|

|

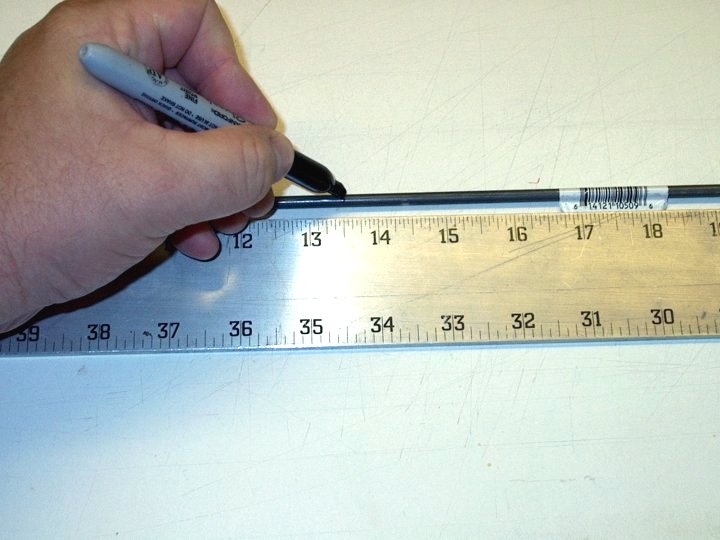

2 - A 3/16" piece of steel rod from the hobby

shop is used for an axle. It is marked for cutting at 13 1/2" in length

| |

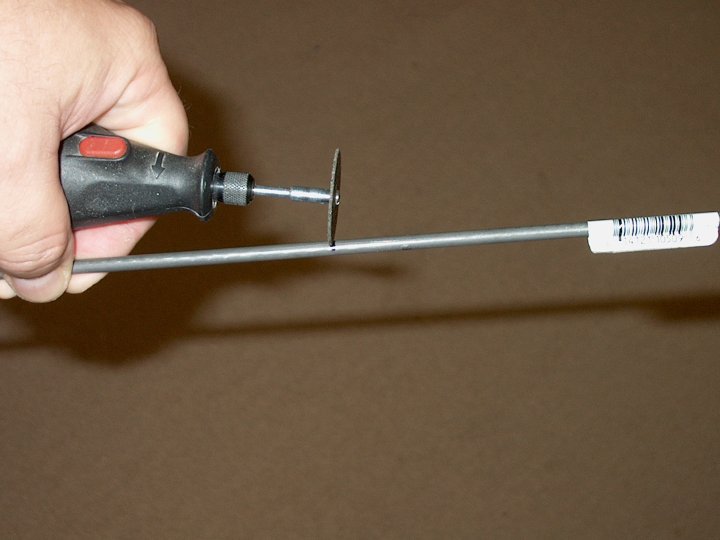

3 - The rod is shown being cut

and the ends are then flattened

| |

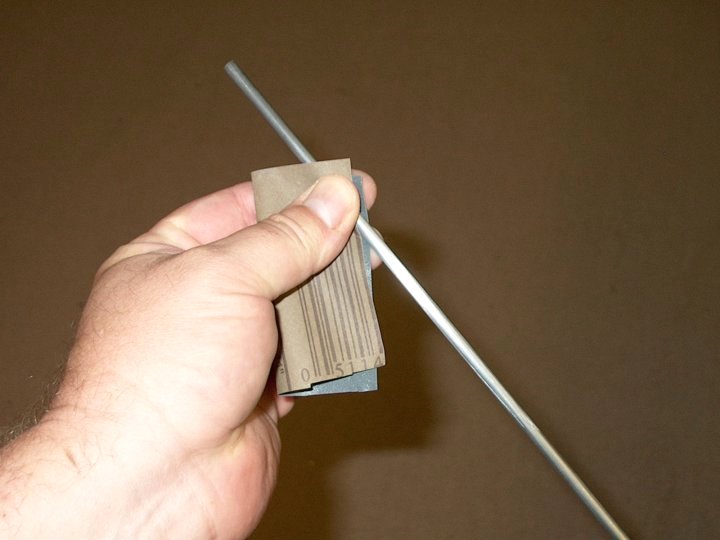

4 - The rod is cleaned with very fine

sandpaper, followed by alcohol

CG. | |

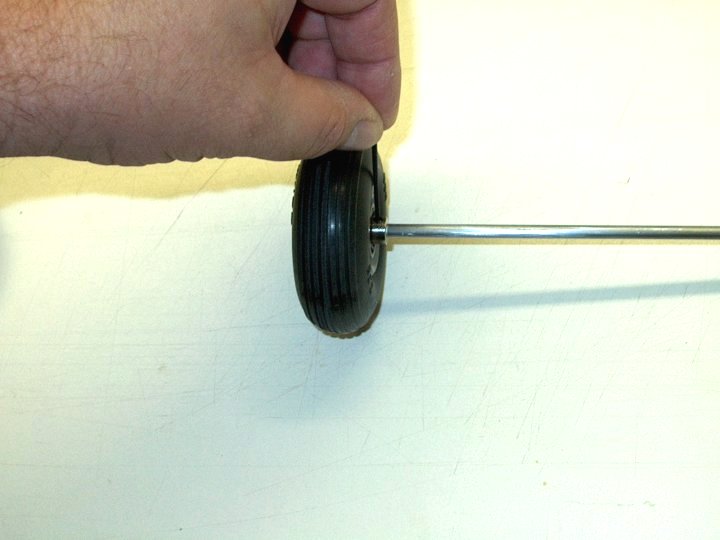

5 - Most wheels have 5/32" axle holes,

so I used a spare pair of 2 3/4" lightweight wheels and

drilled them to 3/16" diameter to fit the axle

| |

6 - You may have to sand/file the hole

so it spins smoothly and without play on the shaft rod you made

| |

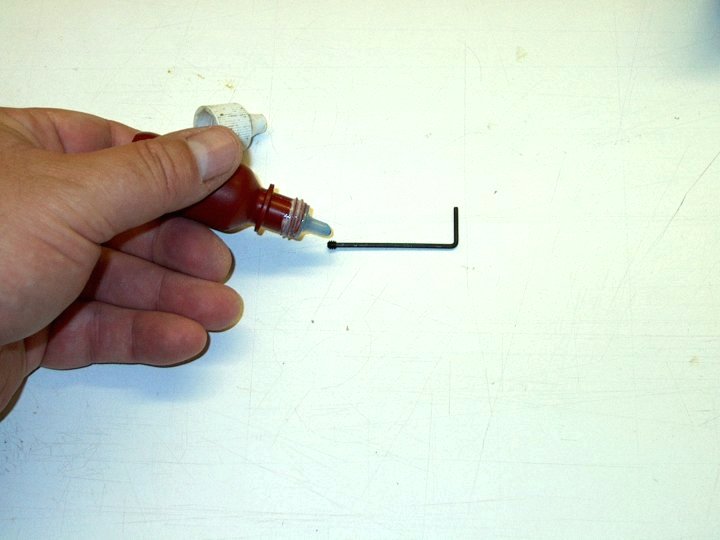

7 - Loktite is used to install the

set screws in six 3/16" wheel collars that are used

| |

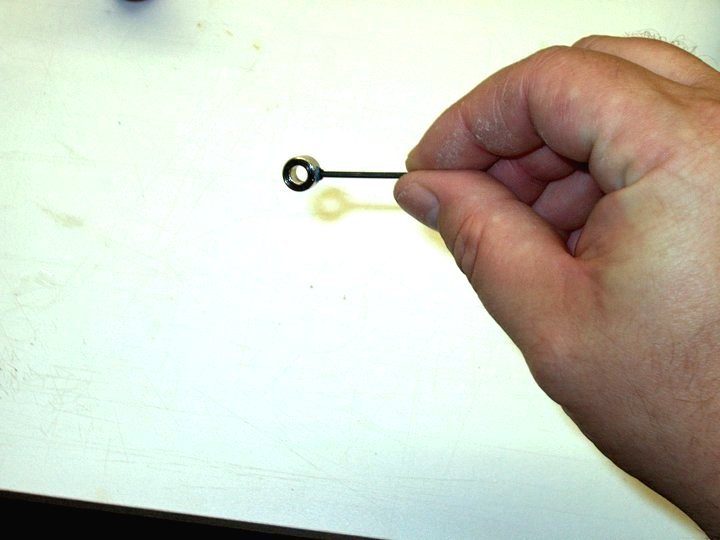

8 - Set screw shown installed in wheel collar

| |

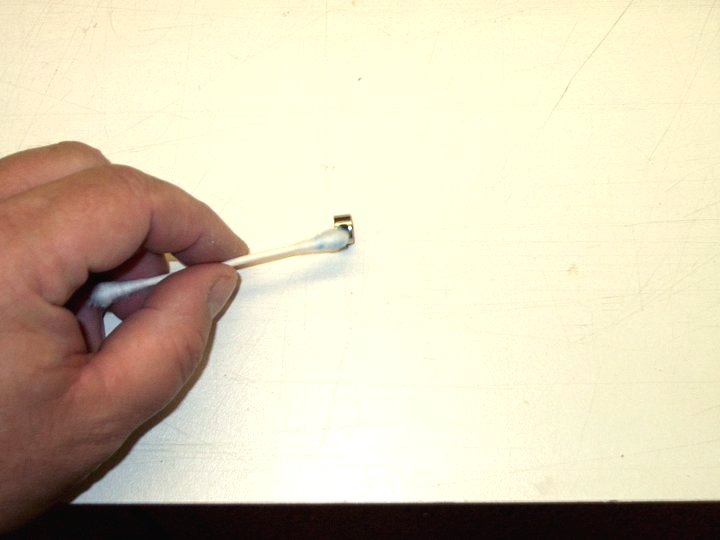

9 - Clean up the excess Loktite with a Q-Tip

| |

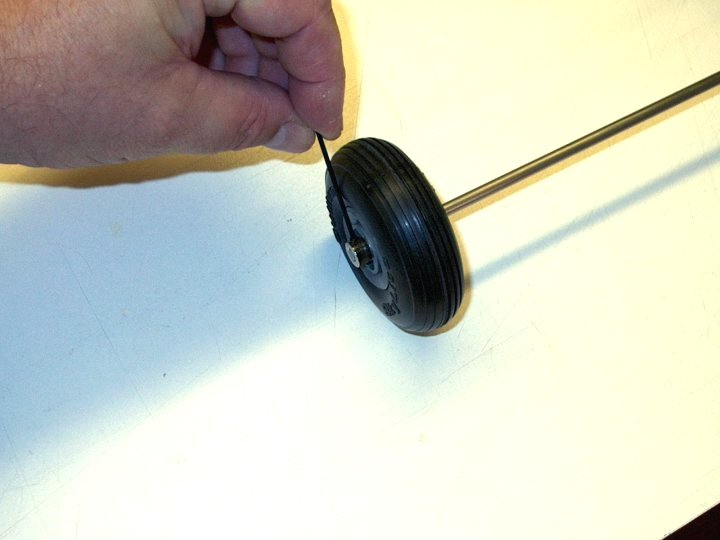

10 - The first Wheel is installed

and the Wheel Collar is tightened flush to the shaft

| |

11 - A second wheel collar is

installed to hold the wheel in position. Make sure

the inside wheel collar is not binding so the wheel

can spin freely

| |

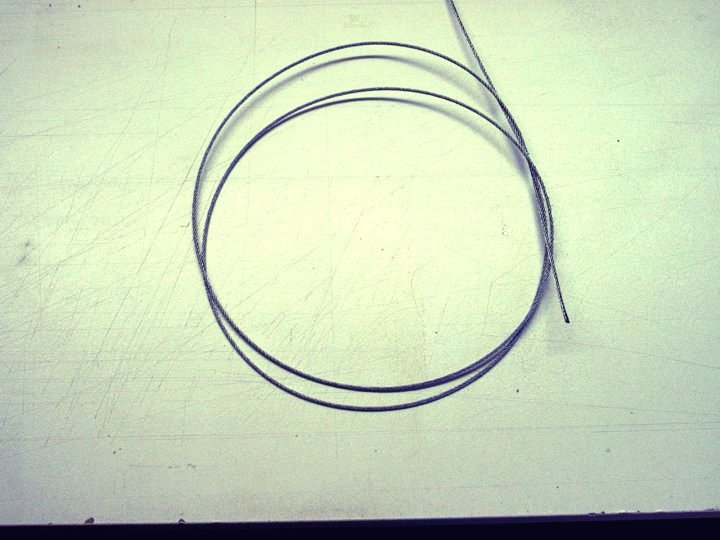

12 - 1/16" braided steel cable is

purchased from Home Depot, Lowes or any other similar store.

You will need about three feet of cable

| |

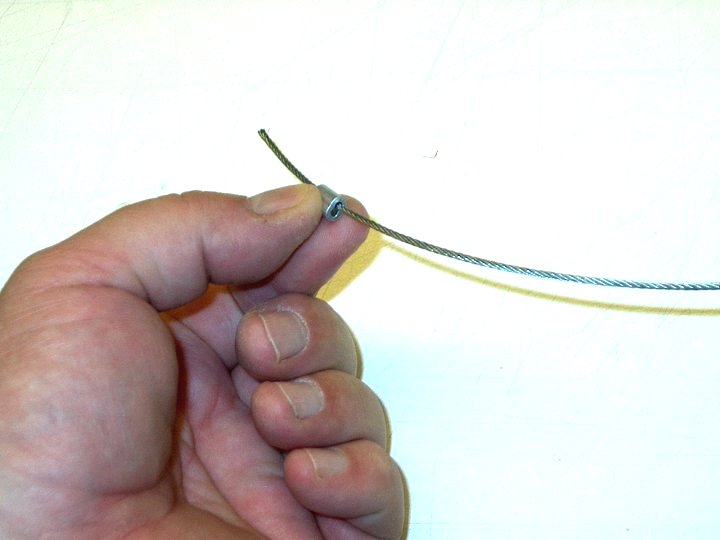

13 - Aluminum Ferrels are also purchased

for the wire. You will need three of them and they come two to a pack

| |

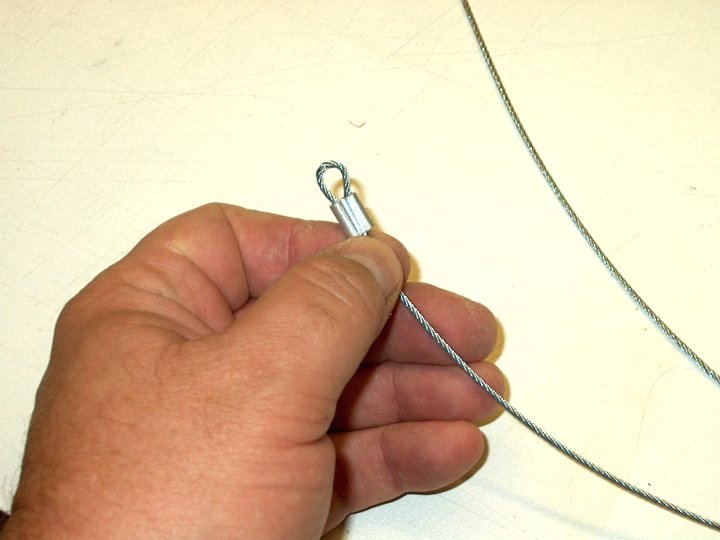

14 - The first ferrel is placed over the wire end

| |

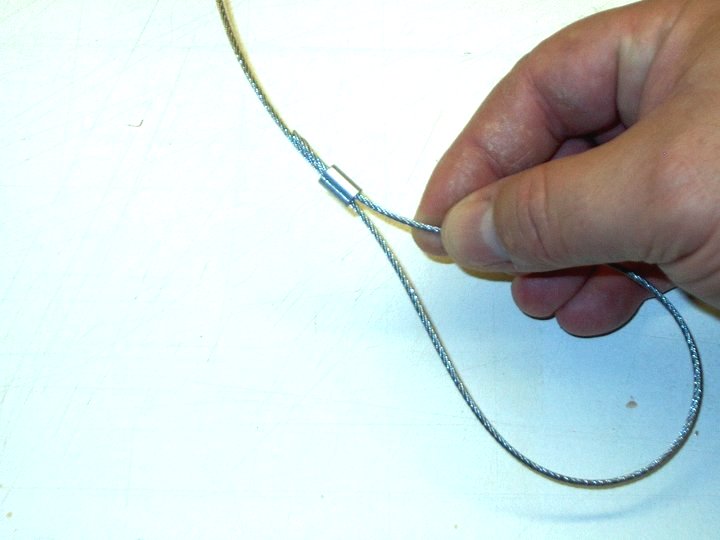

15 - The wire is looped around and

inserted into the other side of the ferrel

| |

16 - The wire is pulled tight so

that the loop can just fit over the 3/16" axle shaft

| |

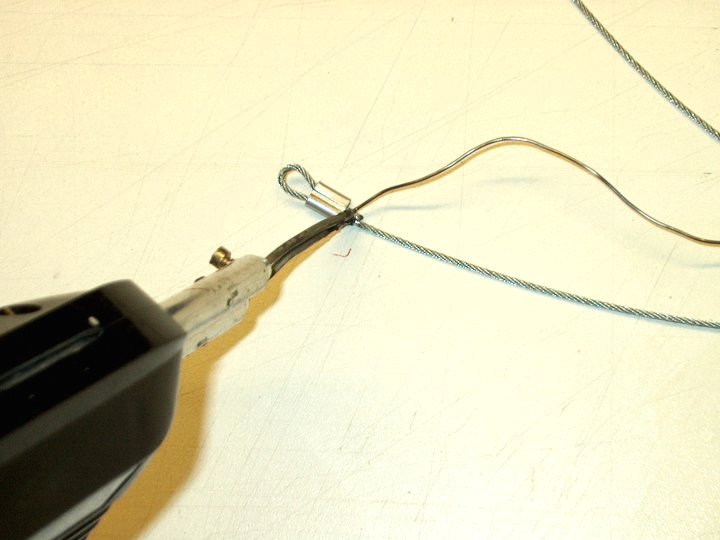

17 - Once crimped, you can solder

the wire together for additional safety

| |

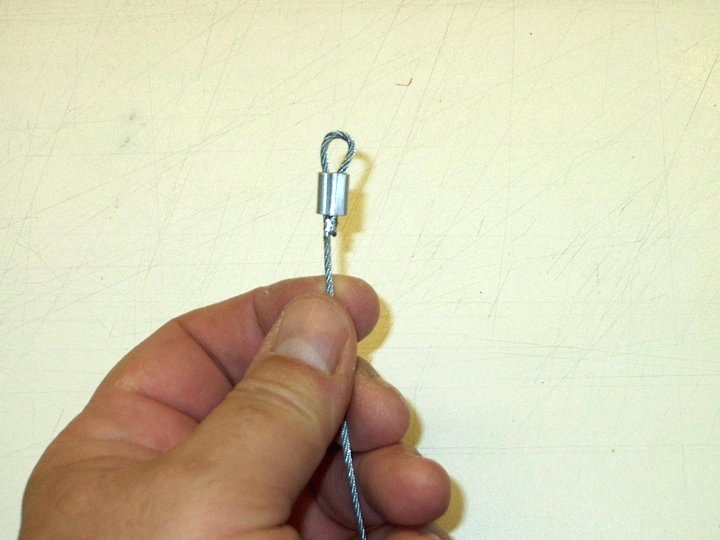

18 - Wire shown crimped and soldered

| |