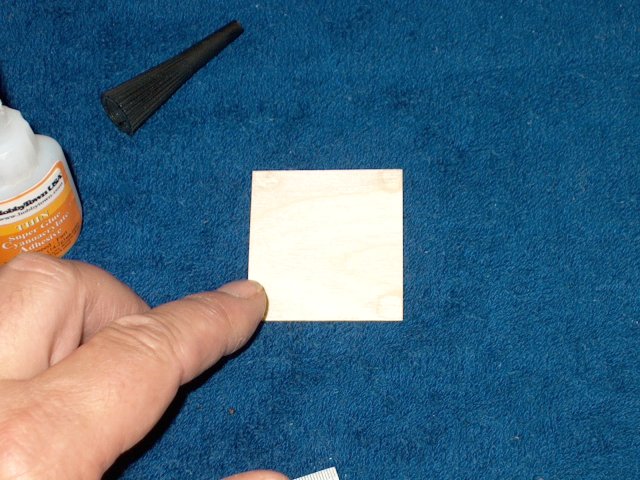

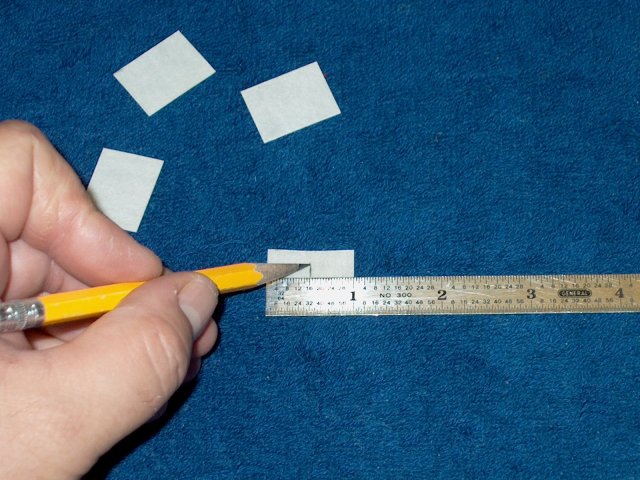

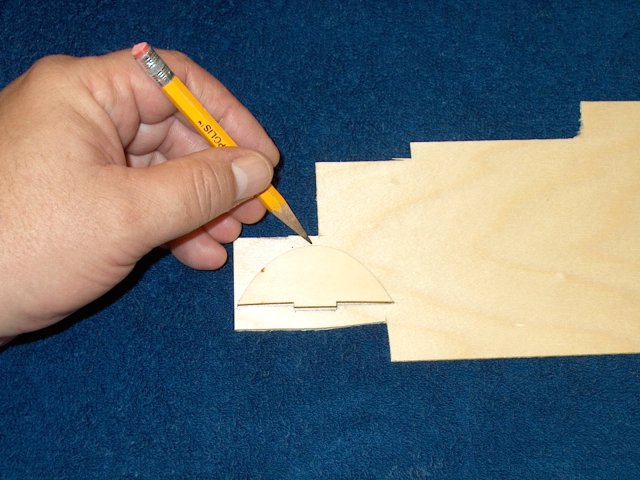

Make some servo hatches by cutting two

pieces of 1/32" ply to the dimensions you just measured

| |

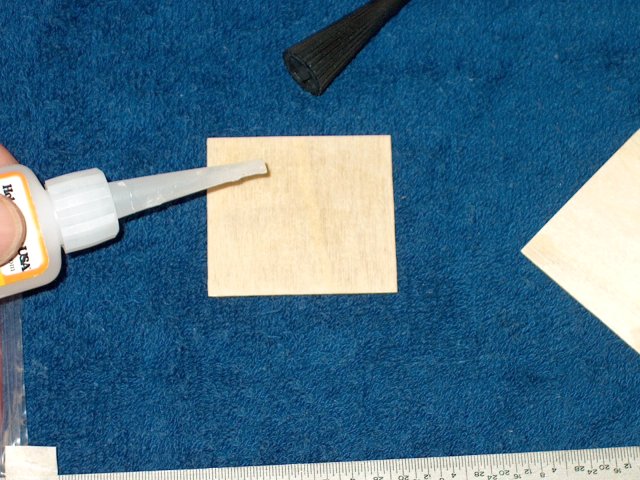

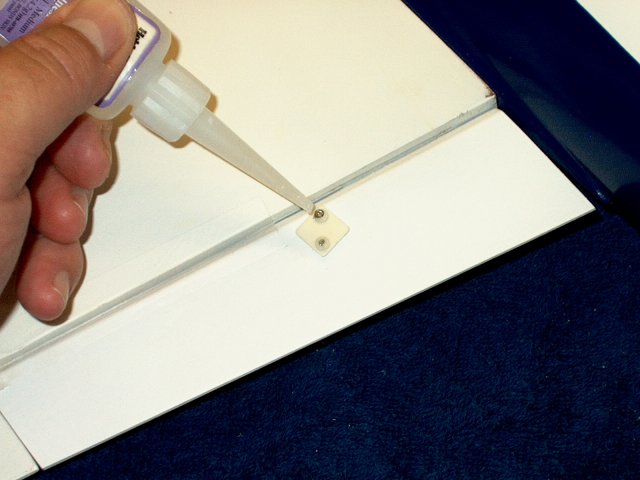

Apply a drop of thin CA to the bottom

corners of each hatch, then sand smooth once dried

| |

Apply CA to the top of each hatch and

allow it to soak in, then sand them to a plastic like finish

and paint if necessary | |

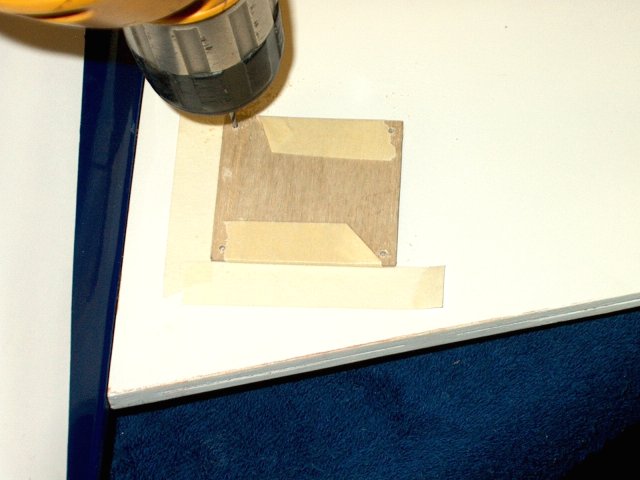

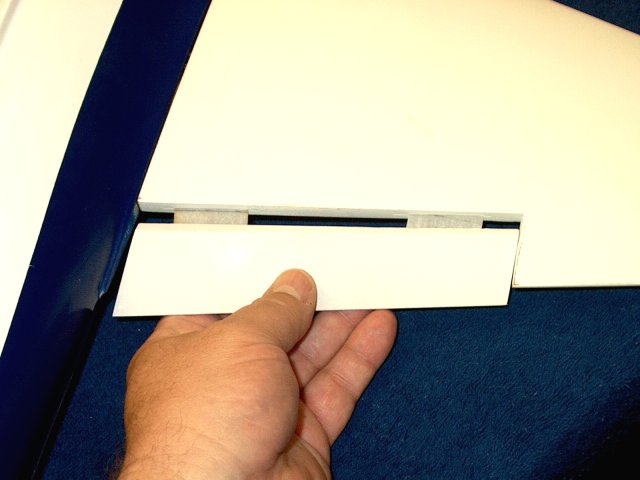

Stack both hatches and hold them together

with masking tape, then drill 1/16" holes at each corner,

about 1/8" in from the sides | |

Use tape to mark the location where the

hatches must be placed so they overlap the opening about 1/4"

on each of the four sides. Drill 1/16" holes into the wing

using the previously drilled holes in the ply as guides

| |

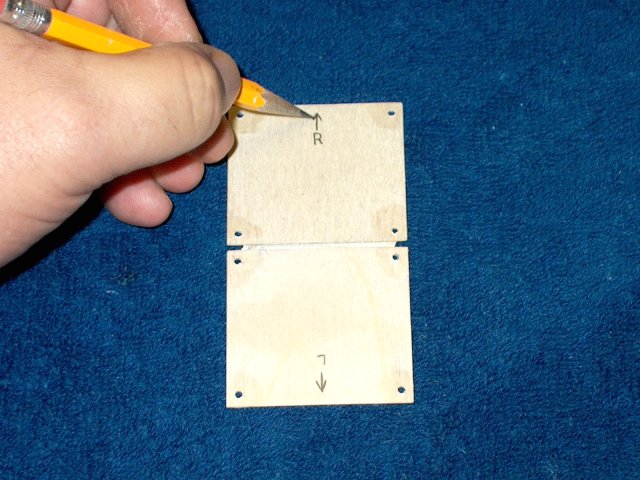

Mark on the inside one hatch for the left

and one for the right and also draw an arrow on each hatch to

show forward placement | |

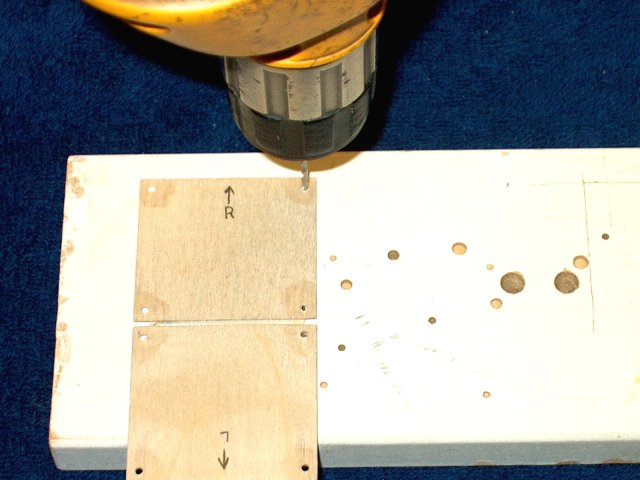

Open up the holes on both hatches with a

3/32" drill. Sand the surface of the holes smooth if

necessary | |

Clean the mounting surface of each wing

servo with Acetone. HS-81MG metal gear servos were used for

the Ailerons | |

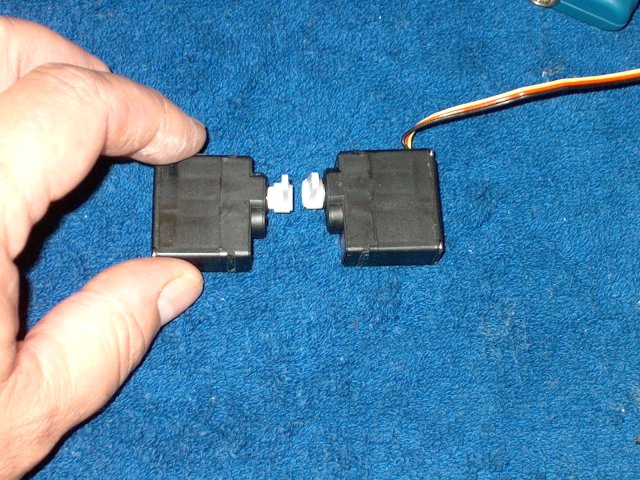

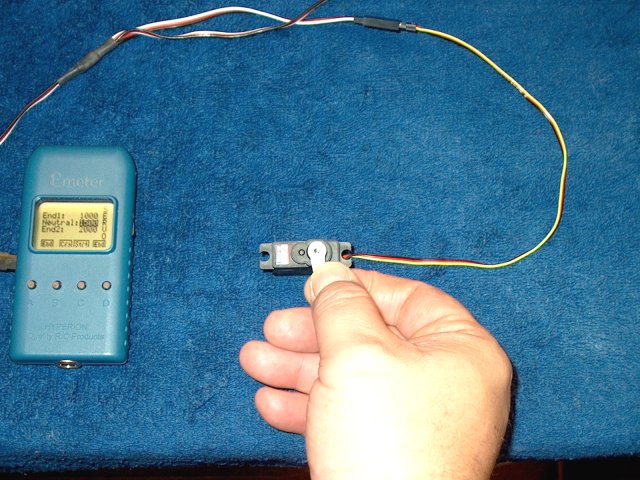

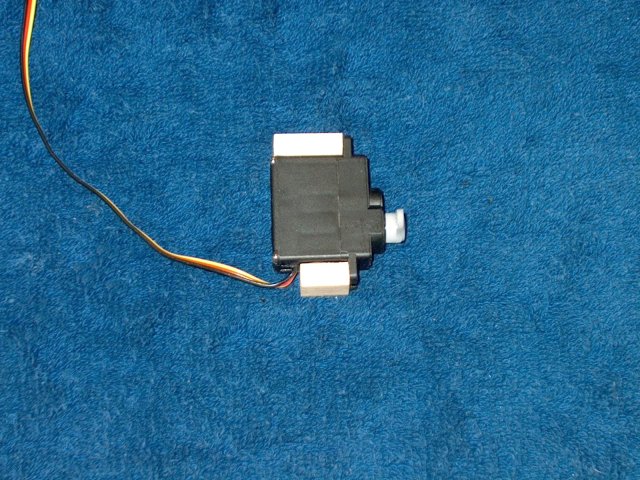

Connect each servo to a receiver or servo

tester and use a horn to make sure the servos are

centered | |

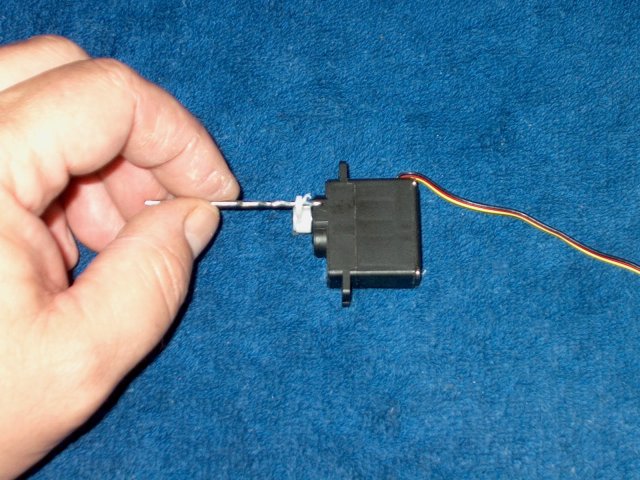

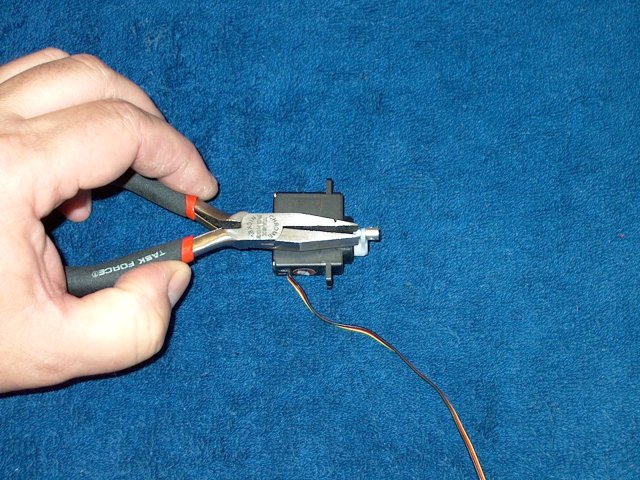

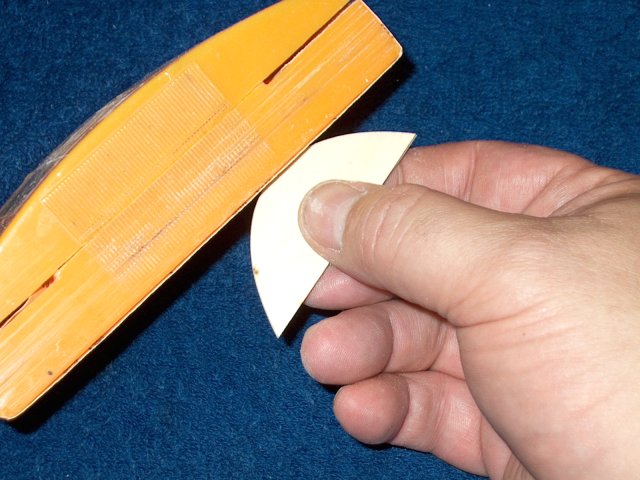

Remove each horn, then cut away the unused

side of each horn | |

Install the horn on each servo and make a

left and a right assembly. Install each servo temporarily in

the wing and make sure the horn is centered and pointed

straight up. Even though the horns may be centered outside the

wing, the servos themselves wind up being tilted downward

toward the front of the wing, so you may have to move the horn

back toward the Aileron a notch for it to be centered in the

well. The servo horns need to be centered in the well or they

will not have full range of motion!

| |

Cut two pieces of servo tape and install

them on the respective bottoms of each servo. Install the horn

screw in each servo | |

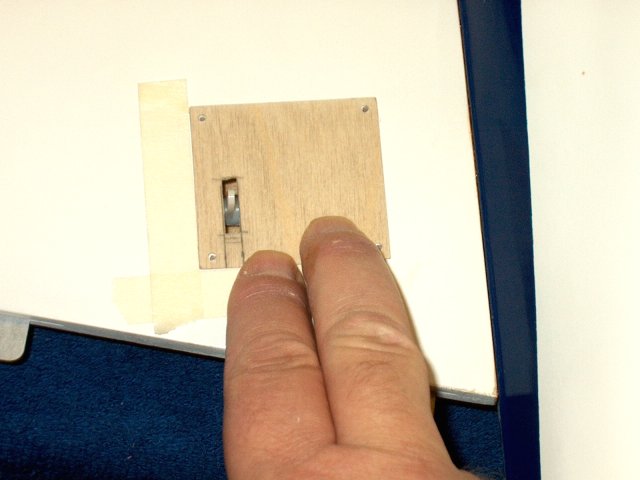

Run the servo wire for one wing through

the hole into the fuselage area | |

Remove the backing from the servo tape,

then install the servo in place, making sure the horn has

clearance and does not bind on the side of the well

opening | |

Position the hatch in place, then slide it

upward and mark a 3/16" slot on the hatch for a horn

opening | |

With the opening drawn, cut out the ply

and use a file and sandpaper to clean up the opening

| |

Position the hatch over its mounting holes

and check the fit of the horn, then sand as necessary. The

opening needs to be about 3/4" long

| |

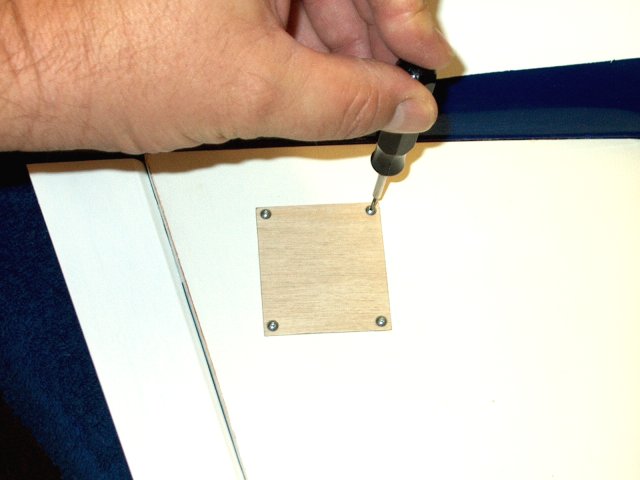

Install the hatch with some #2 button head

screws | |

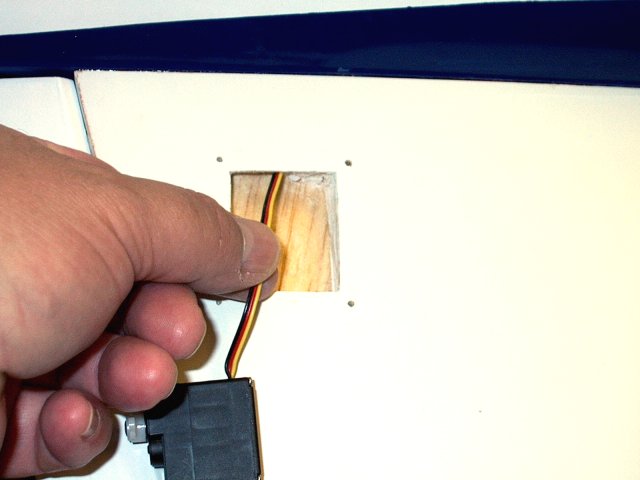

Run the other servo's wires through the

opening and into the fuselage | |

Remove the backing from the servo

tape | |

Install the servo in place, making sure

the horn has clearance and does not bind on the side of the

well opening | |

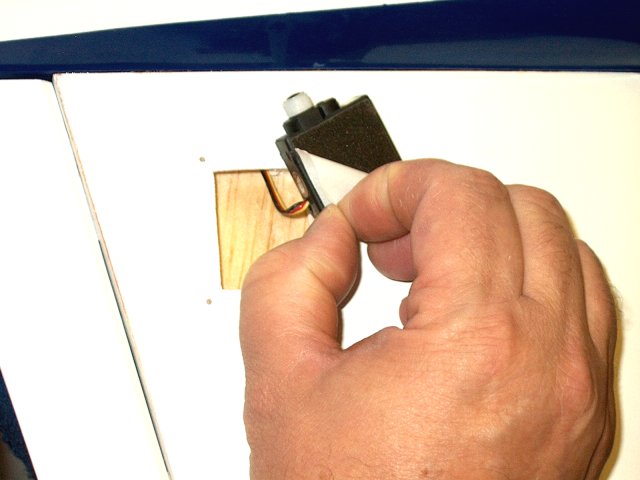

Install the hatch and cut out the slot in

the same way you did the first hatch

| |

Install the second wing hatch and check

for horn clearance. Both hatches are shown installed

| |

Measure and mark the center on each of the

Aileron hinges | |

Draw a line down the center of each

hinge | |

Install each hing into the wing up to the

line. Open the slots with a razor if necessary and position

the hinges at least 1/2" in from each end

| |

Instal an Aileron, making sure there is

clearance on both ends. Make sure the hinges remain square in

the slots and are not pushed into the fuselage

| |

Tilt the Aileron downward so there is

enough deflection, then apply thin CA to each hinge from the

top and bottom. The CA should wick into the slots

| |

Install the second Aileron, making sure

there is clearance on both ends | |

Tilt the second Aileron downward so there

is enough deflection, then apply thin CA to each hinge from

the top and bottom. The CA should wick into the slots

| |

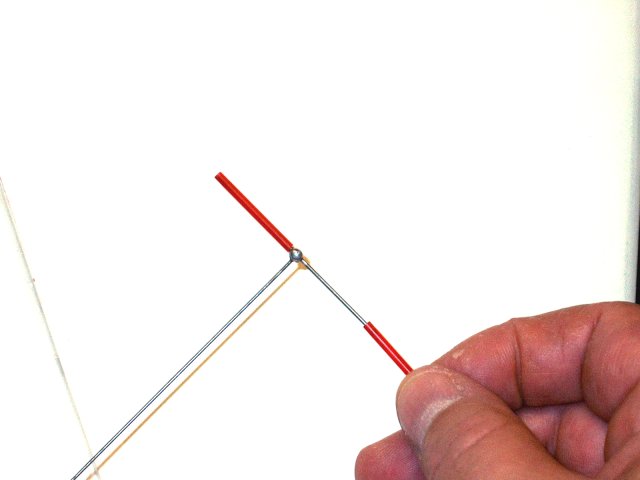

Install a clevis on each of the two

pushrods and center them on the threads

| |

Drill the Aileron servo horn out of

necessary so the clevis has a nice and tight fit

| |

Install the clevis on a servo horn

| |

Install the second clevis on the other

servo horn | |

Remove the tape from maufacturing that is

holding the hatch in place | |

Remove the bottom hatch

| |

Use a piece of tape that is placed

parallel to the servo and place the pushrod parallel to the

tape | |

Install the horn as shown on the inside of

the wire. Use a drill to make a 3/32" hole

| |

Install a screw in the servo horn. It is a

good idea to pre-thread the servo horn caps by using a screw

to cut threads in each cap | |

Install the horn in place as shown

| |

Use the pushrod to keep the horn straight,

then tack it in place with CA | |

Drill the second hole for the horn

screw | |

Install the second screw and check pushrod

alignment | |

Install the cap that you pre-threaded in

place as shown. Do not overtighten the screws

| |

Use tape to align the second pushrod and

drill the holes for the second aileron horn

| |

Install the screws in the aileron

horn | |

Position and install the horn in the

Aileron and screw on the cap. Be careful not to

overtighten | |

Clamp the end of the Aileron so it is even

with the wing | |

Connect a servo to a receiver or servo

tester, then center the servo | |

Mark the location of the Aileron horn hole

on the pushrod | |

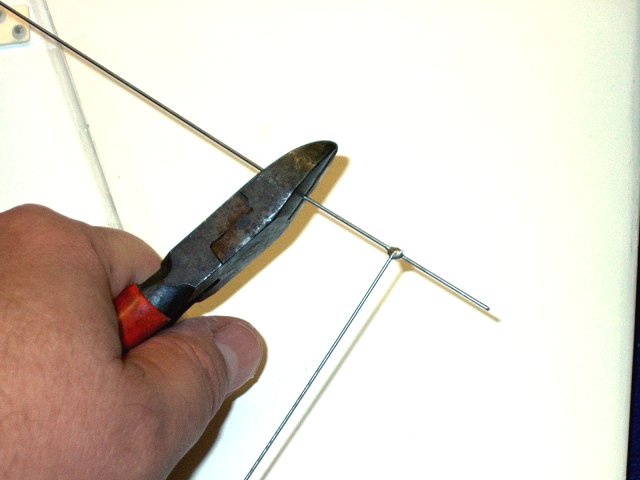

Begin making a Z-Bend at the mark

| |

Finish the Z-Bend and trim off the excess

pushrod. Clean up the end tip with a grinder

| |

Open up the Aileron horn with a drill so

the pushrod will fit | |

Install a pushrod on the Aileron

horn | |

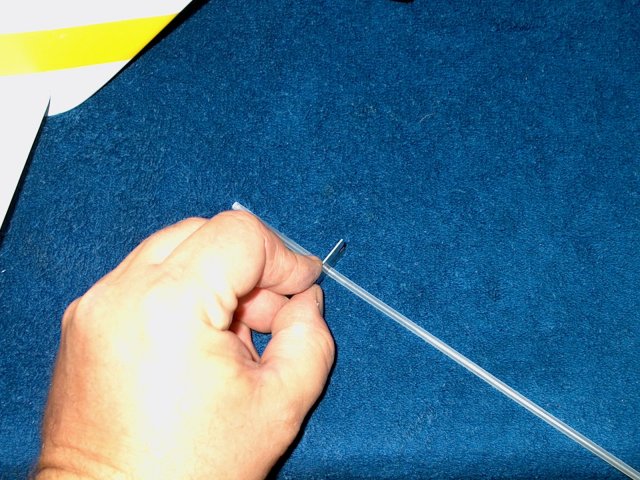

Clip the clevis in place on the servo

horn. A piece of fuel tubing is used as a safety retainer on

the clevis | |

Clamp the end of the second Aileron so it

is even with the wing | |

Connect a servo to a receiver or servo

tester, center the servo, then mark the location of the

Aileron horn hole on the pushrod | |

Make another Z-Bend at the end of the

pushrod as you did with the first Aileron

| |

Drill the Aileron horn and fit the

pushrod, then clip the clevis to the second servo horn.

Completed Aileron installation is shown

| |

Use a grinder to carefully cut the

remaining screw threads flush to the plastic cap Do not

overheat by cutting to hard or you can deform the cap. Do a

little and allow the screw to cool | |

Apply some thick CA to the top of the

threads to prevent snagging or cutting

| |

Mark center lines down each of the four

Elevator hinges | |

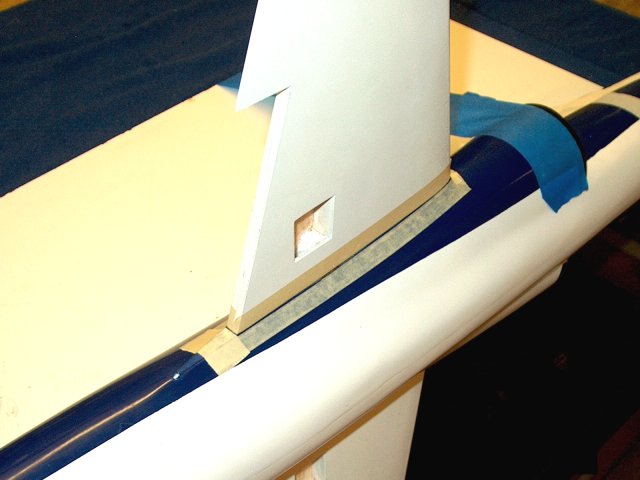

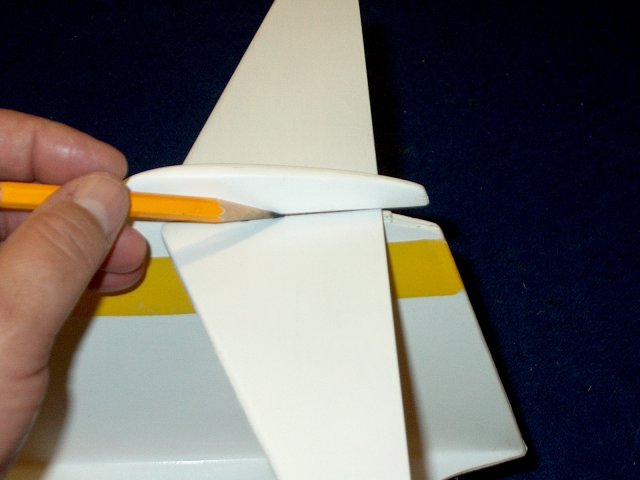

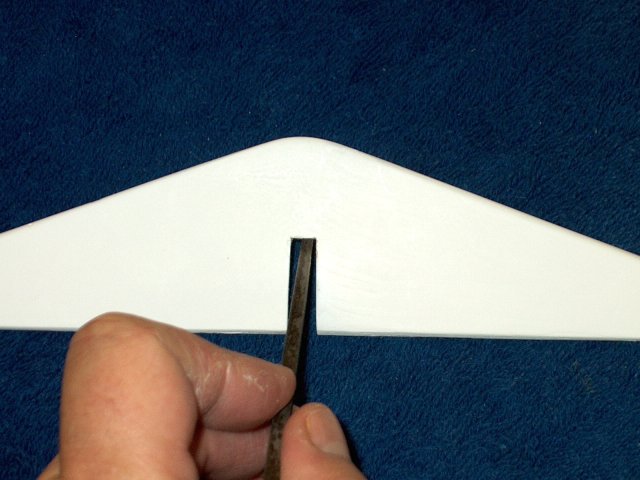

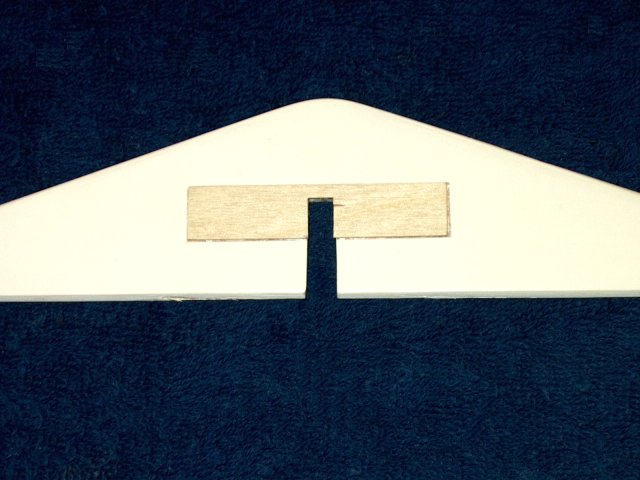

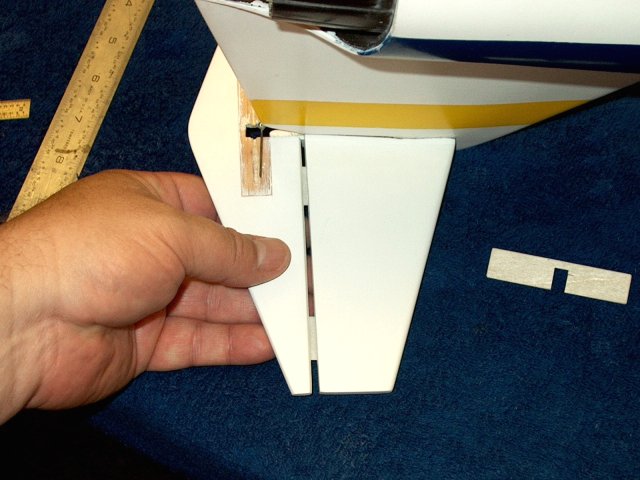

Install the Horizontal Stab in the slot

from the rear until it is flush with the vertical stab

joint | |

IMPORTANT: Make sure the Stab is

perpendicular to the vertical stab before proceding. Use a

pencil to mark the stab and fuselage at all points where they

join and mark both the top and bottom sides

| |

Remove the stab and cut just inside the

pencil mark to remove the excess covering material. Do this to

both the top and bottom | |

Lightly sand inside the pencil marks on

the vertical stab where the horizontal stab will reside for a

good glue purchase | |

Rough up the top and bottom of the

vertical stab slot, taking care not to change the shape of the

slots | |

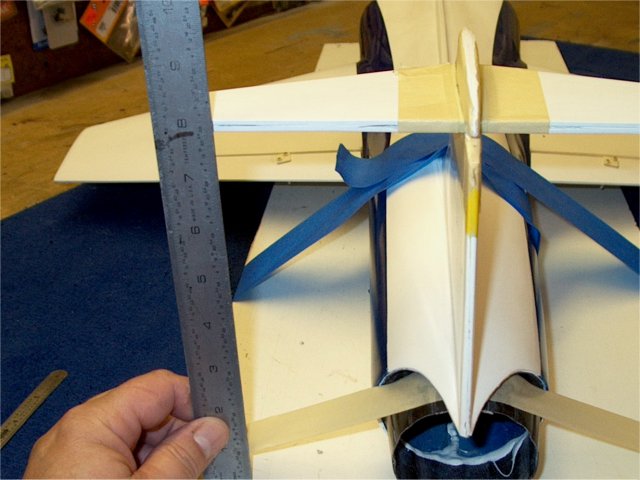

Install the horsizontal stab and measure

at the rear both sides to insure it is centered

| |

Tape the stab even to the joint to catch

excess epoxy | |

Finish by taping the vertical stab above

and below the horizintal as shown | |

Place the model on a flat surface and use

tape to hold the center in pace | |

Run masking tape over the exhaust tube and

slightly forward, then pull tight so the pivots back and the

rear is flush with the surface | |

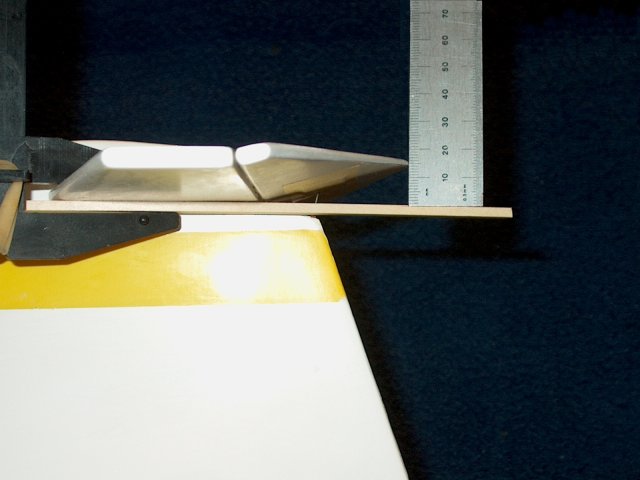

Use a square to rotate the model and

adjust the vertical stab so it is perpendicular to the

surface | |

Remove the horizontal stab

| |

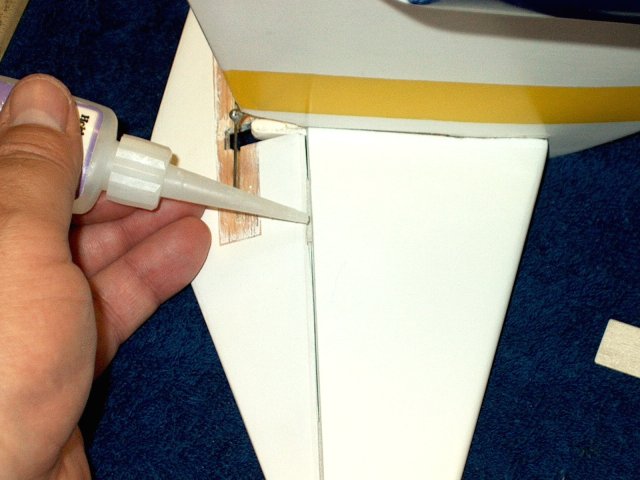

Use 15 minute epoxy so you have enough

time to adjust and apply epoxy to the top and bottom of the

vertical stab slot, as well as the forward sides of the

stab | |

Apply epoxy to the horizontal stab on the

forward slot and rear exposed surfaces

| |

Install the horzintal stab on the

fuselage | |

Clean any excess epoxy with paper towels

and alcohol | |

Insure the rear of the stab is centered

and the same distance from the vertical stab on both

sides | |

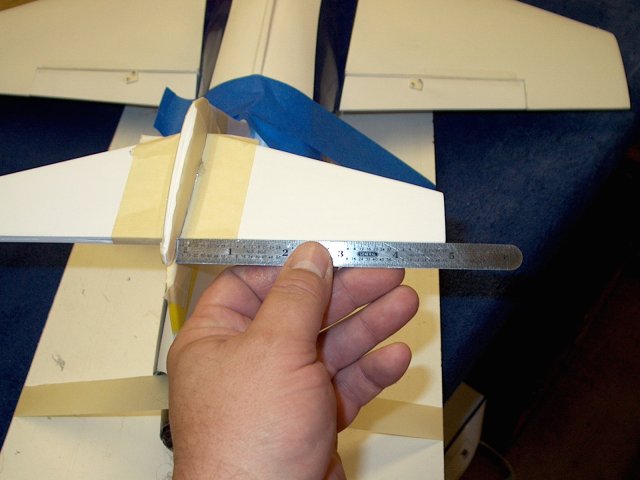

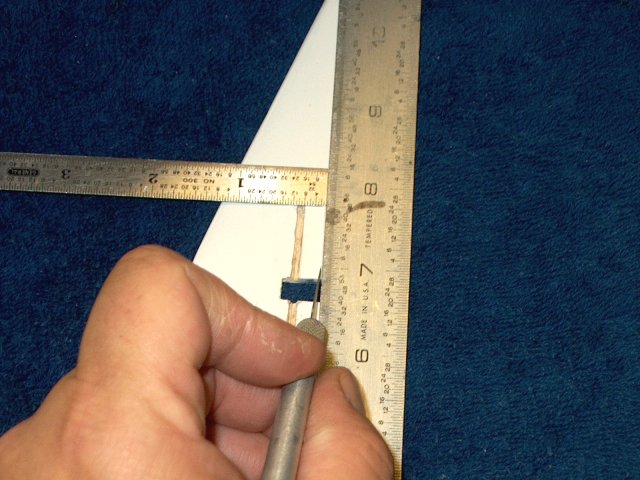

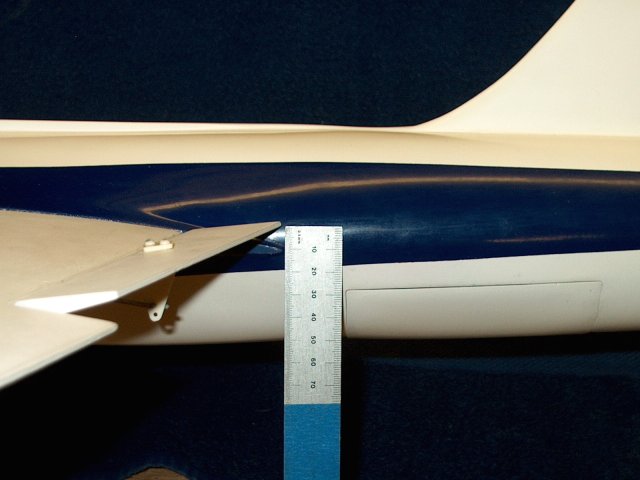

Use a ruler and make sure the horizontal

stab is parallel. Adjust if necessary before the epoxy

sets | |

Horizontal stab sown installed

| |

Install the hinges in the horizontal stab

up to the center line | |

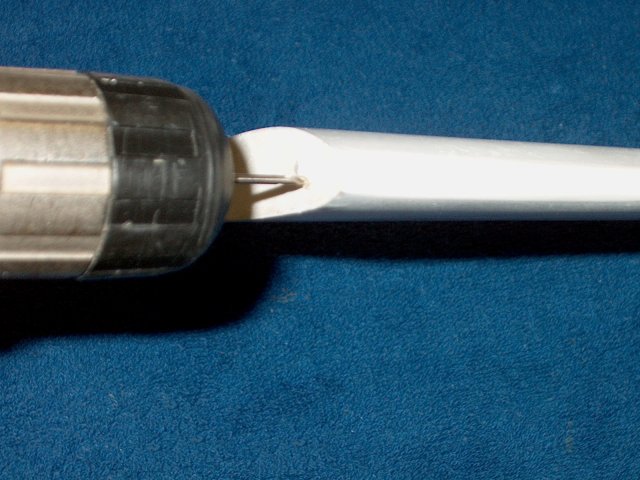

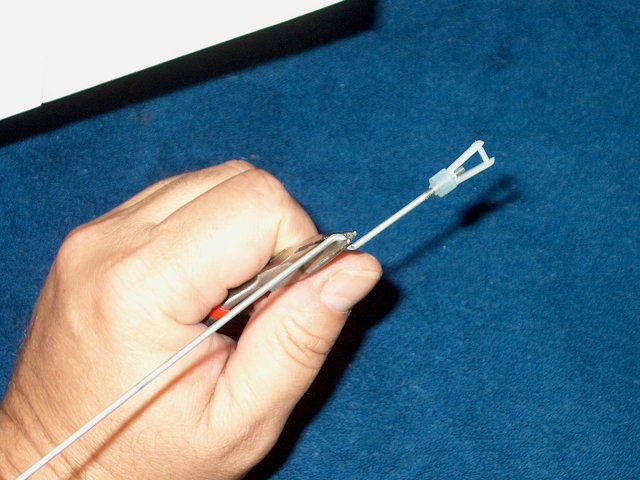

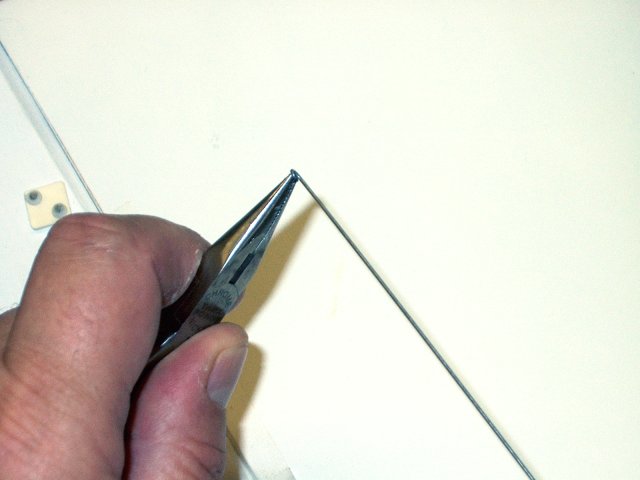

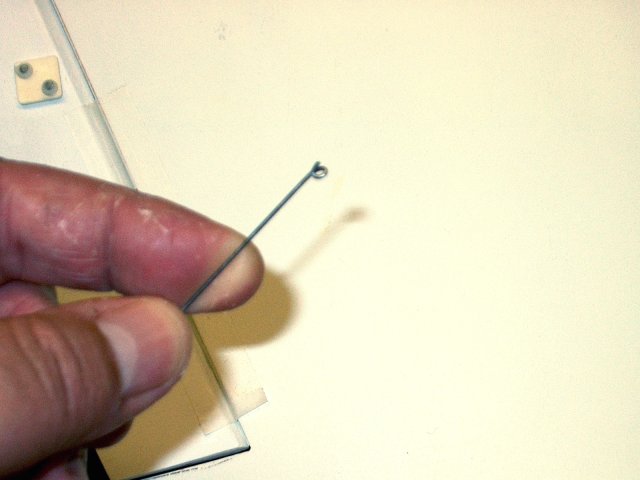

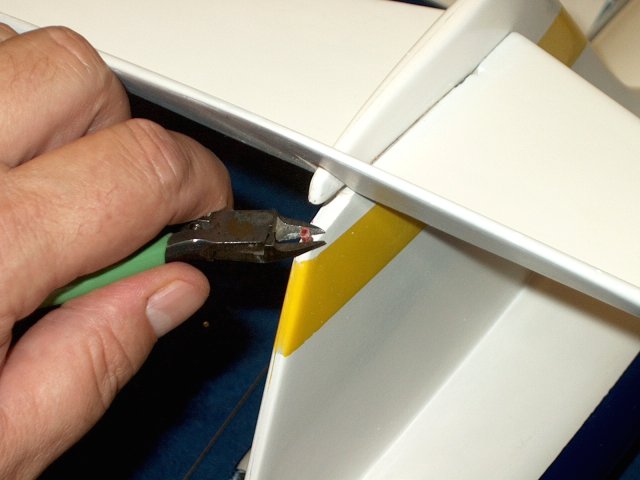

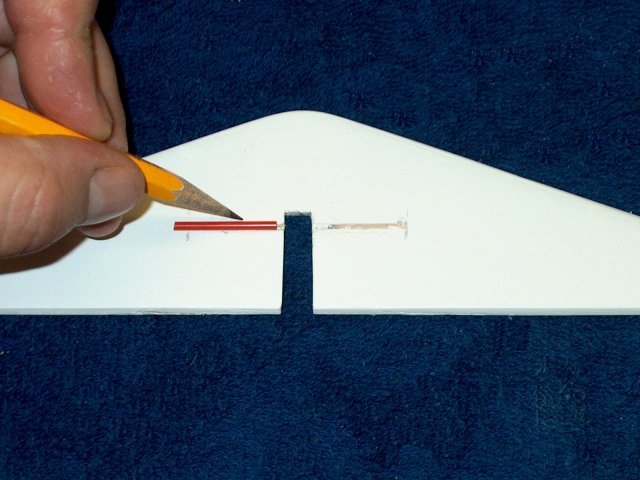

Cut off the Z-Bend on the pushrod wire,

then make a very small loop and a half with needle nose

pliers | |

Loop shown, which should be just round

enough for the wire to pass through

| |

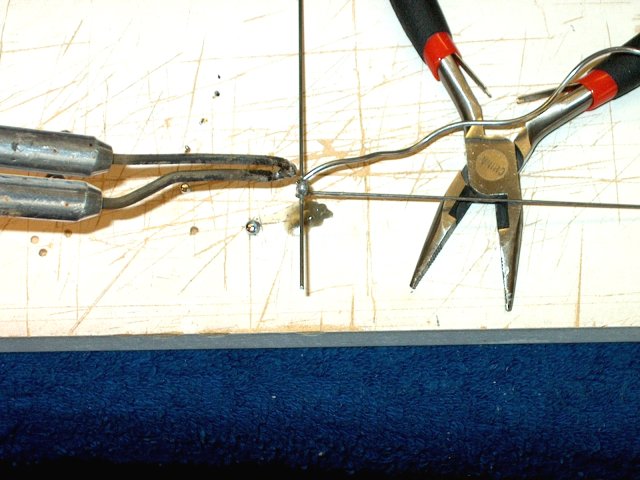

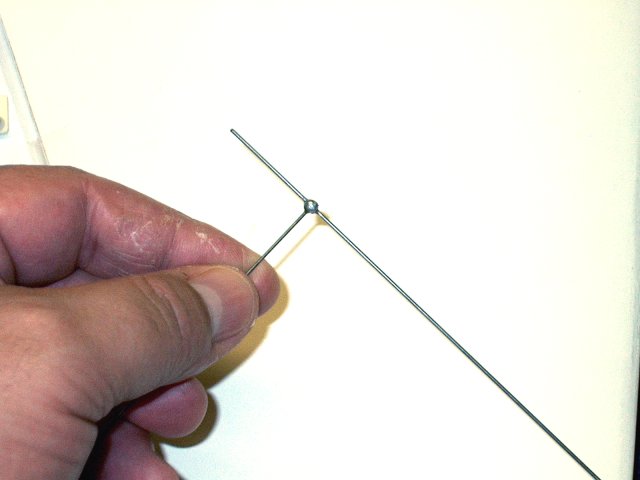

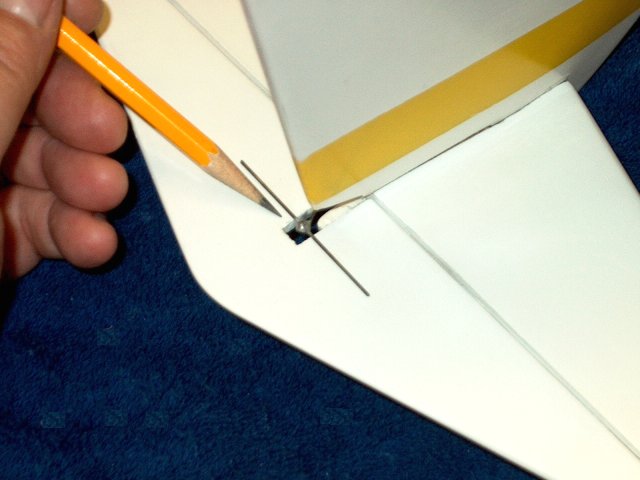

Cut a 2 1/2" piece of wire from the other

end and install it in the loop so that 1" protrudes from a

side | |

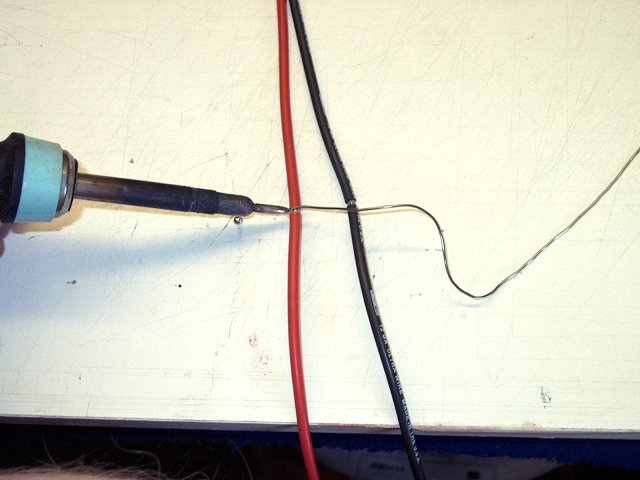

Use soldering flux, good solder such as

Deans and a high power gun and solder the joint. Make sure the

short wire remains perpendicular to the long wire before the

solder hardens | |

Solder joint shown completed

| |

Trim the other end so the you have 1" of

rod on each side of the joint | |

Cut two 1" pieces of plastic sleve from

the pushrod assembly and install them over the wires as

shown | |

Box cut and file the rear of the fuselage

so it is square | |

Mark the top rear of the vertical stab

with a punch | |

Use a 1/16" drill to open a small hole at

the marked location | |

Open the hole with a 3/32" drill

| |

Install the pushrod sleeve

| |

Install the pushrod and test for

binding | |

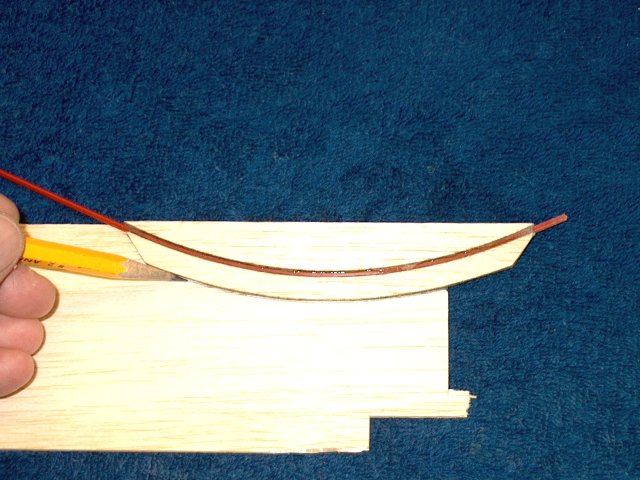

Place the pushrod sleeve across the

rounded mount plate. Leave about a 1/4" overhang on one side

and make a mark on the sleeve where it meets the other end of

the balsa mount | |

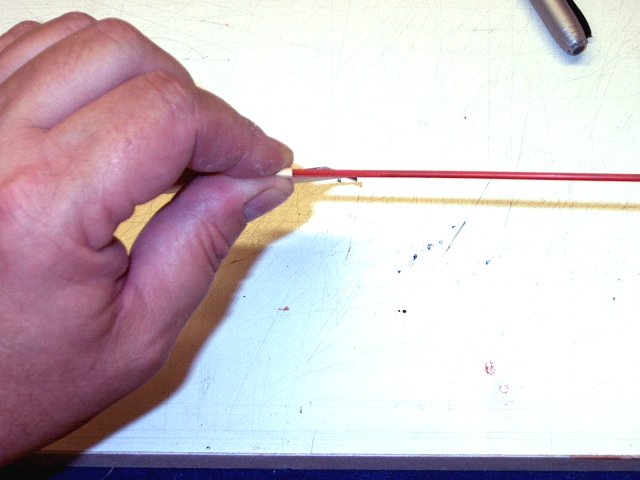

Sand the sleeve with 60 grit sandpaper

just enough to score it for good glue purchase. Sand from the

mark to the 1/4" overhang | |

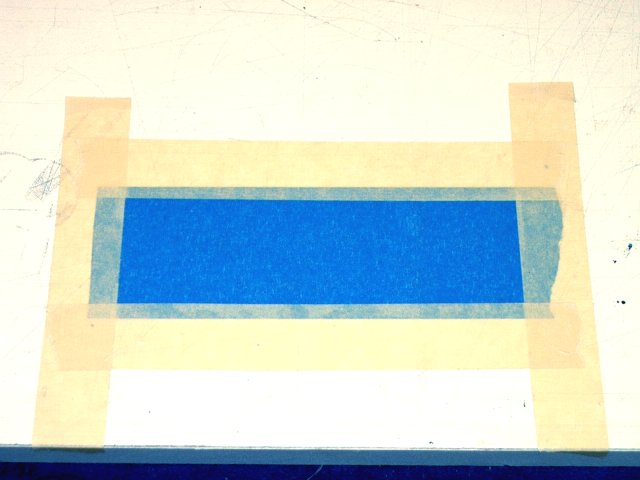

Install a piece of tape, as shown in blue,

sticky side up and about 6" wide | |

Apply epoxy to the rounded edge of the

mount | |

Place the mount piece on the tape as

shown | |

Apply epoxy to the curved edge of the

outer mount balsa plate | |

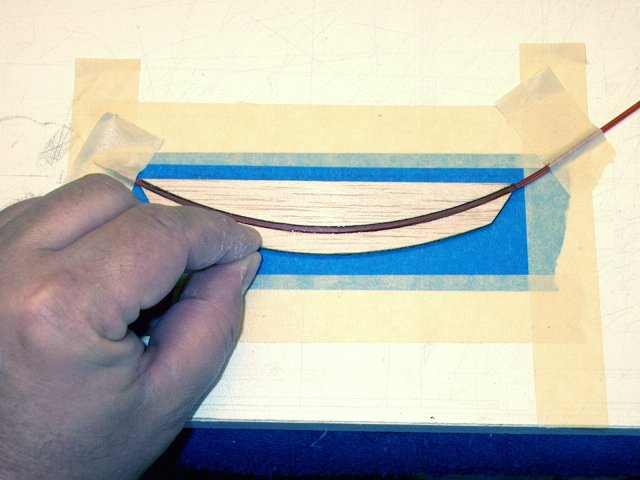

Starting at one end, leave 1/4" or so of

sleeve extending past the mount as shown on the left and use

masking tape to anchor it in place | |

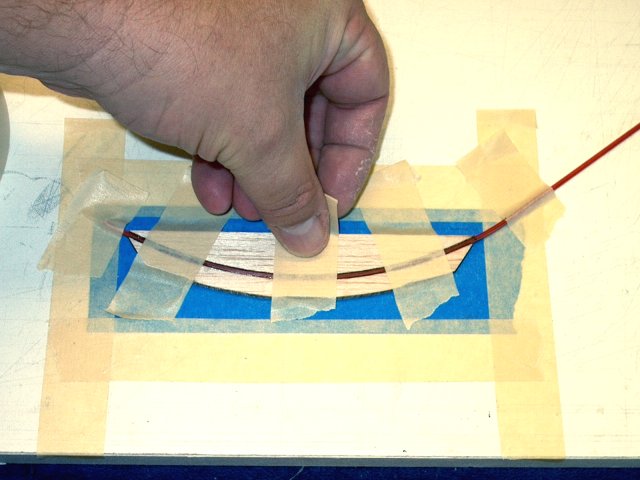

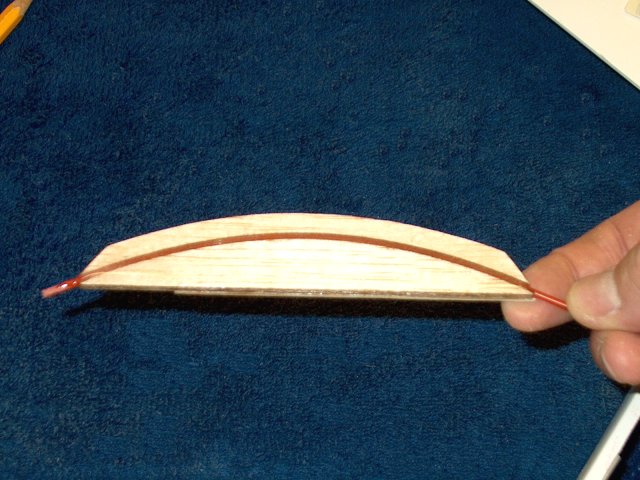

Bend the sleeve around the curve

| |

Install the outer mount in place, making

sure the sleeve is tightly wedged between both plates. Make

sure the ends of the plates are aligned with eachother

| |

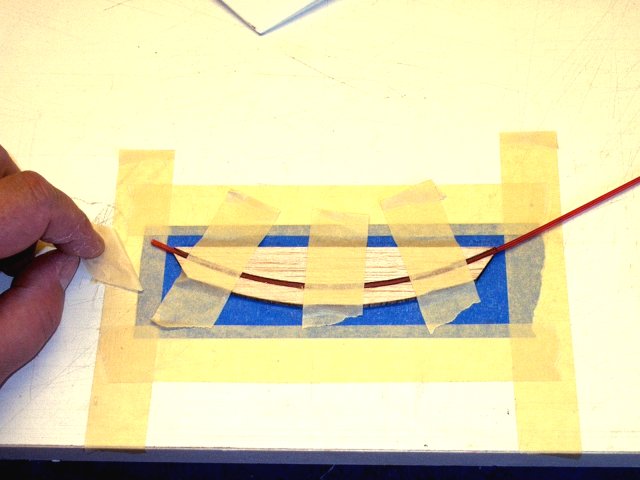

Tape the sleeve down as shown and allow

the epoxy to set. You can also cover the assembly with a

plastic sheet and block of wood to weight it down and keep it

flat | |

Once the epoxy sets, remove the tape from

the assembly | |

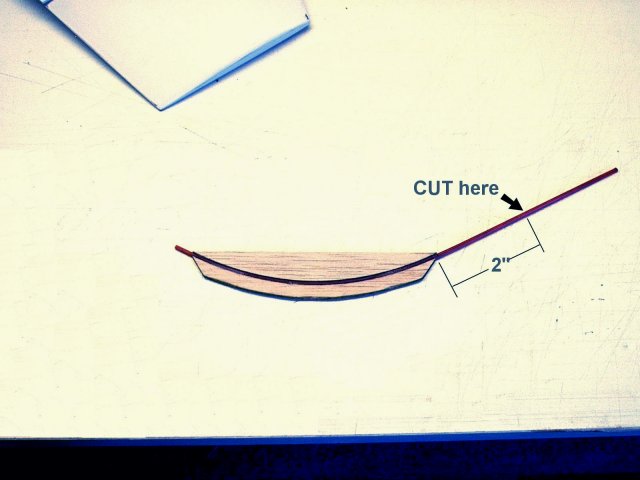

Trim the long side of the plastic sleeve

2" past the balsa mount as shown | |

Grind the other end of the pushrod to a

rounded shape so it doesn't bind when installed inside the

sleeve | |

Place a scrap piece of 3/32" balsa over

the mount, leaving 1" of open area at the short end as

shown | |

Draw and cut out the balsa cover

| |

Sand the mount cover even with the

mount | |

Apply epoxy to the entire side of the

mount as shown. Make sure you apply epoxy to the correct

side | |

Apply a thin coat of epoxy to the

cover | |

Install the cover on the mount

| |

Clamp the assembly together until the

epoxy sets | |

Pushrod mount assembly shown

completed | |

Slightly bevel the outer flat area so it

tapers toward the short end of the sleeve. Test fit it in the

inside of the vertical stab and taper until you hae a good

fit | |

Apply a thick layer of epoxy to the sleeve

side of the mount | |

Make sure the entire mount is covered.

Install short end first and make sure the 1/4" of sleeve exits

the hole in the top of the vertical stab. It is ok if not all

the 1/4" exits | |

Install the plate to the side of the

vertical stab as shown. The end of the plate should be

recessed about 1/8" inside the stab opening

| |

Trim the pushrod sleeve flush to the top

of the vertical stab | |

Install the pushrod in the sleeve

| |

Install the Elevator and while keeping the

pushrod parallel to the stab, trace the outline of the

pushrod | |

Use a knife to remove the covering for the

pushrod. Re-install the elevator to make sure the cut is

centered | |

Center a pushrod sleeve over the removed

covering and draw an outline of the sleeve on each side. Cut

the drawn slot area halfway down into the stab. DO NOT CUT all

the way through to the other side (top of the stab)

| |

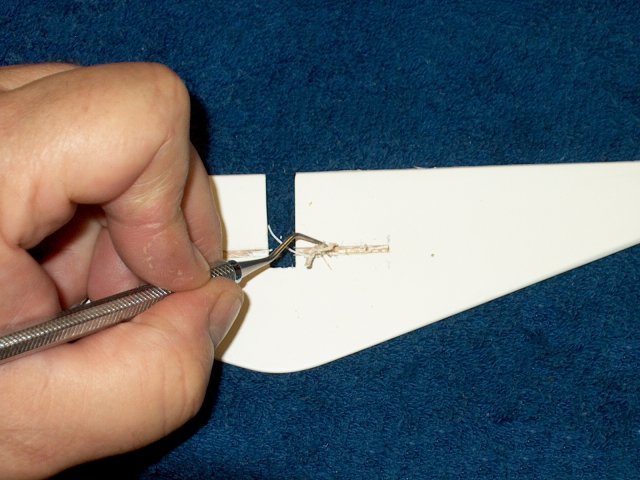

Use a pick or tool to remove the balsa

from each slot as shown | |

Make sure the slot depth is even all the

way across each slot. A 3/32" drill makes a good tool for this

and be sure to make the slot deep enough to completely recess

the sleeves | |

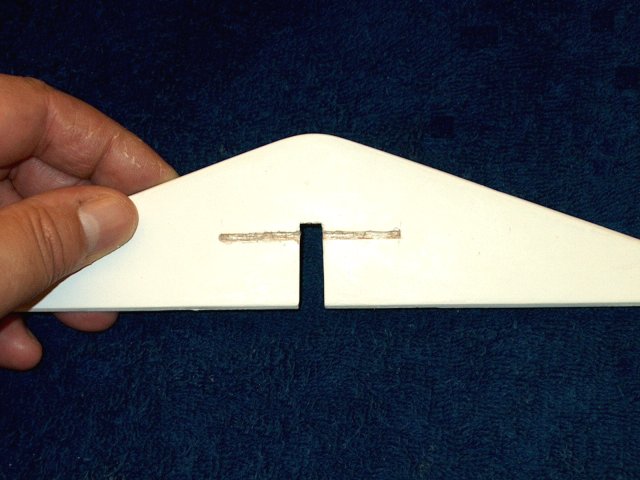

Slots are shown completed

| |

Measure and remove the covering about 1/4"

away from the slot on each side, as well as the ends

| |

Covering shown removed

| |

Cut a piece of 1/64" or 1/32" ply plate to

cover the opening | |

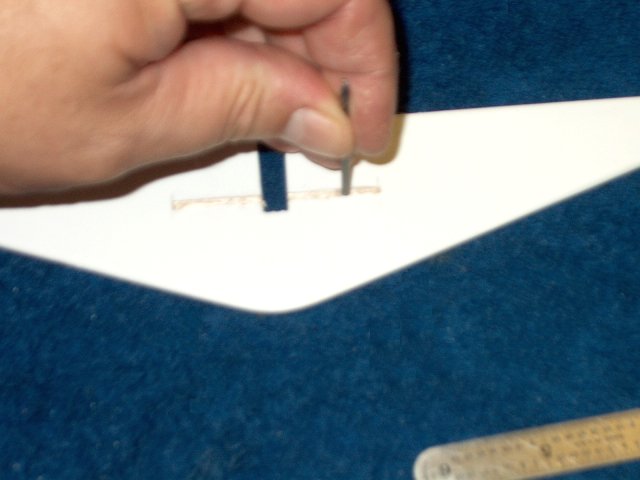

Tape the plate temporarily in place

| |

Turn the elevator over and draw the slot

opening on the ply plate | |

Draw the back of the slot at the

rear | |

Remove the plate and use a tool or knife

to cut out the slot | |

Install the plate and sand even with the

slot opening | |

Install the Elevator to the stab

| |

Flex the Elevator downward at lease 15mm

and use thin CA to glue the Elevator in place. Be sure to glue

from both the top and bottom | |

Install the poshrod sleeves on the

poshrod | |

Apply a thin layer of epoxy to the ply

plate. Make sure you apply epoxy to the correct side

| |

Tape off the edges of the plate area and

apply epoxy to the slots | |

Press the pushrod sleeves into the slots

as shown | |

Install the ply plate and clean up any

excess epoxy with alcohol | |

Clamp the plate in place until the epoxy

sets | |

Elevator installation completed

| |

Trim a horn for your servo so that one arm

and two holes are showing | |

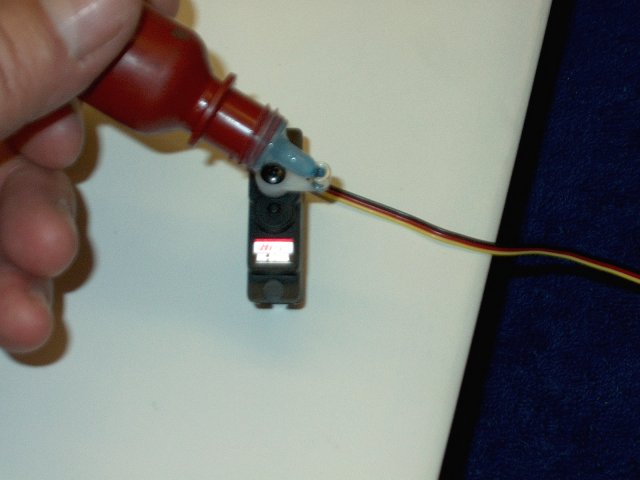

Center the servo, using a servo tester or

receiver | |

Install the arm as shown, centered on the

servo | |

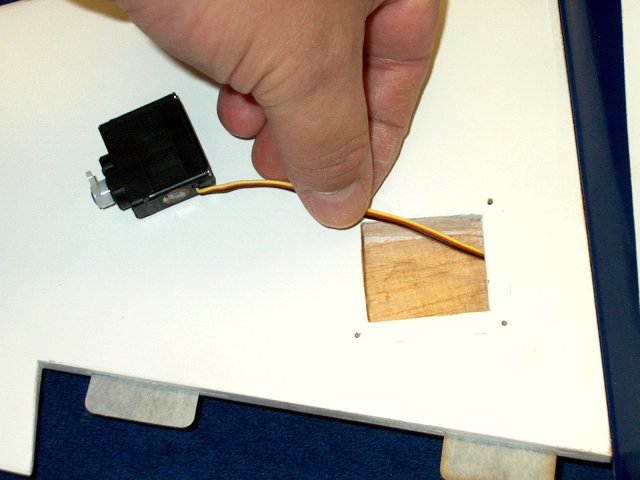

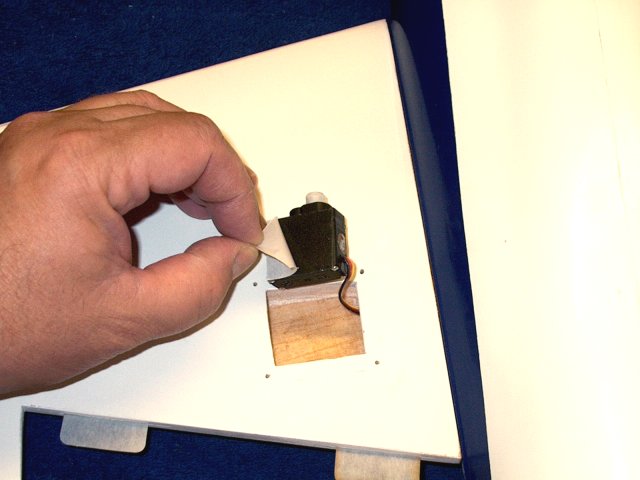

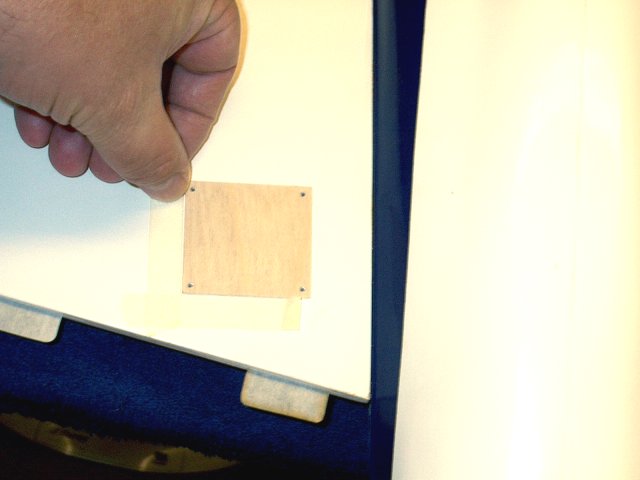

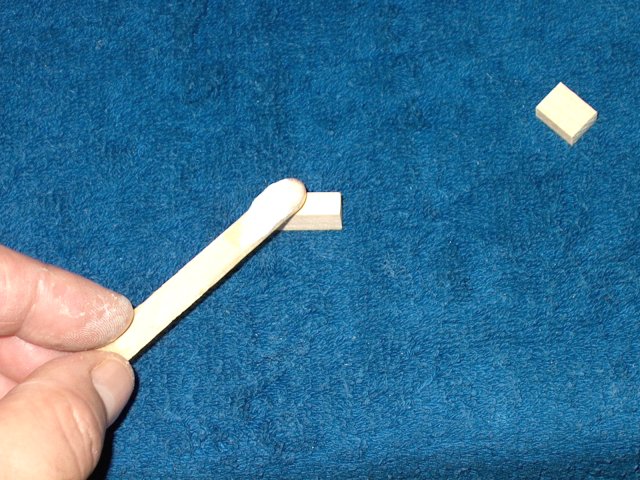

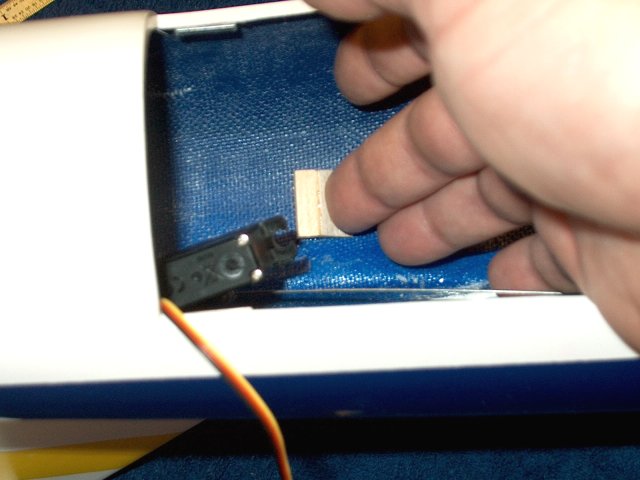

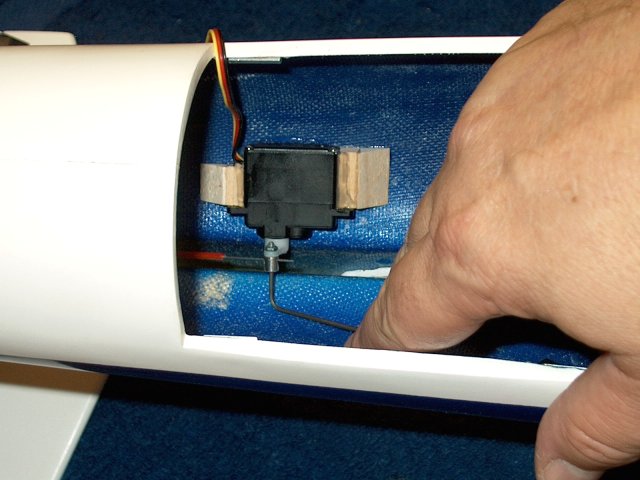

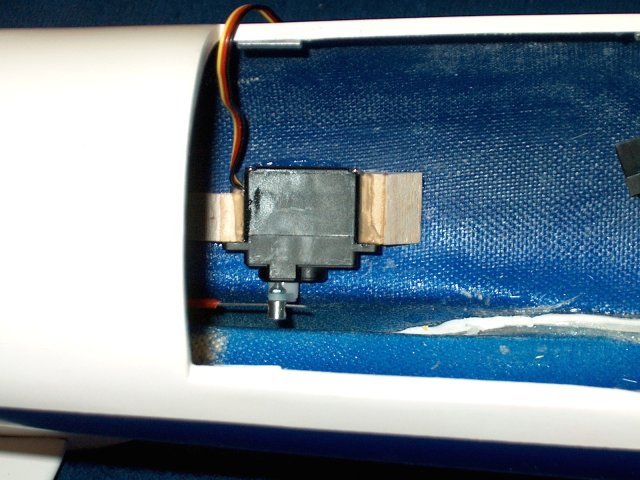

Use some scrap 1/4" x 3/8" pieces of

hardwood and cut them to fit the sides of the servo

| |

Hardwood shown cut to size

| |

Drill the horn hole with a 1/16"

bit | |

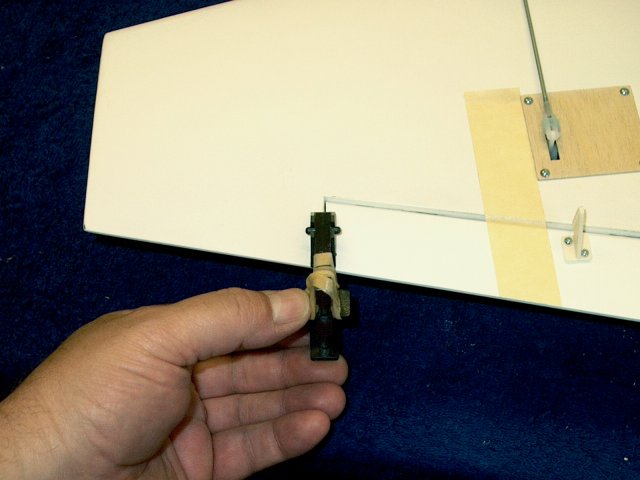

Install a Sullivan #550 pushrod connector

in the horn | |

Apply Loktite to the connector

threads | |

Install the nut snug, but loose enough for

the connector to spin. Apply a drop of CA to the threads to

hold the nut in place | |

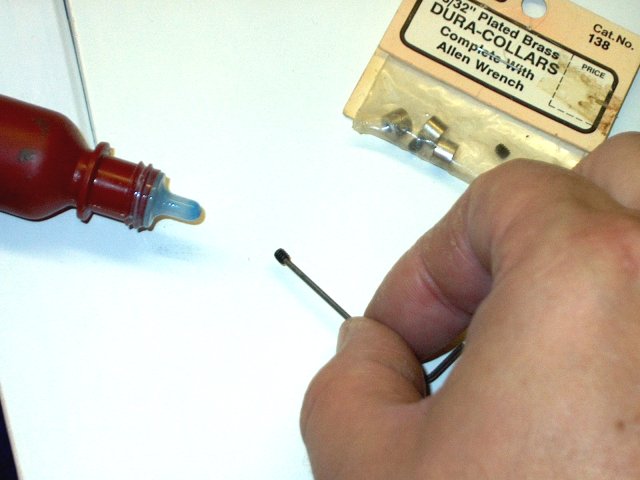

The connector comes with a retaining bolt,

but it is too long. You can instead use a 4-40 set screw from

a bag of small wheel collars to secure the pushrod. Apply

Loktite to the set screw | |

Apply Loktite to the connector retainer

threads and install the set screw | |

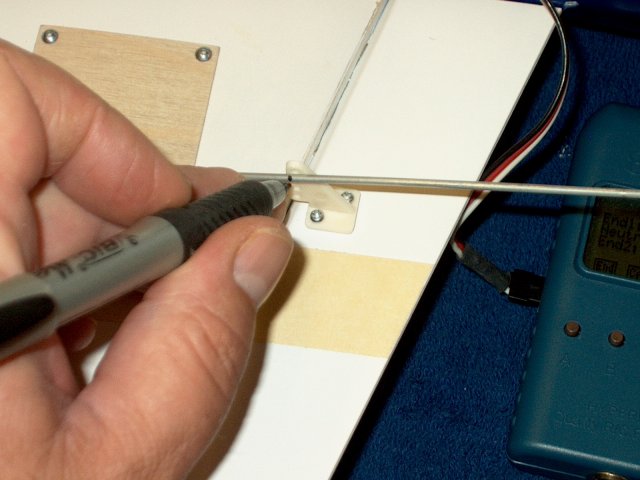

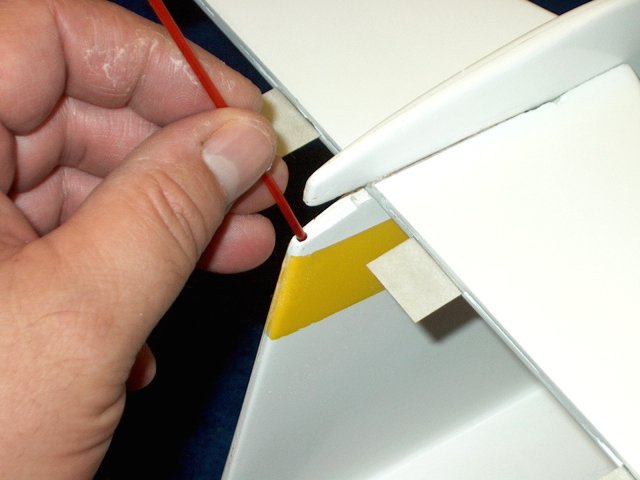

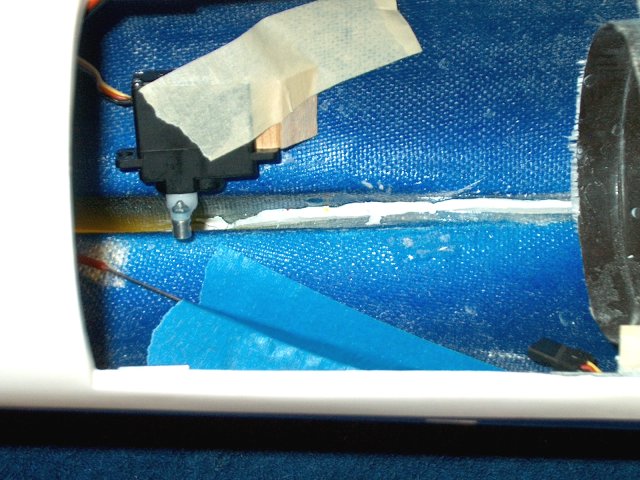

Slide the pushrod through the connector

and position the servo. Move the horn all the way toward the

red pushrod sleeve and position so there is still clearance as

shown | |

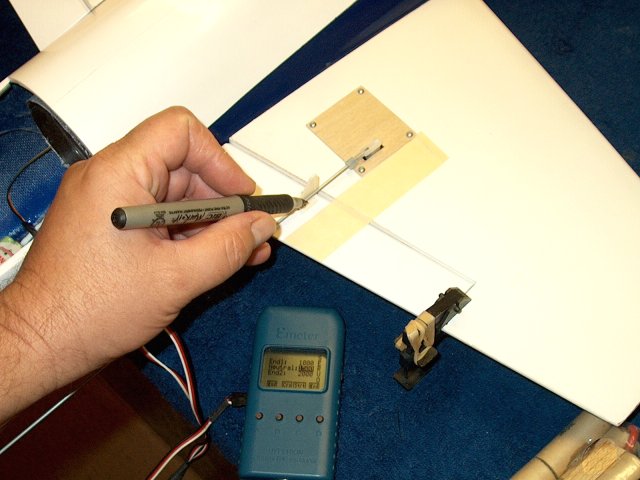

Make sure the pushrod is centered over the

vertical stab opening and mark the sides of the servo

| |

Rough up the servo area with 60 grit

sandpaper, sanding about 3/4" past each line

| |

Apply fifve minute epoxy to the bottom of

the long hardwood block | |

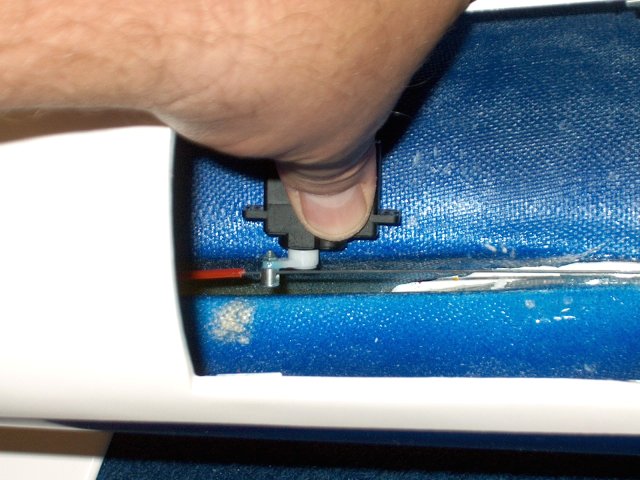

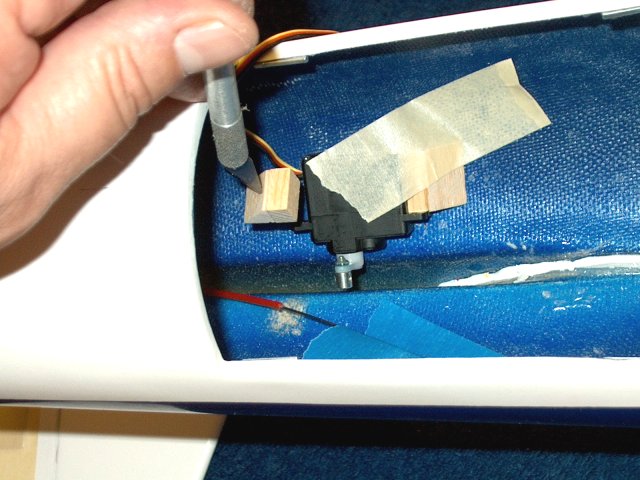

Hold the servo in place and install the

hardwood block. Make sure the servo is held square until the

epoxy sets | |

Apply epoxy to a piece of 1/2"

triangle | |

Install the triangle against the hardwood

block as shown | |

Install triangle stock to the short

hardwood block | |

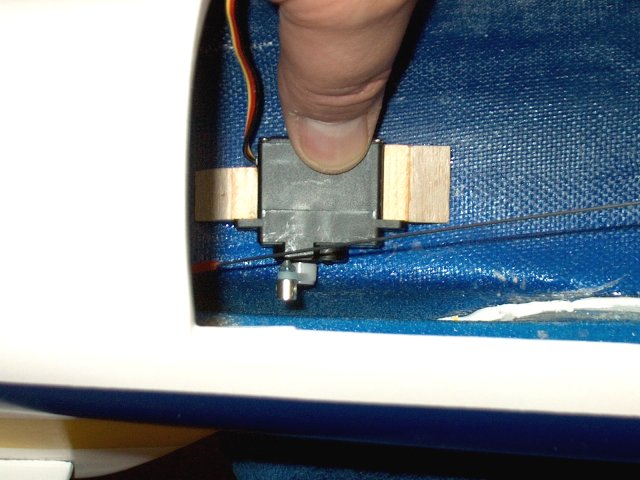

Remove the pushrod from the servo and use

a piece of tape to hold the sevo in place

| |

Apply epoxy to the the smaller hardwood

block and use a knife to install it against the side of the

servo | |

Remove the servo and install a couple

pieces of servo tape in the center to build up the area that

will be against the curved side of the fuselage. Apply an

ample ammount of clear silicon to the top and bottom of the

servo | |

Install the servo between both blocks and

apply a bead of silicon across the top of each block where it

meets the servo | |

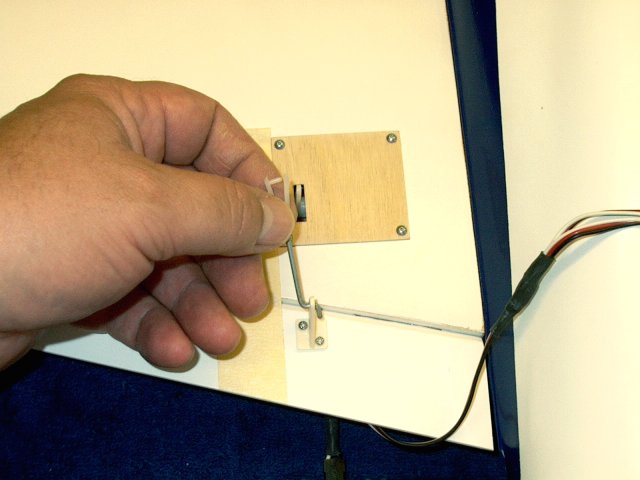

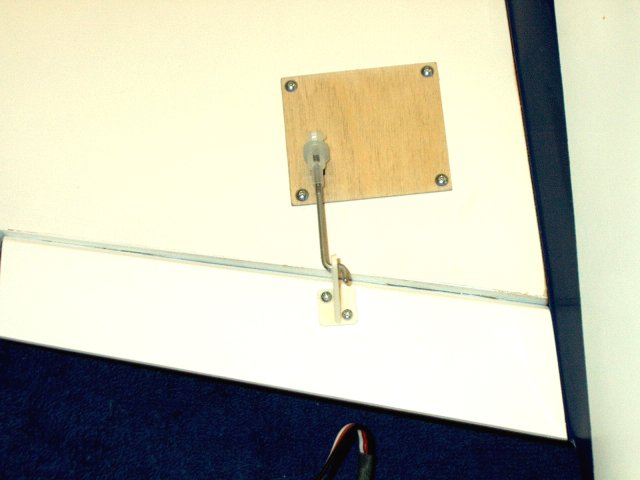

Hook up your receiver or servo tester once

again and center the servo | |

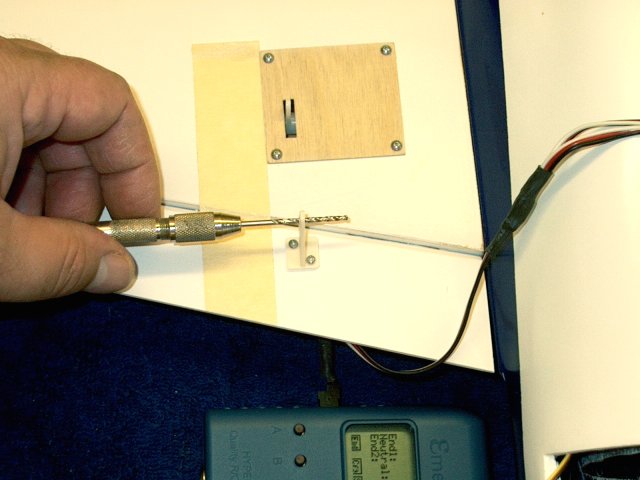

Clamp the Elevator so it is in a neutral

position | |

Cut the pushrod to length at least 1/4"

past the end of the horn connector | |

Unplug the servo from the tester, move the

arm to the right and install the pushrod. Center the servo

once more with your receiver or tester

| |

Use an allen wrench to tighten the

setscrew on the horn connector | |

Elevator Servo installation

completed | |

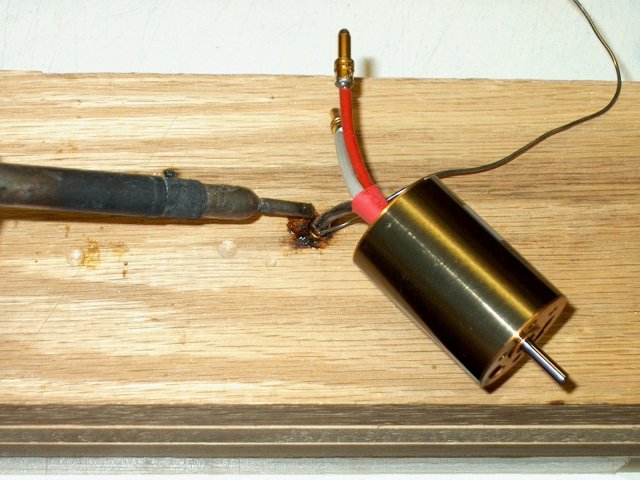

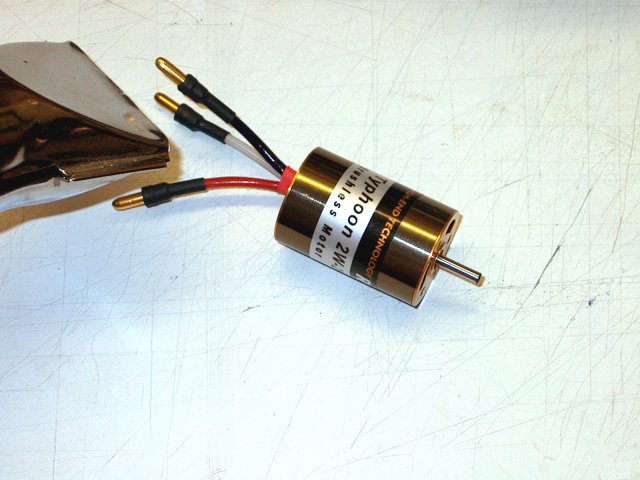

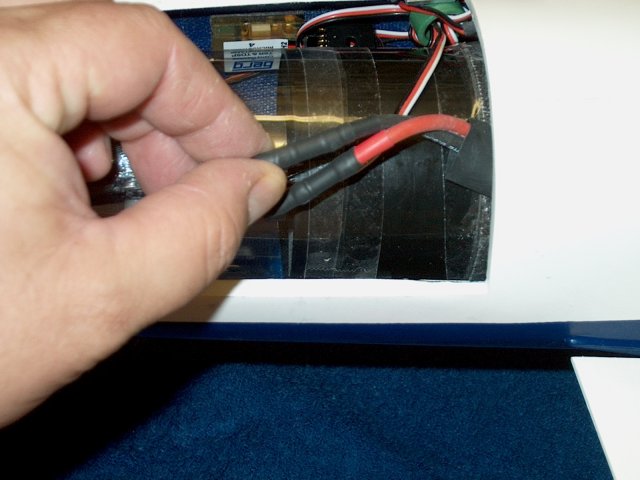

Install 3.5mm connectors on your motor

leads. Always use plugs on the non-power side

| |

Install heatshrink over the plugs

| |

Apply Loktite ONLY to the motor threads as

shown and wipe up all excess. DO NOT get Loktite on the

plastic parts or it will disintegrate them. You can also use

Green Loktite, which is plastic safe

| |

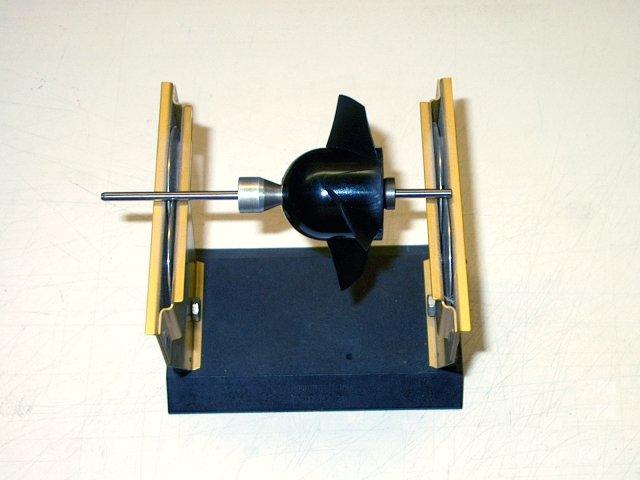

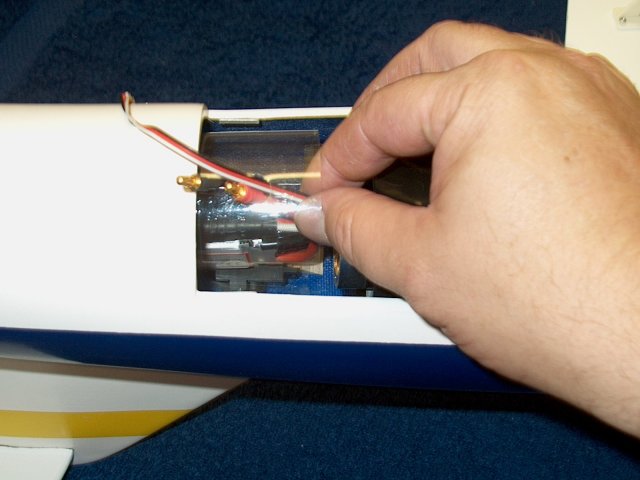

Install the motor into the fan shroud

(HET-RC 6904 Ducted Fan shown). If you are using a HET-RC

motor, you can use three bolts for the installation. Do not

tighten the bolts | |

Slide the heatsink (supplied with HET-RC

Fan) lip end first, over the rear of the motor, then apply a

few drops of CA to the inner lip and install it flush inside

the shroud. The heatsink will help center the motor

| |

Tighten the motor mount bolts

| |

Install the fan adapter over the motor

shaft | |

Make sure the fan is balanced. HET-RC 6904

Fans come pre-balanced, but check them anyway and balance if

necessary. See installation instructions for your fan or find

them at www.warbirds-rc.com | |

Apply some Loktite to the center adapter

shaft | |

Install the Fan over the adapter

shaft | |

Install the fan retaining bolt

| |

Tighten the retaining bolt, making sure

there is at least 1/16" clearance between the rear of the fan

and the front of the shroud motor mount area. Check for free

movement once tightened | |

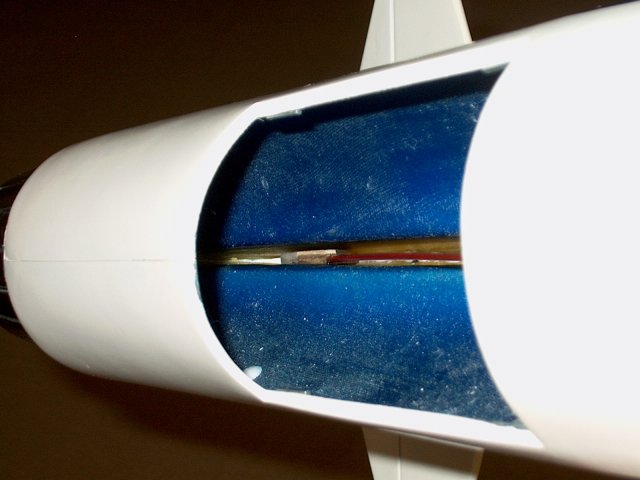

Fan assembly completed

| |

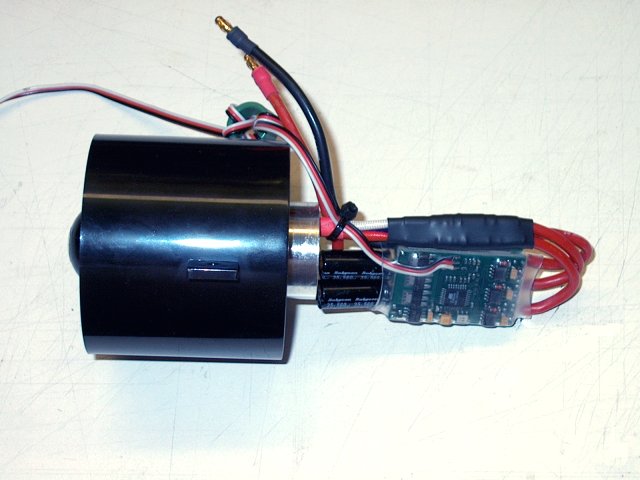

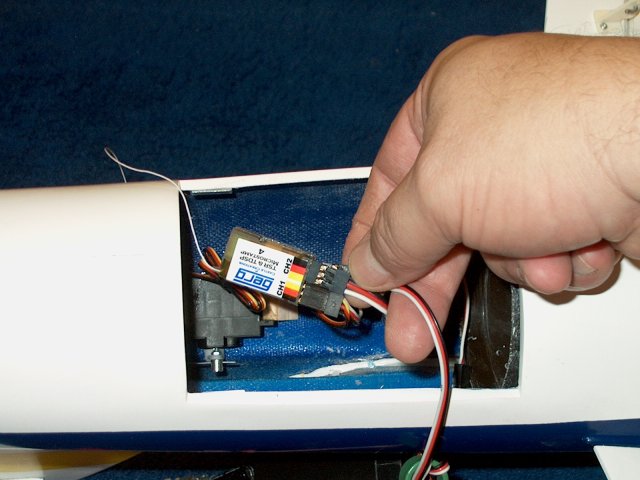

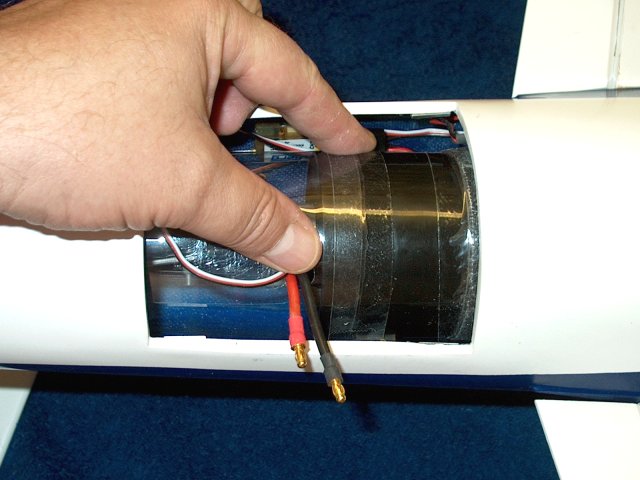

Plug the three ESC wires into the motor

and use a piece of large heatshrik to keep them from pulling

apart. Dress up the assembly with tie wraps

| |

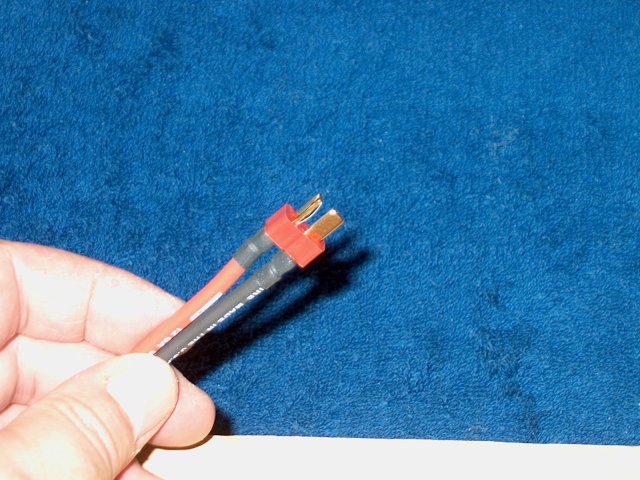

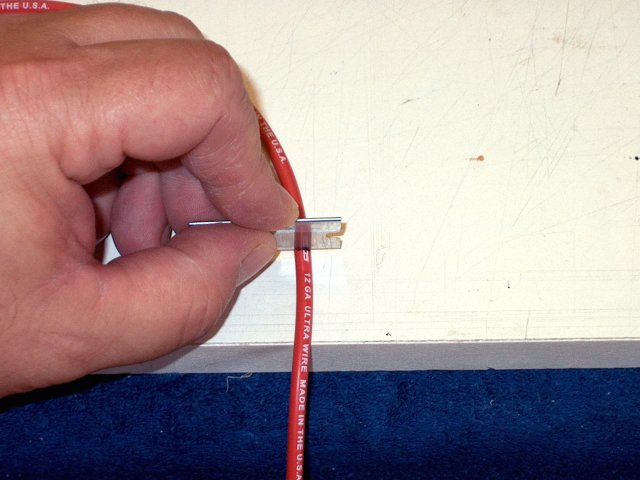

Two feet of 12ga Deans wire was used and

sockets for the ESC power wires were installed at one

end | |

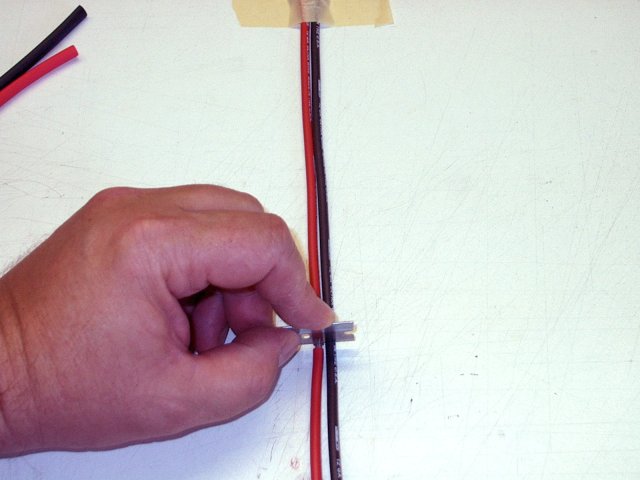

Install a Deans Ultra Plug at the other

end of the wires. Note the orientation of the black and red

wires | |

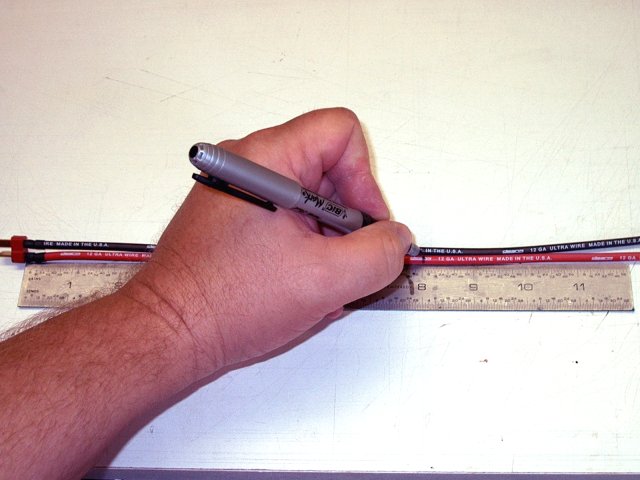

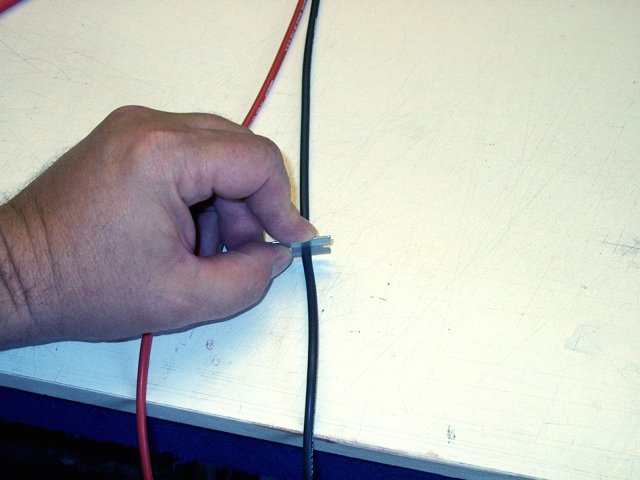

Make marks on the wire harness at 8" and

16" away from the power plug end | |

Make a cut at each mark with a razor,

cutting only through the rubber insulation

| |

Make a second cut about 1/8" past the

first | |

Using the first wire for reference, make

two similar cuts to the other wire | |

Cuts shown completed, showing bare wire.

Make similar cuts at the 16" marks | |

Use Rosin and solder to tin each

wire | |

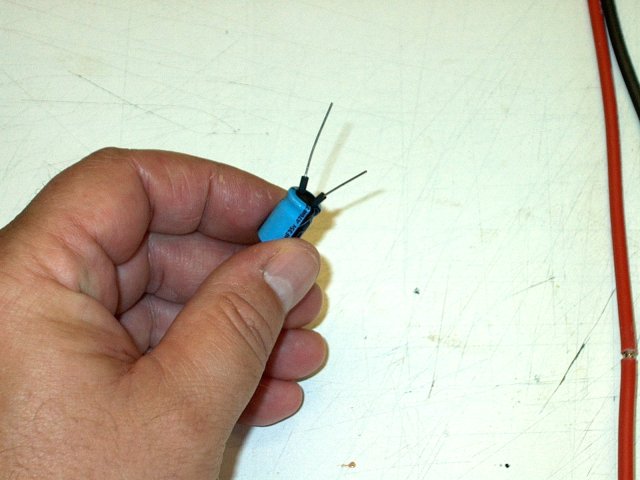

Install some small heatshring on two leads

of a 470uf Electrolytic capacitors, available at Radio Shack,

part # 272-1030 | |

Pull the rod through the motor area,

working the harness to the back | |

Tape the harness ESC wires to the side of

the fuselage for now so they don't get pushed forward

| |

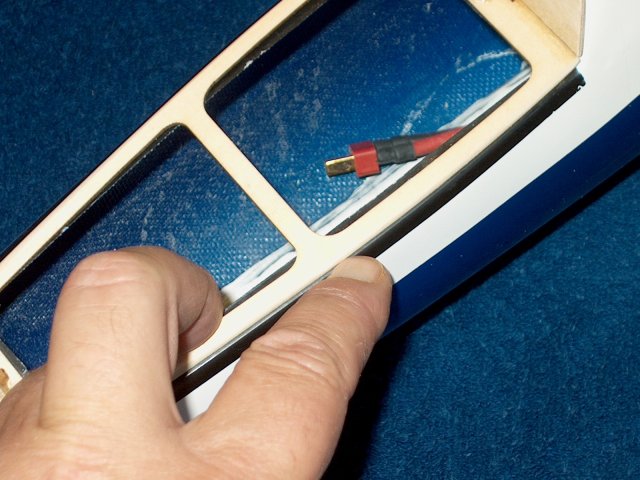

The Battery leads are shown in the correct

position under the cockpit area | |

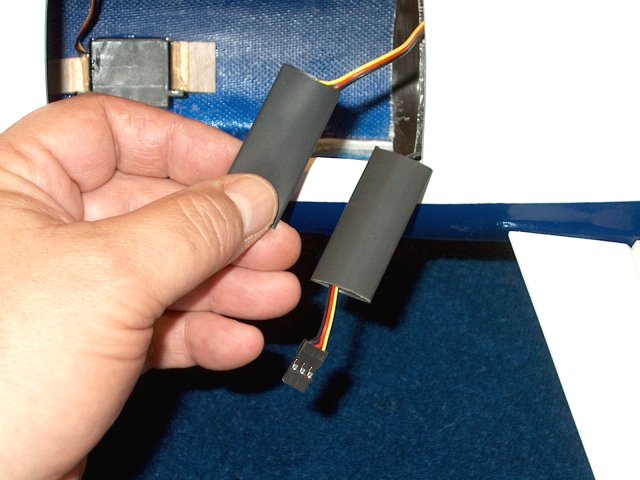

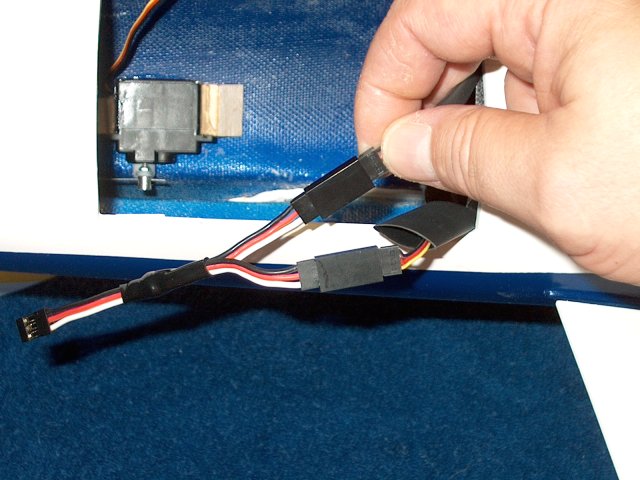

Slide some heat shrink over the Aileron

servo leads | |

Connect the Aileron leads to a "Y"

harness | |

Seal the heatshrink around the servo plugs

so they cannot be pulled out by accident

| |

Use a tie wrap to gather up the excess

Elevator servo leads if necessary | |

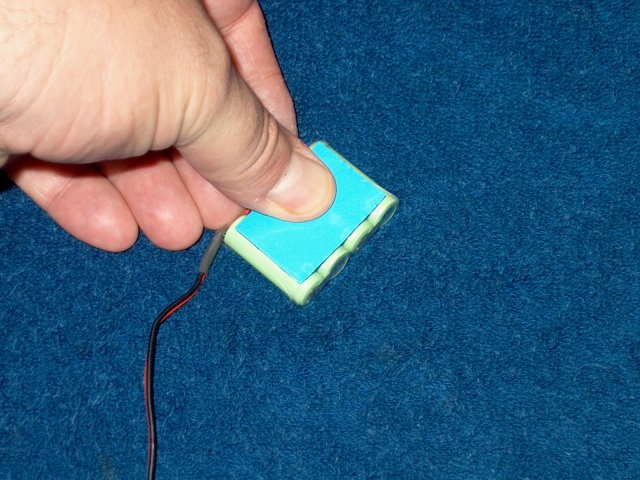

Apply a couple layers of servo tape to the

bottom of your receiver. Be sure to use a full range, high

quality receiver for this model | |

Remove the backing from the tape and

install the receiver on the side of the fuselage

| |

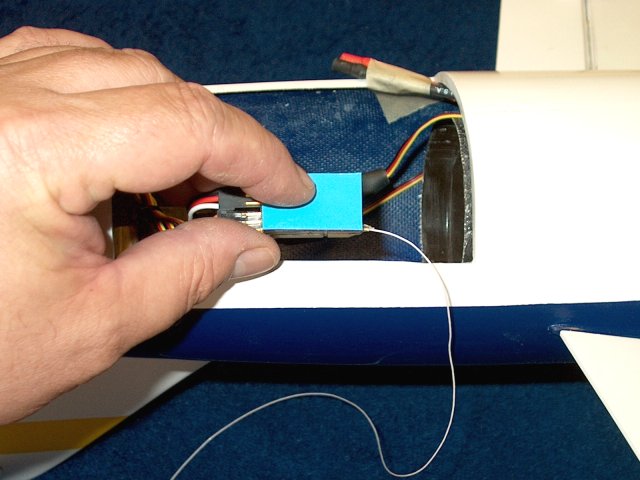

If you are using a power configuration and

require the use of an external BEC, apply servo tape to the

bottom of your BEC unit or receiver battery pack. A 400mah

NiMH receiver pack is shown | |

Remove the backing fom the servo

tape | |

The Battery or BEC is positioned in the

bottom center of the fuselage, just behind the intake's fan

lip | |

Closeup of BEC location

| |

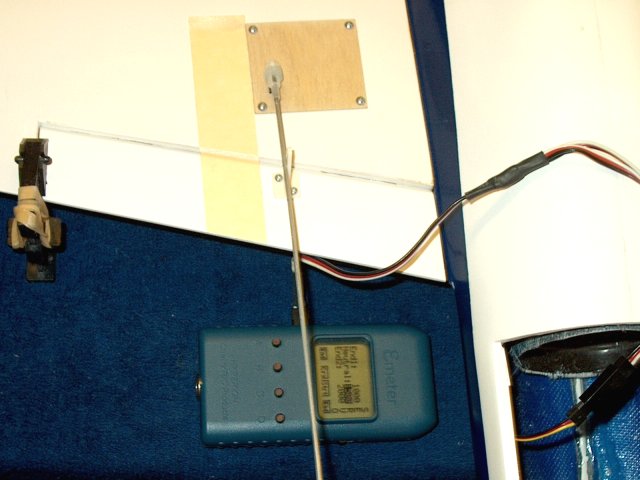

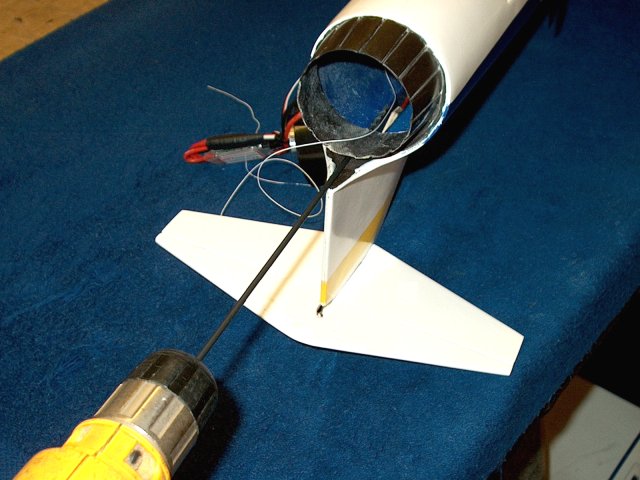

NOTE: Antenna placement may differ on your

model depending on the type of receiver you use. ALWAYS range

check before flying. Drill a 1/8" hole between the vertical

stab and exhaust, centered on the bottom of the stab

tail | |

Install a piece of antenna tube in the

hole that was drilled | |

Extend the tube into the fuselage about

1/4" past the inside wall and make a mark on the outside about

1/8" past the exhaust as shown | |

Cut the antenna tube to length

| |

Rough up the bottom side of the tube that

will be glued with 60 grit sandpaper

| |

Apply a bead of epoxy along the sanded

bottom of the antenna tube | |

Install the tube in the fuselage. A

toothpick makes a good tool to ease installation

| |

Center the tube over the vertical stab

tail, then tape the toothpick down to hold the antenna tube in

place until the epoxy sets | |

Remove the masking from the outside of the

tubing | |

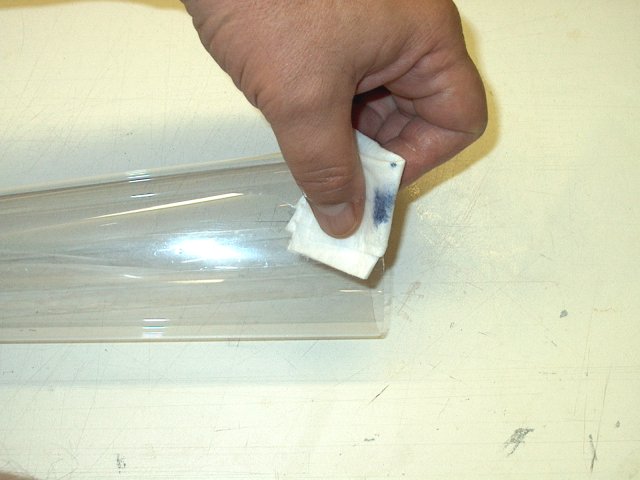

Clean any marks you made with

alcohol | |

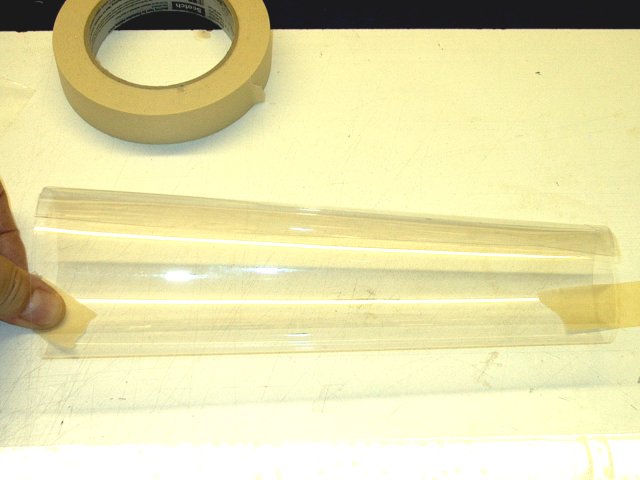

Tape the tube , seam side up, to a hard

surface as shown | |

Apply a 1" wide strip down the center of

the outer seam of the tube | |

Use a burnishing tool to press the tape

down the entire length of the seam | |

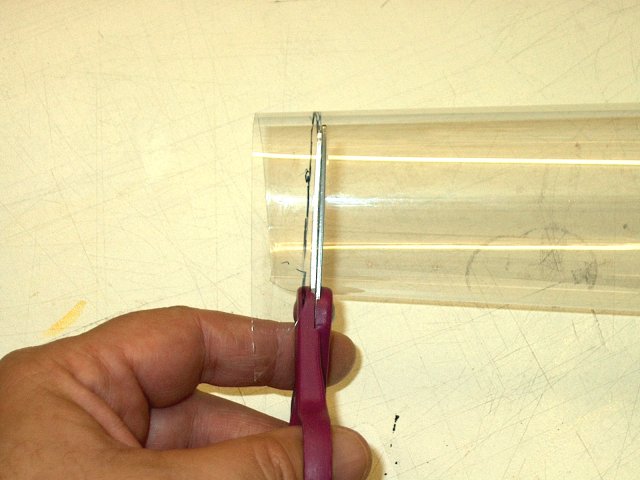

Use two large 3/8" washers sandwiched

between the plastic as a cutting jig to cut a circle near the

fan end of the tubing for the ESC wires. Make the hole about

3/4" from the end of the tube | |

Temporarily install the tube over the fan

and mark the outside where it exits the fuselage

| |

Cut the excess tail material from the

tube | |

Install the tubing in the fuselage. Fold

it first as shown for easier installaion

| |

Run the wires of your ESC through the hole

cut in the thrust tube | |

Install the tube over the fan unit, then

use a 3/4" wide strip of packing tape to secure it

| |

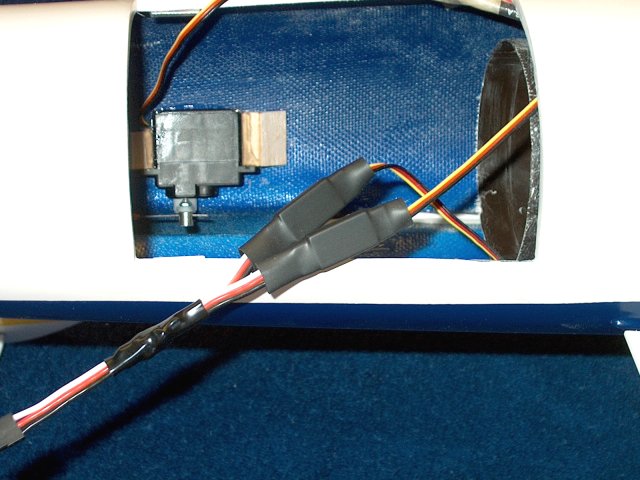

Connect the two ESC power wires to the

harness, then use heat shrink to hold them in place. Plug the

ESC control wire into the receiver | |

Power assembly installation

completed | |

Install the cover over the fan

compartment. A couple strips of clear tape can be used to

insure it holds in place | |

Basic fuselage assembly is

completed | |

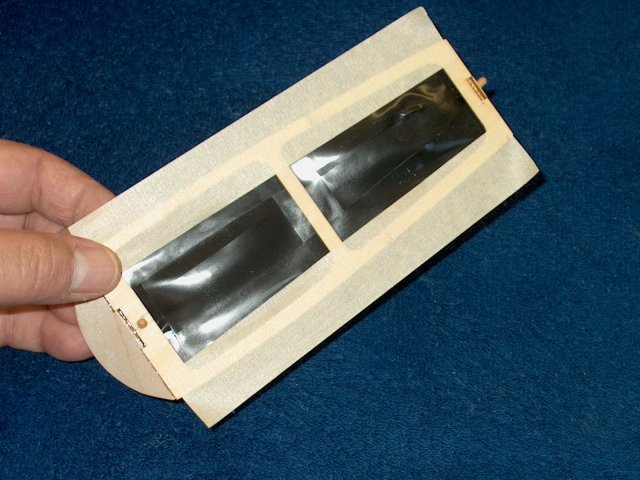

Gather the parts from the kit that you

will need to assemble the cockpit | |

The larger piece was badly warped

| |

A new piece was drawn and cut from a scrap

sheet of ply | |

Stack the two pieces and sand the new

piece until it is even with the original

| |

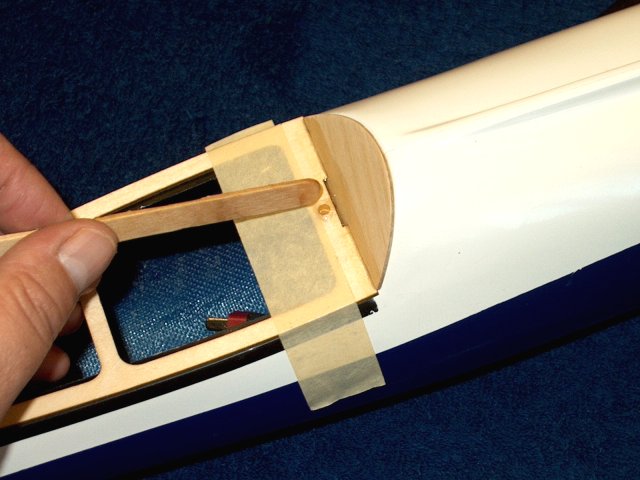

Install the two end pieces into the

cockpit frame and check for fit | |

Cover the cockpit area with thin plastic

wrap | |

Install the cockpit frame, making sure it

is centered at the front and back. Tape the frame in

place | |

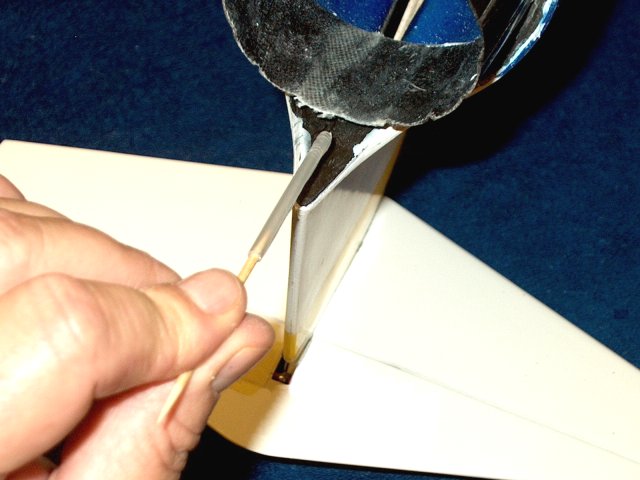

Apply epoxy to the small forward ply

piece | |

Install the piece in place as shown. Use a

toothpick to apply a small fillet of epoxy at the joint for

strength | |

Apply epoxy to the rear ply piece

| |

Install the piece in place and tape it

flush to the rear of the cockpit area. Allow the epoxy to

set | |

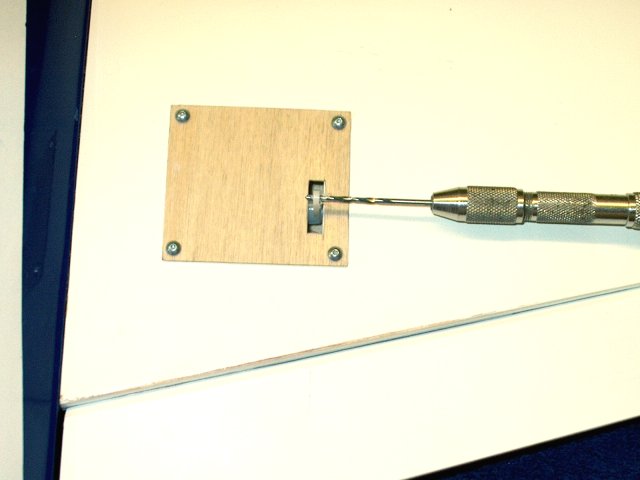

Drill the center of the front cockpit wall

with a 1/8" bit | |

Install and center the cockpit frame, then

use tape to hold it in place and use a hand drill to continue

the hole through the front plate to the fuselage

| |

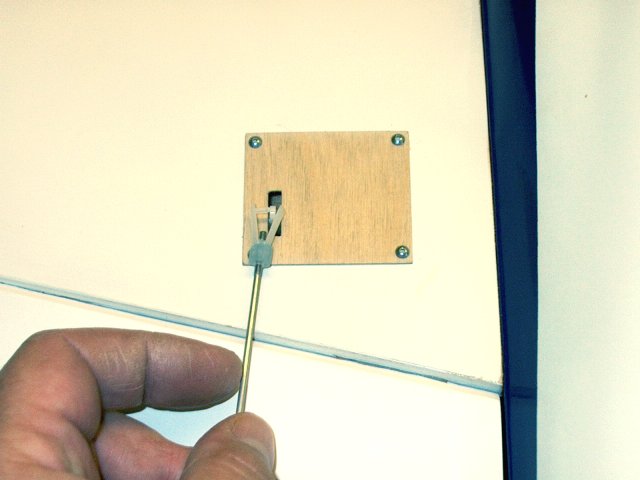

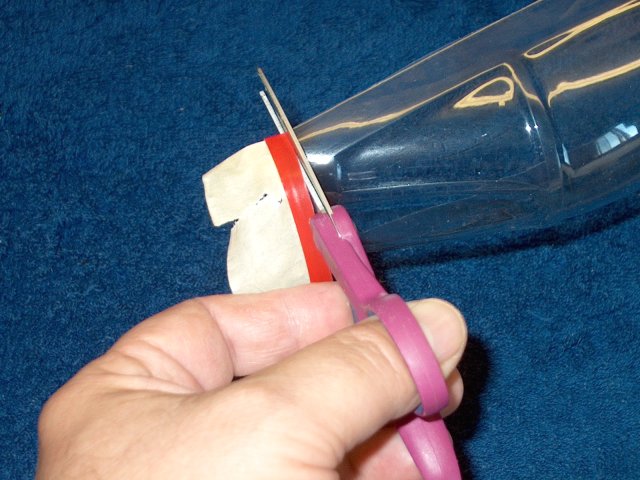

Round one end of the supplied wood dowel

so it will more readily install in the fuselage

| |

Epoxy the dowel in the hole, applying

epoxy only to the wood frame and dowel and not the fiberglass

fuselage | |

Add a small fillet of epoxy around the

dowel pin | |

Cut the ends off the canopy. Trim as

little as possible to remove the end caps

| |

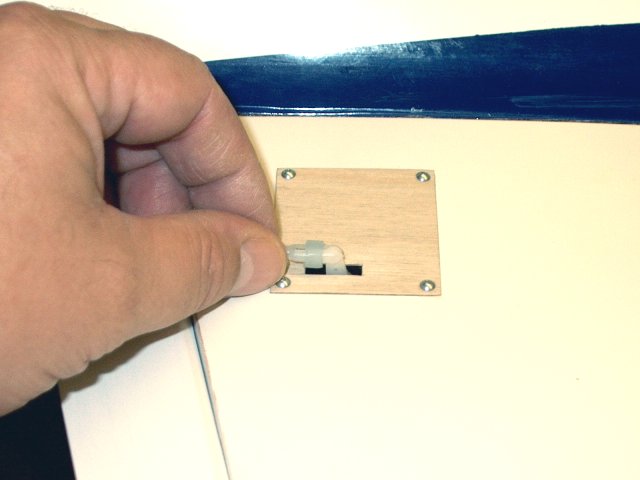

Use a punch to make a center mark in the

rear of the cockpit frame as shown | |

Drill through the frame and fuselage with

a 1/8" bit | |

Make a pin 1/2" long from a piece of scrap

1/8" diameter wood dowel and round one end

| |

Install the pin as shown, leaving a little

bit of the pin exposed at the top. | |

Add a fillet of epoxy around the dowel

pin. This pin will be used to insure the rear of the cockpit

is centered when installed | |

Center the canopy on the front of the

fuselage, making sure the window frame is centered and the

side windows are the same distance from the cockpit frame.

Tape the canopy in place as shown | |

Use some vinyl trim tape on the canopy to

mark a cutting point that is flush with the firewall

|

|

Cut along the tape and remove the excess

material | |

Lightly sand the canopy front so it is a

perfect fit, then tape it's edge flush to the fuselage

firewall. Center and secure the rear of the canopy with

masking tape | |

Using the same method, mark the rear of

the canopy with vinyl tape, then remove and trim it. Check the

fit on the fuselage | |

Apply some clear packing tape, then

masking tape to the sides, front and back of the

fuselage | |

Sand the sides so they match the inward

taper of the fuselage | |

Draw a edge mark with the back of a pencil

along both sides of the cockpit frame. Lightly sand to the

line so the edges of the frame will be slightly

recessed | |

Sanding the sides will leave a small lip

at the fuselage joint as shown. This recess allows the canopy

to sit flush with the sides of the fuselage

| |

Center the canopy an tape it down at the

front and back. Use vinyl tape along the edges to mark a cut

at the fuselage shelf | |

Remove the canopy and cut the canopy at

the mark. You may have to repeat until you have a good

fit | |

Canopy fitting completed. Detail the

cockpit as desired | |

Appl masking tape along the bottom of the

cockpit frame as shown | |

Apply canopy glue to both sides of the

cockpit frame | |

Position the canopy, holding it tight to

the frame, then fold the masking tape up to hold the canopy in

place while the glue dries | |

Apply CA to the rear corners of the

cockpit frame on both the top and bottom sides

| |

Position a magnet as shown and mark its

location with a pencil. Repeat for the other corner

| |

Drill the holes with a 1/4" drill or

forstner bit | |

Carefully enlarge the holes with a dremel

and router bit. Do not over-enlarge

| |

Place the frame on the fuselage and

transfer the hole locations to the fuselage with a

pencil | |

Drill the hole with a 1/4" bit or

forstner. Open the holes so the magnets fit tightly.

| |

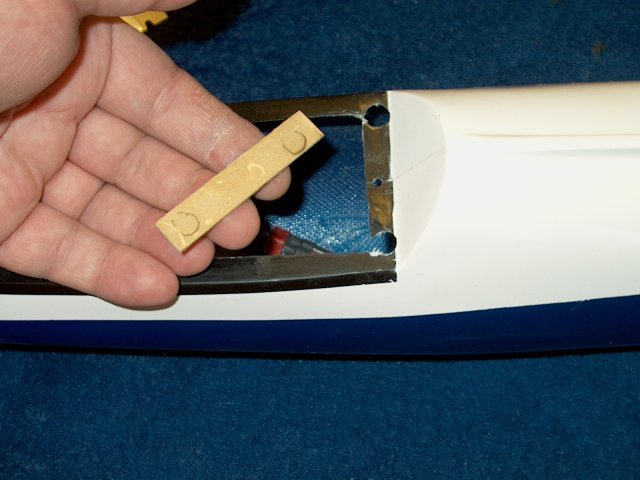

cut a piece of 1/32" ply 1/2" wide and to

a length equal to the width of the fuselage rear. This will be

used to support the magnets | |

Apply Epoxy to the ply and install it in

place | |

Clamp the plate and before the epoxy sets,

install two magnets in the holes so they are flush with the

top of the fuselage | |

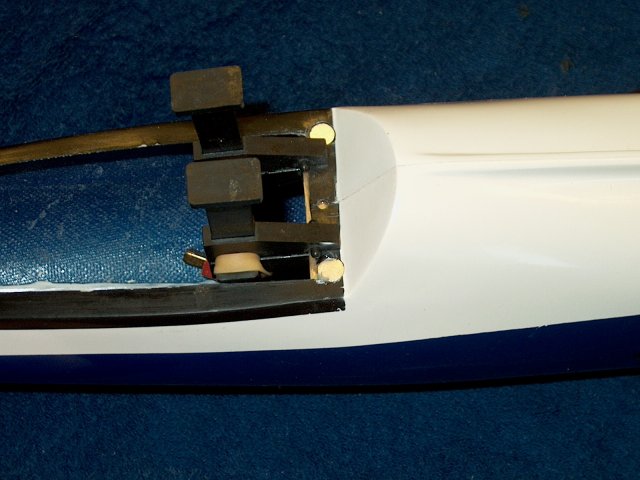

Apply masking tape to the bottom of the

cockpit frame | |

IMPORTANT: Check the position of the two

top magnets so they attract rather than repel from the magnets

in the fuselage. They must be mounted on the correct side.

Rough up the opposite side of each magnet

| |

Press the magnets into the frame holes IN

THE CORRECT DIRECTION so they are flush with the tape on the

bottom of the frame | |

Apply Epoxy to the hole filling the well

and allow the glue to set | |

Apply a piece of masking tape to the

bottom of the fuselage even with the front lip of both

intakes | |

The block inside the fuselage for the tow

hook is shown | |

Measure and make a mark 1/4" behind the

tape at the center seam of the fuselage

| |

Drill the hole with a small drill for the

towhook |

|

Rough up with 60 grit sandpaper the

towhook on the side that inserts into the fuselage

| |

Apply epoxy to the towhook and hole in the

fuselage | |

Install the towhook and clean up any

excess epoxy with alcohol. Make sure the hook is pointing

straight back | |

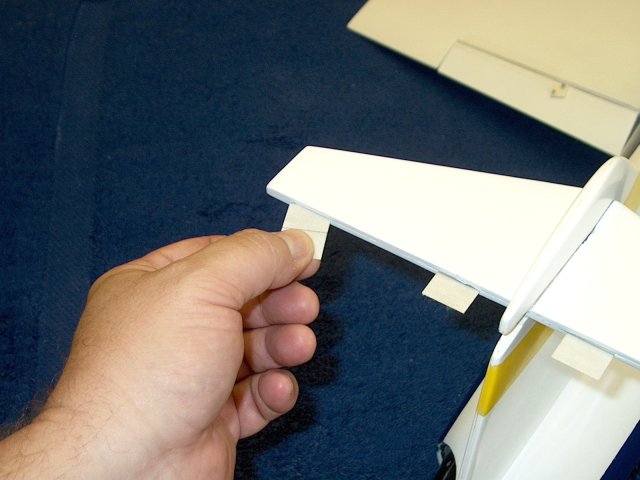

Mark the CG location at 52mm back from the

leading edge of each wing as shown | |

Install the retainer strap in the supplied

battery tray as shown. Some Epoxy can be applied along the the

bottom side edges of the straps to make sure it does not pull

apart | |

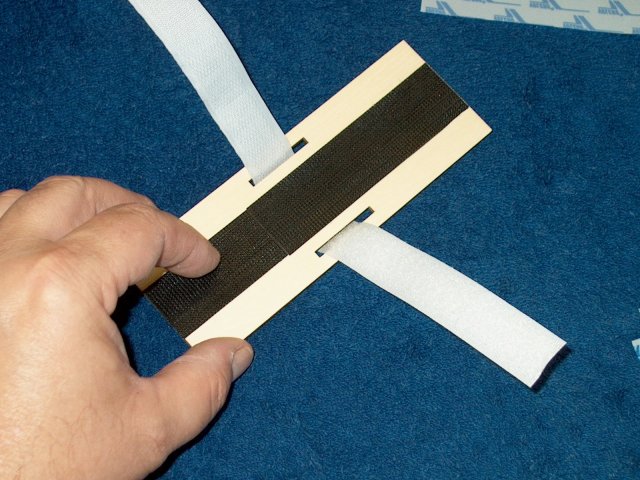

Add a long strip of Velcro to the entire

length of the battery tray. Also apply a couple squares of

Velcro cloth to the battery itself. This method allows

re-positioning of the battery for CG and prevents the battery

from slipping backward, which is what happens if the straps

are used without Velcro added to the tray

| |

Install the battery and tray in the

fuselage | |

Move the assembly forward or backward

until CG is achieved, then mark the front location of the tray

with masking tape | |

Remove the battery and position the tray

to the tape's edge, then apply epoxy along the edges of the

battery tray, gluing it permanently in position

| |

Adjust Elevator throws to 15mm UP

| |

Adjust Elevator throws to 10mm DOWN and

set Expo at 60% for a starting point if desired

| |

Adjust Aileron throws to 12mm up and 6mm

down | |

F-104 Top View | |

F-104 Side View

| |

The HET-RC F-104 Starfighter EDF Jet

| |

This Website and all documents herin are Copyright © 2012 www.scalerocketry.com -

All rights reserved.

| |